Page 1

Great Plains Mfg., Inc.

Installation Instructions

3-8 Shank Sub-Soiler Inline Ripper

Inline Ripper Gauge Wheel Jack Kit

Used with:

• 3-8 Shank Sub-Soiler Inline Ripper

General Information

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

!

the lives of others depend on it!

These instructions explain how to install the Inline Ripper Gauge Wheel Jack Kit. The Inline Ripper Gauge

Wheel Jack Kit allows for jacks to be added to the Inline Ripper Gauge Wheels to adjust the depth of the

ripper. These instructions apply to:

596-157A Inline Ripper Gauge Wheel Jack Kit

Manual Update

Refer to the 3-8 Shank Sub-Soiler Inline Ripper operator’s man ual for detailed information on safely

operating, adjusting, troubleshooting and maintaining

the Inline Ripper Gauge Wheel Jack. Ref er to the

parts manual for part identification.

596-086M Operator’s Man ual

596-086P Parts Manual

Assembly Instructions

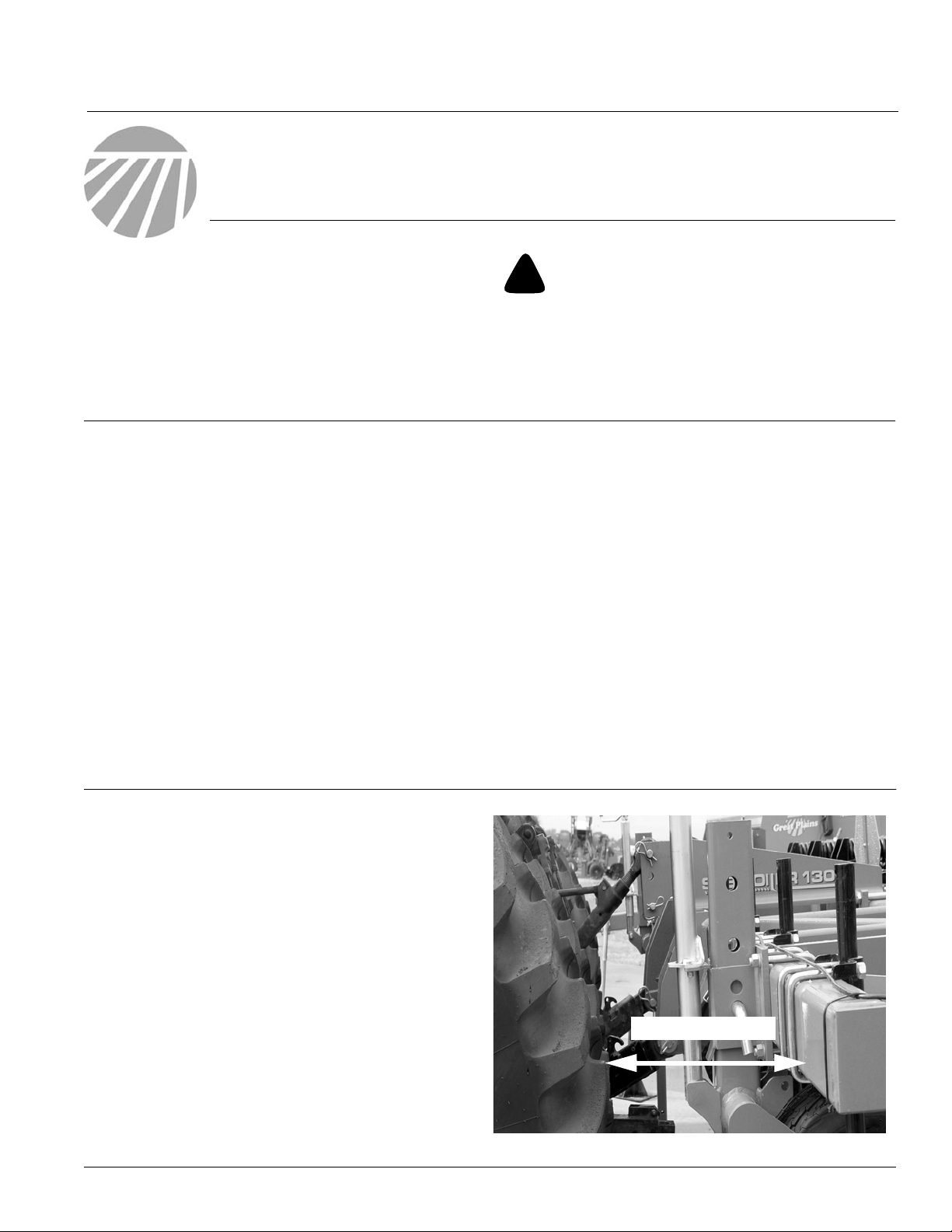

Refer to Figure 1

NOTE: Mounting the jack to the gauge wheel arm may

cause clearance problems with the Great Plains SubSoiler Hitch or with tractor tires if the ripper is 3-point

mounted. If gauge mounts line up with tires or

hitch, be sure there is at least 12" clearance between front of the frame tube and tires or hitch. If

the 12" clearance exists, the gauge wheels will mount

on the front side of the front frame tube. Please refer to

the following instructions on page 2. If there is not 12"

clearance, the gauge wheels will need moved out towards the end of the frame or need mounted on the

back side of the front frame tube. Please ref er to page

4 for these instructions.

Before You Start

Page 7 is a detailed listing of parts included in the

Inline Ripper Gauge Wheel Jack Kit. Use this list

to inventory parts received.

T ools Required

• Basic Hand Tools

• Welder

• DA Grinder

12" Clearance

© Copyright 2005 Printed

5/4/2005

Figure 1

23176

596-158M

Page 2

Inline Ripper Gauge Wheel Jack Kit

2

Mounting the Jack on Gauge Wheels with 12"

Clearance

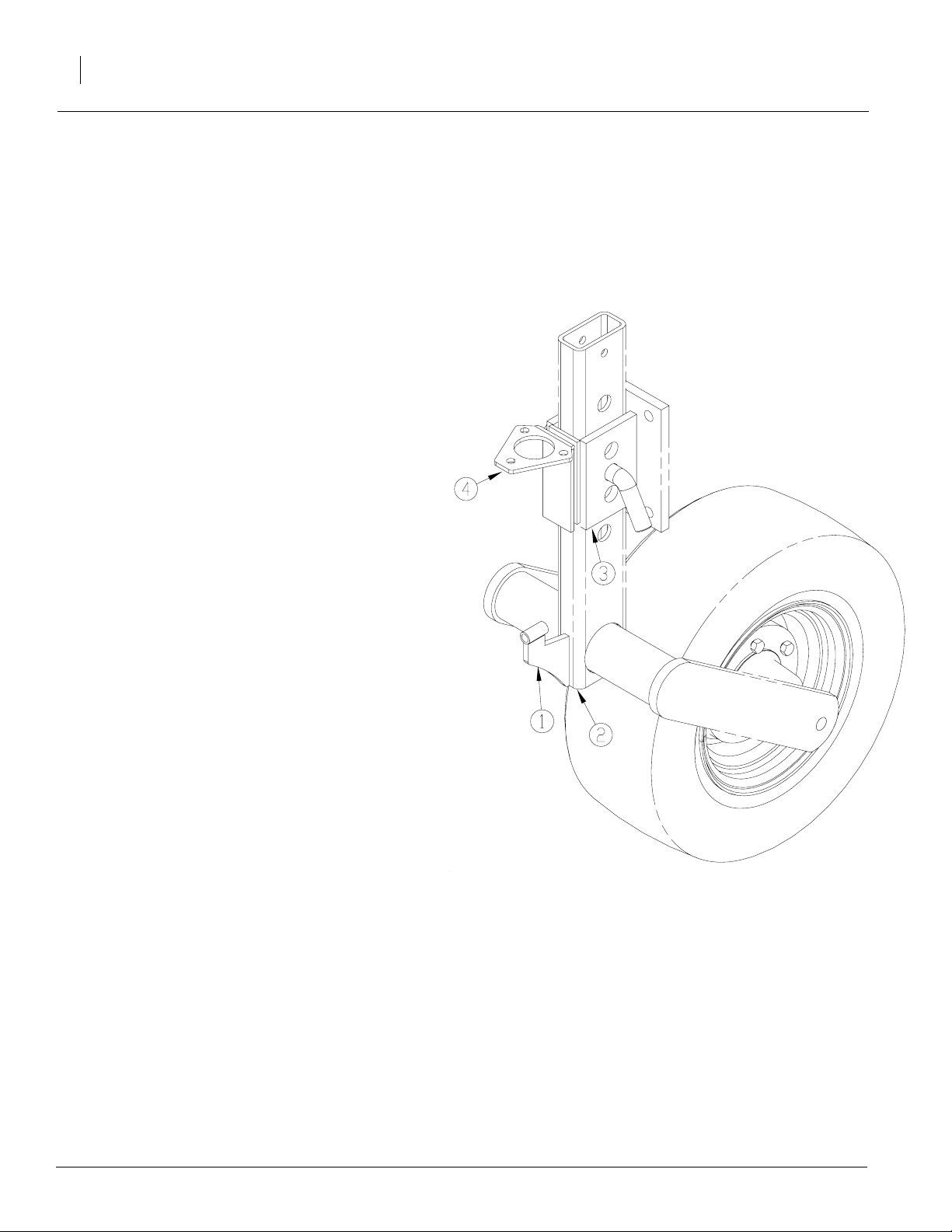

Refer to Figure 2

1. After determining 12" clearance between the front

of the frame tube to tires or hitch, grind paint on

bottom portion of front of the gauge wheel arm

(2).

2. Center and align gauge wheel jack lower mount

(1) flush with the bottom of the gauge wheel arm

(2). Weld mount (1) on arm (2).

3. Grind paint on the gauge wheel mount (3). Center

and align upper jack mount plate (4) flush with the

bottom of the gauge wheel mount (3). Weld plate

(4) to gauge wheel mount (3).

Great Plains Mfg., Inc.

4. Repeat steps 1-3 on opposite side of inline ripper

frame. Paint new parts with Great Plains Green

available at the nearest authorized Great Plains

dealer.

Figure 2

23175

596-158M 5/4/2005

Page 3

Great Plains Mfg., Inc.

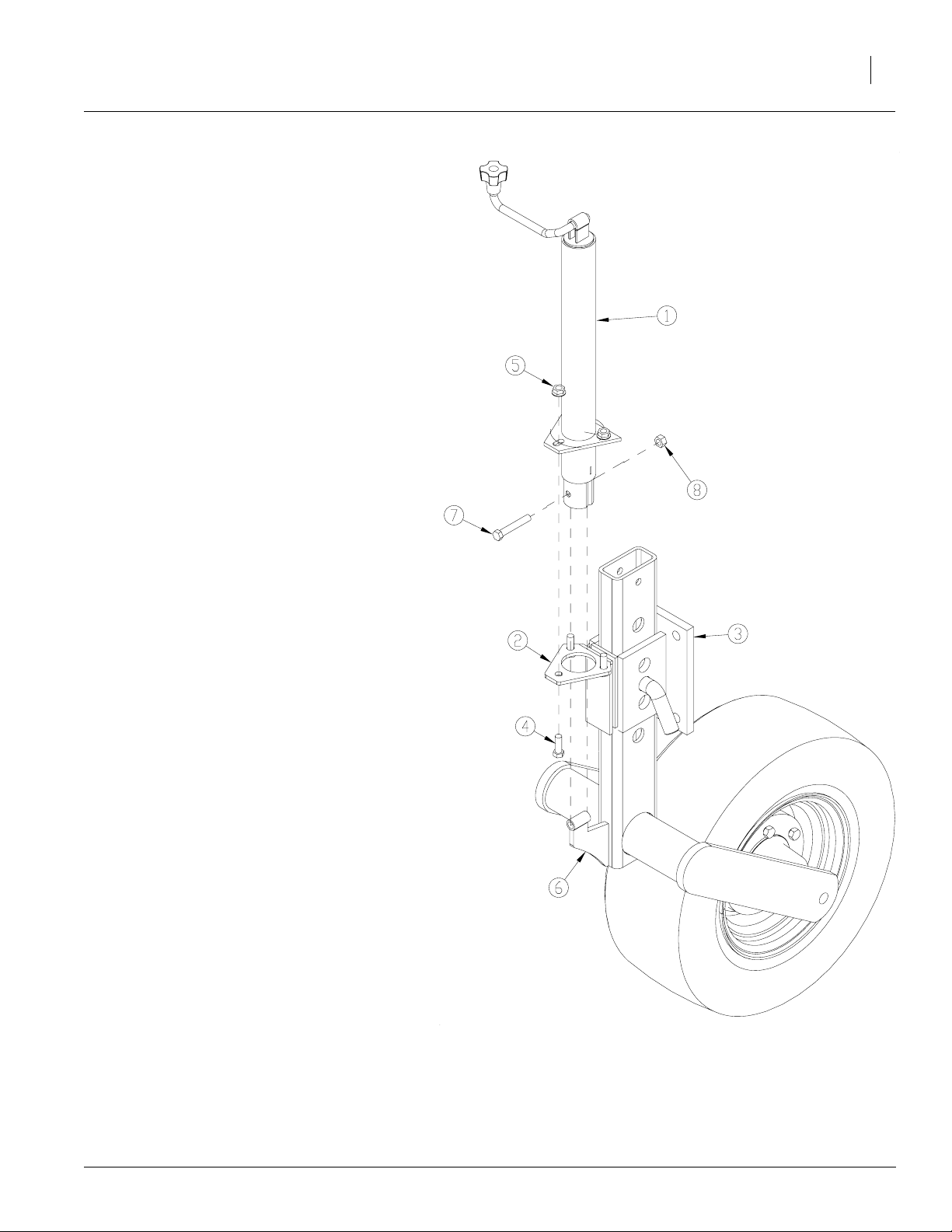

Refer to Figure 3

5. Assemble jack (1) by inserting jack through upper

jack mount plate (2) located on gauge wheel

mount (3). Secure plate (2) to jack (1) with three

7/16-14 x 1 1/4 bolts (4) and nut hex flange locs

(5).

6. Secure jack (1) to gauge wheel jack lower mount

(6) with 7/16-14 x 2 3/4 bolt (7) and nut hex lock

(8).

7. Repeat steps 5 and 6 on opposite side of inline

ripper frame.

NOTE: The jacks should only be used to help r aise

and lower the gauge wheels. The cross pin still needs

to be used in order to avoid overloading the jack.

Installation Instructions

3

5/4/2005

Figure 3

23177

596-158M

Page 4

Inline Ripper Gauge Wheel Jack Kit

4

Mounting the Jack on Gauge Wheels without 12"

Clearance

NOTE: There are two options f or mounting jacks to gauge

wheels without 12" clearance. Option 1 moves the gauge

wheels out towards the ends of the frame so they are not

lined up with the tractor tires or hitch. If you choose this option, move the gauge wheels and f ollow steps on page 2 listed under Mounting Jack on Gauge Wheels with 12"

Clearance. Option 2 mounts the gauge wheels on the back

side of the front frame tube as shown in Figure 4. If you

choose this option, follow the steps below.

Refer to Figure 4

1. Remove pin securing gauge wheel arm to gauge wheel

mount and remove gauge wheel and arm.

2. Unscrew U-bolts attaching gauge wheel mount to front

side of front frame tube. Keep parts for reuse .

3. Remove gauge wheel mount. Turn mount around so

gauge wheel can be mounted on back side of front

frame tube (3) as shown in Figure 4.

Great Plains Mfg., Inc.

4. Attach gauge mount (1) to back side of front frame tube

(3) with U-bolts (4) removed in step 1.Place gauge

wheel arm (2) on gauge wheel mount (1) and secure

with pin.

Figure 4

23179

596-158M 5/4/2005

Page 5

Great Plains Mfg., Inc.

Installation Instructions

5

Refer to Figure 5

5. Grind paint on bottom portion of back of the gauge

wheel arm (2).

6. Center and align gauge wheel jack lower mount (1) flush

with the bottom of the gauge wheel arm (2). Weld mount

(1) on arm (2).

7. Grind paint on the gauge wheel mount (3). Center and

align upper jack mount plate (4) flush with the bottom of

the gauge wheel mount (3). Weld plate (4) on gauge

wheel mount (3).

8. Repeat steps 5-7 on opposite side of inline ripper frame.

Paint new parts with Great Plains Green availab le from

the nearest authorized Great Plains dealer.

5/4/2005

Figure 5

23174

596-158M

Page 6

Inline Ripper Gauge Wheel Jack Kit

6

Refer to Figure 6

9. Assemble jack (1) by inserting jack (1)

through upper jack mount plate (2) located on

gauge wheel mount (3). Secure plate (2) to

jack (1) with three 7/16-14 x 1 1/4 bolts (4)

and nut hex flange locs (5).

10. Secure jack (1) to gauge wheel jack lower

mount (6) with 7/16-14 x 2 3/4 bolt (7) and nut

hex lock (8).

11. Repeat steps 9 and 10 on opposite side of inline ripper frame.

NOTE: The jacks should only be used to help

raise and lower the gauge wheels. The cross pin

still needs to be used in order to avoid ov erloading

the jack.

Great Plains Mfg., Inc.

Figure 6

596-158M 5/4/2005

23178

Page 7

Great Plains Mfg., Inc.

596-157A Inline Ripper Gauge Wheel Jack Kit

Your kit includes:

Qty. Part No. Part Description

2 596-159H GAUGE WHEEL JACK LOWER MOUNT WELD

2 596-232D UPPER JACK MOUNT PLATE

2 802-315C HHCS 7/16-14 x 2 3/4 GR5

6 802-673C HHCS 7/16-14 x 1 1/4 GR5

2 803-200C NUT HEX LOCK 7/16-14 PLT

6 803-229C NUT HEX FLANGE LOC 7/16-14 PLT

2 890-875C SCREW JACK 2000# TP-WND A-FRAM

Installation Instructions

7

596-158M5/4/2005

Loading...

Loading...