Great Plains Mfg., Inc. Parts Installation Instructions 1

Two-Outlet Hydraulic Kit

2- and 3-Section Drills

Used with drill models:

• 2S-2600/F/HD/HDF

• 3S-3000/F/HD/HDF

• 3S-4000/F/HD/HDF

• 3S-5000/F/HD/HDF

General Information

These instructions explain how to install the Two-Outlet

Hydraulic Kit. This combines the drill’s two Lift circuits

(Opener and Transport) into a single circuit at the hitch.

With this kit, a tractor having only two remotes can

operate a drill which would otherwise require three

circuits.

These instructions apply to:

Kit Kit Description

194-122A 3S TWO OUTLET TRACTOR HYD. KIT

This kit relies on some existing drill components.

This kit includes some parts not required, depending on

drill vintage, and drill options already present or also

being installed at this time.

If Markers are also to be installed, install the Two-Outlet

Hydraulic Kit first.

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life

and the lives of others depend on it!

U

R

F

B

L

D

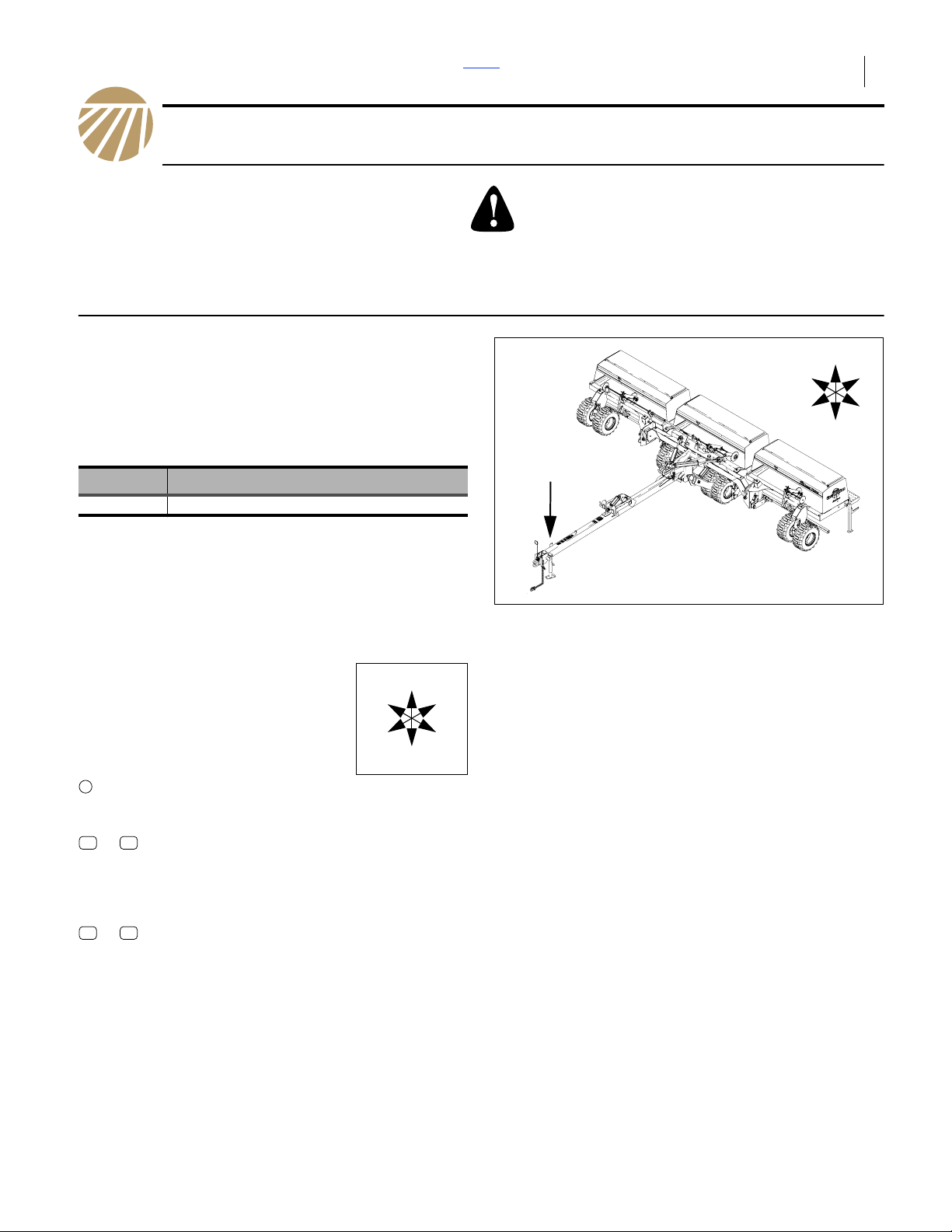

Figure 1

Location of New Valve

15485

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An

orientation rose in the line art

illustrations shows the directions of

Left, Right, Front, Back, Up, Down.

1

11 24

to

51 62

to

Each kit converts one drill.

single-digit or single-letter callouts identify

components in the currently referenced Figure

or Figures.

two-digit callouts in the range 11 through 24

reference new parts from the list on page 9.

The descriptions match those on the cartons,

bags or item tags, as well as in your updated

Parts Manual.

two-digit callouts in the range 51 through 62

reference affected existing parts from the table

on page 9. The descriptions match those in

your Parts Manual.

U

F

L

R

B

D

2014-04-15 ©Copyright 2014 194-033M

2 2-Outlet Selector Front Parts Great Plains Mfg., Inc.

Before You Start

Review these instructions, and make sure you

understand which existing system components are reused, and where they are located. The new components,

and the existing components to be re-used or discarded,

are located on the tongue of the drill, near the hitch.

Inventory the contents per “New Parts: Kit 194-122A”

on page 9.

Tools Required

• basic hand tools

• a tractor with two hydraulic circuits and suitable hitch

• liquid thread sealant

(for NPT fittings only - do not use PTFE tape)

• buckets for recovery of hydraulic oil from open hoses

These instructions presume a drill that has seen some

use, and may have pressure in the hydraulic system. The

installation may be done with the drill folded or unfolded.

Negative Tongue Weight Hazard:

If unfolded, the drill must be hitched to a tractor during

Opener Lift, to avoid negative tongue weight. Hitch loads can

range between +4000 pounds (folded) and -1000 pounds

(unfolded), depending on drill model and configuration.

Pre-Assembly Preparation

Inspect the Mounting Site

Refer to Figure 2

1. Examine the mounting site on the tongue. See if a

valve is already on the valve mount , and if any

hoses are under the clamps just aft of the mount.

2. Make sure the clamp hardware ( or ) is present.

It may be one of two different styles, depending on

the drill vintage. If there are no hoses under the

clamp, remove and save any: bolts, lock washers,

flat washers, clamp hold-downs, clamps and hose

guards.

If the drill does not have markers installed, a valve

mount welded on the tongue is available. The TwoOutlet selector valve mounts there, and includes a

bracket to provide a second mount point for another

valve.

If the drill already has markers installed, the valve mount

welded on the tongue already will already have a valve

mounted on it. You can mount the Two-Outlet selector

valve above it, or exchange their positions, using the

bracket in this kit.

1

1

A B

A

B

1

U

R

F

B

L

D

Figure 2

Valve Mount & Clamp

27023

194-033M Front Parts 2014-04-15

Great Plains Mfg., Inc. Front Parts Installation Instructions 3

Hydraulic Pressure Relief

High Pressure Fluid Hazard:

Only trained personnel should work on system hydraulics!

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin, causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a

piece of paper or cardboard, NOT BODY PARTS, to check for

leaks. Wear protective gloves and safety glasses or goggles

when working with hydraulic systems. If an accident occurs,

see a doctor immediately. Any fluid injected into the skin must

be surgically removed within a few hours or gangrene will

result.

Installation of this kit may require, at a later step, breaking

sealed hydraulic connections at quick-disconnect

couplers. It is crucial to safety that these lines be

depressurized.

3. If the available tractor has hydraulic circuits with

“float” capability, connect the Transport and Opener

Lift circuits, and relieve any residual system pressure

by floating the circuits.

If no suitable tractor is available, “crack” (carefully

loosen) the connections for both Lift circuits the at

the bleeding points specified in the drill Operator

manual. Leave them cracked for later bleeding.

Bleed only at:

JIC (Joint Industry Conference, 37° flare) or

NPT (National Pipe Thread, tapered) fittings.

Never bleed at:

ORB (O-Ring Boss) or

QD (Quick Disconnect) fittings.

Assembly

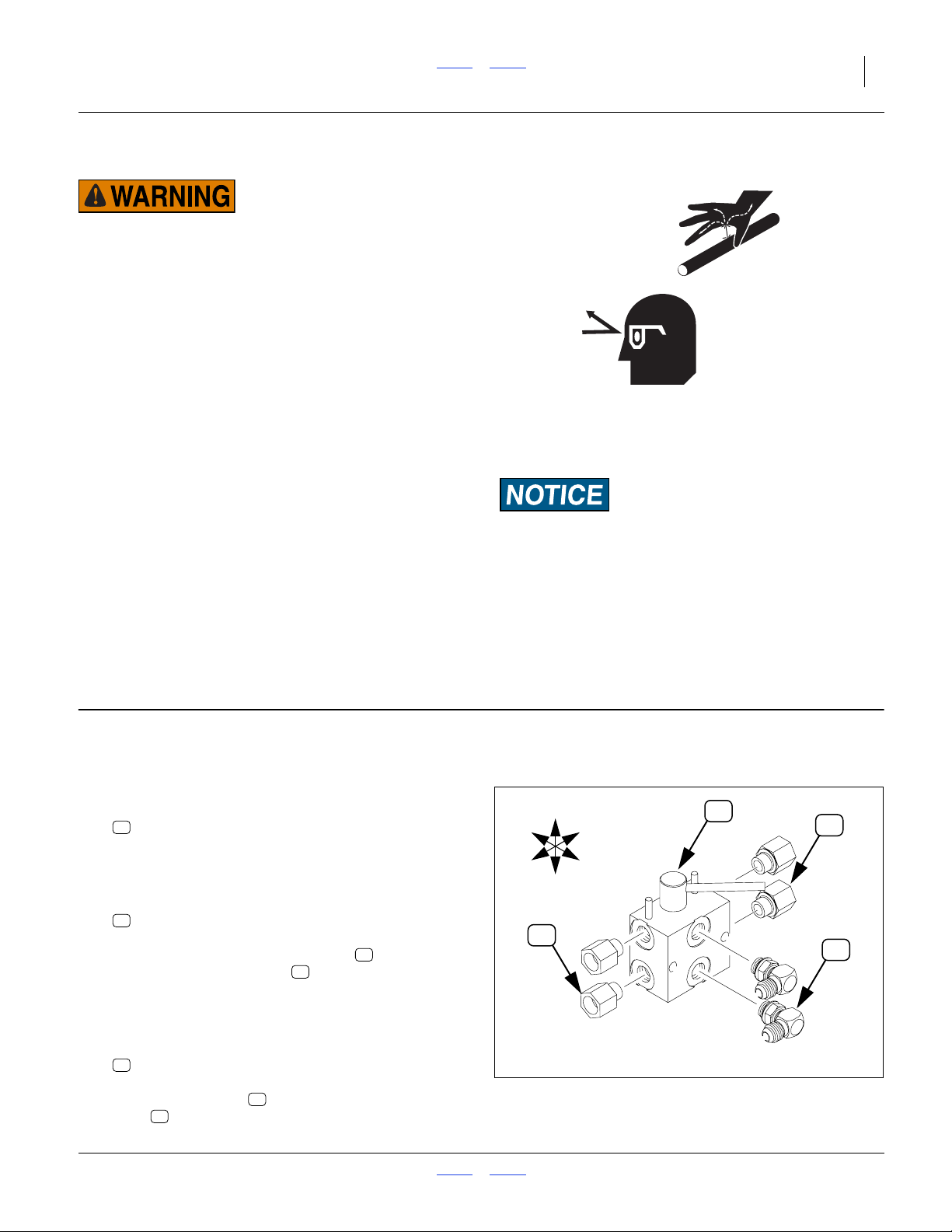

Assemble Selector Valve

Note: Do not use thread sealant on ORB fittings.

Refer to Figure 3

4. Select: one new

19

810-274C DOUBLE SELECTOR VALVE 3/4FORB

The face openings of the valve are to machine left

after installation.

5. Select: two new

22

811-063C EL 3/4MJIC 3/4MORB

Install the ORB ends of the elbows in the face

(center) of the valve body (“1” and “2” are

stamped into the valve body at those ports). Before

tightening the jam nuts, orient the JIC ends so that

they face forward when the valve is mounted.

6. Select: four new

20

811-021C AD 1/2FNPTS 3/4MORB

Install the adaptors in the end ports of the valve

19

body (ports stamped “1A”, “1B”, “2A” and “2B”).

19

20

22

R

F

20

U

D

B

L

Valve and Fittings

Figure 3

19

20

22

27024

2014-04-15 Front Parts 194-033M

4 2-Outlet Selector Front Parts Great Plains Mfg., Inc.

Install Valve Mount

If markers are already installed, and a valve is already

present at the mount, skip to Step 8 on page 4.

Mount as First Valve

Refer to Figure 4

7. Select: one new

12

194-249D BRACKET, 2ND SELECTOR VALVE,

two new

16

802-168C HHCS 3/8-16X3 1/4 GR5,

and two new

18

803-013C NUT LOCK 3/8-16 PLT.

18

12

U

R

1

F

B

L

D

16

Position the valve assembly to the left of the

tongue valve mount , handle pointing to machine

left. Position the new bracket to the right of the

mount , with the bottom holes of the bracket

aligned with the mount holes.

Insert the screws through the valve, mount and

bracket. Secure with lock nuts .

1

1

16

2

12

18

Mount as Second Valve

Refer to Figure 5

(shown with hoses disconnected from existing valve for

clarity)

If markers are already installed, a valve is already

present on the tongue mount. The new valve mounts on

the bracket from the kit, but the old valve screws must be

removed to mount the bracket.

8. Select: one new

12

194-249D BRACKET, 2ND SELECTOR VALVE

Remove the existing nuts from the existing

screws and install the bracket . Align the

bottom holes of the new bracket with the screws.

9. Select: two new

16

and two new

18

Mount the new valve assembly on the left side of

the new bracket , above the existing valve .

Insert the screws from the left and secure with

lock nuts .

56 12

802-168C HHCS 3/8-16X3 1/4 GR5

803-013C NUT LOCK 3/8-16 PLT

12 1

16

18

57

1

2

2

Figure 4

Mount as First Valve

18

12

1

R

F

27025

U

B

L

D

16

57

56

2

Figure 5

Mount as Second Valve

Note: Although this sequence leaves the marker/fold

selector valve on the bottom, you may prefer to

have it on top (a more intuitive location, as the

markers are above the lift cylinders). The existing

valve may be moved, or you can change the hose

connections later (the valves are identical parts).

27026

194-033M Front Parts 2014-04-15

Great Plains Mfg., Inc. Front Parts Installation Instructions 5

Prepare New Hitch Hoses

Two circuits (Transport Lift and Opener Lift), which were

intended for direct connection to tractor remote ports, are

reconnected to the new selector valve starting at step 19.

Any Quick Disconnects (QDs) or hose handles on those

hoses are transferred or replaced.

The kit includes two new hitch hoses to the tractor. For

newer drills (with hose handles), continue at “2012+

Remove/Transfer Hose Handles”. For older drills

(without hose handles), continue at “2011- Remove/Add

Quick Disconnects” on page 6.

2012+ Remove/Transfer Hose Handles

10. Identify the two existing lift hoses.

• Transport Lift - Base End and Rod End

• Opener Lift - Base End and Rod End

23

Typically one set has blue hose handles and the

other red.

1

1

2

Verify that pressure is relieved, per step 3 on

page 3, in all four hoses.

Refer to Figure 6

11. Remove and save four sets of hose handle

bodies from both sets of existing lift hoses .

Save the blue handles. The red handles are not

reused.

Protect the exposed MORB-threaded hose ends

from contamination.

12. Remove four QD assemblies consisting of:

60

62

Do not disassemble these fittings.

Save one set of QD assemblies .

The other set is not reused.

13. Select: two new

23

Attach one QD assembly to each hose .

Re-assemble the blue hose handles on these hose

assemblies. Ensure that a no-icon handle half is on

each hose.

Continue at “2012+ Prepare Circuit Hoses” on page 6.

1 2

3

811-394C CP 3/4FORB MALE QD POPPET TYPE

811-919C AD 3/4MORB 3/4FORB (HG)

3

811-272C HH1/2R2 096 3/4MORB 3/4FJIC

323

62

3

60

Figure 6 2012+

2012+ Transfer Hose Handles

Note: Hose handles body halves are present in three

varieties (in addition to color):

• Extended cylinder icon

(upper left handle in Figure 6)

• Retracted cylinder icon

(upper right handle in Figure 6)

• No icon

(lower handles halves in Figure 6)

Note: If the existing hoses have a metal hose clamps or

plastic label with cylinder aspect icons, leave that

clamp or icon in place for future hose

identification.

34784

2014-04-15 Front Parts 194-033M

6 2-Outlet Selector Front Parts Great Plains Mfg., Inc.

2011- Remove/Add Quick Disconnects

If the drill lift circuits have hose handles, follow the steps

at “2012+ Remove/Transfer Hose Handles” on page 5.

The new hitch hoses provided in the kit are terminated

with MORB fittings. Older drills would have FNPT QDs.

The kit includes new FORB QDs.

Refer to Figure 7 (new hoses not shown)

61

2

2

61

2

23

61

24

24

24

Figure 7 2011-

Remove/Add Quick Disconnects

23

27023

14. Identify four hydraulic hoses for the following:

Transport Lift - Base End and Rod End

Opener Lift - Base End and Rod End

15. Remove the QD couplers or hose handles at

their FNPT threaded ends. They are not reused.

Protect the exposed NPT-threaded hose ends from

contamination.

16. Select: two new

23

811-272C HH1/2R2 096 3/4MORB 3/4FJIC

(96 inch hoses) and two new:

24

811-394C CP 3/4FORB MALE QD POPPET TYPE

Attach the two new QD couplers to the new

hoses .

If any blue cable ties or blue electrical tape is

available, use ties or tape to color-code the new

hoses near the QD end.

17. Continue at “Connect Lift Circuit Hoses” on

page 7.

23

2012+ Prepare Circuit Hoses

For older drills with MNPT-terminated lift hoses, continue

at “Connect Lift Circuit Hoses” on page 7.

Refer to Figure 8

18. Select: four new

21

811-023C AD 1/2MNPT 3/4FORB

Attach these adaptor to each existing lift hose .

2

21

2

Figure 8 2012+

Add MNPT-FORB Adaptors

36253

194-033M Front Parts 2014-04-15

Great Plains Mfg., Inc. Front Parts Installation Instructions 7

Connect Lift Circuit Hoses

Refer to Figure 9 (depicting 2012+ hoses - 2011- hoses are

MNPT-terminated without adaptors)

Note: Do not use thread sealant on JIC or ORB

connections.

Note: It may be necessary to loosen the FNPTS-MORB

adaptors on the valve in order to tighten hose

NPT connections without twisting the hoses.

Alternatively, hoses can be disconnected at

cylinder-end JIC connections.

19. Connect the Transport Lift hoses to the forward

valve ports (stamped “1B” and “2B”).

Connect the rod (retract) hose to the upper port

(stamped “1B”). Connect the base (extend) hose to

the lower port (stamped “2B”).

20. Connect the Opener Lift hoses to the aft valve

ports (stamped “1A” and “2A”).

20

B

A

R

F

U

D

B

B

L

A

20

Connect the rod (retract) hose to the upper port

(stamped “1A”). Connect the base (extend) hose to

the lower port (stamped “2A”).

21. Connect the new common Lift hoses to the

center (face) valve ports (stamped “1” and “2”).

Connect one hose to the upper port (stamped “1”).

Connect the other hose to the lower port

(stamped “2”).

22. Re-tighten any adaptor or cylinder JIC

connections loosed for these steps.

20

23

Figure 9

Connect Hoses to Valve

23

27027

2014-04-15 Front Parts 194-033M

8 2-Outlet Selector Front Parts Great Plains Mfg., Inc.

Secure Hoses

Refer to Figure 10

There are two or four hoses to clamp, requiring one or

two clamps. How to clamp them depends on the

available hardware. Figure 10 shows the recommended

stacking for four possible combinations.

The clamp components are:

13

196-146D 3-HOSE CLAMP BRACKET

14

196-885D HOSE CLAMP HOLDDOWN

15

802-010C HHCS 5/16-18X1 1/4 GR5

17

802-172C HHCS 5/16-18X2 1/2 GR5

51

1/4 MARKER HYD HOSE GUARD

52

HOSE CLAMP BRACKET

55

HHCS 5/16-18X1 1/4 GR5

58

WASHER LOCK SPRING 5/16 PLT

59

WASHER FLAT 5/16 USS PLT

23. Clamp new and any existing hoses. If markers are

yet to be installed, place the upper clamp hardware

in preparation for marker hoses.

Closeout

24. If no additional hydraulic options are to be installed

at this time, bleed the Lift systems per the

instructions in the drill Operator Manual. Follow

hitching instructions carefully, due to high positive

and negative hitch loads in various drill

configurations.

25. Confirm selector valve handle(s) forward is

Transport, handle(s) aft is Field, and all Extend/

Retract settings operate Base/Rod cylinder ends as

expected.

15

58

59

14

13

17

58

14

13

14

13

Figure 10

Hose Clamp Combinations

55

58

52

51

17

58

52

51

14

13

27030

194-033M Front Parts 2014-04-15

Great Plains Mfg., Inc. Front Parts Installation Instructions 9

Parts Lists

New Parts: Kit 194-122A

The part call-out numbers in this list match all Figures in

the installation instructions.

Callout Quantity Part Number Part Description

11 1

12 1

13 1

14 1

15 2

16 2

17 2

18 2

19 1

20 4

21 4

22 2

23 2

24 2

194-033M

194-249D

196-146D

196-885D

802-010C

802-168C

802-172C

803-013C

810-274C

811-021C

811-023C

811-063C

811-272C

811-394C

MANUAL TWO OUTLET HYD KIT

BRACKET, 2ND SELECTOR VALVE

3-HOSE CLAMP BRACKET

HOSE CLAMP HOLDDOWN

HHCS 5/16-18X1 1/4 GR5

HHCS 3/8-16X3 1/4 GR5

HHCS 5/16-18X2 1/2 GR5

NUT LOCK 3/8-16 PLT

DOUBLE SELECTOR VALVE 3/4FORB

AD 1/2FNPTS 3/4MORB

AD 1/2MNPT 3/4FORB

EL 3/4MJIC 3/4MORB

HH1/2R2 096 3/4MORB 3/4FJIC

CP 3/4FORB MALE QD POPPET TYPE

Your kit includes the following parts.

Existing Parts Affected

The following existing parts may be involved in the kit

installation. Which clamp bracket and fasteners are

present depends on drill vintage.The Disposition column

indicates whether parts are left in place, moved or not reused.

The part call-out numbers in the list match all Figures in

the installation instructions. Descriptions match those in

your drill Parts manual.

On an existing drill that has seen some use, and on

which markers have never been installed, the clamp may

be missing.

Part numbers are provided for ordering replacements.

The current bracket set is at left above, based on clamp

196-146D, which has replaced clamp 196-112D.

Quick Disconnects may vary from these parts.

Existing Parts List

Callout Part No. Part Description Part Disposition

51

52

53

54

55

56

57

58

59

60

61

62

113-370D

196-112D

196-146D

196-885D

802-010C

802-168C

803-013C

804-009C

804-010C

811-394C

811-856C

811-919C

1/4 MARKER HYD HOSE GUARD

HOSE CLAMP BRACKET

3-HOSE CLAMP BRACKET

HOSE CLAMP HOLDDOWN

HHCS 5/16-18X1 1/4 GR5

HHCS 3/8-16X3 1/4 GR5

NUT LOCK 3/8-16 PLT

WASHER LOCK SPRING 5/16 PLT

WASHER FLAT 5/16 USS PLT

CP 3/4FORB MALE QD POPPET TYPE

CP 1/2FNPT MALE QD

AD 3/4MORB 3/4FORB (HG)

Re-used unless no markers are present, and you use the

newer 196-146D clamp.

Re-used unless no markers are present, and you elect to

replace it with the newer 196-146D clamp.

Saved and re-used. Re-mount even if no use planned.

Saved and re-used. Re-mount even if no use planned.

Not re-used. Identical parts are provided in the kit.

Saved and re-used.

Saved and re-used.

Saved and re-used.

May be re-used.

If present, 2 of 4 are saved and re-used.

If present, not re-used.

If present, 2 of 4 are saved and re-used.

2014-04-15 Front Parts 194-033M

10 2-Outlet Selector Front Parts Great Plains Mfg., Inc.

Reference Information

Abbreviations Torque Values

AD Adaptor

CP Coupler

EL Elbow

GR Grade

HG Hose Grip

HH Hydraulic Hose

HHCS Hex Head Cap Screw (Bolt)

HYD Hydraulic

JIC

NPT (Female/Male) National Pipe Thread

NPTS NPT Swivel

ORB (Female/Male) O-Ring Boss

PLT Plated

QD Quick Disconnect

USS U.S. Standard

(Female/Male) Joint Industry Conference 37°

flare fittings

Fastener/Fitting Ft-Lbs N-m

3

⁄8-16 Grade 5 31 42

1

⁄2 NPT 11⁄2-3 turns past finger tight

5

⁄16-18 Grade 5 24 17

3

⁄4 JIC 27-39 37-53

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

194-033M Front Parts 2014-04-15

Loading...

Loading...