Page 1

Great Plains Mfg., Inc.

Installation Instructions 1

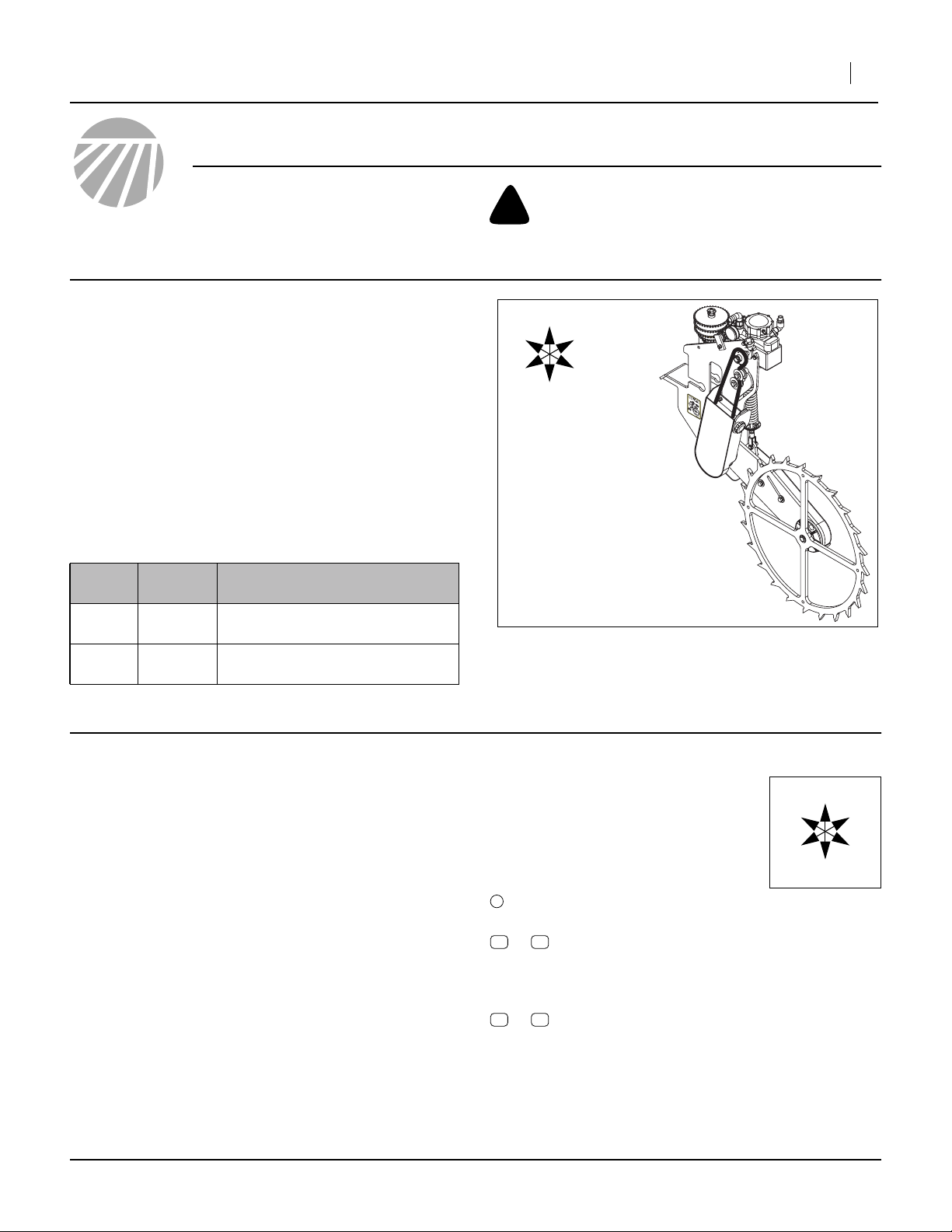

Ground Drive Fertilizer Pump

Yield Pro Planters

Used with:

• 2006- Yield Pro

® 1225/1625

General Information

These instructions explain how to install the Ground

Drive Fertilizer Pump enhancement kit on a planter

which already has a fertilizer pump coupled to the meter

drive system. Installing this kit eliminates the need to

adjust the pump whenever seed rates are changed.

This kit is not needed for 2007+ planters, as their

optional fertilizer systems already include these components. This kit requires a pre-existing fertilizer system,

and re-uses many existing system components.

These instructions apply to:

Planter

Model

YP1225 407-148A YP GROUND DRIVE FERT

YP1625 407-148A YP GROUND DRIVE FERT

Kit Kit Description

PUMP KIT

PUMP KIT

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

U

F

L

R

B

D

Figure 1

New Ground Drive Assembly

25302

Before You Start

Each kit converts an entire planter. Inventory the contents per “New Parts: Kit 407-148A” on page 7.

Review these instructions, and make sure you understand which existing system components are re-used,

and where they are located. The new components, and

the existing components to be re-used or discarded, are

located on the back of the left wing of the planter, about

halfway out on the toolbar.

Tools Required

• pipe sealant such as RECTORSEAL® NO. 21

• basic hand tools

• a second or third person for Step 28

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

1

11 27

to

51 71

to

callouts identify components in the currently

referenced Figure or Figures.

callouts reference new parts from the list on

page 7. The descriptions match those on the

cartons, bags or item tags, as well as your

updated Parts Manual.

callouts reference affected existing parts from

the table on page 9. The descriptions match

those in your Parts Manual.

U

F

L

R

B

D

©Copyright 2006 Printed 04/23/2007 407-149M

Page 2

2 Ground Drive Fertilizer Pump

Pre-Assembly Preparation

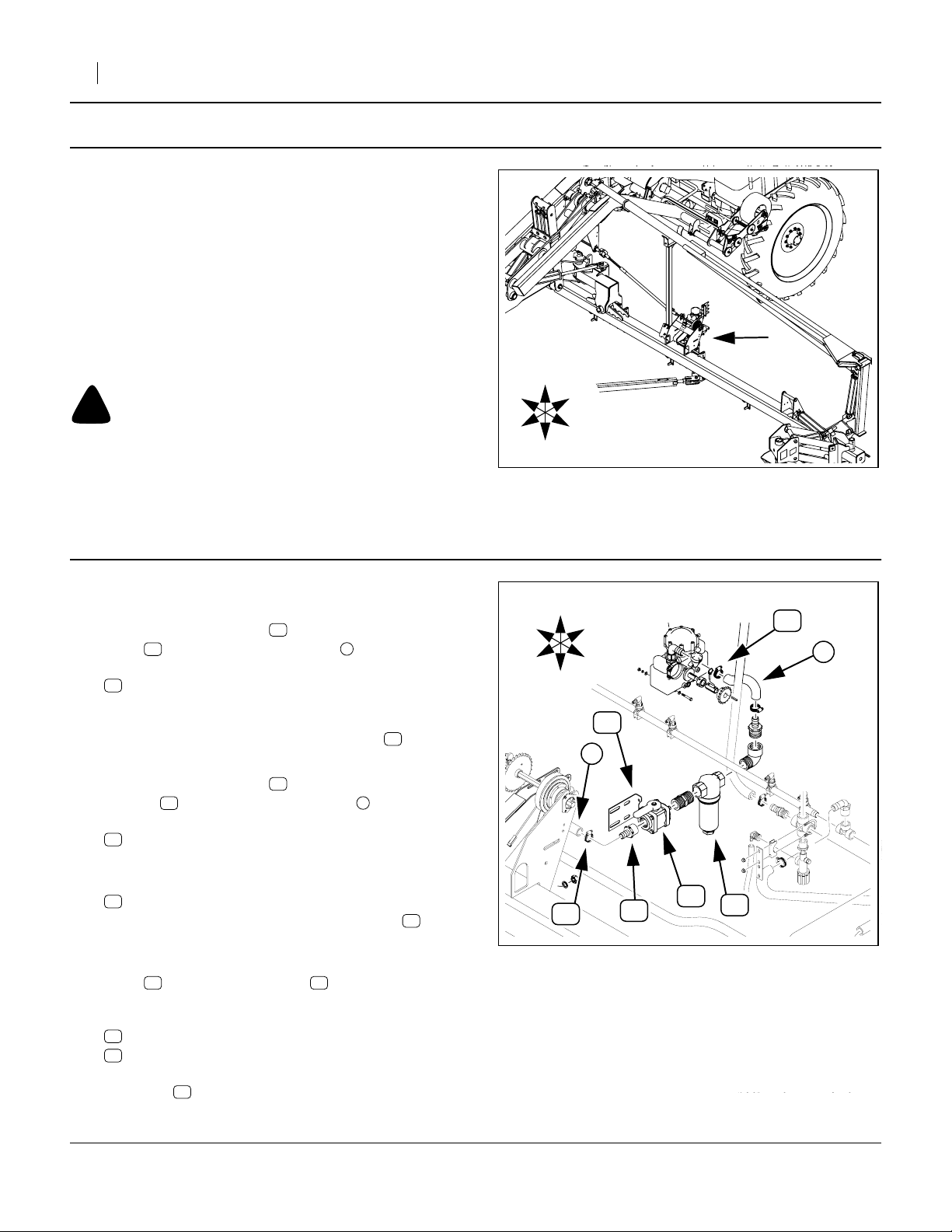

Refer to Figure 2,

which depicts the planter with row units removed for clarity.

The ground drive pump is installed on the left wing,

at or near the location of the existing shaft-driven

fertilizer pump.

1. Unfold the planter. The planter must be raised for

unfolding, but may be raised or lowered for all

tasks prior to Step 28. If left raised, installed lift/

transport locks. Secure the tractor.

2. Flush the existing fertilizer system with water. Fluids will drain off during updates to the plumbing.

!

CAUTION

Exercise caution when working with a used fertilizer system.

The chemicals are usually very caustic. Unless you fully

operate the planter while flushing with water, some chemicals

will drain from components during disassembly. Trace

amounts may remain in any case.

R

F

U

D

B

L

Figure 2

Location of Components

Great Plains Mfg., Inc.

25303

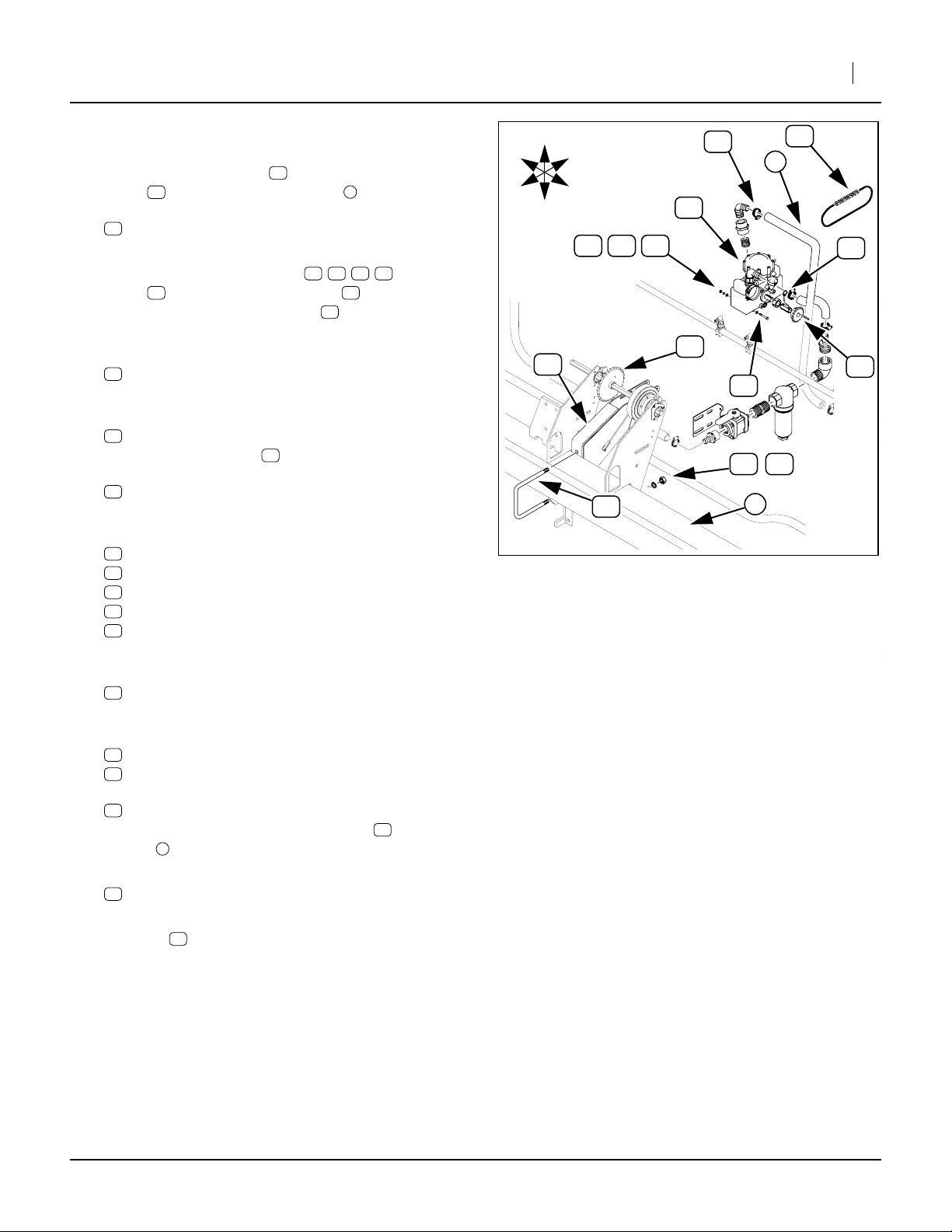

Remove Existing Components

Dismount Valve and Strainer

Refer to Figure 3

3. Loosen the hose clamp on the inlet port of

67 1

valve and disconnect the hose .

Remove and save:

56

CLAMP WRM DRV #16 SS (.68-1.5)

If the hose can reach the ground, protect the open

end from contamination, for example, by clamping

a plastic bag over the end. If the strainer is due

for maintenance, this is an ideal time to clean it.

4. Loosen the hose clamp on the outlet port of

strainer and disconnect the hose .

Remove and save:

56

Protect hose end from contamination.

5. Remove:

69

plastic adaptor fitting from the inlet of valve .

This fitting is not re-used.

6. Remove the fasteners (not shown) that attach

valve to valve mount plate , and that attach

the plate to the planter frame.

Remove and save the valve/strainer assembly:

70

67

and its interconnecting and outlet fittings.

The plate and the fasteners are not re-used.

70 2

CLAMP WRM DRV #16 SS (.68-1.5).

AD 1 1/2MNPT X 1HB POLYPROP

67 52

STRAINER BANJO LST150-80 MESH

VALVE 1 1/2FNPT BALL POLYPROP

52

56

70

56

67

R

F

U

D

56

B

L

52

1

69

Dismount Strainer

67

Figure 3

56

2

70

25304

407-149M 04/23/2007

Page 3

Great Plains Mfg., Inc.

Installation Instructions 3

Dismount Pump and Pump Sprocket

Refer to Figure 4

7. Loosen the hose clamp on the inlet port of

71 1

pump and disconnect the hose .

Remove and save:

56

CLAMP WRM DRV #16 SS (.68-1.5)

Protect hose end from contamination.

8. Loosen two sets of bolts/nuts , , , holding

71 55

pump on fertilizer pump mount . Slide pump

forward to obtain slack in chain .

9. Remove retaining clip (not shown) in chain link,

and remove:

51

CHAIN RL #40 60, 63 or 66 PITCHES

This chain is not re-used.

10. Remove and save

63

PIN LINCH 3/16 X 1 9/16 LONG

which retains sprocket on pump shaft.

Remove:

65

SPKT 40C17, 24 or 30 X 7/8 HEX BORE

It is not re-used.

11. Remove three sets of:

57

HHCS 5/16-18X3 1/4 GR5

58

NUT HEX 5/16-18 PLT

60

WASHER LOCK SPRING 5/16 PLT

62

WASHER FLAT 5/16 SAE PLT

65

SPKT 40C17, 24 or 30 X 7/8 HEX BORE

These fasteners are not re-used.

12. Remove and save:

71

PUMP HYPRO D30AP-A DIAPHRAM

Also save attached fittings and hose.

13. Remove two sets of:

59

NUT HEX 5/8-11 PLT

61

WASHER LOCK SPRING 5/8 PLT

and one:

64

U-BOLT 5/8-11 X 7 1/32 X 8 1/2

These attach the fertilizer pump mount to wing

toolbar . These fasteners are not re-used.

14. Remove:

55

Mount is not re-used.

2

FERTILIZER PUMP MOUNT

56

57 58 60 62

51

65

55

R

F

U

D

55

B

L

6058 62

64

Dismount Pump

71

66

Figure 4

56

51

1

63

65

57

6159

2

25304

15. Sprocket , on wing drive shaft, is not re-used,

but may be left in place.

04/23/2007 407-149M

66

Page 4

4 Ground Drive Fertilizer Pump

Install New Components

Determine Ground Drive Location

These instructions do not specify a precise location for

mounting the new ground drive, due to the wide variety

of factory configurations and end user modifications.

The hose connections to the fertilizer feed line, strainerto-pump line and pump-to-distribution manifold permit

considerable flexibility in placement of the strainer and

pump.

The strainer (on a new mount) requires a vertical surface with mounting holes, typically the inside or outside

of either plate of the wing drive shaft bracket. Unless

you add hose, it needs to be within existing hose length

of the feed line.

The optimal placement for the drive unit itself is halfway

between rows (row units or row unit pairs in twin-row),

and within hose length of the strainer and manifold. If

you add hose, you have more flexibility.

These instructions assume that the strainer is mounted

inside the wing drive shaft brackets, on the inboard

plate, and the ground drive assembly is mounted about

a foot outboard of the wing drive shaft brackets.

Great Plains Mfg., Inc.

Install Strainer Mount

Refer to Figure 5

16. Select one new:

15

407-171D FERT VALVE MNT

three new:

16

802-034C HHCS 1/2-13X1 1/4 GR5

six new:

21

804-016C WASHER FLAT 1/2 SAE PLT

three new:

20

804-015C WASHER LOCK SPRING 1/2 PLT

and three new:

18

803-020C NUT HEX 1/2-13 PLT.

17. Make sure that at least two of the four slotted holes

in the mount can be aligned with holes at your

intended mounting point (in this illustration, the left

side of the inboard plate of the left wing drive

shaft bracket).

Mount is intended to place with the short bent

end to the Back and facing away from the mounting

surface.

18. Insert each bolt through one flat washer and

then through at least two of the four holes in the

mount and the frame plate .

15

1

15

16 21

15 1

18

1

20

21

15

Figure 5

Install New Valve Mount

21

R

F

U

B

L

D

16

25305

19. Add another flat washer , lock washer and

18

nut to each bolt and finger tighten.

407-149M 04/23/2007

21 20

Page 5

Great Plains Mfg., Inc.

Installation Instructions 5

Re-Install Valve and Strainer

Refer to Figure 6

20. Select one saved:

70

STRAINER BANJO LST150-80 MESH

67

VALVE 1 1/2FNPT BALL POLYPROP

and its interconnecting and outlet fittings.

Select one new:

27

830-145C AD 1 1/2MNPT X 1FNPT POLYPROP

and select one new:

26

830-127C EL 1MNPT X 1HB POLYPROP

The valve assembly attaches to the mount

using two bolts already present in the valve, which

pass through the holes in the short bent end of the

mount.

21. Hand-position valve/strainer assembly / to

determine:

• mounting clearance,

• hose clearance,

• operator access,

• clearance for valve operation,

• preferred inlet elbow orientation, and

• clearance for strainer maintenance.

22. Apply pipe sealant to male threads of adaptor

and screw it into the inlet port of valve . Apply

sealant to the male threads of elbow and screw

it into adaptor , adjusting final orientation to

desired angle.

Note: Do not use tape sealant on pipe threads. Tape

fragments will clog strainer and block orifices.

27

15

67 70

67

26

27

R

F

26

U

D

B

L

21

27

2

67

Re-Install Valve and Strainer

70

Figure 6

1

25306

23. Adjust mount to provide suitable final position

and tighten bolts/nuts installed in Step 19.

24. Loosen nuts on mounting side of valve and

remove bolts , noting placement of washers.

Position valve on mount , re-insert bolts, washer

and nuts, and tighten.

25. Re-connect fertilizer feed line hose (not shown)

and secure with clamp (not shown).

04/23/2007 407-149M

15

167

2

15

56

Page 6

6 Ground Drive Fertilizer Pump

Great Plains Mfg., Inc.

Install Ground Drive Assembly

Refer to Figure 7, which depicts the new ground drive with guards

removed. Guards may be left in place until final sprocket mounting.

26. Select one new:

14

407-147K FERTILIZER PUMP DRIVE ASY KIT

two new:

25

806-102C U-BOLT 3/4-10 CORNER 7 SQ

four sets new (not shown):

23

804-025C WASHER FLAT 3/4 SAE PLT

22

804-023C WASHER LOCK SPRING 3/4 PLT

19

803-027C NUT HEX 3/4-10 PLT

27. Position the two U-bolts over the tool bar at

the mount location.

28. Have assistant(s) hold the drive assembly at

the mount point. Insert the U-bolts . Temporarily

hold the assembly in place with four nuts .

29. Remove one nut at a time. Place a flat washer

23 22

(not shown), lock washer (not shown) and

19

nut on the U-bolt. Tighten each until the drive

assembly’s mount is flat against the tool bar.

Tighten to torque spec.

19

22 1

14

25

19

Re-Install Pump

Refer to Figure 8

30. Select the saved

71

PUMP HYPRO D30AP-A DIAPHRAM

three new

17

802-314C HHCS M8X1.25X20 GR8.8

and three new

24

804-157C WASHER SPRING LOCK M8 PLT

31. Place lock washers on each bolt .

24 17

17

25

24

14

1

Figure 7

Install Ground Drive

1

U

F

L

R

B

D

25307

3

2

32. Position the pump at the top cut-out of the contact wheel mount weldment . Align the pump

against the inside of the left plate , so that the

upper air chamber of the pump is Up, the inlet

elbow is in Front, and the threaded holes on the

three-hole side of the pump match the three holes

in the plate

3

71

1

1

2

L

B

U

F

R

71

D

Insert three bolts/washers / and tighten.

33. Re-connect hose from strainer to pump inlet (not

shown) and secure with saved clamp.

34. Re-connect manifold hose (not shown) to pump

outlet elbow and secure with saved clamp.

407-149M 04/23/2007

3

17 24

Figure 8

Re-Install Pump

25308

Page 7

Great Plains Mfg., Inc.

Closeout

Refer to Figure 9

To complete the installation the Driving and Driven

sprockets need to be mounted on the drive. If you do

not know the next fertilizer rate desired, sprocket

change does not need to be completed at this time.

Setup and use of the Ground Drive Fertilizer Pump is

described in the 401-226M Operator’s Manual, a copy

of which is included in this kit.

To change sprockets, remove the knob securing the

drive guard , and remove the guard. Remove the linch

pins securing the sprockets on drive shafts and storage shafts . Exchange sprockets per the Drive Type

table of the Fertilizer Rate chart, and re-pin.

2

4

1

3

Installation Instructions 7

U

D

R

B

4

F

L

4

3

2

1

3

Parts Lists

New Parts: Kit 407-148A

The part call-out numbers in this list match all Figures in

the installation instructions.

Callout Quantity

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

1 407-149M This manual

1 401-226M MANUAL OP 12 & 16 ROW YP PLTR

1 401-226P MANUAL PARTS 12 & 16 ROW YP PL

1 407-147K FERTILIZER PUMP DRIVE ASY KIT

1 407-171D FERT VALVE MNT

3 802-034C HHCS 1/2-13X1 1/4 GR5

3 802-314C HHCS M8X1.25X20 GR8.8

3 803-020C NUT HEX 1/2-13 PLT

4 803-027C NUT HEX 3/4-10 PLT

3 804-015C WASHER LOCK SPRING 1/2 PLT

6 804-016C WASHER FLAT 1/2 SAE PLT

4 804-023C WASHER LOCK SPRING 3/4 PLT

4 804-025C WASHER FLAT 3/4 SAE PLT

3 804-157C WASHER SPRING LOCK M8 PLT

2 806-102C U-BOLT 3/4-10 CORNER 7 SQ

1 830-127C EL 1MNPT X 1HB POLYPROP

1 830-145C AD 1 1/2MNPT X 1FNPT POLYPROP

Part

Number

Ground Drive Type

Your kit includes the following parts..

Part Description

Figure 9

25319

04/23/2007 407-149M

Page 8

8 Ground Drive Fertilizer Pump

Existing Parts Affected

The following parts are involved in the upgrade. The Disposition column indicates whether they are left in place,

moved or discarded.

The part call-out numbers in the list on page 9 match all

Figures in the installation instructions.

This is not a comprehensive list of all pre-existing parts of

the fertilizer system. Other than fasteners used on

removed parts, parts not listed remain in place.

71

62

6058

63

65

51

Great Plains Mfg., Inc.

U

R

F

B

L

D

64

59

66

61

55

52

67

69

57

68

70

Figure 10

Existing Parts

56

53

54

25304

25309

25310

407-149M 04/23/2007

Page 9

9 Ground Drive Fertilizer Pump

Existing Parts List

Callout Part No. Qty Part Description Part Disposition

Multiple 1 CHAIN RL #40 60, 63 or 66 PITCHES Not re-used. Function replaced by chain

51

included with wheel assembly

148-410D 1 VALVE MOUNT PLATE Not re-used, suggest removing

52

401-226M 1 Operator’s Manual Replaced with new manual

53

(same part number)

401-226P 1 Parts Manual Replaced with new manual

54

(same part number)

407-120H 1 FERTILIZER PUMP MOUNT Not re-used, suggest removing

55

800-123C CLAMP WRM DRV #16 SS (.68-1.5) Re-used

56

802-390C 1 HHCS 5/16-18X3 1/4 GR5 Not re-used, and replaced by new fasteners

57

803-008C 2 NUT HEX 5/16-18 PLT Not re-used, and replaced by new fasteners

58

803-021C 2 NUT HEX 5/8-11 PLT Not re-used, and replaced by new U-bolts

59

with new fasteners

804-009C 2 WASHER LOCK SPRING 5/16 PLT Not re-used, and replaced by new fasteners

60

804-022C 2 WASHER LOCK SPRING 5/8 PLT Not re-used, and replaced by new U-bolts

61

with new fasteners

804-036C 4 WASHER FLAT 5/16 SAE PLT Not re-used, and replaced by new fasteners

62

805-240C 1 PIN LINCH 3/16 X 1 9/16 LONG Re-used

63

806-052C 1 U-BOLT 5/8-11 X 7 1/32 X 8 1/2 Not re-used, and replaced by new U-bolts

64

with new fasteners

Multiple 1 SPKT 40C17, 24 or 30 X 7/8 HEX BORE Not re-used, and replaced by new sprocket

65

Multiple 1 SPKT 40C23 or 30 X 7/8 HEX BORE Not re-used, but may be left in place

66

829-013C 1 VALVE 1 1/2FNPT BALL POLYPROP Re-used - placed on new mount

67

830-045C 1 AD 1 1/2MNPT POLYPROP

68 67

830-254C 1 AD 1 1/2MNPT X 1HB POLYPROP Not re-used, and replaced by new fitting

69

831-029C 1 STRAINER BANJO LST150-80 MESH

70 67

831-045C 1 PUMP HYPRO D30AP-A DIAPHRAM Re-used - placed on new mount

71

Re-used - moved with valve

Re-used - moved with valve

Great Plains Mfg., Inc.

Great Plains Manufacturing, Inc.

Corporate Office P.O. Box 5060

Salina, Kansas 67402-5060 USA

407-149M 04/23/2007

Page 10

10 Ground Drive Fertilizer Pump

Reference Information

Abbreviations

AD Adaptor

ASY Assembly

DRV Drive

EL Elbow

FERT Fertilizer

GR Grade

HB Hose Barb

HHCS Hex Head Cap Screw (Bolt)

MNT Mount

NPT (Female/Male) National Pipe Thread

PLT Plated

POLYPROP Polypropylene

RL Roller

SAE Society of Automotive Engineers

SPKT Sprocket

SQ Square

SS Stainless Steel

WRM Worm

Great Plains Mfg., Inc.

Torque Values

Fastener/Fitting Ft-Lbs N-m

M8X1.25 Class 8.8 26 19

1

⁄

-13

2

3

⁄

-10 U-bolt

4

105 76

360 265

407-149M 04/23/2007

Loading...

Loading...