Page 1

Great Plains Mfg., Inc.

Installation Instructions

Full Press Drill

Post Conversion Update

Used with:

• 30’ 3-Section Full Press Drill

• 30’ High Clearance Full Press Drill

General Information

These instructions explain how to install the Full

Press Post Conversion Kit.

These instructions apply to:

104-008A RH Full Press Post and Conv. Kit

104-009A LH Full Press Post and Conv. Kit

104-011K RH Full Press Conv. Kit

104-012K LH Full Press Conv. Kit

When you see this symbol, the subsequent instructions and

warnings areserious- follow without exception. Your life and

!

!

the lives of others depend on it!

!

Use caution when using tools which emit sparks such

as torches, welders and grinders. Do not use spark

emitting tools in areas where flammable or explosive

materials may be present. Do not allow anyone to enter into the path of sparks.

CAUTION!

Manual Update

Refer to theFull Press Drill operator’s manual for

detailed information on safely operating, adjusting, troubleshooting and maintaining the Full

PressPostConversion.Referto thepartsmanual

for part identification.

105-100M Operator’s/Parts Manual

129-035M Operator’sManual

129-035P Parts Manual

Before You Start

Pages 6 and 7 are a detailed listing of parts included in the Full Press Post Conversion

package. Use this list to inventory parts received.

Tools Required

• Basic hand tools

• Acetylene torch

• Welder

• Grinder

Definitions

Right-hand and left-hand as used in this manual

are determined by facing the direction the machine will travelwhile inuse unlessotherwise

stated.

Note: These instructions are written with the assumption that the existing pivotpost isin usable

condition and does not need replaced. This requires kits 104-011K and 104-012K.

If the existing pivotpost needs replaced order kits

104-008A and 104-009A and skip steps 14

through 22.

© Copyright 2002 Printed

9/9/2002

104-010M

Page 2

Post Conversion Update

2

Assembly Instructions

1. Remove the left-hand drill boxfrom thelefthand pivot post.

2. Remove the left-hand hydraulic cylinder.

3. Removethe left-hand pivot post from thedrill

main frame.

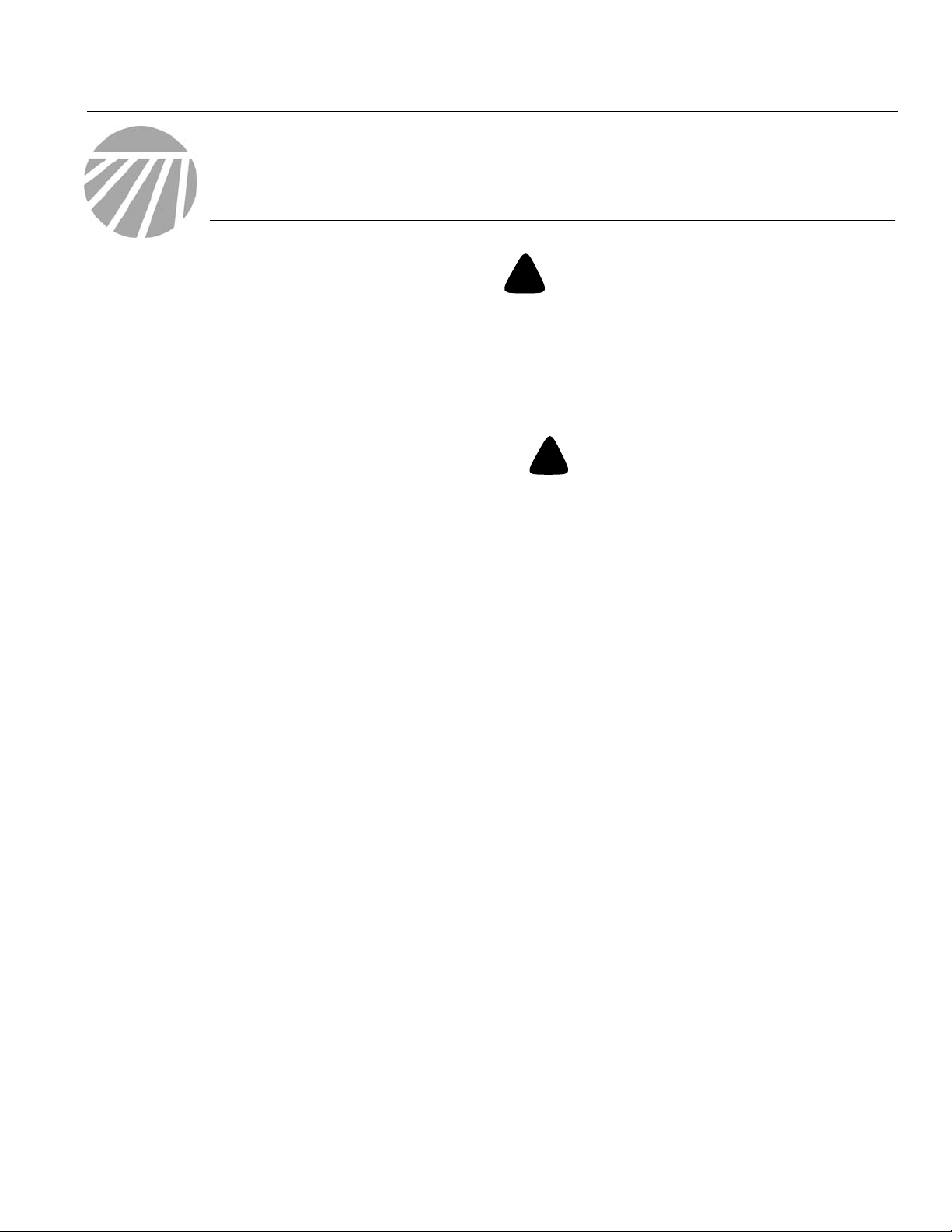

Refer to Figure 1

4. Measure 12 25/32" from the front surface of

square tube (1) towards the outer end of

square tube (2).

Note:Cut tube alittlelongerto allowforgrindingto

make the end square.

5. Using a torch, carefully cut tube (2).

6. Grind the surfacesofthesquaretubesmooth.

Great Plains Mfg., Inc.

Refer to Figure 2

7. Placethespindlehubassembly(1) on the top

surfaceof the squaretube (2). Measurefrom

the center point of the spindle hub assembly

to the front surface of the square tub 13 7/8".

8. Use the spindle hub assembly as a template

to mark whereto cutasaddle into thesquare

tube.

9. Use a torch to make a saddle cut in the

square tube and smooth the surfaces with a

grinder.

Note: Be carefulwhen using the spindlehub as a

template,there are bearing cupsontheinside.Do

not use as a gig for torching the saddle cut.

20224

Figure 1

Remove Old Pivot Ball

20225

Figure 2

Marking for the Saddle Cut

104-010M 4/9/2004

Page 3

Great Plains Mfg., Inc.

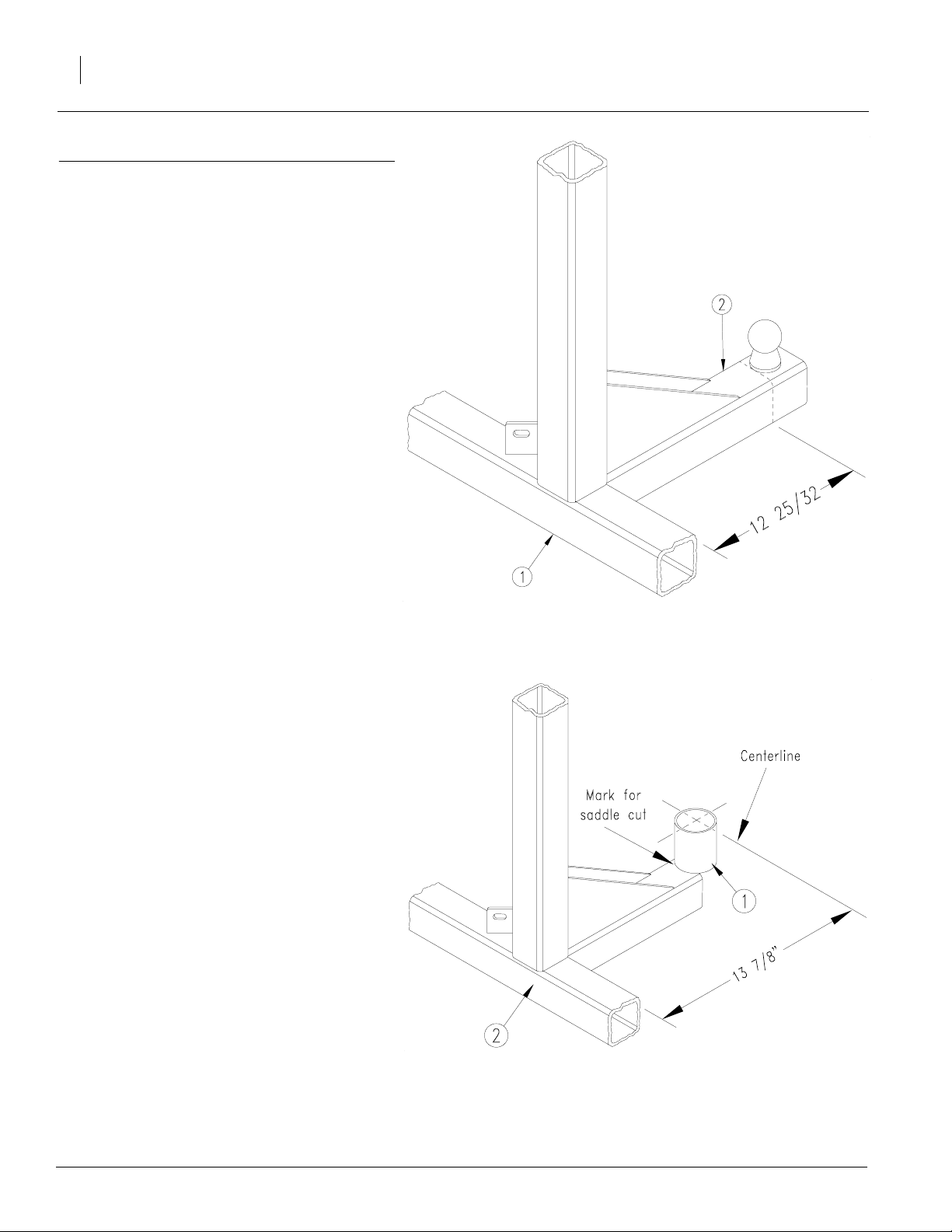

Refer to Figure 3

10. Center the spindle hub assembly (1) on the

square tube wherethe saddlecut was made.

Positionthe hub so the top edge is raised 1/4"

above the topsurface of thetube. Make sure

the centerline of the hub is 13 7/8" from the

front surface of the square tube.

11. Clamp the spindle hub assembly (1) in place

and make sure it is plum with the upright

square tube (2). Clamp only to theoutside of

the hub.

Note: Make sure the measurementsare accurate

andthehub is plum with the tube. Securely clamp

the hub in place before welding.

12. Coverthe openings of the spindle hub assembly (1) so not to allow any welding sparks or

beadstoget inside. Thisisnecessaryinorder

to protect the bearing cups on the inside of

the hub.

13. Weld the spindle hub assembly (1) in place

using a weld with high tensile strength.

20226

Installation Instructions

Figure 3

Spindle Hub Assembly

3

Refer to Figure 4

14. If you are reusing the pivot post (1) it will be

necessary to removethe old pivot bracket(2).

15. Afterremovingoldbracket(2) smooth the surfaces of the pivot post(1).

4/9/2004

20227

Figure 4

Pivot Post

104-010M

Page 4

Post Conversion Update

4

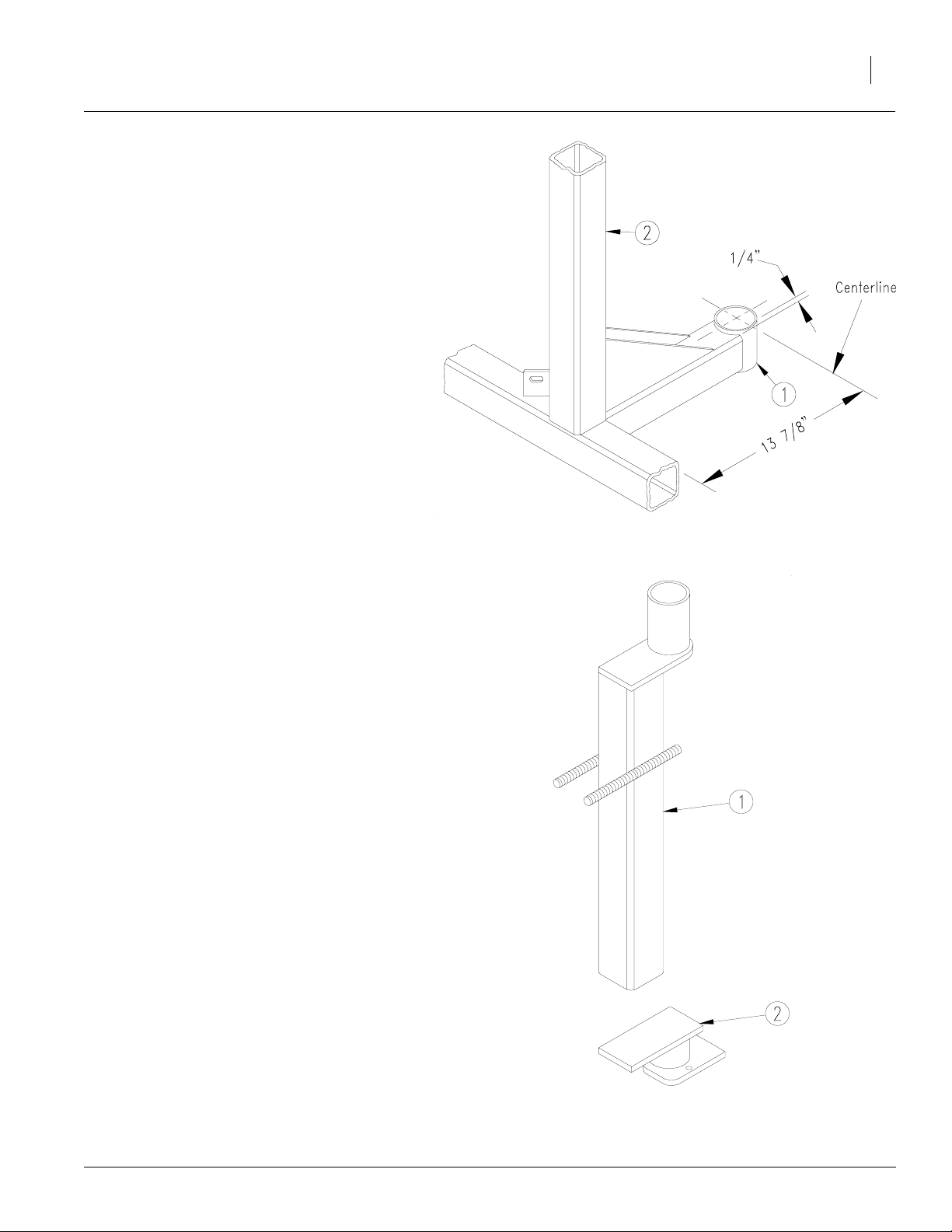

Refer to Figure 5

16. Attachthe U-joint post side plates (1) toopposite sides of the old pivot post (2). Place the

plates with the their holes down and extending out in thesame direction as theround pivot tube (3) on top.

17. Measure 31 7/16" from the top edge of the

round pivot tube (3)to the centerlineof the Ujoint post side plates (1). Measure back 1/8"

from the frontedge of the oldpivotpost (2) to

the centerline of the U-joint post side plates

(1).

18. Clamp U-joint post side plates (1) to the old

pivot post (2) and recheck your measurements before welding.

19. Insert the 6 3/4" long post pivot bolt (4)

through the holes in the U-joint post side

plates (1). Thebolt should movefreely, if not,

check your measurements.

Great Plains Mfg., Inc.

20. Hold the 1/4" squarekey (5) againstthe plate

(1) and head of bolt (4). Tack weldit tothe

plate.This willkeepthe boltfromturningwhile

tightening the nut later.

21. Remove the bolt (4).

22. Weld U-joint post side plates (1) and 1/4"

square key in place using a weld with high

tensile strength.

Refer to Figure 6

23. Afterallowingthespindlehubassembly(1) to

cool, remove anydirt or foreign material

which might have gotten inside.

24. Packthe topbearing cone (2) with wheel

bearing greaseand insert it in the top of the

spindle hub assembly (1).

25. Install the grease seal (3) and insert the lefthand U-joint spindle (4).

26. Packthe bottom bearing cone (5) with wheel

bearing greaseand insert it in the bottom of

the spindle hub assembly (1).

20221

Figure 5

Old Pivot Post

27. Install the 7/8" flat washer (6) and thread on

the 7/8" slotted hex nut (7). Snug the nut(7)

while moving the U-jointspindle (4) back and

forth. Afterthe snuggingthe nut back it off

about 1/2 a turn. Line one of the slots in the

nut (7) with the hole in the U-joint spindle (4)

and insert the cotter pin (8).

28. Install the hub cap (9) on the spindle hub assembly (1).

104-010M 4/9/2004

20222

Figure 6

Spindle Hub Assembly

Page 5

Great Plains Mfg., Inc.

Refer to Figure 7

29. Install the top round tube of the pivot post (1)

into the pivot post cap on themain drillframe.

30. Rotate the U-joint spindle (2) so the hole for

the cylinder clevis (6) is facing towards the

closing cylinder lug (7).

31. Align the holes in the U-joint post side plates

on the pivot post (1) with the U-joint spindle

(2).

32. Insert the 6 3/4" long pivot bolt (3) and position it so the head rests against the 1/4"

squarekeyso the boltwillnotturnwhilebeing

tightened. Secure bolt with the 1 1/4" lock

washer(4)and 1 1/4" hex nut(5).Tightennut.

Installation Instructions

5

Refer to Figure 8

33. Place the closing cylinder lug (1) on top of

square tube (2).

34. From the centerline of the hole in the closing

cylinder lug (1) measure 16 7/8"to the centerline of the square tube(3). Measure fromthe

centerline of the lug (1) 1 3/8" to the edge of

the square tube (2).

35. Clamp lug (1) and weld in place using a high

tensile strength weld.

36. Reinstall the hydraulic cylinder.

37. Reattach the left-hand drill box tothe pivot

post.

38. Repeat the procedureto install thepivotpost

conversion kit on the right-hand side of the

drill substituting right forleft.

20223

Figure 7

Installing Pivot Post

20229

4/9/2004

Figure 8

Closing Cylinder Lug

104-010M

Page 6

Great Plains Mfg., Inc.

104-008A RH FULL PRESS POST AND CONV KIT

Your kit includes:

Qty. Part No. Part Description

1 104-011K RH FULL PRESS CONV KIT

1 128-002H HC POST WELDED ASSEMBLY RH

Installation Instructions

6

104-009A LH FULL PRESS POST AND CONV KIT

Your kit includes:

Qty. Part No. Part Description

1 104-012K LH FULL PRESS POST KIT

1 128-001H HC POST WELDED ASSEMBLY LH

104-010M4/9/2004

Page 7

Great Plains Mfg., Inc.

104-011K RH FULL PRESS POST CONV KIT

Your kit includes:

Qty. Part No. Part Description

1 104-010M MANUAL FULL PRESS POST CON

1 109-031D JACK SHAFT - KEY

1 125-001H U JOINT SPINDLE RH

1 125-005S SPINDLE HUB ASSEMBLY

1 125-066D CLOSING CYLINDER LUG

2 128-053D U-JOINT POST SIDE PLATE

1 156-022H POST PIVOT BOLT

1 800-001C GREASE ZERK STRAIGHT 1/4-28

1 803-029C NUT HEX SLOTTED 7/8-14 PLT

1 803-034C NUT HEX 1 1/4-7 PLT

1 804-026C WASHER FLAT 7/8 SAE PLT

1 804-030C WASHER LOCK 1 1/4 SPRING PLT

1 805-016C PIN COTTER 3/16 X 1 1/4 PLT

1 816-012C SEAL 3.375 X 2.0 X.438 CR2

1 822-014C BEARING CONE 25590

1 822-016C BEARING CONE 25877

1 890-032C HUB CAP

Installation Instructions

7

104-012K LH FULL PRESS CONVERSION KIT

Your kit includes:

Qty. Part No. Part Description

1 104-010M MANUAL FULL PRESS POST CON

1 109-031D JACK SHAFT - KEY

1 125-002H U JOINT SPINDLE LH

1 125-005S SPINDLE HUB ASSEMBLY

1 125-066D CLOSING CYLINDER LUG

2 128-053D U-JOINT POST SIDE PLATE

1 156-022H POST PIVOT BOLT

1 800-001C GREASE ZERK STRAIGHT 1/4-28

1 803-029C NUT HEX SLOTTED 7/8-14 PLT

1 803-034C NUT HEX 1 1/4-7 PLT

1 804-026C WASHER FLAT 7/8 SAE PLT

1 804-030C WASHER LOCK 1 1/4 SPRING PLT

1 805-016C PIN COTTER 3/16 X 1 1/4 PLT

1 816-012C SEAL 3.375 X 2.0 X.438 CR2

1 822-014C BEARING CONE 25590

1 822-016C BEARING CONE 25877

1 890-032C HUB CAP

4/9/2004

104-010M

Loading...

Loading...