Page 1

Great Plains Manufacturing, Inc. 1

Flex Harrow Light Kit

Installation Instructions

General Information

These Instructions explain how to install the flex harrow

light update kit. The lights will be shipped mounted to

brackets.

MetaData: of <Safety Topics>Introduction

Tools Required

• Basic Hand Tools

• Drill & Drill Bits

• Welder (optional)

Models Covered

Flex Harrow 6000

Note: Refer to Parts manual (564-070P) for machine parts

breakdown. The brackets may be welded on instead

of drilling holes and bolted on. Use drill placement

drawings if welding on. Align holes in brackets to dimensions in drawings. Remove old wiring harness

and light brackets.

564-091A FLEX HARROW LIGHT KIT

Part #

564-088H LIGHT BRACKET 2

564-090H LIGHT BRACKET 2

801-081C SCREW HEX SELF TAP 1/4-20X3/4 8

564-092M

FLEX HARROW LIGHT UPDATE

802-005C HHCS 1/4-20X1 GR5 12

802-091C HHCS 1/2-13X1 1/2 GR5 4

803-007C NUT-LOCK 1/4-20 PLT 12

803-020C NUT HEX 1/2-13 PLT 4

804-015C WASHER LOCK SPRING 1/2 PLT 4

838-603C DECAL REFLECTOR ORANGE 2X9 2

838-614C DECAL REFLECTOR RED 2X9 2

838-615C DECAL REFLECTOR AMBER 2X9 4

890-901C SAFETY LIGHT KIT 1

Description Qty.

KIT

1

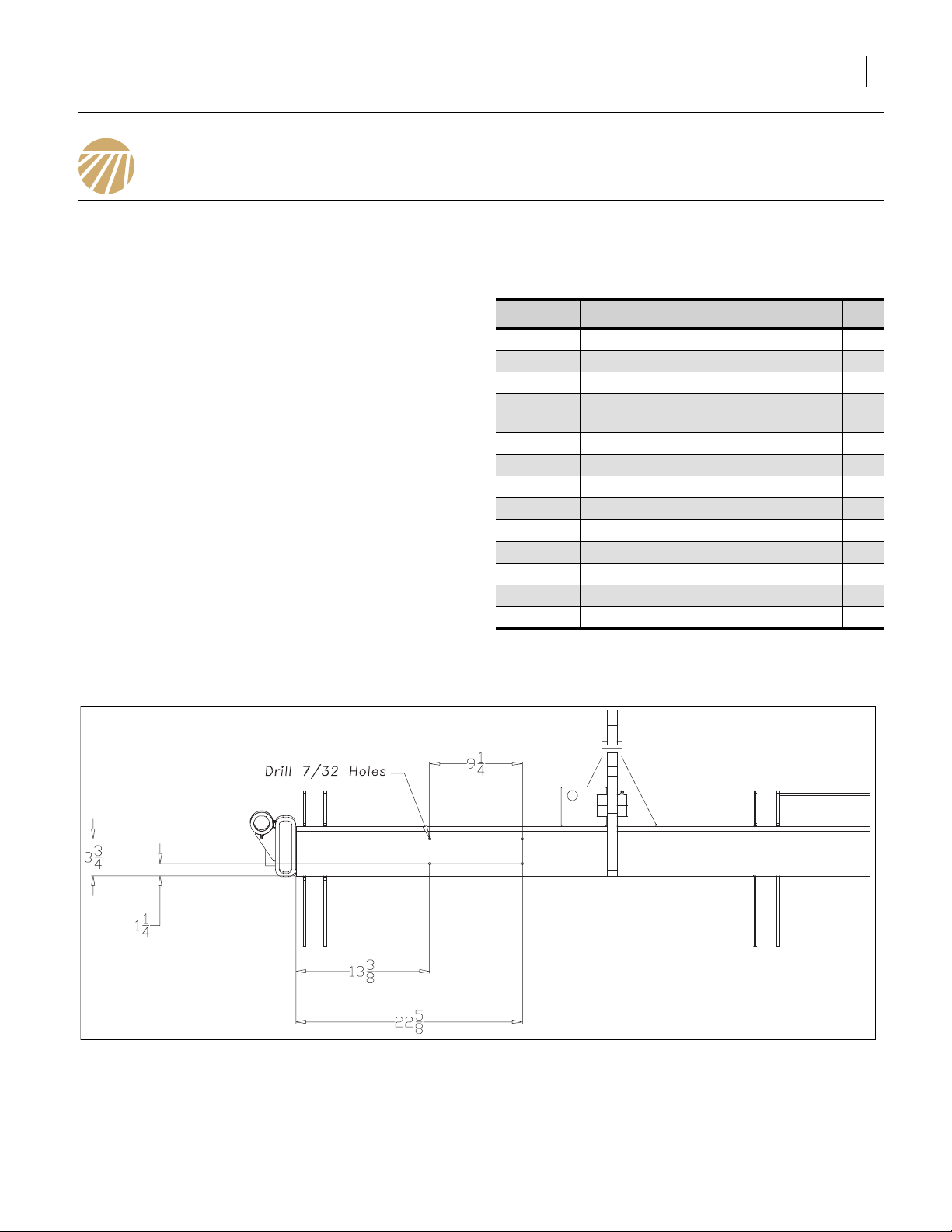

Bottom Hole Placement

Refer to Figure 1

1. Drill four 7/32 holes in location shown on both sides.

Null4:

Bottom Hole Placement

Null4:

Null4:

Figure 1

42305

12/15/2011 564-092M

Page 2

2 Light Kit Great Plains Manufacturing, Inc.

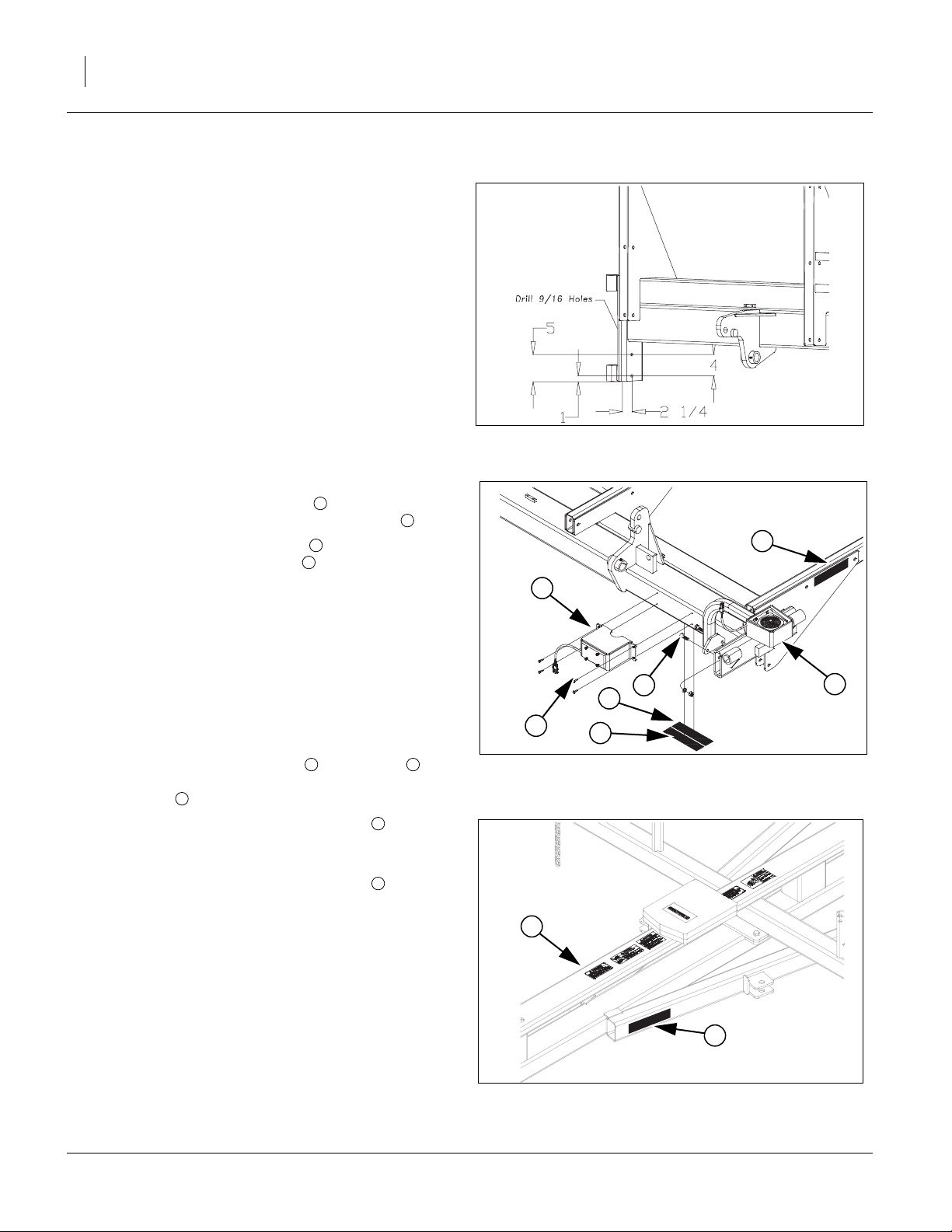

Side Hole Placement

Refer to Figure 2

2. Drill two 9/16 holes in location shown on both sides.

Light Bracket Mounting

Refer to Figure 3

3. Fasten light bracket assembly to the pre-drilled

holes with the 1/4 x 3/4 self tapping screws .

4. Fasted light bracket assembly in position shown

with the 1/2 x 1 1/2 hex bolts , 1/2 lock washers

and 1/2 nuts.

5. Tighten all bolts.

6. Route wiring harness from front of hitch along

hydraulic hoses and across to light brackets. Route

wires through bent tubing on outer light brackets and

plug ends into lights as marked on harness.

7. Fasten wiring harness with plastic ties or hose clips.

Be sure wire is fastened securely so it doesn’t drag

or get pinched when folding machine.

8. Clean surface and attach red and orange

decals on bottom of tube in line with light bracket

assembly as shown on both sides.

1

9. Clean surface and attach amber decal in position

shown on both sides of center frame bracket.

Refer to Figure 4

10. Clean surface and attach amber decal in position

shown on both sides of hitch angle tube.

1

2

3

4

5 6

7

7

FigureSpacer:

FigureSpacer:

Figure 2

42306

Side Hole Placement

7

1

4

3

5

2

6

Figure 3

Light Bracket Mounting

42307

7

7

FigureSpacer:

Figure 4

Amber Decals Hitch Location

564-092M 12/15/2011

42406

Loading...

Loading...