Page 1

Operator’ s Manual

FCP1000

Three-Meter Drill and Hitch

Manufacturing, Inc.

www .g reatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious- follow without exception. Your life and the lives of

others depend on it!

© Copyright 2004 Printed

7/5/2005

21895

Cover illustration may show optional equipment not supplied with standard unit.

148-693M-A

Rev. C

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Important Safety Information . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Description of Unit. . . . . . . . . . . . . . . . . . . . . . . . 8

Intended Usage. . . . . . . . . . . . . . . . . . . . . . . 8

Using This Manual. . . . . . . . . . . . . . . . . . . . . . . . 8

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 1 Preparation and Setup . . . . . . . . . . . . . . 9

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring Drill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hitching Tractor to Implement . . . . . . . . . . . . . . 10

Hydraulic Hook-up. . . . . . . . . . . . . . . . . . . . . . . 11

Bleeding Hydraulic Systems . . . . . . . . . . . . . . . 11

Bleeding Tongue Cylinder . . . . . . . . . . . . . . 11

Bleeding Transport Lift Cylinders . . . . . . . . 11

Bleeding Marker Hydraulics . . . . . . . . . . . . 12

Section 2 Operating Instructions . . . . . . . . . . . . . 13

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . . . 13

Field Operation . . . . . . . . . . . . . . . . . . . . . . . . . 13

Opener Operation . . . . . . . . . . . . . . . . . . . . 13

Pivot Lock Tubes. . . . . . . . . . . . . . . . . . . . . 13

Marker Operation . . . . . . . . . . . . . . . . . . . . 14

Transport Lift Cylinders . . . . . . . . . . . . . . . . 14

Fertilizer Operation . . . . . . . . . . . . . . . . . . . . . . 14

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Section 3 Adjustments . . . . . . . . . . . . . . . . . . . . . 16

Seeding Depth. . . . . . . . . . . . . . . . . . . . . . . . . . 16

Coulters. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Openers . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Coulter Depth . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hydraulic Control. . . . . . . . . . . . . . . . . . . . . 16

Coulter Mounting Height . . . . . . . . . . . . . . . 17

Coulter Down Pressure . . . . . . . . . . . . . . . . . . . 17

Added Weight . . . . . . . . . . . . . . . . . . . . . . . 17

Coulter Springs . . . . . . . . . . . . . . . . . . . . . . 17

Opener Depth . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Press Wheel Adjustment. . . . . . . . . . . . . . . 18

Opener Mounting Height. . . . . . . . . . . . . . . 18

Opener Down Pressure. . . . . . . . . . . . . . . . . . . 18

Disk Scraper Adjustment. . . . . . . . . . . . . . . . . . 18

Harrow Adjustment . . . . . . . . . . . . . . . . . . . . . . 19

Leaf Spring Adjustment. . . . . . . . . . . . . . . . . . . 19

Marker Adjustments. . . . . . . . . . . . . . . . . . . . . . 19

Folding Speed . . . . . . . . . . . . . . . . . . . . . . . 19

Disk Adjustments . . . . . . . . . . . . . . . . . . . . . 20

Pivot Lock Tube Adjustment. . . . . . . . . . . . . . . . 20

Seed-Lok Lock Up . . . . . . . . . . . . . . . . . . . . . . . 20

Setting the Seeding Rate . . . . . . . . . . . . . . . . . . 20

Changing Drive Sprockets . . . . . . . . . . . . . . 21

Setting Seed-Rate Handle . . . . . . . . . . . . . . 21

Positioning Seed-Cup Doors . . . . . . . . . . . . 21

Checking Seeding Rate . . . . . . . . . . . . . . . . 22

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Fertilizer Rate Calibration. . . . . . . . . . . . . . . . . . 26

Fertilizer Meter Rate Charts . . . . . . . . . . . . . . . . 27

Density Conversion Chart . . . . . . . . . . . . . . 28

Small Seeds Attachment . . . . . . . . . . . . . . . . . . 29

Small Seed Rate Charts. . . . . . . . . . . . . . . . . . . 29

Section 4 Troubleshooting. . . . . . . . . . . . . . . . . . . 30

Section 5 Maintenance and Lubrication. . . . . . . . 32

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Fertilizer Clean Out . . . . . . . . . . . . . . . . . . . 32

Transport Cylinder Support Brace . . . . . . . . 32

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Vertical Pivot Bushings, Top and Bottom . . . 33

Coulter Swing Arm Pivot . . . . . . . . . . . . . . . 34

Coulter Hub Bearings. . . . . . . . . . . . . . . . . . 34

Seed-Cup-Drive Sprocket . . . . . . . . . . . . . . 34

Tongue to Main Frame Pivot . . . . . . . . . . . . 34

Transport Wheel Bearings . . . . . . . . . . . . . . 35

Optional Folding Markers. . . . . . . . . . . . . . . 35

Additional Lubrication, Fertilizer Drills . . . . . 36

Section 6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Harrow Attachment. . . . . . . . . . . . . . . . . . . . . . . 37

Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mud Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Acremeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Seed-Cup Plugs . . . . . . . . . . . . . . . . . . . . . . . . . 38

Seed-Lok Firming Wheels . . . . . . . . . . . . . . . . . 38

Small Seeds Attachment . . . . . . . . . . . . . . . . . . 38

Section 7 Specifications and Capacities . . . . . . . 39

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . 40

Torque Values Chart. . . . . . . . . . . . . . . . . . . . . . 40

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

© Copyright 2004 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the

time of its publication,and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains, Seed-Lok

All other brands and product names are trademarks or registered trademarks of their respective holders.

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

Great Plains Manufacturing, Incorporated T r ademarks

Printed in the United States of America.

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

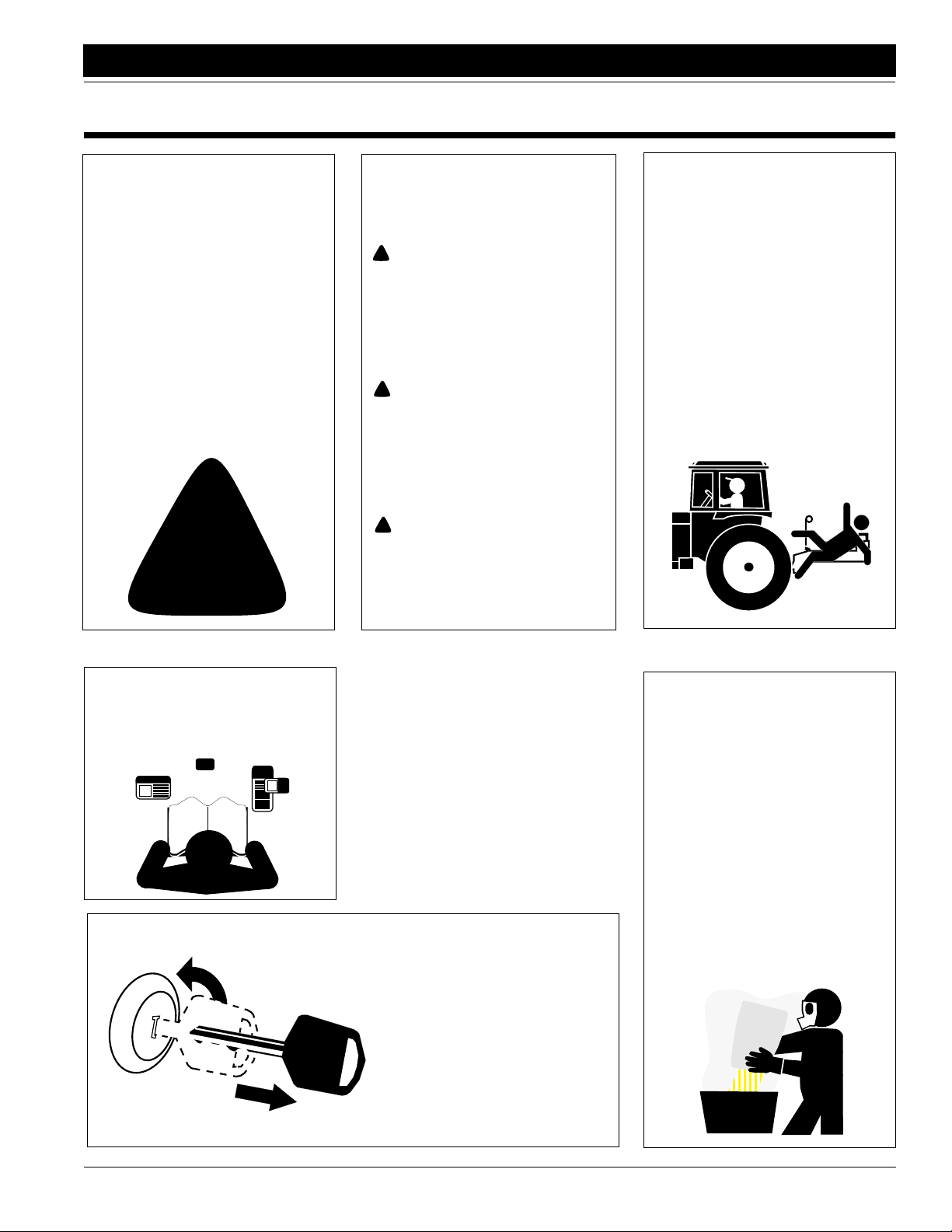

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to

personal safety involved and extra

safety precaution must be taken.

When you see this symbol, be alert

and carefully read the message that

follows it. In addition to design and

configuration of equipment, hazard

control and accident prevention are

dependent upon the awareness,concern, prudence and proper training of

personnel involved in the operation,

transport, maintenance and storage

of equipment.

!

Be Aware of Signal Words

Signal words designate a degree or

level of hazard seriousness. The signal words are:

!

DANGER!

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for functional purposes, cannot be guarded.

!

WARNING!

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may

also be used to alert against unsafe

practices.

!

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Keep Riders

Off Machinery

Riders obstruct the operator’s view.

Riders could be struck by foreign

objects or thrown from machine.

▲ Never allow riders on implement.

▲ Never allow children to operate

equipment.

For Your Protection

▲ Thoroughly read and understand

Safety Decals, page 4. Read all

instructions noted on decals.

OFF

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine,

and remove key.

▲ Detach and store implement in an

area where children normally do

not play. Secure implement with

blocks and supports.

Handle

Chemicals Properly

Agricultural chemicals can be dangerous. Improper use can seriously

injure persons, animals, plants, soil

and property.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Follow instructions on container

label.

▲ Avoid inhaling smoke from any

type of chemical fire.

▲ Store or dispose of unused chem-

icals as specified by chemical

manufacturer.

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

1

Page 4

Important Safety Information

Great Plains Mfg., Inc.

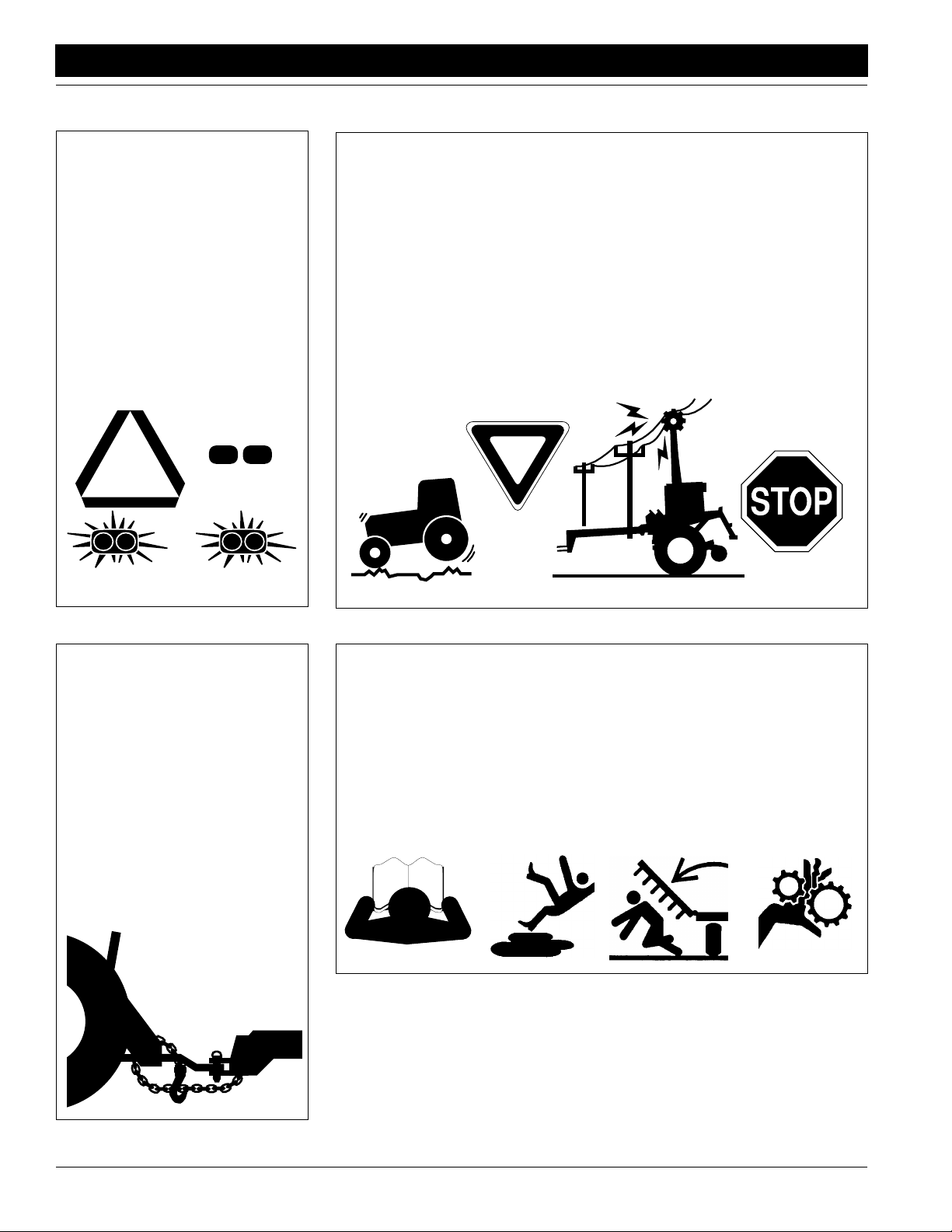

Use Safety

Lights and Devices

Slow-moving tractors, self-propelled

equipment and towed implements

can create a hazard when driven on

public roads. They are difficult to see,

especially at night.

▲ Use flashing warning lights and

turn signals whenever driving on

public roads.

▲ Use lights and devices provided

with implement.

Transport

Machinery Safely

Maximum transport speed for implement is 32 kph (20 mph). Some

rough terrains require a slower

speed. Sudden braking can cause a

towed load to swerve and upset.

▲ Do not exceed 32 kph (20 mph).

Never travel at a speed that does

not allow adequate control of

steering and stopping.

▲ Comply with state and local laws.

▲ Reduce speed if towed load is not

equipped with brakes.

▲ Do not tow an implement that,

when fully loaded, weighs more

than 1.5 times the weight of towing vehicle.

Use A Safety Chain

▲ Use a safety chain to help con-

trol drawn machinery should it

separate from tractor drawbar.

▲ Use a chain with a strength rat-

ing equal to or greater than

gross weight of towed machinery.

▲ Attach chain to tractor drawbar

support or other specified

anchor location. Allow only

enough slack in chain to permit

turning.

▲ Replace chain if any links or end

fittings are broken, stretched or

damaged.

▲ Do not use safety

chain for towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment. Refer to this manual

for additional information.

▲ Work in a clean, dry area.

▲ Lower implement to ground, put

tractor in park, turn off engine,

and remove key before performing

maintenance.

▲ Allow implement to cool completely.

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before operation.

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

2

Page 5

Great Plains Mfg., Inc.

Important Safety Information

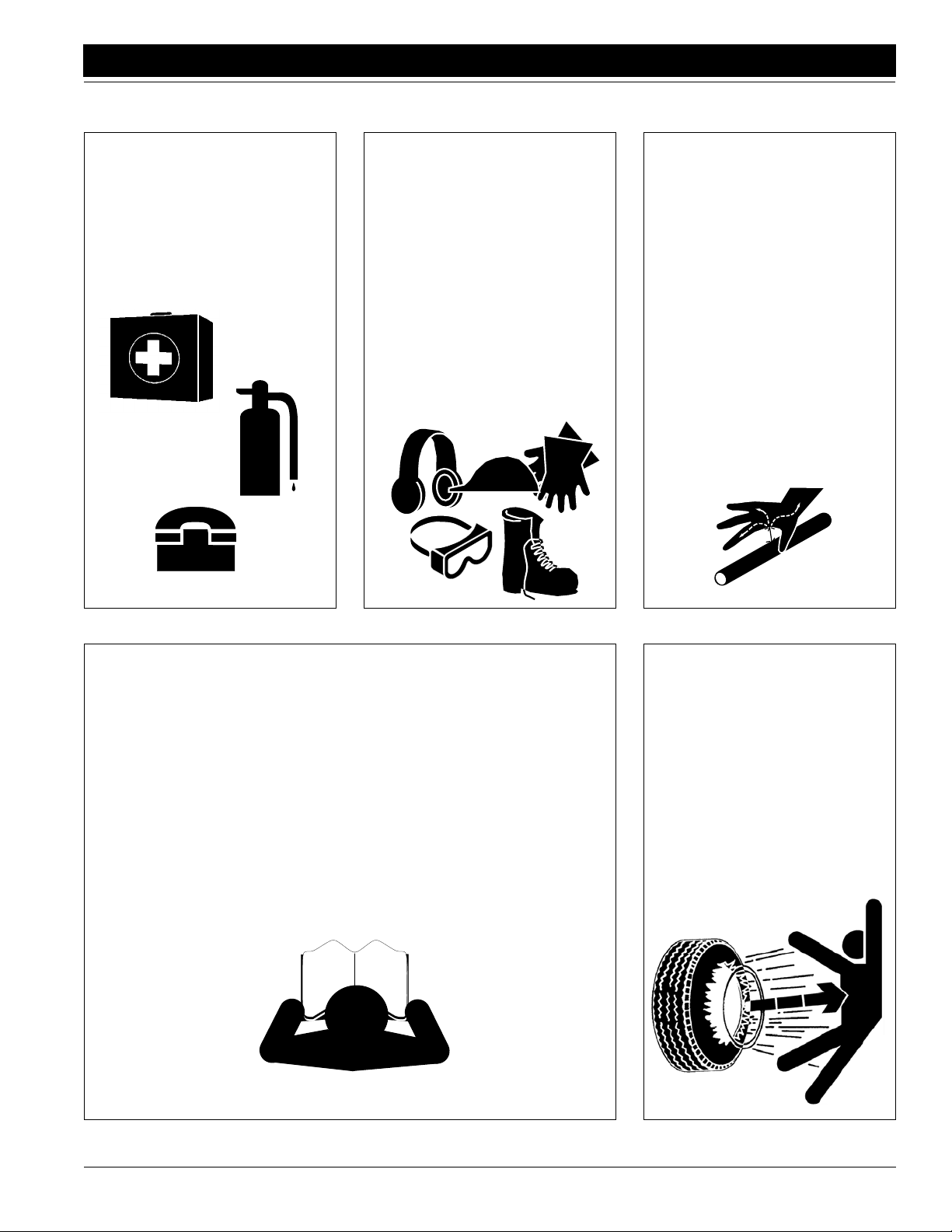

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first-aid kit and fire extin-

guisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, wear

suitable hearing protection such

as earmuffs or earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

Avoid High

Pressure Fluids Hazard

Escaping fluid under pressure can

penetrate skin, causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines.

▲ Use a piece of paper or card-

board, not body parts, to check for

suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a doc-

tor immediately. Any fluid injected

into the skin must be surgically

removed within a few hours or

gangrene may result.

Safety at All Times

Thoroughly read and understand this

manual before operation. Refer to

Safety Decals,

instructions noted on decals.

▲ Be familiar with all implement

functions.

▲ Operate implement from driver’s

seat only.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Do not dismount a moving tractor.

Dismounting a moving tractor could

cause serious injury or death.

page 4. Read all

▲ Do not stand between tractor and

implement during hitching.

▲ Keep hands, feet and clothing

away from power-driven parts.

▲ Wear snug-fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of working area.

▲ Do not turn tractor too tight, caus-

ing implement to ride up on

wheels. This could result in injury

or equipment damage.

Tire Safety

Tire changing can be dangerous and

should be performed by trained personnel using correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side–NOT in front of or over

the tire assembly. Use a safety

cage if available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for weight

involved.

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

3

Page 6

Important Safety Information

Safety Decals

Your implement comes equipped with all safety decals in place.

They were designed to help you safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new decals

from your Great Plains dealer. Refer to this section for

proper decal placement.

Great Plains Mfg., Inc.

4. When ordering new parts or components, also request corresponding safety decals.

5. To install new decals:

a. Clean the area on which the decal is to be placed.

b. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

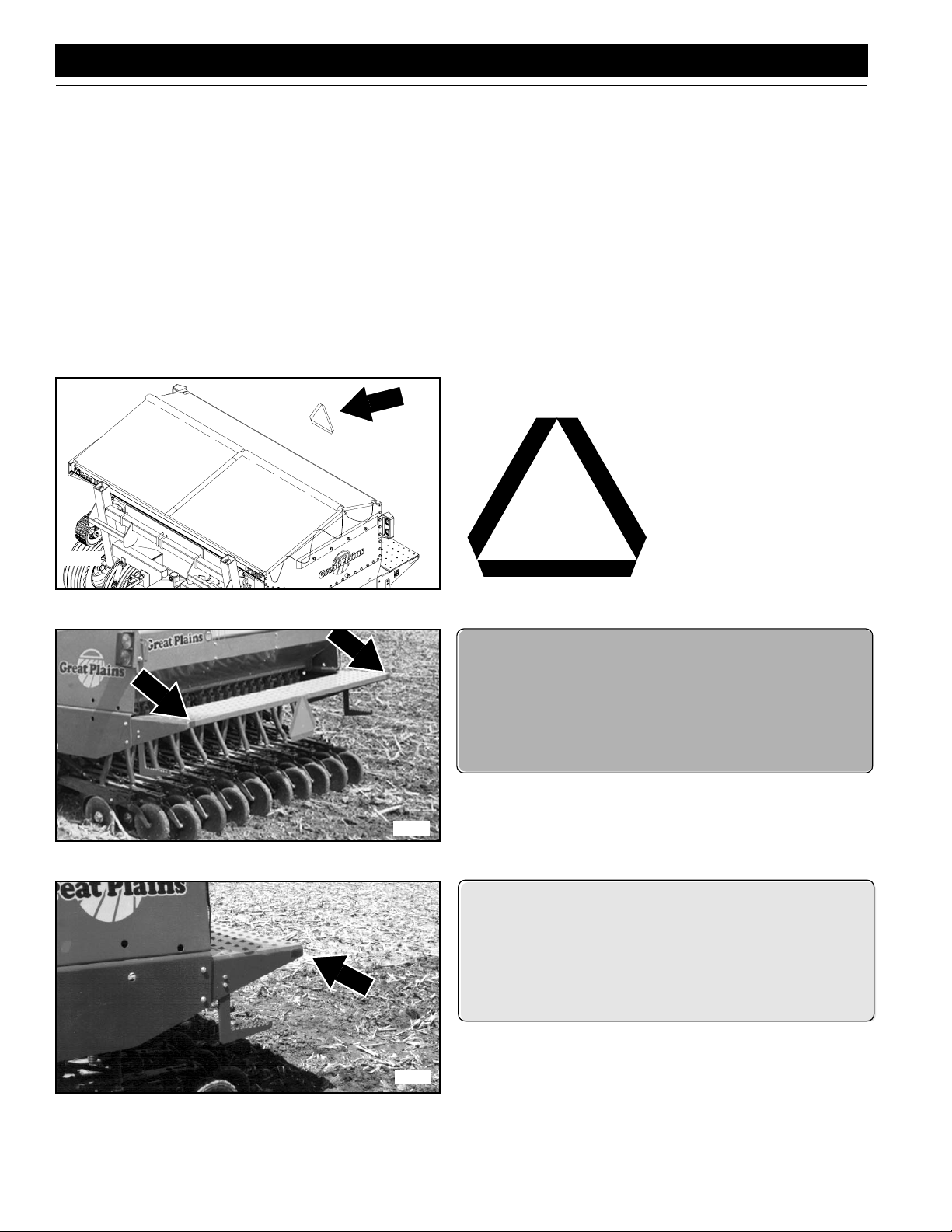

21895

17214

818-003C

Slow Moving Vehicle Label

On the back ofthe box,one

total

838-266C

Red Reflectors

Both ends of walkboard;

two decals total

838-265C

17862

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

4

Amber Reflectors

Both ends of walkboard;

two decals total

Page 7

Great Plains Mfg., Inc.

Important Safety Information

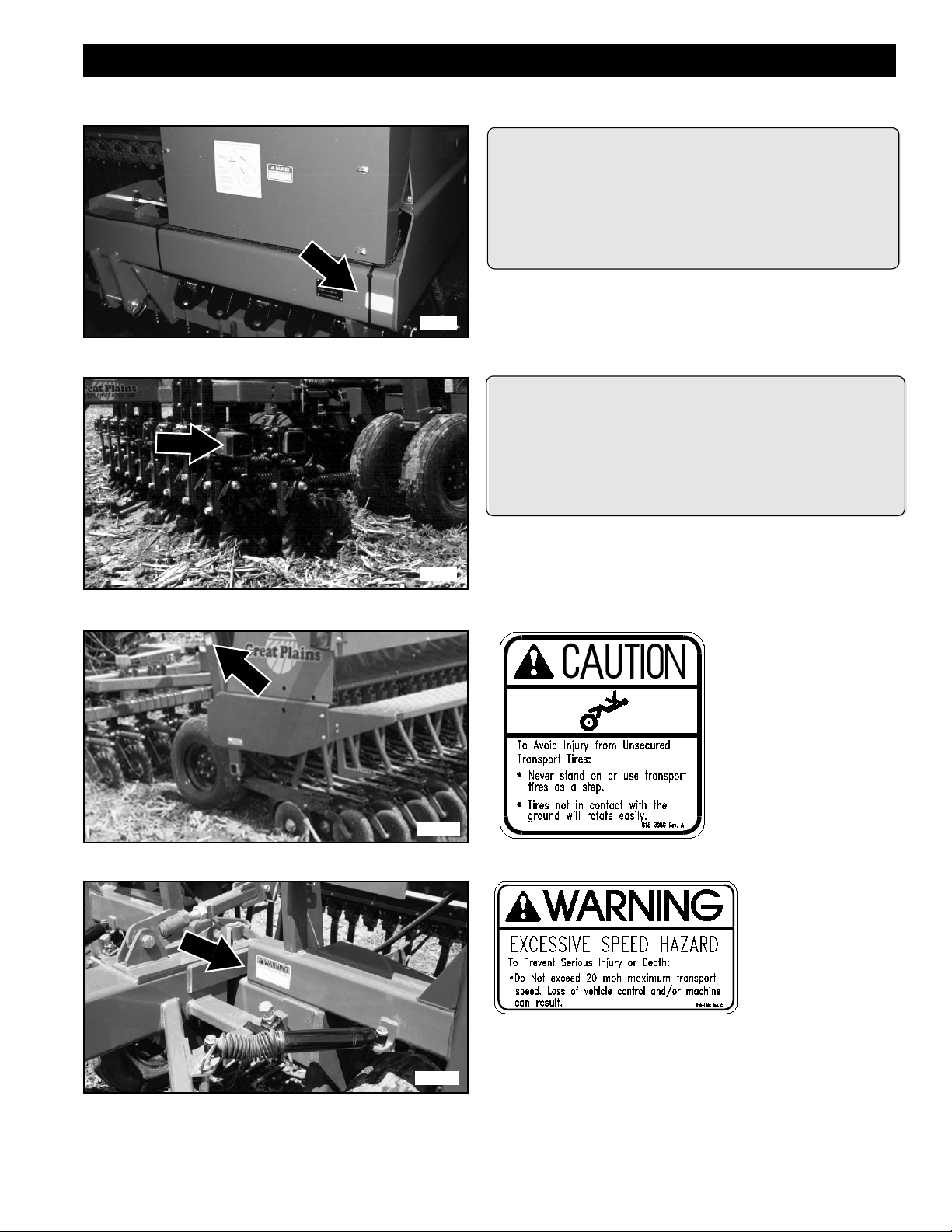

17858

838-265C

Amber Reflectors

Both ends of drill frame

tube; two decals total

17861

17206

838-265C

Amber Reflectors

Both ends of coulter tool-

bar; two decals total

818-398C

Caution–Tires Not a Step

Decal on each frame

post; two decals total

7/5/2005

17219

818-188C

Warning 20 MPH

Transport

FCP1000 Three-Meter Drill and Hitch 148-693M-A

5

Page 8

Important Safety Information

Great Plains Mfg., Inc.

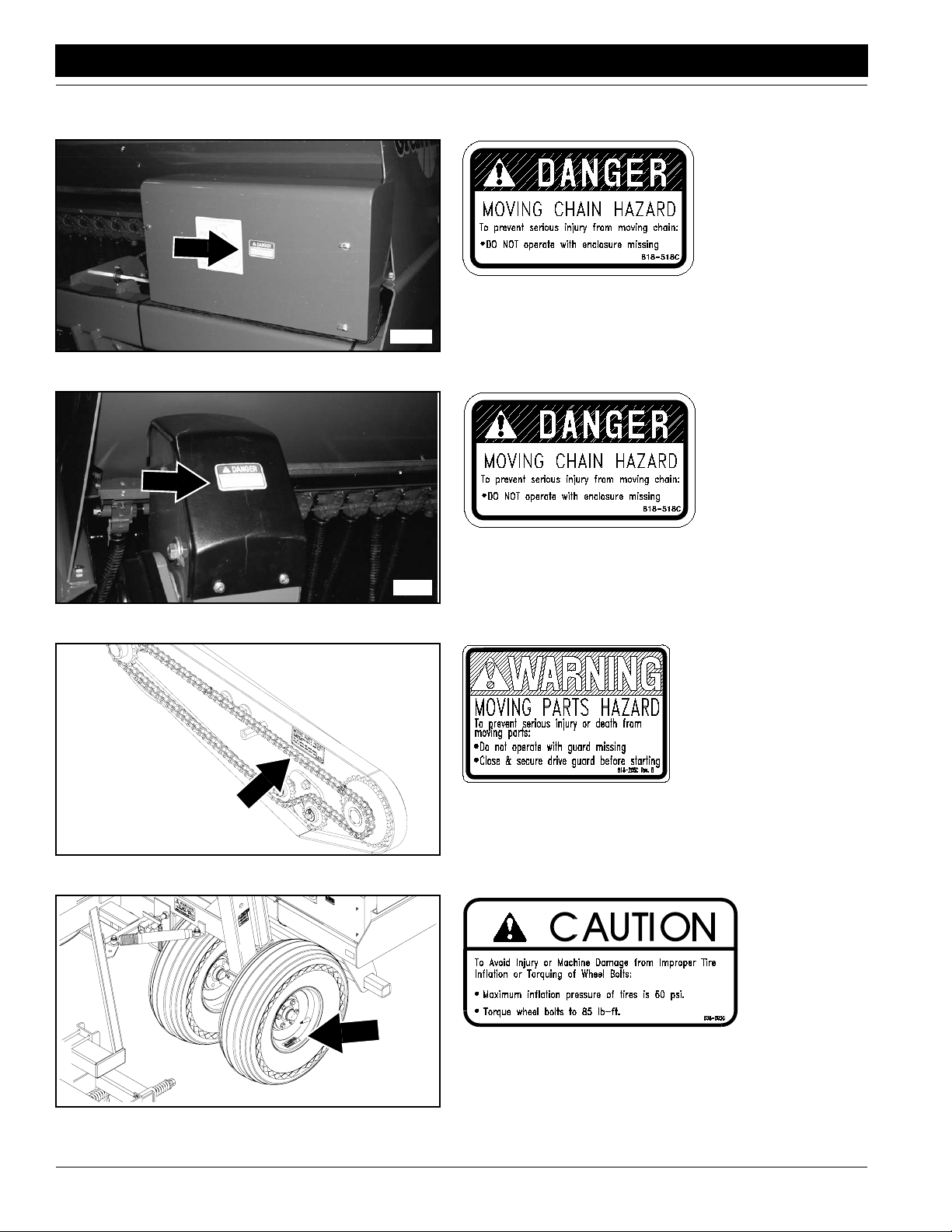

818-518C

Danger Moving Chain

17858

17865

818-518C

Danger Moving Chain

17859

818-205C

Warning Moving Parts

Hazard

838-092C

Caution Tire Inflation

17903

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

6

One Per Gauge Wheel

Page 9

Great Plains Mfg., Inc.

Important Safety Information

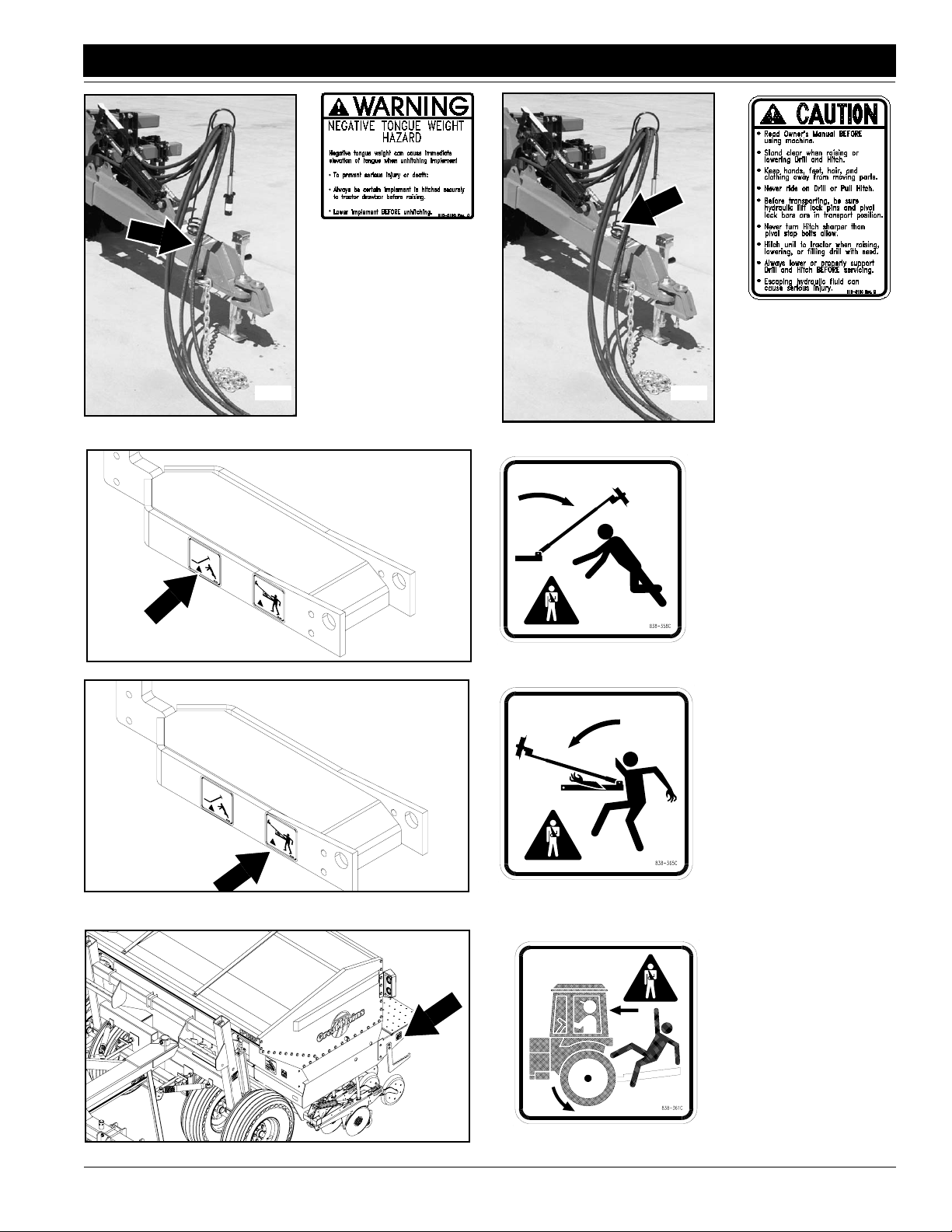

818-019C

Warning Neg Tongue

Weight

818-016C

Caution Pivot Pull

Hitch

21504

17209

21504

17209

838-367C

Warning Overhead Marker

One per marker

838-365C

Warning Pinch/Shear

One per marker

7/5/2005

21500

838-361C

Do Not Ride

One on each end of

walkboard

FCP1000 Three-Meter Drill and Hitch 148-693M-A

7

Page 10

Introduction

Introduction

Great Plains welcomes you to its growing family of new

product owners. This implement has been designed with

care and built by skilled workersusing quality materials.

Proper setup, maintenance and safe operating practices

will help you get years of satisfactory use from the

machine.

Description of Unit

The FCP1000 is a pull-type seeding implement. The

implement consists of a three-point drill mounted on a

centre-pivot hitch. The hitch and drill are integrallyconnected. No-till coulters are mounted on the hitch to zonetillstrips forseedfurrows.Straight-armopeners onthe drill

prepareseedbeds andplace the seed.The pivotingaction

of the hitch helps drill openers track the coulters. A contract-drive tire on the drill powers seeding off a hitch tire.

The tongue cylinder controls coulter depth and transport

cylinders raise the drill for turns and transport.

Intended Usage

Use this implement for seeding production-agriculture

crops only.Do not modify implement for use with attachments other than those specified by Great Plains. Use

implement in no or minimum tillage.

Great Plains Mfg., Inc.

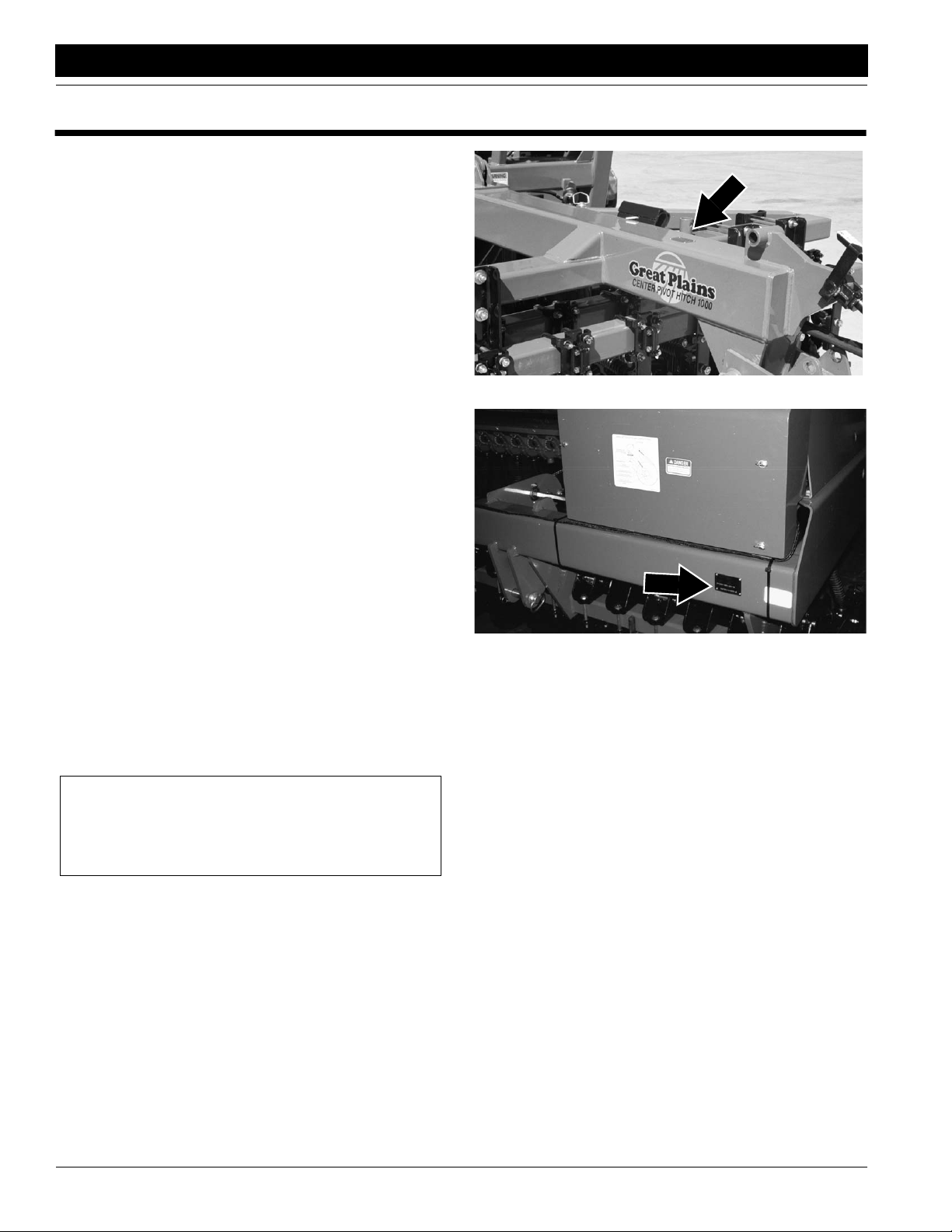

Figure A

Serial Number Plate, Hitch

Using This Manual

This manual will familiarize you with safety, assembly,

operation, adjustments, troubleshooting and maintenance.Readthis manualand followtherecommendations

to help ensure safe and efficient operation.

Theinformation in this manual iscurrent at printing. Some

parts maychange to assure top performance.

Definitions

Right-handand left-hand as used in thismanual are determined by facing the direction the machinewill travel while

in use unless otherwise stated.

IMPORTANT: A crucial point of information related to

the preceding topic. For safe and correct oper ation,

read and follow the directions provided before continuing.

NOTE: Useful information related to the preceding topic.

Owner Assistance

If you need customer service or repair parts, contact a

Great Plains dealer. They have trained personnel, repair

parts and equipment specially designed for Great Plains

products.

Your machine’sparts were specially designed and should

onlybereplaced withGreat Plainsparts.Alwaysuse serial

and model numbers when ordering parts from yourGreat

Plainsdealer.The serial-number plates arelocated on the

implement as shown in Figure A and Figure B.

Figure B

Serial Number Plate, Drill

Recordyourimplement modeland serialnumbers herefor

quick reference:

Model Number: _________________________________

Serial Numbers: _________________________________

Your Great Plains dealer wants youto be satisfied with

your new machine. If you do not understand any part of

this manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealershipservice manager.Make sure they are aware of anyproblems so

they can assist you.

2. If you are still not satisfied, seek out theowner or general manager of the dealership.

3. For further assistance write to:

Product Support

Great Plains Mfg. Inc., Service Department

PO Box 5060

Salina, KS 67402-5060

USA

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

8

Page 11

Great Plains Mfg., Inc.

Section 1 Preparation and Setup

Section 1 Preparation and Setup

This section will help you prepare your tractor and implement

for use.

Prestart Checklist

1. Read and understand “Important Safety Information,”

page 1.

2. Check that all working parts are moving freely, bolts are

tight, and cotter pins are spread.

3. Check that all grease fittings are in place and lubricated.

Refer to Lubrication,“Maintenance and Lubrication,”

page 33.

4. Check that all safety decals and reflectors are correctlylocated and legible.Replace if damaged. See Safety De-

cals,“Important Safety Information,”

page 4.

5. Inflate tires to pressure recommended and tighten wheel

bolts as specified. See “Appendix,” page 40.

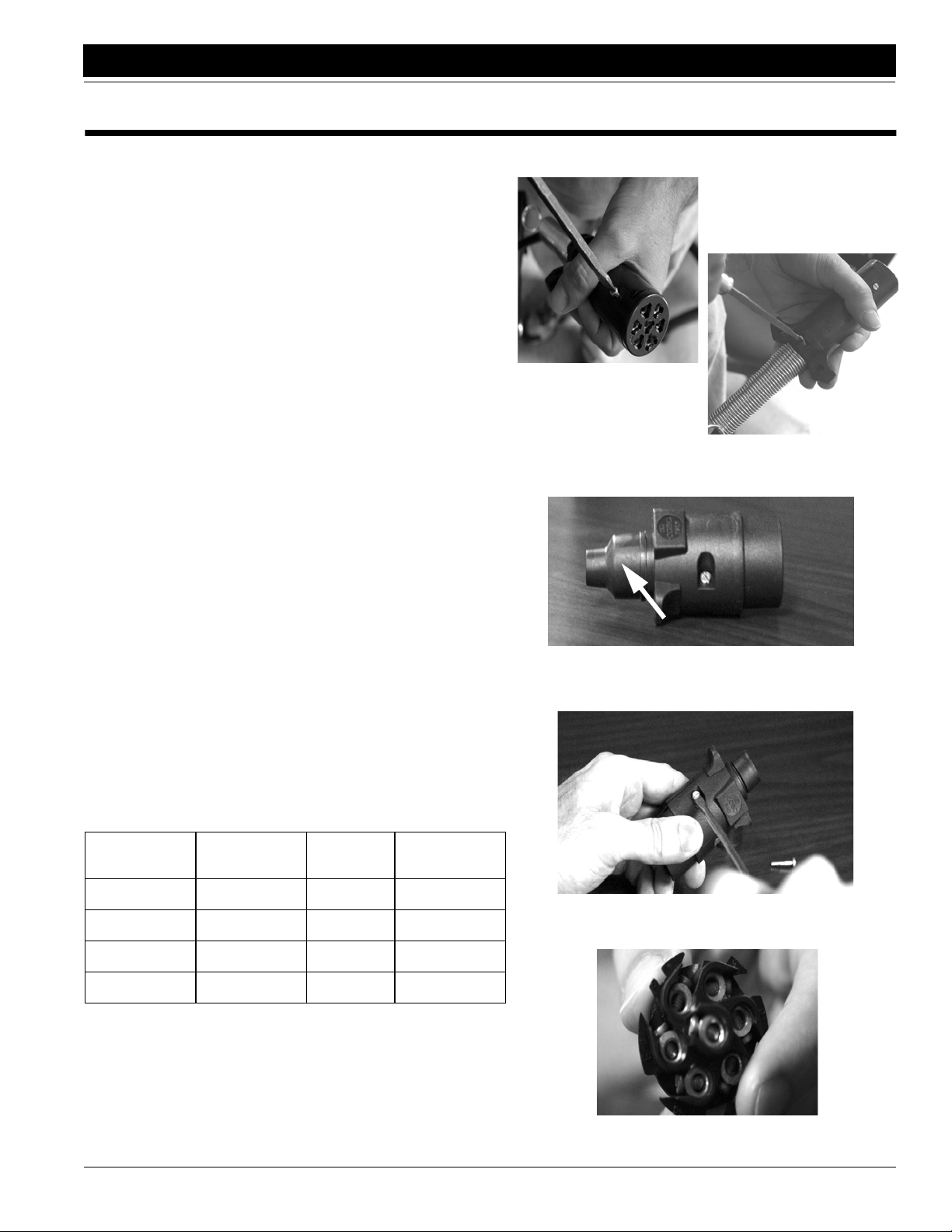

Wiring Drill

NOTE: If tractor does not comply with ASAE connector, use

the European adapter.

1. Remove screw from outer casing of ASAE connector.

Loosen screw holding wires in place from outer casing of

ASAE connector. Pull outer casing apart. Disconnect

wiresfrom connector by removing screws.See Figure 1-1.

2. Completely remove outer casing from wires.

3. Remove black rubber end piece from European adapter.

Thread wires through blackrubber end piece starting with

the smaller end. See Figure 1-2.

4. Removethetwo screwsholding the outercasing of the European adapter together. Keep for reuse. See Figure 1-3.

5. Removeconnector from outercasing. Thread wires under

metal bar in bottom of outer casing.

6. Attach wires to connector using the terminal number indicators on the back of the connector and the table below.

See Table below and Figure 1-4.

10. Slideblackrubber endpiece overthe endof theouter

casing securing the wires.

23264

23265

Figure 1-1

Removing ASAE Connector

23252

End Piece

Figure 1-2

European Adapter

23254

Conductor

Indicator

Wire

Color

Terminal

Number

Circuit

Wht White 3 Ground

Yel Yellow 1 Left Blinker

Grn Green 4 Right Blinker

Brn Brown 6 Tail Lamps

7. Align connector in bottom of outer casing.

NOTE: BE SURE CONNECTORAND CASING ARE PROP-

ERLY ALIGNED,OTHERWISE CASING WILL NOT FIT CORRECTLY.

8. Tighten screws securing wires and metal bar in place.

9. Replace top of outer casing. Insert and tighten screws removed in Step 3.

7/5/2005

Figure 1-3

Remove Screws to Outer Casing

23255

Figure 1-4

Back of Connector

FCP1000 Three-Meter Drill and Hitch 148-693M-A

9

Page 12

Section 1 Preparation and Setup

Great Plains Mfg., Inc.

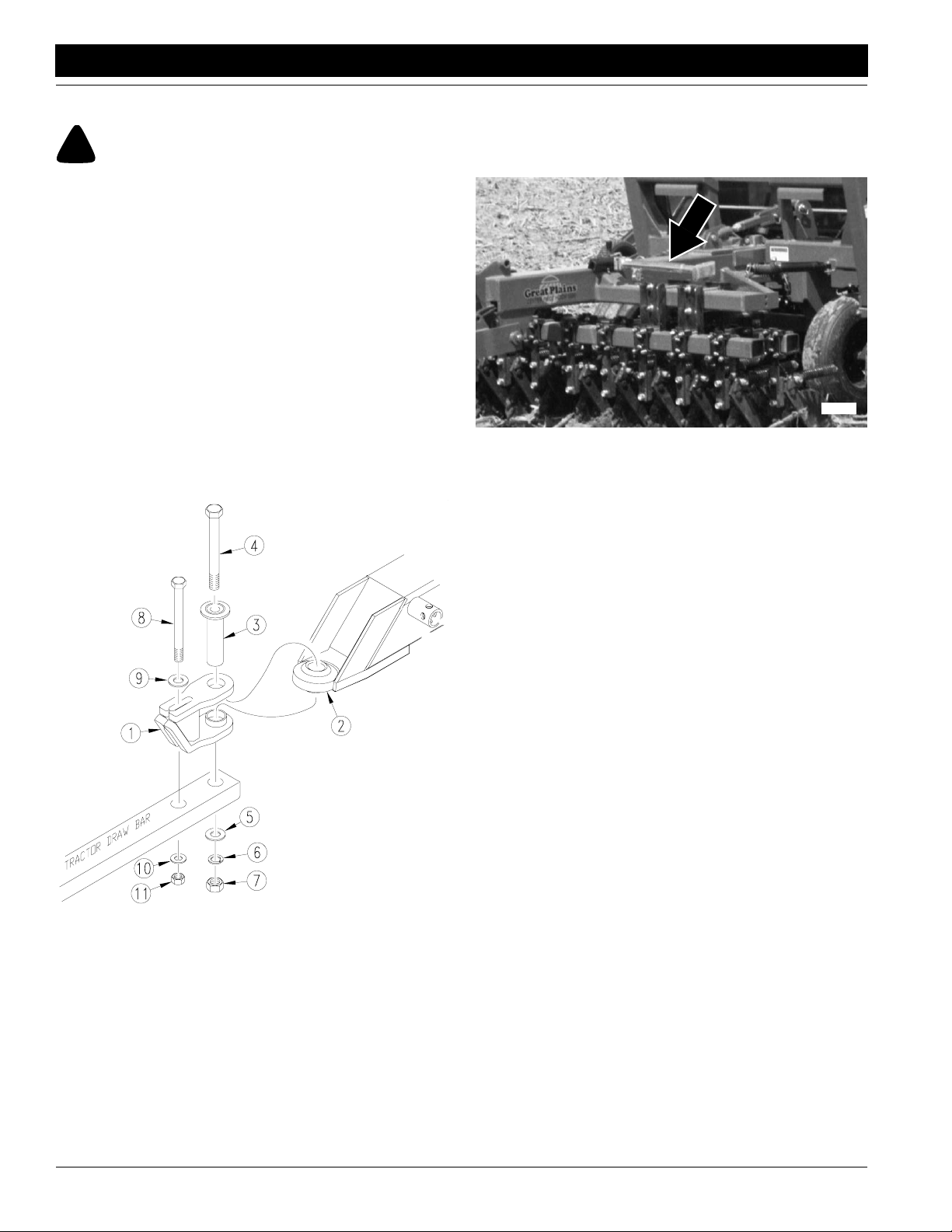

Hitching Tractor to Implement

!

DANGER!

You may be severely injured or killed by being crushed between

the tractor and drill. Do not stand or place any part of your

body between drill and moving tractor. Stop tractor engine and

set park brake before installing pins. Refer to Figure 1-1.

Refer to Figure 1-5.

1. Place hitch weldment (1) over ball swivelon hitch

tongue (2). Hold hitch weldment in place byinserting

spacer tube (3) through hitch clevis and ball swivel.

2. Back tractor up to hitch and bolt hitch weldment to

tractor drawbar using 1-by-10-inch bolt (4), large flat

washer (5), lockwasher (6), and nut (7).

3. Use 3/4-by-9-inch bolt (8) to bolt hitch weldment

through its slotted hole and onto secondary hole of

tractor drawbar. Install a 3/4-inch flat washer (9) next

to top slotted hole and fasten with a lock washer (10)

and nut (11). Tighten both bolts.

4. Securely attach safety chain to tractor-drawbar frame.

5. Remove jack from stob on side of hitch tongue and

place in transport position on implement. See Figure

1-6.

17219

Figure 1-6

Jack in Transport Position

17215

Figure 1-5

Drawbar Assembly Illustration

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

10

Page 13

Great Plains Mfg., Inc.

Section 1 Preparation and Setup

Hydraulic Hook-up

!

WARNING!

Escaping fluid under pressurecan have sufficient force to penetrate the skin. Check all hydraulic lines and hoses before applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

from a doctor that is familiar with this kind of injury. Foreign

fluids in the tissue must be surgically removed within a few

hours or gangrene will result.

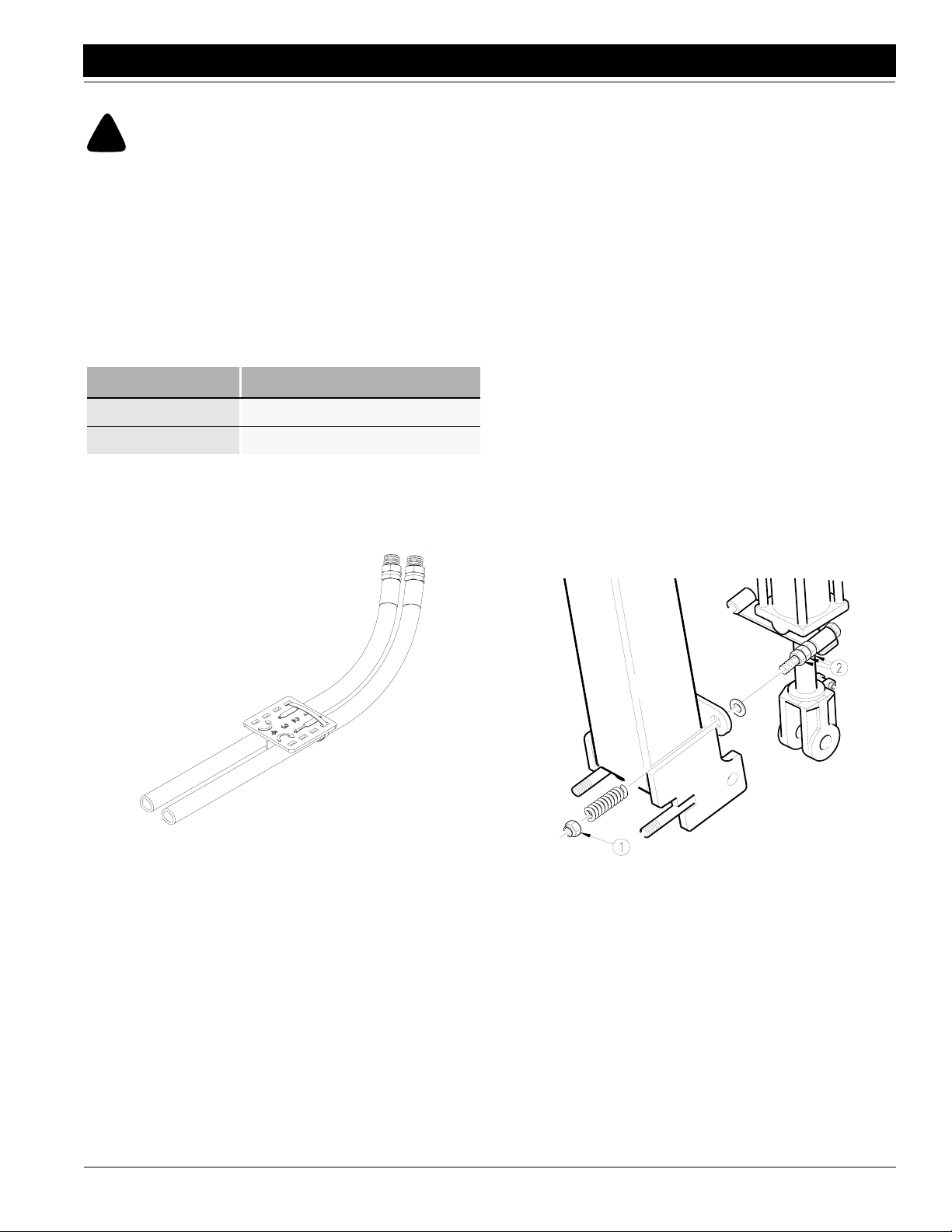

Great Plainshydraulic hoses are colour coded tohelp you

hook-uphoses to your tractoroutlets. Hoses that go tothe

same remote valve are marked with the same colour.

Colour Hydraulic Function

Red T ransport Lift Cylinders

Blue T ongue Cylinder

Todistinguish hoseson the samehydraulic circuit, referto

plastic hose holder. See Figure 1-7. Connect hose under

extended cylinder to outlet you choose for cylinder extension. Connect hose under retracted symbol to outlet for

cylinder retraction.

2. proper level. Add fluid to system as needed. Tongue

cylinder capacity is 1.89 litres (one-half gallon).

3. Raise and safely support hitch, transport frame and

front tongue.

4. Unpin rod end of tongue cylinder. Block, wire or otherwise safely support cylinder so when rod end is fully

extended it does not contact anything.

5. Cycle cylinder completely in and out at least three

times to purge air from cylinder and hoses.

6. Fully extend cylinder and repin rod end.

7. Recheck tractor reservoir and fill to proper level.

Bleeding Transport Lift Cylinders

The transport-lift cylinders are rephasing cylinders and require a special procedure for bleeding air from the circuit.

Read and follow procedure carefully. Cylinders will not

function properly with air in the hydraulic circuit.

1. Check hydraulic fluid in tractor reservoir and fill to

proper level. Add fluid to system as needed. Transport-lift-cylinder capacity is about 7.57 litres (2 gallons).

2. Jack up and support hitch frame.

3. Remove1/2-inch nylocknuts (1) onspring side of cylinder-support brace.Unpin cylinders. Do not alter position of jam nuts (2) on centre of support-brace bolts.

See Figure 1-8.

17641

Figure 1-7

Hydraulic Hose Color Ties

Connect hydraulichoses fromtongue cylinder toone tractor remote valve. Connect hoses from transport-lift cylinders to another tractor remote valve.

Bleeding Hydraulic Systems

For safe and smooth operation, the hydraulic systems

must be free of air.The hydraulicsystems shouldbe bled

during initial implement set-up. If they were not bled, or if

you replace a hydraulic component during the life to the

drill, bleed the hydraulics.

Bleeding Tongue Cylinder

1. Check hydraulic fluid in tractor reservoir and fill to

7/5/2005

17864

Figure 1-8

Unpin Cylinders

4. Turn cylinders to a position where rodends are higher

than base ends. Support cylinders in a safe location.

5. Start tractor and run engine at idle speed. With rod

ends higher than base ends, hydraulicallyextend cylinders.After cylinderrods are fullyextended, continue

to hold control lever for one minutebefore hydraulically retracting cylinders.

6. Repeatstep5 threetimes tocompletely bleedsystem.

If air is still trapped in either cylinder, it will operate in

jerky, erratic motions. Repeat steps until cylinder

movement is smooth and even.

FCP1000 Three-Meter Drill and Hitch 148-693M-A

11

Page 14

Section 1 Preparation and Setup

7. Repin cylinders to hitch frame. Reinstall short compression springs on cylinder-support-brace bolts and

re-tighten 1/2-inch nylocknuts until springs are compressed to 32 mm (1 1/4 inches). If for any reason the

1/2-inch jam nuts in centre of support-brace bolts

were changed, referto Transport Cylinder Support

Brace, page 32, for proper adjustment.

8. Refill tractor hydraulic-fluid reservoir to proper level.

Bleeding Marker Hydraulics

!

CAUTION!

You may be injured if hit by a folding or unfolding marker.

Markersmayfall quickly and unexpectedlyif the hydraulics fail.

Neverallow anyonenear the drill when folding or unfolding the

markers.

1. Check that tractor hydraulic reservoir is full.

2. With both markers lowered into field position, loosen

hydraulic-hosefittings atrod and base endsof marker

cylinders. Loosen fittings on back side of sequence

valve.

Great Plains Mfg., Inc.

IMPORTANT: Never bleed an O-ring fitting. Instead,

bleed a nearby pipe or JIC fitting.

3. Withtractor idling, activatetractor hydraulicvalveuntil

oilseeps out around a loosenedfitting. Tighten that fitting.

IMPORTANT: JIC fittings do not require high torque.

JIC and O-ring fittings do not require sealant. Always

use liquid pipe sealant when adding or replacing pipethread fittings. Toavoid cracking hydraulic fittings from

over tightening, do not use plastic sealant tape.

4. Reactivate tractor hydraulic valve until oil seeps out

around another loosened fitting. Tighten that fitting.

Repeat process until all loosened fittings have been

bled and tightened.

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

12

Page 15

Great Plains Mfg., Inc.

Section 2 Operating Instructions

Section 2 Operating Instructions

This section coversgeneral operation. Experience,

machine familiarity and the following information will lead

to efficient operation and good working habits. Always

operate farm machinery with safetyin mind.

Prestart Checklist

1. Carefully read “Important Safety Information,” beginning on page 1.

2. Lubricate implement as indicated under Lubrication,

“Maintenance and Lubrication,” page 33.

3. Check all tires for proper inflation as indicated on Tire

Inflation Chart,“Appendix,” page 40.

4. Check all bolts,pins and fasteners. Torque as specified on Torque Values Chart,“Appendix,” page 40.

5. Check implement for worn or damaged parts. Repair

or replace beforegoing to the field.

6. Checkhydraulichoses,fittings andcylinders forleaks.

Repair or replace before going to the field.

17129

Figure 2-1

Pivot Lock Tube

Duringnormalfield operation,operate hitchwith pivot-lock

tubes unsecured so hitch can pivot and drill openers can

properly track coulters. Refer to Figure 2-2.

Field Operation

1. Hitchimplement to asuitable tractor.Referto Hitching

Tractorto Implement,“Assemblyand Setup,”page 9.

2. For proper coulter-to-opener tracking, unlock pivotlock tubes. Refer to Pivot Lock Tubes, this page.

3. Hydraulically adjust coulters to desired depth. Note

reference measurement on tongue-cylinder gauge to

help you achieve the same coulter depth with each

field pass. Refer to Coulter Depth,“Adjustments,”

page 16, forfurther adjustment instructions.

4. Set seeding rate. Refer to Setting the Seeding Rate,

“Adjustments,” page 20.

5. Load box with clean seed.

6. Pull forward, lower coulters to desired depth, lower

drill, and begin seeding.

7. Alwayslift drill out of groundwhen turningat row ends

and for other short turns. Seeding will stop automatically as drill is raised.

Opener Operation

Neverback up with openers in ground. If you do, check all

openers to be sure none are clogged or damaged.

For information on seeding depth and opener adjustments, refer to Seeding Depth,“Adjustments,” page 16.

For more information on troubleshooting opener problems, see “Troubleshooting,” page 30.

Pivot Lock Tubes

The pivot-locktubes are behind the stabilizer cylinders on

each side of implement. See Figure 2-1.

11880

Figure 2-2

Pivot Lock Tubes Unsecured–Normal Field Position

When drilling on steep slopes or transporting, secure

pivot-locktubes. To lock tubes,turn tubes so theyare horizontal with hitch frame. Refer to Figure 2-3.

10555

Figure 2-3

Pivot Lock Tubes Secured–Transport Position

Youcan adjust spring tension on pivot-locktubes. Referto

Pivot Lock Tube Adjustment, “Adjustments,” page 20.

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

13

Page 16

Section 2 Operating Instructions

Great Plains Mfg., Inc.

Marker Operation

Optional markers are powered off the same circuit as the

tongue cylinder. After setting coulter depth with tongue

cylinder,turn selectorvalve to the left tooperate markers.

See Figure 2-4.

17466

Figure 2-4

Turn Selector Valve for Marker Operation

Transport Lift Cylinders

The transport-lift cylinders are rephasing hydraulic cylinders. After a period of normal use, the cylinders may get

outof sequence. If this happens,the hitch will lift unevenly

or one set of tires will not retract from the soil.

To rephase cylinders, raise drill completely and hold

hydrauliclever onfora fewseconds toallow cylinderstime

to rephase.

3. Checkthat divider dooris closed soseed and fertilizer

cannot pass between compartments.

4. Check that cleanout door (1) is latched securely as

shown in Figure 2-5. Close all door latches before

loading fertilizer compartment.

1

16377

Figure 2-5

Cleanout Door Latched

5. Fill fertilizer compartment.

Fertilizer Operation

The fertilizer drill is equippedwith a moveable divider that

partitions the drill box between the seed and the fertilizer.

Use only dry, granular fertilizer in the fertilizer compartment.

1. Clean anyseed or debris from fertilizercompartment.

2. Calibratefertilizer-application rate as explainedunder

Fertilizer Rate Calibration,“Adjustments,” page 26.

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

14

Page 17

Great Plains Mfg., Inc.

Section 2 Operating Instructions

Transporting

!

WARNING!

Towing the implement at high speeds or with a vehicle that is

not heavy enough can lead to loss of vehicle control. Loss of vehicle control can lead to serious road accidents, injury and

death. To reduce the hazard:

• Do not exceed 32 kph (20 mph).

• Do not tow an implement that, when fully loaded, weighs

more than 1.5 times the weight of the towing vehicle.

1. Check that implement is securely hitched to a sufficient tractor. Refer to Hitching Tractor to Implement,

“Preparation and Setup,” page 9. Make sure safety

chain is secured to tractor.

2. Unload seed box before transporting if atall possible.

The implement can be transported with a full boxof

grain, but added weight will increase stopping distance and decrease manoeuvrability.

3. Check that tires are properly inflated. Refer to Tire In-

flation Chart,“Appendix,” page 40.

4. Know implement dimensions in transport position.

Choose a route that provides adequate clearance

from all obstructions. Refer to “Specifications and

Capacities,” page 39, for dimensions.

5. Hydraulically lift drill with transport-lift cylinders.

6. Install transport lock pins in vertical axle tubes.

8. Install lock channel over extended tongue-cylinder

rod. See Figure 2-7.

17217

Figure 2-7

Lock Channel Installed

9. Plug light-harness lead into tractor connector. Always

use warning lights when transporting drill.

10. Comply with all laws when travelling on public roads.

Parking

Perform the followingsteps when parking implement.

Refer to Storage,“Maintenance and Lubrication,” page

33, for information on long-term storage preparation.

1. Park implement on a firm, level area. Lower coulters

and drill to ground.

2. Block tires securely to prevent rolling.

3. Release pressure on hydraulic system, then disconnect hydrauliclines. Check that hose ends do not rest

on ground.

4. Movejack from transport position and place it on stob

on side of hitch tongue.

5. Extend jack until all weight is off tractor drawbar. Remove 1-by-10-inch bolt, washerand nut.

6. Disconnect implement light harness.

17208

Figure 2-6

Lock Pin Installed

7. Secure pivot-lock tubes for transport. Position tubes

sothey are horizontal against hitch frame. See Figure

2-3 on page 12.

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

15

Page 18

Section 3 Adjustments

Section 3 Adjustments

Great Plains Mfg., Inc.

Seeding Depth

To set drill seeding depth, you must:

• Set coulter depth with tongue cylinder.

• Set opener depth with T-handles on press wheel.

• If field conditions make itnecessary, increase coulter

down pressure by adding weights.

• If necessary, adjust individual coulters or openers to

seed in tire tracks.

The following is an introduction to how the coulters and

double-disk openers are designed to control seeding

depth.

Coulters

A no-till coulter is mounted on the hitch directly ahead of

each opener on the drill. The coulters cut through heavy

trash and makea groove in the soil for the openers.

Coulter cutting depth is controlled bythe tongue cylinder.

You also can change the depth of individual coulters by

changingcoulter-mounting height.Referto CoulterDepth,

page 16, forinformation on these adjustments.

The amount of coulter down pressure needed to cut a soil

groovevaries with soil conditions. Adding weightor shortening the coulter spring increases coulter down pressure

and cutting force. Refer to Coulter Down Pressure, page

17, for more information on these adjustments.

Openers

Opener double disks widen the coulter groove to make a

seed bed. Mounted on the rear of each opener is a press

wheel. The press wheels control opener seeding depth

and firm the seed into the soil.

To maintain a consistent seeding depth, upward press

wheel movement is restricted byan independently adjustable stop on each opener. Moving this stop changes the

depth at which seed is placed. The mounting height of

openers that run in tiretracks also can be changed.Refer

to Opener Depth, page 18 for information on these adjustments.

The amount of opener down pressure needed to cut and

widen the coulter groove and to firm theseed into the soil

varies with soil conditions. Opener downpressure canbe

adjusted for all openers or individual openers. Refer to

Opener Down Pressure,page 18, for information on how

to make these adjustments.

Coulter Depth

Adjust coulters to run 13 to 25 mm (1/2to 1 inches) below

the drill openers. Coulter depth can be adjusted hydraulically for all coulters or manually for individual coulters.

Hydraulic Control

Make the following adjustment when drilling in level

ground with the seed box half full.

1. Retract tongue cylinder to transfer weight to coulter

toolbar.

2. Set tongue cylinder so coulters are at desired depth.

Notesetting oncylindergauge (seeFigure 3-1)so you

can return to the same depth.

NOTE: Use cylinder gauge only as a reference. Gauge

does not measure actual coulter depth.

17218

Figure 3-1

Cylinder Gauge

3. With coulters and drill lowered to desired seeding

depth, check that hitch frame (1) runs parallel with

ground as shown in Figure 3-2.

21501

Figure 3-2

Levelling Implement

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

16

Page 19

Great Plains Mfg., Inc.

Section 3 Adjustments

4. If the hitch frame is not level, remove or replace spacers (1) from transport-lift-cylinder rods until hitch is

level.See Figure 3-3.

17854

Figure 3-3

Remove or Install Spacers

Coulter Mounting Height

You can change the depth of individual coulters by adjusting coulter-mounting height. If you adjust coulter height,

be sure to rebolt coulters vertically straight and correctly

spaced. To raise or lower individual coulters:

1. Loosenmountingclamps andadjust coultertodesired

height. Do not lower coulter spring bar below top ubolts on coulter clamp.

2. To re-tighten clamps, refer to Figure 3-4. Snughexheadclamp bolts (1)just until u-boltsare tight on each

side of spring bar.

3. Tighten nuts (2) on u-bolts.

4. Finish tightening hex-head clamp bolts.

Coulter Down Pressure

Added Weight

Inhard soil conditionswhere coulter penetrationis limited,

you can add suitcase weights to the weight brackets on

thehitch. Youcan addup to567 kilograms(1,200 pounds)

21613

to the front brackets.Place an equal amount of weighton

the right and left side to balance the weight distribution.

Figure 3-5

Weight Brackets

Coulter Springs

Coulter-spring length is preset at the factory to 254 mm

(10inches), givingcoulters aninitial operatingforce of 181

kg(400 pounds).Thissetting isadequate formany difficult

no-till conditions. For lighter no-till conditions where rocks

or other obstructions are a problem, you can reduce coulter down pressure to give coulters better impact

protection.Referto thefollowing chartforadjusting coulter

down pressure.

10300

Figure 3-4

Individual Coulter Mounting

NOTE:Evenwhen coulter is heldsecurely,theremay be a

gap between clamp halves.

Spring Length Coulter Down Pressure

267 mm (10 1/2 in) 79 kg (175 lbs)

260 mm (10 1/4 in) 136 kg (300 lbs)

254 mm (10 in) 181 kg (400 lbs)

248 mm (9 3/4 in) 238 kg (525 lbs)

NOTE: Do not reset coulter-spring length shorter than

248mm (9 3/4 inches). Shortening springs more than 248

mm (9 3/4 inches) may contribute to premature failure of

parts and warranty will be voided.

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

17

Page 20

Section 3 Adjustments

Great Plains Mfg., Inc.

Opener Depth

When making opener adjustments, keep in mind that

openers will not run any deeper than coulters till the soil.

Press Wheel Adjustment

Changing the height of the press wheels automatically

changes seeding depth. To adjust, lift T-handle and slide

forward or back as shown in Figure 3-1.

• For shallower seeding, slide handle ahead toward im-

plement.

• For deeperseeding, slide handle back away from imple-

ment.

16671

Figure 3-1

Press Wheel Adjustment

Opener Down Pressure

To adjust downpressure on individual openers that run in

tire tracks, change opener-spring length. To increase

down pressure,loosen thejam nut at lower end of opener

spring, then turn flange nut. See Figure 3-3. Each 6 mm

(1/4-inch) turn adds about 6 kg (13 pounds) of pressure.

After adjusting flange nut, tighten jam nut.

16688

Figure 3-3

Individual Spring Adjustment

IMPORTANT:Do not turnflange nut more than 25 mm

(one inch). Turning flange nut more than 25 mm (one

inch) could cause opener damage.

Opener Mounting Height

Youalso can lowerindividual opener bodies thatrunin tire

tracks. To lower an opener, move opener-pivot bolt to

lower hole in opener mount. See Figure 3-2.

16672

Figure 3-2

Individual Opener Height Adjustment

Disk Scraper Adjustment

To keepopener disks turning freely, dirt scrapers are

mounted between disks to clean as the disks rotate. As

field conditionsvary, you mayneed to adjust the scrapers.

To adjust, loosen 3/8-inch bolt shown in Figure 3-4 and

raise or lowerscraper as needed.

16634

Figure 3-4

Disk Scraper

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

18

Page 21

Great Plains Mfg., Inc.

Section 3 Adjustments

Harrow Adjustment

Figure 3-5 shows a successful harrow position for no-till

conditions. Because of differentsoil moisture, trash levels

and trash types, you may need to reposition the tube

frame or tines. Initially position the frame and tines as

shown in Figure 3-5, then readjust as necessary.

12667

Figure 3-5

Tine Angle For No-Till Drilling

To adjust the frame, refer to Figure 3-6. Loosen the four

hexnuts (1)on the u-bolts androtate the frame tube(2) as

necessary.

To adjust the tines, refer to Figure 3-6. Loosen the four

1/2-inchhex nuts(3) on the 1/2-inchu-bolts (4) on the support bar (5). Rotate tine tubes (6) so the tines (7) are

against the stop bushings (8) and are angled back as necessary. Re-tighten hexnuts on u-bolts.

16297

Leaf Spring Adjustment

Aleaf spring islocated just aheadof the verticalpivot. See

Figure 3-7. The spring is designed to provide just enough

forceto keepthe hitchsquare andstable forturning atfield

ends and to add stability for drilling in rough field conditions. Proper leaf-spring adjustment is important for

smooth implement operation.

Toadjust properly, referto Figure 3-7.Square tongue with

transport frame and adjust 3/8-inch u-bolts (1) on each

side until leaf-spring rollers (2) just make contact with

roller pads (3) on transport frame. Make sure both right

and left sides are adjusted properly.

17133

Figure 3-7

Leaf Spring Adjustment

Marker Adjustments

Folding Speed

Adjust folding speed with hex adjustment screws on the

sequence-valvebody. See Figure3-8. There isone adjustment screw for raising speed (1) and one for lowering

speed (2). Identify adjustment screws by markings

stamped in valve body.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed.Turn adjustment screws

clockwise to decrease folding speed and counterclockwise to increase folding speed. Excessivefolding speed

could damage markers and void the warranty.

After adjusting the folding speed, tighten jam nuts on hex

adjustment screws to hold settings.

7/5/2005

Figure 3-6

Harrow Adjustment

14048

Figure 3-8

Speed Adjustment, Sequence Valve

FCP1000 Three-Meter Drill and Hitch 148-693M-A

19

Page 22

Section 3 Adjustments

Great Plains Mfg., Inc.

Disk Adjustments

Refer to Figure 3-9.

If mark left bymarker diskis noteasy to see, change disk

angleto make awider mark. Loosen two 1/2-inchcarriage

bolts (1) holding disk mount. Rotate disk mount as

desired.

If the marker disk is not square with the ground when the

markeris loweredin thefield, or ifmarkerarm tends tofold

up while lowered in the field, change disk angle relative to

ground. Loosen 1/2-inch bolts (2) and rotate marker

mount until marker disk is square with ground.

To adjustwhere the disk marks,loosen u-bolt (3) andslide

marker-mount tube in or out as necessary. Re-tighten ubolt.

Seed-Lok Lock Up

Optional Seed-Lok firming wheels provide additional

seed-to-soilcontact. The wheelsare spring loadedand do

not require adjusting. In some wet and stickyconditions

the wheels mayaccumulate soil.

To lockup firming wheels, hook one end of chain in the

opener-body hole just above the wheel arm (1). Pull firming-wheel arm (2) up as high as possible and wrap chain

around arm. Hook other end of chain in a link. Leave no

slack in chain; secure wheel arm in its highest position.

1

2

16856

15667

Figure 3-9

Disk Angle

Pivot Loc k Tube Adjustment

To adjust tension on pivot-lock tubes, loosen jam (1) nut

and screw bolt (2) in or out to desired setting and re-tightening jam nut. When pivot frameis 90 degreesto tongue,

bolt head should be about 2 mm (1/16 inch) away from

stop on pivot frame (3).

Figure 3-11

Seed-Lok Lock Up

Setting the Seeding Rate

Calibrating the seeding rate requires four steps:

• set correct drive type,

• setting seed-rate handle,

• positioning seed-cup doors, and

• checking seeding rate.

Refer to the seed-rate charts starting on page 23. These

charts list proper sprocketsizesand seed-rate-handle settings for various seeds and seeding rates.

The seed-rate charts are based on cleaned, untreated

seed of average size and test weight. The charts are

based on 13.0/55-16 12 PR AWtires. Many factors will

affect seeding rates including foreignmaterial, seed treatment, seed size,field conditions, tire pressure and test

weight. You likely will need to make minor adjustments.

Set and check the seeding rate using procedures below,

then readjust rate as necessary.

17855

Figure 3-10

Adjust Tension on Pivot-Lock Tube

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

20

Page 23

Great Plains Mfg., Inc.

Section 3 Adjustments

Changing Drive Sprockets

Forcorrect drive type,refer to seed-ratecharts starting on

page 23. The charts lists drive types as 1, 2, 3 or4. Refer

to the following table for correct-sized sprocket for each

drive type.

DriveType Sprocket Speed

Type 1 72-tooth Slowest

Type 2 34 tooth Two Times FasterThan Type 1

Type 3 23-tooth Three Times FasterThan Type 1

Type 4 14-tooth Five Times Faster Than Type 1

To changedrivetypes, removethechain guard (1) byloosening wing nuts (2). See Figure 3-12.

2

2

1

21502

Figure 3-12

Chain Guard

Setting Seed-Rate Handle

Positionseed-rate handle shownin Figure 3-14 to setting

indicated on seed-rate charts.

To adjust,loosen wing nutunder handle.Slide handle until

indicator is just past the correct setting, then move the

handle back until indicator lines up with correct setting.

16653

Figure 3-14

Seed-Rate Handle

Positioning Seed-Cup Doors

For wheat and other small seeds, move seed-cup-door

handles to the highest position. For soybeans and other

large seeds, lowerhandles to second position. If excessiveseed cracking occurs, lower handles to third position.

For seed-cup clean out, move handles tothe fourth, wideopen position.Make sure all handles are in the same position before drilling.

Loosen idler (1) and remove drivechain shown in Figure

3-13. Remove lynch pin from shaft (2) and re-arrange

sprockets on shaft.

1

2

17211

Figure 3-13

Drive Sprockets

NOTE:Be sure chain isinstalled with the chainconnector

link retainer towardsthe centerline and the clip opening

(split end) facesthe opposite way of the chain travel.

16651

Figure 3-15

Seed-Cup-Door Handle

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

21

Page 24

Section 3 Adjustments

Checking Seeding Rate

!

WARNING!

You may be severely injured or killed by being crushed by the

falling implement. Always have transport locks in place and

frame sufficiently blocked up when working on the implement.

1. Raisedrillwith tractor hydraulicsso gaugewheels are

off ground.Rotate drive(farright) gauge wheel to see

that metering system is working properly and free

from foreign material.

2. Check that implement tires are 13.0/55-1612 PR AW

and properly inflated. Refer to Tire Inflation Chart,

“Appendix,” page 40.

3. Record weight of an empty containerlarge enoughto

hold seed metered for one hectare (acre).

4. Place several kilos (pounds) of seed overthree seed

cups on an outside end of the seed box. Pull seed

tubes off of these three openers.

5. Turn crank on contact-wheel shaft on right-hand side

of drill several times to fill seed cups. Turn crank until

seed drops to ground from each seed cup.

6. Place a container under these three tubes to gather

metered seed.

7. Turn crank on contact-wheel shaft clockwise 32 revolutionsfor 1/100 hectare seeding rate(13 rotations for

a 1/100 acre seeding rate). While turning, checkthat

the seed cups haveplenty of seed coming into them.

NOTE: If implement is not equipped with a calibration

crank, turn drive gauge wheel 319 rotations for a one-hectare seeding rate or 127 rotation for a one-acre seeding

rate.

8. Weighmeteredseed.Subtract initialcontainerweight.

Multiply weight by

• 633.33 for 158 mm (6.2 inch) row spacing or

to determine total kilogramsper hectare (pounds per

acre) seeded. If this figure is different than desired,

adjust seed-rate handle accordingly.

NOTE:You maywantto repeat thecalibration procedure if

your results vary greatly from the seed-rate chart.

9. When drilling, check seeding rate by noting acres

drilled, amount ofseed added to drill and seed levelin

seed box. If you are seeding more or less than desired, adjust rate slightly to compensate for field conditions.

Great Plains Mfg., Inc.

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

22

Page 25

Great Plains Mfg., Inc.

Section 3 Adjustments

Seed Rate Charts

White Rows, Metric

Shaded Rows, English Units

Seed-Rate Handle

Space

Alfalfaor

Rape

Drive Type 1

(Based on 60#/bushel; .772 kb/har)

Barley

Drive Type 1

(Based on 51#/bushel; .656 kb/har)

Barley

Drive Type 2

6.2 in.

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row

2.2 5.5 8.3 12.0 15.4 19.1 22.80 27.2 31.5 36.7 41.0 44.8 49.6 54.2 59.0 63.2 68.7 73.9 79.30 81.6 84.0

2.6 6.4 9.6 13.9 17.9 22.2 26.5 31.6 36.6 42.6 47.6 52.0 57.6 63.0 68.5 73.4 79.8 85.8 92.1 94.8 97.6

1.9 4.5 7.6 10.7 14.4 18.1 22.2 26.1 30.1 34.5 38.9 43.3 47.8 52.8 57.1 61.7 65.5 69.1 72.6 73.1 73.7

2.2 5.2 8.8 12.4 16.7 21.0 25.8 30.3 35.0 40.1 45.2 50.3 55.5 61.3 66.3 71.7 76.1 80.3 84.3 84.9 85.6

3.5 8.7 15.9 21.6 29.8 37.0 45.1 53.7 61.8 71.0 76.4 87.0 95.8 104.1 113.5 122.7 132.8 142.4 151.6 154.0 156.4

4.1 10.1 18.5 25.1 34.6 43.0 52.4 62.4 71.8 82.5 88.8 101.1 111.3 120.9 131.9 142.5 154.3 165.4 176.1 178.9 181.7

Seeding Rate, Pounds per Acre/Kilograms Per Hectare

(Based on 51#/bushel; .656 kb/har)

6.2 in.

8.5 21.2 38.8 52.7 72.9 90.4 110.3 131.3 151.1 173.7 194.1 212.7 234.4 254.6 277.7 300.0 324.7 348.3 370.6 376.5 382.4

Barley

Drive Type 3

(Based on 51#/bushel; .656 kb/har)

Buck-

157.9mm

6.2 in.

157.9mm

9.9 24.6 45.1 61.2 84.7 105.0 128.1 152.5 175.5 201.8 225.5 247.1 272.3 295.8 322.6 348.5 377.2 404.6 430.5 437.4 444.2

0.0 11.3 21.0 29.4 41.9 52.2 65.0 77.9 92.4 108.8 123.1 135.7 150.4 165.4 179.5 195.4 209.3 224.0 252.6 241.9 244.5

0.0 13.1 24.4 34.2 48.7 60.6 75.5 90.5 107.3 126.4 143.0 157.6 174.7 192.1 208.5 227.0 243.1 260.2 293.4 281.0 284.0

wheat

Drive Type 4

(Based on 48#/bushel; .618 kb/har)

6.2 in.

0.0 3.7 8.2 11.7 16.1 20.1 24.1 28.3 32.8 37.0 41.8 45.7 49.9 54.4 59.1 64.7 69.80 75.7 81.9 83.2 84.9

Flax or

157.9mm

0.0 4.3 9.5 13.6 18.7 23.4 28.0 32.9 38.1 43.0 48.6 53.1 58.0 63.2 68.7 75.2 81.1 87.9 95.1 96.7 98.6

Sudan

Drive Type 1

(Based on 55#/bushel; .708 kb/har)

6.2 in.

1.4 4.7 8.2 11.7 15.7 19.5 23.4 27.2 31.5 35.7 39.8 44.0 48.5 52.4 57.0 61.7 66.00 70.8 75.8 77.0 78.1

Millet

Drive Type 1

(Based on 60#/bushel; .722 kb/har)

157.9mm

1.6 5.5 9.5 13.6 18.2 22.7 27.2 31.6 36.6 41.5 46.2 51.1 56.3 60.9 66.2 71.7 76.7 82.2 88.1 89.5 90.7

6.2 in.

0.0 4.7 8.8 13.0 17.7 22.5 27.80 33.5 39.0 44.8 51.5 56.7 62.8 68.8 74.7 80.8 86.6 91.7 97.70 100.3 102.1

Milo

Drive Type 1

(Based on 64#/bushel; .824 kb/har)

157.9mm

0.0 5.5 10.2 15.1 20.6 26.1 32.3 38.9 45.3 52.0 59.8 65.9 73.0 79.9 86.8 93.9 100.6 106.5 113.5 116.5 118.6

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

23

Page 26

Section 3 Adjustments

White Rows, Metric

Shaded Rows, English Units

Great Plains Mfg., Inc.

Seed-Rate Handle

Space

6.2 in.

Oats

Drive Type 3

(Based on 37#/bushel; .476 kb/har)

Peas

Drive Type 3

(Based on 61#/bushel; .785 kb/har)

Pinto

Beans

Drive Type 1

(Based on 61#/bushel; .785 kb/har)

Rice-

Long Grain

Drive Type 3

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row

0.0 5.2 12.1 17.3 24.0 31.5 38.7 46.8 54.8 63.2 72.2 79.7 88.0 96.1 104.5 112.2 121.2 129.6 138.6 140.3 139.7

0.0 6.0 14.1 20.1 27.9 36.6 45.0 54.4 63.7 73.4 83.9 92.6 102.2 111.6 121.4 130.3 140.8 150.6 161.0 163.0 162.3

0.0 9.5 18.9 34.1 51.9 68.7 83.9 101.9 118.9 137.4 154.3 169.4 186.2 201.5 218.2 235.4 250.8 266.1 281.4 282.9 284.1

0.0 11.0 22.0 39.6 60.3 79.8 97.5 118.4 138.1 159.6 179.3 196.8 216.3 234.1 253.5 273.5 291.4 309.1 326.9 328.6 330.0

0.0 0.0 8.5 12.9 17.4 23.6 29.60 35.3 41.2 47.1 53.0 58.2 63.7 68.8 74.4 80.8 85.4 90.7 96.60 96.4 96.3

0.0 0.0 9.9 15.0 20.2 27.4 34.4 41.0 47.9 54.7 61.6 67.6 74.0 79.9 86.4 93.9 99.2 105.4 112.2 112.0 111.9

0.0 0.0 13.2 21.6 31.6 41.9 52.7 61.2 70.7 80.8 89.8 98.1 106.5 115.5 125.3 134.7 144.3 153.3 161.0 167.1 172.9

0.0 0.0 15.3 25.1 36.7 48.7 61.2 71.1 82.1 93.9 104.3 114.0 123.7 134.2 145.6 156.5 167.6 178.1 187.0 194.1 200.9

Seeding Rate, Pounds per Acre/Kilograms Per Hectare

(Based on 47#/bushel; .605 kb/har)

6.2 in.

0.0 0.0 21.5 35.3 51.5 68.2 85.9 99.8 115.3 131.8 146.3 160.0 173.7 188.3 204.3 219.6 235.3 249.9 262.5 272.5 281.9

Rice-

Long Grain

Drive Type 4

(Based on 47#/bushel; .605 kb/har)

Rice-

Short Grain

Drive Type 3

(Based on 43#/bushel; .553 kb/har)

Rice-

Short Grain

Drive Type 4

(Based on 43#/bushel; .553 kb/har)

Drive Type1

(Based on 57#/bushel; .553 kb/har)

Rye

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

0.0 0.0 25.0 41.0 59.8 79.2 99.8 115.9 133.9 153.1 170.0 185.9 201.8 218.7 237.3 255.1 273.3 290.3 304.9 316.6 327.5

2.9 11.0 18.0 28.3 38.3 45.6 55.5 63.5 73.3 83.7 95.6 106.8 117.2 127.9 138.6 147.9 156.5 165.1 174.1 174.1 174.1

3.4 12.8 20.9 32.9 44.5 53.0 64.5 73.8 85.2 97.2 111.1 124.1 136.2 148.6 161.0 171.8 181.8 191.8 202.3 202.3 202.3

4.7 17.9 29.4 46.1 62.5 74.4 90.5 103.5 119.5 136.5 155.9 174.1 191.1 208.5 225.9 241.2 255.1 269.2 283.9 283.8 283.9

5.5 20.8 34.2 53.6 72.6 86.4 105.1 120.2 138.8 158.6 181.1 202.3 222.0 242.2 262.4 280.2 296.4 312.7 329.8 329.7 329.8

0.0 2.8 7.8 12.6 18.5 24.0 28.0 34.6 40.7 47.0 52.0 58.0 62.9 68.3 73.8 80.5 86.50 93.5 101.0 101.7 102.1

0.0 3.3 9.1 14.6 21.5 27.9 32.5 40.2 47.3 54.6 60.4 67.4 73.1 79.3 85.7 93.5 100.5 108.6 117.3 118.1 118.6

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

24

Page 27

Great Plains Mfg., Inc.

Section 3 Adjustments

White Rows, Metric

Shaded Rows, English Units

Seed-Rate Handle

Space

Soy-

beans

Drive Type 2

(Based on 58#/bushel; .747 kb/har)

Soy-

6.2 in.

157.9mm

6.2 in.

157.9mm

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row

0.0 5.8 16.0 26.9 39.6 47.5 58.9 69.3 80.4 91.8 101.6 113.9 125.3 136.1 146.8 158.2 167.4 178.6 190.1 191.1 191.7

0.0 6.7 18.6 31.2 46.0 55.2 68.4 80.5 93.4 106.6 118.0 132.3 145.6 158.1 170.5 183.8 194.5 207.5 220.8 222.0 222.7

0.0 11.5 22.5 40.4 59.5 70.7 88.9 101.0 116.3 131.3 148.1 164.0 180.7 196.3 213.6 227.5 248.2 265.3 284.0 283.8 284.3

0.0 6.7 18.6 31.2 46.0 55.2 68.4 80.5 93.4 106.6 118.0 132.3 145.6 158.1 170.5 183.8 194.5 207.5 220.8 222.0 222.7

beans

Drive Type 3

(Based on 58#/bushel; .747 kb/har)

6.2 in.

0.0 19.0 37.0 66.0 97.0 115.0 145.0 165.0 190.0 214.0 241.0 267.0 295.0 320.0 348.0 371.0 405.0 433.0 463.0 463.0 464.0

Soy-

157.9mm

0.0 22.1 43.0 76.7 112.7 133.6 168.4 191.7 220.7 248.6 280.0 310.2 342.7 371.7 404.3 431.0 470.5 503.0 537.9 537.9 539.0

beans

Drive Type 4

(Based on 58#/bushel; .747 kb/har)

6.2 in.

0.0 0.0 2.0 4.2 6.1 8.3 10.7 12.9 15.4 17.8 20.2 22.5 24.9 27.3 29.7 39.1 34.10 36.0 38.8 39.4 40.7

Sunflow-

157.9mm

0.0 0.0 2.3 4.9 7.1 9.6 12.4 15.0 17.9 20.7 23.5 26.1 28.9 31.7 34.5 45.4 39.6 41.8 45.1 45.8 47.3

ers

Drive Type 1

(Based on 28#/bushel; .360 kb/har)

Seeding Rate, Pounds per Acre/Kilograms Per Hectare

6.2 in.

Wheat

Drive Type 2

(Based on 64#/bushel; .824 kb/har)

157.9mm

Wheat

Drive Type 3

(Based on 64#/bushel; .824 kb/har)

157.9mm

Wheat

Grass

Drive Type 1

(Based on 23#/bushel; .296 kb/har)

157.9mm

0.0 12.5 21.9 30.4 39.5 49.7 57.4 69.9 80.4 91.4 104.7 115.1 127.4 140.3 152.2 164.2 177.1 189.9 203.0 205.7 205.9

0.0 14.5 25.4 35.3 45.9 57.7 66.7 81.2 93.4 106.2 121.6 133.7 148.0 163.0 176.8 190.8 205.7 220.6 235.8 239.0 239.2

6.2 in.

0.0 15.9 30.6 44.7 59.5 74.2 87.5 103.6 120.1 136.5 153.3 168.0 185.6 202.4 220.2 239.9 255.8 273.6 289.8 296.7 298.8

0.0 18.5 35.5 51.9 69.1 86.2 101.6 120.4 139.5 158.6 178.1 195.2 215.6 235.1 255.8 278.7 297.2 317.8 336.7 344.7 347.1

6.2 in.

0.0 0.9 2.1 3.0 4.2 5.1 6.0 7.4 8.4 9.6 10.8 11.9 13.1 14.2 15.4 16.8 17.9 19.3 18.50 20.8 21.1

0.0 1.0 2.4 3.5 4.9 5.9 7.0 8.6 9.8 11.2 12.5 13.8 15.2 16.5 17.9 19.5 20.8 22.4 21.5 24.2 24.5

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

25

Page 28

Section 3 Adjustments

Fertilizer Rate Calibration

The fertilizer rates are controlled by a sprocket speed

change selection and by a slide gate which controls the

meter opening size.The charts shownare calculated with

the openings at 100% open. Anyadjustments to the opening at less than 100% open will have to be calibrated for

the correct rate. (See calibration instructions below.)

Fertilizerapplication rates will vary with fertilizertype, density and particle size. Relativehumidity and field conditions canalso affect application rates.The charts on page

27 are based on fertilizer with average particle size and a

density of 1.04 kilograms per litre (65 pounds per cubic

foot). Initially set rate according to charts, then calibrate

drill to your material as described on this page.

1. Refer to fertilizer rate charts on page 27 forcorrect

sprocket sizes for your drill and desired meter rate.

IMPORTANT:The rate charts are for granularfertilizer

with a density of 1.04 kilograms per litre (65 pounds

per cubic foot). If you are applying fertilizer with a different density, use density conversion chart on page

28.

2. To switch between high and low range,loosen and

slide idler sprocket (1) out of chain shown in Figure 3-

1. Remove lynch pin from end of shaft and install correct sprocket.

•Forhigh range, install 16-tooth sprocket and shorten

chain by removing 16-pitch strand.

•Forlow range, install44-tooth sprocket andlengthen

chain by reinstalling 16-pitch strand.

•For extra-high range, install 12-tooth sprocket and

shorten chain by removing 16-pitch strand.

•For special high range, install12-tooth sprocketand

shorten chain by removing 16-pitch strand.

NOTE: Special High Range Fertilizer Sprocket

In order to run special high rate fertilizer it will be necessary to change the final drivesprocket from a 12tooth to a

19 tooth sprocket.Refer to Figure 3-2.

a. Loosen the idler sprocket on the fertilizer final

drive chain.

b. Remove the lynch pin and remove the 12 tooth

sprocket.

c. Install the 19 tooth sprocketand replace thelynch

pin.

d. Tighten the idler sprocket on the fertilizer final

drive chain

Moveidler sprocketbackinto placeso chainhas 6mm

(1/4-inch) slack.

12/16/44T

1

16379

Figure 3-1

Hi/Low Range Sprocket

Great Plains Mfg., Inc.

19T

21896

Figure 3-2

Special High Range Sprocket .

3. To change driver/driven ratio, refer to Figure 3-3..

Loosenand slideidler sprocketsout ofchain. Remove

lynch pins from shafts. Place correct sprockets on

shafts. Store sprockets not used on ends of shafts.

Reinstall chain and slide idlers back into place so

chain has 6 mm (1/4-inch) slack.

Driven

iver

Dr

16378

Figure 3-3

Driver/Driven Sprockets

4. Raise drill with tractor hydraulics so the contact

wheels are not touching the gauge wheels. Rotate

drive gauge wheel to see that metering system is

working properly and free from foreign material.

5. Check that your gauge-wheel tires are 13.0/55-16 12

PR AW and properly inflated. Refer to Tire Inflation

Chart,“Appendix,”page 40.

6. Place severalkilos (pounds) of fertilizer over three fertilizer feed cups on outside end of drill box. Pull fertilizer tubes off of these three disk openers.

7. Weigh an empty container large enough to hold fertilizer applied to one hectare (acre).

8. Turn drive wheeluntil fertilizer starts to drop toground.

9. Place container under the three tubes to gather metered fertilizer.

10. Turndrivegauge wheel319rotations foraone-hectare

seeding rate or 127 rotations for a one-acre seeding

rate. Check that feedcups have plenty of fertilizer coming into them.

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

26

Page 29

Great Plains Mfg., Inc.

Section 3 Adjustments

11. Weighmetered material. Subtractweight of empty container. Divide by three. Multiply by number

of openers on your drill to determine total kilograms (pounds) metered per hectare (acre). If

this figure is different than desired, reset sprockets accordingly.

NOTE:You maywant to repeat calibration procedure

if your results vary greatly from fertilizer rate chart.

12. When drilling, check metering rate bynoting hectares(acres) drilled, amount of fertilizer added to

drill and levelof material in drill box.If you are applying more or less fertilizer than desired, adjust

meteringrate slightly tocompensate forfield conditions.

Fertilizer Meter Rate Charts

Based on 1.04 kilograms-per-litre (65 pounds-per-cubic-foot) density

For 157.9 mm (6. 2 in.) Row Spacing

Metering

Rate

kg/har lb/acre Range Driver Driven kg/har lb/acre Range Driver Driven

48.8 42 Low 12T 21T 141.7 122 High 12T 20T

51.1 44 Low 12T 20T 142.9 123 Low 20T 12T

54.6 47 Low 12T 19T 148.7 128 High 12T 19T

56.9 49 Low 12T 18T 151.0 130 Low 21T 12T

60.4 52 Low 12T 17T 156.8 135 High 12T 18T

63.9 55 Low 12T 16T 166.1 143 High 12T 17T

69.7 60 Low 17T 21T 190.5 164 High 17T 21T

73.2 63 Low 17T 20T 199.8 172 High 17T 20T

76.7 66 Low 17T 19T 210.3 181 High 17T 19T

81.3 70 Low 20T 21T 224.2 193 High 20T 21T

90.6 78 Low 21T 20T 247.4 213 High 21T 20T

95.3 82 Low 21T 19T 260.2 224 High 21T 19T

99.9 86 Low 21T 18T 274.2 236 High 21T 18T

105.7 91 Low 21T 17T 290.4 250 High 21T 17T

112.7 97 Low 21T 16T 333.4 287 High 17T 12T

122.0 105 Low 17T 12T 352.0 303 High 18T 12T

128.9 111 Low 18T 12T 371.7 320 High 19T 12T

134.8 116 High 12T 21T 391.5 337 High 20T 12T

135.9 117 Low 19T 12T 410.1 353 High 21T 12T

Sprockets Metering

Rate

Sprockets

7/5/2005

FCP1000 Three-Meter Drill and Hitch 148-693M-A

27

Page 30

Section 3 Adjustments

Great Plains Mfg., Inc.

For 157.9 mm (6. 2 in.) Row Spacing (Special Range)

Metering Rate Sprockets

kg/har lb/acre Special

173.2 155 12:12 12T 21T

182.2 163 12:12 12T 20T

191.1 171 12:12 12T 19T

201.6 180 12:12 12T 18T

213.6 191 12:12 12T 17T

244.9 219 12:12 17T 21T

256.9 229 12:12 17T 20T

270.3 241 12:12 17T 19T

288.2 257 12:12 20T 21T

318.1 284 12:12 21T 20T

334.5 299 12:12 21T 19T

352.4 315 12:12 21T 18T

373.3 333 12:12 21T 17T

428.6 383 12:12 17T 12T

452.5 404 12:12 18T 12T

477.9 427 12:12 19T 12T

503.3 449 12:12 20T 12T

527.1 471 12:12 21T 12T

Range

Driver Driven

For 157.9 mm (6. 2 in.) Row Spacing (Special High Range)

Metering Rate Sprockets

kg/har lb/acre Special

274.3 245 12:12 12T 21T

288.5 258 12:12 12T 20T

302.6 270 12:12 12T 19T

319.2 285 12:12 12T 18T

338.1 302 12:12 12T 17T

387.8 346 12:12 17T 21T

406.7 363 12:12 17T 20T

428.0 382 12:12 17T 19T

456.3 407 12:12 20T 21T

503.6 450 12:12 21T 20T

529.6 473 12:12 21T 19T

558.0 498 12:12 21T 18T

591.1 528 12:12 21T 17T

678.6 606 12:12 17T 12T

716.4 640 12:12 18T 12T

756.6 676 12:12 19T 12T

796.8 711 12:12 20T 12T

834.6 745 12:12 21T 12T

Range

Driver Driven

Density Conversion Chart

The fertilizer meter ratecharts are based on fertilizer with a density of 1.04 kilogramsper litre (65 pounds per cubic foot).

If you are applying fertilizer of a different density, use the following table to convert the application rate.

Density, kg/l (lb/ft3) 0.72 (45.0) 0.80 (50.0) 0.88 (55.0) 0.96 (60.0) 1.04 (65.0) 1.12 (70.0) 0.87 (75.0) 0.81 (80.0)

Conversion Factor 1.45 1.30 1.20 1.10 1.00 0.93 0.87 0.81

Example:Your fertilizerhas adensity of 0.72kilogramsper litre,and youwant toapply 100kilograms perhectare. Multiply

desired application rate by the conversion factor.

100 x 1.45 = 145

Adjust drill to setting closest to 145 kilograms per hectare.

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

28

Page 31

Great Plains Mfg., Inc.

Section 3 Adjustments

Small Seeds Attachment

To set and calibratethe seeding rate on the optionalsmallseeds attachment, follow these steps.

1. Set seed-rate handle on small-seeds attachment to

setting indicated on Small Seeds Rate Chart.

2. Calibrate small-seeds attachment to your material by

following the steps under Checking Seeding Rate,

page 22.

Small Seed Rate Charts

Optional Equipment

Seed-Rate-

Handle Setting

Alfalfa,

Crimson Clover

and Red Alsike

Row

Space

6.2 in.

157.9mm

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Seeding Rate, Pounds per Acre/Kilograms Per Hectare

0.0 2.2 3.5 4.8 6.0 7.5 8.7 9.8 11.2 12.5 13.8 15.1 16.4 17.5 18.6 20.2 21.4 22.9 24.0 25.2

0.0 1.8 2.8 3.9 4.8 6.0 7.0 7.9 9.0 10.1 11.1 12.2 13.2 14.1 15.0 16.3 17.2 18.4 19.3 20.3

Annual Rye

Grass, Kentucky

Blue Grass and

Fescue

Bermuda, Red Top,

Unhulled Lespede-

za, Sand, Sercia and

Weeping Love Grass

Hulled Lespede-

za, Red Clover

and Sweet Clover

Orchard Grass

Millet and

Reed Canary

Canary Grass,

Canola, Timothy

and Ladino Clover

6.2 in.

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

6.2 in.

157.9mm

0.0 0.2 1.2 1.9 2.7 3.3 4.1 4.6 5.2 5.8 6.3 6.8 7.3 7.8 8.3 8.8 9.2 9.7 10.0 10.5

0.0 0.2 1.4 2.2 3.1 3.8 4.8 5.3 6.0 6.7 7.3 7.9 8.5 9.1 9.6 10.2 10.7 11.3 11.6 12.2

0.0 0.7 1.1 1.7 2.6 3.3 4.1 5.0 5.9 6.6 7.2 7.8 8.4 9.0 9.5 10.2 10.9 11.6 12.2 12.9

0.0 0.8 1.3 2.0 3.0 3.8 4.8 5.8 6.9 7.7 8.4 9.1 9.8 10.5 11.0 11.8 12.7 13.5 14.2 15.0

0.0 1.5 3.4 5.2 7.1 9.0 11.3 13.2 15.3 17.0 19.0 20.8 22.5 24.5 26.4 28.3 30.1 32.1 33.8 35.6

0.0 1.7 3.9 6.0 8.2 10.5 13.1 15.3 17.8 19.7 22.1 24.2 26.1 28.5 30.7 32.9 35.0 37.3 39.3 41.4

0.0 0.0 0.3 0.7 0.9 1.3 1.5 2.0 2.4 2.8 3.3 3.5 3.9 4.4 4.8 5.0 5.5 5.7 6.1 6.3

0.0 0.0 0.3 0.8 1.0 1.5 1.7 2.3 2.8 3.3 3.8 4.1 4.5 5.1 5.6 5.8 6.4 6.6 7.1 7.3

0.4 1.4 2.4 3.5 4.4 5.5 6.5 7.5 8.5 9.5 10.5 11.5 12.5 13.6 14.6 15.6 16.6 17.6 18.5 19.0

0.5 1.6 2.8 4.1 5.1 6.4 7.6 8.7 9.9 11.0 12.2 13.4 14.5 15.8 17.0 18.1 19.3 20.4 21.5 22.1

0.0 1.1 2.1 3.3 4.7 6.1 7.6 9.2 10.7 12.2 13.8 15.5 17.0 18.5 20.3 21.7 23.4 25.4 27.3 29.2

0.0 1.3 2.4 3.8 5.5 7.1 8.8 10.7 12.4 14.2 16.0 18.0 19.7 21.5 23.6 25.2 27.2 29.5 31.7 33.9

Sudan and Bird’s-

Foot Trefoil

7/5/2005

6.2 in.

157.9mm

0.0 1.7 3.3 5.2 6.8 8.7 10.7 12.7 14.7 16.8 19.2 21.2 23.4 25.6 28.0 29.9 32.1 34.2 36.3 38.4

0.0 2.0 3.8 6.0 7.9 10.1 12.4 14.8 17.1 19.5 22.3 24.6 27.2 29.7 32.5 34.7 37.3 39.7 42.2 44.6

FCP1000 Three-Meter Drill and Hitch 148-693M-A

29

Page 32

Section 4 Troubleshooting

Section 4 Troubleshooting

Problem Solution

Great Plains Mfg., Inc.

Drill raising and lowering rough and uneven Check for too little play in slide-block area. Refer to Maintenance, “Maintenance

Coulters not going deep enough Retract tongue cylinder.

Drill not tracking behind coulters Check if coulters are aligned with openers.

Openers plugging in no-till conditions Drill across standing residue.

Drill seeding too deep

Uneven seed spacing or uneven stand

and Lubrication,” page 32.

Check for air trapped in hydraulic lines or cylinders. Bleed hydraulicsif necessary.

Refer to Bleeding the Hydraulic Systems, “Preparation and Setup,” page 11.

Add weight to hitch frame. Refer to Coulter Down Pressure,“Adjustments,” page

17.

Too much weight is being used by openers; set drill openers to lightest spring set-

ting. Refer to Opener Down Pressure, “Adjustments,” page 18.

Shorten coulter springs to increase down pressure. Refer to Coulter Down Pres-

sure, “Adjustments,” page 17.

Check that pivot-lock tubes are in drilling position. Refer to Figure 2-2, page 13.

Check if leaf spring is out of alignment. Refer to Leaf Spring Adjustment, “Adjust-

ments,” page 19.

Change the press-wheel setting. Refer to Opener Depth,“Adjustments,” page 18.

Remove weight from hitch.

Check for plugging in seed cups.

Check if seed tubes are plugged.

Reduce ground speed.

Check that opener disks turn freely.

Use a faster drive type and a lower seed-rate-handle setting. Refer to Setting the

Seeding Rate, “Adjustments,” page 20.

Increase opener down pressure so opener disks penetrate. Referto Opener Down

Pressure, “Adjustments,” page 18.

Check for trash or mud build-up on optional Seed-Lok® wheels.

Opener disks not turning freely

FCP1000 Three-Meter Drill and Hitch 148-693M-A 7/5/2005

30