Great Plains EWNT7 1523Q-1630Q Operator Manual

Operator’s Manual

EWNT7 and EWNT10

End Wheel No Till Drill

Model Serial No.

EWNT7 1523Q - 1630Q

EWNT10 4142U - 4568U

Manufacturing, Inc.

www.greatplainsmfg.com

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

© Copyright 1999 Printed

4/12/2005

13844

Cover illustration may show optional equipment not supplied with standard unit.

150-082M-A

General Information

Important Notice

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains

Manufacturing, Inc. assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages

resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to

revise and improve its products as it sees fit. This publi-

This Operator’s Manual applies to the

7’ & 10’ End Wheel No-Till

Owner’s Information

Name: _____________________________________

cation describes the state of this product at the time of its

publication, and may not reflect the product in the future.

Printed in the United States of America.

For your convenience, record your Serial Number, Model Number and the Date Purchased in the spaces provided below. Have this information available when

calling your Great Plains Authorized Dealer.

Serial Number ________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Name of Dealership ___________________________

Dealer’s Name _______________________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Model Number ________________

Date Purchased _______________

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A 4/25/06Great Plains Mfg., Inc.

Table of Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 1 Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Operation & Repair . . . . . . . . . . . . . . . . . . . . 3

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tire Handling & Repair . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 2 Assembly Instructions & Set-Up . . . . . . . . . . 6

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Torque Values Chart for Common Bolt Sizes . . . . . . . 6

Pre-Assembly Checklist. . . . . . . . . . . . . . . . . . . . . . . . 7

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tractor Drawbar Hook-Up . . . . . . . . . . . . . . . . . . . . . . 8

Tractor Drawbar Hook-Up For Ball Swivel Hitch . . . . . . 8

Tractor Hydraulic Hook-Up. . . . . . . . . . . . . . . . . . . . . . 9

Bleeding the Hydraulic Lifting System . . . . . . . . . . . . . 9

Section 3 Basic Operation . . . . . . . . . . . . . . . . . . . . . . . 10

Operating the Lifting Hydraulic System . . . . . . . . . . . 10

Transporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operating Transport Lock . . . . . . . . . . . . . . . . . . . . . 10

Lock Out Hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 4 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive System Clutch . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive Train Operation. . . . . . . . . . . . . . . . . . . . . . . . . 11

Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Change Drive Sprockets . . . . . . . . . . . . . . . . . . . . . . 12

Set Seed-Rate Handle. . . . . . . . . . . . . . . . . . . . . . . . 12

Position Seed-Cup Doors . . . . . . . . . . . . . . . . . . . . . 12

Check Seeding Rate . . . . . . . . . . . . . . . . . . . . . . . . . 13

Seed Rate Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fertilizer Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fertilizer Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7’ & 10’ Fertilizer Application Chart . . . . . . . . . . . . . . . 19

Native Grass Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Native Grass Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Native Grass Seeding Adjustments. . . . . . . . . . . . . . . 20

Native Grass Seed Rate Charts & Sprockets . . . . . . . 21

Planting Depth Adjustments . . . . . . . . . . . . . . . . . . . . 22

Coulter Hydraulic Depth Control . . . . . . . . . . . . . . . . . 22

Down Pressure Requirements . . . . . . . . . . . . . . . . . . 22

Individual Opener & Coulter . . . . . . . . . . . . . . . . . . . . 23

Disk Opener Spring Pressure Setting . . . . . . . . . . . . . 23

Individual Opener Height. . . . . . . . . . . . . . . . . . . . . . . 23

Opener Press Wheel Depth . . . . . . . . . . . . . . . . . . . . 24

Press Wheel Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Section 5 Field Operations . . . . . . . . . . . . . . . . . . . . . . . 25

Drill Preparations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Section 6 Maintenance & Lubrication. . . . . . . . . . . . . . . 26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fertilizer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Section 7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 29

Section 8 Specifications & Warranty . . . . . . . . . . . . . . . 31

4/25/06 Great Plains Mfg., Inc. EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A

-1

Using this Manual

Using this Manual

For your safety and to help in developing a better understanding of your equipment, read this manual. Reading

these sections not only provides valuable training but

Introduction

This manual has been prepared to instruct you in the

safe and efficient operation of your End Wheel No-Till.

Read and follow all instructions and safety precautions

carefully.

The parts on your End Wheel No-Till have been specially designed and should only be replaced with genuine

Great Plains parts. Therefore, should your End Wheel

No-Till require replacement parts go to your Great

Plains Dealer.

The right hand and left hand as used throughout this

manual is determined by facing in the direction the machine will travel when in use unless otherwise stated.

Serial Number

The serial number plate is located on the front right side

of the frame. It is suggested that the serial number and

purchase date also be recorded for your convenience in

the space provided on the checklist page at the beginning of this manual.

The serial number provides important information about

your drill and may be required to obtain the correct replacement part. Always use the serial number and model number when sending correspondence or when

ordering parts from your Great Plains dealer.

also familiarizes you with helpful information and its location. After reviewing your manual store it in a dry, easily accessible location for future reference.

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment; hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Watch for the following safety notations throughout your

operator’s manual:

!

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal

word is limited to the most extreme situations.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

DANGER!

!

WARNING!

!

CAUTION!

!

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

safety precautions must be taken. When you see this

2

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A 4/25/06

NOTE: Indicates a special point of information which

requires your attention.

Great Plains Mfg., Inc.

Section 1 Safety Rules

Section 1 Safety Rules

Most accidents are the result of negligence and carelessness, usually caused by failure of the operator to follow simple but necessary safety precautions. The

following safety precautions are suggested to help prevent such accidents. The safe operation of any machinery is a big concern to consumers and

manufacturers.Your End Wheel No-Till has been designed with many built-in safety features. However, no

one should operate this product before carefully reading

this operator’s manual.

!

General Operation & Repair

1. Never allow the drill to be operated by anyone who is unfamiliar with the operation of all functions of the unit. All

operators should read and thoroughly understand the instructions given in this manual prior to moving the unit.

2. Make sure safety rules are understood before operating

machinery or tractor.

3. Never permit any persons other than the operator to ride

on the tractor.

4. Never permit any persons to ride on or stand near the

drill while it is in operation.

5. Regulate your speed to the field conditions, maintaining

complete control at all times.

6. After repairing or adjusting, make sure all tools and

parts are removed from the implement before attempting

to operate it.

7. Do not grease or oil machine while it is in operation.

8. Loose fitting clothing should not be worn as it may catch

in moving parts.

9. Never dismount from a moving tractor.

10. Do not leave the tractor or the implement unattended

with the engine running.

11. Do not stand between the tractor and the implement during hitching.

12. Detach and store implements in an area where children

normally do not play. Stabilize implements by using suitable supports and block wheels.

13. If a hydraulic leak develops, correct it immediately. Escaping hydraulic oil can have extremely high pressure. A

stream of high pressure oil may easily penetrate the skin.

It is imperative that the connections are tight and that all

lines and pipes are in good condition. If an injury is

caused by the escaping hydraulic fluid, see doctor at

once!

14. Use a piece of cardboard or wood to detect leaks of hydraulic oil under pressure.

15. Be sure to relieve all hydraulic pressure before disconnection any lines or pipes between the implement and the tractor hydraulic system. Keep all guards and shields in place.

Transporting

1. Use good judgement when transporting tractor and implements on the highway. Always maintain complete control of the machine.

2. Limit transport speed to 20 mph. Transport only with a

farm tractor of sufficient size and horse power. See

“Tractor Requirements” Section 2,page 8.

3. Always make sure flashing safety lights, “Slow Moving

Vehicle” emblem, and reflectors are in place and visible

prior to transporting the machine on public roads.

4. Know your state and local laws concerning highway

safety and regulations. Comply with these laws when

transporting machinery.

5. Use warning flags or approved warning lights at night

and during other periods of poor visibility. Do your best

to prevent highway accidents.

Tire Handling & Repair

1. Tire changing can be dangerous and should be preformed by trained personnel using the correct tools and

equipment.

2. Do not re-inflate a tire that has been run flat or seriously

under inflated. Have it checked by qualified personnel.

3. When removing and installing wheels, use wheel handling equipment adequate for the weight involved.

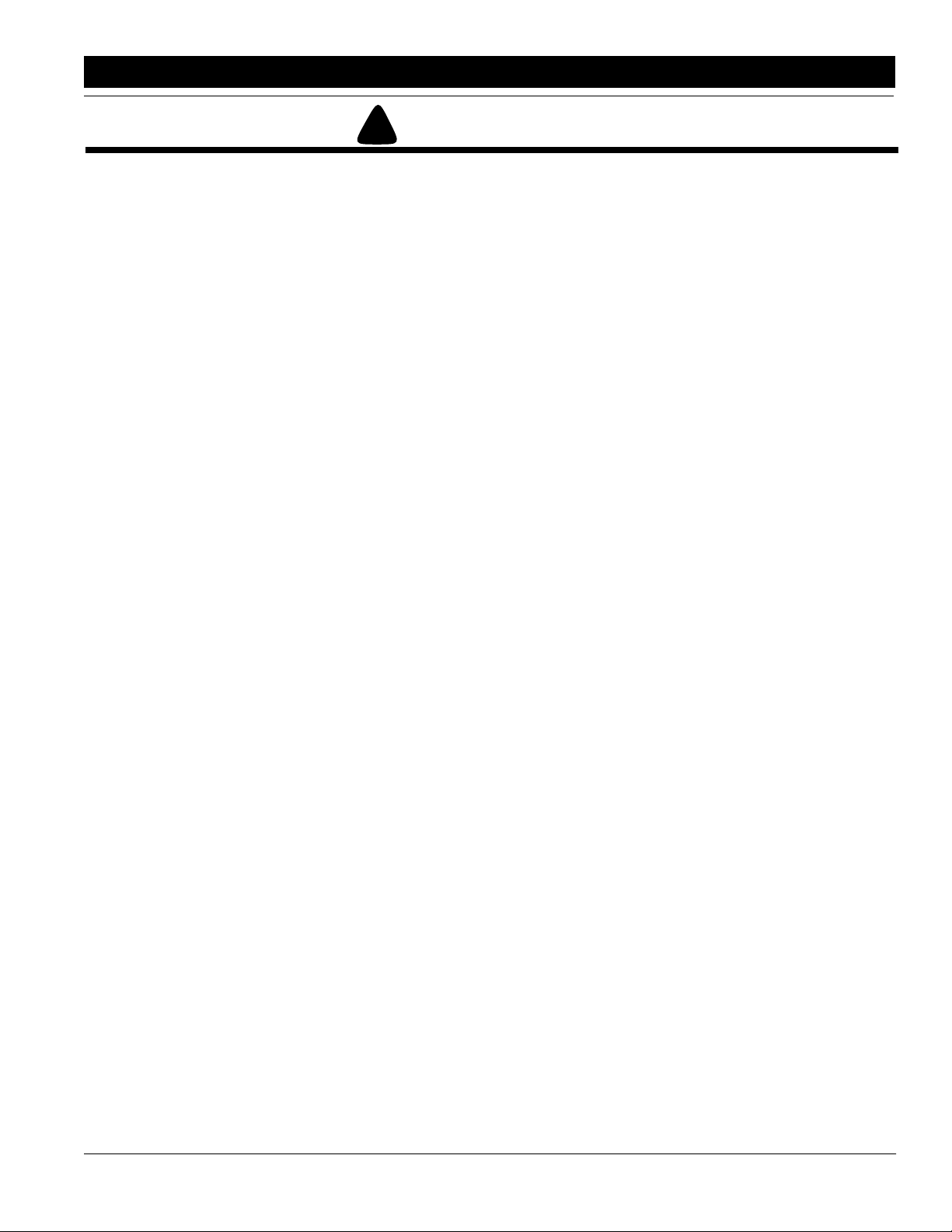

Safety Decals

1. Your End Wheel No-Till comes equipped with all safety

decals in place. They were designed to help you safely

operate your drill. Read and follow their directions.

2. Keep safety decals clean and legible.

3. Replace all damaged or missing safety decals. To order

new safety decals go to your Great Plains dealer and refer to the parts section for safety decal package part number.

4. Replace these decals whenever they become worn or unreadable. To install new safety decals:

a. Clean the area the decal is to be placed

b. Peel backing from the decal. Press firmly on to sur-

face being careful not to cause air bubbles under the

decal.

4/25/06 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A

-3

Section 1 Safety Rules

13846

13846

818-188C

Transport Speed Warning

838-265C

Amber Reflectors

13847

818-188C

Transport Speed Warning

838-266C

13849

4

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A 4/25/06

Red Reflector

Great Plains Mfg., Inc.

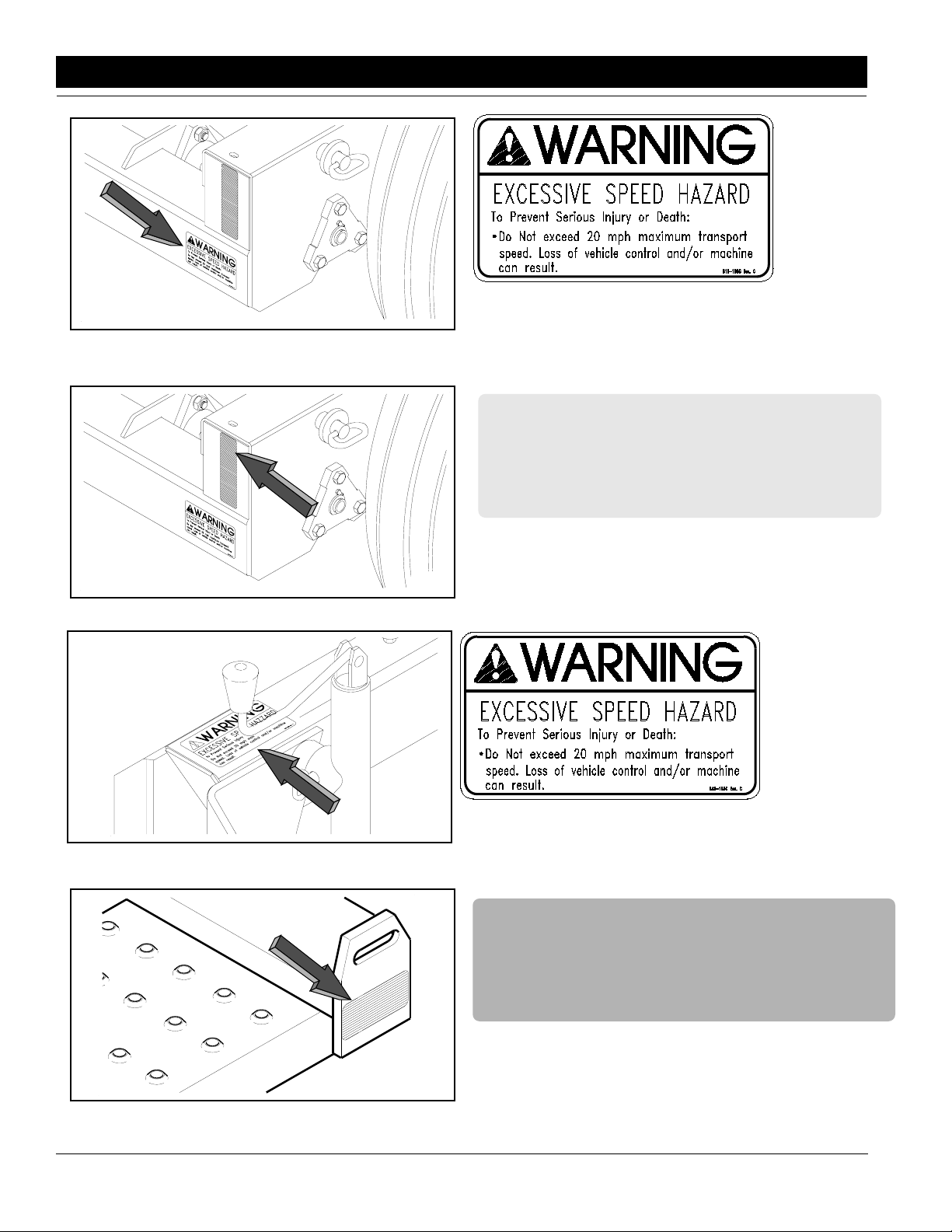

Section 1 Safety Rules

13848

818-003C

Slow Moving Vehicle Emblem

4/25/06 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A

-5

Section 2 Assembly Instructions & Set-Up

Section 2 Assembly Instructions & Set-Up

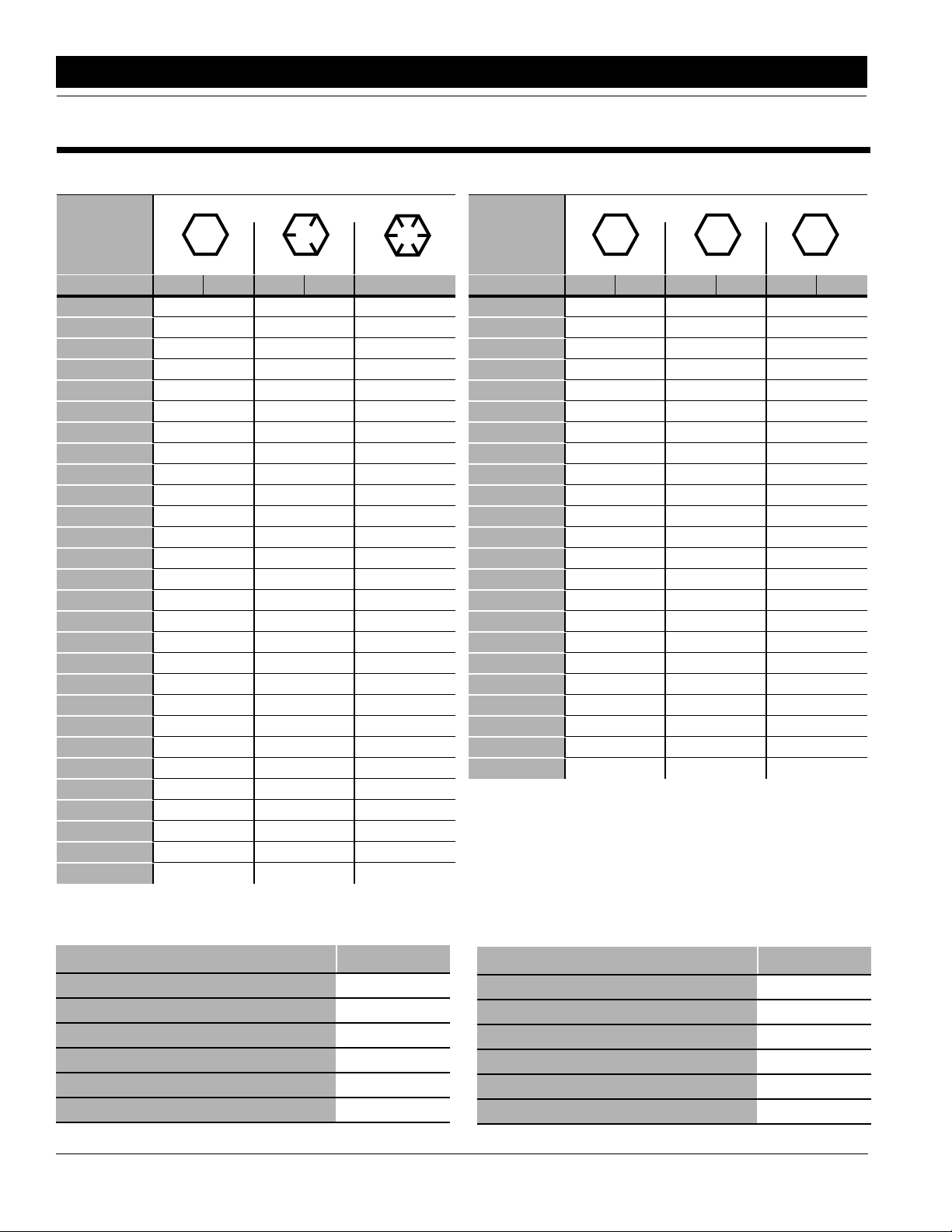

Torque Values Chart for Common Bolt Sizes

Bolt Head Identification

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 436597

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch4N · m ft-lb N · m ft-lb N · m ft-lb

Grade 8

Bolt Size

(Metric)

1

in-tpi = nominal thread diameter in inches–threads per inch

2

N· m = newton-meters

3

ft-lb= foot pounds

4

mm x pitch = nominal thread dia. in millimeters x thread pitch

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

Tire Inflation Chart

Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28

9.0 x 22.5 10-Ply Highway Service 70 70

9.0 x 24" 8-Ply Rib Implement 40

9.5L x 15" 6-Ply Rib Implement 32

9.5L x 15" 8-Ply Rib Implement 44

9.5L x 15" 12-Ply Rib Implement 60

6

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A 4/25/06

Tire Size Inflation PSI

11L x 15" 6-Ply Rib Implement 28

11L x 15" 12-Ply Rib Implement 52

12.5L x 15" 8-Ply Rib Implement 36

12.5L x 15" 10-Ply Rib Implement 44

16.5L x 16.1" 10-Ply Rib Implement 36

41 x 15" x 18 - 22-Ply Rib Implement 44

Great Plains Mfg., Inc.

Section 2 Assembly Instructions & Set-Up

Pre-Assembly Checklist

Check

All major components

Fasteners that were shipped with the End Wheel No-Till Drill.

NOTE: Some of the hardware from the factory has been installed in the location where it will be used.

Have a minimum of 2 people at hand while assembling the End Wheel No-Till Drill.

Have a fork lift or loader along with chains and safety stands ready for the assembly task.

If you are unsure where a fastener is used, use the parts section of this manual to identify it. Be sure the part gets

used in the correct location.

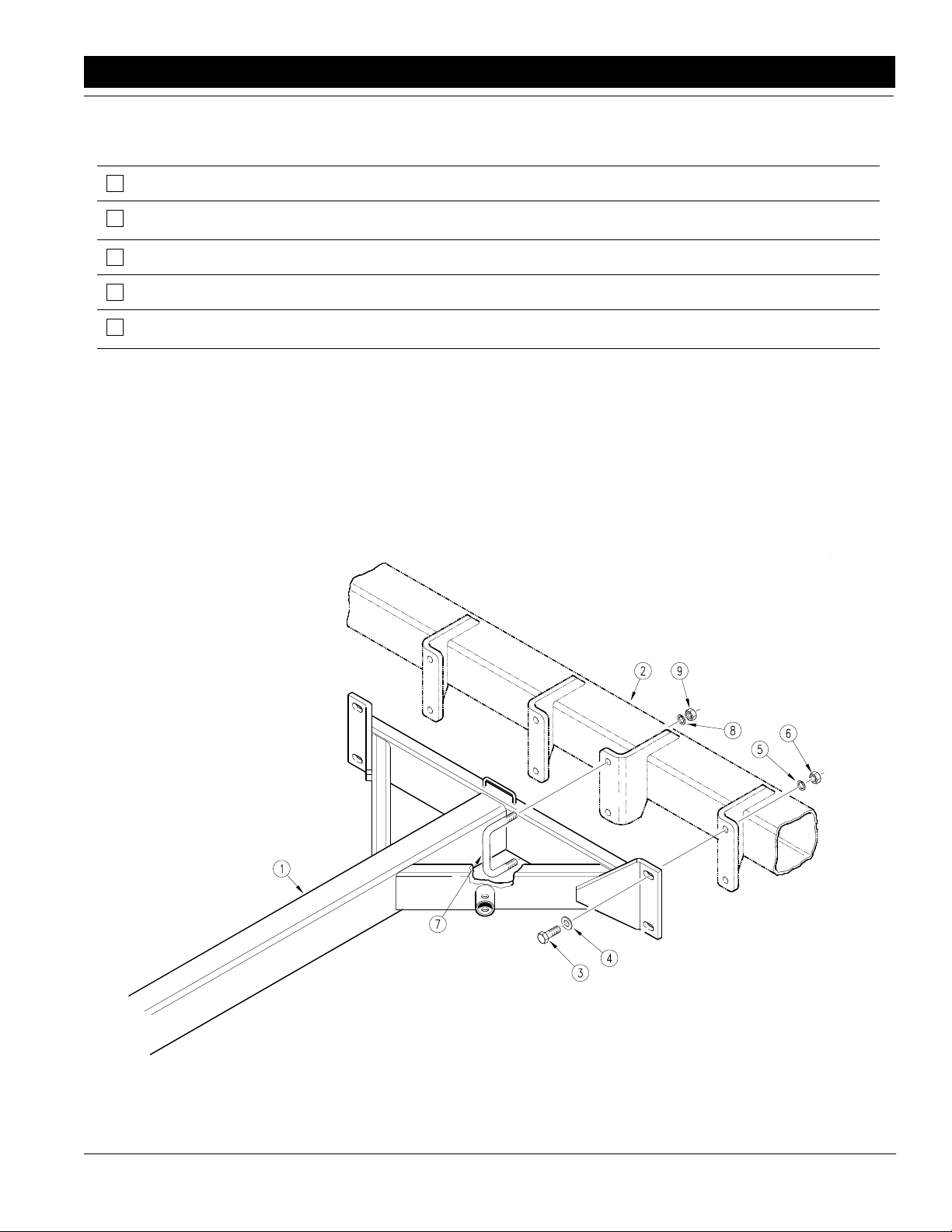

Refer to Figure 2-1:

Before starting the drill assembly, be sure that the drill

frame is safely supported and the end wheel tires are

blocked.

Bolt the outside legs of the tongue weldment (#1) to the

drill frame (#2) using 3/4" x 2 1/4" long bolts (#3), 3/4"

SAE flat washers (#4), 3/4" lock washers (#5), and 3/4"

hex nuts (#6).

Connect the rear tube of the tongue (#1) to the drill frame

(#2) using 3/4" x 6 1/32" x 3 1/4" long u-bolts (#7), 3/4"

lock washers (#8), and 3/4" hex nuts (#9).

Tighten all hardware to the torque specification listed in

the "Nut & Bolt Torquing Chart" on page 6.

4/25/06 Great Plains Mfg., Inc.

Tongue & Pull Bar Assembly

Figure 2-1

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A

10681

-7

Section 2 Assembly Instructions & Set-Up

Tractor Requirements

To operate your Great Plains End Wheel No-Till Drill in

most field conditions, a tractor of adequate size should

be used. For 7’ drills, a 55 horsepower tractor is required. For 10’ drills, a 75 horsepower tractor is required.

7’ and 10’ drills require one set of remote outlets.

Tractor Drawbar Hook-Up

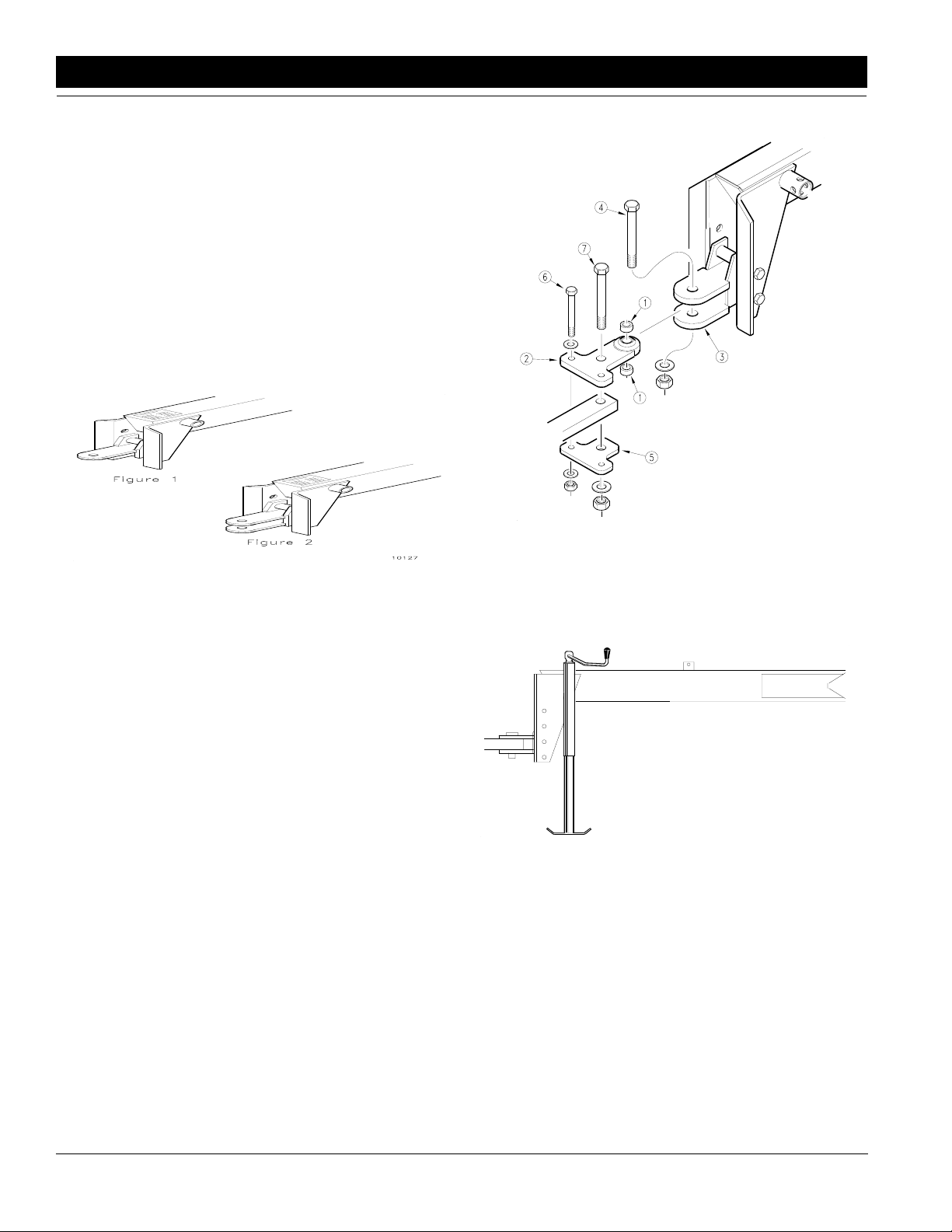

Refer to Figure 2-2 & Figure 2-3:

The Great Plains No-Till Drill is equipped with either a

single strap, Figure 2-2, clevis style hitch, Figure 2-3, or

a ball swivel hitch, Figure 2-5. For proper field operation,

the tongue of the drill should run level, parallel to the

ground in field position.

11549

10127

Single Strap Hitch

Figure 2-2

Clevis Style Hitch

Figure 2-3

Tractor Drawbar

Hook-Up For Ball Swivel Hitch

Refer to Figure 2-4:

Place a spacer tube (#9) above and below the ball swivel. Bolt the ball swivel {top hitch weldment} (#1) and

spacer tubes (#9) to the drill clevis hitch with a 1" x 5"

long bolt (#10), 1" USS flat washer (#11), and 1" nylock

nut (#12).

Back the tractor to the drill hitch. Using the screw jack,

adjust the drill tongue up or down to center the drawbar

below the upper hitch plate (#1). Place hitch weldment

(#1) on top of the tractor drawbar, aligning the rear hole

in the hitch weldment with the large hole in the drawbar.

Place the lower hitch plate (#2) under the drawbar and

attach to the hitch weldment (#1) with {2} 5/8" x 4" long

bolts (#3), 5/8" flat washers (#4), 5/8" nylock nuts (#5).

Bolt the top hitch weldment (#1) through the hole in the

drawbar to the lower hitch plate (#2) with a 1" x 5 1/2"

long bolt (#6), 1" USS flat washer (#7), and 1" nylock nut

(#8).

Ball Swivel Hitch

Figure 2-4

Refer to Figure 2-5:

1. With the drill lowers and in the field position, adjust

the tongue jack to level the tongue.

Jack In Vertical Position

Figure 2-5

2. Back the tractor draw bar up to the drill hitch to determine the amount of adjustment required.

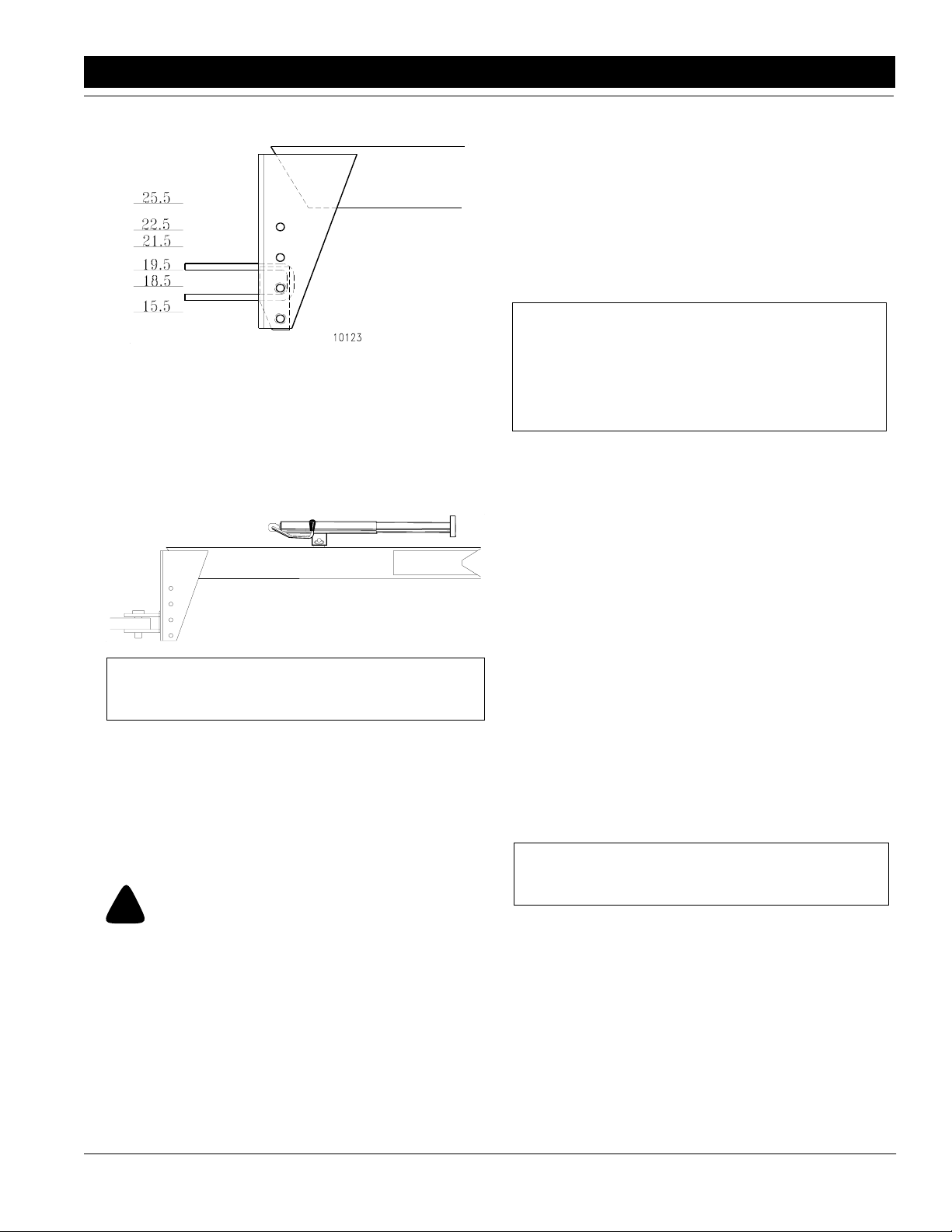

Refer to Figure 2-6:

3. The mounting holes in the hitch have been offset so

the hitch can be turned over and bolted on in three

different hitch positions, giving you six different hitch

heights.

10150

8

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A 4/25/06

Great Plains Mfg., Inc.

Section 2 Assembly Instructions & Set-Up

Bleeding the

Hydraulic Lifting System

The implement lifting system is equipped with rephasing

type hydraulic cylinders that require a special procedure

for bleeding air from the hydraulic circuits. Read and follow the procedure carefully. The rephasing type cylinders will not function properly with air in the hydraulic

circuit. Bleeding the system may have been done during

initial set up of the drill.

10123

Hitch Height Adjustment

Figure 2-6

4. Connect the hitch to the tractor using a pin of adequate strength (minimum 1" diameter).

Refer to Figure 2-7:

5. Unpin the tongue jack, and pin it on top of the

tongue.

Jack In Transport Position

Figure 2-7

NOTE: Make sure the hitch is securely bolted to the

drill tongue.

Your drill comes equipped with a hitch safety chain. The

safety chain should be securely attached to the drill hitch

and the tractor drawbar whenever towing or planting.

11833

Tractor Hydraulic Hook-Up

Route the lift hydraulic hoses along the tongue and

through the hose loop on the front of the tongue. Connect the hoses to the tractor remote outlets.

NOTE: Check the hydraulic fluid in the tractor reservoir and fill to the proper level. Add fluid to the system as needed. A low reservoir level may draw air

back into the system, causing jerky or uneven cylinder movements. The drill system capacity is approximately 1 gallon.

1. Jack up and support the front member of the drill at

a point close to each end wheel. If the end wheel cylinders have previously been engaged, they may be

used to assist in raising the frame.

2. With the frame blocked and supported, unpin the

cylinders from the drill frame and turn the cylinders

upside down and wire or otherwise safely support

the rod end port higher than the base end port.

3. With the tractor engine at an idle speed, hold the remote lever on to put fluid into the lifting circuit. When

the cylinders have completely extended, hold the remote lever on for one minute.

4. Retract the cylinders. Extend the cylinders again

and hold the remote lever on for one more minute.

Repeat this step two more times to completely bleed

the system.

5. Repin the cylinders to the drill frame, rod end to the

wheel arm. If air is trapped in either cylinder, the affected cylinder will have a spongy, erratic movement

and the drill will not raise evenly. Refill the tractor hydraulic fluid reservoir to its proper level.

NOTE: After the drill is raised, a slight settling will occur due to the action of the rephasing cylinders.

!

Escaping fluid under pressure can have sufficient force to penetrate the skin. Check all hydraulic lines and hoses before applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

from a doctor that is familiar with this of injury. Foreign fluids

in the tissue must be surgically removed within a few hours or

gangrene will result.

4/25/06 Great Plains Mfg., Inc.

CAUTION!

IMPORTANT: When using sealant on pipe threads the

friction between the threads is reduced; therefore, be

certain not to over tighten causing damage to the cylinder port or fitting.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M-A

-9

Loading...

Loading...