Page 1

Operator’s Manual

EWNT7 and EWNT10

End Wheel No Till Drill

Model Serial No.

EWNT7 1237Q to 1522Q

EWNT10 2333U to 4141U

Manufacturing, Inc.

P.O. Box 5060 l Salina, Kansas 67402-5060

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

© Copyright 1997 Printed

4/17/2001

16685

Cover illustration may show optional equipment not supplied with standard unit.

150-082M

Page 2

General Information

Important Notice

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been

taken in the preparation of this manual, Great Plains

Manufacturing, Inc. assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages

resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to

revise and improve its products as it sees fit. This publi-

This Operator’s Manual applies to the

7’ & 10’ End Wheel No-Till

Owner’s Information

Name: _____________________________________

cation describes the state of this product at the time of its

publication, and may not reflect the product in the future.

Printed in the United States of America.

For your convenience, record your Serial Number, Model Number and the Date Purchased in the spaces provided below. Have this information available when

calling your Great Plains Authorized Dealer.

Serial Number ________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Name of Dealership ___________________________

Dealer’s Name _______________________________

Address ____________________________________

City________________State ____ Zip ___________

Phone_______________________

Model Number ________________

Date Purchased _______________

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/25/06Great Plains Mfg., Inc.

Page 3

Table of Contents

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 1 Safety Rules . . . . . . . . . . . . . . . . . . . . . . . 3

General Operation & Repair. . . . . . . . . . . . . . . . . 3

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tire Handling & Repair . . . . . . . . . . . . . . . . . . . . . 3

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 2 Assembly Instructions & Set-Up . . . . . . 6

Torque Values Chart. . . . . . . . . . . . . . . . . . . . . . . 6

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . . 6

Pre-Assembly Checklist . . . . . . . . . . . . . . . . . . . . 7

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . 8

Tractor Drawbar Hook-Up. . . . . . . . . . . . . . . . . . . 8

Hook-Up For Ball Swivel Hitch . . . . . . . . . . . . . . . 8

Tractor Hydraulic Hook-Up . . . . . . . . . . . . . . . . . . 9

Bleeding The Hydraulic Lifting System. . . . . . . . . 9

Section 3 Basic Operation . . . . . . . . . . . . . . . . . . . 10

Operating The Lifting Hydraulics . . . . . . . . . . . . 10

Operating Transport Lock . . . . . . . . . . . . . . . . . . 10

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 4 Adjustments . . . . . . . . . . . . . . . . . . . . . . 11

Drive System Clutch. . . . . . . . . . . . . . . . . . . . . . 11

Drive Train Operation . . . . . . . . . . . . . . . . . . . . . 11

Clutch Shaft & Miter Gear Adjustment . . . . . . . . 12

Seed Rate Adjustments . . . . . . . . . . . . . . . . . . . 12

Fertilizer Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fertilizer Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7’ & 10’ Fertilizer Application Chart . . . . . . . . . . 19

Native Grass Drive . . . . . . . . . . . . . . . . . . . . . . . 20

Native Grass Rate . . . . . . . . . . . . . . . . . . . . . . . 20

Native Grass Seeding Adjustments . . . . . . . . . . 20

Sprocket Selection Chart . . . . . . . . . . . . . . . . . . 21

Coulter Adjustments . . . . . . . . . . . . . . . . . . . . . . 22

Coulter Hydraulic Depth Control. . . . . . . . . . . . . 22

Down Pressure Requirements . . . . . . . . . . . . . . 22

Individual Opener & Coulter . . . . . . . . . . . . . . . . 23

Disk Opener Spring Pressure Setting . . . . . . . . 23

Individual Opener Height . . . . . . . . . . . . . . . . . . 23

Opener Press Wheel Depth . . . . . . . . . . . . . . . . 23

Press Wheel Angle. . . . . . . . . . . . . . . . . . . . . . . 24

Section 5 Field Operations. . . . . . . . . . . . . . . . . . . 25

Drill Preparations . . . . . . . . . . . . . . . . . . . . . . . . 25

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . 25

Section 6 Maintenance & Lubrication . . . . . . . . . . 26

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fertilizer Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Section 7 Troubleshooting. . . . . . . . . . . . . . . . . . . 29

Section 8 Specifications & Warranty. . . . . . . . . . . 31

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4/17/2001 Great Plains Mfg., Inc. EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-1

Page 4

Using this Manual

Using this Manual

For your safety and to help in developing a better understanding of your equipment we highly recommend that

you read the operator sections of this manual. Reading

these sections not only provides valuable training but

also familiarizes you with helpful information and its lo-

Introduction

This manual has been prepared to instruct you in the

safe and efficient operation of your End Wheel No-Till.

Read and follow all instructions and safety precautions

carefully.

The parts on your End Wheel No-Till have been specially designed and should only be replaced with genuine

Great Plains parts. Therefore, should your End Wheel

No-Till require replacement parts go to your Great

Plains Dealer.

The right hand and left hand as used throughout this

manual is determined by facing in the direction the machine will travel when in use unless otherwise stated.

Serial Number

The serial number plate is located on the front right side

of the frame. It is suggested that the serial number and

purchase date also be recorded for your convenience in

the space provided on the checklist page at the beginning of this manual.

The serial number provides important information about

your drill and may be required to obtain the correct replacement part. Always use the serial number and model number when sending correspondence or when

ordering parts from your Great Plains. Dealer.

cation. The parts sections are for reference only and

don’t require cover to cover reading. After reviewing your

manual store it in a dry, easily accessible location for future reference.

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment; hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Watch for the following safety notations through-out your

Operators Manual:

!

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal

word is limited to the most extreme situations.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

DANGER!

!

WARNING!

!

CAUTION!

!

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

safety precautions must be taken. When you see this

2

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

NOTE: Indicates a special point of information which

requires your attention.

Great Plains Mfg., Inc.

Page 5

Section 1 Safety Rules

Section 1 Safety Rules

Most accidents are the result of negligence and carelessness, usually caused by failure of the operator to follow simple but necessary safety precautions. The

following safety precautions are suggested to help prevent such accidents. The safe operation of any machinery is a big concern to consumers and

manufacturers.Your End Wheel No-Till has been designed with many built-in safety features. However, no

one should operate this product before carefully reading

this Operators Manual.

!

General Operation & Repair

1. Never allow the drill to be operated by anyone who is unfamiliar with the operation of all functions of the unit. All

operators should read and thoroughly understand the instructions given in this manual prior to moving the unit.

2. Make sure safety rules are understood before operating

machinery or tractor.

3. Never permit any persons other than the operator to ride

on the tractor.

4. Never permit any persons to ride on or stand near the

drill while it is in operation.

5. Regulate your speed to the field conditions, maintaining

complete control at all times.

6. After repairing or adjusting, make sure all tools and

parts are removed from the implement before attempting

to operate it.

7. Do not grease or oil machine while it is in operation.

8. Loose fitting clothing should not be worn as it may catch

in moving parts.

9. Never dismount from a moving tractor.

10. Do not leave the tractor or the implement unattended

with the engine running.

11. Do not stand between the tractor and the implement during hitching.

12. Detach and store implements in an area where children

normally do not play. Stabilize implements by using suitable supports and block wheels.

13. If a hydraulic leak develops, correct it immediately. Escaping hydraulic oil can have extremely high pressure. A

stream of high pressure oil may easily penetrate the skin

as with modern needle-less vaccination equipment - but

with the exception that hydraulic fluid may cause blood

poisoning. It is imperative that the connections are tight

and that all lines and pipes are in good condition. If an

injury is caused by the escaping hydraulic fluid, see doctor at once!

14. Use a piece of cardboard or wood to detect leaks of hydraulic oil under pressure.

15. Be sure to relieve all hydraulic pressure before disconnection any lines or pipes between the implement and the tractor hydraulic system. Keep all guards and shields in place.

Transporting

1. Use good judgement when transporting tractor and implements on the highway. Always maintain complete control of the machine.

2. Limit transport speed to 20 mph. Transport only with a

farm tractor of sufficient size and horse power. See

“Tractor Requirements” Section 2,page 8.

3. Always make sure flashing safety lights, “Slow Moving

Vehicle” emblem, and reflectors are in place and visible

prior to transporting the machine on public roads.

4. Know your state and local laws concerning highway

safety and regulations. Comply with these laws when

transporting machinery.

5. Use warning flags or approved warning lights at night

and during other periods of poor visibility. Do your best

to prevent highway accidents.

Tire Handling & Repair

1. Tire changing can be dangerous and should be preformed by trained personnel using the correct tools and

equipment.

2. Do not re-inflate a tire that has been run flat or seriously

under inflated. Have it checked by qualified personnel.

3. When removing and installing wheels, use wheel handling equipment adequate for the weight involved.

Safety Decals

1. Your End Wheel No-Till comes equipped with all safety

decals in place. They were designed to help you safely

operate your drill. Read and follow their directions.

2. Keep safety decals clean and legible.

3. Replace all damaged or missing safety decals. To order

new safety decals go to your Great Plains Dealer and refer to the parts section for safety decal package part number.

4. Replace these decals whenever they become worn or unreadable. To instal new safety decals:

a. Clean the area the decal is to be placed

b. Peel backing from the decal. Press firmly on to sur-

face being careful not to cause air bubbles under the

decal.

4/17/2001 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-3

Page 6

Section 1 Safety Rules

13846

818-188C

Transport Speed Warning

818-229C

Amber Reflectors

13846

13847

818-188C

Transport Speed Warning

818-230C

Red Reflector

13849

4

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

Page 7

Section 1 Safety Rules

13848

818-003C

Slow Moving Vehicle Emblem

4/17/2001 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-5

Page 8

Section 2 Assembly Instructions & Set-Up

Section 2 Assembly Instructions & Set-Up

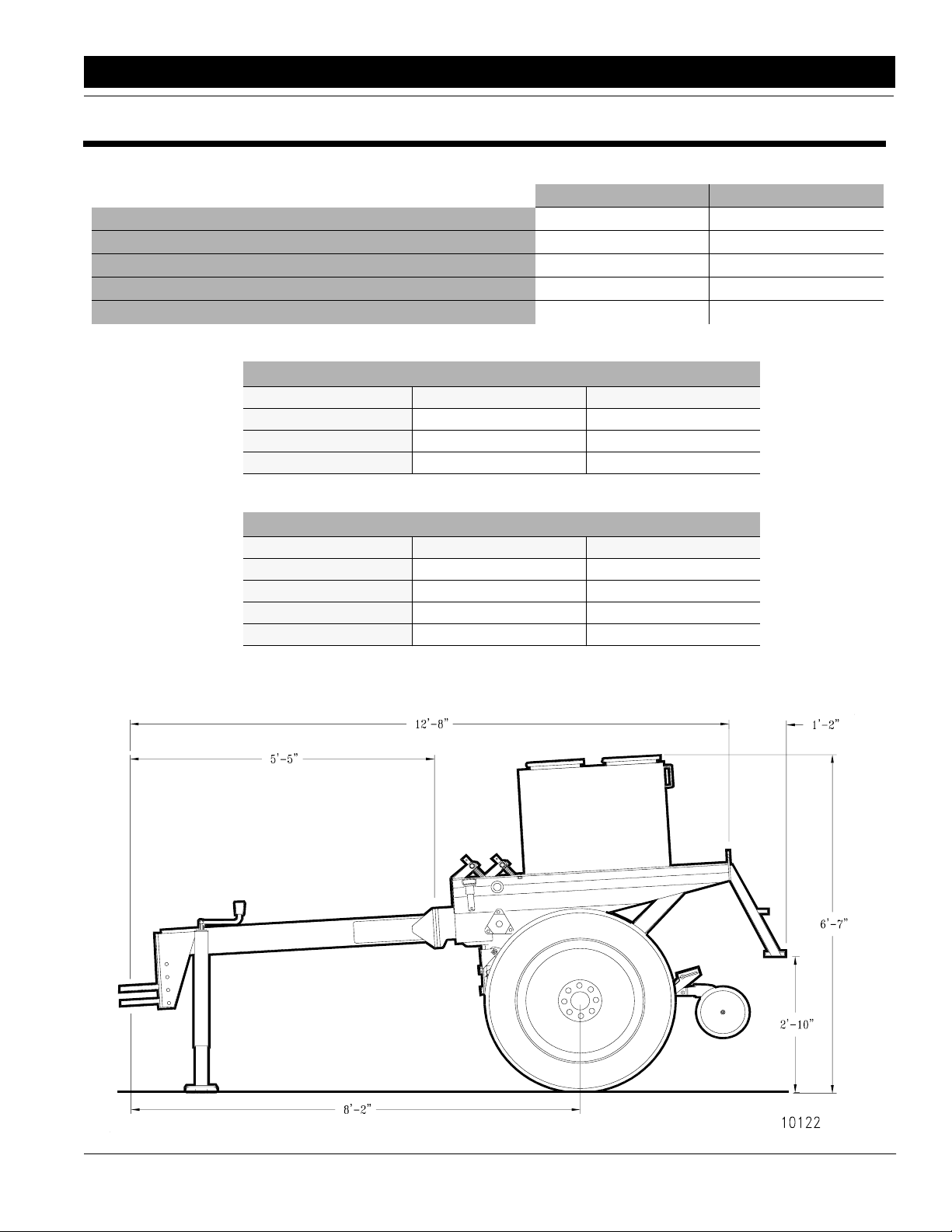

Torque Values Chart for Common Bolt Sizes

Bolt Head Identification

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 436597

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch4N · m ft-lb N · m ft-lb N · m ft-lb

Grade 8

Bolt Size

(Metric)

1

in-tpi = nominal thread dia .in inches-threads per inch

2

N· m = newton-meters

3

ft-lb= foot pounds

4

mm x pitch = nominal thread dia. in millimeters x thread pitch

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

Tire Inflation Chart

Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28

9.0 x 22.5 10-Ply Highway Service 70 70

9.0 x 24" 8-Ply Rib Implement 40

9.5L x 15" 6-Ply Rib Implement 32

9.5L x 15" 8-Ply Rib Implement 44

9.5L x 15" 12-Ply Rib Implement 60

6

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Tire Size Inflation PSI

11L x 15" 6-Ply Rib Implement 28

11L x 15" 12-Ply Rib Implement 52

12.5L x 15" 8-Ply Rib Implement 36

12.5L x 15" 10-Ply Rib Implement 44

16.5L x 16.1" 10-Ply Rib Implement 36

41 x 15" x 18 - 22-Ply Rib Implement 44

Great Plains Mfg., Inc.

Page 9

Section 2 Assembly Instructions & Set-Up

Pre-Assembly Checklist

Check

All major components

Fasteners that were shipped with the End Wheel No-Till Drill.

NOTE: Some of the hardware from the factory has been installed in the location where it will be used.

Have a minimum of 2 people at hand while assembling the End Wheel No-Till Drill.

Have a fork lift or loader along with chains and safety stands ready for the assembly task.

If you are unsure where a fastener is used, use the parts section of this manual to identify it. Be sure the part gets

used in the correct location.

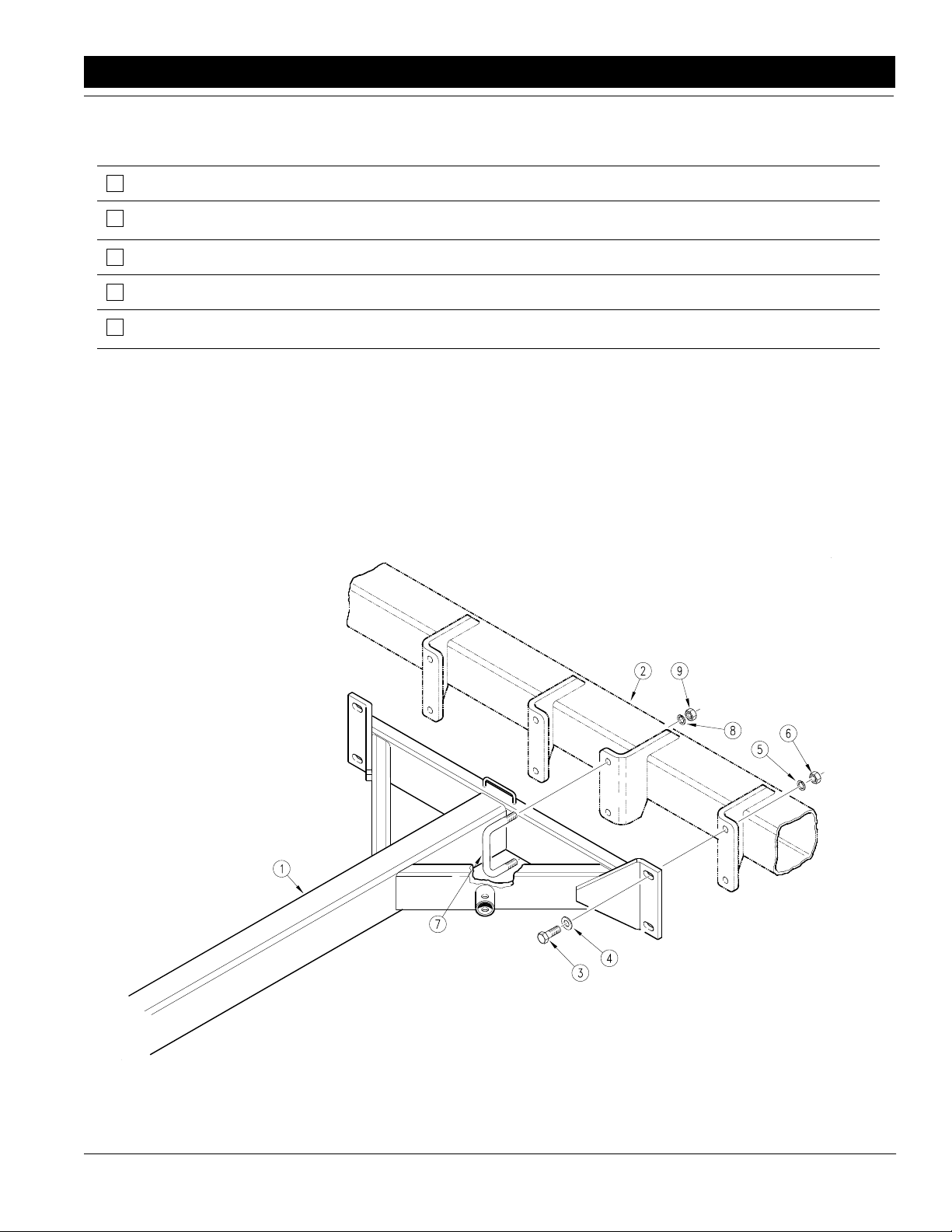

Refer to Figure 2-1:

Before starting the drill assembly, be sure that the drill

frame is safely supported and the end wheel tires are

blocked.

Bolt the outside legs of the tongue weldment (#1) to the

drill frame (#2) using 3/4" x 2 1/4" long bolts (#3), 3/4"

SAE flat washers (#4), 3/4" lock washers (#5), and 3/4"

hex nuts (#6).

Connect the rear tube of the tongue (#1) to the drill

frame (#2) using 3/4" x 6 1/32" x 3 1/4" long u-bolts (#7),

3/4" lock washers (#8), and 3/4" hex nuts (#9).

Tighten all hardware to the torque specification listed in

the "Nut & Bolt Torquing Chart" on page 6.

4/17/2001 Great Plains Mfg., Inc.

Tongue & Pull Bar Assembly

Figure 2-1

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

10681

-7

Page 10

Section 2 Assembly Instructions & Set-Up

Tractor Requirements

To operate your Great Plains End Wheel No-Till Drill in

most field conditions, a tractor of adequate size should

be used. For 7’ drills, a 55 horsepower tractor is required. For 10’ drills, a 75 horsepower tractor is required.

7’ and 10’ drills require 1-set of remote outlets.

Tractor Drawbar Hook-Up

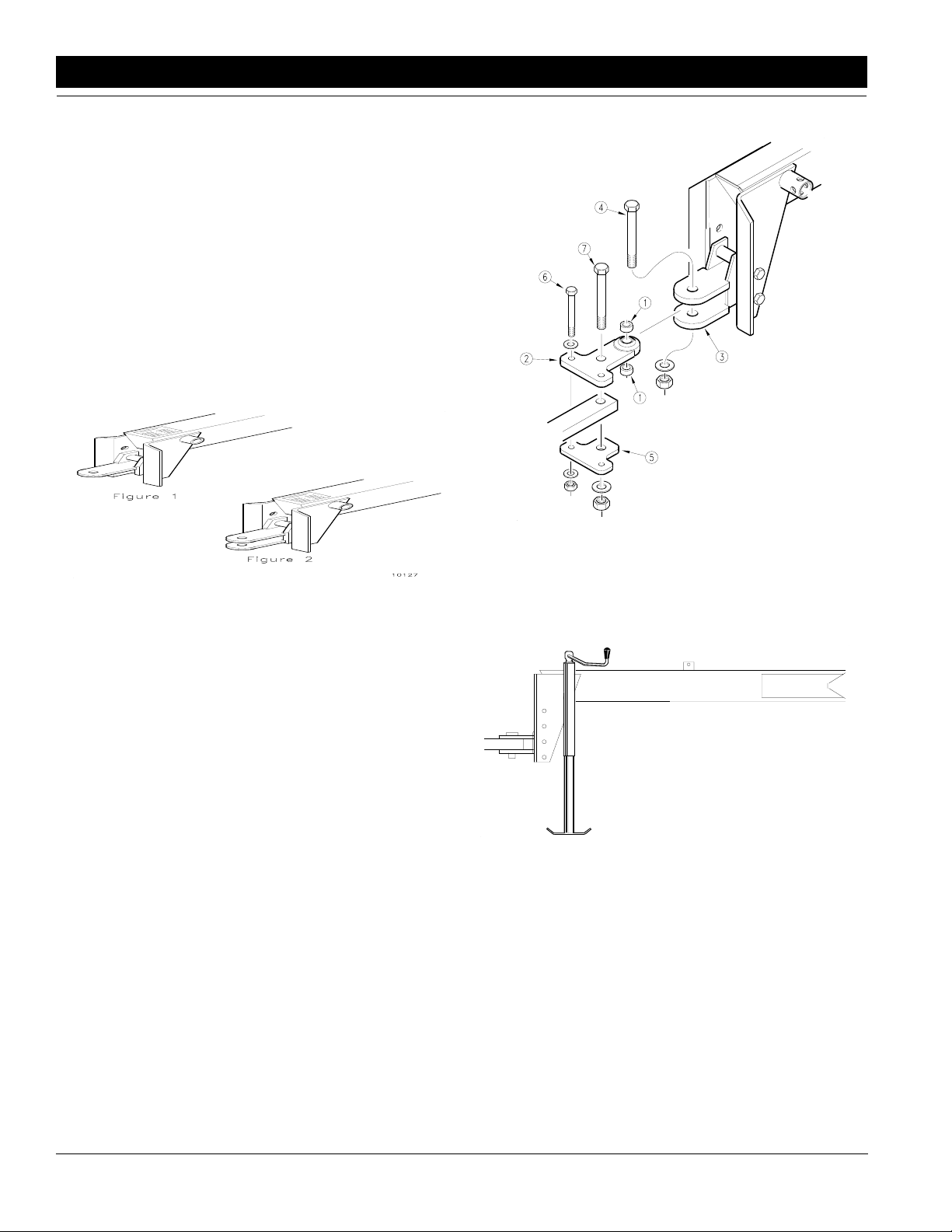

Refer to Figure 2-2 & Figure 2-3:

The Great Plains No-Till Drill is equipped with either a

single strap, Figure 2-2, clevis style hitch, Figure 2-3, or

a ball swivel hitch, Figure 2-5. For proper field operation,

the tongue of the drill should run level, parallel to the

ground in field position.

11549

10127

Single Strap Hitch

Figure 2-2

Clevis Style Hitch

Figure 2-3

Tractor Drawbar

Hook-Up For Ball Swivel Hitch

Refer to Figure 2-4:

Place a spacer tube (#9) above and below the ball swivel. Bolt the ball swivel {top hitch weldment} (#1) and

spacer tubes (#9) to the drill clevis hitch with a 1" x 5"

long bolt (#10), 1" USS flat washer (#11), and 1" nylock

nut (#12).

Back the tractor to the drill hitch. Using the screw jack,

adjust the drill tongue up or down to center the drawbar

below the upper hitch plate (#1). Place hitch weldment

(#1) on top of the tractor drawbar, aligning the rear hole

in the hitch weldment with the large hole in the drawbar.

Place the lower hitch plate (#2) under the drawbar and

attach to the hitch weldment (#1) with {2} 5/8" x 4" long

bolts (#3), 5/8" flat washers (#4), 5/8" nylock nuts (#5).

Bolt the top hitch weldment (#1) through the hole in the

drawbar to the lower hitch plate (#2) with a 1" x 5 1/2"

long bolt (#6), 1" USS flat washer (#7), and 1" nylock nut

(#8).

Ball Swivel Hitch

Figure 2-4

Refer to Figure 2-5:

1. With the drill lowers and in the field position, adjust

the tongue jack to level the tongue.

Jack In Vertical Position

Figure 2-5

2. Back the tractor draw bar up to the drill hitch to determine the amount of adjustment required.

Refer to Figure 2-6:

3. The mounting holes in the hitch have been offset so

the hitch can be turned over and bolted on in three

different hitch positions, giving you six different hitch

heights.

10150

8

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

Page 11

Section 2 Assembly Instructions & Set-Up

Bleeding the

Hydraulic Lifting System

The implement lifting system is equipped with rephasing

type hydraulic cylinders that require a special procedure

for bleeding air from the hydraulic circuits. Read and follow the procedure carefully. The rephasing type cylinders will not function properly with air in the hydraulic

circuit. Bleeding the system may have been done during

initial set up of the drill.

10123

Hitch Height Adjustment

Figure 2-6

4. Connect the hitch to the tractor using a pin of adequate strength (minimum 1" diameter).

Refer to Figure 2-7:

5. Unpin the tongue jack, and pin it on top of the

tongue.

Jack In Transport Position

Figure 2-7

NOTE: Make sure the hitch is securely bolted to the

drill tongue.

Your drill comes equipped with a hitch safety chain. The

safety chain should be securely attached to the drill hitch

and the tractor drawbar whenever towing or planting.

11833

Tractor Hydraulic Hook-Up

Route the lift hydraulic hoses along the tongue and

through the hose loop on the front of the tongue. Connect the hoses to the tractor remote outlets.

NOTE: Check the hydraulic fluid in the tractor resevoir and fill to the proper level. Add fluid to the system as needed. A low resevoir level may draw air

back into the system, causing jerky or uneven cylinder movements. The drill system capacity is approximately 1 gallon.

1. Jack up and support the front member of the drill at

a point close to each end wheel. If the end wheel

cylinders have previously been engaged, they may

be used to assist in raising the frame.

2. With the frame blocked and supported, unpin the

cylinders from the drill frame and turn the cylinders

upside down and wire or otherwise safely support

the rod end port higher than the base end port.

3. With the tractor engine at an idle speed, hold the remote lever on to put fluid into the lifting circuit. When

the cylinders have completely extended, hold the remote lever on for one minute.

4. Retract the cylinders. Extend the cylinders again

and hold the remote lever on for one more minute.

Repeat this step two more times to completely bleed

the system.

5. Repin the cylinders to the drill frame, rod end to the

wheel arm. If air is trapped in either cylinder, the affected cylinder will have a spongy, erratic movement

and the drill will not raise evenly. Refill the tractor hydraulic fluid reservoir to its proper level.

NOTE: After the drill is raised, a slight settling will occur due to the action of the rephasing cylinders.

!

Escaping fluid under pressure can have sufficient force to penerate the skin. Check all hydraulic lines and hoses before applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

from a doctor that is familiar with this of injury. Foreign fluids

in the tissue must be surgically removed within a few hours or

gangrene will result.

4/17/2001 Great Plains Mfg., Inc.

CAUTION!

IMPORTANT: When using sealant on pipe threads the

friction between the threads is reduced; therefore, be

certain not to over tighten causing damage to the cylinder port or fitting.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-9

Page 12

Section 3 Basic Operation

Section 3 Basic Operation

Operating the

Lifting Hydraulic System

The lift cylinders may after a period of time get out of

time or phase. The effects of this can be seen when one

side of the drill is running too low or too high because its

lift cylinder is either overextended or overretracted compared to the other lift cylinder. To rephase the cylinders,

raise the drill completely up and hold the tractor hydraulic lever on for a few seconds to give the cylinders time to

rephase. This should be done each time the drill is

raised out of the ground. Momentarily reversing the hydraulic lever immediately after rephasing to allow the cylinders to retract about 1/2" will help in maintaining a level

drill.

Transporting

Operating Transport Lock

Refer to Figure 3-1:

When transporting your drill, you should always lock

your drill in the raised position. Fully extend the lift cylinders to raise the drill for transporting. Remove the lock

pins from the storage position, Figure 3-1. {One on each

side of the drill frame.}

Lock Out Hubs

Before transporting the drill, you should always check

the following items:

1. Make sure that drill is securely attached to the draw

bar of the tractor and that the hitch safety chain has

been securely attached.

2. Check to see that the transport tires have the proper

inflation as noted on page 6.

Refer to Figure 3-3:

3. Make sure the drive lockout hub (left side) is disengaged before transporting, see Figure 3-3. This will

protect from excessive wear on the gauge wheel

drive system.

4. This drill comes equipped with a transport lock pin

located on each side of the drill frame. Make sure

the pin is in its transport position as shown in

Figure 3-2.

5. Comply with all Federal, State and Local Safety

Laws when traveling on public roads.

6. Remember, the drill is wider than the tractor and extreme care must be taken to allow for safe clearance.

10151

11890

10252

Lock Pin In Field - Storage Position

Figure 3-1

Refer to Figure 3-2:

Place the lock pin through the frame channel as shown

in Figure 3-2. Before lowering the drill, you must first extend the lift cylinders completely and move the lock pins

to their storage position.

11838

Lock Pin In Transport Position

Figure 3-2

10

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

!

This Drill should never be pulled faster than 20 miles per

hour.

CAUTION!

Drive Lock Out Hub

Figure 3-3

Great Plains Mfg., Inc.

Page 13

Section 4 Adjustments

Section 4 Adjustments

Drive System Clutch

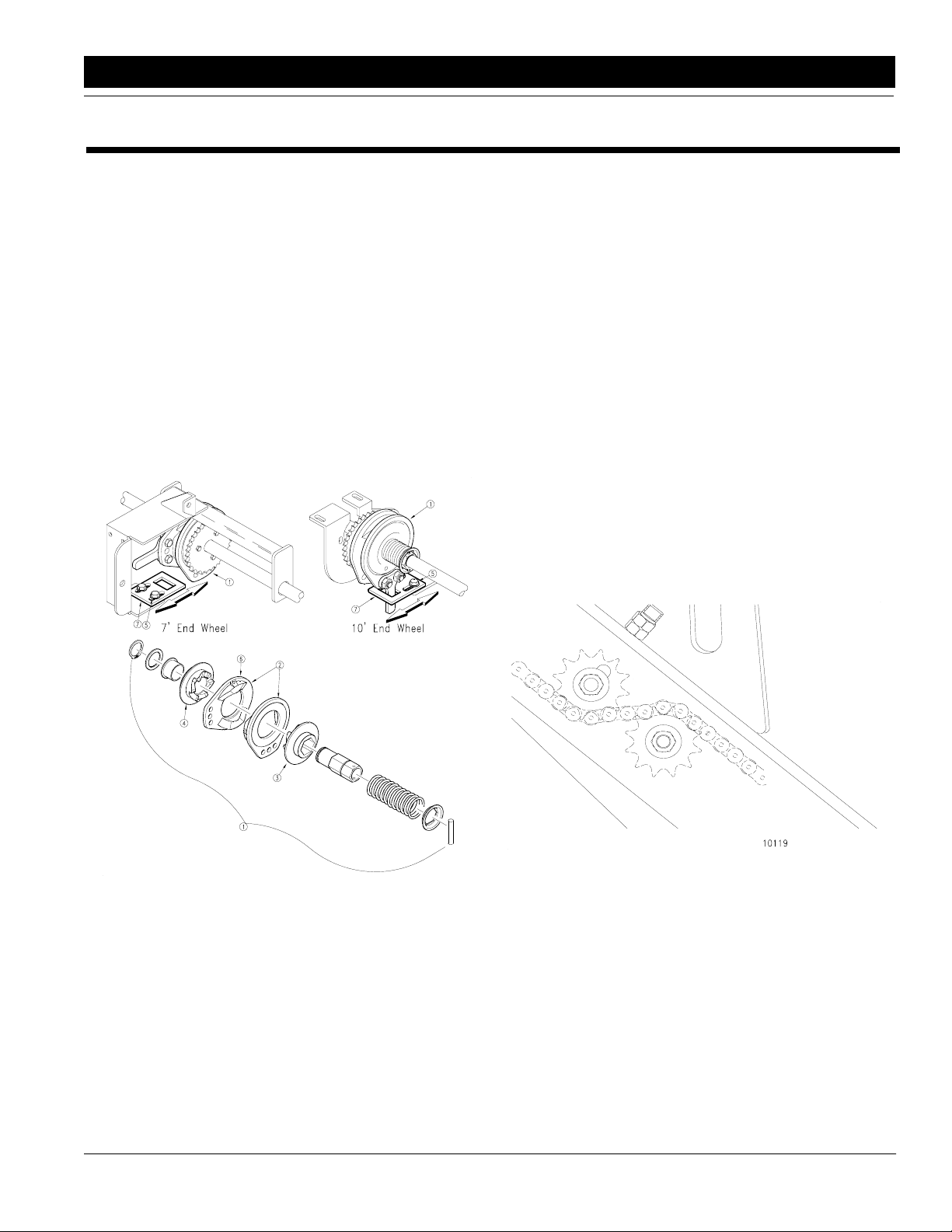

Refer to Figure 4-1:

The main drive clutch (#1) on your drill is a mechanical

release - jaw style design which may require some adjustments before using your drill. Raise the drill to the

transport position. Check between the two cam plates

(#2) which disengage the jaws (#3) & (#4) of the clutch

halves. The clutch jaws (#3) & (#4) should be completely separated at this point.

Adjustments can be made to the cam plate (#6) by loosening the bolts, and nuts (#5) in the clutch tab(#7).

Whenever adjusting the clutch, check to be sure the

clutch jaws (#3) & (#4) are engaged completely when

the drill is lowered to the field position. The clutch jaws

(#3) & (#4) should also be completely disengaged when

the drill is raised for transport.

Drive Train Operation

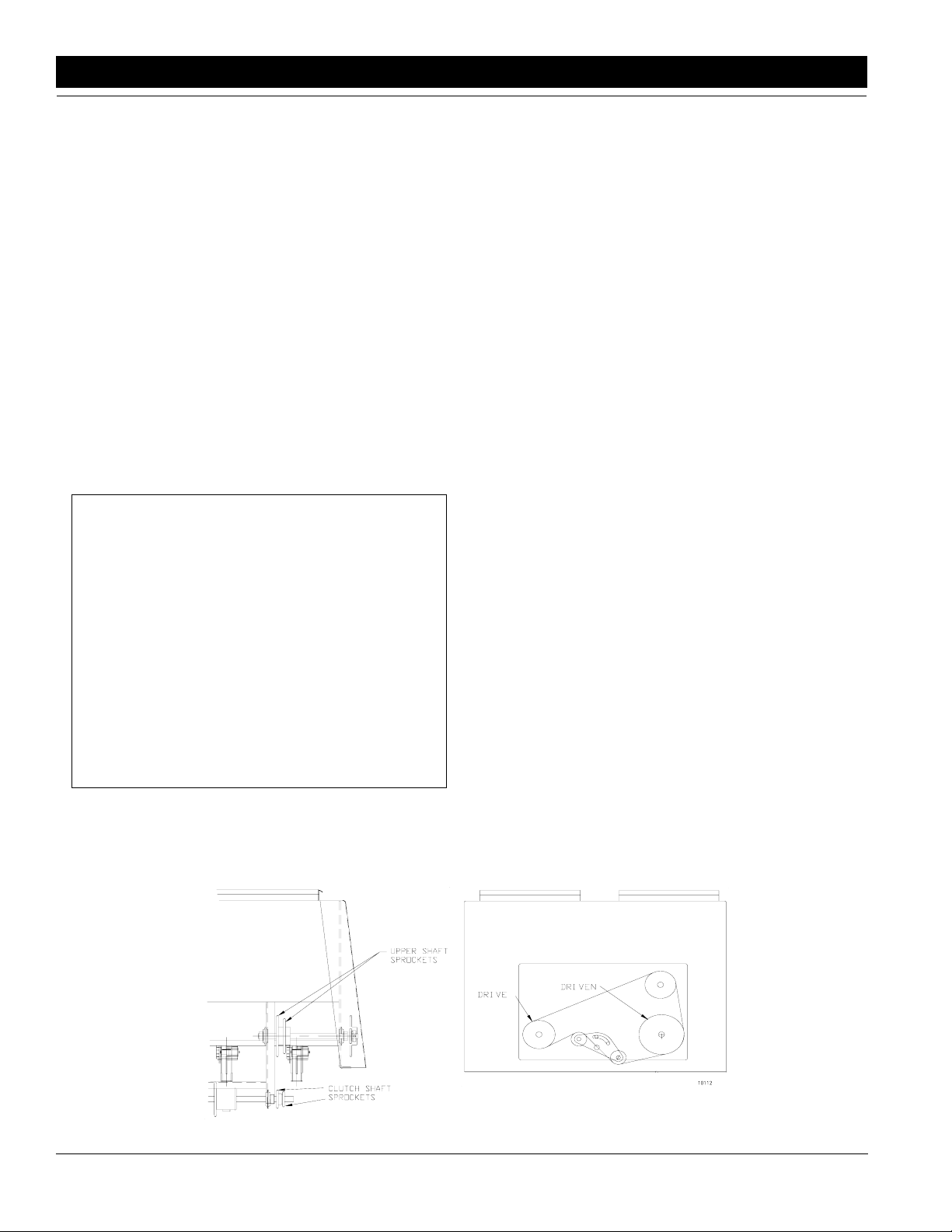

Refer to Figure 4-2:

Your grain drill uses standard no. 40 roller chain through

out its drive system. The drive system is simple and designed for low maintenance. All chain idlers should be

checked at the beginning of each season to insure that

they are adjusted properly.

To do a maintenance inspection, simply check each idler

to insure that it is taking up any excess chain slack. On

fertilizer and native grass drills the inspection cover for

the drive is located on the outside of the left box end panel and this cover must be removed to inspect the fertilizer

and native grass drive chain and idler.

In the left wheel arm are two idler sprockets, Figure 4-2,

which should be readjusted after the first 100 acres of

drill use and then at the beginning of each season. To

adjust, move the front idler sprocket, on the top of the

chain, down, by loosening the jam nut and screwing the

adjustment stud in. Chain idlers should always be kept

snug against the slack side of the chain. Do not over

tighten chains, it will cause excessive wear on idlers and

drive components. Retighten the jam nut to maintain the

idler position.

14018

Jaw Clutch Adjustment

Figure 4-1

4/17/2001 Great Plains Mfg., Inc.

10119

Idler Sprocket Adjustments

Figure 4-2

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-11

Page 14

Section 4 Adjustments

Clutch Shaft & Miter Gear Alignment

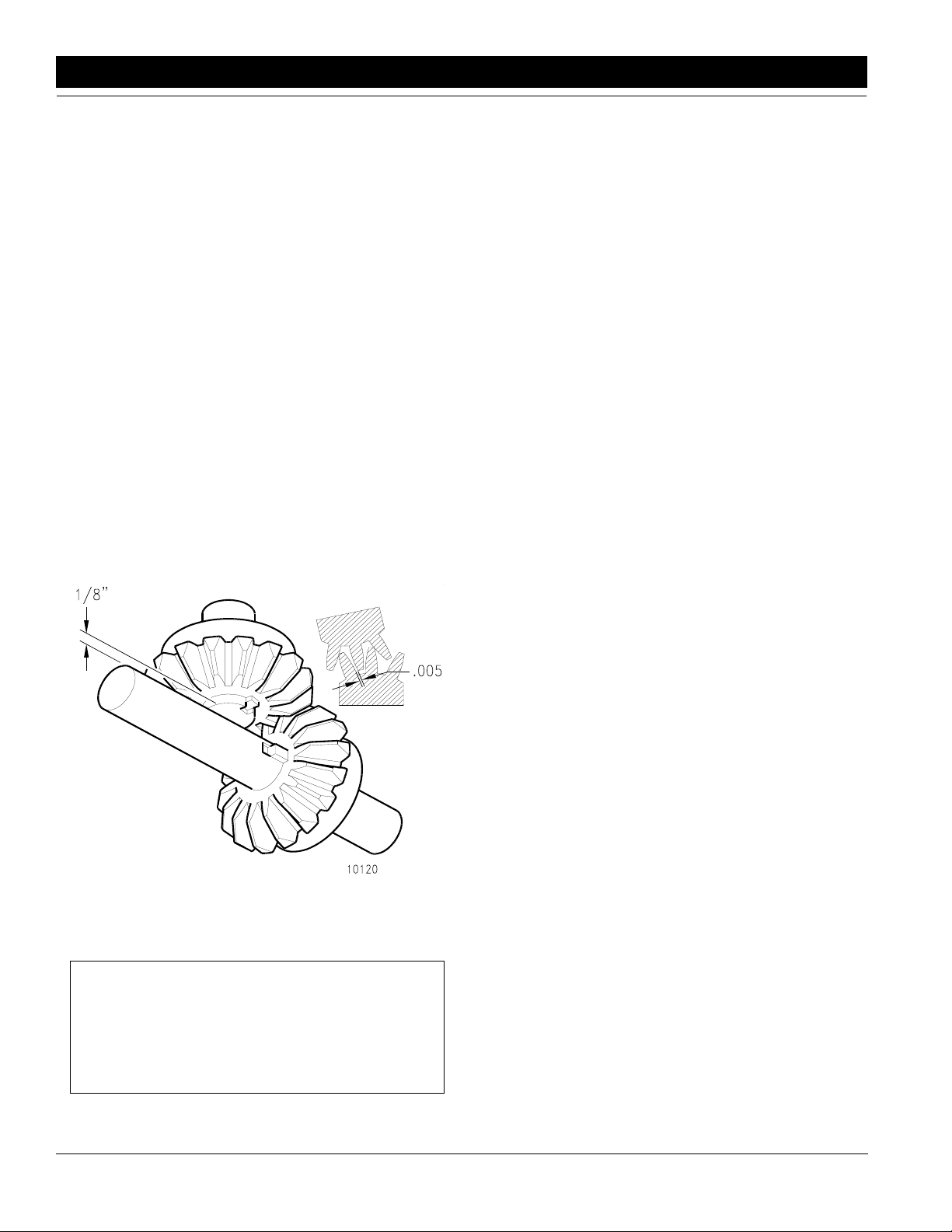

Refer to Figure 4-3:

The speed change box is designed to give you a variety

of speeds for different types of seeds and rates. It is a

linear shift pattern design with constant mesh gearing

and totally sealed to keep the dirt out. There should be

no lubrication required unless service is needed. The input shaft is located on the bottom of the box and is driven

with mitered gears. It is recommended that lubrication

not be applied to the gears. If the gears are lubricated

the lubrication will attract dirt and increased wear will result. It is very important that the mitered gears back lash

is set correctly. Using a (.005) wire type feeler gauge or

a piece of wire measuring (.005) in diameter, insert it between the teeth of the two gears where they mesh, Figure 4-3. The adjustment is done by loosening the set

screws in the bearing on the jack shaft nearest the gear.

Loosen the bearing bracket mounting bolts under the

gearbox. Then slide bearing bracket, bearing and gear

over to gear on the gear box input shaft with wire gauge

inserted between the teeth and tighten the bearing set

screws, then tighten the bearing bracket mounting bolts.

After adjustments are made, rotate the jackshaft to see

that no binding occurs within the gears.

10120

Speed Change Miter Gears

Figure 4-3

Seed Rate Adjustments

NOTE: Seeding rates will vary greatly with variations

in sizes of the seeds. Although the seeding rates listed in this manual are based on an average seed

size, we recommend that you test and adjust your

drill using the procedures listed below to help insure

an accurate seeding rate.

Refer to Figure 4-4:

1. To adjust your seeding rate, first you must decide

which drive type you need (see "Seed Rate Charts"

on the following pages). In order to change drive

types, move the lever on the speed change box to

desired setting, Figure 4-4.

2. There are many factors which will affect seeding

rates: seed treatment, weight of seed, size of seed,

surface condition of seed, and tire configuration,

pressure and slippage. Minor adjustments will probably be needed to compensate for the above factors.

3. The pounds-per-acre in the seed charts are based

on drills having 9.00 x 24 rib implement tires with

proper inflation as listed on page 6.

4. The large differences in seed sizeand treatment can

cause a wide variation in actual seeding rates. The

seed rate charts on the following pages are based

on average size seed. This may differ from the seed

you are using. Use the seed rate charts as a guide.

Set the pounds-per-acre desired at the indicator

number for your row spacing and complete the following procedure to calibrate the drill for your specific seed.

a. Lower the drill hydraulically to planting position

in order to activate the clutch.

b. Raise the drive (left) end tire off the ground us-

ing a jack.

c. Rotate the tire to see that the drive system is

working properly and that the feed cups are free

from foreign matter.

d. Place several pounds of seed over three of the

feeder cups at the outboardend of the seed box.

Make sure all feed cup handles are set in the

same position on all the feeder cups.

e. Set the feed cup adjustment lever to the desired

setting.

f. Pull the seed tubes out of these openers.

g. Place a container under the three seed tubes to

gather the seed as it is metered.

h. Rotate the drive gauge wheel until one acre has

been tallied on the acremeter. This will be approximately 422 rotations on a 10’ drill and 592

rotations on a 7’ drill. Be sure to check the three

feeder cups to makesure each cup has plentyof

seed coming into it.

i. Weigh the seed which has been metered. Di-

vide by three. This will give you the ounces/

pounds metered by each feeder cup. Multiply by

the number of openers on your drill to arrive at

the total pounds-per-acre you would meter at

that setting. If this figure is different than desired, set your feed cup adjustment lever accordingly.

12

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

Page 15

Section 4 Adjustments

Seed Rate Adjustment

Figure 4-4

5. You may want to repeat the calibration procedure if

the results of you calibration vary greatly from the

suggested settings contained in this manual.

10152

6. Seed cup plugs are available for your drill, which will

enable you to block off specific rows from metering

seed. Order Great Plains Part #109-009H.

NOTE: This will change the amount of seed metered

from the charts.

IMPORTANT: Tire size and field conditions will also affect seeding rates. Be certain that your drill rib tires are

9.00 x 24 and that they have proper inflation. When drill-

ing, check the amount of seed you are using by noting

acres drilled, amount of seed added to drill, and level of

seed in drill box. If you suspect that you are drilling more

or less than desired, and you have accurately calibrated

the drill to your seed, you may need to adjust the seeding rate slightly to compensate for your field conditions.

4/17/2001 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-13

Page 16

Section 4 Adjustments

Seed Rate Charts

HARD RED WINTER WHEAT SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 11 19 27 35 44 52 62 71 81 91 101 110 122 133 145 153 161 166 174 180

7 1/2" 0 10 17 24 32 40 48 56 65 74 83 92 100 112 121 132 140 147 152 159 164

8" 0 9 16 23 30 39 46 54 62 70 79 88 96 100 112 121 132 140 145 152 156

10" 0 7 13 19 24 31 36 43 49 56 63 70 77 85 92 101 106 112 116 121 125

*Based On 60#/Bushel

HARD RED WINTER WHEAT SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 7 13 18 23 30 35 41 47 54 61 67 73 81 88 97 102 107 111 116 120

7 1/2" 0 6 11 16 21 27 32 38 43 49 55 61 67 74 81 88 93 98 101 106 109

8" 0 6 10 15 20 26 30 36 41 47 53 58 64 71 77 84 89 93 96 101 104

10" 05 9121621242933374247515762677175778183

*Based On 60#/Bushel

RICE SHORT GRAIN SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 2 9 15 21 28 35 41 47 54 61 67 76 81 86 92 98 105 107 107 109

7 1/2' 0 2 8 14 19 26 32 38 45 51 57 64 71 76 82 86 93 98 101 101 103

8" 02 7131825303542475459667175818792959596

10" 01 6111520252934384347535761667074767677

RICE SHORT GRAIN SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 5 15 28 40 50 66 79 93 107 123 136 157 169 180 194 210 223 228 231 232

7 1/2" 0 4 15 26 37 47 63 75 87 101 116 127 148 159 170 182 197 210 214 217 218

8" 0 4 14 25 35 45 58 70 82 95 108 119 139 149 159 171 186 197 201 204 205

10" 0 3 11 20 28 35 47 56 66 76 86 96 111 120 127 137 148 157 161 163 164

RICE LONG GRAIN SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 01 6131927343946525864697478838995959697

7 1/2" 0 1 5 12 17 25 31 36 44 49 55 60 65 70 74 78 84 89 89 90 92

8" 01 5111624293541465156616669737884848586

10" 0 0 4 9 14 19 24 27 33 37 41 46 49 53 56 58 63 67 67 68 69

RICE LONG GRAIN SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 2 9 22 36 50 63 78 90 100 116 131 143 152 165 175 187 202 207 210 211

7 1/2" 0 2 8 21 34 46 59 74 85 94 110 123 135 143 156 165 176 190 196 197 198

8" 0 2 8 19 32 44 56 69 80 88 103 116 126 134 146 154 165 178 183 186 187

10" 0 1 6 15 25 35 45 56 64 71 83 93 101 107 116 124 132 143 147 148 149

BARLEY SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 00 813192530364248535965717682879398104109

7 1/2" 0 0 7 13 18 23 29 34 39 45 50 55 60 66 71 76 82 87 93 89 102

8" 00 7121722272837424752576267727782879397

10" 0 0 6 9 13 18 22 25 29 34 38 41 45 50 54 57 61 65 70 74 78

OATS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 04 8131824303542485460677279869197101106110

7 1./2" 0 3 7 12 16 22 27 32 38 44 49 55 61 66 72 78 83 88 93 97 100

8" 03 7111521263036424753586369757984889296

10" 0 3 6 9 13 17 21 24 29 34 37 42 47 50 55 60 63 67 71 74 76

*Based On 39#/Bushel

14

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

Page 17

Section 4 Adjustments

RYE SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 0 3 6 9 12 15 17 22 23 25 29 32 35 37 41 45 48 49 52 53

7 1/2" 0 0 3 5 8 11 14 16 21 22 24 28 30 33 35 38 42 46 46 49 49

8" 0 0 3 5 8 10 13 15 19 20 23 26 29 31 33 36 39 43 44 46 47

10’ 00 2 4 6 810141617192123252729 3234353738

MILLET SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 1 4 6 9 12 14 16 19 22 25 28 32 35 39 42 46 51 53 53 54

7 1/2" 0 1 3 5 8 11 13 15 17 21 24 27 31 33 36 40 44 47 49 50 51

8" 0 1 3 5 8 10 12 14 16 19 22 25 28 30 34 38 41 45 46 47 48

10" 0 0 2 4 6 8 9 11 13 15 18 21 23 25 27 29 33 36 37 38 39

BUCKWHEAT SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 4 10 18 25 32 40 48 52 63 73 82 86 96 104 117 128 142 151 152 155

7 1/2" 0 3 9 17 23 30 37 46 49 60 68 77 81 90 98 111 121 134 142 146 146

8" 0 3 9 16 21 28 35 43 46 57 63 73 76 85 92 104 113 126 133 134 137

10" 0 3 7 12 18 23 28 34 37 46 52 58 61 68 74 83 91 100 106 107 109

FLAX OR SUDAN SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 1 4 6 8 12 15 17 21 24 27 31 33 36 38 42 47 50 53 56 57

7 1/2" 0 1 3 5 7 11 14 16 20 22 25 29 31 34 36 40 44 47 50 52 54

8" 0 1 3 5 7 10 13 15 19 21 24 27 29 32 34 37 41 44 47 49 51

10" 00 3 4 6 810121517192223252730 3336383941

SUNFLOWERS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 00 0 3 6 9121517202529323537414446495255

7 1./2" 0 0 0 3 6 8 11 14 16 19 23 27 30 33 35 38 41 44 46 49 52

8" 00 0 3 5 8101315182225283134353841444649

10" 0 0 0 2 4 6 8 10 12 15 17 21 23 25 26 29 31 33 35 37 39

SOYBEANS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 0 8 21 34 46 59 70 82 95 107 118 132 144 154 166 174 184 195 201 207

7 1/2" 0 0 7 20 31 42 54 64 75 87 98 108 120 131 141 152 159 168 178 184 189

8" 0 0 7 19 29 40 51 61 71 83 93 103 114 125 134 145 152 160 169 175 180

10" 0 0 6 15 23 32 41 49 57 66 75 82 91 100 107 116 121 128 135 140 144

*Based On 59.1#/Bushel

SOYBEANS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 0 2 7 11 15 19 23 27 31 35 38 43 47 50 54 57 60 63 65 67

7 1/2" 0 0 2 6 10 13 17 21 24 28 32 35 39 42 46 49 52 54 58 60 61

8" 0 0 2 6 9 13 17 20 23 27 30 33 37 40 43 47 49 52 55 57 58

10" 0 0 2 5 8 10 13 16 18 21 24 27 30 32 35 37 39 41 44 45 47

*Based On 59.1#/Bushel

SOYBEANS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 0 5 14 22 30 39 49 55 64 72 79 88 96 103 111 116 123 130 134 138

7 1/2" 0 0 5 13 20 28 36 42 50 58 65 72 80 87 94 101 106 112 118 123 126

8" 0 0 4 12 19 26 34 40 47 55 62 68 76 83 89 96 101 107 113 117 120

10" 00 41016212732384450556167707781859109396

*Based On 59.1#/Bushel Setting the feed cup adjustment lever between 50 & 80 allows for optimum seeding of soybeans.

4/17/2001 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-15

Page 18

Section 4 Adjustments

PEAS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 0 6 20 24 41 52 67 81 96 110 126 140 153 168 183 194 208 209 210 211

7 1/2" 0 0 5 19 22 38 50 63 76 91 103 118 131 144 158 172 182 196 196 197 198

8" 0 0 5 18 21 36 46 59 72 84 97 111 123 135 148 161 171 183 184 184 186

10’ 0 0 4 13 17 29 37 47 57 68 78 89 99 108 119 129 137 147 148 149 150

PINTO BEANS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 0 0 0 2 3 6 11 16 22 27 34 38 41 46 52 61 62 64 65 67

7 1/2" 0 0 0 0 1 2 5 10 15 21 26 31 36 39 43 49 57 59 60 61 63

8" 00 0 0 1 2 5 91419253034364146 5355565759

10" 00 0 0 0 2 4 81318202427293337 4344454648

RAPE SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 3 5 7 10 12 14 16 18 21 24 27 30 33 36 39 43 46 49 50 50

7 1/2" 0 3 4 7 9 11 12 14 17 19 22 25 27 30 33 36 39 42 44 46 46

8" 0 3 4 6 8 10 12 14 16 18 21 23 26 29 31 34 37 40 42 42 43

10" 0 2 3 5 7 8 9 11 13 15 17 19 21 23 25 27 30 32 34 34 34

*Based On 49#/Bushel

ALFALFA SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 4 5 8 10 14 16 19 22 25 28 30 33 35 37 40 42 44 47 49 50

7 1/2" 0 3 5 7 10 12 15 17 20 22 25 28 30 32 34 37 38 40 43 44 46

8" 0 3 5 7 9 12 14 17 19 21 24 26 29 30 33 35 37 39 41 42 44

10" 02 4 5 7 911131517192123242628 2931333435

*Based On 60.7#/Bushel

MILO SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 2 4 7 10 13 17 19 23 26 29 32 35 39 42 46 50 54 57 57 57

7 1/2" 0 2 4 6 9 12 15 18 21 24 26 29 32 35 38 42 46 49 52 52 52

8" 0 2 3 6 9 12 14 17 20 22 25 28 31 34 37 40 44 47 49 50 50

10" 02 3 5 7 911141618202224272932 3537394040

*Based On 62.4#/Bushel

WHEAT GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0001233445667888 8991010

7 1/2" 0 0 0 0 2 3 3 4 4 5 5 6 6 7 7 7 8 8 8 9 10

8" 0000223345566777 77889

10" 000022233444555566788

KENTUCKY BLUE GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 03 7111418212529323639424548525457606365

7 1/2" 0 3 7 10 13 17 20 24 27 30 34 36 40 42 45 48 51 54 57 59 61

8" 0 3 6 9 12 15 18 22 25 28 31 34 37 39 42 45 47 50 53 55 57

10" 0 2 5 7 10 12 14 17 20 22 25 26 29 31 33 36 37 39 41 43 45

KENTUCKY BLUE GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 5 11 17 22 27 33 39 45 49 56 60 65 70 75 80 84 89 93 97 102

7 1 /2" 0 5 10 16 20 26 31 37 42 46 52 56 61 65 70 75 79 83 87 91 95

8" 0 5 10 15 19 24 29 34 39 43 49 52 57 61 65 70 74 78 82 85 89

10" 04 8111519232731343841454851555861646770

16

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

Page 19

Section 4 Adjustments

ORCHARD GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" .3 .8 2.1 3.3 4.4 5.6 6.9 8.0 9.2 10.3 11.6 12.8 13.9 15.1 16.4 17.5 18.7 19.8 21.1 22.3 23.4

7 1/2" .3 .8 2.0 3.1 4.1 5.2 6.4 7.5 8.6 9.7 10.9 12.0 13.0 14.1 15.3 16.4 17.5 18.6 19.8 20.9 21.9

8" .3 .7 1.9 2.9 3.9 4.9 6.0 7.0 8.0 9.0 10.2 11.2 12.2 13.2 14.3 15.3 16.3 17.3 18.5 19.5 20.5

10" .2 .6 1.5 2.2 3.0 3.8 4.7 5.5 6.3 7.1 8.0 8.8 9.6 10.3 11.2 12.0 12.8 13.6 14.5 15.3 16.1

ORCHARD GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" .2 .4 1.0 1.6 2.1 2.7 3.3 3.9 4.5 5.0 5.7 6.2 6.8 7.3 8.0 8.5 9.1 9.6 10.3 10.8 11.4

7 1/2" .1 .4 1.0 1.5 2.0 2.5 3.1 3.7 4.2 4.7 5.3 5.8 6.3 6.9 7.5 8.0 8.5 9.0 9.6 10.1 10.7

8" .1 .3 .9 1.4 1.9 2.4 2.9 3.4 3.9 4.4 4.9 5.4 5.9 6.4 7.0 7.5 7.9 8.4 9.0 9.5 10.0

10" .1 .3 .7 1.1 1.5 1.9 2.3 2.7 3.1 3.4 3.9 4.3 4.7 5.0 5.5 5.9 6.2 6.6 7.1 7.4 7.8

ORCHARD GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" .8 2.0 5.2 8.0 10.8 13.6 16.8 19.6 22.4 25.2 28.4 31.2 34.0 36.8 40.0 42.8 45.6 48.4 51.6 54.4 57.2

7 1/2" .8 1.9 4.9 7.5 10.1 12.8 15.8 18.4 21.0 23.6 26.6 29.3 31.9 34.5 37.5 40.1 42.8 45.4 48.4 51.0 53.6

8" .7 1.8 4.6 7.0 9.5 11.9 14.7 17.2 19.6 22.1 24.9 27.3 29.8 32.2 35.0 37.5 39.9 42.4 45.2 47.6 50.1

10" .6 1.4 3.6 5.5 7.4 9.4 11.6 13.5 15.4 17.3 19.5 21.5 23.4 25.3 27.5 29.4 31.4 33.3 35.5 37.4 39.3

ORCHARD GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" .5 1.2 3.2 4.9 6.6 8.3 10.3 12.0 13.7 15.5 17.4 19.1 20.9 22.6 24.5 26.3 28.0 29.7 31.7 33.4 35.1

7 1/2" .5 1.2 3.0 4.6 6.2 7.8 9.7 11.3 12.9 14.5 16.3 17.9 19.6 21.2 23.0 24.6 26.2 27.8 29.7 31.3 32.9

8" .4 1.1 2.8 4.3 5.8 7.3 9.0 10.5 12.0 13.5 15.2 16.8 18.3 19.8 21.5 23.0 24.5 26.0 27.7 29.2 30.7

10" .3 .8 2.2 3.4 4.6 5.7 7.1 8.3 9.4 10.6 12.0 13.2 14.3 15.5 16.9 18.1 19.2 20.4 21.8 22.9 24.1

BURMUDA GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 8 14 22 28 34 40 47 53 59 65 71 77 83 89 96 102 108 114 120 126

7 1/2" 0 8 13 21 26 32 38 44 49 55 61 67 72 78 84 90 95 101 107 113 118

8" 0 7 12 19 25 30 35 41 46 51 57 62 68 73 78 84 89 94 100 105 111

10" 0 6 10 15 19 24 28 32 36 40 45 49 53 57 61 66 70 74 78 83 87

BURMUDA GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 14 23 36 46 56 66 76 86 96 106 116 126 136 146 156 166 176 186 196 206

7 1/2" 0 13 21 34 43 52 62 71 81 91 99 109 118 127 137 146 156 165 174 184 193

8" 0 12 20 31 40 49 57 67 75 84 92 102 110 119 127 137 145 154 162 172 180

10" 0 9 15 25 32 38 45 52 59 66 73 80 87 93 100 107 114 121 128 135 142

BURMUDA GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41

7 1/2" 0 3 4 7 9 10 12 14 16 18 20 22 24 25 27 29 31 33 35 37 38

8" 0 2 4 6 8 10 11 13 15 17 18 20 22 24 25 27 29 31 32 34 36

10" 0 2 3 5 6 8 9 10 12 13 15 16 17 19 20 21 23 24 25 27 28

BURMUDA GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 2A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 06 9151923273135394347525660646872768084

7 1/2" 0 5 9 14 18 21 25 29 33 37 41 45 48 52 56 60 64 67 71 75 79

8" 05 8131620242731343842454952565953667074

10" 04 6101316192124273033353841444749525558

4/17/2001 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-17

Page 20

Section 4 Adjustments

PERENNIAL RYE GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 5 11 16 22 27 33 38 44 49 55 60 66 71 77 83 88 94 99 105 110

7 1/2" 0 5 10 15 20 26 31 36 41 46 51 57 62 67 72 77 82 88 93 98 103

8" 04 9141924293338434843486267727782879196

10" 03 7111519222630343842454953576064687276

PERENNIAL RYE GRASS SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 8 17 25 34 43 51 60 69 77 86 95 104 112 121 130 138 147 156 164 173

7 1/2" 0 7 16 24 32 40 48 56 64 72 81 89 97 105 113 121 129 138 146 154 162

8" 0 7 15 22 30 37 45 52 60 67 75 83 91 98 106 113 121 128 136 143 151

10" 0 5 12 17 23 29 35 41 47 53 59 65 71 77 83 89 95 104 107 113 119

K-31 FESCUE SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 0 0 3 6 10 14 17 21 23 28 30 34 38 41 44 48 51 54 55 56 57

7 1/2" 0 0 2 6 10 13 16 19 22 26 28 32 36 38 41 45 48 51 51 53 53

8" 0 0 2 5 9 12 15 18 20 24 27 30 33 36 39 42 45 47 48 49 50

10" 0 0 2 4 7 10 12 14 16 19 21 23 26 28 30 33 35 37 38 39 39

K-31 FESCUE SEED RATE INDICATOR SETTING NUMBER

DRIVE TYPE 1A 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Row Spacing Pounds Per Acre

7" 00 4101622273236434752596368747983858787

7 1/2" 0 0 4 9 15 21 25 30 34 40 44 49 55 59 64 69 74 78 79 81 82

8" 0 0 3 8 14 19 24 28 31 38 41 46 51 55 60 64 69 73 74 76 77

10" 0 0 3 7 11 15 19 22 25 30 32 36 40 43 47 51 54 57 58 60 60

Refer to Figure 4-5:

NOTE:This drill is equipped with four-position feed

cup door on each feed cup. The highest handle position is for wheat and other small seeds, the second

handle position is for soybeans and other large

seeds. Should excessive cracking occur to the large

seeds, drop the handle to the second position. The

wide open position will allow complete clean out of

the feed cup. Make sure all handles are in the same

position before drilling.

13867

Feed-cup

Figure 4-5

18

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

Page 21

Section 4 Adjustments

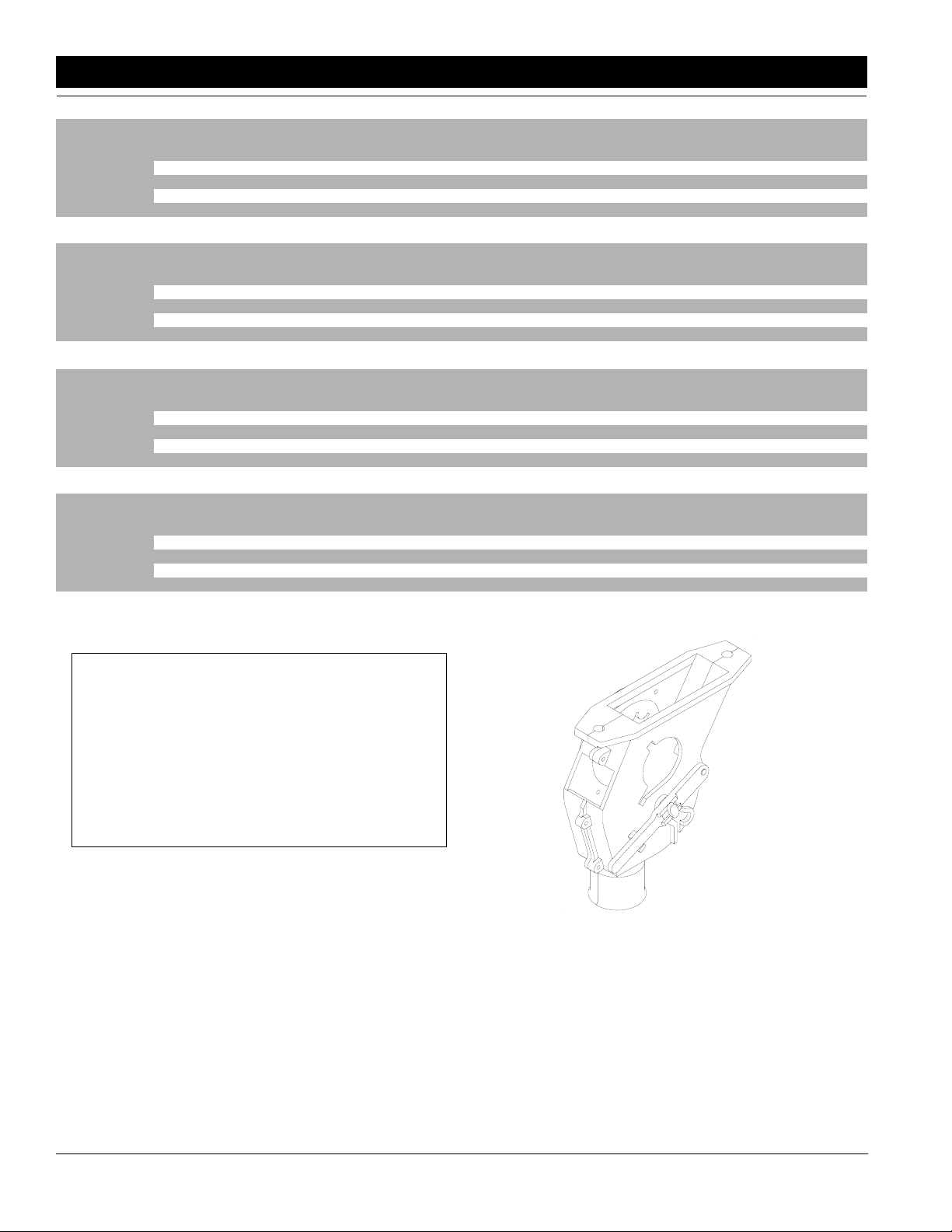

Fertilizer Drive

The fertilizer feed rate is directly related to your ground

speed so there are no chains or sprockets to adjust in order to change your rate. The rate is controlled by the fertilizer outlet opening size which is controlled by the

adjustment knob on the back of the fertilizer tray. For fertilizer rates below.

Fertilizer Rate

Great Plains End Wheel No-Till Fertilizer Drills have a

partition, Figure 4-6, dividing the seed and fertilizer compartments. In the partitions are removable panels to allow the drill to be used with all seed, Figure 4-6.

If fertilizer is not being used with grain, remove chain

fromfertilizer drive sprocket to eliminate unnecessary

wear on the fertilizer drive system.

If total box capacity is desired for grain, remove seed/

fertilizer partitions and set fertilizer rate adjustment lever

at "0" setting so as not to allow any seed to escape

through the fertilizer outlets.

The application rate of dry granular fertilizer is affected

by many factors: Fertilizer type and density, relative humidity, and the moisture content of the material itself.

Due to these variables, the chart below should be used

only to closely approximate the amount of fertilizer being

applied.

10114

Divided Panel Panel Removed

Figure 4-6

7’ & 10’ FERTILIZER APPLICATION CHART

INDICATOR SETTING NUMBER

Row 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Spacing Pounds Per Acre

7" 0 11 21 40 57 75 93 111 128 144 163 181 196 217 232 245 252 258 260

7 1/2" 0 10 19 37 51 69 85 100 116 131 148 164 178 198 211 223 230 234 236

8" 0 10 19 37 51 69 85 100 116 131 148 164 178 198 211 223 230 234 236

10" 0 8 16 29 41 55 68 80 93 105 119 132 143 158 169 178 184 187 189

The preceding chart has been computed using fertilizer that has a density of 65 pounds/cubic foot. If you are

applying fertilizer that has a density other than this, use the following table:

Density 45 50 55 60 65 70 75 80

Conversion Factor 1.45 1.30 1.20 1.10 1.00 0.93 0.87 0.81

EXAMPLE: You are using fertilizer with a 75 pound/cubic

foot density and you desire arate of 100 pounds peracre.

Multiply 100 x 0.87 = 87 pounds. Therefore, use the setting closest to 87 pounds.

4/17/2001 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-19

Page 22

Section 4 Adjustments

Native Grass Drive

Native grass metering is directly related to the revolutions of the clutch shaft per acre. The different sprocket

combinations are required to give a broad range of planting rates. The sprocket changes are made at the left end

of the drill, inside the double wall end panel. For native

grass seeding rates and sprocket combinations, refer to

page 21.

Native Grass Rate

Great Plains End Wheel No-Till Native Grass Drill has a

partition dividing the seed and native grass compartments. Capacity of the seed box is 1.3 bushels per foot,

and the capacity of the native grass box is 1.2 bushels

per foot.

If the native grass is not being used, remove the chain

from the native grass drive sprocket to eliminate wear on

the native grass drive system.

Native Grass Seeding Adjustments

NOTE: Seeding rates vary greatly with variations in

types of seeds being drilled. The seed rate chart on

the following page is based on a seed mix of 5.7# of

pure live seed per 11.1# of bulk. The pure live seed

mix was Big Blue-1.5#, Little Blue-.8#, Side Oats

Grama-.6#, Western Wheat Grass-1#, Switch

Grass-.3#, and Indian Grass-1.5#. Factors which affect seeding rates are: weight of seed, size of seed,

relative humidity and moisture content of the seed itself, ratio of inert material to seed, different proportions of seed types affecting density, and tire

configuration, pressure and slippage. We recom-

mend that you test and adjust your drill using

the procedures listed below to help insure an accurate seeding rate.

1. Rotate the drive wheel to see that the feed cups and

drive are working properly and are free from foreign

matter

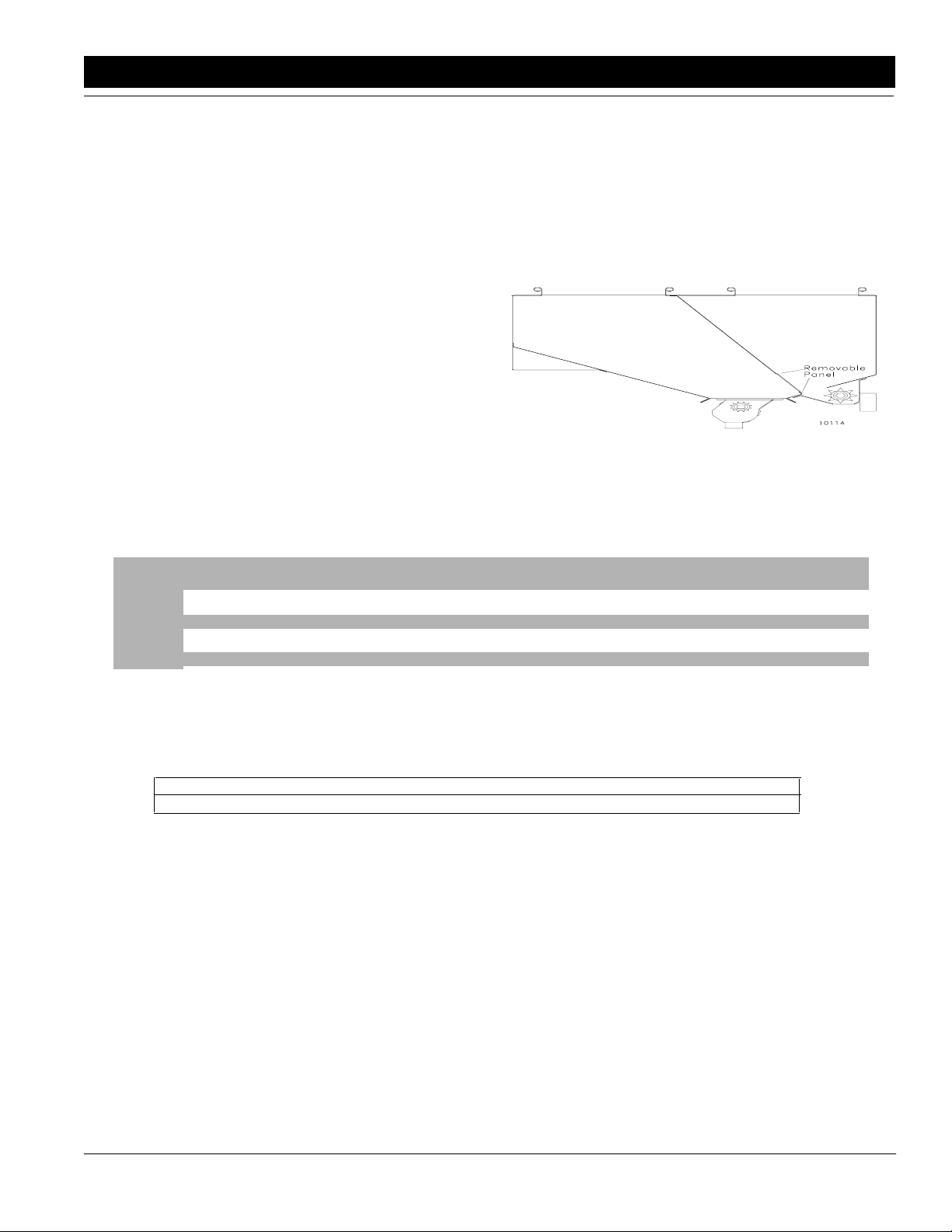

Refer to Figure 4-7:

2. To adjust you seeding rate, first find the row spacing

and the desired pounds/acre on the native grass

seed rate chart {see "Seeding Chart"}. Determine

which sprocket combination is required for the clutch

shaft sprocket and the upper shaft sprocket. This

sprocket combination is designated by the drive

types A, B, D, and D. From the chart, choose the

driver and driven sprocket combination that will deliver the desired native grass seed rate. In order to

change sprockets on the native grass unit, loosen

the idler arm and remove the chain, remove the

lynch pins on the driver and driven sprockets and rearrange the sprockets accordingly.

3. The pounds-per-acre in the seed chart is based on

drills having 9.00 x 24 drill rib tires.

4. After setting up your sprocket arrangement, complete the following procedure to calibrate the drill for

your specific seed type.

a. Fill three or more compartments at least one-

half full of seed at the outboard end of the drill.

b. Pull the seed tubes off the openers under the

compartments.

c. Lower the drill hydraulically to planting position

in order to activate the clutch.

d. Raise the drive (left) end tire off the ground us-

ing jack.

e. Place a container under the seed tubes to gath-

er the seed as it is metered

f. Rotate the tire until one acre has been tallied on

the acremeter. This will be approximately 422

rotations on a 10’ End Wheel No-Till Drill; and

592 rotations on a 7’ End Wheel No-Till Drill. Be

sure to check that the feeder cups have plenty of

seed coming into them.

g. Weigh the seed which has been metered. Di-

vide by the number of cups that were metered.

This will give you the ounces/pounds metered

by each feed cup. Multiply by the number of

openers on your drill to arrive at the total

11837

Sprocket Arrangement Diagram

Figure 4-7

20

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

10112

Page 23

Section 4 Adjustments

pounds-per-acre your drill would meter at that

setting. If this figure is different than desired,

change your sprocket arrangement accordingly.

5. You may want to repeat the calibration procedure if

the results of your calibration varies greatly from

what is listed on the seed rate chart.

IMPORTANT: Tire size and field conditions will also affect seeding rates. Be certain that your drill rib tires are

9.00 x 24 and that they have the proper inflation. When

ing acres drilled, amount of seed added to drill, and level

of seed in drill box. If you suspect that you are drilling

more or less than desired, and you have accurately calibrated the drill to your seed, you may need to adjust the

seeding rate slightly to compensate for your field conditions.

NOTE: Pounds per acre listed below are total

pounds of bulk seed {live and inert material}.

drilling, check the amount of seed you are using by not-

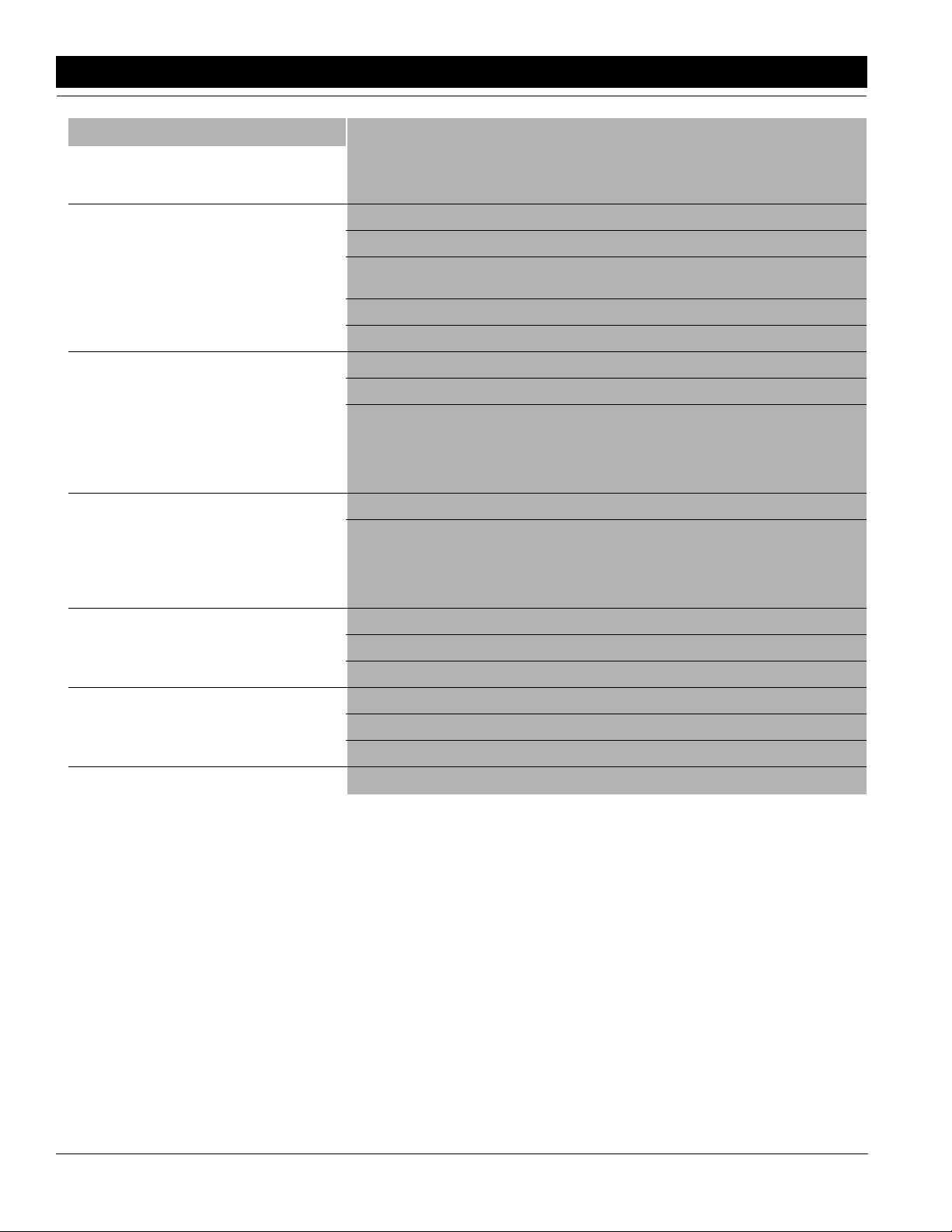

Native Grass Seed Rate Charts & Sprocket Selections

7’ END WHEEL NO-TILL DRILL

Clutch Upper

Row Shaft Shaft Drive

Spacing Spkt. Spkt. Type 15 35 15 30 19 35 19 30 24 35 15 19 30 35 19 19 35 30 19 15 35 24 30 19 35 19 30 15 35 15

12 35 A 2.4 2.8 3.1 3.6 3.9 4.4 4.8 5.6 6.6 7.1 8.2 8.9 10.4 11.2 13.1

12 30 B 2.8 3.3 3.6 4.2 4.5 5.2 5.6 6.6 7.7 8.3 9.6 10.4 12.1 13.1 15.3

10" 15 35 C 3.0 3.5 3.8 4.5 4.8 5.6 6.0 7.0 8.2 8.9 10.3 11.1 13.0 14.1 16.4

15 30 D 3.5 4.1 4.5 5.2 5.6 6.5 7.0 8.2 9.6 10.4 12.0 13.0 15.1 16.4 19.1

12 35 A 3.1 3.6 3.9 4.5 4.9 5.7 6.1 7.2 8.4 9.1 10.4 11.3 13.2 14.3 16.7

8" 12 30 B 3.6 4.2 4.5 5.3 5.7 6.6 7.2 8.4 9.7 10.6 12.2 13.2 15.4 16.7 19.5

7 1/2" 15 35 C 3.8 4.5 4.9 5.7 6.1 7.1 7.7 8.9 10.4 11.3 13.0 14.1 16.5 17.2 20.4

15 30 D 4.5 5.2 5.7 6.6 7.2 8.2 8.9 10.4 12.2 13.2 15.2 16.5 19.2 20.9 ----12 35 A 3.5 4.1 4.4 5.2 5.6 6.5 7.0 8.2 9.5 10.4 11.9 12.9 15.1 16.4 19.1

12 30 B 4.1 4.8 5.2 6.0 6.5 7.5 8.2 9.5 11.1 12.1 13.9 15.1 17.6 19.1 22.3

7" 15 35 C 4.4 5.1 5.5 6.5 7.0 8.1 8.8 10.2 11.9 13.0 14.9 16.4 20.5 23.8 -----

15 30 D 5.1 6.0 6.5 7.6 8.2 9.4 10.2 11.9 13.9 15.1 17.4 18.8 22.0 ----- -----

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Pounds Per Acre

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

10’ END WHEEL NO-TILL DRILL

Clutch Upper

Row Shaft Shaft Drive

Spacing Spkt. Spkt. Type 15 35 15 30 19 35 19 30 24 35 15 19 30 35 19 19 35 30 19 15 35 24 30 19 35 19 30 15 35 15

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Pounds Per Acre

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

Driven

Driver

12 35 A 2.4 2.8 3.1 3.6 3.9 4.4 4.8 5.6 6.6 7.1 8.2 8.9 10.4 11.2 13.1

12 30 B 2.8 3.3 3.6 4.2 4.5 5.2 5.6 6.6 7.7 8.3 9.6 10.4 12.1 13.1 15.3

10" 15 35 C 3.0 3.5 3.8 4.5 4.8 5.6 6.0 7.0 8.2 8.9 10.3 11.1 13.0 14.1 16.4

15 30 D 3.5 4.1 4.5 5.2 5.6 6.5 7.0 8.2 9.6 10.4 12.0 13.0 15.1 16.4 19.1

12 35 A 3.1 3.6 3.9 4.5 4.9 5.7 6.1 7.2 8.4 9.1 10.4 11.3 13.2 14.3 16.7

12 30 B 3.6 4.2 4.5 5.3 5.7 6.6 7.2 8.4 9.7 10.6 12.2 13.2 15.4 16.7 19.5

8" 15 35 C 3.8 4.5 4.9 5.7 6.1 7.1 7.7 8.9 10.4 11.3 13.0 14.1 16.5 17.2 20.4

15 30 D 4.5 5.2 5.7 6.6 7.2 8.2 8.9 10.4 12.2 13.2 15.2 16.5 19.2 20.9 ----12 35 A 3.3 3.8 4.2 4.9 5.3 6.1 6.6 7.7 8.9 9.7 11.2 12.1 14.1 15.3 17.9

12 30 B 3.8 4.5 4.9 5.7 6.1 7.1 7.7 8.9 10.4 11.3 13.1 14.1 16.5 17.9 20.9

7 1/2" 15 35 C 4.1 4.8 5.2 6.1 6.6 7.6 8.2 9.6 11.2 12.1 14.0 15.1 17.7 19.2 22.4

15 30 D 4.5 5.6 6.1 7.1 7.7 8.8 9.6 11.2 13.0 14.2 16.3 17.7 20.6 ----- ----12 35 A 3.5 4.1 4.4 5.2 5.6 6.5 7.0 8.2 9.5 10.4 11.9 12.9 15.1 16.4 19.1

12 30 B 4.1 4.8 5.2 6.0 6.5 7.5 8.2 9.5 11.1 12.1 13.9 15.1 17.6 19.1 22.3

7" 15 35 C 4.4 5.1 5.5 6.5 7.0 8.1 8.8 10.2 11.9 13.0 14.9 16.4 20.5 23.8 -----

15 30 D 5.1 6.0 6.5 7.6 8.2 9.4 10.2 11.9 13.9 15.1 17.4 18.8 22.0 ----- -----

4/17/2001 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-21

Driven

Page 24

Section 4 Adjustments

Planting Depth Adjustments

A no-till coulter is mounted independently and directly

ahead of each opener on the drill. Each coulter cuts

through heavy trash and/or cuts a groove in the firm soil

often encountered in no-till seeding conditions. The

coulters are mounted directly to the drill box frame. Consequently, the cutting depth of all coulters on the drill

change as the drill is raised and lowered. The cutting

depth of the coulters is controlled by an adjustable hydraulic depth stop on the master cylinder. Refer to "Hy-

draulic Depth Control" for information on how to make

this depth adjustment.) Those coulters which run directly in drill and tractor tire tracks may be individually lowered if desired. See "Individual Coulter Adjustment".

Coulter Hydraulic Depth Control

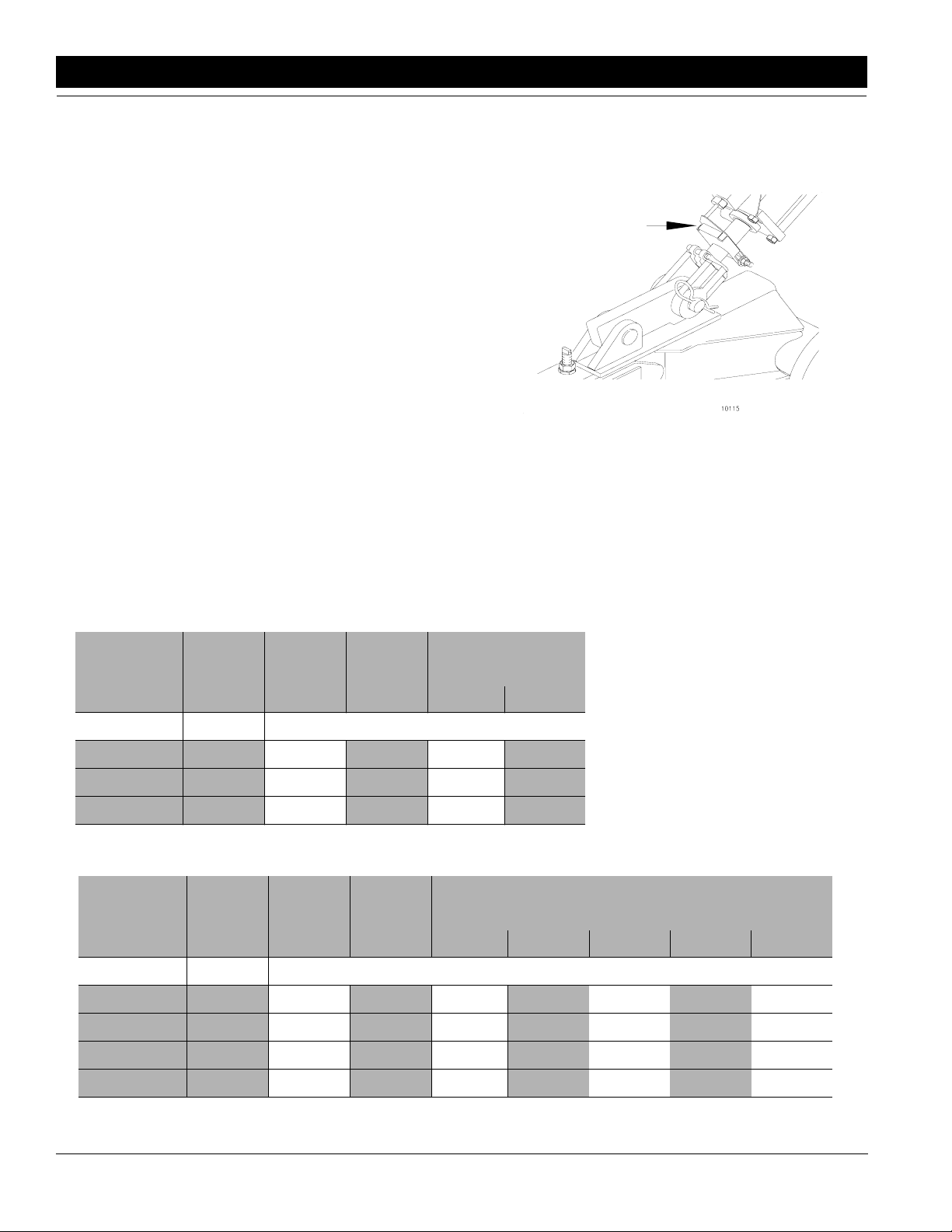

Refer to Figure 4-8:

The master lift cylinder on your drill is equipped with a

hydraulic depth control stop, Figure 4-8. This allows for

a variable adjustment from zero to maximum stroke

which controls the depth of your coulters. In order to adjust the stroke of the cylinder,retract the cylinder until the

coulters are penetrating at the desired depth required.

Next, loosen the bolt on the depth control actuator plate

and slide it up the cylinder until it stops against the

plunger of the control valve on the head of the cylinder.

You will now need to extend your cylinder slightly and

move the depth control actuator plate up to compensate

for the control valve plunger length.

10115

Master Cylinder With Depth Control Stop

Figure 4-8

Down Pressure Requirements

If more weight is required for your soil conditions, it

should be added to the weight bracket of the drill (optional equipment). Be sure the weights are equal at each

end. Refer to chart below for additional weights.

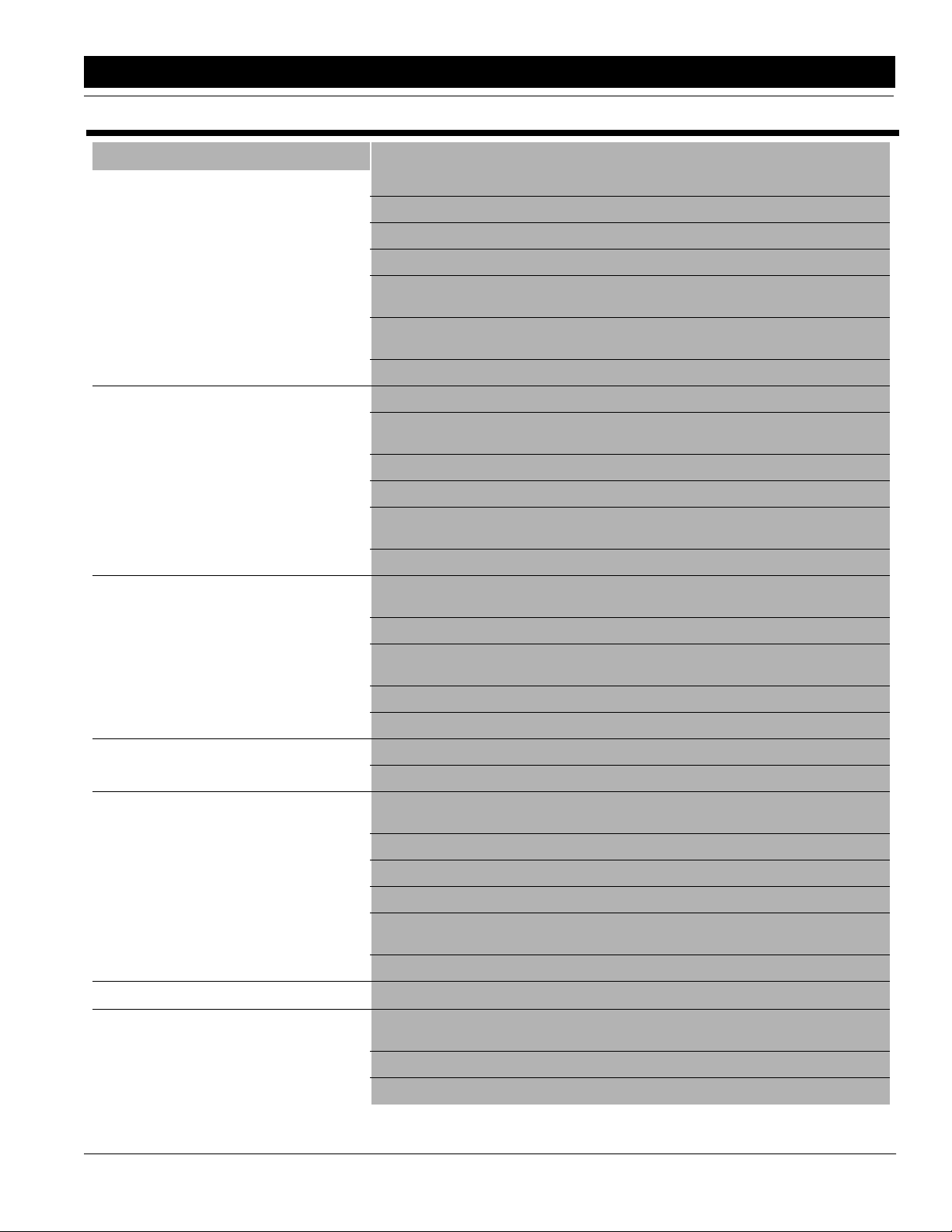

7’ Drill

Row

Spacing

Drill

Weight

Empty

Drill

Only

Drill With

*Weight

Bracket

Pounds Per Coulter

Great Plains Weight

Bracket & Weight

200# 600#

Required

7" 3800# 345# 375# 393# 421#

7 1/2" & 8" 3650# 365# 398# 418# N/A

10" 3350# 418# N/A N/A N/A

10’ Drill

Row

Spacing

Drill

Weight

Empty

Drill

Only

Drill With

*Weight

Bracket

Great Plains Weight Bracket & Weight Required

200# 600# 1000# 1200# 1400#

Pounds Per Coulter

7" 4500# 281# 302# 314# 340# 365# 377# 390#

7 1/2" 4350# 290# 312# 326# 352# 379# 392# N/A

8" 4200# 300# 324# 338# 367# 395# N/A N/A

10" 3750# 340# 371# 390# N/A N/A N/A N/A

*7’ Weight Bracket Part No. 150-010A

**10’ Weight Bracket Part No. 150-011A

22

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

Page 25

Section 4 Adjustments

Individual Opener & Coulter

When coulters and openers follow in tractor tire tracks

and individual coulters do not give satisfactory depth,

the coulter mounting bars can be lowered up to 1 1/2" by

loosening the mountingclamps and adjusting the coulter

and opener to the desired setting. Lowering openers

and coulters will not aid in penetrating hard soil. This is

achieved by adding weight to the drill. Refer to "Coulter

Down Pressure Requirements". To retighten the

clamps, snug the hex head mounting bolts until the ubolts are tight on each side of the spring bar. Tighten

nuts on u-bolts and then tighten hex head mounting

bolts.

NOTE: Transport clearance at these coulters will be

reduced in transport.

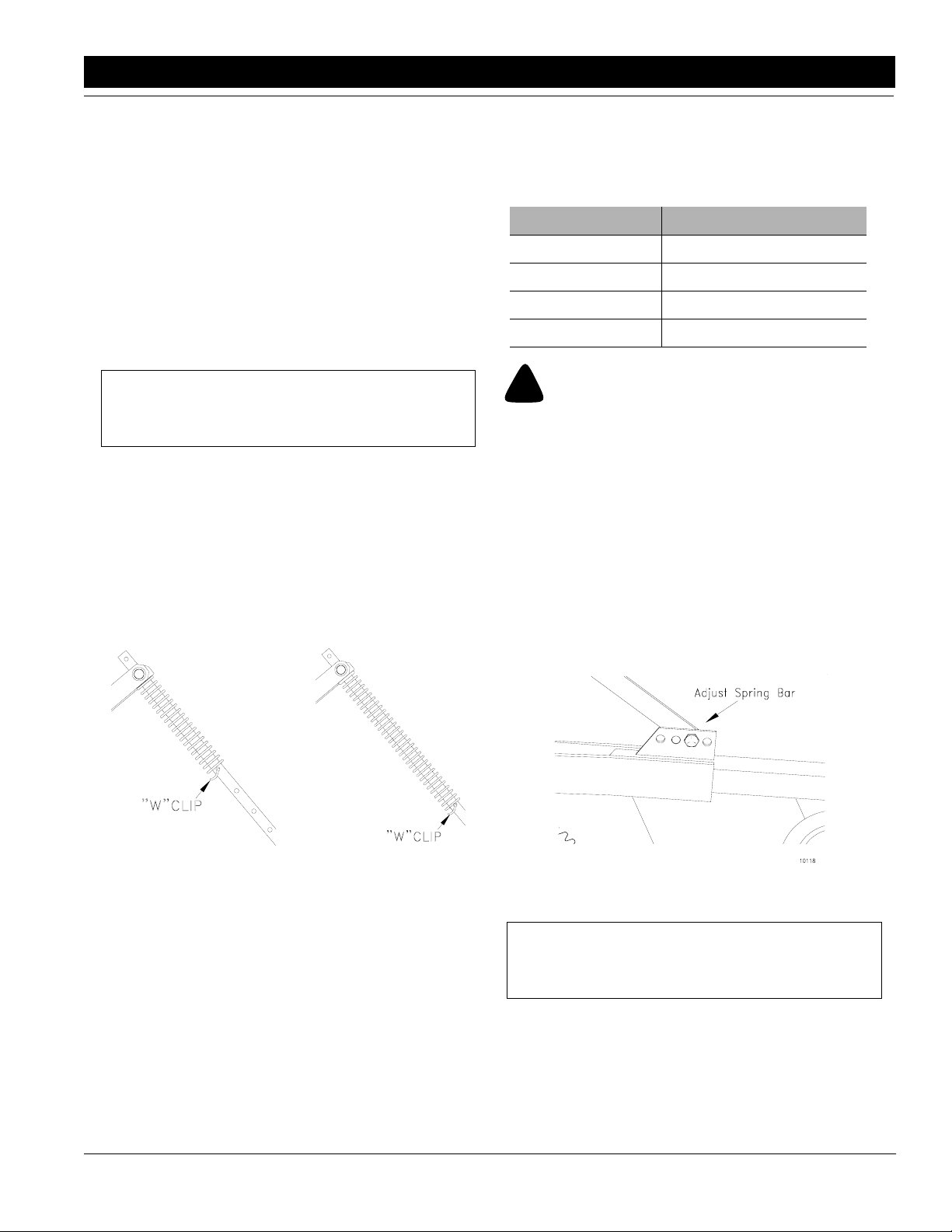

Disk Opener Spring Pressure Setting

Refer to Figure 4-9 & Figure 4-10:

Each opener spring can be individually adjusted for

down pressure. This is useful when penetrating hard

soil and for seeding in tractor tire tracks.

To adjust the pressure, remove the "W" clip at the bottom

of the spring and place it in a higher hole in the spring

rod for more pressure, Figure 4-9, or in a lower hole for

less pressure, Figure 4-10.

sirable to reduce the initial coulter preload to give the

coulters better impact protection. Refer to the following

chart for adjusting the initial coulter force setting.

Spring Length Initial Vertical Coulter Force

10 1/2" 175 lbs.

10 1/4" 300 lbs.

10" 400 lbs.

9 3/4" 525 lbs.

!

Any attempt to reset the coulter spring length shorter than

9 3/4" may contribute to premature failure of parts and warranty shall be voided.

CAUTION!

Individual Opener Height

Refer to Figure 4-11:

The opener depth may be adjusted at each opener.

Openers running in the tractor tire tracks, for example,

may require depth or down pressure adjustments.

The opener depth adjustment is made where the spring

bar connects to the top of the disk opener arm,

Figure 4-11. Connect the spring bar in a higher hole for

deeper opener location, or in a lower hole for a more

shallow opener location.

11836

Maximum Pressure

Figure 4-9

The coulter spring length is preset at the factory to 10",

which gives the coulters an initial operating force of 400

pounds. This setting is adequate for many difficult no-till

planting conditions. For lighter no-till conditions where

rocks or other obstructions are a problem, it may be de-

4/17/2001 Great Plains Mfg., Inc.

10129

Minimum Pressure

Figure 4-10

10118

Spring Bar Adjustment

Figure 4-11

NOTE: Transport clearance at the openers will be

reduced.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-23

Page 26

Section 4 Adjustments

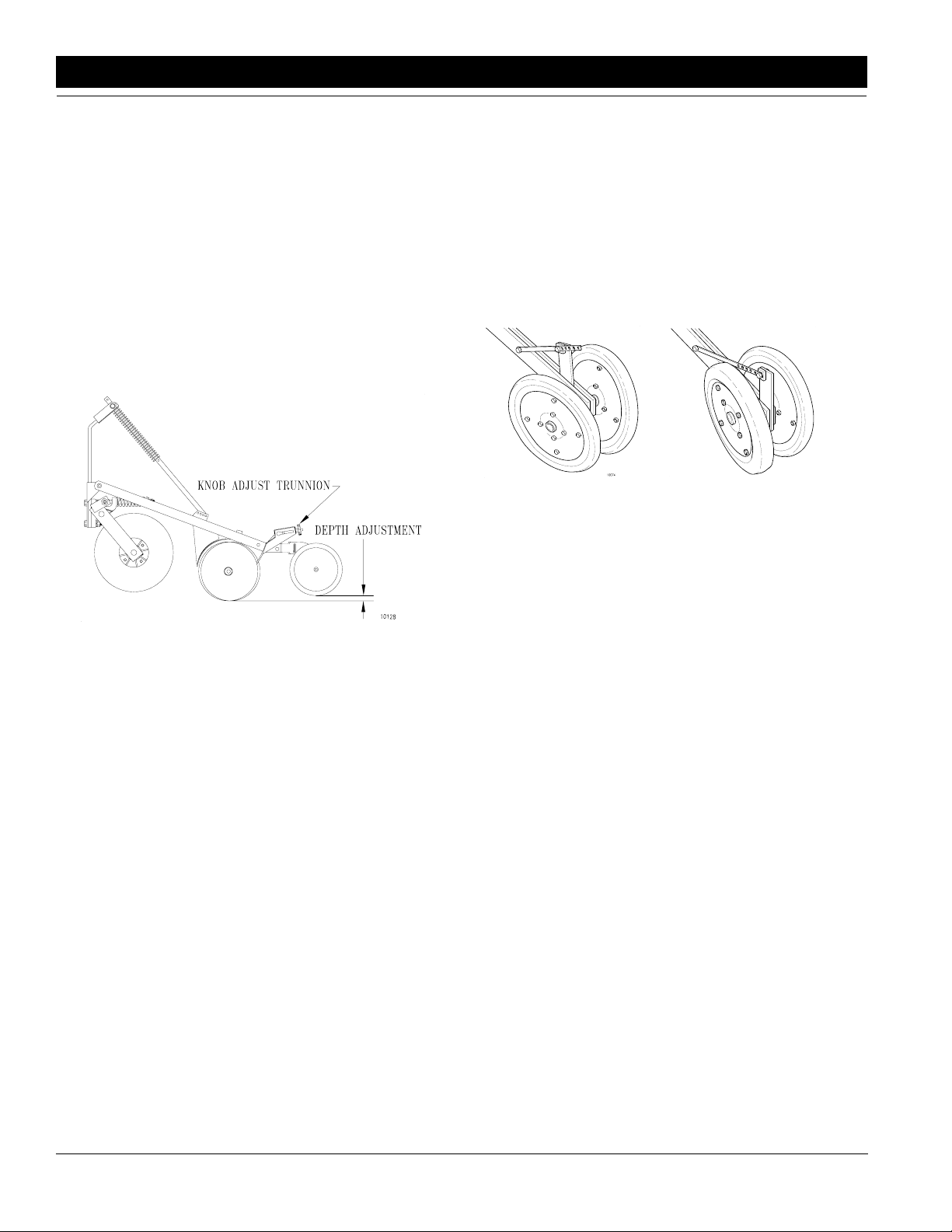

Opener Press Wheel Depth

Refer to Figure 4-12:

The depth of each opener can be adjusted by the position of the press wheel, Figure 4-12. After setting the

coulters to the desired depth by using the depth control

on the end wheel cylinder, see page 22, you can now adjust your press wheels up or down to achieve the correct

seeding depth.

With the drill level and lowered to planting position, adjust the knob and adjustment trunnion located above

each press wheel. This will vary the height of the press

wheel which automaticallychanges the seeding depth of

the opener. Simply rotate the knob until the seeding

depth is correct.

Press Wheel Angle

(2 x 13 Double "V" Press Wheels Only)

Refer to Figure 4-13 & Figure 4-14:

The camber angle of the 2" x 13" double "V" press

wheels may be adjusted by removing the angle bar adjustment pin and moving the angle bar. Moving the angle bar forward will cause the press wheels to pull more

soil over the seed, Figure 4-13. Moving the angle bar

back will cause the press wheel to pull less soil over the

seed, Figure 4-14

.

10074

Forward Position

Figure 4-13

11544

Rear Position

Figure 4-14

Opener Press Wheel Depth Adjustment

Figure 4-12

10128

24

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M 4/17/2001

Great Plains Mfg., Inc.

Page 27

Section 5 Field Operations

Section 5 Field Operations

Drill Preparations

1. Be certain that your rib implement tires are 9.00 x 24

and that they have the proper inflation as listed on

page 6.

2. Load seed box with seed. You should use cleaned

seed to get the best results. You should always have

the drill hitched securely to a tractor and lowered before loading.

3. This drill can be transported with a full box of grain.

It is best not to do this unless necessary because

the increased weight does increase the chances for

problems on the road. Do not exceed 20 miles per

hour.

4. Your drill comes equipped with an acremeter and it

should be mounted on the right end of the jackshaft.

It will accumulate the total acres drilled with the drill.

In order to find out the acres covered, write down the

beginning reading and subtract it from the ending

reading for the total acres planted.

5. Make sure that the feed cup door adjustment handle

on each cup is set the same across the drill.

6. If you notice excessive cracking on large grain

seeds, adjust all feed cup door handles to a wider

setting. Refer to "Speed Change Box" on page 12.

7. Never back up with openers in ground. If you do,

check all openers to be sure none are clogged.

8. This drill is not designed to be turned sharply in the

field. Always lift the drill out of the ground when

turning at ends of field rows and other short-radius

turns.

9. Never allow anyone to ride on the drill.

10. Maximum seeding speed should vary according to

soil conditions.

11. Make sure the drive lockout hub (left end wheel) is

engaged, see Figure 3-3 on page 10, to allow the

gauge wheel drive to work.

!

Escaping fluid under pressure can have sufficient force to penetrate the skin. Check all hydraulic lines and hoses before applying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

from a doctor that is familiar with this type of injury. Foreign

fluids in the tissue must be surgically removed within a few

hours or gangrene will result.

CAUTION!

Operating Checklist

Check Reference

“Safety Rules” in this Manual “Section 1

“Hook-Up ” & "Operating" instructions in this

Manual

“Field Operations” in this Manual “Section 5 Field

Tire pressure “Tire Inflation

Feeder Cups for foreign matter

Engage drive hub (left end wheel) “Drive Lock Out

Rotate drive (left) wheel to make sure

the drive system operates smoothly.

Set speed change box for drive type

desired.

Rotate gauge wheels to make sure the

drive system operates smoothly.

Set seed rate. See “Seed Rate

Fertilizer agitator for foreign matter

Set fertilizer rate See “Fertilizer

Disconnect fertilizer drive chain when

fertilizer is not used.

Adjustment of disk opener scrapers for

ease in rotation.

Lubricate the drill as needed. See “Lubrica-

Seed & fertilizer tubes

Drill; innitially and periodically for loose

bolts, pins, and chains.

Safety Rules” on

Operations” on

Adjustment” on

Adjustments” on

Opener Spring

page 3

“Section 2

Assembly

Instructions &

Set-Up” on

page 6

page 25

Chart” on

page 6

Hub” on

page 10

“Drive Train

Operation” on

page 11

“Seed Rate

page 13

page 12.

Rate” on

page 19.

See “Disk

Pressure Set-

ting” on

page 23.

tion” on

page 26.

4/17/2001 Great Plains Mfg., Inc.

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

-25

Page 28

Section 6 Maintenance & Lubrication

Section 6 Maintenance & Lubrication

Maintenance

Proper servicing and adjustment is the key to the long

life of any farm implement. with careful and systematic

inspection, you can avoid costly maintenance, time and

repair.

1. After using yourdrill for several hours, check all bolts

to be sure they are tight.

2. Adjust idlers to remove excess slack from chains.

Clean and use chain lube on all roller chains as

needed.

3. Feed cup drive sprocket should be oiled in its square

bore. Move feed cup adjustment lever away from the

sprocket as far as possible in order to get the oil back

into the square.

4. Always maintain the proper air pressure in the rib

implement tires.

5. Disk scrapers should be kept properly adjusted.

6. Replace any worn, damaged or illegible safety decals by obtaining new decals from your Great Plains

Dealer.

Fertilizer Unit

It is recommended that the fertilizer unit be thoroughly

cleaned every two or three days during operating season and before putting the drill in storage for an extended period of time.

4. Feed cup drive sprocket hub should be oiled in its

square bore. Squirt oil on to the square feed cup

shaft and move feed cup adjustment lever back and

forth in order to get the oil back into the square. This

is most important before putting the drill in storage.

5. Store the drill inside if possible for longer drill life.

6. When in storage, lower the drill with openers on a

board or hard surface. Apply a light coat of oil to exposed cylinder rods.

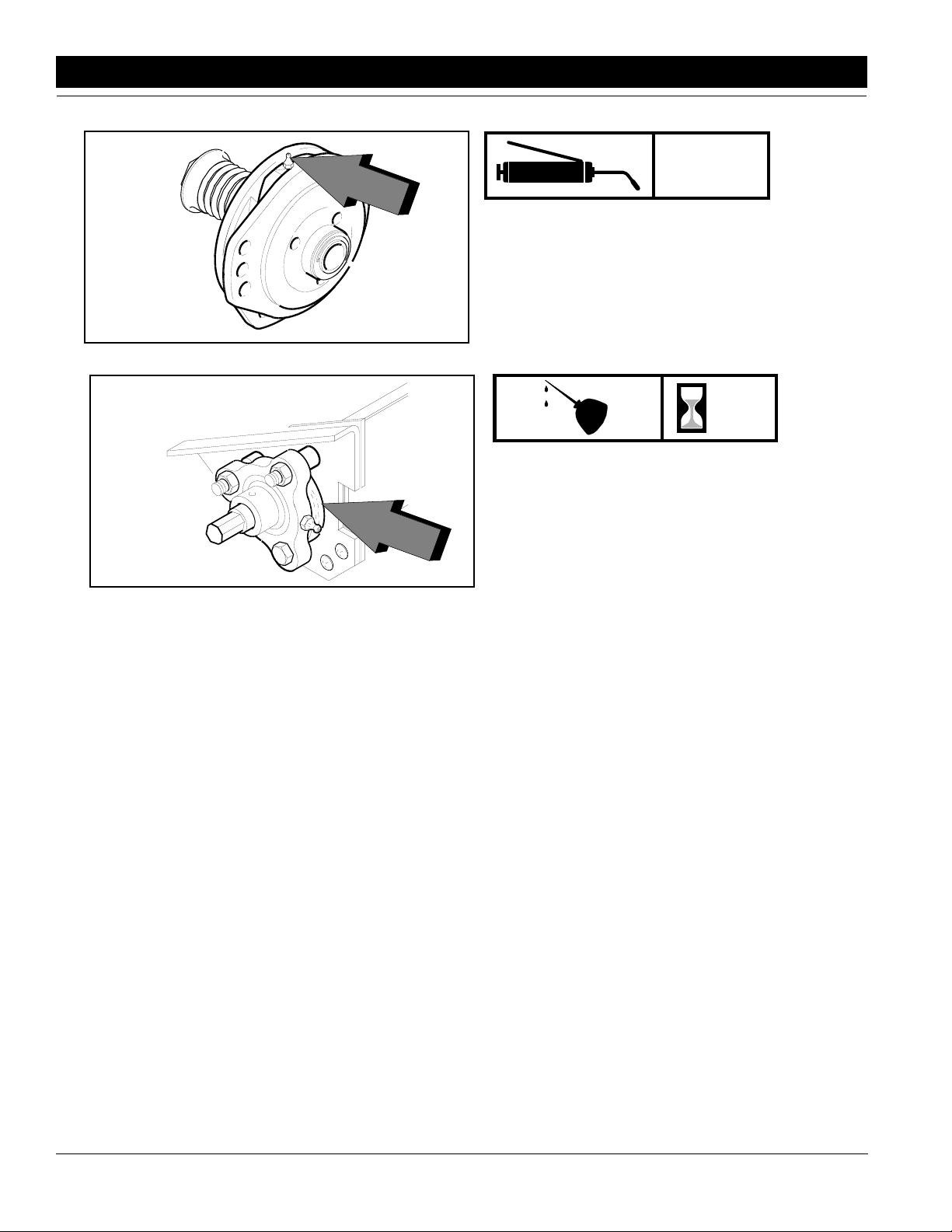

Lubrication

Lubrication Symbols

50

Lubrication is required every 50 hours of operation.

10

Lubrication is required every 10 hours of operation.

As

Required

NOTE: Fertilizer build up on the rotor will affect the

fertilizer application rate. Drop fertilizer tray doors