Page 1

Great Plains Mfg., Inc.

Update Instructions

EWD13 and EWF13

Sprocket Box Update

Used with:

13-Foot, End-Wheel Drills

•

When you see this symbol, the subsequent instructions and

warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

General Information

These instructions explain how to install and adjust the sprocketbox update. The sprocket box replaces the original gearbox on

Great Plains end-wheel drills. This modification improves the

performance and reliability of the original equipment.

Assembly Instructions

Disassembling the Gearbox

1. Remove end-wheel-output and gearbox-output chains.

2. If your drill has 7-, 8- or 10-inch row spacings, you must install a new opener-lift arm and remove the existing arm. If

your drill has 6- or 7.5-inch row spacings, proceed to step

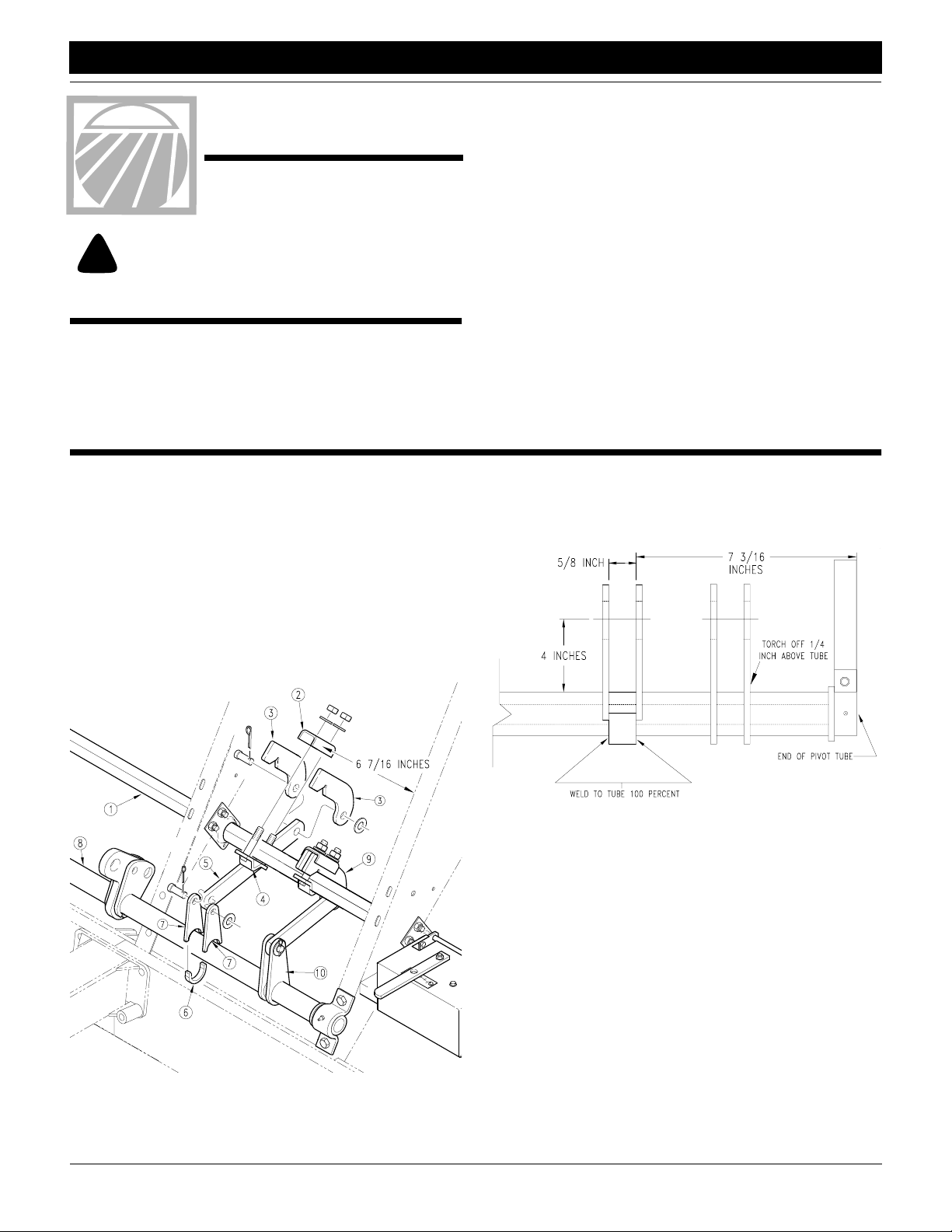

To reposition the opener-lift arm, refer to Figure 1-1.

a. Assemble the clamp on the square opener shaft (1).

Place the channel bracket (2) over the link arms (3). Position the clamp 6 7/16 inches from the frame plate. Secure to shaft with the mounting strap (4), 5/8-inch

washers and bolts.

b. Using a 3/4-inch clevis and cotter pin, pin the link arm

(5) to the newly installed clamp.

These instructions apply to

152-207A 13-Foot EW Sprocket Box Update Kit

Manual Update

Pages 4 and 5 of these instructions cover how to adjust the seeding rate with the new sprocket box. These instructions replace

the "Clutch Shaft and Miter Gear Alignment" and "Seed Calibration" sections in the operator’s manual originally provided with

your drill. As reference, save pages 3 and 4 of these instructions

with your operator’s manual. A copy of the updated parts manual

is available through your Great Plains dealer.

Refer to the drill operator’s manual for detailed information on

safely operating, adjusting, troubleshooting and maintaining the

drill. Refer to the drill parts manual for part identification.

• 13-Foot End Wheel Drill Operator’s Manual . . . . . . . . . . . . . . . . . . . 175-083M

• 13-Foot End Wheel Drill Parts Manual . . . . . . . . . . . . . . . . . . . . . . . 175-083P

Before You Start

Page 6 is a detailed listing of parts included in the sprocket-boxupdate kit. Use this list to inventory parts received.

c. Weld the mount collar (6) and double ears (7) on the

pivot tube (8) so you can pin the link arm to the ears.

Use the link arm as a guide to properly position the collar and ears on the tube. Refer to Figure 1-2 for general

dimensions.

3.

Figure 1-1

Opener Lift Arm

© Copyright 1998 Printed 2/24/98

16597

16598

Figure 1-2

Weld and Torch Diagram

d. Pin the link arm to the double ears using the 3/4-inch

clevis and cotter pins.

e. Remove existing opener-lift arm (9) by torching off the

double ears (10). Cut the ears 1/4 inch above the pivot

tube. Disassemble the existing opener-shaft clamp.

Discard all disassembled parts.

f. Spray paint the pivot tube with the paint provided. Thor-

oughly cover the welds and any paint damage.

152-208M

1

Page 2

Assembly Instructions

Great Plains Mfg., Inc.

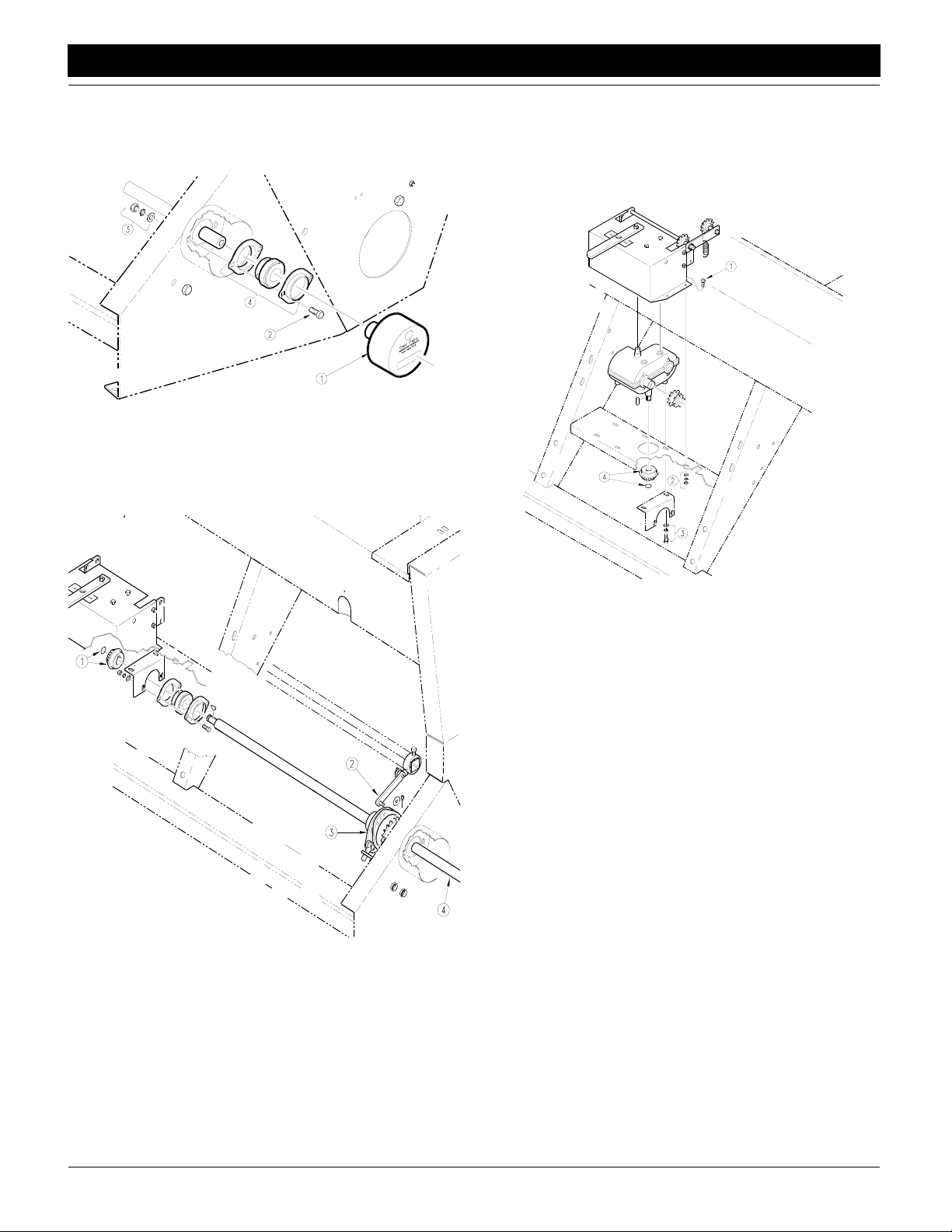

Refer to Figure 1-3.

3. Disassemble acremeter. Unscrew acremeter (1) off shaft.

Remove the 5/16-inch bolts (2), washers and nuts (3). Re

move bearings (4). Save acremeter, bolts, washers, nuts

and bearings for later reinstallation.

16507

Figure 1-3

Acremeter Disassembly

Refer to Figure 1-4.

4. Remove jackshaft. Remove snap ring and miter gear (1)

from gearbox end of shaft. Disconnect clutch link arm (2)

from clutch (3). Slide shaft (4) out of bearings, clutch and

side wall. Save clutch for later reinstallation.

Refer to Figure 1-5.

5. Remove gearbox. Remove 1/4-inch bolts (1), washers and

-

nuts (2) that hold the gearbox cover on mounting plate. Re

move the bolts and washers (3) that hold the bearing bracket

to the mounting plate and gearbox transmission. Remove

the snap ring and miter gear (4). Lift the gearbox off the

mounting plate.

-

16508

16509

Figure 1-5

Gearbox Removal

Figure 1-4

Jackshaft Removal

EWD13 and EWF13 Sprocket Box Update 152-208M 5/2/06

2

Page 3

Great Plains Mfg., Inc.

Assembly Instructions

Installing the Sprocket Box

Refer to Figure 1-6.

1. Drill two 13/32-inch holes for idler bracket. First, bolt the idler

bracket (1) to the mounting plate (2) using a 1/4-inch bolt (3),

washer, lock washer and nut (4) at the location shown. The

idler bracket will wrap around the right-hand side of the

frame plate (5). Use the two bolt holes (6) in the bracket as

a guide for where to drill. When finished drilling, unbolt the

idler bracket from the mounting plate.

2. Assemble bearings (7) on the idler bracket using 5/16-inch

bolts (8), washers, lock washers and nuts (9).

3. Assemble idlers (10) on idler bracket. Bolt the idlers to the

bracket in the order shown (sprocket, 5/8-inch nut, flat wash

er, bracket, flat washer, lock washer, nut).

4. Mount the idler bracket on the mounting plate and through

the frame-plate holes drilled in step

et to the frame plate using 3/8-inch bolts (11), washers, lock

washers and nuts (12).

5. Install sprocket box. Bolt the box (13) to the mounting plate

through four holes using 5/16-inch bolts (14), washers, lock

washers and nuts (15).

6. Install new jackshaft. Slide jackshaft (16) through side wall

and clutch, under mounting plate and through idler bracket.

Install the 12-tooth sprocket (17) on the end of the shaft and

secure with the 1/4-inch key (18).

7. Route 119-pitch chain (19) over sprocket-box input and

idlers as shown. Route 83-pitch chain (20) over gearbox out

-

put, idler and seed-cup-shaft input as shown.

8. Reconnect clutch-link arm and reinstall gauge-wheel-tojackshaft chain. Reassemble acremeter.

1. Mount the idler brack-

-

5/2/06

Figure 1-6

Idler Plate and Gearbox Installation

16514

EWD13 and EWF13 Sprocket Box Update 152-208M

3

Page 4

Seed Calibration

Great Plains Mfg., Inc.

Seeding Adjustment

Calibrating the seeding rate requires four steps: arranging the

drive sprockets, setting the seed-rate handle, positioning the

seed-cup doors, and checking the seeding rate.

Refer to the seed-rate charts. These charts list the proper

sprocket sizes and seed-rate-handle settings for various seeds

and seeding rates.

The seed-rate charts are based on cleaned, untreated seed of

average size and test weight. The charts are based on 9.5 x 20

rib implement tires. Many factors will affect seeding rates including foreign material, seed treatment, seed size, field conditions,

tire pressure and test weight. You likely will need to make minor

adjustments. Set and check the seeding rate using the procedures below, then re-adjust the rate as necessary.

NOTE: A pea-drive adaptor kit is available for the 13-foot endwheel drill. Different seed-rate charts are included in the peadrive kit.

Change Drive Sprockets

The seed-rate charts in your operator’s manual and in your drill

box list drive types as 1, 1A, 2 or 2A. Refer to the seed-rate

charts for the correct drive type.

Figure 1-7 shows sprocket sizes for each drive type.

Type 2

Type 2A

To change the drive types:

1. Refer to Figure 1-8. Loosen the nut (1) holding the idler arm

(2) and turn arm so chain is slack. Remove chain from

sprockets.

2

1

16473

Figure 1-8

Loosen Idler Spacer

2. Refer to Figure 1-9. Rearrange sprocket (1) and plastic

spacers (2) on front shaft so the proper front and rear

sprockets are aligned according to drive type.

3. Slide idlers on idler arms so they are aligned with correct

sprockets. Reinstall chain.

4. Turn idler arm as indicated by drive type to remove slack

from chain. Retighten nut that holds idler arm.

Type 1

Figure 1-7

Sprocket-Box Drive Types

Type 1A

Drive Types

Type 2 is Slowest

Type 2A is Two Times Faster than Type 2

Type 1 is Three Times Faster Than Type 2

Type 1A is Five Times Faster than Type 2

1

Figure 1-9

Rearrange Sprockets on Front Shaft

2

16475

EWD13 and EWF13 Sprocket Box Update 152-208M 5/2/06

4

Page 5

Great Plains Mfg., Inc.

Seed Calibration

Set Seed-Rate Handle

The position the handle shown in Figure 1-10 to the setting indicated on the chart. To adjust the handle, loosen the wing nut under the handle and slide until the indicator lines up with the

correct setting.

12927

Figure 1-10

Seed-Rate Handle

Position Seed-Cup Doors

For wheat and other small seeds, move the seed-cup-door handles to the highest position. For soybeans and other large seeds,

lower the handles to the second position. If excessive seed

cracking occurs, lower the handles to the third position. Move the

handles to the fourth, wide-open position for seed-cup clean out.

Make sure all handles are in the same position before drilling.

Check Seeding Rate

1. Hydraulically lower the drill to planting position to activate

clutch.

2. Check that your gauge-wheel tires are 9.5 x 20 rib implement and properly inflated. Refer to Tire Inflation Chart in

your operator’s manual.

3. Jack the drive (left) end wheel off the ground. Rotate the

wheel to see that the drive system is working properly and

seed cups are free from foreign material.

4. Record the weight of an empty container large enough to

hold the seed metered for one acre.

5. Place several pounds of seed over three seed cups on an

outside end of the drill box. Pull the seed tubes off of these

three openers.

6. Turn the drive wheel several times to fill the seed cups. Turn

wheel until seed drops to the ground from each seed cup.

7. Place a container under the three tubes to gather metered

seed.

8. Rotate the drive wheel until one acre has been tallied on the

acremeter. This will be 348 rotations on a 13-foot drill. Check

that the three seed cups have plenty of seed coming into

them.

9. Weigh the metered seed. Subtract the initial weight of the

container. Divide by three. Multiply by the number of open

ers on your drill to determine total pounds-per-acre seeded.

If this figure is different than desired, reset sprockets accord

ingly.

NOTE: You may want to repeat the calibration procedure if your

results vary greatly from the seed-rate chart.

10. When drilling, check the rate by noting acres drilled, amount

of seed added to drill and seed level in drill box. If you are

seeding more or less than desired, adjust the rate slightly to

compensate for field conditions.

-

-

5/2/06

Figure 1-11

Seed-Cup-Door Handle

13867

EWD13 and EWF13 Sprocket Box Update 152-208M

5

Page 6

Listing of Parts

152-207A 13-Foot End-Wheel Sprocket Box Update Kit

Your Kit Includes:

Qty. Part No. Part Description

1 123-004D KEY 1/4 X 1

1 136-055D CHAIN RL #40 119 PITCHES

1 152-196K 13' SPROCKET BOX ASSEMBLY

1 152-208M MANUAL 13 EW SPKT BOX UPDT

1 152-402D 13' IDLER SUPPORT PLATE

1 152-405D 13' EW LOWER JACK SHAFT

2 152-409D 13' LIFT LUG UPDATE

1 152-410D 13' LIFT LUG SPACER UPDATE

1 175-041H MOUNTING STRAP WELDMENT

1 175-053D OPENER LIFT LINK

1 175-054D PIVOT ARM CHANNEL

1 802-004C HHCS 1/4-20X3/4 GR5

2 802-017C HHCS 3/8-16X1 GR5

3 802-055C HHCS 5/8-11X2 GR5

4 802-159C HHCS 5/16-18X1 GR5

2 802-282C RHSNB 5/16-18X1 GR5

1 803-006C NUT HEX 1/4-20 PLT

6 803-008C NUT HEX 5/16-18 PLT

2 803-014C NUT HEX 3/8-16 PLT

2 803-021C NUT HEX 5/8-11 PLT

6 803-023C NUT HEX JAM 5/8-11 PLT

1 804-006C WASHER LOCK SPRING 1/4 PLT

6 804-009C WASHER LOCK SPRING 5/16 PLT

6 804-010C WASHER FLAT 5/16 USS PLT

2 804-011C WASHER FLAT 3/8 USS PLT

2 804-013C WASHER LOCK SPRING 3/8 PLT

6 804-021C WASHER FLAT 5/8 SAE PLT

5 804-022C WASHER LOCK SPRING 5/8 PLT

2 804-025C WASHER FLAT 3/4 SAE PLT

1 804-075C WASHER FLAT 1/4 USS PLT

2 805-045C PIN COTTER 5/32 X 1 1/4 LG

2 805-083C PIN CLEVIS 3/4 X 1 1/2

1 808-024C SPKT 40B12 X 1 BORE

3 808-046C SPKT 40A17 IDLER

1 809-096C #40 CONNECTOR LINK-PLATED

1 809-135C CHAIN RL #40 X 111 PITCH W/CON

1 818-811C DECAL DRILLS SPROCKET CHANGE

1 821-002C PAINT GP BLACK SPRAY CAN

2 822-032C FLANGETTE 52 MST

1 822-060C BEARING 1 BORE W/LOCK COLLAR

Great Plains Mfg., Inc.

EWD13 and EWF13 Sprocket Box Update 152-208M 5/2/06

6

Loading...

Loading...