Great Plains Electric Hydraulic Boom Solenoid Operator Manual

Operator’ s Manual

Electric Hydraulic Boom Solenoid

Manufacturing, Inc.

Read the operator’s manual entirely.Whenyouseethissymbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

1995+

21552

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 1998 Printed 4/17/2003

500-089M

Table of Contents

Important Safety Information. . . . . . . . . . . . . . . . . 1

Wear Protective Equipment . . . . . . . . . . . . . . . . 5

Handle Chemicals Properly . . . . . . . . . . . . . . . . 6

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Intended Usage . . . . . . . . . . . . . . . . . . . . . . 8

Models Covered. . . . . . . . . . . . . . . . . . . . . . 8

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . 8

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Owner Assistance. . . . . . . . . . . . . . . . . . . . . . . . 8

Preparation and Setup . . . . . . . . . . . . . . . . . . . . . . 9

Tractor Requirements. . . . . . . . . . . . . . . . . . . . . 9

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . 9

Trailer Sprayer Control Box Assembly . . . . . . . . 9

Solenoid Control Box Mount

(Units Other Than TS Sprayers). . . . . . . . . . . . 10

Hydraulic Valve/Boom Mount. . . . . . . . . . . . . . 10

Bypass Valve Assembly Instructions . . . . . . . . 12

Bypass Valve Adjustment. . . . . . . . . . . . . . . . . 14

Operating Instructions. . . . . . . . . . . . . . . . . . . . . 14

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing A Valve . . . . . . . . . . . . . . . . . . . . 15

Installing A Coil . . . . . . . . . . . . . . . . . . . . . 15

Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Torque Values Chart . . . . . . . . . . . . . . . . . . . . 19

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

© Copyright 1998Allrights Reserved

Great Plains Manufacturing, Inc. provides this publication“as is” without warranty of any kind, either expressed or implied. While every precaution has been takenin the

preparationofthismanual,GreatPlainsMan uf acturing,Inc.assumesno responsibility for errorsoromissions.Neither is any liabilityassumedfordamages resulting from

theuseof the information contained herein. Great Plains Manufacturing,Inc. reservestheright to reviseandimproveits products as it sees fit. This publication describes

the state of this product at the time of its publication, and may not reflect the product in the future.

Great Plains Manufacturing, Incorporated Trademarks

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

4/17/2003

500-089M

Important Safety Information

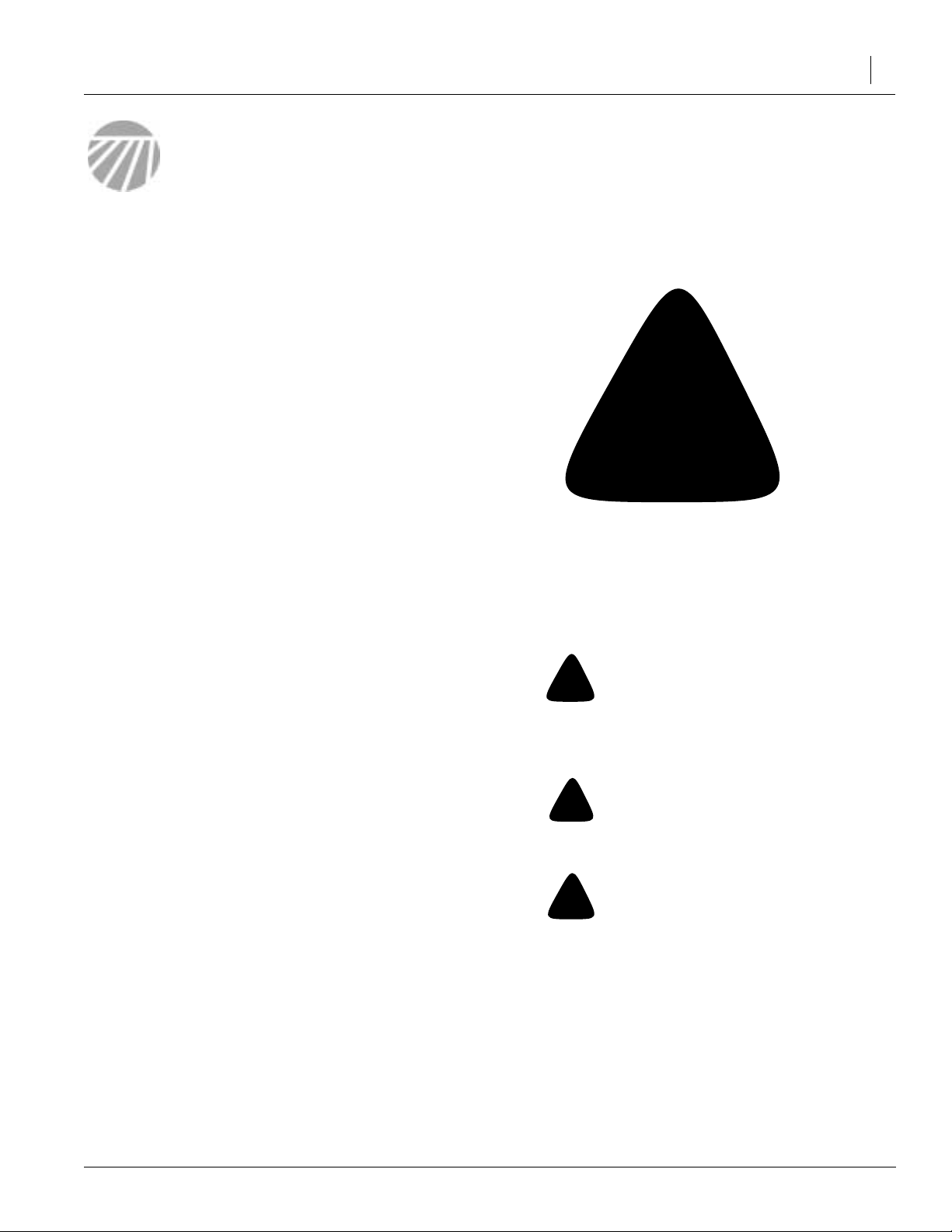

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

apotential hazard to personal safetyinvolvedand

extrasafety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

Important Safety Information

!

1

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations, typically for machine

components that, for functional purposes, cannot

be guarded.

WARNINGindicates a potentially hazardous situationwhich, if not avoided,could resultin death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be

used to alert against unsafe practices.

CAUTION indicates a potentially hazardous situation which, if not avoided,may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER

!

WARNING

!

CAUTION

!

4/17/2003

500-089M

Electric Hydraulic Boom Solenoid

2

Be Familiar with Safety Decals

▲ Read and understand “Safety Decals,” thor-

oughly.

▲ Read all instructions noted on the decals.

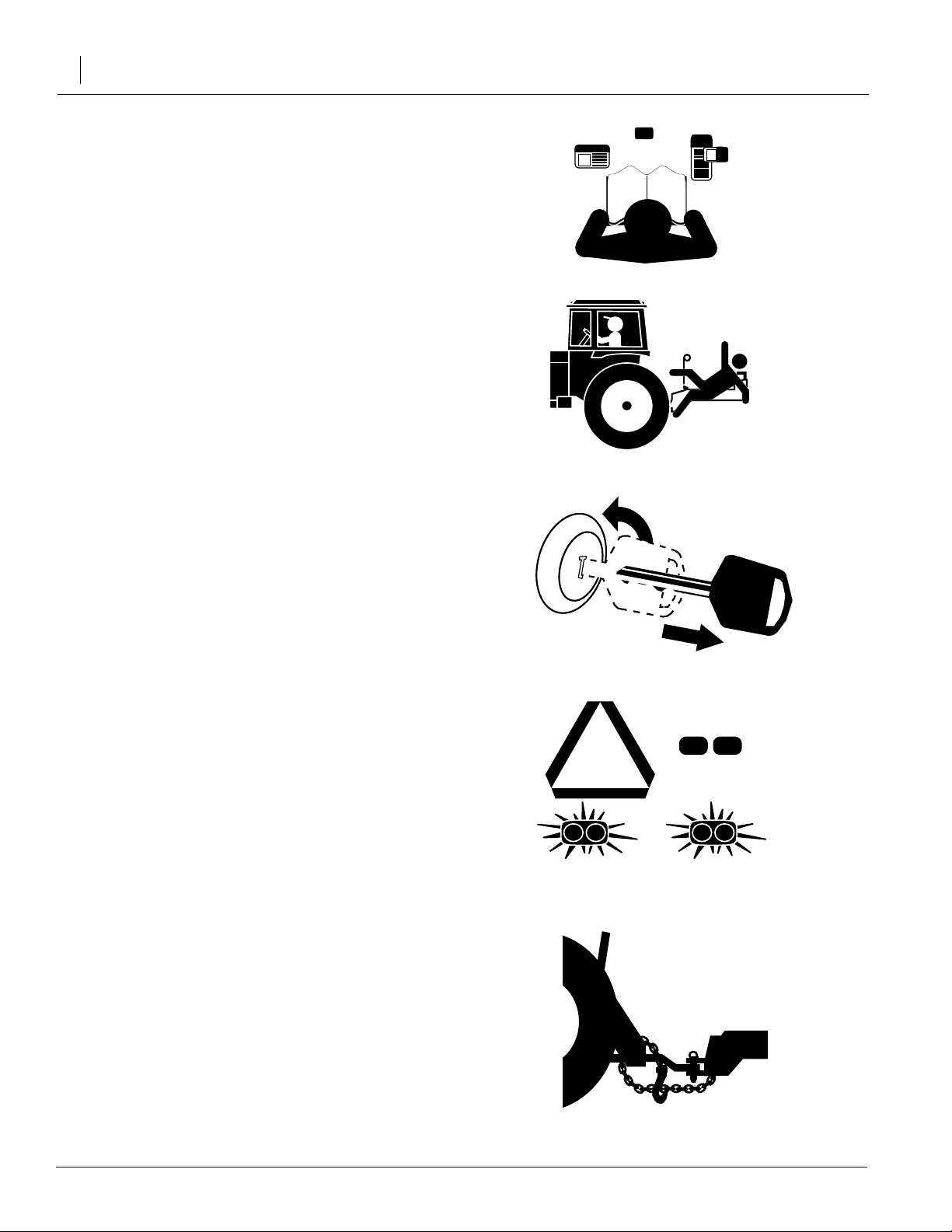

Keep Riders Off Machinery

Riders obstruct the operator’s view.Riders could

be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine dur-

ing operation.

Use Safety Lights and Devices

Slow-moving tractors and towed implements can

create a hazard when driven on public roads.

They are difficult to see, especially at night.

OFF

▲ Use flashing warning lights and turn signals

whenever driving on public roads.

▲ Use lights and devices provided with imple-

ment.

Use A Safety Chain

▲ Use a safety chain to help control drawn

machinery should it separate from tractor

drawbar.

▲ Use a chain with a strength rating equal to or

greater than the gross weight of towed

machinery.

▲ Attach chain to tractor drawbar support or

other specified anchor location. Allow only

enough slack in chain to permit turning.

▲ Replace chain if any links or end fittings are

broken, stretched or damaged.

▲ Do not use safety chain for towing.

500-089M

4/17/2003

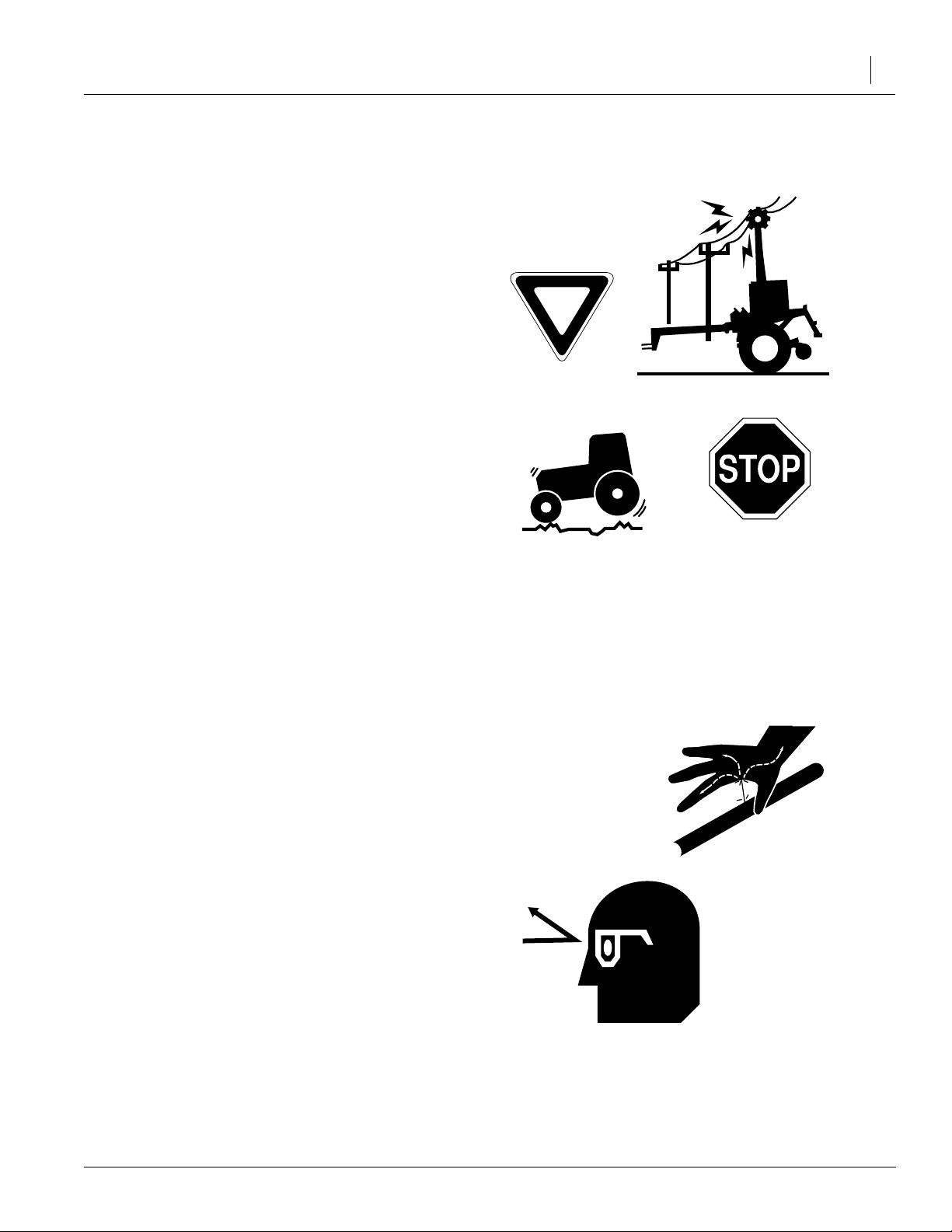

Transport Machinery Safely

Maximum transport speed for implement is 20

mph. Some rough terrains require a slower

speed.Sudden brakingcan cause atowed loadto

swerve and upset.

▲ Do not exceed 20 mph. Never travel at a

speed which does not allow adequate control

of steering and stopping. Reduce speed if

towed load is not equipped with brakes.

▲ Comply with state and local laws.

▲ Do not tow an implement that, when fully

loaded, weighs more than 1.5 times the weight

of towing vehicle.

▲ Carry reflectors or flags to mark implement in

case of breakdown on the road.

▲ Keep clear of overhead power lines and other

obstructions when transporting.

Important Safety Information

3

▲ Do not fold or unfold the sprayer while the trac-

tor is moving.

Avoid High Pressure Fluids

Escaping fluid under pressure can penetrate the

skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before

disconnecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected leaks.

▲ Wear protective gloves and safety glasses or

goggles when working with hydraulic systems.

▲ If an accident occurs, see a doctor immedi-

ately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene may result.

4/17/2003

500-089M

Electric Hydraulic Boom Solenoid

4

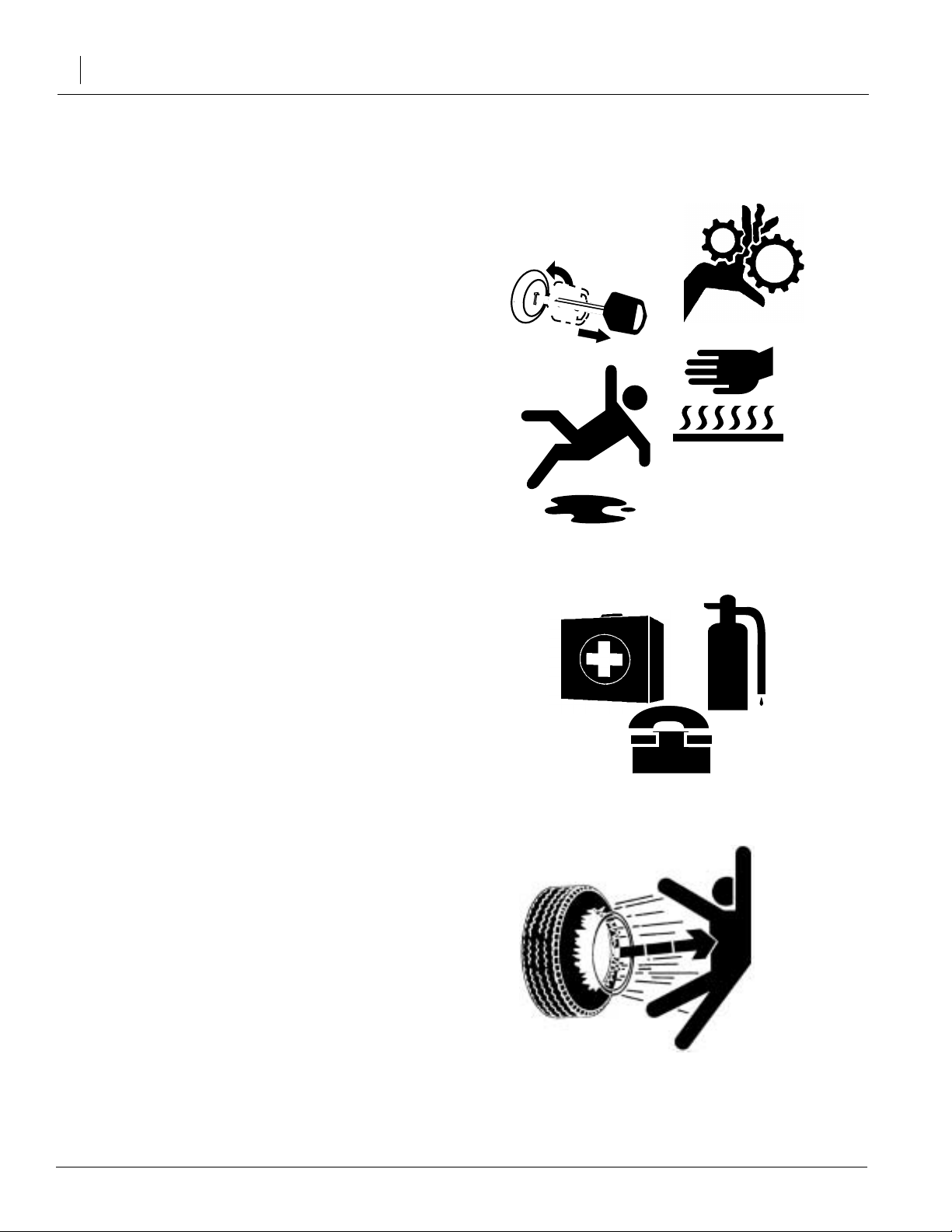

Practice Safe Maintenance

▲ Understand procedure before doing work. Use

proper tools and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Put tractor in park, turn off engine, and

remove key before performing maintenance.

▲ Make sure all moving parts have stopped and

all system pressure is relieved.

▲ Allow sprayer to cool completely.

▲ Disconnect battery ground cable (-) before

servicing or adjusting electrical systems or

before welding on sprayer.

▲ Inspect all parts. Make sure parts are in good

condition and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from

sprayer before operation.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambu-

lance, hospital and fire department near

phone.

Tire Safety

Tire changing can be dangerous and should be

performed by trained personnel using correct

tools and equipment.

OFF

911

▲ When inflating tires, use a clip-on chuck and

extension hose long enough for you to stand

to one side–not in front of or over tire assembly. Use a safety cage if available.

▲ When removing and installing wheels, use

wheel-handling equipment adequate for

weight involved.

500-089M

4/17/2003

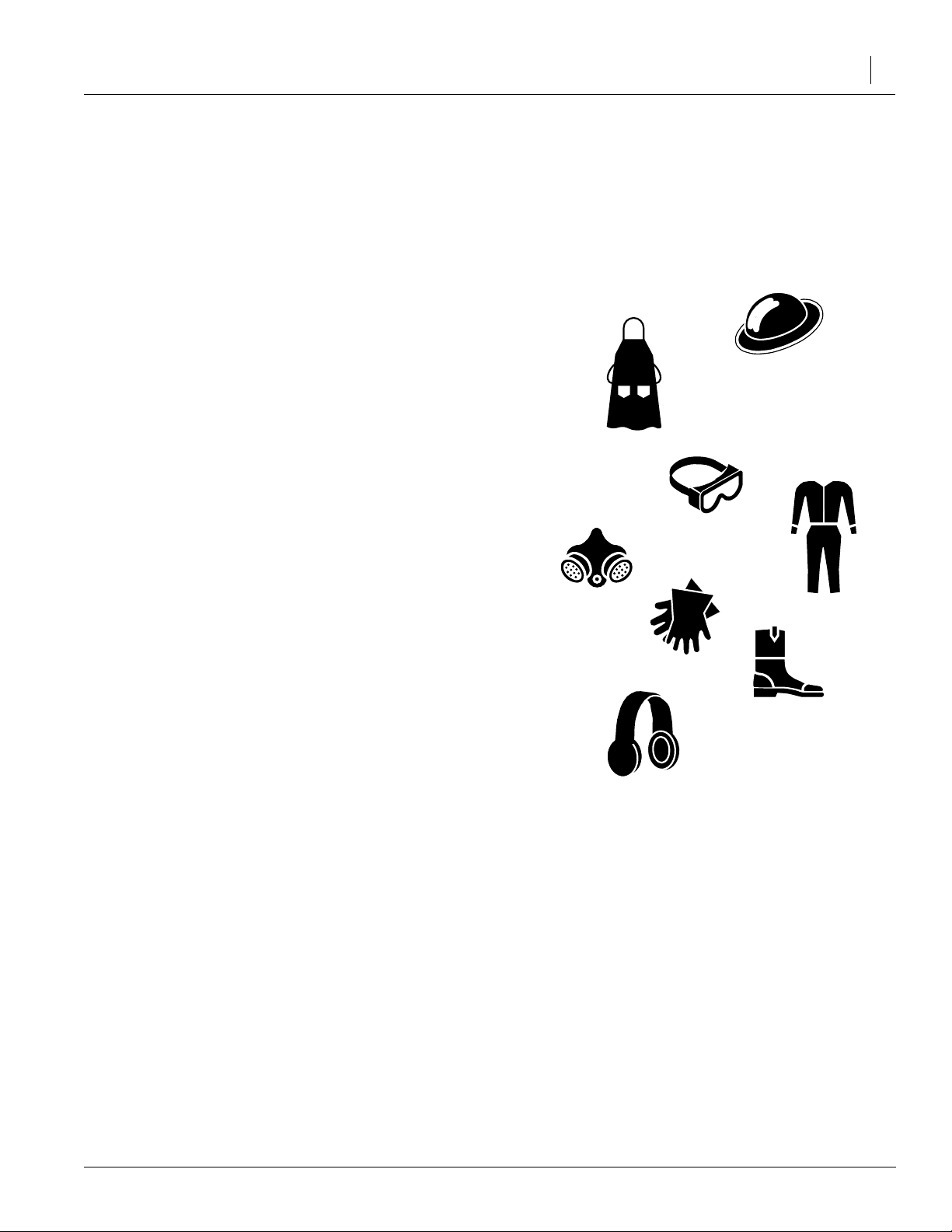

Wear Pr otective Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety

equipment.

▲ Waterproof, wide-brimmed hat

▲ Waterproof apron.

▲ Face shield, goggles or full face respirator.

▲ Goggles with side shields or a full face respirator is

required if handling or applying dusts, wettable powders, or granules or if being exposed to spray mist.

▲ Cartridge-type respirator approved for pesticide

vapors unless label specifies another type of respirator.

▲ Waterproof, unlined gloves. Neoprene gloves are

recommended.

Important Safety Information

5

▲ Cloth coveralls/outer clothing changed daily; water-

proof items if there is a chance of becoming wet with

spray

▲ Waterproof boots or foot coverings

▲ Do not wear contaminated clothing. Wash protective

clothing and equipment with soap and water after

each use. Personal clothing must be laundered separately from household articles.

▲ Clothing contaminated with certain pesticides must

be destroyed according to state and local regulations. Read chemical label for specific instructions.

▲ Wear clothing and equipment appropriate for the job.

Avoid loose-fitting clothing.

▲ Prolonged exposure to loud noise can cause hear-

ing impairment or loss. Wear suitable hearing protection such as earmuffs or earplugs.

▲ Avoid wearing radio headphones while operating

machinery. Operating equipment safely requires the

full attention of the operator.

4/17/2003

500-089M

Loading...

Loading...