Page 1

Installation, Operation and

Maintenance

195-075A, 195-076A, 195-077A, 195-078A

Electric Clutch Package

2- and 3-Section Drills

Manufacturing, Inc.

www.greatplainsmfg.com

Read this manual entirely. When you see this alert symbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

28072

Cover illustration may not show specific package ordered.

© Copyright 2008 Printed 03/24/2009 195-073M

Page 2

Page 3

Great Plains Manufacturing, Inc.

Table of Contents

Important Safety Information ....................................1

General Information ...................................................3

Notations and Conventions ..........................................3

Call-Outs ..................................................................3

Pre-Assembly Preparation ........................................4

Before You Start...........................................................4

Tools Required .............................................................4

Work Location ..............................................................4

Prepare Drill .................................................................4

Install Kit.......................................................................4

2S-2600 Main Box Only Installation..........................5

Update 2S-2600 Left Hand Drive .................................5

Remove 2S-2600 LH Linkage ..................................5

Remove 2S-2600 LH Shaft and Clutch ....................5

Disassemble 2S-2600 LH Clutch..............................6

Pre-Assemble 2S-2600 LH Clutch............................7

Prepare New 2S-2600 LH Power Shaft....................7

Install New 2S-2600 LH Power Shaft .......................8

Install 2S-2600 LH Clutch.........................................9

2S-2600 LH Closeout .............................................10

Update 2S-2600 Right Hand Drive.............................11

Remove 2S-2600 RH Linkage................................11

Release 2S-2600 RH Drive Shaft...........................11

Disassemble 2S-2600 RH Clutch...........................12

Pre-Assemble 2S-2600 RH Clutch.........................12

Install 2S-2600 RH Clutch ......................................13

2S-2600 RH Closeout.............................................14

Install 2S-2600 Electronics.........................................14

2S-2600F & 2S-2600 Small Seeds Installation .......15

Update 2S-2600F/SGS Left Hand Drive ....................15

Remove 2S-2600F/SGS LH Linkage......................15

Remove 2S-2600F/SGS LH Shaft and Clutch........16

Remove 2S-2600F/SGS LH Power Shaft...............16

Disassemble 2S-2600F/SGS LH Clutch.................17

Pre-Assemble 2S-2600F/SGS LH Clutch...............17

Prepare New 2S-2600F/SGS LH Power Shaft.......17

Install New 2S-2600F/SGS LH Power Shaft ..........18

Install 2S-2600F/SGS LH Clutch............................19

2S-2600F/SGS LH Closeout ..................................20

Update 2S-2600F/SGS Right Hand Drive ..................21

Remove 2S-2600F/SGS RH Linkage.....................21

Release 2S-2600F/SGS RH Drive Shaft................ 21

Disassemble 2S-2600F/SGS RH Clutch................ 22

Pre-Assemble 2S-2600F/SGS RH Clutch.............. 22

Install 2S-2600F/SGS RH Clutch ........................... 23

2S-2600F/SGS RH Closeout .................................24

Install 2S-2600F/SGS Electronics.............................. 24

2S Electrical Installation............................................. 25

Install 2S Height Switch .........................................25

Install 2S Drill Cables ............................................. 26

3S-3000 Main Box Only Installation ....................... 27

Update 3S-3000 Left Hand Drive............................... 27

Remove 3S-3000 LH Linkage ................................ 27

Remove 3S-3000 LH Shaft and Clutch .................. 27

Disassemble 3S-3000 LH Clutch ........................... 28

Pre-Assemble 3S-3000 LH Clutch ......................... 28

Prepare New 3S-3000 LH Power Shaft .................29

Install New 3S-3000 LH Power Shaft..................... 29

Install 3S-3000 LH Clutch ......................................30

3S-3000 LH Closeout............................................. 31

Update 3S-3000 Center Drive.................................... 32

Remove 3S-3000 Center Components .................. 32

Install 3S-3000 CTR Clutch Bearing ...................... 33

Install 3S-3000 CTR Driven Shaft .......................... 33

Prepare 3S-3000 CTR Driving Shaft...................... 34

Pre-Assemble 3S-3000 CTR Clutch ......................34

Install 3S-3000 CTR Clutch.................................... 35

3S-3000 Center Closeout....................................... 36

Update 3S-3000 Right Hand Drive ............................ 36

Remove 3S-3000 RH Linkage ...............................36

Replace 3S-3000 RH Drive Shafts......................... 37

Disassemble 3S-3000 RH Clutch........................... 38

Pre-Assemble 3S-3000 RH Clutch......................... 38

Install 3S-3000 RH Clutch...................................... 39

3S-3000 RH Closeout ............................................ 41

Install 3S-3000 Electronics ........................................ 41

3S-3000F & 3S-3000 Small Seeds Installation....... 42

Update 3S-3000F/SGS Left Hand Drive .................... 42

Remove 3S-3000F/SGS LH Linkage ..................... 42

Remove 3S-3000F/SGS LH Shaft and Clutch ....... 43

Disassemble 3S-3000F/SGS LH Clutch ................44

Pre-Assemble 3S-3000F/SGS LH Clutch ..............44

© Copyright 2008. All rights Reserved.

Great Plains Manufacturing, Inc. providesthis publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation

of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at

the time of its publication, and may not reflect the product in the future.

The following are trademarks of Great Plains Mfg., Inc.: Application Systems, Ausherman, Land Pride, Great Plains

All other brands and product names are trademarks or registered trademarks of their respective holders.

03/24/2009 195-073M

Great Plains Manufacturing, Incorporated Trademarks

Printed in the United States of America.

Page 4

Electric Clutch Package Great Plains Manufacturing, Inc.

Prepare New 3S-3000F/SGS LH Power Shaft....... 44

Install New 3S-3000F/SGS LH Power Shaft.......... 45

Install 3S-3000F/SGS LH Clutch ........................... 46

3S-3000F/SGS LH Closeout.................................. 47

Update 3S-3000F/SGS Center Drive......................... 48

Remove 3S-3000F/SGS Center Components ....... 48

Install 3S-3000F/SGS CTR Driven Shaft ............... 49

Prepare 3S-3000F/SGS CTR Driving Shaft........... 50

Pre-Assemble 3S-3000F/SGS CTR Clutch............ 50

Install 3S-3000F/SGS CTR Clutch......................... 51

3S-3000F/SGS Center Closeout............................ 52

Update 3S-3000F/SGS Right Hand Drive.................. 52

Remove 3S-3000F/SGS RH Linkage..................... 52

Replace 3S-3000F/SGS RH Drive Shafts.............. 53

Disassemble 3S-3000F/SGS RH Clutch................ 54

Pre-Assemble 3S-3000F/SGS RH Clutch.............. 55

Install 3S-3000F/SGS RH Clutch........................... 56

3S-3000F/SGS RH Closeout .................................58

Install 3S-3000F/SGS Electronics.............................. 58

3S-3000/F/SGS Electrical Installation........................ 59

Install 3S-3000 Height Switch ................................ 59

Install 3S-3000/F/SGS Drill Cables........................ 60

3S-4000 Installation ................................................. 61

Update 3S-4000 Left Hand Drive............................... 61

Remove 3S-4000 LH Linkage................................ 61

Remove 3S-4000 LH Shaft and Clutch.................. 61

Disassemble 3S-4000 LH Clutch ........................... 62

Pre-Assemble 3S-4000 LH Clutch ......................... 63

Prepare New 3S-4000 LH Power Shaft .................63

Install New 3S-4000 LH Power Shaft..................... 63

Install 3S-4000 LH Clutch ......................................64

3S-4000 LH Closeout............................................. 65

Update 3S-4000 Center Drive.................................... 66

Remove 3S-4000 CTR Linkage ............................. 66

Remove 3S-4000 CTR Mechanical Clutch ............66

Disassemble 3S-4000 CTR Clutch ........................67

Pre-Assemble 3S-4000 CTR Clutch ......................67

Install 3S-4000 CTR Clutch ................................... 68

3S-4000 Center Closeout ...................................... 69

Update 3S-4000 Right Hand Drive ............................ 69

Remove 3S-4000 RH Linkage ...............................69

Release 3S-4000 RH Input Shaft........................... 70

Disassemble 3S-4000 RH Clutch........................... 71

Pre-Assemble 3S-4000 RH Clutch......................... 71

Install 3S-4000 RH Clutch...................................... 72

3S-4000 RH Closeout ............................................ 73

Install 3S-4000 Electronics ........................................ 73

3S-4000F & SGS Installation................................... 74

Update 3S-4000F/SGS Left Hand Drive.................... 74

Remove 3S-4000F/SGS LH Linkage..................... 74

Remove 3S-4000F/SGS LH Shaft and Clutch....... 75

Disassemble 3S-4000F/SGS LH Clutch ................ 76

Pre-Assemble 3S-4000F/SGS LH Clutch .............. 76

Prepare New 3S-4000F/SGS LH Power Shaft ...... 76

Install New 3S-4000F/SGS LH Power Shaft.......... 77

Install 3S-4000F/SGS LH Clutch ........................... 78

3S-4000F/SGS LH Closeout.................................. 79

Update 3S-4000F/SGS Center Drive ........................ 80

Remove 3S-4000F/SGS CTR Linkage .................. 80

Remove 3S-4000F/SGS CTR Mechanical Clutch . 80

Disassemble 3S-4000F/SGS CTR Clutch ............. 81

Pre-Assemble 3S-4000F/SGS CTR Clutch ........... 81

Install 3S-4000F/SGS CTR Clutch ........................ 82

3S-4000F/SGS Center Closeout ........................... 83

Update 3S-4000F/SGS Right Hand Drive ................. 83

Remove 3S-4000F/SGS RH Linkage .................... 83

Release 3S-4000F/SGS RH Drive Shaft ............... 84

Disassemble 3S-4000F/SGS RH Clutch ............... 85

Pre-Assemble 3S-4000F/SGS RH Clutch ............. 85

Install 3S-4000F/SGS RH Clutch........................... 86

3S-4000F/SGS RH Closeout ................................. 87

Install 3S-4000 Electronics ........................................ 87

3S-4000 Electrical Installation ................................... 88

Install 3S-4000 Height Switch................................ 88

Install 3S Drill Cables............................................. 89

Close-Out ................................................................. 90

Install Switch Module in Cab ..................................... 90

Adjust Height Switch.................................................. 90

Operations................................................................ 91

Normal Full Pass ....................................................... 91

Point Row .................................................................. 91

Troubleshooting......................................................... 91

Maintenance............................................................. 92

Electric Clutch Lockup ............................................... 92

Appendix .................................................................. 93

Torque Chart ............................................................. 93

New Parts .................................................................. 94

Kit Contents ............................................................... 94

Existing Parts Affected .............................................. 97

Abbreviations............................................................. 98

Index ......................................................................... 99

195-073M 03/24/2009

Page 5

Great Plains Manufacturing, Inc. 1

Important Safety Information

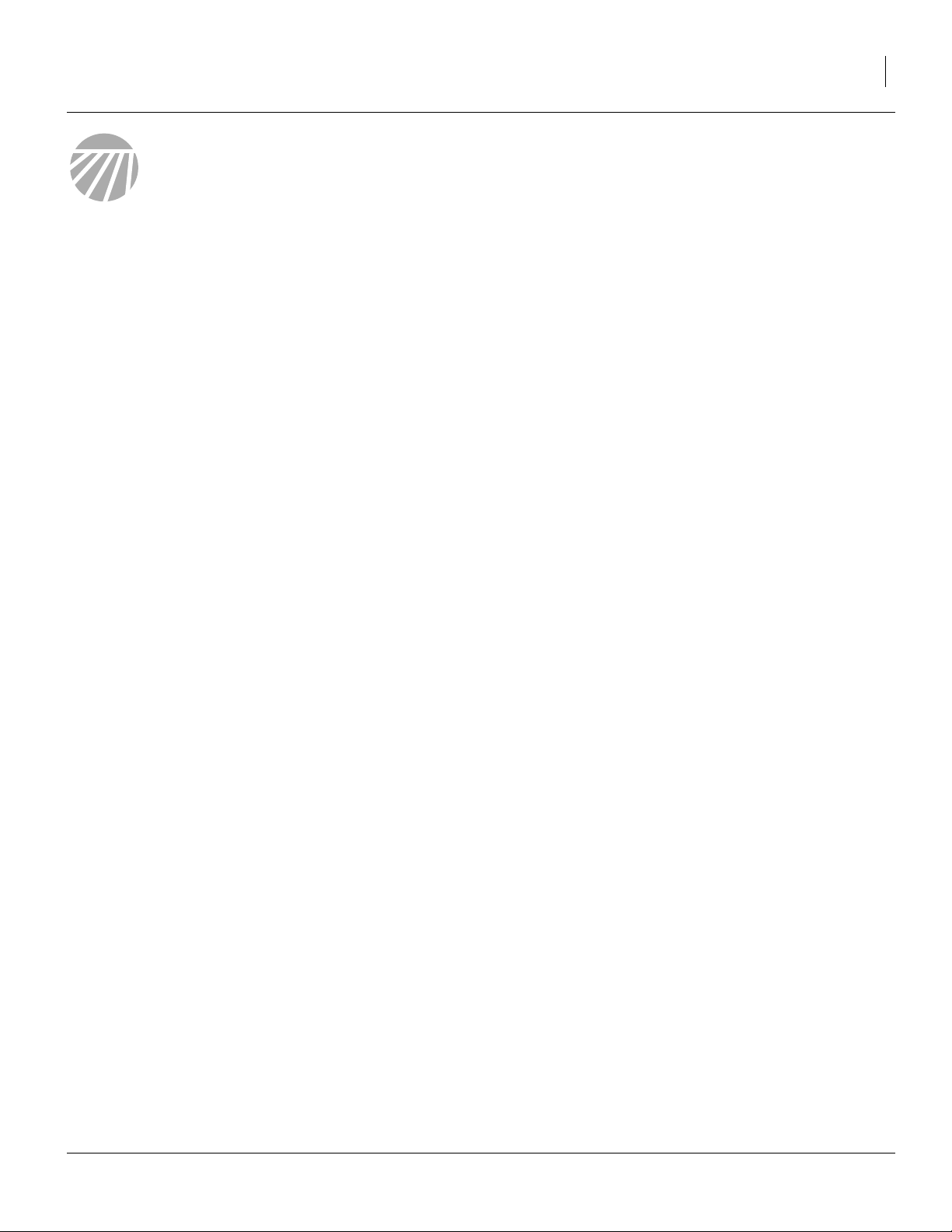

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This signal word is limited to the most extreme situations,

typically for machine components that, for functional purposes, cannot be guarded.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert against

unsafe practices.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices.

!

!

!

!

DANGER

WARNING

CAUTION

Be Familiar with Safety Decals

▲ Read and understand “Safety Reflectors and Decals”in

your Operator manual.

▲ Read all instructions noted on the decals.

03/24/2009 195-073M

Page 6

2 Electric Clutch Package Great Plains Manufacturing, Inc.

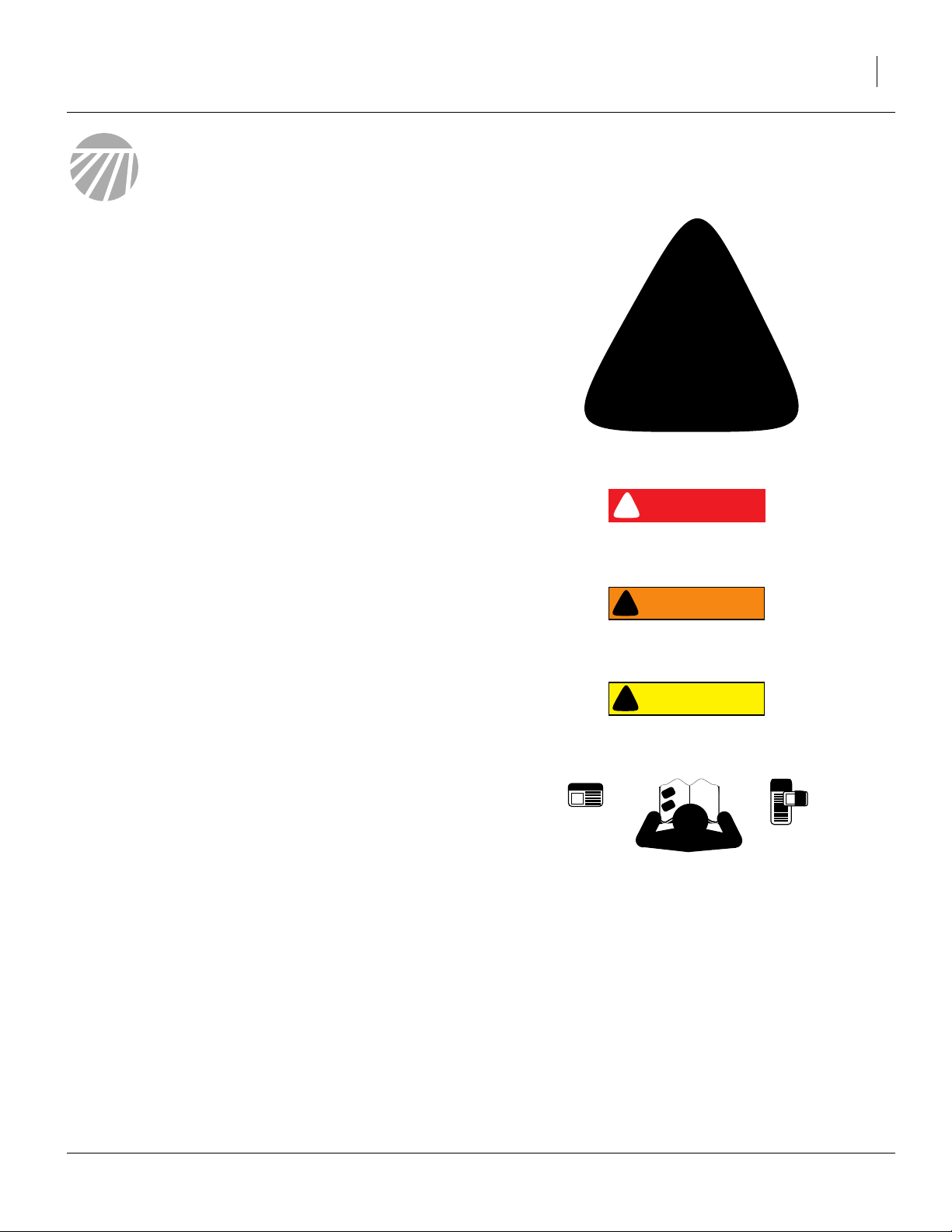

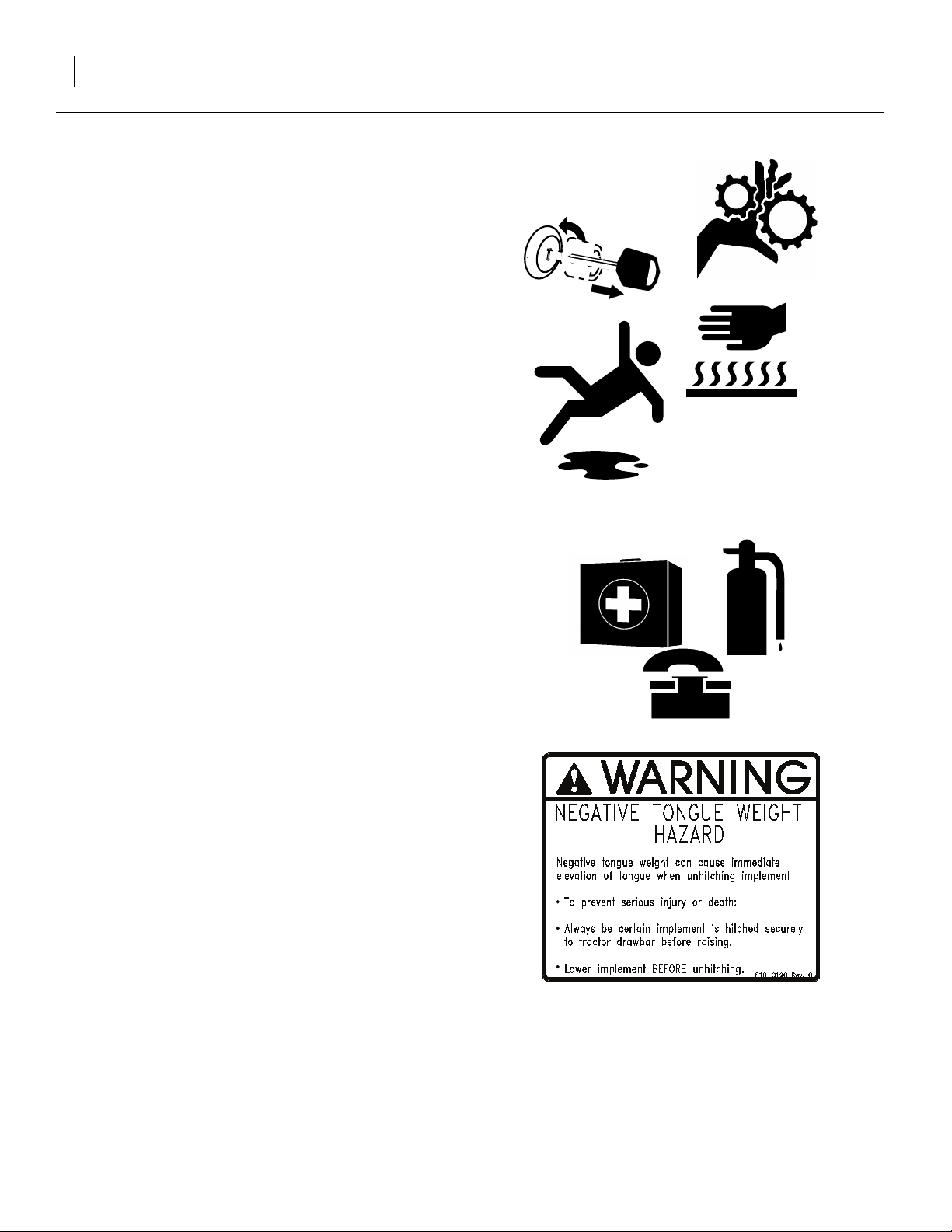

Practice Safe Maintenance

▲ Understand procedure before doing work. Use proper tools

and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Make sure all moving parts have stopped and all system

pressure is relieved.

▲ Inspect all parts. Make sure parts are in good condition and

installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from implement before

operation.

OFF

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambulance, hospital

and fire department near phone.

Safety At All Times

▲ Thoroughly read and understand the instructions in this

manual before operation. Read all instructions noted on the

safety decals.

▲ Be familiar with all implement functions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave implement unattended with tractor engine

running.

▲ Wear snug-fitting clothing to avoid entanglement with mov-

ing parts.

911

195-073M 03/24/2009

Page 7

Great Plains Manufacturing, Inc. 3

General Information

These packages replace the standard lift-actuated

mechanical clutches on each section with electric

clutches control both by a single drill lift switch and by

cab module section switches. This is an alternative way

to provide point row capability, where point row operations do not require raising the non-planting sections

These instructions explain how to install an Electric

Clutch Package, provided as one of four kits:

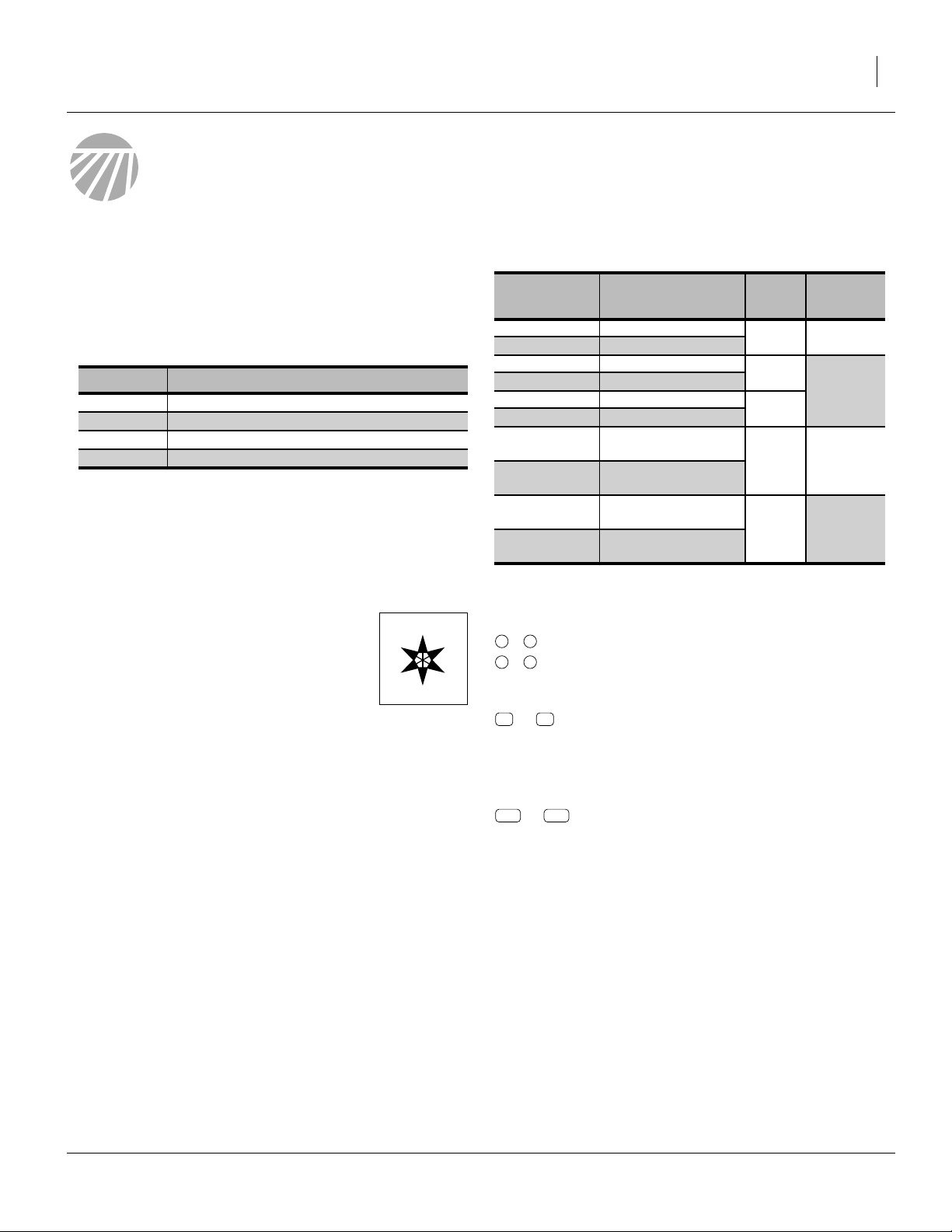

Kit Kit Description

195-075A 3S-40 ELEC CL PKG SML SDS-FERT

195-076A 2S-2600 ELEC CLUTCH PKG

195-077A 2S-26 ELEC CL PKG SML SDS-FERT

195-078A 3S-3000 ELECTRIC CLUTCH PKG

Note: These instructions do not cover the case of adding

electric clutches to a drill which has previously had

the Point Row option installed. In such an unlikely

case, please have the Great Plains dealer contact

the factory for further instructions.

Notations and Conventions

“Left” and “Right” are facing in the direction of machine travel. An orientation rose

in many figures shows the directions of

Left, Right, Front, Back, Up, Down.

Note: Many figures show fully exploded views. Remove

only specified parts.

A crucial point of information related to the preceding

topic. Read and follow the directions provided before

continuing, to ensure safety, avoidance of machine

damage, and to achieve desired field results.

Note: Useful information related to the preceding topic.

A glossary of abbreviations used in part descriptions is

available on page 98.

U

F

L

R

B

D

Each kit updates one drill. Kits are specific to the number

of drill sections, and on 2S-2600, whether or not the

Small Seeds and/or Fertilizer Options are also present:

Drill

Drill Model

2S-2600 s/n DD1152+

2S-2600HD

2S-2600 s/n DD1152+

2S-2600HD

2S-2600F s/n DD1152+

2S-2600HDF

3S-3000

3S-3000F

3S-3000HD

3S-3000HDF

4S-4000

4S-4000F

4S-4000HD

4S-4000HDF

Vintage

any

any

any

1996+, s/n S1563+

any

s/n YY1152+

any

Small

Seeds

No 195-076A

Ye s

n/a

any 195-078A

any 195-075A

Uses

Kit

195-077A

Call-Outs

1 9

-,

a z

-

11 61

to

101 138

to

Single-digit/letter callouts identify components in the currently referenced Figure or

Figures. These references are reused for different items from section to section.

Two-digit callouts in the range 11 to 61 reference new parts from the new parts lists

beginning on page 94. The descriptions

match those on the parts, bags or cartons,

and in your updated Parts Manual.

Three-digit callouts in the range 101 to 138

reference affected existing parts from the

table on page 97. The descriptions match

those in your Parts Manual. The narrative

and table indicate any re-use of the parts.

03/24/2009 195-073M

Page 8

4 Electric Clutch Package Great Plains Manufacturing, Inc.

Pre-Assembly Preparation

Before You Start

• If the drill is not an “HD” model, check (against the

table on page 3) the drill serial number and production

date to ensure it has existing parts compatible with the

kit. Electric clutch kits are not available for earlier drills.

• Inventory: make sure all parts are present. A complete

material list begins on page 94.

• Comprehension: review this manual make sure the

installers understand where each part or assembly is

installed, and what tools are required for the task.

Tools Required

• updated drill parts manual,

• tractor (installing cab control module requires access

to the tractor used in field operations with this drill),

• 23 foot or longer cable snake,

• scrap wire for tying springs in compression,

• basic hand tools, including:

- punch for driving out

5

-

⁄

in long-arm hex wrench.

32

1

⁄

in roll pins

4

Work Location

1. Move the drill to a location with:

• room to unfold it, and;

• adequate illumination.

Prepare Drill

Consult Operator Manual if any steps are unfamiliar.

2. Unfold the drill:

• Fully unfold a 2S drill.

• Partially unfold a 3S drill. Stop unfolding before

the right transfer drive jaws come into line with

the center section jaws, so that center shaft can

be removed, and the right hand shaft moved left.

3. Remove transport locks and lower the drill.

Lower the row units.

4. Put tractor in Park, and shut down.

Install Kit

Installation is described separately for each kit:

2-Section, main box only, 195-076A kitpage 5

2-Section, w/Option box(es), 195-077A kitpage 15

3S-3000, main box only, 195-078A kitpage 27

3S-3000, w/option box(es), 195-078A kitpage 42

3S-4000, main box only, 195-075A kitpage 61

3S-4000, w/option box(es), 195-075A kitpage 74

Note: This manual has you update one drill section at a

time, to prevent part confusion. Parts are different

for each drill section (bolt lengths in particular).

If you dismantle all removed hardware at once,

there is risk of re-installing incorrect parts from

another drill section.

195-073M 03/24/2009

Page 9

Great Plains Manufacturing, Inc. Update 2S-2600 Left Hand Drive 5

2S-2600 Main Box Only Installation

This section describes installation of kit 195-076A for:

• 2S-2600 s/n DD1152+ drills with only a main seed

box, and no Small Seeds or Fertilizer options, or;

• 2S-2600HD drills with only a main seed box, and

no Small Seeds or Fertilizer options.

Update 2S-2600 Left Hand Drive

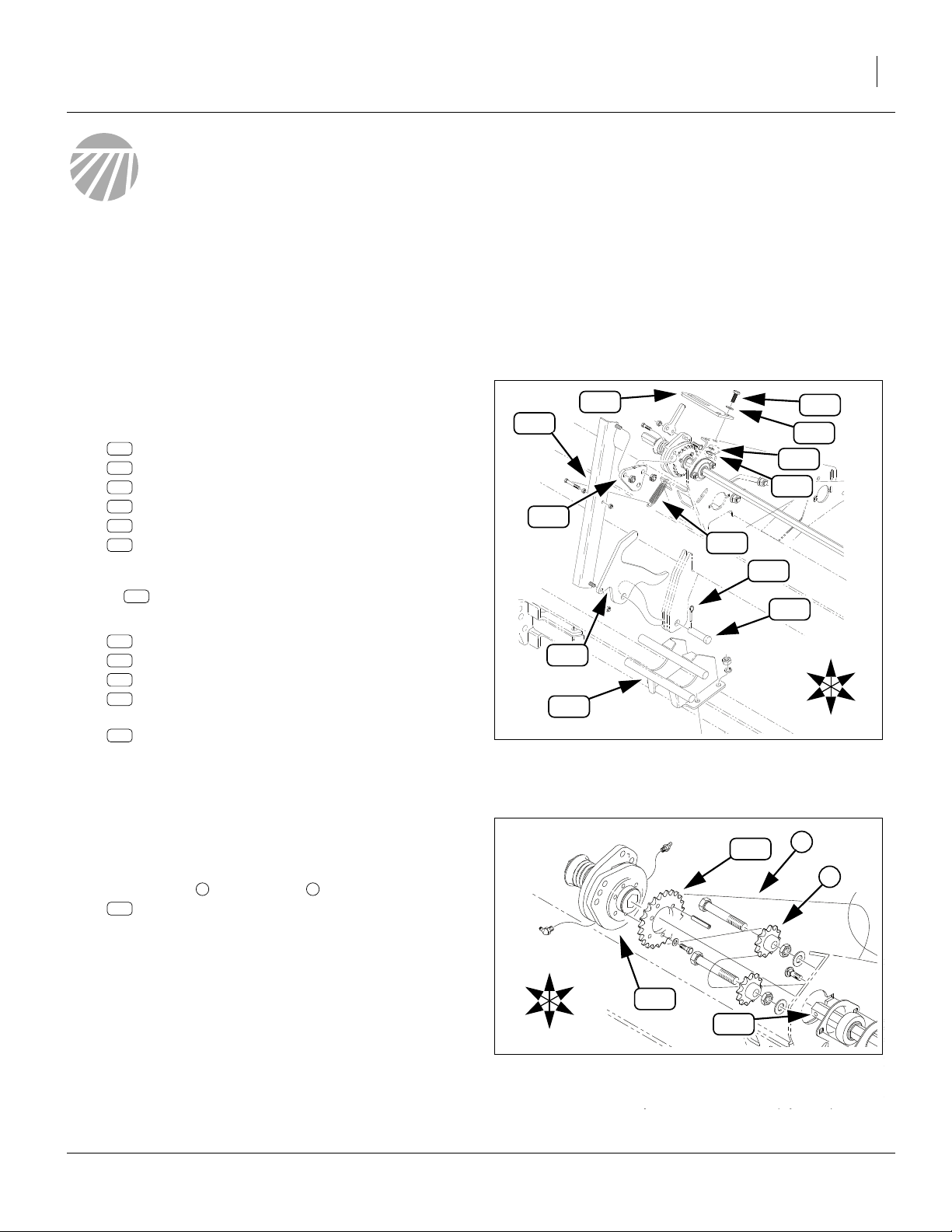

Remove 2S-2600 LH Linkage

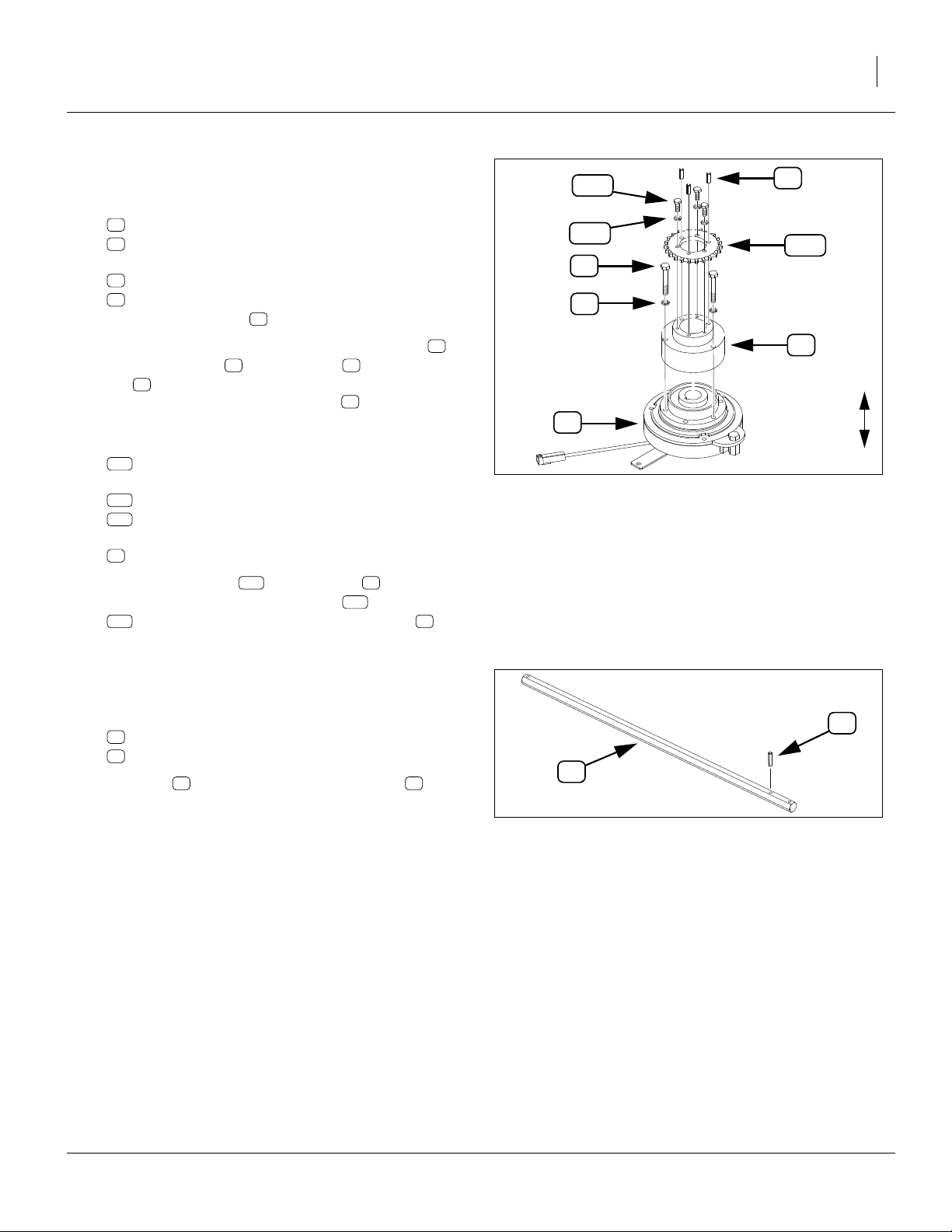

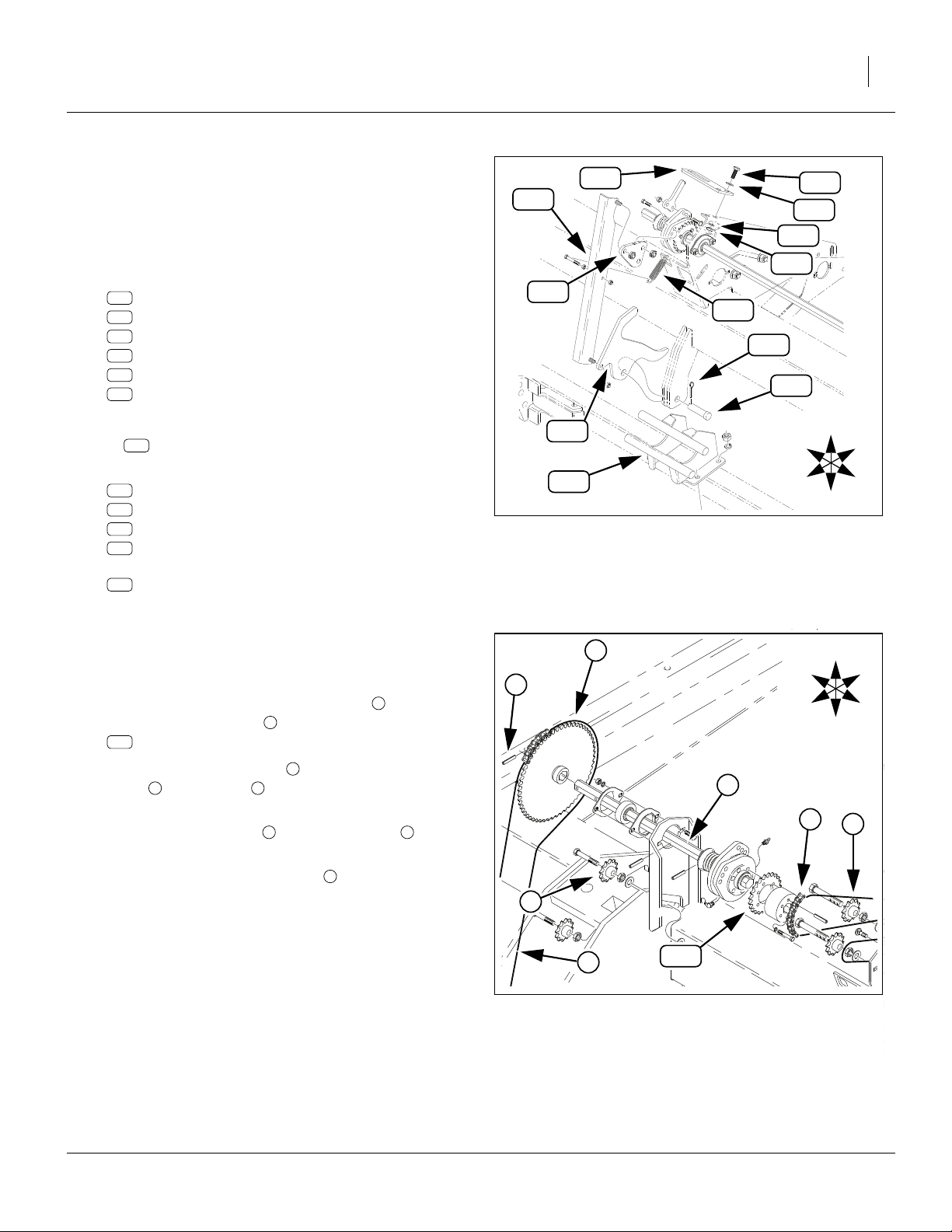

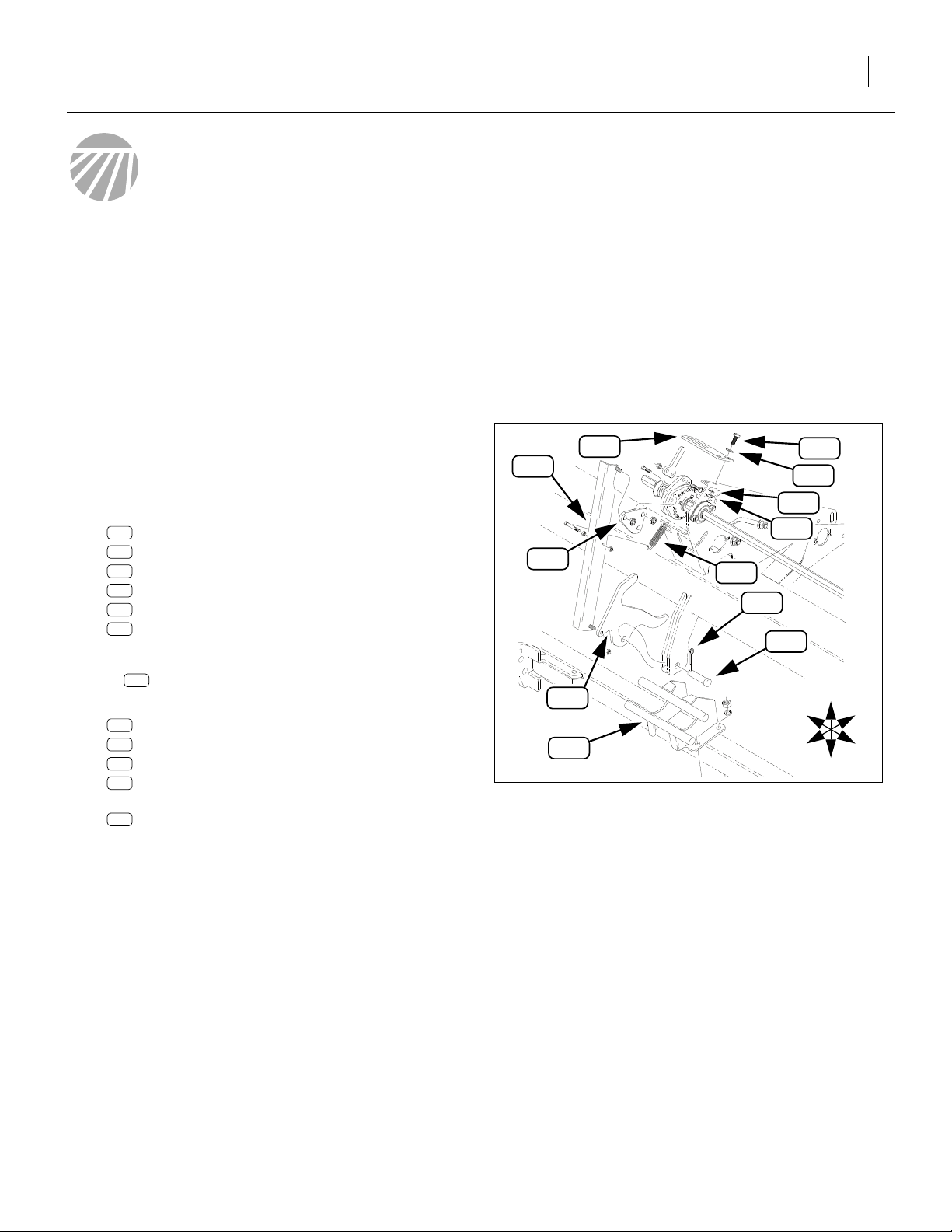

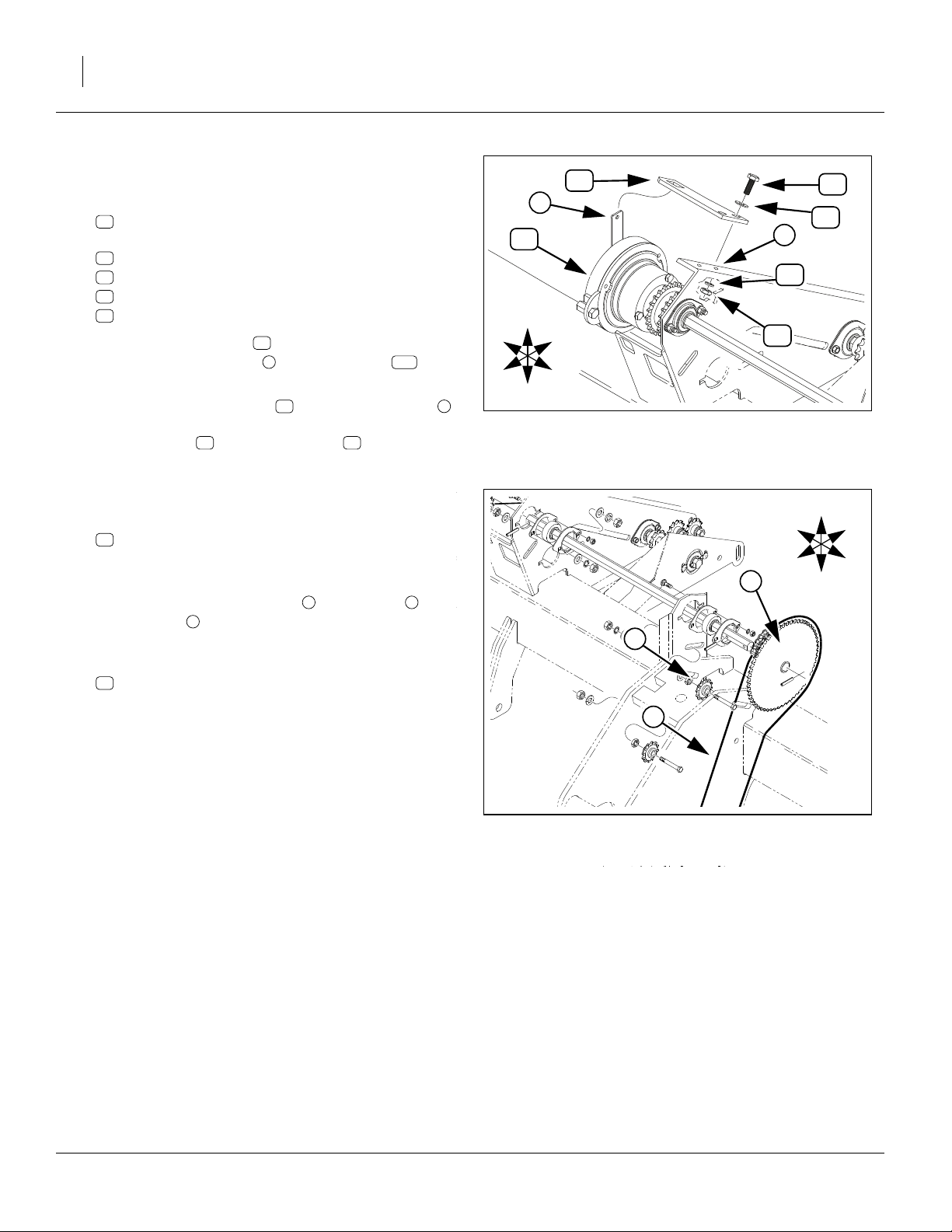

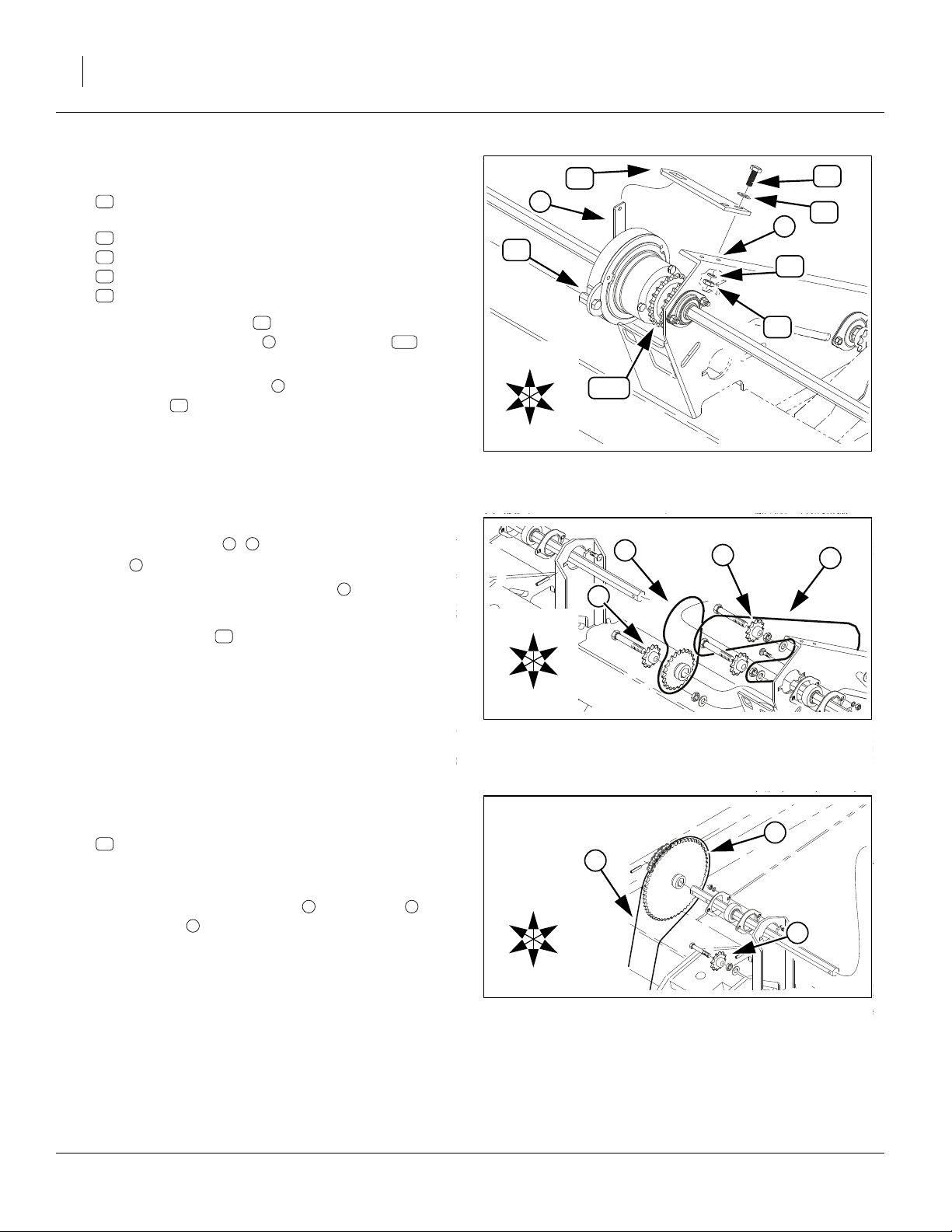

Refer to Figure 1

5. Remove individually or as an assembly:

106

195-130H CLUTCH SHUTOFF LINK, 00 SERIES

108

195-144D CLUTCH SHUTOFF CAM, 00 SERIES

118

195-254D CLUTCH PULL TAB

132

805-083C PIN CLEVIS 3/4 X 1 1/2

133

805-109C PIN COTTER 1/8 X 1 1/4 PLT

134

807-072C SPRING EXT 1 1/16 ODX.120WX5.5

These parts are not re-used.

Note: This part may be removed or left in place:

107

195-131H SUBFRM CLUTCH BRKT,SOLID STAND

6. Remove two sets:

124

802-079C HHCS 3/8-16X1 1/4 GR5

129

804-011C WASHER FLAT 3/8 USS PLT

130

804-013C WASHER LOCK SPRING 3/8 PLT

127

803-014C NUT HEX 3/8-16 PLT

and remove the:

101

152-263D CLUTCH ENGAGE TAB

These parts are not re-used.

For other kits, see:

2S-2600, w/option box(es), 195-077A kitpage 15

3S-3000, main box only, 195-078A kitpage 27

3S-3000, w/option box(es), 195-078A kitpage 42

3S-4000, main box only, 195-075A kitpage 61

3S-4000, w/option box(es), 195-075A kitpage 74

101

106

124

129

130

127

118

134

133

132

108

R

107

Figure 1: 2S-2600:

Remove LH Linkage

F

U

B

L

D

17253

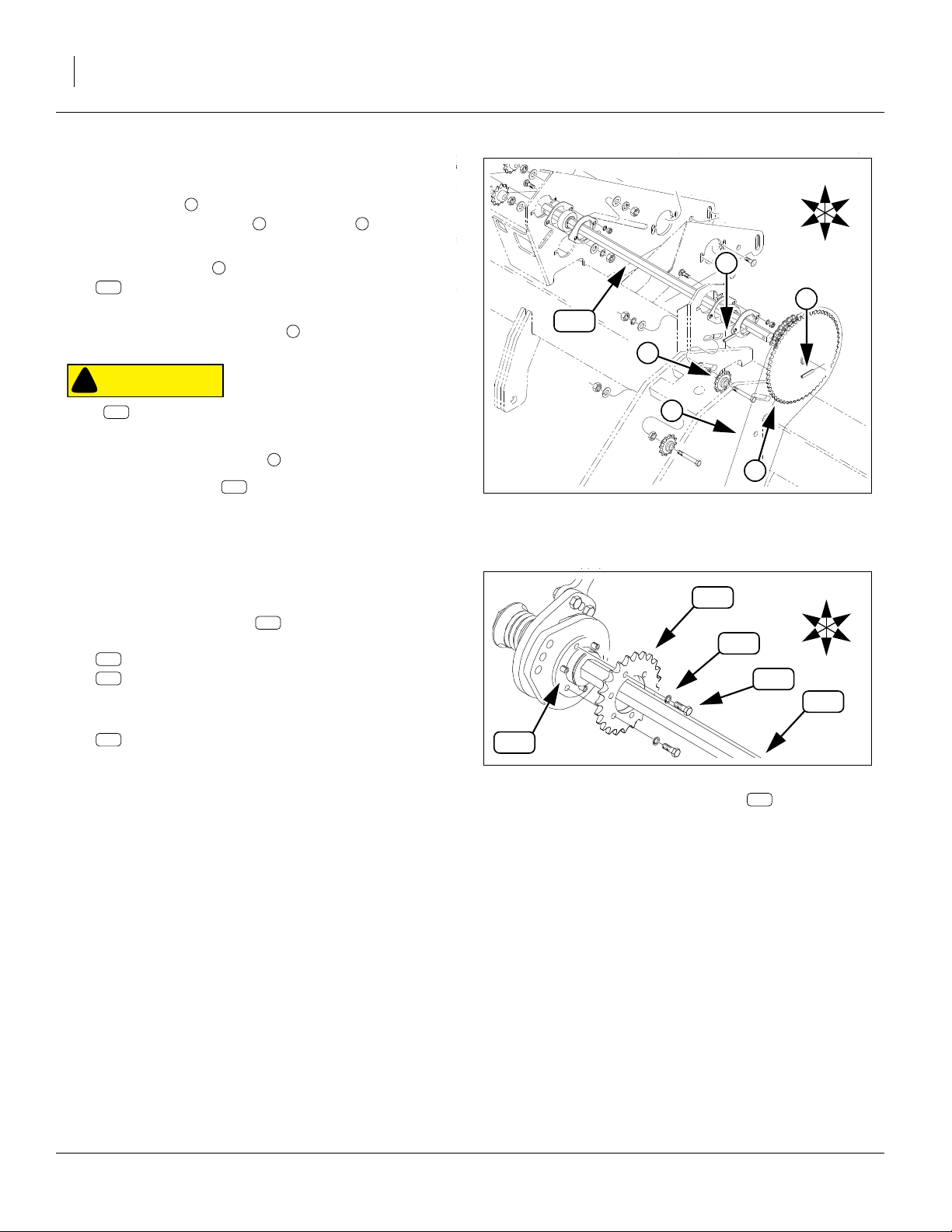

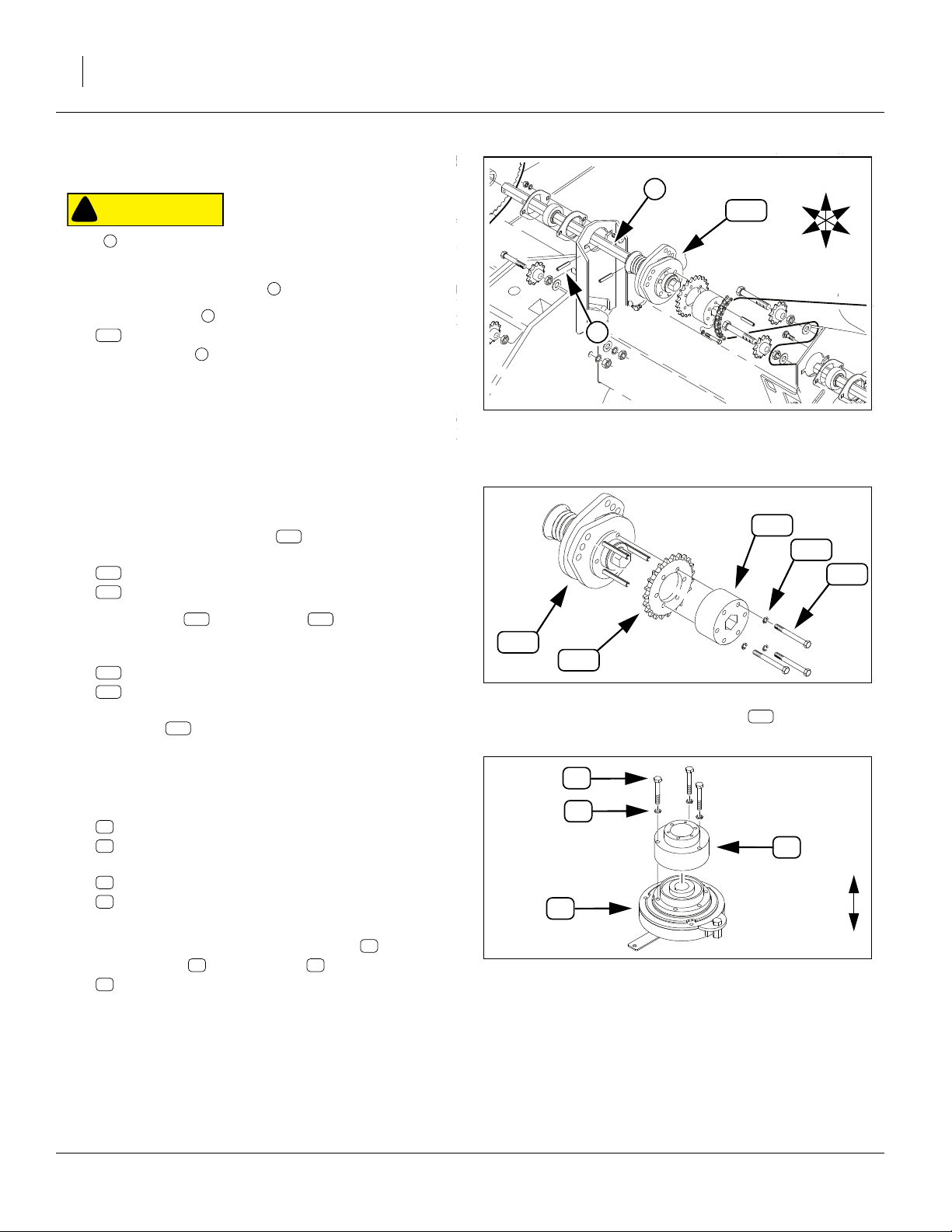

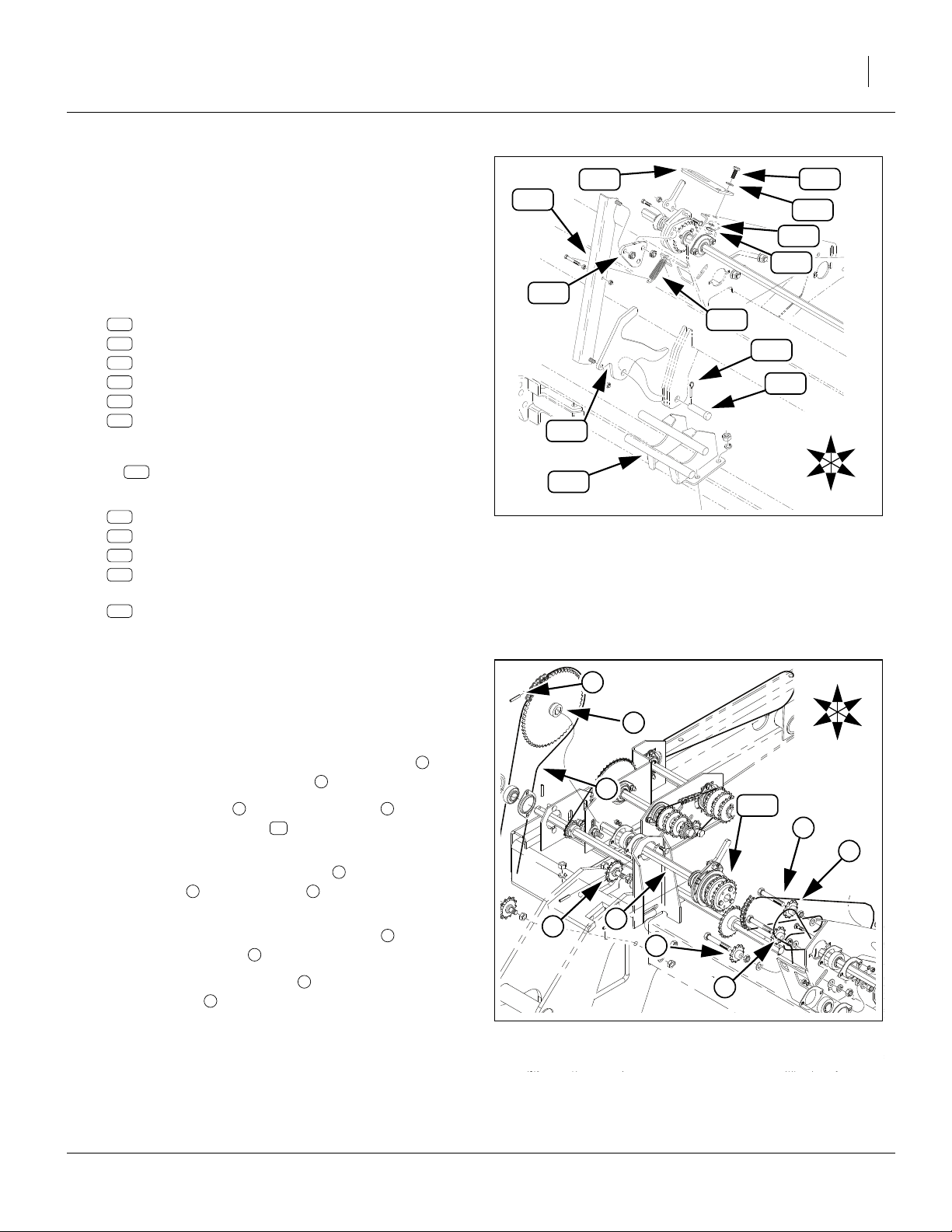

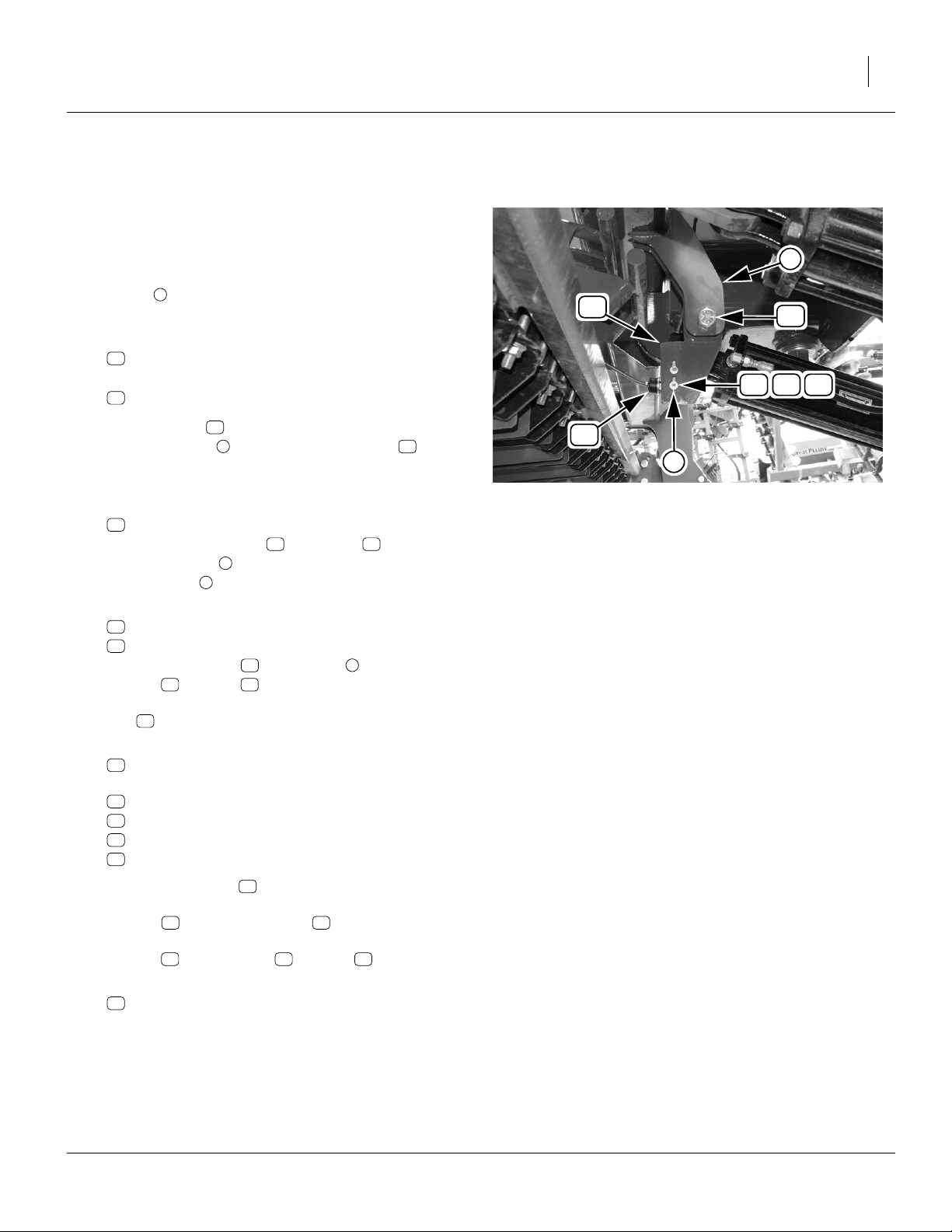

Remove 2S-2600 LH Shaft and Clutch

Dismount Clutch Output Chain

Refer to Figure 2

7. Loosen idler and lift chain off of sprocket:

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

Do not completely remove the chain.

i n

136

n

i

U

R

B

102

F

L

115

D

Figure 2: 2S-2600:

Dismount LH Clutch Chain

03/24/2009 195-073M

21627

Page 10

6 Electric Clutch Package Great Plains Manufacturing, Inc.

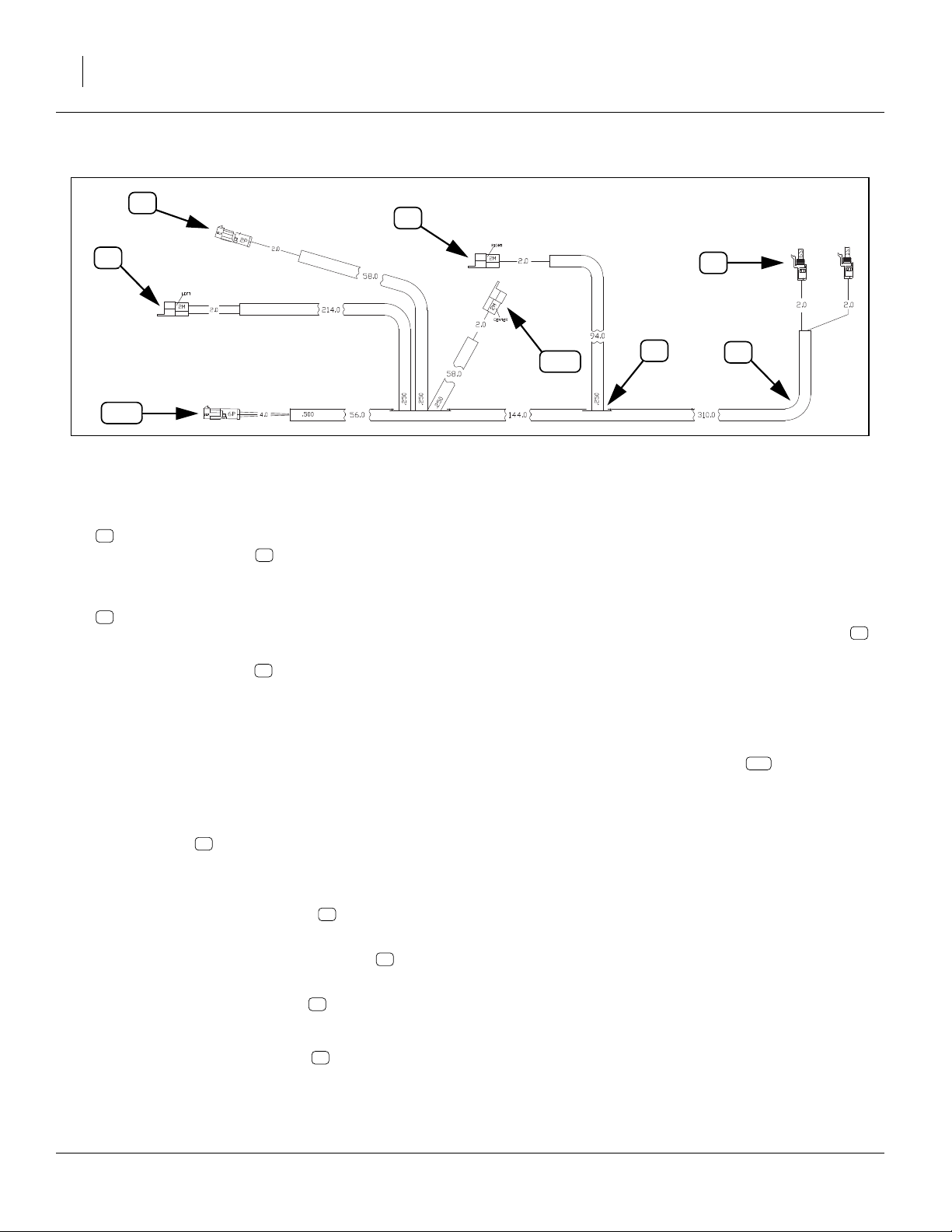

Dismount Ground Drive Chain & Sprocket

R

F

U

B

L

D

e

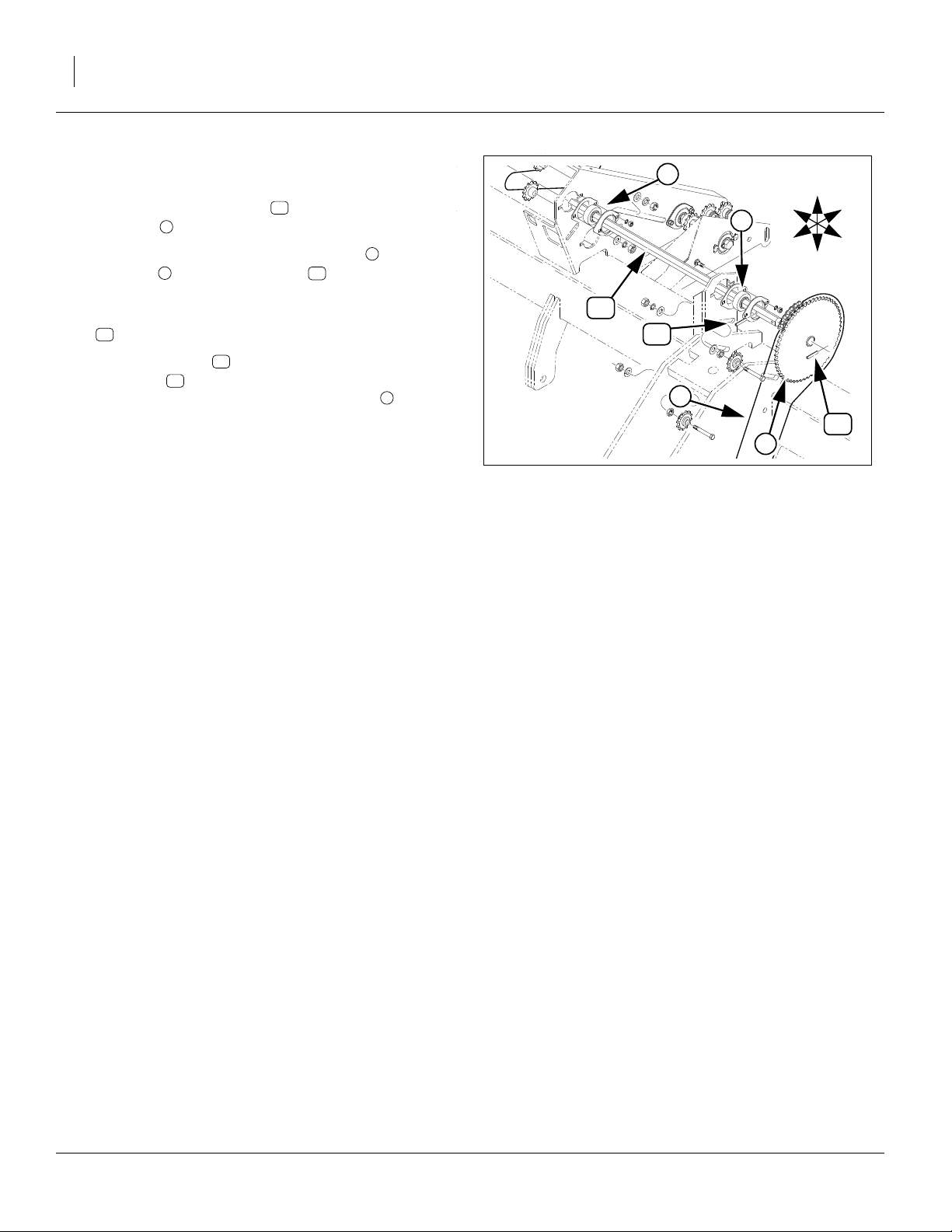

Refer to Figure 3

8. Loosen idler in gauge wheel assembly.

Lift ground drive chain off sprocket .

Do not completely remove the chain.

9. Drive the roll pin out of the left end of shaft:

115

195-189D POWER SHAFT 7/8 HEX LH

This pin is not re-used.

10. Remove and save sprocket .

Remove Drive Shaft

CAUTION

!

115

Shaft moves, under spring tension, about

the right as the next pin is removed.

a

c k

e

k

1

⁄

in (13mm) to

2

f

115

a

c

11. Drive out the mid roll pin . Pin is not re-used.

12. Remove the shaft from the drill (slide out to

right, with the clutch still mounted).

115

f

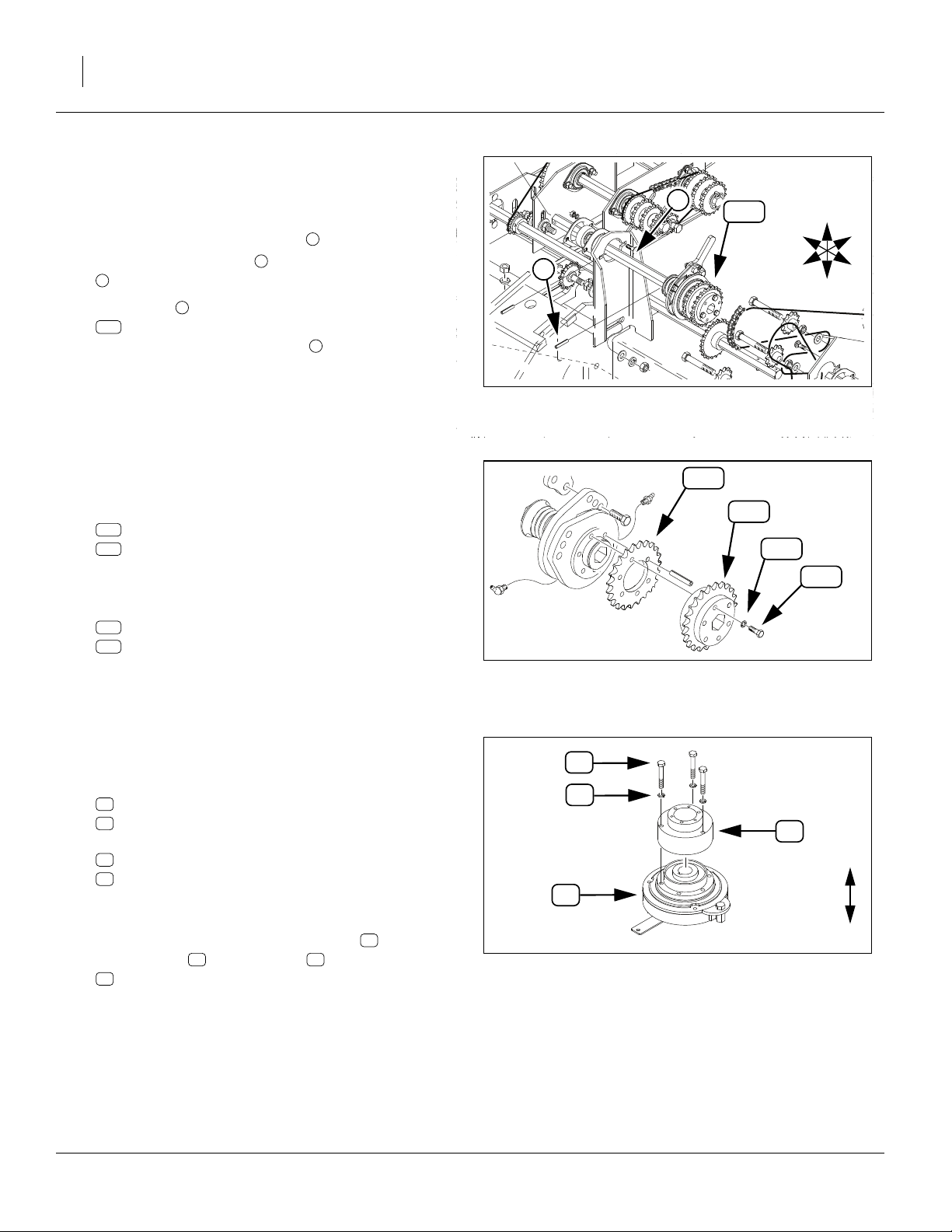

Disassemble 2S-2600 LH Clutch

Refer to Figure 4

13. At the clutch assembly , remove and save three

sets:

123

802-004C HHCS 1/4-20X3/4 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

14. The sprocket may still be held by pins. Remove and

save the sprocket:

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

Any roll pins present, the shaft, and the balance of

the clutch assembly are not re-used.

102

102

Figure 3: 2S-2600:

Release LH Power Shaft

136

128

Figure 4: 2S-2600:

Disassemble LH Clutch

k

123

102

R

F

21627

U

B

L

D

115

28106

195-073M 03/24/2009

Page 11

Great Plains Manufacturing, Inc. Update 2S-2600 Left Hand Drive 7

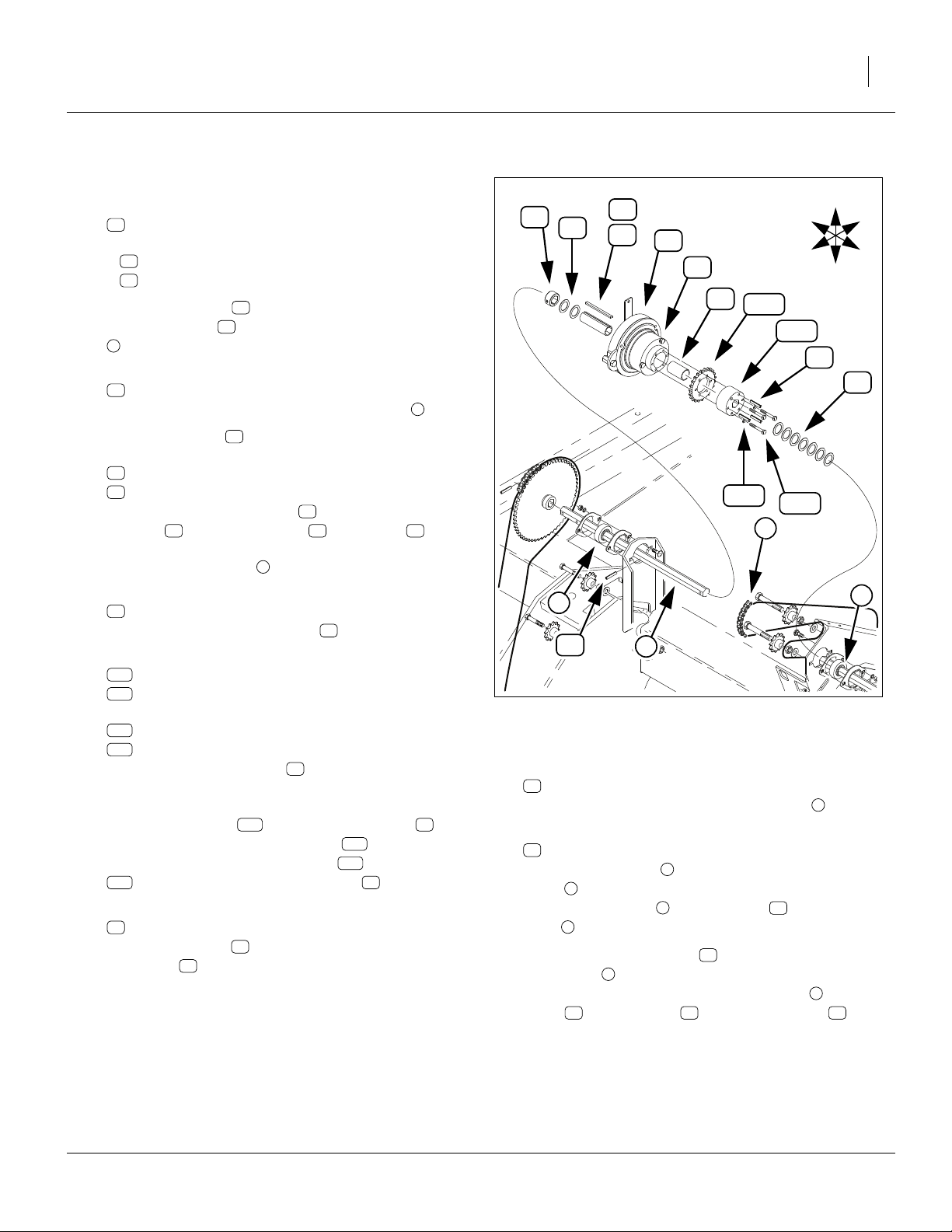

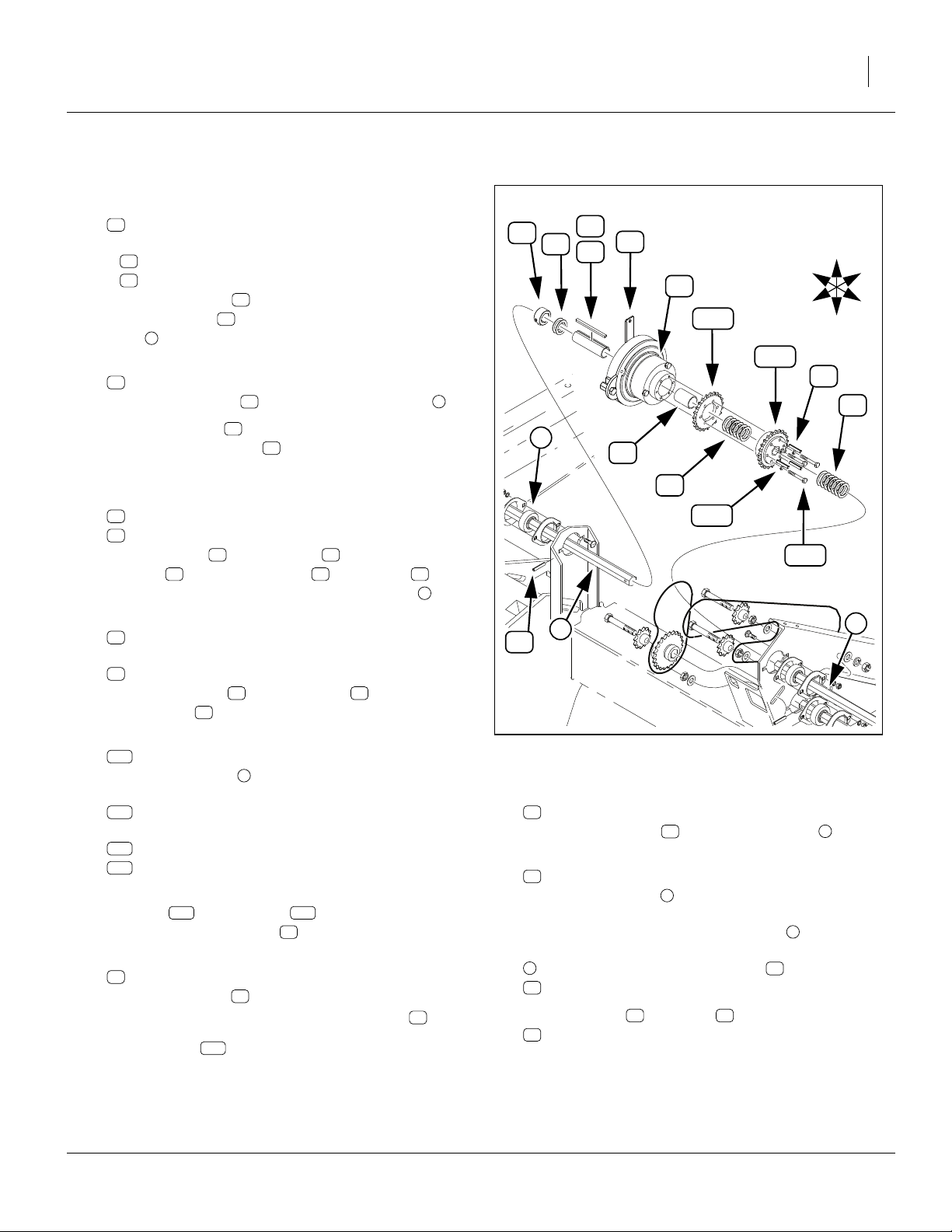

Pre-Assemble 2S-2600 LH Clutch

Refer to Figure 5

15. Select one each new:

54

823-231C OGURA CLUTCH

22

195-347D ELECTRIC CLUTCH ADAPTOR

and three sets new:

34

802-684C HHCS M8X1.25X55 GR8.8

48

804-157C WASHER SPRING LOCK M8 PLT

Place the tab end of down on a work surface.

16. Secure the large end of the 195-347D adaptor to

the Ogura clutch with the bolts and lock wash-

48

ers . Torque to specifications (see page 93).

Note: Note that the 195-347D adaptor has alternating

smooth and tapped (threaded)

54

54 34

22

1

⁄

4

22

in holes.

17. Select the saved:

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

and three sets saved:

123

802-004C HHCS 1/4-20X3/4 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

and three new

49

805-026C PIN ROLL 1/4 X 3/4 PLT

18. Place the sprocket on the clutch and align

136

the holes. Loosely insert the bolts and washers

128

in the threaded holes. Drive the roll pins into

22

123

49

the smooth holes. Tighten bolts to specification.

123

128

34

48

54

Figure 5: 2S-2600

Assemble LH Clutch

49

136

22

U

D

28107

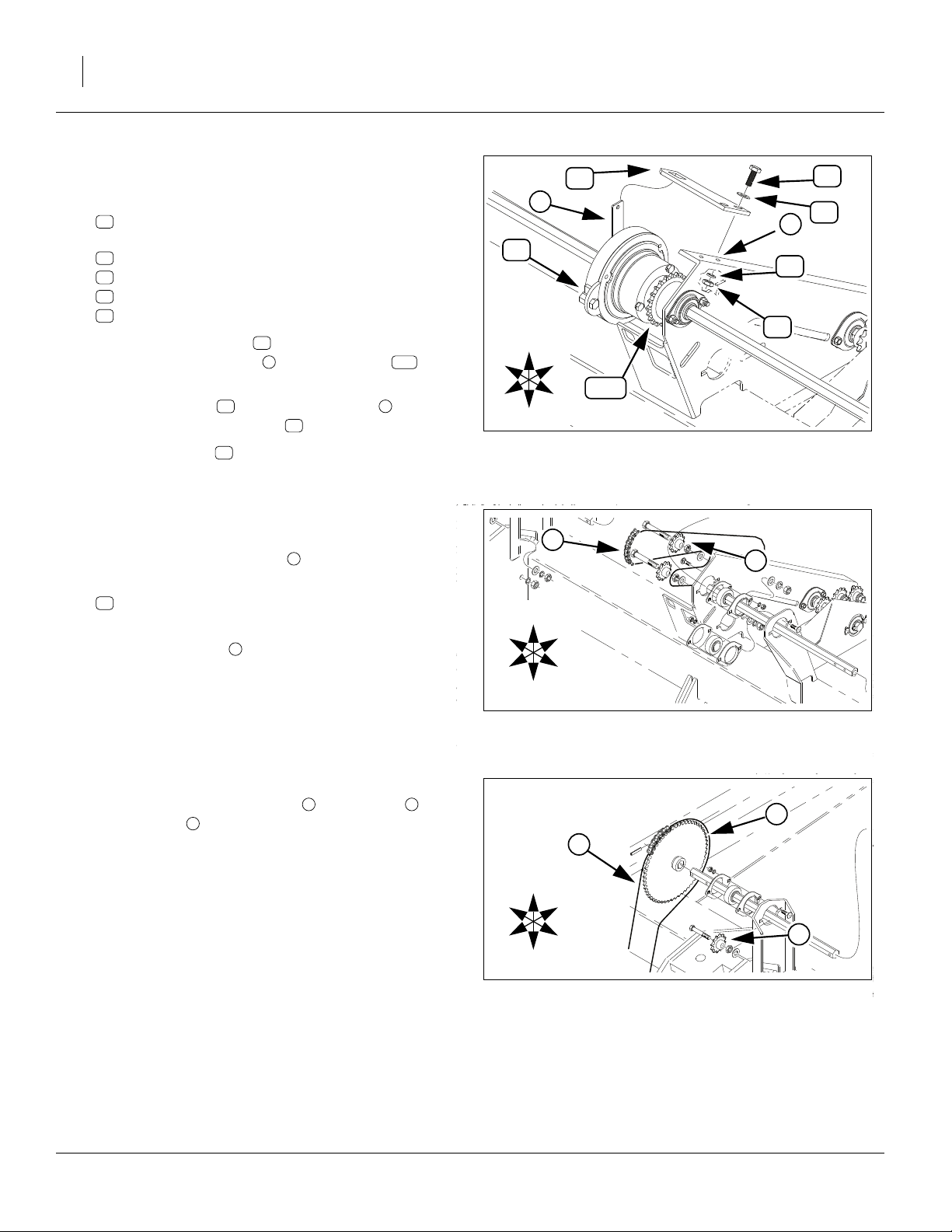

Prepare New 2S-2600 LH Power Shaft

Refer to Figure 6

19. Select one each new:

21

195-346D SHAFT 7/8 HEX 32.44 LG

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

20. Drive pin into the inner hole of the shaft .

50 21

21

Figure 6: 2S-2600:

Pin New LH Shaft

50

28094

03/24/2009 195-073M

Page 12

8 Electric Clutch Package Great Plains Manufacturing, Inc.

Install New 2S-2600 LH Power Shaft

Refer to Figure 7 (which, for clarity, is a fully exploded view)

21. From drill left, insert shaft into the existing flanged

bearings .

22. Select the saved ground drive sprocket . Place the

sprocket onto the new shaft , with the raised

hub of the sprocket to drill right (towards bearings).

23. Select one new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

24. Drive the roll pin into the hole at the left end of

new shaft , securing the sprocket.

Note: Do not remount the ground drive chain at this

time.

b

k21

50

21

21

k

c

b

21

50

c

Figure 7: 2S-2600:

Install LH Power Shaft

U

R

B

b

F

L

D

50

k

28056

195-073M 03/24/2009

Page 13

Great Plains Manufacturing, Inc. Update 2S-2600 Left Hand Drive 9

Install 2S-2600 LH Clutch

Refer to Figure 8

25. Select one new:

27

402-025S LOCK COLLAR, 7/8 HEX W/ SET SC

which, if not pre-assembled, consists of:

60

1 402-058D COLLAR LOCK 7/8 HEX and

61

2 801-035C SCREW SET 5/16-18 SKT KP X 3/8

26. Adjust the set screws to clear the collar hex hole,

and place the collar onto the new drive shaft .

Do not tighten the set screws at this time.

27. Select two new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

Place them on the shaft .

28. Select one new:

23

195-348D CLUTCH SPACER TUBE

Place it on the shaft .

29. Select the clutch assembled at step 18. With the

sprocketed end toward the left (toward bearings),

place it on the shaft , and into the Drive Type

n

chain .

30. Select one each new:

26

196-877D BUSHING 1 1/8 ODX7/8 HEX BORE

58

839-956C KEY 1/4 X 3/16 X 3.80

Insert the bushing in the clutch assembly .

31. Align the keyways of the bushing and the Ogura

clutch. Insert the key .

32. Select two new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

Place them on the shaft .

33. Select one new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Drive the pin into the hole at the right end of the

21

shaft , to secure all the components just installed

on the shaft.

34. Slide the lock collar right until it and the washers

46 54

contact the clutch assembly . Secure the set

screws.

54

50

21

21

21

26 54

58

21

27

21

50

46

58

54

23

26

46

27

Figure 8: 2S-2600

Install LH Clutch

U

R

F

B

L

D

n

i

21

28056

03/24/2009 195-073M

Page 14

10 Electric Clutch Package Great Plains Manufacturing, Inc.

Install 2S-2600 LH Torque Tab

Refer to Figure 9

35. Select one new:

20

195-345D CLUTCH TORQUE ARM TAB

and two sets new:

30

802-079C HHCS 3/8-16X1 1/4 GR5

41

804-011C WASHER FLAT 3/8 USS PLT

42

804-013C WASHER LOCK SPRING 3/8 PLT

36

803-014C NUT HEX 3/8-16 PLT

36. Loosely mount the tab at the same Drive Type

bracket weldment holes used by the tab

removed at step 6.

37. Rotate the clutch housing until the torque arm

is nearly vertical. Route it through the large hole in

the torque tab . Tighten the bolts to torque

specifications.

20

20

h

54 t

30

101

54

20

41

30

t

h

42

36

U

R

B

2S-2600 LH Closeout

Refer to Figure 8 on page 9

38. Re-mount Drive Type chain . Engage idler for

1

⁄

in (13mm) slack in longest chain span.

2

Refer to Figure 10

39. Re-mount gauge wheel chain on sprocket .

Engage idler for 1in (2.7cm) slack in longest chain

span.

40. Select one new (not shown):

55

833-088C OGURA CLUTCH JUMPER HARNESS

Connect the jumper to the clutch cable.

a

n i

c k

F

L

D

Figure 9: 2S-2600:

Install Torque Arm Tab

28082

a

c

U

R

F

B

L

k

D

Figure 10: 2S-2600:

Re-Install LH Gauge Wheel Chain

28056

195-073M 03/24/2009

Page 15

Great Plains Manufacturing, Inc. Update 2S-2600 Right Hand Drive 11

Update 2S-2600 Right Hand Drive

Remove 2S-2600 RH Linkage

Refer to Figure 11 (which depicts the LH linkage, but the

parts to be removed, and their general arrangement, are

identical on the RH side)

41. Remove individually or as an assembly:

106

195-130H

108

195-144D CLUTCH SHUTOFF CAM, 00 SERIES

118

195-254D CLUTCH PULL TAB

132

805-083C PIN CLEVIS 3/4 X 1 1/2

133

805-109C PIN COTTER 1/8 X 1 1/4 PLT

134

807-072C

These parts are not re-used.

Note: This part may be removed or left in place:

107

195-131H SUBFRM CLUTCH BRKT,SOLID STAND

42. Remove two sets:

124

802-079C HHCS 3/8-16X1 1/4 GR5

129

804-011C WASHER FLAT 3/8 USS PLT

130

804-013C WASHER LOCK SPRING 3/8 PLT

127

803-014C NUT HEX 3/8-16 PLT

and remove the:

101

152-263D CLUTCH ENGAGE TAB

These parts are not re-used.

CLUTCH SHUTOFF LINK, 00 SERIES

SPRING EXT 1 1/16 ODX.120WX5.5

101

106

118

134

133

108

107

Figure 11: 2S-2600:

Remove RH Linkage

129

130

127

132

R

F

124

U

B

L

D

17253

Release 2S-2600 RH Drive Shaft

Remove 2S-2600 RH Chains and Input Sprocket

Refer to Figure 12

43. At the Drive Type bracket, loosen idler and lift

Drive Type drive chain off clutch output sprocket

136

. Do not completely remove the chain.

44. Loosen ground drive idler and lift ground drive

c k

chain off sprocket . Do not completely remove

the chain.

45. Drive right end roll pin out of input shaft . Pin is

not re-used.

46. Remove and save the sprocket .

n

a

r d

k

i

R

U

B

k

r

F

L

D

d

n

i

a

c

RH Chains and Input Sprocket

136

Figure 12: 2S-2600:

21629

03/24/2009 195-073M

Page 16

12 Electric Clutch Package Great Plains Manufacturing, Inc.

Remove 2S-2600 RH Clutch

Refer to Figure 13

CAUTION

!

d

Shaft may move, under spring tension, about

to drill right as the next pin is removed.

1

⁄

in (13mm)

2

d

102

R

F

U

B

L

D

47. Drive out the mid roll pin . This pin is not re-used.

48. Move the shaft to the right. Remove the:

102

176-042S JAW CLUTCH CW EXT 7/8 HEX

from the shaft . Leave the shaft in the drill.

d

d

f

Disassemble 2S-2600 RH Clutch

Refer to Figure 14

49. From the clutch assembly , remove and save

three sets:

126

802-551C HHCS 1/4-20X2 1/4 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

50. The adaptor and sprocket may still be held

on by roll pins. Remove and save the adaptor and

sprocket:

111

195-170D CLUTCH ADAPTOR 7/8 HEX BORE

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

Any roll pins present, and the balance of the clutch

assembly , are not re-used.

111 136

102

102

102

f

Figure 13: 2S-2600:

RH Clutch Dismount

136

Figure 14: 2S-2600:

Disassemble RH Clutch

21629

111

128

126

28108

102

Pre-Assemble 2S-2600 RH Clutch

Refer to Figure 15

51. Select one each new:

54

823-231C OGURA CLUTCH

22

195-347D ELECTRIC CLUTCH ADAPTOR

and three sets new:

34

802-684C HHCS M8X1.25X55 GR8.8

48

804-157C WASHER SPRING LOCK M8 PLT

Place the clutch on a work surface, tab end down.

52. Secure the large end of the 195-347D to the

Ogura clutch with the bolts and lock washers

48

. Torque to specifications (see page 93).

195-073M 03/24/2009

54 34

22

34

48

54

Figure 15: 2S-2600:

Pre-assemble RH Clutch

22

U

D

28144

Page 17

Great Plains Manufacturing, Inc. Update 2S-2600 Right Hand Drive 13

Install 2S-2600 RH Clutch

Refer to Figure 16

53. Select one new:

27

402-025S LOCK COLLAR, 7/8 HEX W/ SET SC

which, if not pre-assembled, consists of:

60

1 402-058D COLLAR LOCK 7/8 HEX and

61

2 801-035C SCREW SET 5/16-18 SKT KP X 3/8

54. Adjust set screws to clear the collar hex hole.

Place the collar on the left end of the input shaft

d

. Do not tighten the set screws at this time.

61

27

55. Select two new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

Place them on the left end of the input shaft .

56. Select the clutch assembled at step 52, and one

54

d

each new:

26

196-877D BUSHING 1 1/8 ODX7/8 HEX BORE

58

839-956C KEY 1/4 X 3/16 X 3.80

Place bushing inside clutch . Align keyways of

bushing and Ogura clutch . Insert key . With

26 54 58

54

tab end to drill right, place the clutch assembly on left

end of the input shaft .

d

57. Select one new:

23

195-348D CLUTCH SPACER TUBE

Insert it in the clutch assembly .

22

58. Select one each saved:

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

111

195-170D CLUTCH ADAPTOR 7/8 HEX BORE

three sets saved:

126

802-551C HHCS 1/4-20X2 1/4 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

Note: Note that the 195-347D has alternating smooth

and tapped (threaded)

59. Place the sprocket on the clutch adaptor and

136

align the holes. Place the adaptor on the

sprocket. Loosely insert the bolts and washers

128

in the threaded holes of adaptor .

22

1

⁄

in holes.

4

22

111

126

22

60. Select three new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Drive the roll pins into the smooth holes of the

195-347D . Tighten bolts to specification. Re-seat

22

49

roll pins as required.

27

46

58

26

54

22

23

136

111

128

n

b

50

61. Select seven (7) new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

Place them on the driven acremeter shaft .

62. Select one new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Shift the input shaft to drill left, into Drive Type

n

chain , until the mid roll pin hole appears to the left

of the right bearing . Drive the pin into the input

d

shaft mid hole.

63. Shift the clutch assembly to drill left, into Drive

Type chain , until the left end of clutch has captured the right end of the acremeter shaft . Slide

27 46 54

collar and washers left against clutch .

Secure set screws.

d

Figure 16: 2S-2600:

Install RH Clutch

d

b50

54

n

R

F

126

U

B

L

D

50

46

s

28147

s

s

03/24/2009 195-073M

Page 18

14 Electric Clutch Package Great Plains Manufacturing, Inc.

Install 2S-2600 RH Torque Tab

h

42

30

41

Refer to Figure 17

64. Select one new:

20

195-345D CLUTCH TORQUE ARM TAB

and two sets new:

30

802-079C HHCS 3/8-16X1 1/4 GR5

41

804-011C WASHER FLAT 3/8 USS PLT

42

804-013C WASHER LOCK SPRING 3/8 PLT

36

803-014C NUT HEX 3/8-16 PLT

20

t

54

36

65. Loosely mount the tab at the same Drive Type

bracket weldment holes used by the tab

removed at step 42.

66. Rotate the clutch until the torque arm is in the

large hole in the torque tab .

67. Tighten tab bolts to torque specifications.

20

h

54 t

20

30

101

R

F

U

D

B

136

L

Figure 17: 2S-2600:

Install RH Torque Arm Tab

28148

2S-2600 RH Closeout

Refer to Figure 17 and Figure 18

68. Re-mount Drive Type chain .

69. Select one new (not shown):

55

833-088C OGURA CLUTCH JUMPER HARNESS

Connect the jumper to the clutch cable.

70. Engage chain idler for

est chain span.

Refer to Figure 19

71. Re-mount gauge wheel chain on sprocket .

Engage idler for 1in (2.7cm) slack in longest chain

span.

i

a

n

1

⁄

in (13mm) slack in long-

2

c k

Install 2S-2600 Electronics

Continue at “2S Electrical Installation” on page 25.

These steps are common to both 2S-2600 and 2S2600F/SGS models.

R

F

R

F

n

U

B

L

D

Figure 18: 2S-2600:

Remount RH Drive Type Chain

c

U

B

L

D

i

28057

k

a

Figure 19: 2S-2600:

Remount RH Ground Drive Chain

195-073M 03/24/2009

28057

Page 19

Great Plains Manufacturing, Inc. Update 2S-2600F/SGS Left Hand Drive 15

2S-2600F & 2S-2600 Small Seeds Installation

This section describes installation of kit 195-077A for:

• 2S-2600 s/n DD1152+ drills with Small Seeds,

• 2S-2600F s/n DD1152+ drills,

• 2S-2600HD drills with Small Seeds, or;

• 2S-2600HDF drills,

…referred to as “2S-2600F/SGS” in this section.

Update 2S-2600F/SGS Left Hand Drive

Remove 2S-2600F/SGS LH Linkage

Steps 1-4 are on page 4.

Refer to Figure 20 (which depicts a standard 2S-2600 linkages, but the parts removed for 2600F and SGS are the same)

5. Remove individually or as an assembly:

106

195-130H CLUTCH SHUTOFF LINK, 00 SERIES

108

195-144D CLUTCH SHUTOFF CAM, 00 SERIES

118

195-254D CLUTCH PULL TAB

132

805-083C PIN CLEVIS 3/4 X 1 1/2

133

805-109C PIN COTTER 1/8 X 1 1/4 PLT

134

807-072C SPRING EXT 1 1/16 ODX.120WX5.5

These parts are not re-used.

Note: This part may be removed or left in place:

107

195-131H SUBFRM CLUTCH BRKT,SOLID STAND

6. Remove two sets:

124

802-079C HHCS 3/8-16X1 1/4 GR5

129

804-011C WASHER FLAT 3/8 USS PLT

130

804-013C WASHER LOCK SPRING 3/8 PLT

127

803-014C NUT HEX 3/8-16 PLT

and remove the:

101

152-263D CLUTCH ENGAGE TAB

These parts are not re-used.

For other kits, see:

2S-2600, main box only, 195-076A kitpage 5

3S-3000, main box only, 195-078A kitpage 27

3S-3000, w/option box(es), 195-078A kitpage 42

3S-4000, main box only, 195-075A kitpage 61

3S-4000, w/option box(es), 195-075A kitpage 74

101

106

124

129

130

127

118

134

133

132

108

R

107

Figure 20: 2S-2600F/SGS:

Remove LH Linkage

F

U

B

L

D

17253

03/24/2009 195-073M

Page 20

16 Electric Clutch Package Great Plains Manufacturing, Inc.

Remove 2S-2600F/SGS LH Shaft and Clutch

Dismount Clutch Output Chains

Refer to Figure 21

7. Loosen Drive Type idler and Fertilizer/SGS jackshaft idler . Lift Drive Type chain and Fertilizer/

SGS jackshaft chain off the sprockets on:

113

195-187K 3S-3000F LH WING CLUTCH ASSY

Do not completely remove the chains.

v n

i

u

n

113

U

i

R

F

B

L

D

v

u

r

Release 2S-2600F/SGS LH Power Shaft

Refer to Figure 22

8. Loosen idler in gauge wheel assembly.

Lift ground drive chain off sprocket .

Do not completely remove the chain.

9. Drive the roll pin out of the left end of shaft:

115

195-189D POWER SHAFT 7/8 HEX LH

This pin is not re-used.

10. Remove and save sprocket .

a

c k

e

k

Remove 2S-2600F/SGS LH Power Shaft

CAUTION

!

113

1

⁄

in (13mm) to

2

115

Shaft moves, under spring tension, about

the right as the next pin is removed.

11. Drive out the middle roll pin . Pin is not re-used.

12. Slide the shaft (with clutch still mounted)

out of the drill, to the right.

13. Remove the clutch for disassembly:

113

195-187K 3S-3000F LH WING CLUTCH ASSY

The shaft is not re-used.

115

f

Figure 21: 2S-2600F/SGS:

Remove LH Clutch Chains

f

115

a

c

Figure 22: 2S-2600F/SGS:

Release LH Power Shaft

21628

U

R

F

B

L

D

e

k

21628

195-073M 03/24/2009

Page 21

Great Plains Manufacturing, Inc. Update 2S-2600F/SGS Left Hand Drive 17

Disassemble 2S-2600F/SGS LH Clutch

Refer to Figure 23

14. Remove and save three sets:

125

802-152C HHCS 1/4-20X2 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

The assembly is usually still held together by roll

pins.

15. Pry both sprockets off. Remove and save:

109

195-160H SPKT CLUTCH 40B23T RND BORE

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

The following parts usually remain in the adaptor-

sprocket and do not need to be removed.

138

103

116

The remaining parts are not re-used.

136

817-111C BSHG FLG 1.26IDX1.41ODX.87L

176-065D CLUTCH FRICTION WASHER

195-222D BRG 7/8 HEX ID X 1.254 OD

136

116

113

103

138

Figure 23: 2S-2600F/SGS:

Disassemble LH Clutch

113

109

128

125

16465

Pre-Assemble 2S-2600F/SGS LH Clutch

Refer to Figure 24

16. Select one each new:

54

823-231C OGURA CLUTCH

22

195-347D ELECTRIC CLUTCH ADAPTOR

and three sets new:

34

802-684C HHCS M8X1.25X55 GR8.8

48

804-157C WASHER SPRING LOCK M8 PLT

Set the clutch assembly on a work surface, with the

torque arm end of the Ogura clutch down.

17. Secure the large end of the 195-347D adaptor to

the Ogura clutch with the bolts and lock wash-

48

ers . Torque to specifications (see page 93).

54 34

22

34

48

54

Figure 24: 2S-2600F/SGS:

Pre-assemble LH Clutch

22

U

D

28144

Prepare New 2S-2600F/SGS LH Power Shaft

Refer to Figure 25

18. Select one each new:

21

195-346D SHAFT 7/8 HEX 32.44 LG

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

19. Drive the pin into the inner hole of the shaft .

03/24/2009 195-073M

50 21

21

Figure 25: 2S-2600F/SGS:

Pin New Shaft

50

28094

Page 22

18 Electric Clutch Package Great Plains Manufacturing, Inc.

Install New 2S-2600F/SGS LH Power Shaft

Refer to Figure 26 (which, for clarity, is a fully exploded

view, but omits the option box chain )

20. From drill left, insert shaft into the existing flanged

bearings and the chains , in the Drive Type

bracket.

21. Select the saved ground drive sprocket . Place

sprocket onto the new shaft , with the raised

hub of the sprocket to drill right (towards the bearings).

22. Select one new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Drive the roll pin into the hole at the left end of

new shaft , securing the sprocket.

Note: Do not re-mount the gauge wheel chain until

step 38. This leaves the new shaft free to spin for

ease of installing additional components.

b n u

k21

50

21

u

21

k

c

n

21

Figure 26: 2S-2600F/SGS:

Install LH Power Shaft

b

50

c

U

R

b

F

B

L

D

50

k

28073

195-073M 03/24/2009

Page 23

Great Plains Manufacturing, Inc. Update 2S-2600F/SGS Left Hand Drive 19

Install 2S-2600F/SGS LH Clutch

Refer to Figure 27

23. Select two new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

and one new:

24

195-349D WING FERT CLUTCH OUTER SPCR TB

Place the washers on the shaft , followed by

the spacer .

24

46 21

24. Select one saved:

109

195-160H SPKT CLUTCH 40B23T RND BORE

and three sets saved:

125

802-152C HHCS 1/4-20X2 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

Insert the bolts through the lock washers

125 128

and into every other hole in the sprocket. Insert from

the side with the smaller raised hub. Place the

sprocket, bolt face to left, onto shaft .

21

If the following parts are not present, re-insert them:

138

817-111C BSHG FLG 1.26IDX1.41ODX.87L

103

176-065D CLUTCH FRICTION WASHER

116

195-222D BRG 7/8 HEX ID X 1.254 OD

With any flanged ends to right, place the bushing

138 103 116

, the friction washer , the bearing and

the sprocket onto shaft .

136

21

25. Select one each saved:

136

808-240C

26. Select the clutch assembled at step 17. Note that

the 195-347D adaptor has alternating smooth

and tapped (threaded)

SPKT 40A23X1.813-1.818 BR/6HOL

54

22

1

⁄

in holes.

4

27. Select one new:

25

195-350D WING FERT CLUTCH INNER SPCR TB

Place spacer onto shaft . Place the clutch

over the spacer, adaptor end to left, and inside

both chains , .

25 21 54

22

n u

28. Loosely secure the two sprockets to the clutch using

22

1

⁄

in threaded

4

the bolts and washers at the

125 128

holes of the 195-347D adaptor .

29. Select three sets new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Drive the roll pins into the sprockets and the

smooth

1

⁄

in holes of the 195-347D adaptor .

4

Tighten bolts to specification. Re-seat roll pins

50

22

125

as needed.

50

58

26

U

R

F

D

30. Select one each new:

26

58

Insert the bushing into the right end of the clutch

54

then insert the key .

31. Select two new:

46

Place the washers on the shaft .

32. Select one new:

50

Drive the pin into the right end hole of the shaft

21

33. Route chains ( , ) over the sprockets. Adjust idler

for Drive Type chain to

est chain span. Adjust idler for option jackshaft chain

u

46

54

22

136

103

109

50

24

46

25

116

138

128

125

21

B

n

L

Figure 27: 2S-2600F/SGS:

Install LH Clutch

196-877D BUSHING 1 1/8 ODX7/8 HEX BORE

839-956C KEY 1/4 X 3/16 X 3.80

. Align the keyways of the bushing and clutch,

804-061C WASHER MACH 1.50 X 1.00 X 18GA

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

50

, outside the washers.

n u

1

to

⁄

in (6mm) slack in longest chain span.

4

26

58

u

28101

21

1

n

⁄

in (13mm) slack in long-

2

03/24/2009 195-073M

Page 24

20 Electric Clutch Package Great Plains Manufacturing, Inc.

Install 2S-2600F/SGS LH Torque Tab

Refer to Figure 28

34. Select one new:

20

195-345D CLUTCH TORQUE ARM TAB

and two sets new:

30

802-079C HHCS 3/8-16X1 1/4 GR5

41

804-011C WASHER FLAT 3/8 USS PLT

42

804-013C WASHER LOCK SPRING 3/8 PLT

36

803-014C NUT HEX 3/8-16 PLT

35. Loosely mount the tab at the same Drive Type

bracket weldment holes used by the tab

removed at step 6.

36. Rotate the clutch housing until the torque arm

is nearly vertical. Route it through the large hole in

the torque tab . Tighten the bolts to torque

specifications.

20

20

h

54 t

30

101

54

U

R

F

D

20

30

t

41

h

42

B

36

L

Figure 28: 2S-2600F/SGS:

Install LH Torque Arm Tab

28100

2S-2600F/SGS LH Closeout

37. Select one new (not shown):

55

833-088C OGURA CLUTCH JUMPER HARNESS

Connect the jumper to the clutch cable.

Refer to Figure 29

38. Re-mount gauge wheel chain on sprocket .

Engage idler for 1in (2.7cm) slack in longest chain

span.

39. Select one new (not shown):

55

833-088C OGURA CLUTCH JUMPER HARNESS

Connect the jumper to the clutch cable.

a

c k

R

F

k

a

c

Figure 29: 2S-2600F/SGS:

Re-Install LH Gauge Wheel Chain

U

B

L

D

28056

195-073M 03/24/2009

Page 25

Great Plains Manufacturing, Inc. Update 2S-2600F/SGS Right Hand Drive 21

Update 2S-2600F/SGS Right Hand

130

127

132

R

F

124

129

U

B

L

D

17253

Drive

Remove 2S-2600F/SGS RH Linkage

Refer to Figure 30 (which depicts the standard LH linkage,

but the parts to be removed, and their general arrangement,

are identical for Option box drills on the RH side)

40. Remove individually or as an assembly:

106

195-130H CLUTCH SHUTOFF LINK, 00 SERIES

108

195-144D CLUTCH SHUTOFF CAM, 00 SERIES

118

195-254D CLUTCH PULL TAB

132

805-083C PIN CLEVIS 3/4 X 1 1/2

133

805-109C PIN COTTER 1/8 X 1 1/4 PLT

134

807-072C SPRING EXT 1 1/16 ODX.120WX5.5

These parts are not re-used.

Note: This part may be removed or left in place:

107

195-131H SUBFRM CLUTCH BRKT,SOLID STAND

41. Remove two sets:

124

802-079C HHCS 3/8-16X1 1/4 GR5

129

804-011C WASHER FLAT 3/8 USS PLT

130

804-013C WASHER LOCK SPRING 3/8 PLT

127

803-014C NUT HEX 3/8-16 PLT

and remove the:

101

152-263D CLUTCH ENGAGE TAB

These parts are not re-used.

101

106

118

134

133

108

107

Figure 30: 2S-2600F/SGS:

Remove RH Linkage

Release 2S-2600F/SGS RH Drive Shaft

Remove 2S-2600F/SGS RH Chains and Input

Sprocket

Refer to Figure 31 (which, for clarity, is a fully exploded view

- remove only specified parts)

42. At the Drive Type bracket, loosen Drive Type and

Fertilizer/SGS jackshaft idlers .

43. Lift the Drive Type and Fertilizer/SGS chains off

clutch output sprockets . Do not completely

remove the chains.

44. At the gauge wheel, loosen idler and lift ground

drive chain off of sprocket .

Do not completely remove the chain.

45. At the right end of the clutch input shaft , drive out

the right end roll pin . The pin is not re-used.

46. Remove and save sprocket . Do not completely

remove chain .

n u

11

c k

r

c

v

a

k

i

d

r

k

c

a

d

v

Figure 31: 2S-2600F/SGS:

RH Chains and Input Sprocket

u

112

R

F

n

U

B

L

D

i

21630

03/24/2009 195-073M

Page 26

22 Electric Clutch Package Great Plains Manufacturing, Inc.

Remove 2S-2600F/SGS RH Clutch for Disassembly

Refer to Figure 32 (which, for clarity, is a fully exploded view

- remove only specified parts)

47. Caution: Shaft moves, under spring tension, about

1

⁄

in (13mm) to the right as pin is removed. On the

2

clutch drive input shaft , drive out the mid roll pin

f

. This pin is not re-used.

48. Move shaft to drill right. Remove:

112

195-186K 3S-3000F RH WING CLUTCH ASSY

from the shaft. Leave the shaft in the drill.

d

d

f

d

f

d

113

R

F

U

B

L

D

Disassemble 2S-2600F/SGS RH Clutch

Refer to Figure 33

49. Remove and save three sets:

126

802-551C HHCS 1/4-20X2 1/4 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

The assembly is usually still held together by roll

pins.

50. Pry both sprockets off. Remove and save:

110

195-161H SPKT CLUTCH 40B23T HEX BORE

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

The remaining parts are not re-used.

Pre-Assemble 2S-2600F/SGS RH Clutch

Refer to Figure 34

51. Select one each new:

54

823-231C OGURA CLUTCH

22

195-347D ELECTRIC CLUTCH ADAPTOR

and three sets new:

34

802-684C HHCS M8X1.25X55 GR8.8

48

804-157C WASHER SPRING LOCK M8 PLT

Set the clutch assembly on a work surface, with the

torque arm end of the Ogura clutch down.

52. Secure the large end of the 195-347D to the

Ogura clutch with the bolts and lock washers

48

. Torque to specifications (see page 93).

54 34

22

Figure 32: 2S-2600F/SGS:

Remove RH Clutch

136

Figure 33: 2S-2600F/SGS:

Disassemble RH Clutch

34

48

54

Figure 34: 2S-2600F/SGS:

Pre-assemble RH Clutch

21630

110

128

126

16452

22

U

D

28144

195-073M 03/24/2009

Page 27

Great Plains Manufacturing, Inc. Update 2S-2600F/SGS Right Hand Drive 23

Install 2S-2600F/SGS RH Clutch

Refer to Figure 35

53. Select one new:

27

402-025S LOCK COLLAR, 7/8 HEX W/ SET SC

which, if not pre-assembled, each consist of:

60

1 402-058D COLLAR LOCK 7/8 HEX and

61

2 801-035C SCREW SET 5/16-18 SKT KP X 3/8

Adjust set screws to clear the collar hex hole.

Place the collar on the left end of the clutch input

d

shaft . Do not tighten the set screws at this time.

61

27

54. Select two new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

Place two washers on the clutch input shaft .

55. Select the clutch assembled at step 52. Note that

the 195-347D adaptor has alternating smooth

and tapped (threaded)

46 d

54

22

1

⁄

in holes.

4

56. Select one each new:

26

196-877D BUSHING 1 1/8 ODX7/8 HEX BORE

58

839-956C KEY 1/4 X 3/16 X 3.80

Place bushing inside clutch . Align keyways of

bushing and Ogura clutch . Insert key .

Place the tab end of the clutch on input shaft .

26 54

26 54 58

d

57. Select one new:

23

195-348D CLUTCH SPACER TUBE

and six (6) new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

Insert the spacer in the adaptor , followed by

the washers .

25 22

46

58. Select one saved:

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

d

Place it on the

shaft .

59. Select one saved:

110

195-161H SPKT CLUTCH 40B23T HEX BORE

and three sets saved:

126

802-551C HHCS 1/4-20X2 1/4 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

60. Loosely secure the two sprockets to the clutch using

the bolts and washers at the threaded holes

of the 195-347D adaptor .

126 128

22

61. Select three new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Drive the roll pins into the sprockets and the

smooth

1

⁄

in holes of the 195-347D adaptor .

4

62. Tighten bolts to specification. Re-seat roll pins

50

22

126

as necessary.

27

50

63. Select seven (7) new:

46

Place all 7 washers on acremeter shaft .

64. Select one new:

50

Shift the drive shaft and clutch assembly to drill

left (and into both chains), until the mid roll pin hole

appears to the left of the right bearing . The hex

bore sprocket needs to capture the acremeter shaft

s50

21

65. Shift the collar , washers and clutch assembly

54

58

26

54

U

46

R

22

F

136

D

110

50

46

b

23

46

128

126

d

Figure 35: 2S-2600F/SGS:

Install RH Clutch

804-061C WASHER MACH 1.50 X 1.00 X 18GA

46 s

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

d

b

before that occurs. Drive the pin into the shaft

mid hole.

27 46

to drill left. Secure set screws in collar.

s

28109

B

L

03/24/2009 195-073M

Page 28

24 Electric Clutch Package Great Plains Manufacturing, Inc.

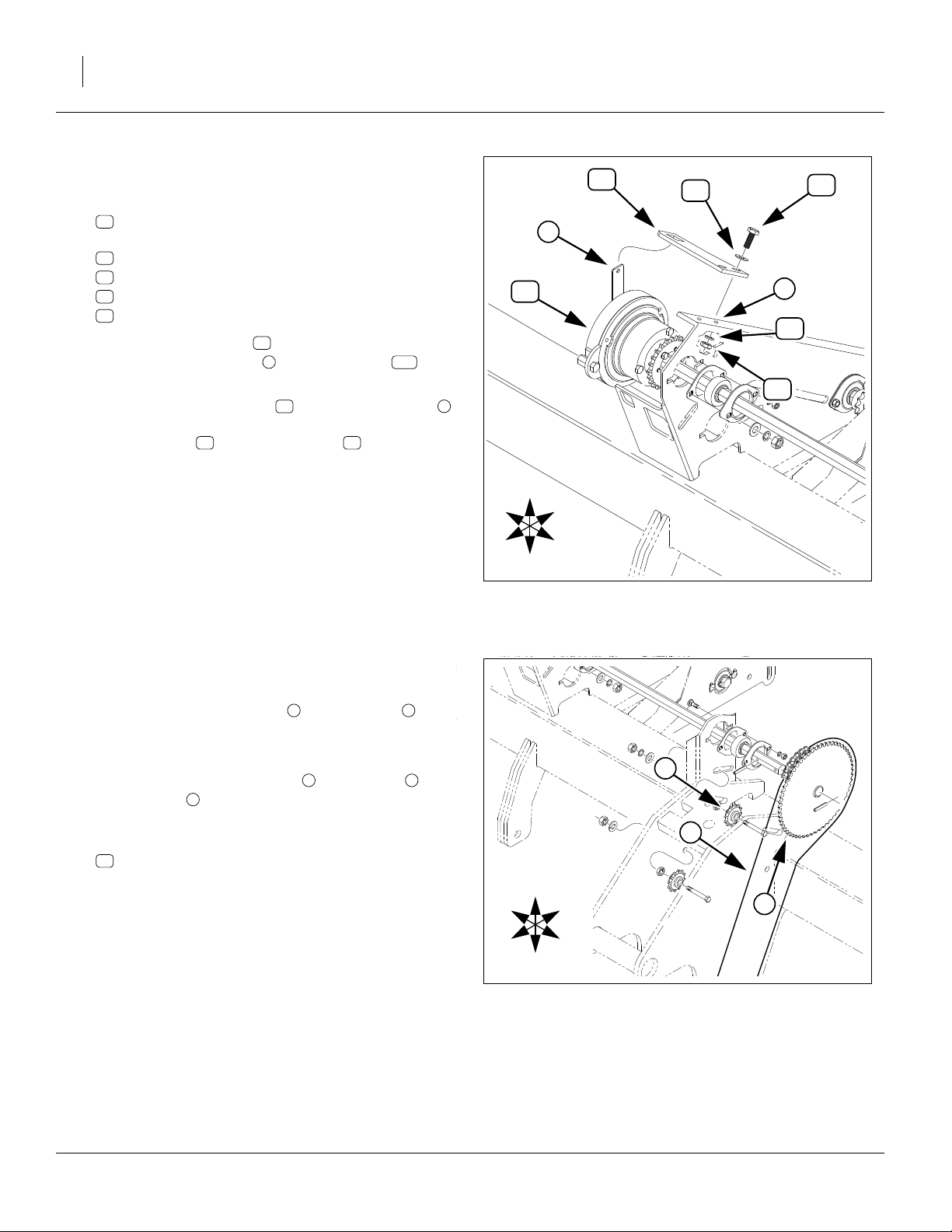

Refer to Figure 36

66. Select one new:

20

195-345D CLUTCH TORQUE ARM TAB

and two sets new:

30

802-079C HHCS 3/8-16X1 1/4 GR5

41

804-011C WASHER FLAT 3/8 USS PLT

42

804-013C WASHER LOCK SPRING 3/8 PLT

36

803-014C NUT HEX 3/8-16 PLT

67. Loosely mount the tab at the same Drive Type

bracket weldment holes used by the tab

removed at step 41.

68. Center clutch torque arm in the large hole in the

torque tab .

20

20

h

t

101

R

F

54

U

20

t

36

B

136

L

30

41

h

42

D

Refer to Figure 36 and Figure 37

69. Re-mount chains ( , ). Engage Drive Type chain

idler for

Engage option jackshaft chain idler for

slack in longest chain span.

70. Tighten tab bolts to torque specifications.

1

i

⁄

2

n u

in (13mm) slack in longest chain span.

1

v

⁄

in (6mm)

4

30

2S-2600F/SGS RH Closeout

71. Select one new (not shown):

55

833-088C OGURA CLUTCH JUMPER HARNESS

Connect the jumper to the clutch cable.

Refer to Figure 38

72. Re-mount gauge wheel chain on sprocket .

Engage idler for 1in (2.7cm) slack in longest chain

span.

a

c k

Install 2S-2600F/SGS Electronics

Continue at “2S Electrical Installation” on page 25.

These steps are common to both 2S-2600 and 2S2600F/SGS models.

R

F

R

F

Figure 36: 2S-2600F/SGS:

Install RH Torque Arm Tab

u

v

U

B

L

D

Figure 37: 2S-2600F/SGS:

Remount RH Drive Type Chain

c

U

B

L

D

Figure 38: 2S-2600F/SGS:

Remount RH Ground Drive Chain

28146

i

n

28057

k

a

28057

195-073M 03/24/2009

Page 29

Great Plains Manufacturing, Inc. 2S Electrical Installation 25

2S Electrical Installation

Install 2S Height Switch

Refer to Figure 39 (which depicts a 3S center section - installation on the 2S left section is identical)

The electric clutch system is activated by cab switches

and by a single height switch at the right hand shutoff

pivot plate (where a mechanical linkage was

x

removed).

1. Select one each new:

32

802-212C HHCS 3/4-10X2 1/2 GR5

and three:

44

804-024C WASHER FLAT 3/4 USS PLT

19

47

32

45

x

38

2. Insert the bolt part way into the right side of the

right pivot plate . Add three flat washers (not

32

x44

shown) in between the plates. Continue inserting the

bolt to retain the washers.

3. Select one each new:

19

195-344D LIMIT SWITCH BRACKET

Add the switch bracket to the bolt at the left

side of the plate . Orient the bracket extension with

the #10 slots toward drill rear.

z

19 32

x

4. Select one each new:

43

804-023C WASHER LOCK SPRING 3/4 PLT

37

803-027C NUT HEX 3/4-10 PLT

Secure the bracket to the plate with a lock

washer and nut , finger tight. Orient the rear

43 37

19 x

edge of the bracket to approximately vertical. Tighten

32

bolt to torque specification.

5. Select one new:

59

VER-28383 VERIS SPEED SNSR SWITCH HRNESS

and two sets new:

29

801-067C SCREW RD HD 8-32 X 1 1/2LG PLT

47

804-088C WASHER FLAT #8 SAE PLT

45

804-043C WASHER LOCK #8

38

803-064C NUT HEX 8-32

6. Position the switch , with the actuator arm to the

59

rear, and the cable up, against the left side of the

bracket . Insert a #8 screw (not shown)

19 29

through the switch body and bracket. Secure with flat

washer , lock washer and nut .

47 45 38

7. Select one new (not shown):

57

833-489C 2-WIRE AMP - WEATHERPACK ADAPT

Connect the adaptor to the switch lead.

The final position of the switch is adjusted at “Adjust

Height Switch” on page 90.

59

z

Figure 39: 2S:

Height Switch Installation

28096

03/24/2009 195-073M

Page 30

26 Electric Clutch Package Great Plains Manufacturing, Inc.

Install 2S Drill Cables

S

R

L

n/c

Figure 40

2-Section Drill Cabling

Refer to Figure 40 (dimensions are inches)

8. From the bundle:

56

833-294C 40P PNT RW CLTCH CNTRL & HRNSS

select the drill harness . which is a long cable

assembly with 7 connectors.

9. Select all of:

28

800-082C CABLE TIE .31X21.5 6DIA 120LB

10. Fish the cable snake through the tongue tube.

11. Wrap hitch connectors of the harness so that

they cannot snag, and secure that end of the harness to the rear end of the snake.

Route Cables

12. Pull the cable forward until it appears at the hitch end

of the tongue tube. Continue pulling until:

there is ample slack for making tractor connections

at the hitch, but not so much that the cable can touch

the ground in operations, and do not pull the first

cable junction into the tube.

13. Route the rear end of the cable, following hydraulic

hoses, to the right clutch.

J

H

H

T

n/c

Dress and Secure Cables

17. Dress cables to prevent entanglement with or chafing by drill moving parts. Leave ample slack at drill

center for folding (ideally, route the wing cables

directly above wing pivot center lines). Coil any

excess cable at drill center.

18. At the hitch end of the harness, use one cable tie

to secure the harness to clamped hydraulic hoses.

19. Use 1 tie to secure the switch lead and harness

switch leg.

20. Use 3 ties on each wing to secure the wing runs.

21. Near the right clutch, coil the unused “CENTER” and

“PUMP” (or unlabeled) cable legs and any any

excess cable. Use one tie to secure them.

J

H

28096

28

n/c

14. Mate harness connector “Right” to the jumper

cable on the right clutch.

15. Route harness cable leg “Height Switch” down to

the switch, and mate the connectors.

16. Route harness cable leg “Left” back to drill center, and out to the left clutch. Route across the rear

of the tongue, and not across the gap between the

wing tool bars. Mate connector to the left clutch

jumper cable.

195-073M 03/24/2009

R

S

L

L

Page 31

Great Plains Manufacturing, Inc. Update 3S-3000 Left Hand Drive 27

3S-3000 Main Box Only Installation

This section describes installation of kit 195-078A for:

• 3S-3000 s/n S1563+ (1996+) drills with only main

seed box, and no Small Seeds/Fertilizer options or;

• 3S-3000HD drills with only a main seed box, and no

Small Seeds or Fertilizer options.

Update 3S-3000 Left Hand Drive

Remove 3S-3000 LH Linkage

Steps 1-4 are on page 4.

Refer to Figure 41 (which depicts a 2S-2600 linkage, but the

parts removed for 3S-3000 are the same)

5. Remove individually or as an assembly:

106

195-130H CLUTCH SHUTOFF LINK, 00 SERIES

108

195-144D CLUTCH SHUTOFF CAM, 00 SERIES

118

195-254D CLUTCH PULL TAB

132

805-083C PIN CLEVIS 3/4 X 1 1/2

133

805-109C PIN COTTER 1/8 X 1 1/4 PLT

134

807-072C SPRING EXT 1 1/16 ODX.120WX5.5

These parts are not re-used.

Note: This part may be removed or left in place:

107

195-131H SUBFRM CLUTCH BRKT,SOLID STAND

6. Remove two sets:

124

802-079C HHCS 3/8-16X1 1/4 GR5

129

804-011C WASHER FLAT 3/8 USS PLT

130

804-013C WASHER LOCK SPRING 3/8 PLT

127

803-014C NUT HEX 3/8-16 PLT

and remove the:

101

152-263D CLUTCH ENGAGE TAB

These parts are not re-used.

For other kits, see:

2S-2600, main box only, 195-076A kitpage 5

2S-2600, w/option box(es), 195-077A kitpage 15

3S-3000, w/option box(es), 195-078A kitpage 42

3S-4000, main box only, 195-075A kitpage 61

3S-4000, w/option box(es), 195-075A kitpage 74

101

106

124

129

130

127

118

134

133

132

108

R

107

Figure 41: 3S-3000:

Remove LH Linkage

F

U

B

L

D

17253

Remove 3S-3000 LH Shaft and Clutch

Dismount Clutch Output Chain

Refer to Figure 42

7. Loosen idler and lift chain off of sprocket:

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

Do not completely remove the chain.

i n

136

n

i

U

R

B

102

F

L

115

D

Figure 42: 3S-3000:

Dismount LH Clutch Chain

03/24/2009 195-073M

21627

Page 32

28 Electric Clutch Package Great Plains Manufacturing, Inc.

Dismount Ground Drive Chain & Sprocket

R

F

U

B

L

D

e

Refer to Figure 43

8. Loosen idler in gauge wheel assembly.

Lift ground drive chain off sprocket .

Do not completely remove the chain.

9. Drive the roll pin out of the left end of shaft:

115

195-189D POWER SHAFT 7/8 HEX LH

This pin is not re-used.

10. Remove and save sprocket .

Remove 3S-3000 LH Drive Shaft

CAUTION

!

115

Shaft moves, under spring tension, about

the right as the next pin is removed.

a

c k

e

k

1

⁄

in (13mm) to

2

f

115

a

c

11. Drive out the mid roll pin . Pin is not re-used.

12. Remove the shaft from the drill (slide out to

right, with the clutch still mounted).

115

f

Disassemble 3S-3000 LH Clutch

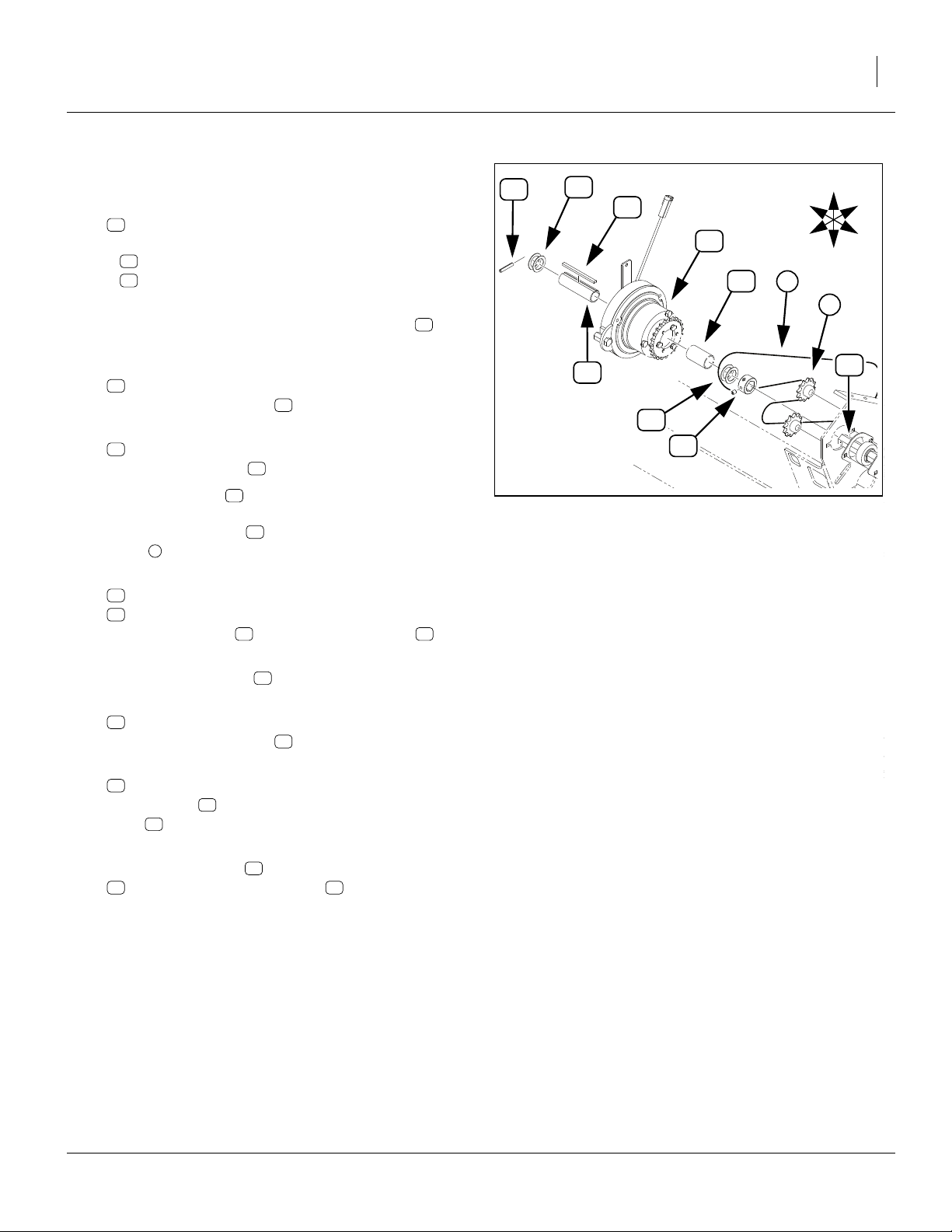

Refer to Figure 44

13. At the clutch assembly , remove and save three

sets:

123

802-004C HHCS 1/4-20X3/4 GR5

128

804-006C WASHER LOCK SPRING 1/4 PLT

14. The sprocket may still be held by pins. Remove and

save the sprocket:

136

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

Any roll pins present, the shaft, and the balance of

the clutch assembly are not re-used.

102

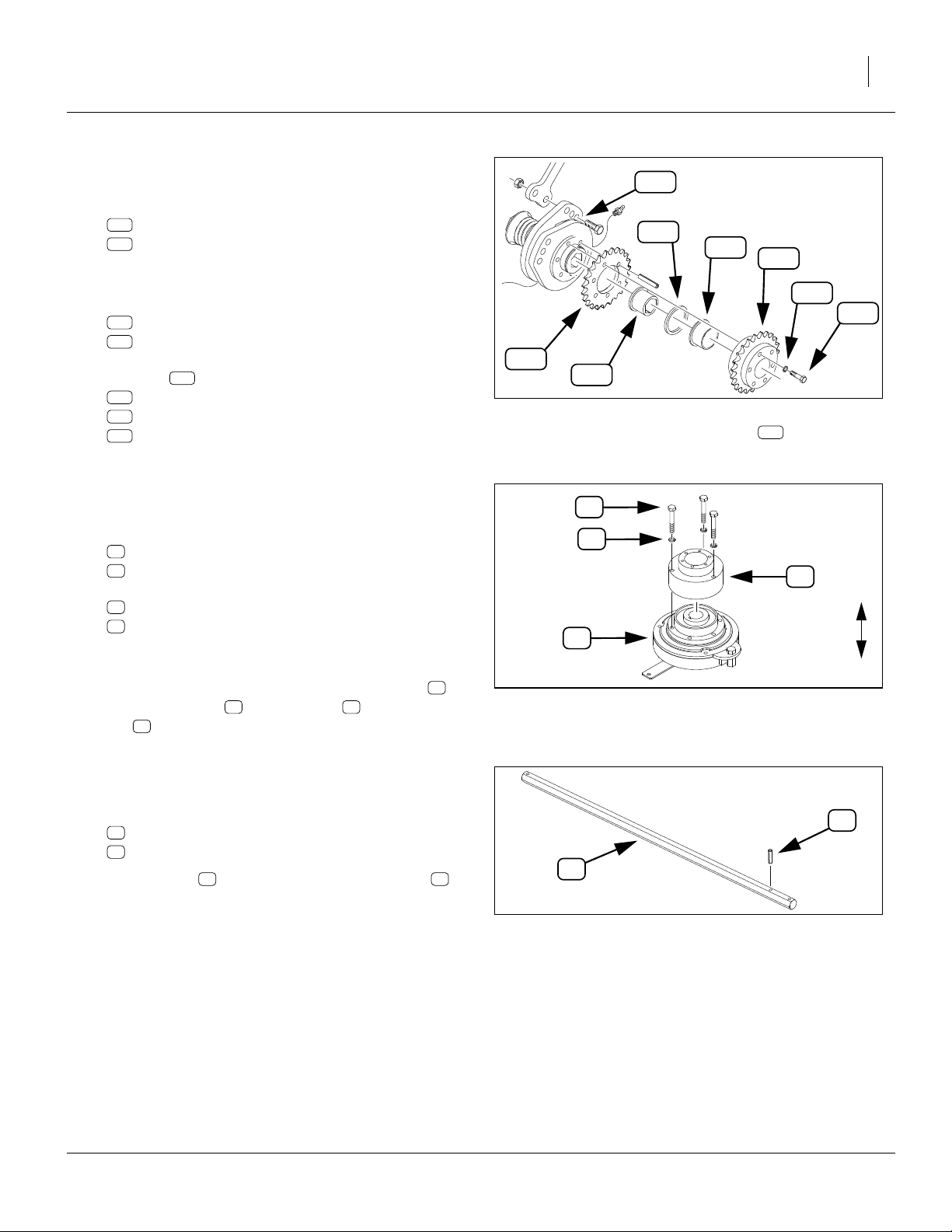

Pre-Assemble 3S-3000 LH Clutch

Refer to Figure 45

15. Select one each new:

54

823-231C OGURA CLUTCH

22

195-347D ELECTRIC CLUTCH ADAPTOR

and three sets new:

34

802-684C HHCS M8X1.25X55 GR8.8

48

804-157C WASHER SPRING LOCK M8 PLT

Place the tab end of down on a work surface.

Note that the 195-347D adaptor has alternating

smooth and tapped (threaded)

16. Secure the large end of the 195-347D adaptor to

the Ogura clutch with the bolts and lock wash-

48

ers . Torque to specifications (see page 93).

54

22

1

⁄

in holes.

4

54 34

22

102

Figure 43: 3S-3000:

Release LH Power Shaft

Figure 44: 3S-3000:

Disassemble LH Clutch

34

48

54

Figure 45: 3S-3000

Pre-assemble LH Clutch

136

128

k

123

102

22

R

F

21627

U

B

L

D

115

28106

U

D

28144

195-073M 03/24/2009

Page 33

Great Plains Manufacturing, Inc. Update 3S-3000 Left Hand Drive 29

Prepare New 3S-3000 LH Power Shaft

Refer to Figure 46

17. Select one each new:

21

195-346D SHAFT 7/8 HEX 32.44 LG

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

18. Drive pin into the inner hole of the shaft .

50 21

21

50

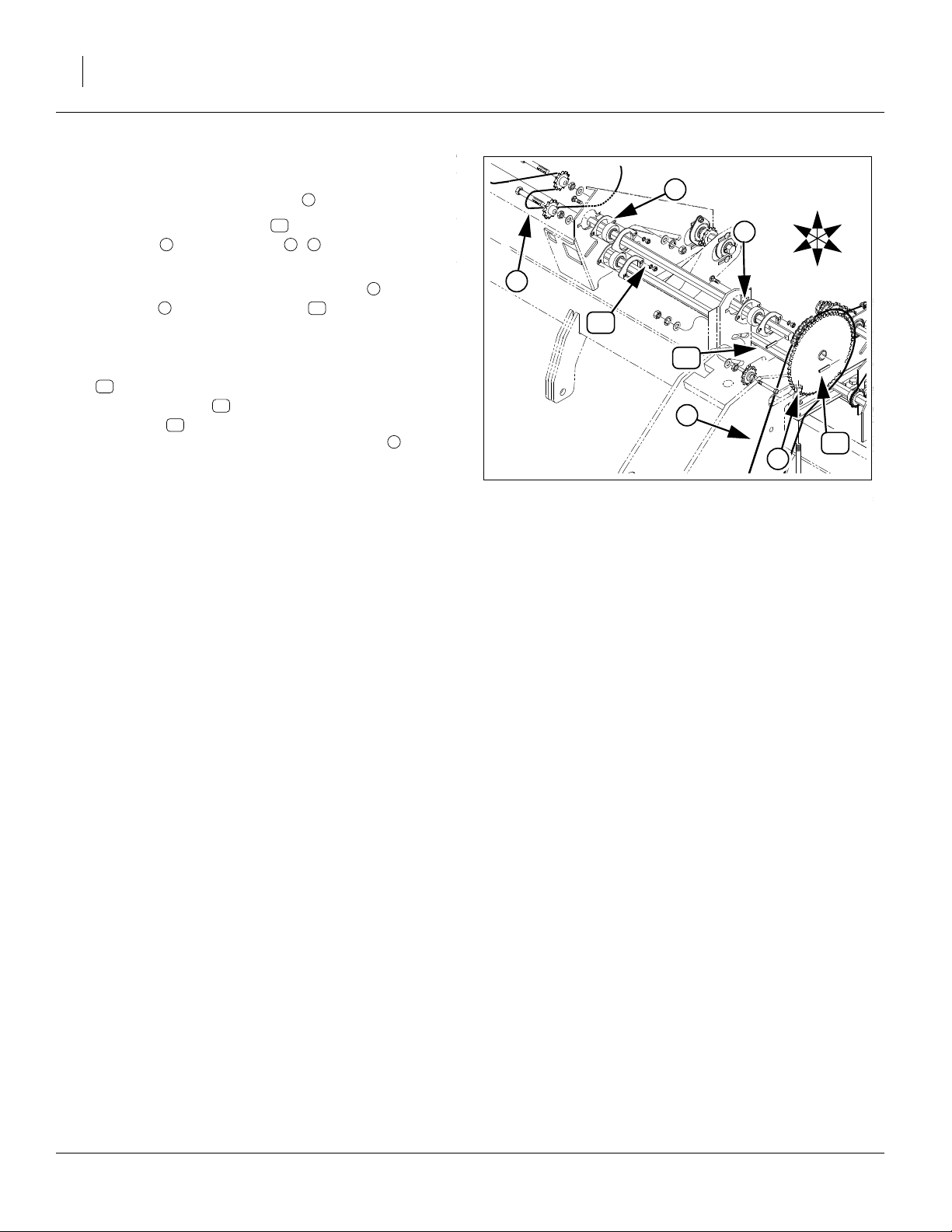

Install New 3S-3000 LH Power Shaft

Refer to Figure 47 (which, for clarity, is a fully exploded

view)

19. From drill left, insert shaft into the existing flanged

bearings .

20. Select the saved ground drive sprocket . Place the

sprocket onto the new shaft , with the raised

hub of the sprocket to drill right (towards bearings).

21. Select one new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

22. Drive the roll pin into the hole at the left end of

new shaft , securing the sprocket.

Note: Do not remount the ground drive chain at this

time.

b

k21

50

21

21

k

c

R

28094

U

B

Figure 46: 3S-3000:

Pin New LH Shaft

b

b

F

n

L

D

21

50

c

50

k

Figure 47: 3S-3000:

Install LH Power Shaft

28056

03/24/2009 195-073M

Page 34

30 Electric Clutch Package Great Plains Manufacturing, Inc.

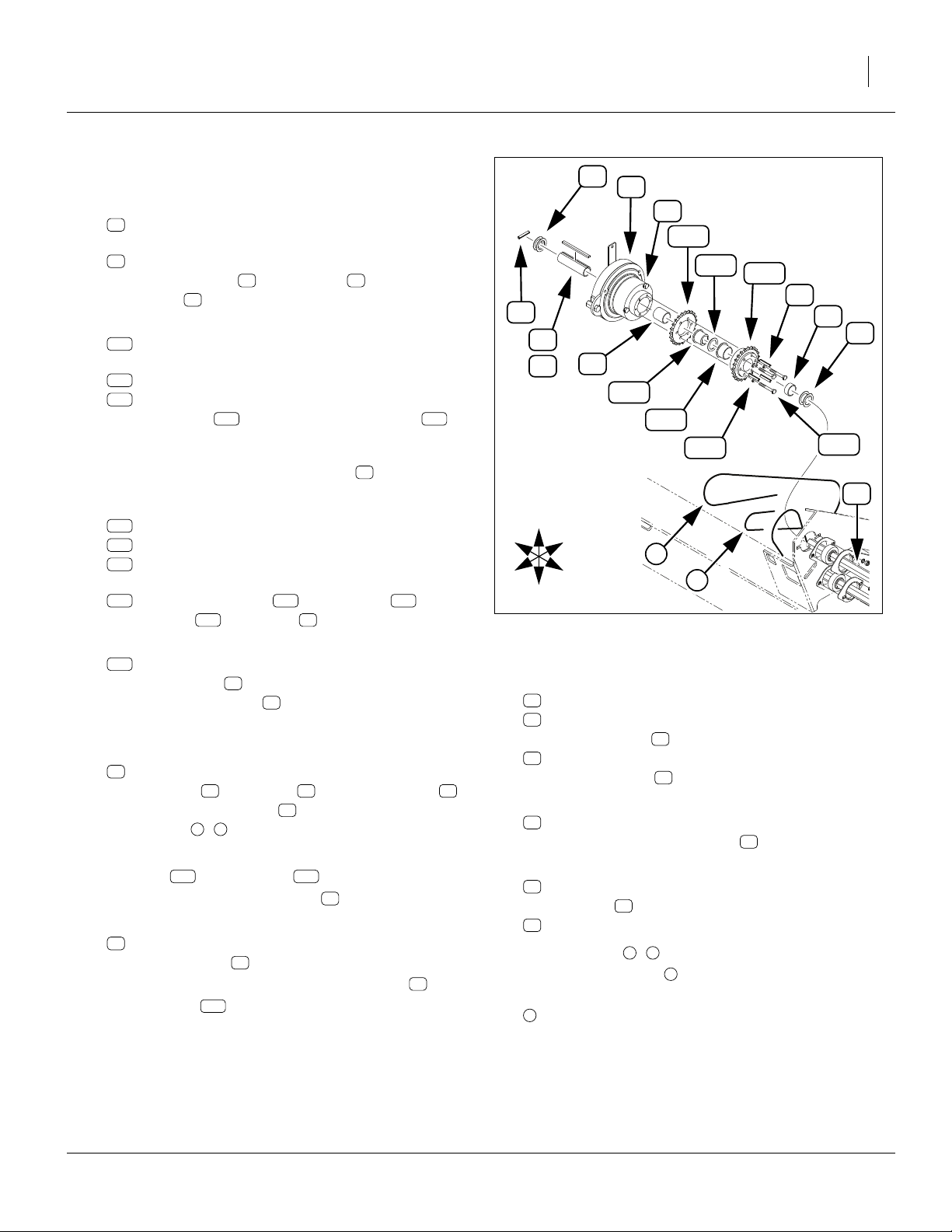

Install 3S-3000 LH Clutch

Refer to Figure 48

23. Select two new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

and one new:

24

195-349D WING FERT CLUTCH OUTER SPCR TB

Place the washers , followed by the spacer , on

the shaft .

24. Select one each new:

13

195-160H

51

817-111C BSHG FLG 1.26IDX1.41ODX.87L

12

176-065D CLUTCH FRICTION WASHER

15

195-222D BRG 7/8 HEX ID X 1.254 OD

With any flanged ends to the right, place the bushing

51 12 15

, the friction washer and the bearing inside

the sprocket .

25.

Select three sets new:

31

802-152C HHCS 1/4-20X2 GR5

39

804-006C WASHER LOCK SPRING 1/4 PLT

Orient the sprocket with the larger raised hub to

drill right. Place the bolts through the lock washers and into every other hole of the left face.

Place sprocket , bolt face left, on the shaft .

26. Select the saved:

136

and one new:

25

195-350D WING FERT CLUTCH INNER SPCR TB

Place them on the shaft .

27. Select the clutch assembled at step 16 and one

each new:

26

196-877D BUSHING 1 1/8 ODX7/8 HEX BORE

58

839-956C KEY 1/4 X 3/16 X 3.80

Insert the bushing in the clutch assembly .

Align the keyways of the bushing and the Ogura

clutch. Insert the key

28. With the tab end to drill right, place the clutch

assembly on shaft . Align the threaded holes

of the adaptor with the bolts . Screw in the

bolts, finger-tight.

29. Select three new

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Drive the roll pins into the smooth holes. Tighten

bolts to specification. Re-seat roll pins as required.

21

39

808-240C SPKT 40A23X1.813-1.818 BR/6HOL

54 21

46 24

SPKT CLUTCH 40B23T RND BORE

18

18

31

18 21

21

54

26 54

58

22 31

50

50

46

54

30. Move the clutch assembly to drill left.and into the

Drive Type chain

31. Select two new:

46

804-061C WASHER MACH 1.50 X 1.00 X 18GA

Place them on the shaft .

32. Select one new:

50

805-180C PIN ROLL 1/4 X 1 1/2 LG PLT

Drive the pin into the hole at the right end of the

shaft , to secure all the components just installed

on the shaft.

Note: One of the sprockets attached to the clutch is

unused on the standard 3S-3000. The second

sprocket is provided to ease any future upgrade to

Fertilizer and/or Small Seeds capability.

21

58

26

22