Page 1

Great Plains Manufacturing, Inc. 1

Disk Harrow Update

Gauge Wheel Update

General Information

These Instructions explain how to install the gauge wheel

kit update. These instructions apply to kit number: 558185A GAUGE WHEEL DISK UPDATE KIT. The gauge

MetaData: of <Safety Topics>Introduction

Tools Required

• Basic Hand Tools

Manual Update

Refer to the Disk Harrow operator’s manual for detailed

safety and maintaining of machine. Refer to parts manual for part identification.

556-100M Operator Manual

556-100P Parts Manual

Assembly Instructions

Move machine to level ground, near a welder and unfold

wings. Remove old gauge wheel assemblies from wing

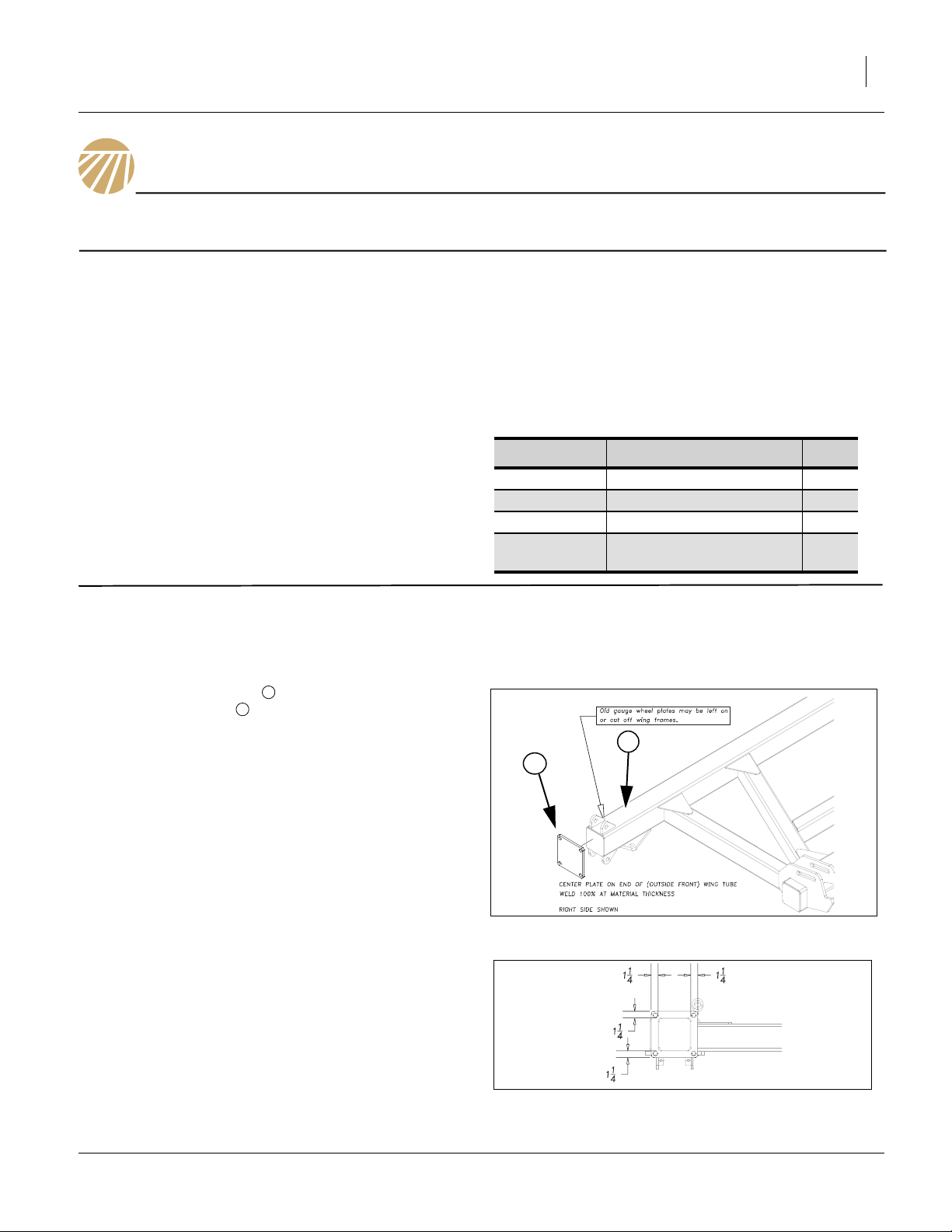

Refer to Figure 1

1. Center the 556-474D over the end of the outer tube

of the wing frame .

1

2

wheel will come completely assembled. The plates will

have to be welded on to wing frame.

• Torque Wrench

• Welder

558-185A Kit

Part Number

Description Qty.

556-220K GAUGE WHEEL ASY RH 1

556-221K GAUGE WHEEL ASY LH 1

556-474D PLATE - TORCHED 2

821-001C

PAINT GP GREEN

SPRAY CAN

1

frame. The old gauge wheel plates may stay on or may

be cut off.

2

1

FigureSpacer:

Refer to Figure 2

Figure 1

Plate Assembly

2. Position the plate as shown.

3. Weld the back side of the plate to the tube

FigureSpacer:

Figure 2

Plate Location

08/23/2010 558-185M

41867

41869

Page 2

2 Disk Guage Wheel Update Great Plains Manufacturing, Inc.

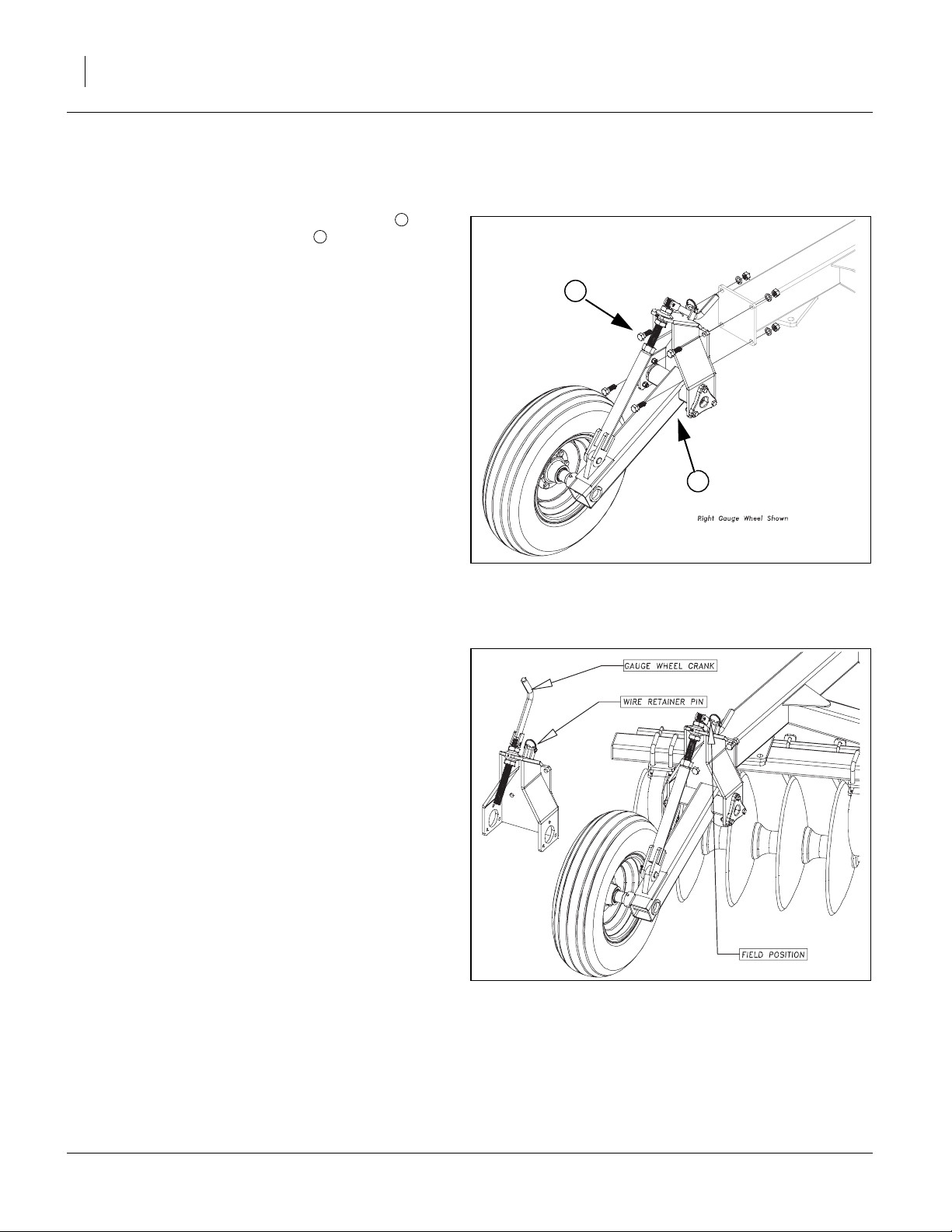

Refer to Figure 3

Note: There is a RH (right hand) and LH (left hand)

assembly. The RH is shown.

4. Now the 556-220K gauge wheel assembly may be

installed using the 3/4 x 2 hex bolts , 3/4 lock washers

2

1

and 3/4 nuts.

5. Torque the bolts to 265 ft-lb.

6. Repeat the same procedure for the left hand side.

2

1

Refer to Figure 4.

7. To change the gauge wheel setting, remove the wire

retaining pin and fold gauge wheel crank up to adjust.

Lower or raise the gauge wheel by turning the gauge

wheel crank. Raise the wheels up until you have the disk

adjusted in the fore-and-aft, side to side and the desired

working depth you desire. Fold the gauge wheel crank

back down in the field position and reinstall the wire retaining pin. As you are running the disk through the field, stop

the tractor leaving the disk in the ground. Now you can

adjust the gauge wheels 1/2” to 1-1/2” above the ground.

After initial adjustment you can turn gauge wheel crank the

same amount as the depth stop crank (if changed, but

crank turns opposite way than depth control crank to keep

initial setting). This position should be maintained to prevent excessive wear to gauge wheel parts.

FigureSpacer:

FigureSpacer:

Figure 3

Gauge Wheel Assembly

Figure 4

Gauge Wheel Adjustment

41868

41870

558-185M 08/23/2010

Loading...

Loading...