Page 1

TABLE OF CONTENTS

Safety Notices ...................................................................................................... 1

System Overview ................................................................................................. 3

Virtual Terminal (VT).......................................................................................................... 3

Master Switch .................................................................................................................... 4

Working Set Master (WSMT) Module PDC (Planter Drill Control) ..................................... 4

Working Set Member (WSMB) Module (Optional) ............................................................. 5

Implement Lift Switch (Optional) ........................................................................................ 5

CAN Terminators ............................................................................................................... 5

System Requirements ......................................................................................... 7

Performance Features ....................................................................................................... 7

Compatibility ...................................................................................................................... 8

Installation ............................................................................................................ 9

Virtual Terminal.................................................................................................................. 9

Master Switch .................................................................................................................... 9

Working Set Master (WSMT) Module .............................................................................. 10

Working Set Member (WSMB) Module............................................................................ 12

Cab Harness Connections ............................................................................................... 16

Sensor Installation ........................................................................................................... 22

Seed Sensors.................................................................................................................................. 22

Hopper Level Sensors..................................................................................................................... 24

RPM/Fan Sensors ........................................................................................................................... 24

Air Pressure Sensors ...................................................................................................................... 24

System Modes.................................................................................................... 25

System Modes ................................................................................................................. 25

User Level Access ........................................................................................................... 25

Operate Mode .................................................................................................................. 25

Available Buttons in Operate Mode ................................................................................. 26

Next Channel .................................................................................................................................. 26

Next Screen .................................................................................................................................... 26

Increment ........................................................................................................................................ 26

Decrement....................................................................................................................................... 26

Inc/Dec Reset to Target .................................................................................................................. 26

Turn On/Off Channel....................................................................................................................... 27

Summary ......................................................................................................................................... 27

Setup/Configuration Mode ............................................................................................... 28

Available Buttons in Setup Mode ..................................................................................... 28

Planter Fill Disk ............................................................................................................................... 28

Row Monitor Setup.......................................................................................................................... 28

Control Setup .................................................................................................................................. 28

Speed Set ....................................................................................................................................... 29

Diagnostics...................................................................................................................................... 29

Alarm Log ........................................................................................................................................ 29

System Accumulators ..................................................................................................................... 29

Module Configuration ...................................................................................................................... 29

Screen Configuration ...................................................................................................................... 29

Planter Output Module (POM) Configuration (Optional) ................................................................. 29

Configuration ................................................................................................................................... 29

IntelliAg PDC User 2 & 3

11001-1501-200811

i

Page 2

TABLE OF CONTENTS

System Configuration ....................................................................................... 31

Control Setup Overview................................................................................................... 31

Material/Channel Setup Steps......................................................................................................... 31

Control Channel and Material Selection .......................................................................................... 33

Material Assignment (Matrl 1-16) .................................................................................................... 33

Material Setup ................................................................................................................................. 34

Create a Material Name .................................................................................................................. 34

Type................................................................................................................................................. 35

Units ................................................................................................................................................ 36

Preset Method Enabled ................................................................................................................... 36

Preset Method Disabled .................................................................................................................. 37

Material Setup Constants - Planter Ctrl ........................................................................... 38

Target Rate...................................................................................................................................... 38

Max Rate ......................................................................................................................................... 38

Min Rate .......................................................................................................................................... 38

Inc/Dec % ........................................................................................................................................ 38

Seeds Per Rev ................................................................................................................................ 39

Disc High Limit................................................................................................................................. 39

Disc Low Limit ................................................................................................................................. 39

Prod Level Alarm ............................................................................................................................. 39

High and Low Population Alarm ...................................................................................................... 39

Row Width ....................................................................................................................................... 40

On/Off Pattern ................................................................................................................................. 40

Row Fail Rate .................................................................................................................................. 40

Material Setup Constants-Gran Seed and Gran Fertilizer Control .................................. 41

Target Rate...................................................................................................................................... 41

Max Rate ......................................................................................................................................... 41

Min Rate .......................................................................................................................................... 41

Inc/Dec % ........................................................................................................................................ 41

Density............................................................................................................................................. 42

Spreader Constant .......................................................................................................................... 42

High Shaft RPM ............................................................................................................................... 42

Prod Level Alarm ............................................................................................................................. 42

Seeds Per Pound ............................................................................................................................ 43

High and Low Population Alarm ...................................................................................................... 43

Row Width ....................................................................................................................................... 43

On/Off Pattern ................................................................................................................................. 44

Row Fail Rate .................................................................................................................................. 44

Material Setup Constants-Liquid Flow............................................................................. 45

Target Rate...................................................................................................................................... 45

Max Rate ......................................................................................................................................... 45

Min Rate .......................................................................................................................................... 45

Inc/Dec % ........................................................................................................................................ 45

Low Flow Limit ................................................................................................................................. 46

High Flow Limit ................................................................................................................................ 46

Product Level Alarm ....................................................................................................................... 46

Material Setup - Monitor Only.......................................................................................... 47

Type................................................................................................................................................. 47

Target Population ............................................................................................................................ 47

High and Low Population Alarms .................................................................................................... 47

Row Width ....................................................................................................................................... 47

On/Off Pattern ................................................................................................................................. 48

Row Fail Rate .................................................................................................................................. 48

Material Setup Constants - RPM Control ........................................................................ 49

Target Rate...................................................................................................................................... 49

Max Rate ......................................................................................................................................... 49

Min Rate .......................................................................................................................................... 49

Inc/Dec % ........................................................................................................................................ 49

ii

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 3

TABLE OF CONTENTS

Material Setup Constants - Granular Seed Monitor and Fertilizer Monitor ...................... 51

Target Rate ..................................................................................................................................... 51

Density ............................................................................................................................................ 51

Spreader Constant .......................................................................................................................... 51

Low Shaft RPM ............................................................................................................................... 51

High Shaft RPM .............................................................................................................................. 52

Prod Level Alarm............................................................................................................................. 52

Seeds Per Pound ............................................................................................................................ 52

High and Low Population Alarm...................................................................................................... 52

Row Width....................................................................................................................................... 53

On/Off Pattern ................................................................................................................................. 53

Row Fail Rate.................................................................................................................................. 53

Spreader Calibration ........................................................................................................ 53

Material Setup Constants - Split Air Regulation............................................................... 54

Target Rate ..................................................................................................................................... 54

Max Rate......................................................................................................................................... 54

Min Rate .......................................................................................................................................... 54

Inc/Dec %........................................................................................................................................ 54

Control Channel Setup..................................................................................................... 55

Planter Control Setup....................................................................................................... 56

Type ................................................................................................................................................ 56

Material Name ................................................................................................................................. 56

Control Mode................................................................................................................................... 56

Drive Type....................................................................................................................................... 57

Drive Frequency.............................................................................................................................. 57

Sensor Constant ............................................................................................................................. 57

Gear Ratio ....................................................................................................................................... 57

Number (#) of Seed Rows............................................................................................................... 57

Channel Width................................................................................................................................. 57

Precharge Time............................................................................................................................... 57

Flush Enable ................................................................................................................................... 59

Valve Calibration - Planter Control................................................................................... 60

Fill Disk............................................................................................................................................ 61

Fill Disk for a Control Channel ........................................................................................................ 61

Test Ground Speed ......................................................................................................................... 63

Row ................................................................................................................................................. 63

Test Target Pop .............................................................................................................................. 63

Test Seed Count ............................................................................................................................. 64

5 Rev Test........................................................................................................................ 65

Test Ground Speed ......................................................................................................................... 65

Row ................................................................................................................................................. 65

Test Target Pop .............................................................................................................................. 65

Test Seed Count ............................................................................................................................. 66

Remote Test Switch......................................................................................................... 66

Granular Seed and Granular Fert Setup.......................................................................... 67

Manual w/o Feedback ...................................................................................................................... 67

Valve Calibration - Gran Seed and Gran Fert.................................................................. 71

Channel On ..................................................................................................................................... 71

Limit Output ..................................................................................................................................... 72

Spreader Calibration - Gran Seed and Gran Fertilizer..................................................... 73

Density ............................................................................................................................................ 73

Spreader Constant .......................................................................................................................... 74

Target Meter RPM........................................................................................................................... 74

Number (#) Meter Revs................................................................................................................... 74

Pulse Count..................................................................................................................................... 74

New Spreader Constant .................................................................................................................. 74

Amount Dispensed.......................................................................................................................... 74

Shaft Turn ....................................................................................................................................... 74

IntelliAg PDC User 2 & 3

11001-1501-200811

iii

Page 4

TABLE OF CONTENTS

Liquid Flow Setup ............................................................................................................ 76

Manual w/o Feedback ..................................................................................................................... 76

Valve Calibration - Liquid................................................................................................. 79

Channel On ..................................................................................................................................... 79

Limit Output ..................................................................................................................................... 80

Liquid Flow Calibration .................................................................................................... 81

Initiating a Liquid Flow Calibration Procedure ................................................................................. 81

Granular Seed and Fertilizer Monitor Setup .................................................................... 83

Input Filter........................................................................................................................................ 83

Sensor Constant .............................................................................................................................. 83

Gear Ratio ....................................................................................................................................... 84

# Seed Rows ................................................................................................................................... 84

Channel Width ................................................................................................................................. 84

Spreader Calibration - Gran Seed Monitor and Gran Fertilizer Monitor .......................... 85

Density............................................................................................................................................. 85

Spreader Constant .......................................................................................................................... 86

Number (#) Meter Revs ................................................................................................................... 86

Pulse Count ..................................................................................................................................... 86

New Spreader Constant .................................................................................................................. 86

Amount Dispensed .......................................................................................................................... 86

RPM Control Setup.......................................................................................................... 87

Type................................................................................................................................................. 87

Material Name ................................................................................................................................. 87

Manual w/o Feedback ..................................................................................................................... 87

Drive Type ....................................................................................................................................... 88

Drive Frequency .............................................................................................................................. 88

Input Filter........................................................................................................................................ 88

Sensor Constant .............................................................................................................................. 88

Master Switch Off ............................................................................................................................ 88

Ramp Up/Down ............................................................................................................................... 88

Disable Control On Control Failure Alarm ....................................................................................... 89

Valve Calibration - RPM Control...................................................................................... 90

Channel On ..................................................................................................................................... 90

Limit Output ..................................................................................................................................... 91

Split Air Regulation Control ............................................................................................. 93

Type................................................................................................................................................. 93

Control Mode ................................................................................................................................... 93

Manual w/o Feedback ......................................................................................................................93

Drive Type ....................................................................................................................................... 93

Drive Frequency .............................................................................................................................. 94

Input Filter........................................................................................................................................ 94

Pressure Drop ................................................................................................................................. 94

Pressure Slope ................................................................................................................................ 94

Pressure Offset................................................................................................................................ 94

Planter Selection ..............................................................................................................................94

Sensitivity Adjust ..............................................................................................................................94

Module Configuration ...................................................................................................... 95

Serial Number and Module Type..................................................................................................... 95

Module Address............................................................................................................................... 96

Clutch Folding Module ..................................................................................................................... 96

Auto Sort.......................................................................................................................... 97

Auto Configuration........................................................................................................... 97

Auto Sort and Auto Config Examples .............................................................................. 98

Row Assignment............................................................................................................ 102

iv

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 5

TABLE OF CONTENTS

Row Status/Row Width Setup........................................................................................ 103

Row Width..................................................................................................................................... 103

Auto Update Width ........................................................................................................................ 103

Imp Width ...................................................................................................................................... 104

On/Off Pattern ............................................................................................................................... 104

Blockage Pattern ........................................................................................................................... 105

Hopper Assignment ....................................................................................................... 106

# of Hoppers.................................................................................................................................. 106

Hopper Set..................................................................................................................... 107

Logic Level .................................................................................................................................... 107

Alarm Delay................................................................................................................................... 108

Channel......................................................................................................................................... 108

Accessory Assignment................................................................................................... 108

# Of Pressure/RPM Sensors ......................................................................................................... 109

RPM Setup..................................................................................................................... 109

High Alarm .................................................................................................................................... 109

Low Alarm ..................................................................................................................................... 110

High Alarm Delay .......................................................................................................................... 110

Low Alarm Delay ........................................................................................................................... 110

RPM Constant ............................................................................................................................... 110

RPM Filter ..................................................................................................................................... 110

Disable Control on Low Alarm....................................................................................................... 110

Pressure Sensor Setup.................................................................................................. 111

High Alarm .................................................................................................................................... 111

Low Alarm ..................................................................................................................................... 111

High Alarm Delay .......................................................................................................................... 111

Low Alarm Delay ........................................................................................................................... 112

Pressure Filter ............................................................................................................................... 112

Row Monitor Setup ........................................................................................................ 113

Material Name ............................................................................................................................... 113

High Alarm Delay .......................................................................................................................... 114

Low Alarm Delay ........................................................................................................................... 114

Population Adjust .......................................................................................................................... 114

Population Filter ............................................................................................................................ 114

Row Fail Rate................................................................................................................................ 114

Ground Speed Setup ..................................................................................................... 115

Source........................................................................................................................................... 115

GSPD Constant............................................................................................................................. 116

Shut Off Speed.............................................................................................................................. 116

Minimum Override ......................................................................................................................... 116

Master Sw Timeout ....................................................................................................................... 117

Ground Fail Alarm Delay............................................................................................................... 117

Precharge Ground Speed ............................................................................................................. 117

Flush Enable Speed...................................................................................................................... 117

Implement Lift................................................................................................................................ 117

Ground Speed Calibration ............................................................................................. 118

10” VT Aux Input/Function Assignment ......................................................................... 118

5” VT Aux Input/Function Assignment ........................................................................... 120

Work Screen Configuration............................................................................................ 123

Bargraph Setup ............................................................................................................................. 123

Return System Active Delay ......................................................................................................... 124

IntelliAg PDC User 2 & 3

11001-1501-200811

v

Page 6

TABLE OF CONTENTS

Data Items ........................................................................................................ 127

Clearing Accumulators .................................................................................................. 127

Control Actual Channels 1-4.......................................................................................... 127

Control Target Channels 1-4 ......................................................................................... 127

Control Rate Channels 1-4 ............................................................................................ 128

Control Scan.................................................................................................................. 128

Pop Row Scan............................................................................................................... 128

Pop Min Max Row Scan ................................................................................................ 128

Pop Min Row ................................................................................................................. 129

Pop Max Row ................................................................................................................ 129

Pop Avg ......................................................................................................................... 129

Spacing Row Scan ........................................................................................................ 129

Spacing Min Max Row Scan.......................................................................................... 129

Spacing Min Row........................................................................................................... 130

Spacing Max Row.......................................................................................................... 130

Spacing Avg .................................................................................................................. 130

Seed/Distance Row Scan .............................................................................................. 130

Seed/Distance Min Max Row Scan ............................................................................... 130

Seed/Distance Min Row ................................................................................................ 131

Seed/Distance Max Row ............................................................................................... 131

Seed/Distance Average................................................................................................. 131

Singulation Average ...................................................................................................... 131

Singulation Row Scan ................................................................................................... 131

Singulation Min Max Scan ............................................................................................. 131

Ground Speed ............................................................................................................... 132

Total Area ...................................................................................................................... 132

Field 1 Area ................................................................................................................... 132

Field 2 Area ................................................................................................................... 132

Channels 1 - 4 Area....................................................................................................... 133

Area Scan...................................................................................................................... 133

Control Feedback Scan ................................................................................................. 133

Area Per Hour................................................................................................................ 133

System Active Time ....................................................................................................... 133

Seed Count Accum Row ............................................................................................... 134

Distance Accumulator.................................................................................................... 134

Channels 1 - 4 Material Accum ..................................................................................... 134

Accessory Input Scan .................................................................................................... 134

Pressure Scan ............................................................................................................................... 134

RPM Scan ..................................................................................................................................... 135

Channel 1-4 Product Level ............................................................................................ 135

Hopper Level Status Scan............................................................................................. 135

Boom Status .................................................................................................................. 135

Guidance Status ............................................................................................................ 135

vi

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 7

TABLE OF CONTENTS

System Operation ............................................................................................ 137

Row Fill (Split Air Regulation) ........................................................................................ 137

Pre-Operating Preparation............................................................................................. 137

Fill Disk ...........................................................................................................................137

Start ............................................................................................................................... 138

Stop................................................................................................................................ 139

Operate Screen Symbols............................................................................................... 140

Target Rate ................................................................................................................................... 140

Increase/Decrease % Rate ........................................................................................................... 140

Target Preset Rate ........................................................................................................................ 140

Implement Lift Switch .................................................................................................................... 140

Task Controller .............................................................................................................................. 140

Row Indicators .............................................................................................................................. 140

Autopilot Steering Navigation......................................................................................... 141

Accumulators ................................................................................................................. 141

Population Row Scan.................................................................................................................... 141

Singulation Average Population.................................................................................................... 141

Material Name ............................................................................................................................... 141

Population Max Row ..................................................................................................................... 142

Population Min Row ...................................................................................................................... 142

Precharge Feature ......................................................................................................... 143

Flush Enable .................................................................................................................. 144

System Information and Diagnostics ............................................................................. 145

Accumulators/Seed Count/Distance Screen.................................................................. 145

Powered On Time ......................................................................................................................... 145

System Active Time ...................................................................................................................... 145

System Active Area ....................................................................................................................... 146

Distance ........................................................................................................................................ 146

Diagnostics .................................................................................................................... 146

CH Setpoint ................................................................................................................................... 146

CH Target...................................................................................................................................... 147

CH Actual Rate ............................................................................................................................. 147

CH RPM/GPM ............................................................................................................................... 147

CH PWM ....................................................................................................................................... 147

CH Pulse Count ............................................................................................................................ 147

CH Freq Filt ................................................................................................................................... 147

Freq REL GSPD............................................................................................................................ 147

Freq Dig GSPD ............................................................................................................................. 147

Freq Press 1.................................................................................................................................. 147

IO Hopper 1................................................................................................................................... 148

IO Imp Lift...................................................................................................................................... 148

APP ID .......................................................................................................................................... 148

Sol PWR Volt ................................................................................................................................ 148

ECU PWR Volt .............................................................................................................................. 148

Snsr Pwr Volt ................................................................................................................................ 148

Gnd Volt ........................................................................................................................................ 148

Diagnostics Manual Valve Position................................................................................ 148

Manual Open of Channel .............................................................................................................. 149

Seed Count Screen........................................................................................................ 149

Information Screen......................................................................................................... 150

Resetting NOVRAM Values ........................................................................................... 151

Acknowledging Alarm Conditions .................................................................................. 151

Alarm Log....................................................................................................................... 152

Alarm Detail ................................................................................................................... 153

Alarm Reset .................................................................................................................................. 154

IntelliAg PDC User 2 & 3

11001-1501-200811

vii

Page 8

TABLE OF CONTENTS

Task Controller ................................................................................................ 155

Implement Offset ........................................................................................................... 155

Calculating Implement Offset ........................................................................................................ 155

Channel Linking ............................................................................................................................. 156

Material Application Rates ............................................................................................. 156

Import/Export Data ........................................................................................................ 157

Troubleshooting & Alarms ............................................................................. 161

Appendix .......................................................................................................... 171

Warranty............................................................................................................ 173

viii

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 9

OPERATOR’S MANUAL

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to potential

hazards.

This Safety Alert Symbol identifies important safety

messages in this manual. When you see this

symbol, carefully read the message that follows. Be

alert to the possibility of personal injury or death.

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or serious

injury.

Use of the word CAUTION with the Safety Alert Symbol indicates a

potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Use of the word CAUTION without the safety alert symbol

indicates a potentially hazardous situation which, if not avoided,

may result in equipment damage.

IntelliAg PDC User 2 & 3

11001-1501-200811

SAFETY NOTICES / 1

Page 10

OPERATOR’S MANUAL

2 / SAFETY NOTICES

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 11

OPERATOR’S MANUAL

SYSTEM OVERVIEW

The DICKEY-john IntelliAg Planter Drill Control system controls planting,

liquid, and granular applications. The IntelliAg is designed to ISO 11783

CAN communication standards providing the capability of communicating

with other manufacturer’s ISO 11783-compatible equipment.

The IntelliAg consists of:

• 5” Virtual Terminal or a 10” Virtual Terminal

• Master Switch

• Working Set Master Module

• Up to 11 Working Set Member Modules (monitors up to a total of 214

rows of seed input) (optional)

• Implement Lift (optional)

• CAN Terminators

• TECU (10” VT only)

• Video Surveillance (10” VT only)

All of the devices communicate using the ISO 11783 CAN communications

standard. System components are described in the following section.

NOTE: Examples shown throughout

this manual depict display

screens of the 10” Virtual

Terminal display.

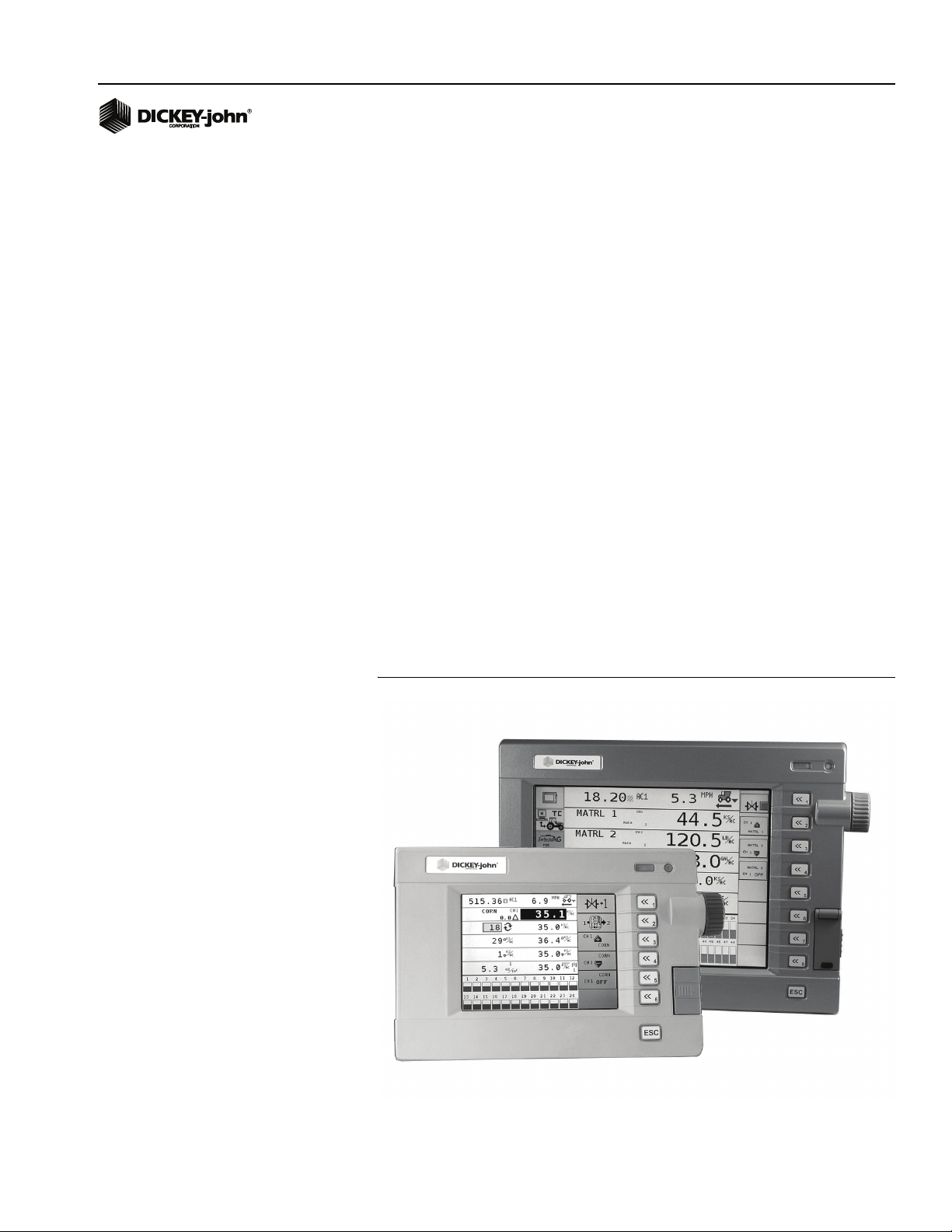

VIRTUAL TERMINAL (VT)

A 5” or 10” Virtual Terminal provides user interface with the IntelliAg system

used for output and input of data. Reference the VT operator’s manual for

setup and configuration instructions.

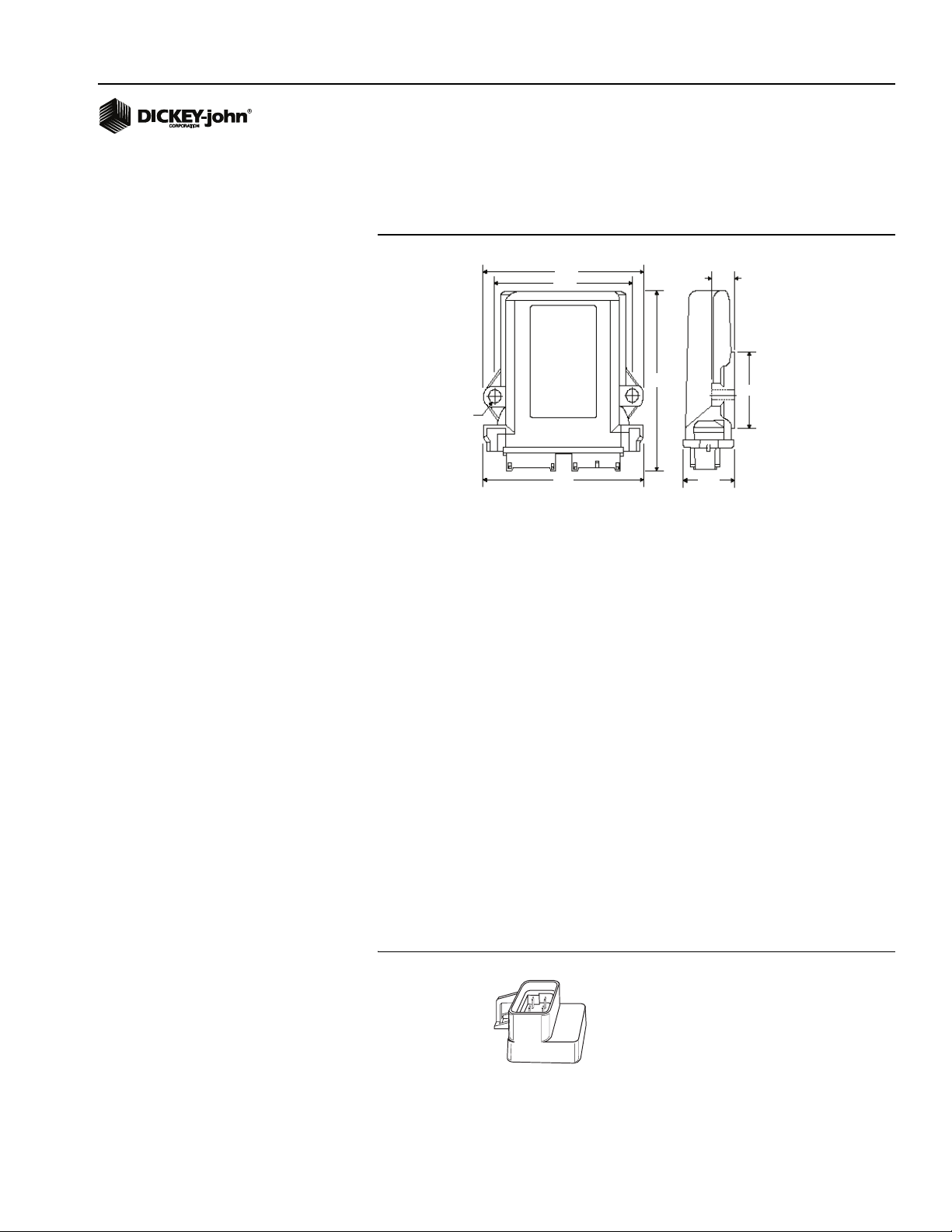

Figure 1

5” or 10” Virtual Terminal

IntelliAg PDC User 2 & 3

11001-1501-200811

SYSTEM OVERVIEW / 3

Page 12

OPERATOR’S MANUAL

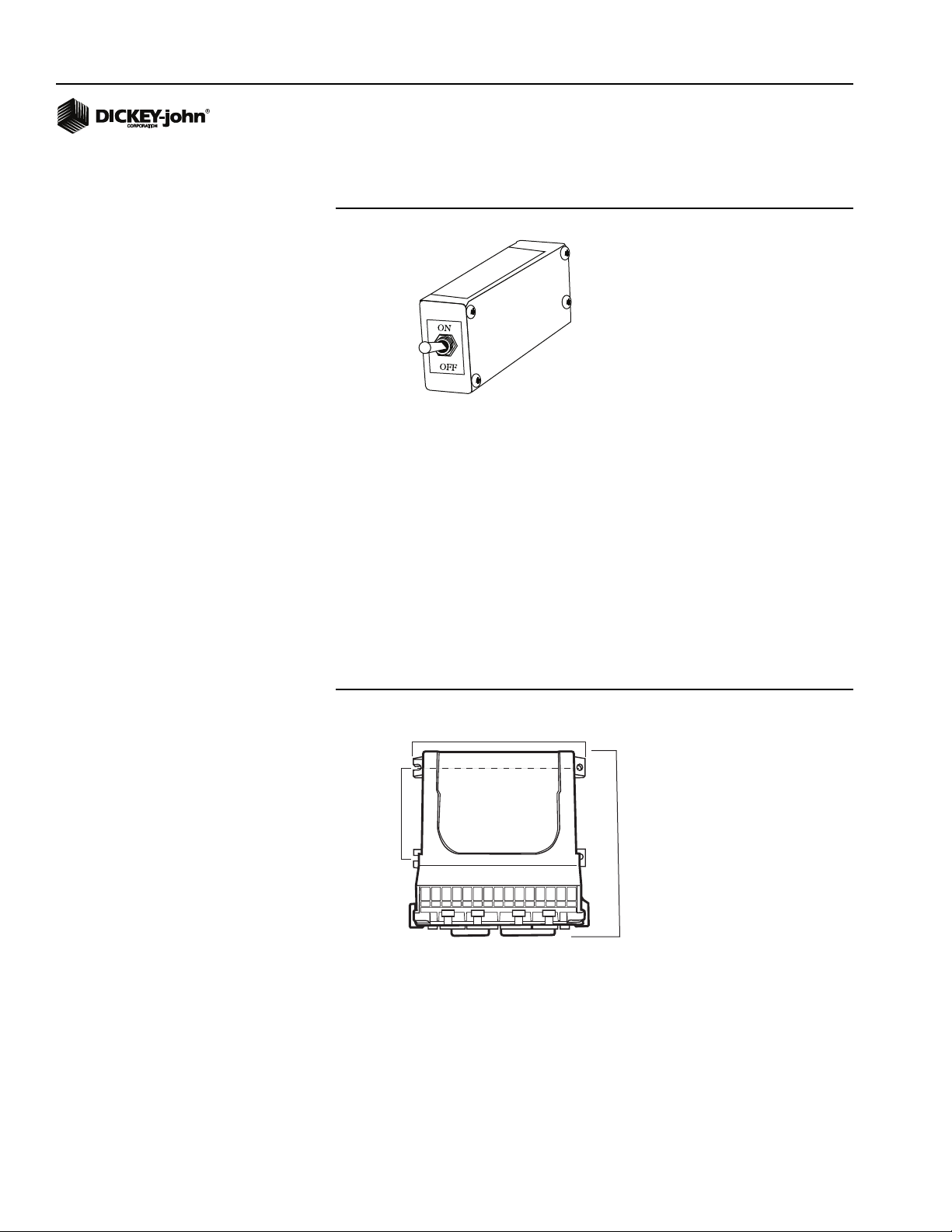

MASTER SWITCH

Figure 2

Master Switch

The Master Switch starts and stops product application through a single

switch. The two switch positions are ON and OFF. The normal operating

position for field application is ON. In this position, ground speed controls

the application rate. When ground speed is reduced to zero, all application

ceases. The OFF position inhibits all product flow. When set to the OFF

position, the system shuts off for safety and travel purposes. Setup and

configuration of the system is accomplished when the Master Switch is in

the OFF position. The Master Switch is also housed inside the cab of the

tractor.

WORKING SET MASTER (WSMT) MODULE PDC

(PLANTER DRILL CONTROL)

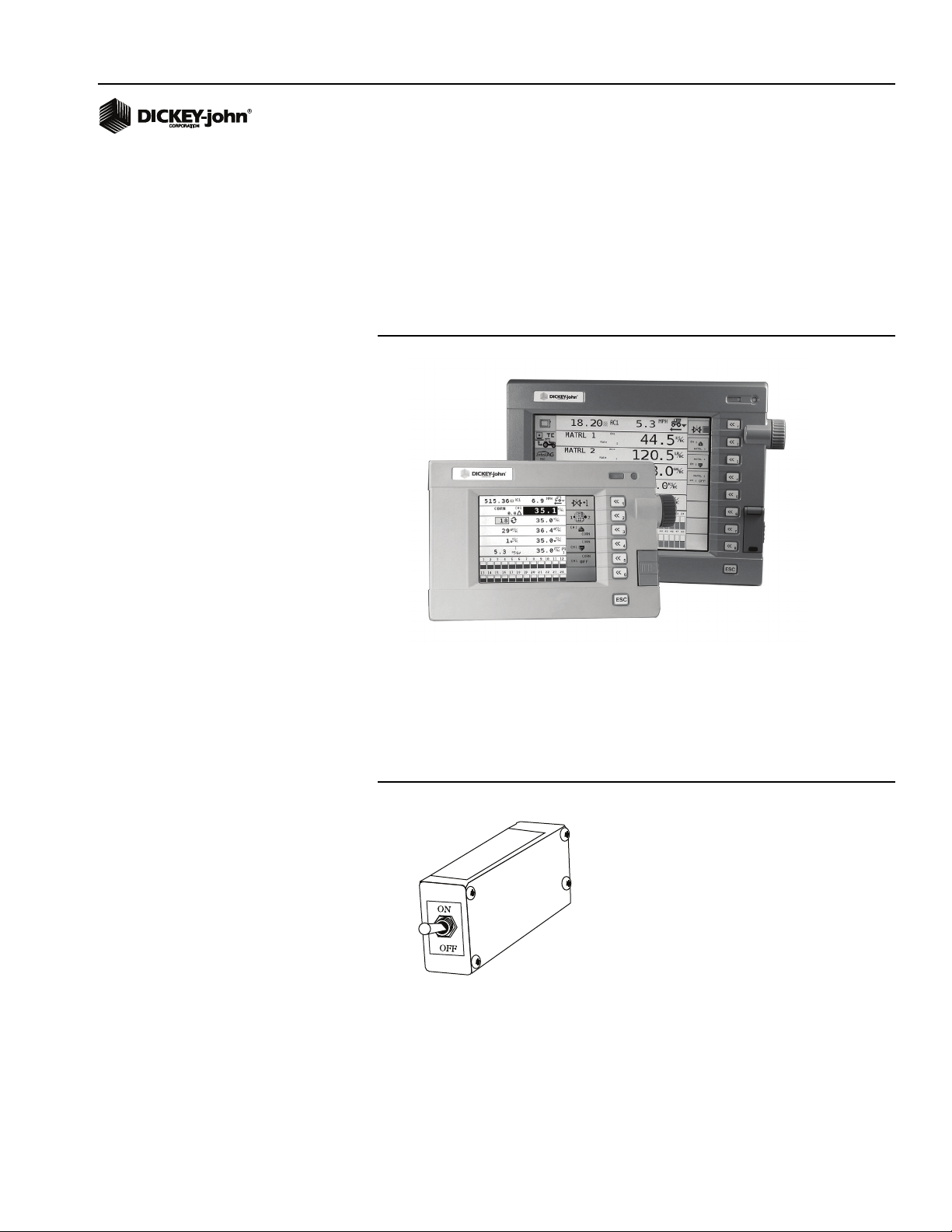

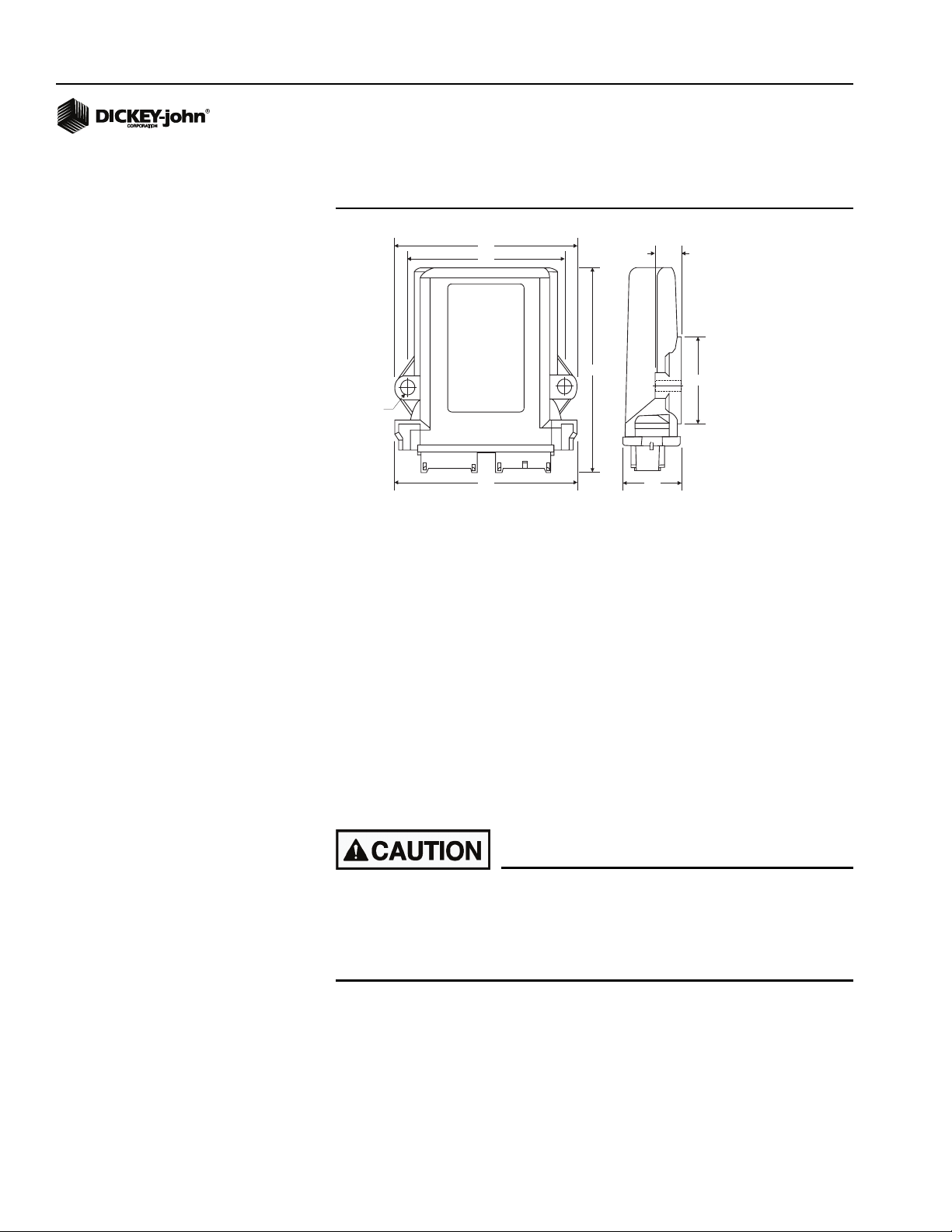

Figure 3

Working Set Master Module

7.45”

7.0”

3.93”

6.80”

The Working Set Master (WSMT) module houses the system’s primary

interface device. All system parameters, constants and memory are stored

in the WSMT. The WSMT has four channels for planter, granular seeding,

granular fertilizer, liquid control or RPM. In addition, the WSMT can accept

inputs from 1 hopper level, 1 RPM or pressure sensor, 1 lift switch, 1 ground

speed sensor and up to 16 seed sensors. The WSMT module uses a 48-pin

connector with a jackscrew to secure the connector to the module. The

WSMT is typically mounted on the implement.

4 / SYSTEM OVERVIEW

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 13

OPERATOR’S MANUAL

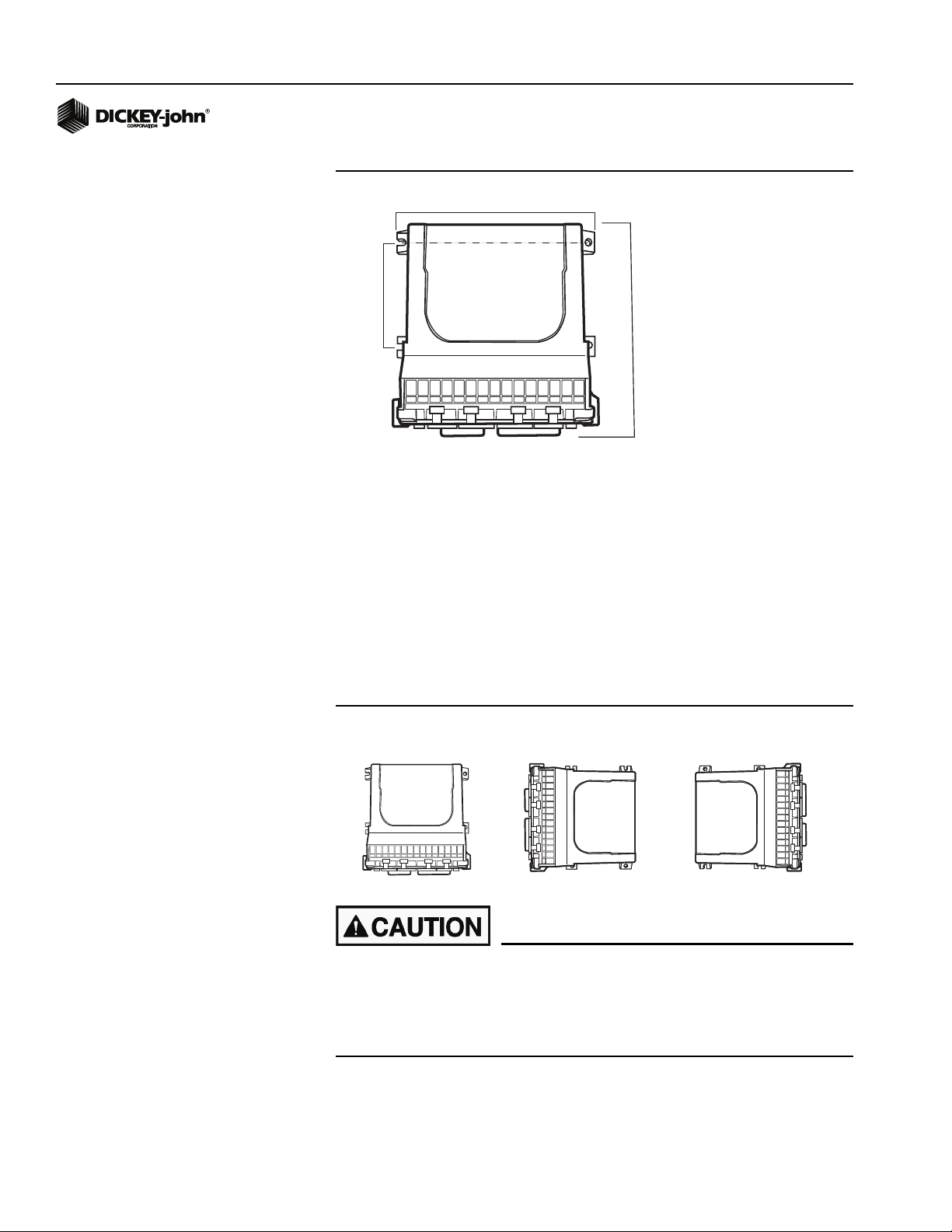

4.63

4.00

5.24

.291

2 holes

4.68

1.37

2.36

0.630

WORKING SET MEMBER (WSMB) MODULE

(OPTIONAL)

Figure 4

Working Set Member Module

Each Working Set Member (WSMB) module is an auxiliary to the Working

Set Master (WSMT). Each WSMB can accept up to 18 rows of seed

sensors. The WSMB passes information directly to the WSMT. Up to 11

WSMB’s can be installed to monitor up to 214 rows. The flexible design of

the WSMB allows for installation virtually anywhere on the implement.

IMPLEMENT LIFT SWITCH (OPTIONAL)

The Implement Lift Switch detects the position of the implement. When

using an Implement Lift Switch, the Master Switch can be left in the ON

position during operation, and the system will be turned OFF and ON as the

implement is raised and lowered. The Master Switch should be turned OFF

when in transport, when stationary, or when the operator has left the cab.

CAN TERMINATORS

CAN Terminators are necessary for proper communication between each

component of the system.

• One terminator is located on the cab harness, approximately 30 inches

from the Virtual Terminal connector.

• One terminator plugs into the implement harness of the last module

connected to the CAN bus.

Figure 5

Can Terminator

IntelliAg PDC User 2 & 3

11001-1501-200811

SYSTEM OVERVIEW / 5

Page 14

OPERATOR’S MANUAL

6 / SYSTEM OVERVIEW

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 15

OPERATOR’S MANUAL

SYSTEM REQUIREMENTS

The minimum requirements to operate the IntelliAg Planter/Drill Control

system consist of:

• Virtual Terminal

•Master Switch

• Working Set Master

• Two CAN terminators

• TECU (10” VT only)

Optional and not required for system operation:

• Working Set Member(s)

• Clutch/Switch Folding Module and Planter Output Module

• Remote Test Switch (required for Continuous Test and 5 Rev Test)

PERFORMANCE FEATURES

• Three user access levels for viewing and setting constants

– User Level 1 (End User)

– User Level 2 (Dealer)

– User Level 3 (OEM)

• Monitoring of up to 214 rows, ground speed, one hopper level, one

shaft sensor, one lift switch

• Easy and flexible configuration

• View of functions including:

– control actual rates

– control target rates

– control rate

– control scan

– population row scan

– population min/max scan

– population min row

– population max row

– population average

– spacing row scan

– spacing min/max scan

– spacing min row

– spacing max row

– spacing average

– seeds per distance row scan

– seeds per distance min/max row scan

– seeds per distance min row

– seeds per distance max row

– seeds per distance average

– singulation average

– singulation row scan

– singulation min/max scan

IntelliAg PDC User 2 & 3

11001-1501-200811

SYSTEM REQUIREMENTS / 7

Page 16

OPERATOR’S MANUAL

Viewable functions continued-

– ground speed

– total area

– field area - 1 and 2

– channel areas 1-4

– area scan

– pressure scan

–RPM scan

– control feedback scan

– area per hour

– system active time

– seed count accumulator

– distance accumulator

– control channel material accumulation 1-4

– channel product level 1-4

– hopper level status scan

– boom status

– guidance status

COMPATIBILITY

• Compatible with DICKEY-john sensors

8 / SYSTEM REQUIREMENTS

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 17

OPERATOR’S MANUAL

INSTALLATION

VIRTUAL TERMINAL

Reference the Virtual Terminal (VT) operator’s manual for installing the VT

to the tractor cab. Once the Virtual Terminal has been mounted, connect

the Tractor (Cab) Harness as illustrated in Figure 13 or Figure 14.

Figure 6

5” and 10” Virtual Terminals

MASTER SWITCH

1. Install the master switch within easy reach of the operator.

2. Once mounted, connect the master switch to the tractor (cab) harness

as illustrated in (Figure 13) or (Figure 14).

Figure 7

Master Switch

IntelliAg PDC User 2 & 3

11001-1501-200811

INSTALLATION / 9

Page 18

OPERATOR’S MANUAL

Figure 8

Working Set Master Module

7.45”

7.0”

3.93”

6.80”

WORKING SET MASTER (WSMT) MODULE

1. Select an area on the implement to mount the WSMT that allows for

easy hookup and access. Use the enclosure as a template to mark the

location of the mounting holes. Drill four 9/32 inch diameter holes

where marked.

IMPORTANT: Do not use the enclosure as a guide when drilling. Do

not overtighten nuts as this may damage the mounting

tabs of the enclosure.

The WSMT may be mounted in any of the following orientations:

Figure 9

Acceptable Orientation

PREFERRED

ACCEPTABLE

ACCEPTABLE

Do not install the module in any orientation other than shown in

(Figure 9). The connection wires must not be mounted upward, as

moisture can collect inside the unit and damage the circuits.

Ensure that module connectors do not face upward when

implement is in a folded position as well.

10 / INSTALLATION

2. Mount with the label side of module facing out. Do not mount with the

connector facing up (see caution).

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 19

OPERATOR’S MANUAL

3. Connect any additional adapter harnesses to the module harness. The

WSMT Module harness can accept the following adapter harnesses:

– Actuator Harness: This harness allows for up to 4 output control

channels, 4 control channel feedbacks, a hopper level sensor input,

a shaft sensor input, a ground speed input, and an implement

switch input. In addition, a pair of 6-pin connectors are available for

Servo connection which use FB1/FB2 respectively. Install sensors,

valves, etc. per the instructions included with the items. Install the

PWM valve assembly and feedback sensor for each control loop

and connect the devices to their respective inputs on the harness,

making certain to match PWM 1/Servo 1 with FB 1, PWM 2/Servo 2

with FB 2, etc. Secure any unused and excess cable lengths where

necessary. Refer to (Figure 15) for additional information.

– Seed Sensor Harness: This harness accommodates any standard

Dj Seed Sensor harness (PM style) or SE style harness depending

on the WSMT harness. A wide variety of harnesses are available to

accommodate various numbers of sensor inputs. Install all seed

sensors per the instructions included with the individual sensors.

Secure any unused or excess cable lengths as necessary.

IntelliAg PDC User 2 & 3

11001-1501-200811

INSTALLATION / 11

Page 20

OPERATOR’S MANUAL

4.00

.291

2HOLES

4.63

4.68

1.37

0.630

2.36

5.24

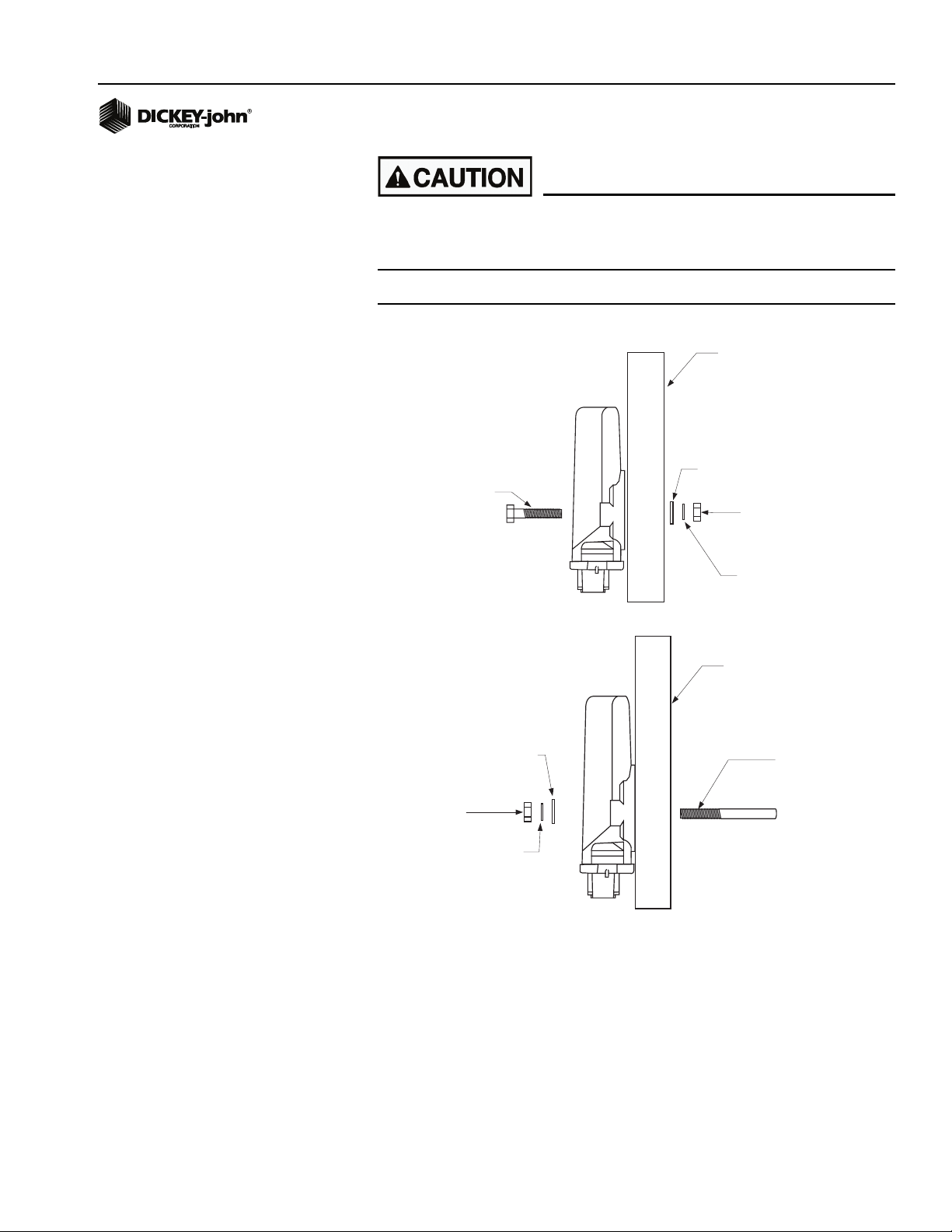

WORKING SET MEMBER (WSMB) MODULE

Figure 10

Working Set Member Module

IMPORTANT: For applications using multiple modules, it is

recommended that the WSMB’s are mounted on the

implement by increasing serial number order from left to

right. This step will minimize setup time at the Module

Configuration screen pressing the Auto Sort button will

group same module types together and in the order the

modules are mounted on the implement.

After Auto Sort is performed, modules will appear on the

Module Configuration screen in groups by serial number

order and module type.

1. Select an area on the implement to mount the member that allows for

easy hookup and access. Extensions may be used to reach members

installed on remote areas of the implement.

2. The module can be mounted in the same orientations as the Working

Set Master (WSMT) as illustrated in (Figure 9).

Do not install the module in any orientation other than illustrated

in (Figure 9). The connection wires must not be mounted upward

as moisture can collect inside the unit and damage the circuits.

Ensure that module connectors do not face upward when

implement is in a folded position as well.

3. Mount with the label side of the module facing out.

4. To bolt the member to a frame:

• Use the enclosure as a template to mark the location of the mounting

holes.

• Drill two 9/32 inch diameter holes where marked.

• Attach to frame using 1/4 x 20 bolts or other fastening devices as

illustrated in (Figure 11).

12 / INSTALLATION

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 21

OPERATOR’S MANUAL

Do not use the enclosure as a guide when drilling. Do not

overtighten nuts as this may damage the mounting tabs on the

enclosure.

Figure 11

Working Set Member Installation (Bolted)

IMPLEMENT

FRAME

1/4 FLAT WASHER

1/4 x 20 BOLT

1/4 NUT

1/4 FLAT WASHER

1/4 NUT

1/4 SPLIT LOCKWASHER

1/4 SPLIT

LOCKWASHER

IMPLEMENT

FRAME OR

SUPPORT

1/4 x 20

THREADED "U"

BOLT OR

OTHER

FASTENING

DEVICE

IntelliAg PDC User 2 & 3

11001-1501-200811

INSTALLATION / 13

Page 22

OPERATOR’S MANUAL

IMPLEMENT

FRAME

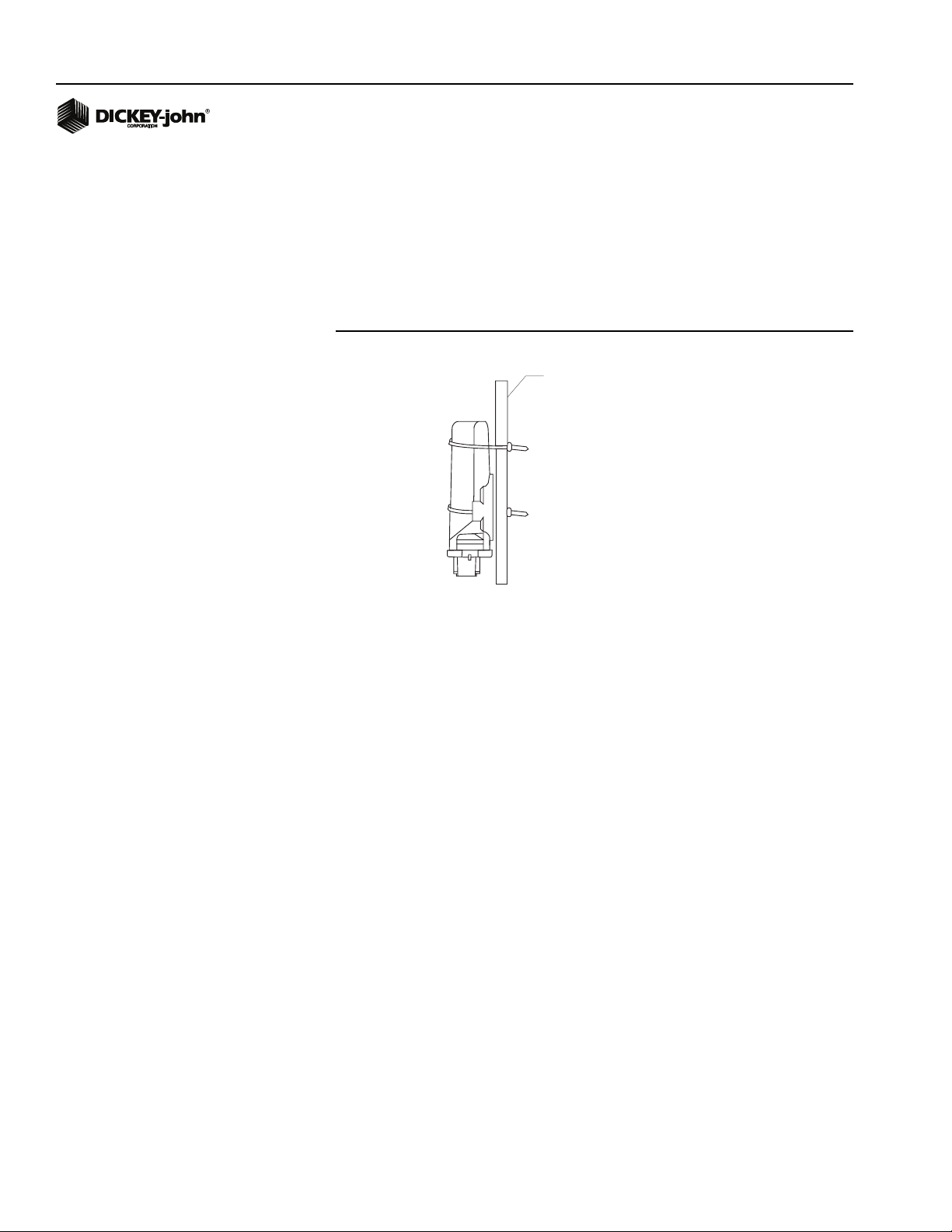

5. To tie-strap the member to a frame:

• Use one long tie-strap to loop around the member body and through

both mounting holes as illustrated in (Figure 12).

• If necessary, drill mounting holes following the procedure described

above.

• Securely tighten tie-strap.

• Install a second tie-strap toward the label end of the enclosure for

additional support.

Figure 12

Working Set Member Installation (Tie-Strap)

6. Connect a WSMB harness to the WSMB module and connect the

WSMB harness to the Power/CAN backbone, refer to (Figure 16).

7. Connect each module harness to its module, inserting both connectors

until the connector locking tabs engage.

8. Lay out the planter harness along the frame of the implement to each

of the seed sensors. For seed sensors, extensions will most likely not

be necessary.

9. Route sensor wires in locations where they will not be damaged by

chains, drive shafts, sprockets, etc.

10. Secure the harness to the toolbar with a minimum of 3” straight wire

exiting the module before bending and attaching with tie-straps ensure

good wire sealing.

11. Coil and secure any unused sensor connections.

12. The WSMB Module harness can accept a standard DICKEY-john PM

style planter harness (single round 37-pin connector) or an SE style

planter harness (1 gray 12-pin, 1 black 12-pin rectangular connector)

depending on the WSMB harness used. Harnesses are available for a

number of row configurations.

• Route the planter harness on the implement, securing as necessary.

• Install seed sensors per the instructions included with the sensors.

Refer to the implement harness diagram for additional information

(Figure 13) or (Figure 14).

14 / INSTALLATION

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 23

OPERATOR’S MANUAL

NOTE: The last module harness in the

system must have a CAN

Terminator installed for proper

system operation. Refer to

Implement Harness (Figure 13)

or (Figure 14) for additional

information.

IMPORTANT: Be sure the locking tabs engage when inserting the

connectors. The connection is sealed only when the

locking tabs have fully engaged.

IntelliAg PDC User 2 & 3

11001-1501-200811

INSTALLATION / 15

Page 24

OPERATOR’S MANUAL

Battery

+

-

CAB HARNESS CONNECTIONS

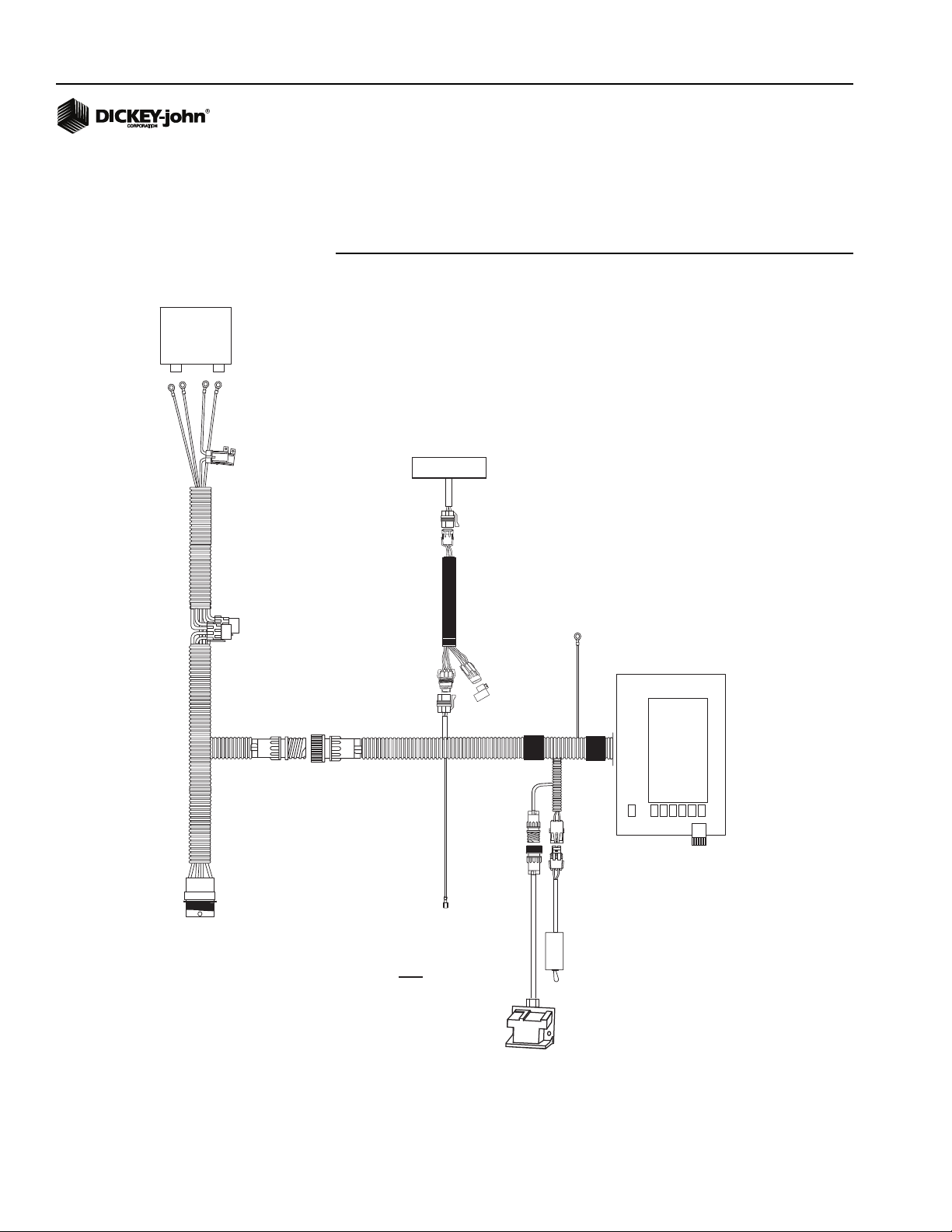

The following diagrams illustrate cab harness layout and connections for

DICKEY-john 5” and 10” Virtual Terminals.

Figure 13

Cab Harness Layout and Connections (5” Virtual Terminal)

CFM (optional)

System Power Harness

467980455

To Implement CAN

Harness

Tractor

Harness

467980452

Connect to switched

must be connected to

switched +12VDC

Ignition

+12VDC

NOTE: This wire

Chassis

Ground

CAN

Terminator

467980126

Virtual

Terminal

467980501

Master

Switch

467980124S1

Radar Speed Sensor

(if not connected to WSMT)

16 / INSTALLATION

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 25

OPERATOR’S MANUAL

NOTE: The ignition lead must be

connected to switched +12VDC

for the system to power up and

down properly.

5” VIRTUAL TERMINAL CAB HARNESS CONNECTIONS

1. Connect the power leads directly to the battery.

2. Connect the ignition wire to a switched +12VDC.

3. Connect the Chassis Ground lead to a bare point of the cab frame that

offers a good chassis ground connection.

4. Connect the Master Switch, CAN Terminator and Radar Speed Sensor

to their respective connectors on the cab harness. If the Speed Sensor

is to be connected to the WSMT, do not connect anything to the Speed

Sensor connector on the Cab Harness.

IntelliAg PDC User 2 & 3

11001-1501-200811

INSTALLATION / 17

Page 26

OPERATOR’S MANUAL

Battery

+

-

Figure 14

Implement Harness Connections (10” Virtual Terminal)

CFM (optional)

System Power

Harness

467980455

To Implement CAN

Harness

Tractor

ECU

467985060S1

Tractor

Harness

467980451A

Connect to switched

NOTE: This wire

must be connected to

switched +12VDC

Ignition

+12VDC

CAN

Terminator

467980126

Chassis

Ground

RS232

GPS

Master

Switch

467980124S1

Virtual

Terminal

467980503

18 / INSTALLATION

Radar Speed Sensor

(If not connected to WSMT)

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 27

OPERATOR’S MANUAL

NOTE: The ignition lead must be

connected to switched +12VDC

for the system to power up and

down properly.

10” VIRTUAL TERMINAL CAB HARNESS CONNECTIONS

Connect the power leads directly to the battery.

1. Connect the ignition wire to a switched +12VDC.

2. Connect the Chassis Ground lead to a bare point of the cab frame that

offers a good chassis ground connection.

3. Connect the Master Switch, CAN Terminator, Radar Speed Sensor,

GPS, and Tractor ECU to their respective connectors on the cab

harness. If the Speed Sensor is to be connected to the WSMT, do not

connect anything to the Speed Sensor connector on the Cab Harness.

IntelliAg PDC User 2 & 3

11001-1501-200811

INSTALLATION / 19

Page 28

OPERATOR’S MANUAL

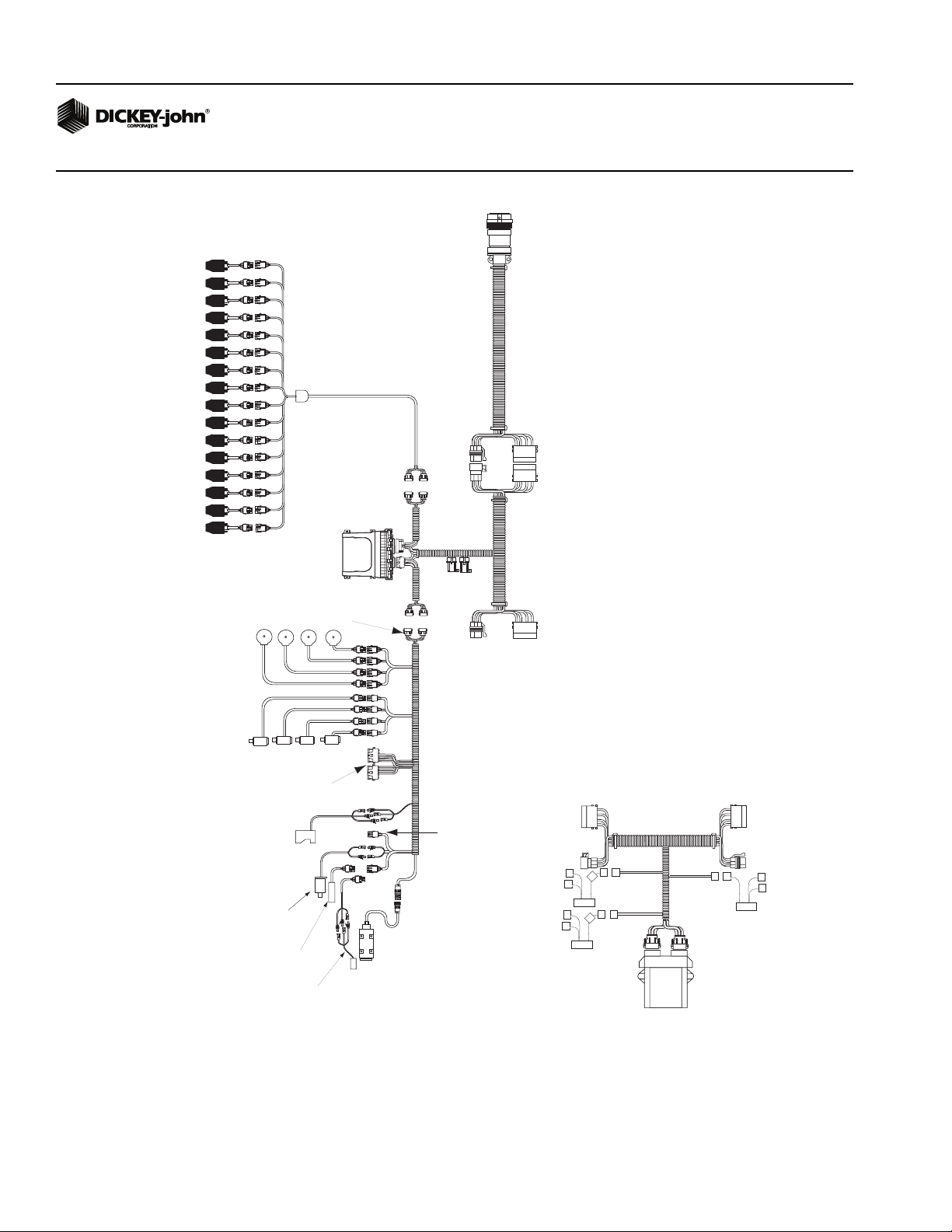

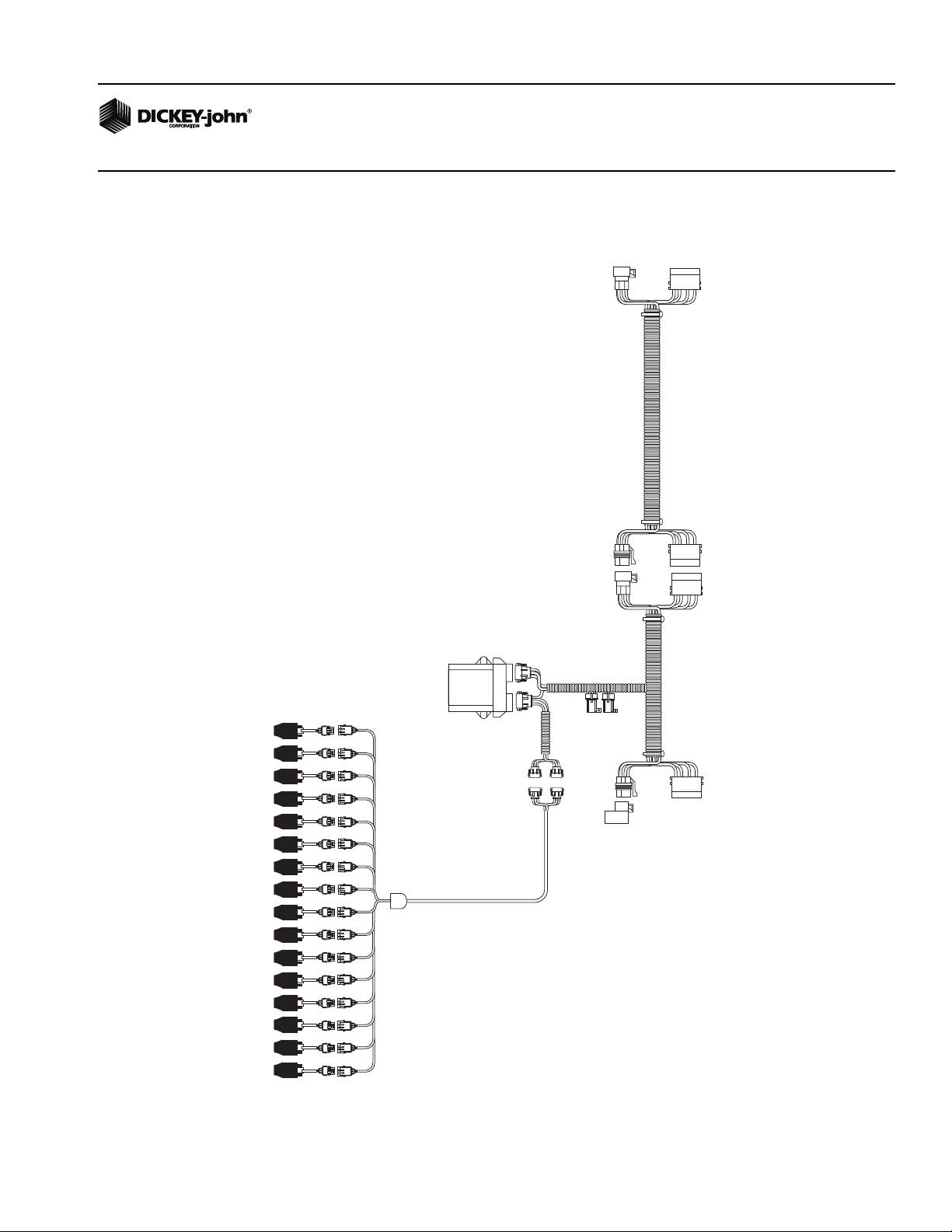

Figure 15

Implement Harness

Connect harnesses and accessory devices as

shown. Verify that PWM Solenoid Valves have a

properly connected feedback sensor.

Connect to

Cab Harness

.

Implement CAN Breakaway Harness

46798013X (multiple lengths)

Standard Dj SE Style

Planter Harness

NOTE: Connect the WSMT Actuator Harness

and the Dj Planter Harness to the mating

connectors of the WSMT Module Harness

Application Rate

Sensors x 4

(Channel 1-4 Feedback)

Labeled FB1-FB4

PWM Solenoid

Valves

Channel 1-4

Control

Labeled PWM 1-PWM 4

Servo Valve

Connectors

Hopper Level Sensor

Labeled HOPPER 1

Implement Lift Sensor

Labeled IMP LIFT

If no Implement Lift

Sensor is used, connect

the IMP LIFT leads

together

Fan/Shaft RPM Sensor

Labeled RPM1 or

Air Pressure

Sensor 46682-0920S1

46798081S1

WSMT

MODULE

PLANTER/DRILL

CONTROL

Accessory Sensor

Connection

Connect to next module

harness or implement

extension harness

(See Figure 15)

(Connect CAN terminator

if this is the last module

on the CAN bus)

WSMT Actuator Harness

46798016X

Remote

Test Swtich

Radar Speed Sensor

Labeled GND Speed

WSMT Module Harness

46798085X

Switch 5

Switch 6

464820510

Switch 3

Switch 4

464820510

OPTIONAL

467983500

Planter

Output

Module

46798200051

Switch 1 (Output 1)

Switch 2 (Output 2)

464820510

20 / INSTALLATION

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 29

OPERATOR’S MANUAL

Figure 16

Implement Harness (Continued)

From Previous

Module Harness or

Extension Harness

(See Figure 15)

Implement CAN Extension

Harness 46798014X

(Multiple Lengths)

WSMB

Module

Seed Monitor

Standard Dj SE Style

Planter Harness

467981100S1

CAN

Terminator

WSMB Module

Harness

46798120X1

Connect to next module

harness or implement

extension harness

(Connect CAN terminator

if this is the last module

on the CAN bus)

IntelliAg PDC User 2 & 3

11001-1501-200811

INSTALLATION / 21

Page 30

OPERATOR’S MANUAL

1. Connect the Implement CAN Breakaway extension to the mating

connector of the Cab Harness. Route the harness along the implement

hitch to the WSMT module harness (use an Implement Extension

Harness if additional length is needed). Secure harness as needed.

2. Connect the Module Harness to the mating connectors of the

Implement CAN harness, and then connect the module to the harness.

The WSMT module uses a 30 and 18 way connector with a jackscrew

to secure the connector to the module. The WSMB uses a pair of

12-pin connectors. Secure module harness as needed.

SENSOR INSTALLATION

For proper system operation, all sensors used with the system must be

connected properly as described in the following sections. Sensors that are

incorrectly installed will not be properly identified by the system and will

result in incorrect numbering of the sensors.

SEED SENSORS

The system is compatible with all existing DICKEY-john seed sensors.

Seed sensors may be connected to the WSMT module and all WSMB

Planter Monitor Modules. Any number of sensors up to the maximum

capacity of the module may be connected. A maximum of 214 seed sensors

can be connected to the system.

22 / INSTALLATION

IntelliAg PDC User 2 & 3

11001-1501-200811

Page 31

OPERATOR’S MANUAL

When connecting seed sensors to the modules, the following requirements

must be observed:

All seed sensors installed must be connected to the seed sensor

harness SEQUENTIALLY, starting with the Row 1 input. In the event

that not all row inputs on the module will be used, the unused inputs

must be the last inputs on that module.

Figure 17

Correct Seed Sensor Module Connection

CORRECT

Module Seed Sensor

Harness

Row1Row2Row

3

Row

Row

Row6Row7Row8Row

5

4

CORRECT

Module Seed Sensor

Row1Row2Row

3

Row

Row

Row6Row7Row8Row

5

4

Figure 18

Incorrect Seed Sensor Module Connection

INCORRECT

Module Seed Sensor

9

Harness

9

Harness

Row

10

Row

10

Row

11

Row

11

Row

12

Row

12

IntelliAg PDC User 2 & 3

11001-1501-200811

Row1Row2Row

3

Row

4

Row

Row6Row7Row8Row

5

Row

Row

9

10

Row

11

12

Failure to correctly install seed sensors will result in incorrect row

assignment on the planter monitor display functions and alarms.

INSTALLATION / 23

Page 32

OPERATOR’S MANUAL

HOPPER LEVEL SENSORS

The system is compatible with the DICKEY-john planter hopper level

sensors. One hopper level sensor can be connected to the actuator

harness and another 4 hopper sensors can be connected using an