Page 1

OPERATOR’S MANUAL

Row-Pro Down Pressure Control

11001-1572-201008

Page 2

INSTALLATION INSTRUCTIONS

11001-1572-201008

Page 3

OPERATOR’S MANUAL

10258

10261

WSMB-DPLCM

WSMB-DPLCM

3

4

150 150

ROW-PRO DOWN PRESSURE SETUP

The IntelliAg system monitors and adjusts down pressure to ensure the

same amount of force is applied to each row unit to maintain consistent

seed depth placement. The operator sets the desired down pressure into

the IntelliAg virtual terminal and then sets the spring pressure above the

target down pressure.

NOTE: Row-Pro Down Pressure is a

limited automatic adjustment

that works in conjunction

with the down pressure

springs. It does not

independently control the full

range of down pressure.

NOTE: The Row-Pro system is only

compatible with Great Plains

planters.

Down pressure setup can only be accessed in User Level 2 or Level 3

mode.

REQUIREMENTS

The Down Pressure feature is an option available for use with the IntelliAg

system and requires the following components to operate:

• Down Pressure Module that interfaces with 2 load cells

• A maximum of 3 load cell modules can be connected

• Down pressure module harness

SETUP

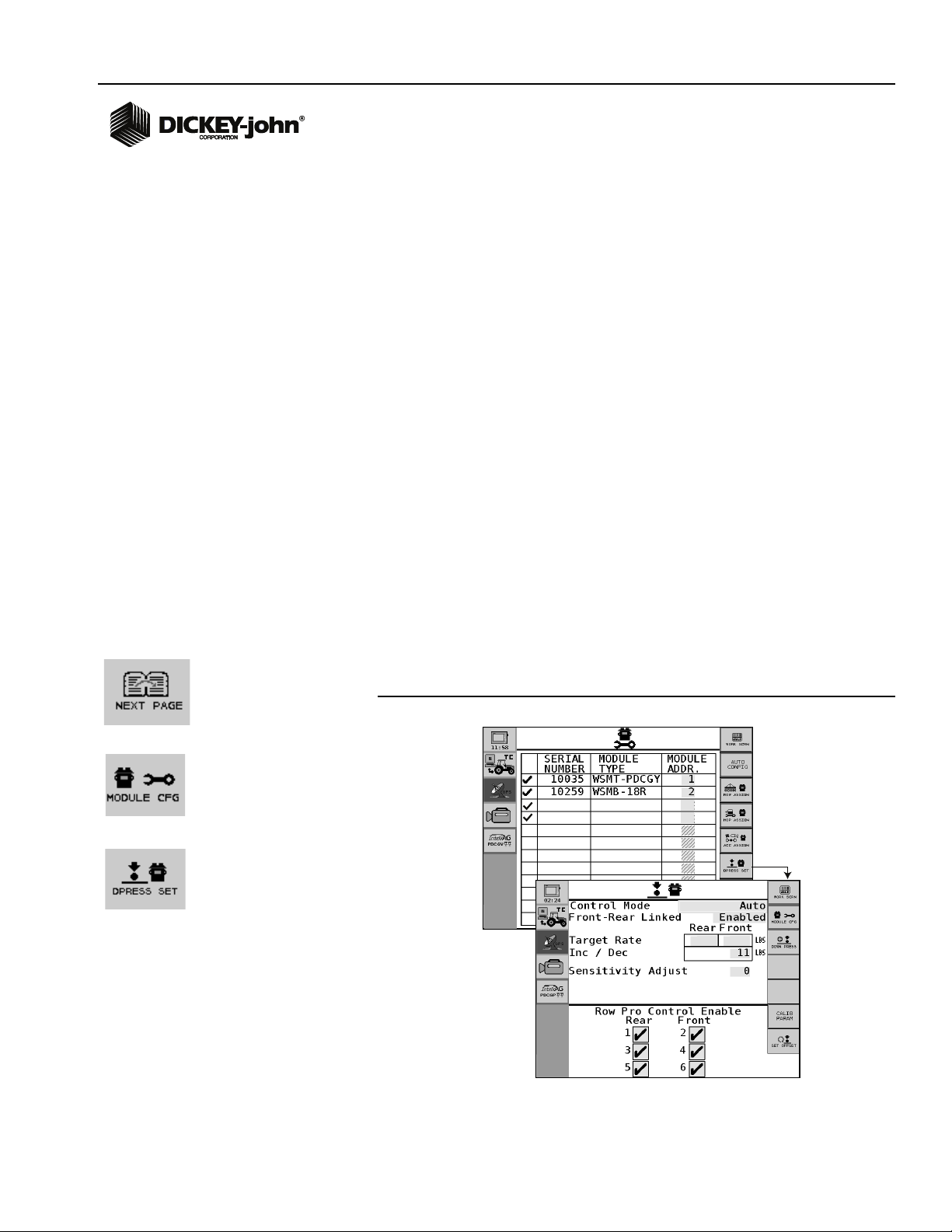

Down Pressure setup is configured at the Module Configuration screen.

1. At the Main Work screen, press the Next Page button.

2. Press the Module Cfg button.

3. At the Module Configuration screen, press the DPress Set button.

4. At the Down Pressure Set screen, enter desired constants.

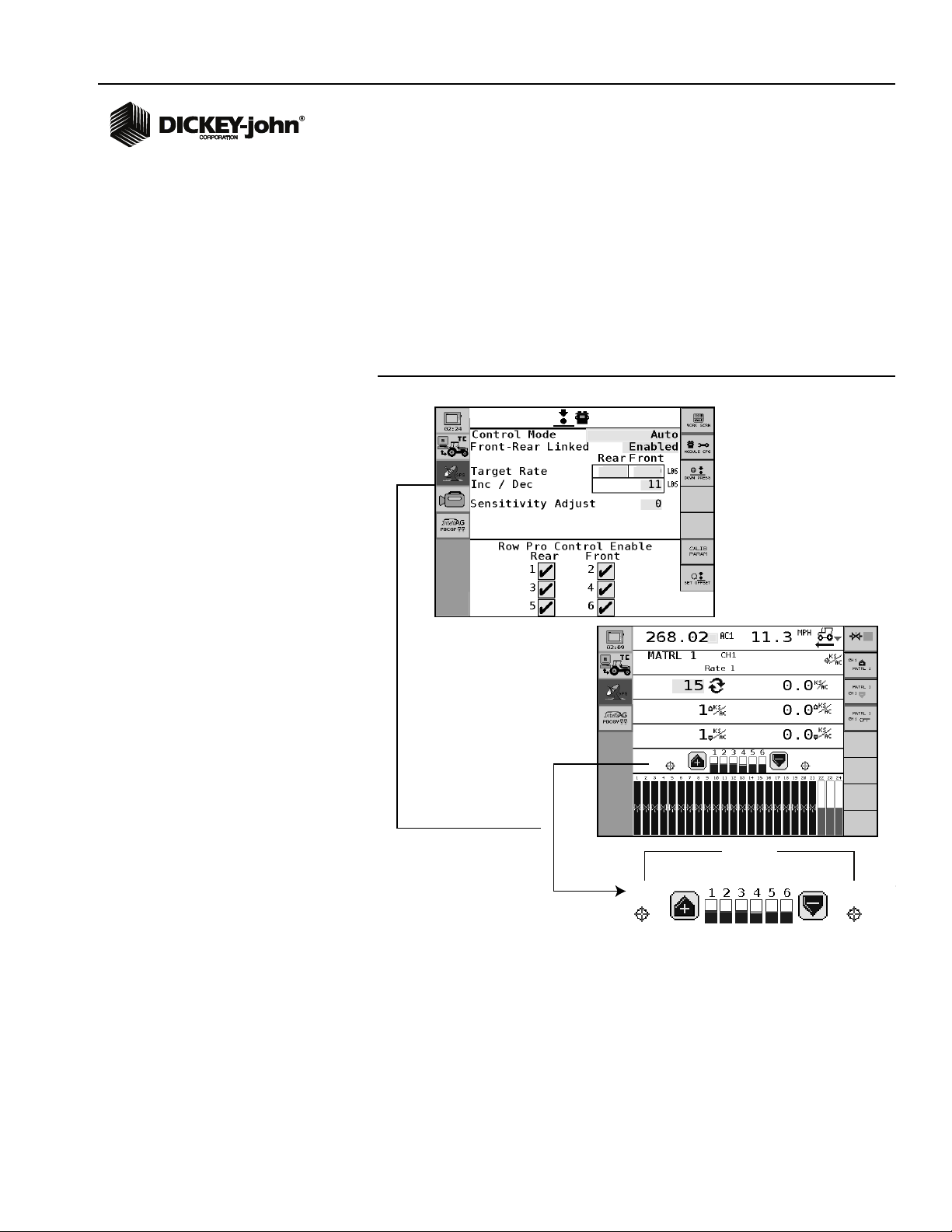

Figure 1

Down Pressure Setup

Row-Pro Down Pressure Control

11001-1572-201008

ROW-PRO DOWN PRESSURE SETUP / 1

Page 4

OPERATOR’S MANUAL

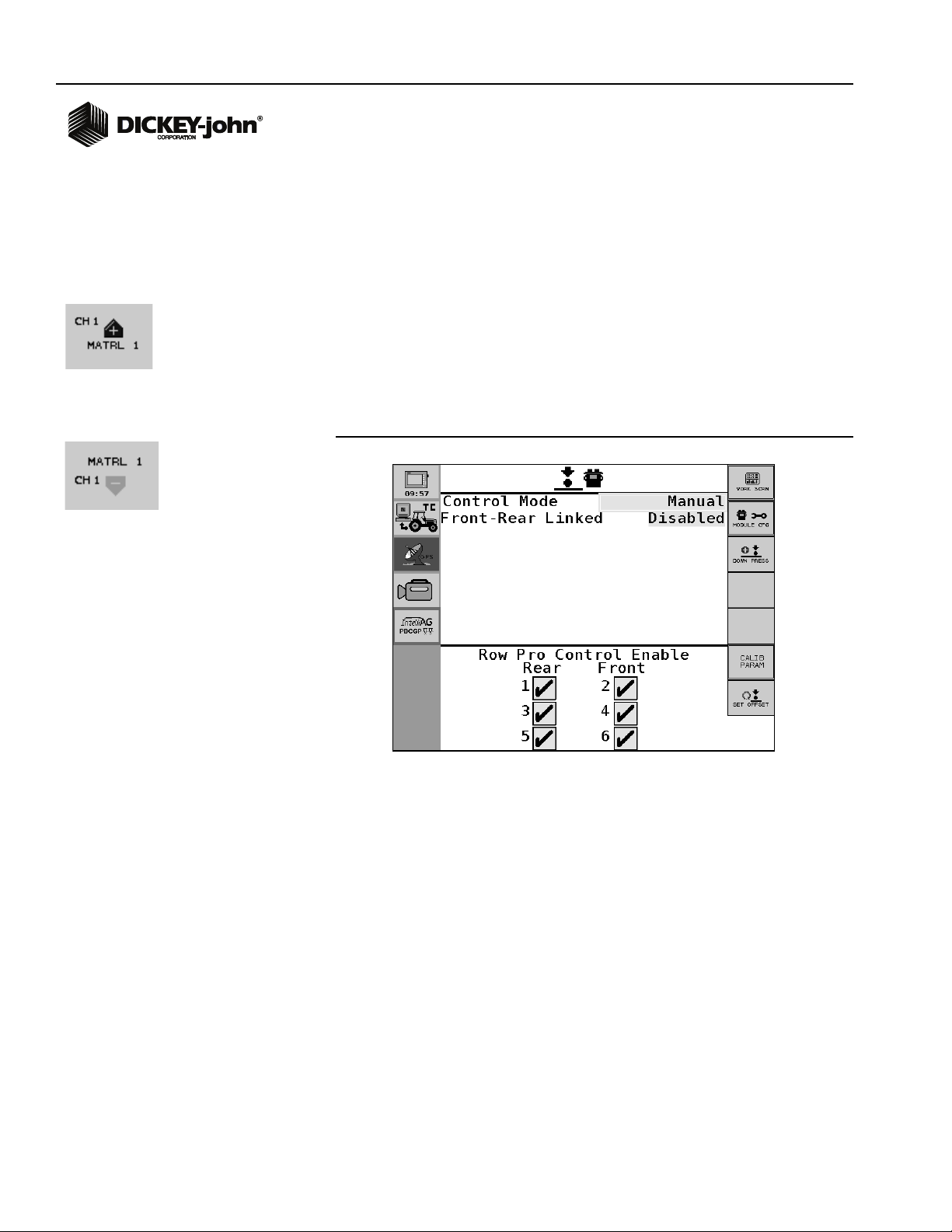

CONTROL MODE

Down pressure has two control modes:

• Automatic

• Manual

Automatic

When control mode is set to Automatic, down pressure adjusts

automatically during operation based on feedback sensor readings.

Manual

When control mode is set to Manual, down pressure operates at the set

pressure setting and will only change when pressure is adjusted by the

operator on the Main Work screen using the Increase/Decrease buttons.

Figure 2

Manual Control Mode

2 / ROW-PRO DOWN PRESSURE SETUP

Row-Pro Down Pressure Control

11001-1572-201008

Page 5

OPERATOR’S MANUAL

(1) linked

Increase/Decrease

adjustment for front

and rear

Front/Rear

Targets Linked

270

Increase

%

Decrease

%

Down Pressure force

applied relative

to target

0 . 0

150 150

150

130

150

130

FRONT- REAR LINKED

Enabled

Links the front and rear row units so that the same pressure increase/

decrease set at this screen is applied to front/rear row units. When enabled

only one increase/decrease value is entered.

Bar graph indicators on the Main Work screen identify the amount of force

applied in relation to the target set. In this mode, only one set of Increase/

Decrease buttons appear on the Main Work screen that will adjust the

percentage for both front and rear.

Figure 3

Front-Rear Linkage Enabled

Row-Pro Down Pressure Control

11001-1572-201008

ROW-PRO DOWN PRESSURE SETUP / 3

Page 6

OPERATOR’S MANUAL

(2) Increase/

Decrease

adjustments

for front

and rear

Down Pressure force

applied relative

to target

Increase

%

Decrease

%

Increase

%

Decrease

%

150

150

147 121

147

121

Disabled

The increase/decrease rate for front and rear row units is not linked and two

values must be entered at this screen. When disabled, two sets of

Increase/Decrease buttons appear on the Main Work screen that allows

adjustment of front and rear rates independently.

Figure 4

Front-Rear Linkage Disabled

4 / ROW-PRO DOWN PRESSURE SETUP

TARGET RATE

Target rate is the desired amount of down pressure (lbs). The system will

monitor and adjust pressure to meet the defined rate set at this screen.

INCREASE/DECREASE RATE

The increase/decrease rate establishes a set amount of pressure change

for each increase/decrease. This value is applied to the target rate while on

the Main Work screen. Refer to Front-Rear Linked description for linking

front/rear row units.

Row-Pro Down Pressure Control

11001-1572-201008

Page 7

OPERATOR’S MANUAL

1 and 2

Row Modules

Disabled

150 150

142

123

SENSITIVITY ADJUST

Sensitivity Adjust sets the response time of the control channel. Increasing

the adjustment above zero provides a quicker response time; decreasing

the adjustment to a negative number provides a slower response time.

Use caution when selecting a sensitivity adjustment. A rate set too

high could potentially cause equipment damage.

DISABLE DOWN PRESSURE MODULES

Modules interfacing with feedback sensors can be independently disabled

so that down pressure from disabled sensors do not display or are used in

adjustment calculations. Modules disabled are ignored by the system and

will not report down pressure data or react to soil conditions.

Figure 5

Down Pressure Modules

Row-Pro Down Pressure Control

11001-1572-201008

ROW-PRO DOWN PRESSURE SETUP / 5

Page 8

OPERATOR’S MANUAL

When planter is lifted,

OK button appears

to reset values.

112

106

128

120

115 111

RESET OFFSET VALUE

Resetting Offset Values clears previous down pressure readings and resets

values to zero.

Reset Offset Values:

1. At the Main Work screen, press the Next Page button.

2. Press the Module Cfg button.

3. At the Module Configuration screen, press the Dpress Set button.

4. At the Down Pressure Setting screen, press the OK button to clear

values.

IMPORTANT: The implement must be lifted and the implement lift

switch in the up state before the OK button appears and

values can be cleared.

Figure 6

Reset Offset Values

NOTE: Verify that side depth wheels

are not stuck in a position to

leave a residual pressure on

the load cell.

6 / ROW-PRO DOWN PRESSURE SETUP

Row-Pro Down Pressure Control

11001-1572-201008

Page 9

OPERATOR’S MANUAL

Select

Down

Pressure

ENABLE DOWN PRESSURE ON WORK SCREEN

To view down pressure functionality on the Main Work screen, the Down

Pressure data item must be selected on the Work Configuration screen.

To select Down Pressure:

1. At the Main Work screen, press the Next Page button and select the

Screen Config button.

2. Press a highlighted box and scroll through Data Items until Down

Pressure Scan appears.

3. Press the Checkmark button to select.

4. Press the Work Screen button to return to the Main Work screen.

Figure 7

Work Screen Configuration

DOWN PRESSURE DIAGNOSTICS

The Down Pressure Diagnostics screen is informational only and used for

troubleshooting purposes.

Screen displays:

• Load cell voltage/weight of 6 inputs

• Rear/front average

• Bar graphs displaying real-time monitoring of 6 inputs

To view Down Pressure Diagnostics:

1. At the Main Work screen, press the Module Cfg button.

2. At the Module Configuration screen, press the DPress Set button.

3. At the Down Pressure Setting screen, press the Down Press button.

Row-Pro Down Pressure Control

11001-1572-201008

ROW-PRO DOWN PRESSURE SETUP / 7

Page 10

OPERATOR’S MANUAL

158

144

144

139

126

135

151

146

Figure 8

Down Pressure Diagnostics Screen

8 / ROW-PRO DOWN PRESSURE SETUP

Row-Pro Down Pressure Control

11001-1572-201008

Page 11

OPERATOR’S MANUAL

40.5

Down

Pressure

147 147

1

2

3

127

111

OPERATION

Constants defined at the Down Pressure Setup screen will monitor and

control down pressure and display on the Main Work screen when the

master switch is turned ON.

NOTE: Row-Pro Down Pressure is a

limited automatic adjustment

that works in conjunction

with the down pressure

springs. It does not

independently control the full

range of down pressure .

The Down Pressure data item has to be selected in the Work Screen

Configuration before appearing on the Main Work screen. Refer to Viewing

Down Pressure on Work Screen.

Figure 9

Main Work Screen with Down Pressure Enabled

1) Press the increase (+) button on the Main Work screen to increase the

target rate. The rate will change based on the increase setting defined at

the Setup screen.

2) Press the decrease (-) button on the Main Work screen to decrease the

target rate. The rate will change based on the decrease setting defined at

the Setup screen.

3) Down pressure bar graph indicators display the amount of force being

applied relative to the target rate defined at the Setup screen. Number of

bar graphs shown is based on the number of modules installed and inputs

enabled.

Row-Pro Down Pressure Control

11001-1572-201008

Figure 10

Down Pressure

OPERATION / 9

Page 12

OPERATOR’S MANUAL

10 / OPERATION

Row-Pro Down Pressure Control

11001-1572-201008

Page 13

OPERATOR’S MANUAL

TROUBLESHOOTING

Alarms will display on the Virtual Terminal with an audible alarm. The alarm

can be silenced by pressing the Alarm Cancel or ESC button. Detailed

descriptions of the alarm can be viewed by pressing the Alarm Detail

button. Some alarm conditions display instructions to aid in troubleshooting

the situation. Each alarm type has an associated alarm number for

reference.

DOWN PRESSURE UNABLE TO CONTROL

Alarm 265

The system is unable to monitor or control down pressure. Full screen

alarm identifies the module unable to control.

Corrective Action

• Check for sufficient tank pressure.

• Check load cell sensor for damage.

• Check air valve for damage.

• Inspect module and module harness for damage.

• Verify constants entered at the Down Pressure Setup screen are

correct.

Figure 11

Down Pressure Unable to Control Alarm

Contact DICKEY-john Technical Support Group at 1-800-637-3302 for

troubleshooting assistance or questions.

Row-Pro Down Pressure Control

11001-1572-201008

TROUBLESHOOTING / 11

Page 14

OPERATOR’S MANUAL

12 / TROUBLESHOOTING

Row-Pro Down Pressure Control

11001-1572-201008

Page 15

Dealers have the responsibility of calling to the attention of their customers the following

warranty prior to acceptance of an order from their customer for any DICKEY-john product.

DICKEY-john® WARRANTY

DICKEY-john warrants to the original purchaser for use that, if any part of the product

proves to be defective in material or workmanship within one year from date of original

installation, and is returned to DICKEY-john within 30 days after such defect is discovered,

DICKEY-john will (at our option) either replace or repair said part. This warranty does not apply

to damage resulting from misuse, neglect, accident, or improper installation or maintenance; any

expenses or liability for repairs made by outside parties without DICKEY-john’s written consent;

damage to any associated equipment; or lost profits or special damages. Said part will not be

considered defective if it substantially fulfills the performance expectations. THE FOREGOING

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PURPOSE, AND OF ANY OTHER TYPE, WHETHER

EXPRESS OR IMPLIED. DICKEY-john neither assumes nor authorizes anyone to assume for it

any other obligation or liability in connection with said part and will not be liable for

consequential damages. Purchaser accepts these terms and warranty limitations unless the

product is returned within fifteen days for full refund of purchase price.

For DICKEY- john Service Department, call

1-800-637-3302 in either the U.S.A. or Canada

Headquarters:

5200 Dickey-john Road, Auburn, IL USA 62615

TEL: 217 438 3371, FAX: 217 438 6012, WEB: www.dickey-john.com

Europe:

DICKEY-john Europe S.A.S, 165, boulevard de Valmy, 92706 – Colombes – France

TEL: 33 (0) 1 41 19 21 80, FAX: 33 (0) 1 47 86 00 07 WEB: www.dickey-john.eu

Copyright 2009 DICKEY-john Corporation

Specifications subject to change without notice.

Loading...

Loading...