Page 1

OPERATOR’S MANUAL

Safety Notices ..................................................................................................... 1

Introduction ......................................................................................................... 3

Auto Section Control Features .......................................................................................... 3

Requirements ....................................................................................................................3

Auto Section Control Installation ....................................................................................... 4

Cab Terminal Mount ......................................................................................................................... 4

Harness Connections ........................................................................................................ 5

Auto Section Terminal ........................................................................................ 7

Auto Section Power Up ..................................................................................................... 9

Understanding the Field Map ............................................................................................ 9

Path-Driven Outline .......................................................................................................................... 9

Imported External Boundary .......................................................................................................... 10

Tractor/Implement Position ............................ ... .. ................................ .. ... ... ................................... 11

Intelliag PDC Setup ........................................................................................... 13

Implement Setup .......................................................................... .... ... ... ... .... ... ............... 13

Physical Layout ............................................................................................................... 14

3 Point Hitch and Towed Hitch ....................................................................................................... 15

Rigid Cart Mount ............................................................................................................................ 16

Tow-Behind Cart ............................................................................................................................ 16

Physical Check ............................................................................................................... 17

Clutch Configuration ....................................................................................................... 18

Multiple Tru Count Output Module Assignment ............................................. ................................ 18

Tru Count Output Module Assignment ................ ... .. ................................ ... .. ... .............................. 18

Assigning Rows .............................................................................................................................. 19

Assigning Row Shutoff Switches .................................................................................................... 20

Module Output Assignment Example .................. ... .. ................................ ... .. ... .. ... ......................... 21

Implement Section Check .............................................................................................................. 21

Auto Section Control Setup ............................................................................. 23

GPS Setup ...................................................................................................................... 23

GPS Source ................................................................................................................................... 23

GPS Lag ......................................................................................................................................... 23

Baud Rate and Data Mode (RS232 only) ....................................................................................... 23

GPS Output .................................................................................................................................... 23

Tractor Setup (Articulated) ................................ .. ... .. ................................ ... .. ... .............................. 25

GPS Calibration .............................................................................................................. 26

Important GPS Calibration Notes ............................................. ... .. ... ................................ .. ... .. ....... 27

Field Preparation ............................................................................................... 29

Setting Overlap ...................................... ... ... ... .... ... ... ... .... ...................................... ... .... .. 29

Run In Overlap ............................................................................................................................... 29

Run Out Overlap ............................................................................................................................ 29

Run In Skip ..................................................................................................................................... 29

Run Out Skip .................................................................................................................................. 29

Side-to-Side Overlap ......................... .. ... ... ............................... ... .. ................................ ... .. ............ 29

Important Functionality Notes ........................................................................................................ 31

Create Task .................................................................................................................................... 33

Import A Task or Field Boundary File ............................................................................. 34

Overwrite Field Boundary ............................................................................................................... 36

Auto Section Control Status ........................................................................................................... 36

Auto Section Control System

11001-1561B-201207

/I

Page 2

OPERATOR’S MANUAL

System Operation ............................................................................................. 37

Auto Section Main Screen .............................................................................................. 37

Enable Auto Section Control .................................... .... ... ... ....................................... ... .. 39

Disable Auto Section Control .......................................................................................... 39

Auto Mode ............................. ....................................... ... ... ... .... ... ... ... ... .... ..................... 40

Manually Force Sections Off in Auto .............................................................................................. 40

Manual Mode .................................................................................................................. 41

Manual On/Off Control of Sections ................................................................................................. 41

Additional Operating Conditions ......................................................... ... .... ... ... ... .... ........ 42

Adjusting Implement Position ......................... ... ................................ .. ... .. ...................................... 42

Marking/Planting Headlands ........................................................................................................... 42

Storing Headlands .................................... ...................................................................................... 43

Lost GPS Signal ............................................................................................................. 43

Out of Field Range ......................................................................................................... 44

Terminal Storage Capacity .............................................................................. 45

Clear Task ......................................................................................................................45

Diagnostics ....................................................................................................... 47

GPS Status ..................................................................................................................... 47

System Information .......................................... ... ... ... .... ... ... ... ....................................... .. 48

Clutch Section Check ..................................... ................................ ... .. ... ........................................ 49

Troubleshooting ............................................................................................... 51

Error Codes ....................................................................................................... 55

Appendix A ............................................... .... .... .... ..... .... .... .... .... ..... .... .... .... .... .. 56

AGCO GTA Console ...................................................................................................................... 56

Appendix B ............................................... .... .... .... ..... .... .... .... .... ..... .... .... .... .... .. 57

John Deere GS2 Console ............................................................................................................... 57

Deere GS2 Console Cab Harness Connecti on s .................................... .. ................................ ... .. . 58

Warranty.............................................................................................................. 63

II /

Auto Section Control System

11001-1561B-201207

Page 3

OPERATOR’S MANUAL

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to potential

hazards. An absence of specific alerts does not mean that there are no

safety risks involved.

This Safety Alert Symbol identifies important safety

messages in this manual. When you see this symbol,

carefully read the message that follows. Be alert to

the possibility of personal injury or death.

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or serious

injury.

Use of the word CAUTION with the Safety Alert Symbol indicates a

potentially hazardous situation which, if not avoid ed, may result in

minor or moderate injury.

Use of the word CAUTION without the safety alert symbol

indicates a potentially hazardous situatio n which, if not avoided,

may result in equipment damage.

Auto Section Control System

11001-1561B-201207

SAFETY NOTICES / 1

Page 4

OPERATOR’S MANUAL

2 / SAFETY NOTICES

Auto Section Control System

11001-1561B-201207

Page 5

OPERATOR’S MANUAL

Auto Section Control

Terminal

IntelliAg

Virtual Terminal

INTRODUCTION

Auto Section Control is an automated row shutoff system that can be added

to the IntelliAg planter system to automatically shutoff individual planter

sections utilizing a GPS signal as previously planted areas are approached.

A dedicated Auto Section Control terminal displays a field map for easy

identification of external field boundaries, seeded areas, and nonseeded

areas.

Figure 1

Auto Section Control Terminal and IntelliAg Virtual Terminal

AUTO SECTION CONTROL FEATURES

• Real-time viewing of planting operation within the field without

interruption of application rate and seed monitoring information

• Unique GPS latency adjustment for calibration of row shutoff at the

precise time the planter enters a previously seeded area

• Manual override of planter sections in the event of a lost GPS signal or

in special conditions

• Section(s) shutoff and turn on when exiting or entering a headland

• Day and night mode

• Saving field data by customer, farm, field, and task structure for

viewing at a later date

REQUIREMENTS

The Auto Section Control system will only interface and operate with an

IntelliAg Planter Control system and compatible virtual terminal.

The Auto Section Control system requires the following to operate:

• Compatible with IntelliAg A1+ virtual terminal, John Deere GS2 2600

display, or AGCO C2000 virtual terminal

• Auto Section Control terminal

• GPS receiver (5 Hz minimum)

• Tru Count WSMB module

• Tru Count WSMB harness

• Implement lift switch

• Row section control switch box

Auto Section Control System

11001-1561B-201207

INTRODUCTION / 3

Page 6

OPERATOR’S MANUAL

Secure VT to bracket using

4 Metric screws (included)

Secure bracket to

tractor cab using 4

SAE screws (included)

1

2

3

4

AUTO SECTION CONTROL INSTALLATION

The Auto Section Control cab kit includes:

• Swath Control display

• Display mount

• Display to CAN harness

Refer to (Figure 3) harness connections.

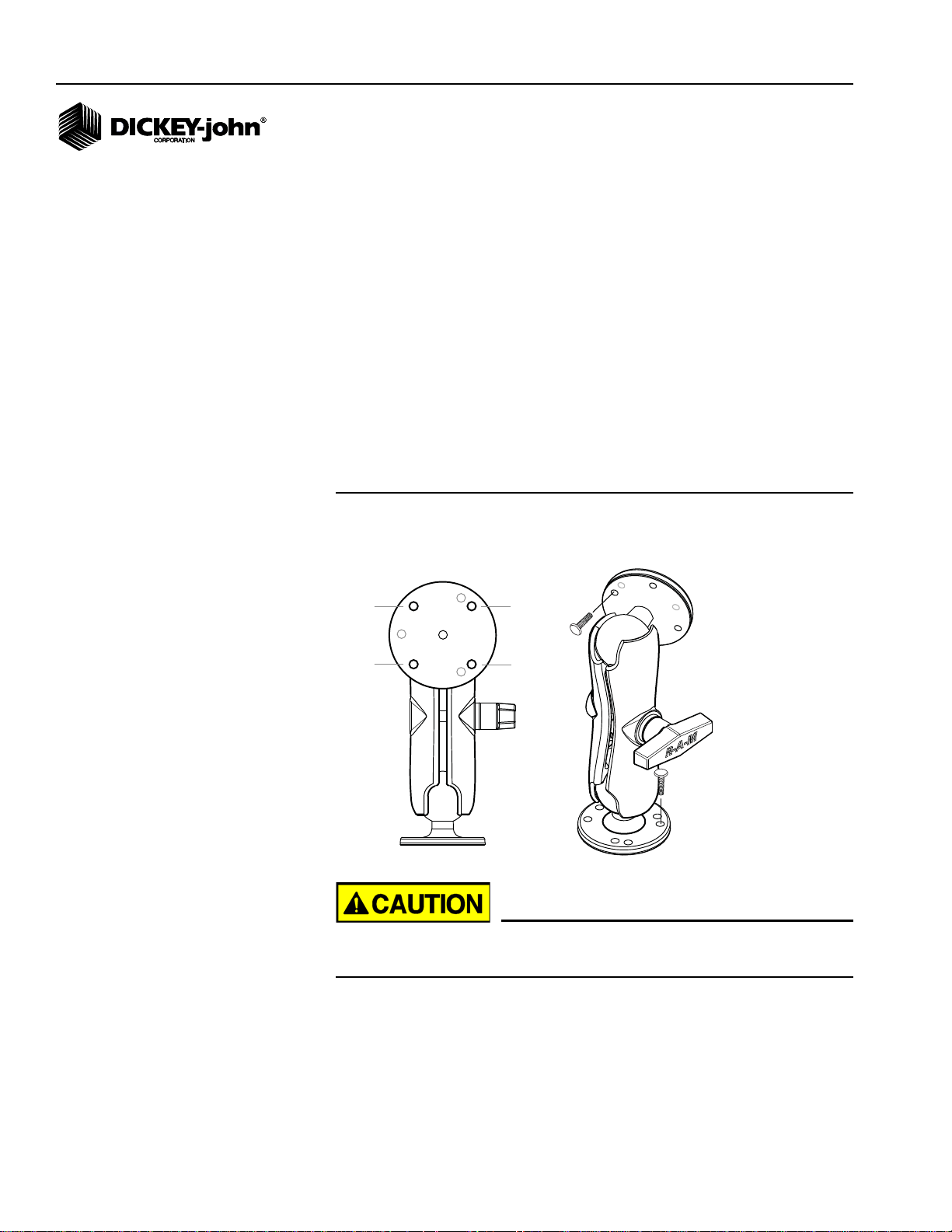

CAB TERMINAL MOUNT

The Auto Section Control terminal is secured in the tractor cab by a ram

mount bracket.

• Ball mount at top and bottom of bracket allows for orientation in many

different positions.

• Wing bolt in middle of bracket tightens and secures the terminal to the

desired position.

Figure 2

Auto Section Control Terminal Mount

4 / INTRODUCTION

Position terminal so that operator view is not obstructed and does

not interfere with tractor operation.

Auto Section Control System

11001-1561B-201207

Page 7

OPERATOR’S MANUAL

Auto Section

Control Terminal

ISO

Tractor

Hitch

WSMT 2 ‘T’ Harness

467980850

Add a CAN Extension

or

CAN Terminator

WSMB

Tru Count

Output Module

Tru Count

Solenoid

Modules

(available from

Tru Count)

Tru Count

Clutch Harness

467983505

IntelliAg

Virtual Terminal

Hitch Extension

Harness

46798013x

Battery

Tractor

Power

Harness

467980455

CFM Switch

Module or

Row Control

Switch Module

467984264S1

WSMT 2

PDC Module

Tractor ECU

Master

Switch

Radar

RS232 (not

used with

Auto Section

Control)

Tractor A1

Harness

467980451A

RSM/CFM to

CAN Harness

467980330

Auto

Section

Terminal

Interface

Harness

467980458

GPS Receiver

(See Note)

Ignition

NOTE: GPS receiver connects

direct to RS232 on Auto Section

Terminal harness. Refer to

Auto Section Control Setup to

transmit GPS signal over CAN.

HARNESS CONNECTIONS

The Auto Section Control terminal connects to the IntelliAg tractor harness

for communication with the IntelliAg ISO virtual terminal. A GPS receiver is

required to provide implement position via CAN or RS232 communication.

A row control switch module/clutch folding switch module provides quick

access of turning sections on and off when manual override is required.

Ignition wire connects to switched power source.

NOTE: Refer to Appendix A and B for

harness connections when

using an AGCO or John Deere

Console.

Figure 3

Harness Connections

A DICKEY-john Tru Count output module WSMB and harness are required

for interfacing with Tru Count solenoid modules. Tru Count solenoid

modules are not supplied by DICKEY-john. The below items outlined

indicate parts required for Auto Section Control functionality.

Auto Section Control System

11001-1561B-201207

:

INTRODUCTION / 5

Page 8

OPERATOR’S MANUAL

6 / INTRODUCTION

Auto Section Control System

11001-1561B-201207

Page 9

OPERATOR’S MANUAL

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15

16

Day Mode Night Mode

AUTO SECTION TERMINAL

The Auto Section Control terminal displays the field coverage map that

shows real-time viewing of the planting operation and indicates the vehicle’s

current location.

NOTE: All Auto Section Control setup

is entered on the IntelliAg

virtual terminal or other

compatible displays.

• Field map appearance on the screen is adjusted using the buttons

located on the left and right side of the terminal (Figure 4).

Figure 4

Auto Section Control Terminal Functions

(1) Tractor - Returns to current field position after using the Pan buttons and

centers the tractor to screen middle

(2 - 5) Pan - Positions field map on screen to the left, right, up, or down

(6) - Night Mode/Day Mode - Adjusts screen colors for operating at night or

during the day

Figure 5

Day and Night Mode

(7) - Max In - Enlarges map to the most detailed view

(8) - Zoom In - Enlarges field map with each button press

Auto Section Control System

11001-1561B-201207

(9) - Zoom Out - Reduces field map with each button press

(10) - Max Out - Shows entire field

(11) Increases screen brightness

AUTO SECTION TERMINAL / 7

Page 10

OPERATOR’S MANUAL

17 18

19

(12) Decreases screen brightness

(13) Terminal - non functional

(14) Cycle button - Adjusts the implement to its actual heading (North,

South, East, West direction) if the initial tractor movement is reverse, such

as backing to a corner. The Flip button also performs the same function.

(15) Terminal - non functional

(16) Rotary button - non operational

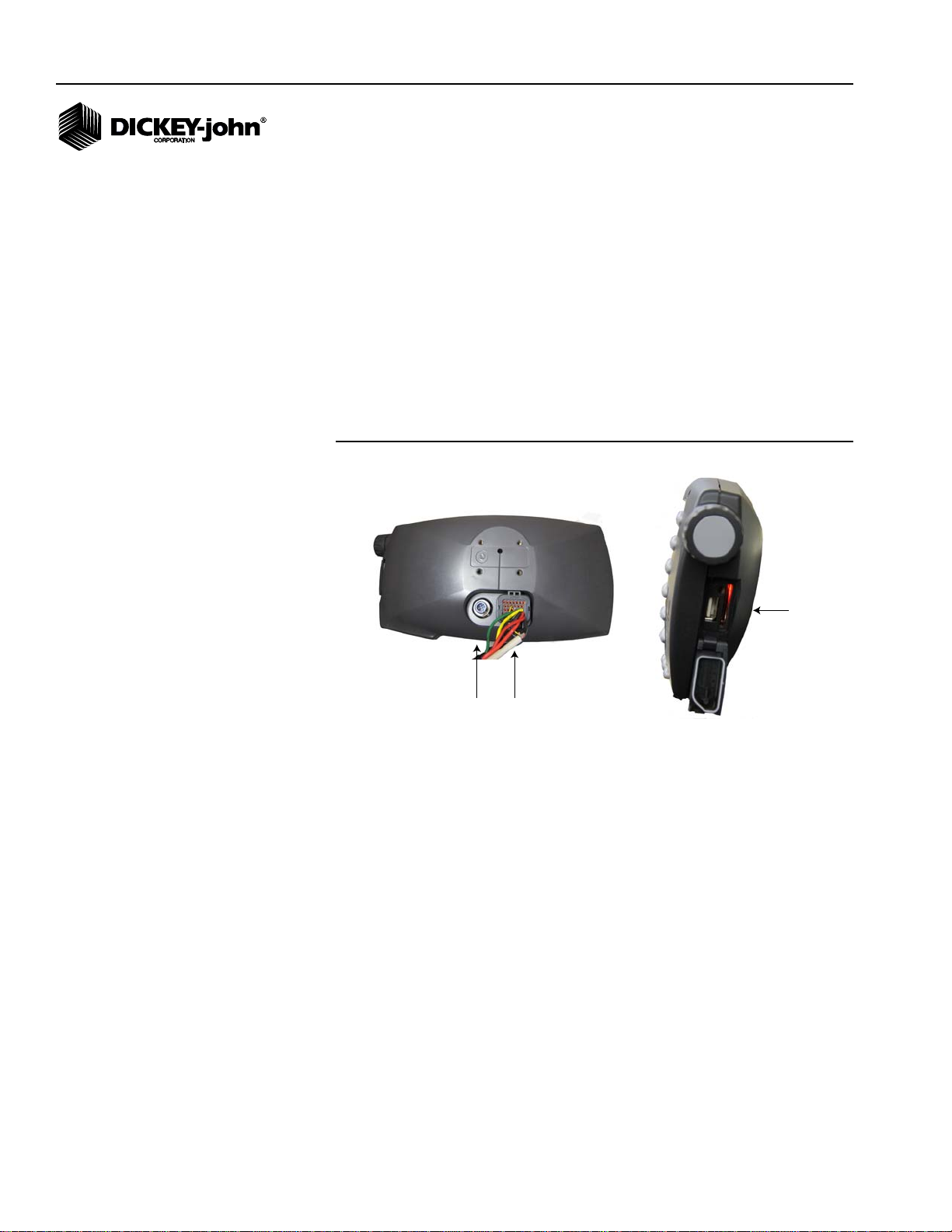

(17) Video connection - non functional

(18) Terminal harness connection

(19) SD card slot - import task data files

USB port - terminal software reprogramming

Figure 6

Auto Section Control Terminal Side and Back View

8 / AUTO SECTION TERMINAL

Auto Section Control System

11001-1561B-201207

Page 11

OPERATOR’S MANUAL

Auto

Initializing....

Please Wait

1 Path-driven field outline

2 Seeded area

3 Nonseeded area

4 Over applied area

1

2

3

4

AUTO SECTION POWER UP

The terminal automatically powers on and off when the ignition switch is

powered on and off. At startup, the screen will indicate that the system is

initializing until a connection is made with GPS and the IntelliAg PDC

controller.

When the power is turned off, an orange LED appears in the upper right

corner for approximately 1 minute while data is saving and disappears after

completing the save.

Figure 7

Initializing

UNDERSTANDING THE FIELD MAP

The Auto Section Control Terminal displays field coverage maps for

real-time viewing of the planting operation without interruption of application

rate and seed monitoring information. The full-color display identifies

path-driven outlines, external boundaries, areas planted, and areas left to

plant.

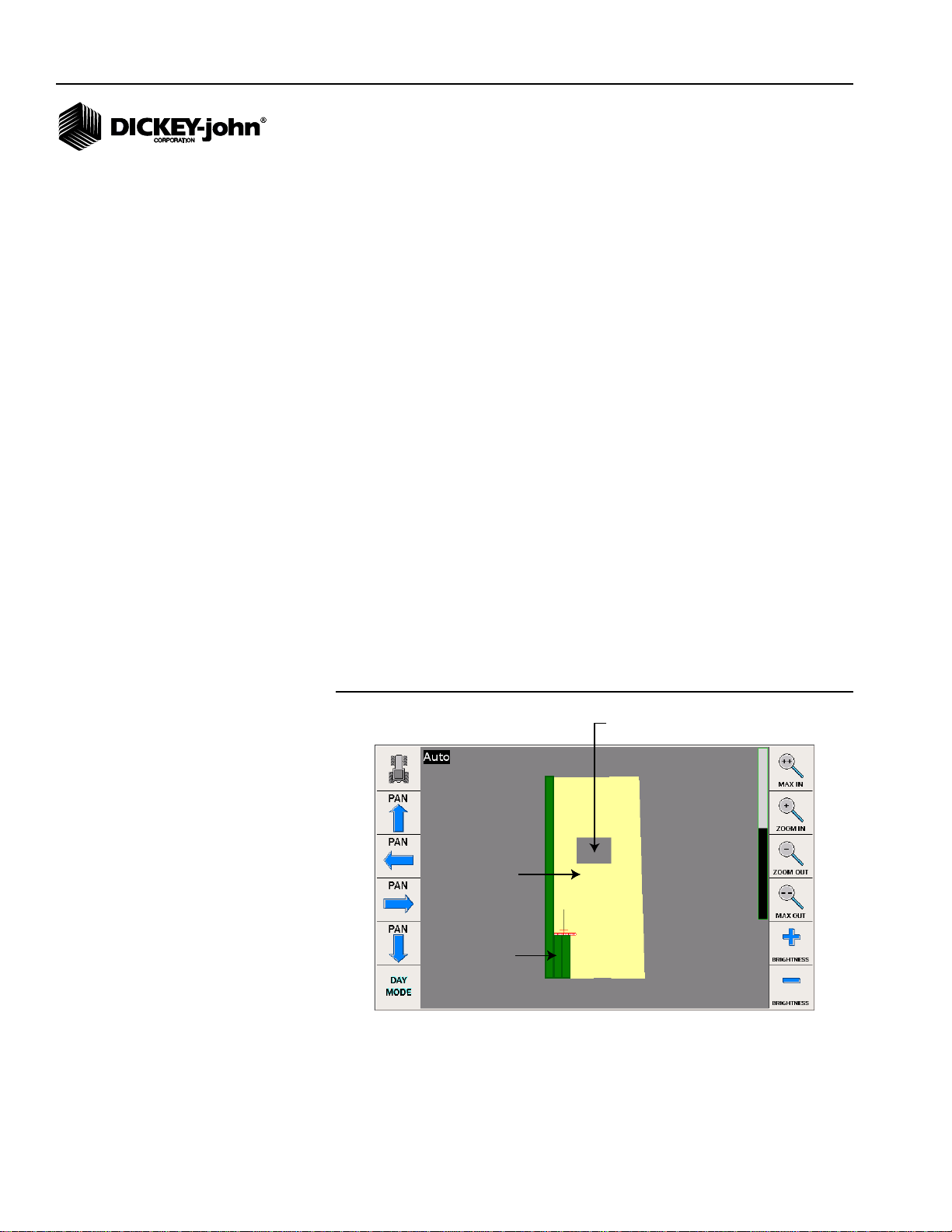

PATH-DRIVEN OUTLINE

The outline of a field can be driven to use as a visual aid when planting.

This is not considered an external boundary so automatic row shutoff will

not occur when driving past the outline.

Figure 8

Path-Driven Field Outline Map

Auto Section Control System

11001-1561B-201207

AUTO SECTION TERMINAL / 9

Page 12

OPERATOR’S MANUAL

Internal

Boundary

Field

(yellow)

Seeded

Area

(green)

External

boundary

(gray)

Field Map Descriptions:

(1) Path-driven field outline - Driving an external field path provides a visual

outline of the field. Automatic row shutoff does NOT occur when a section

extends past the outline.

(2) Seeded area - Areas planted with seed is defined in green.

(3) Nonseeded area - Any areas not seeded remain in yellow or brown

(4) Over applied area - Areas with twice applied seed appears in blue

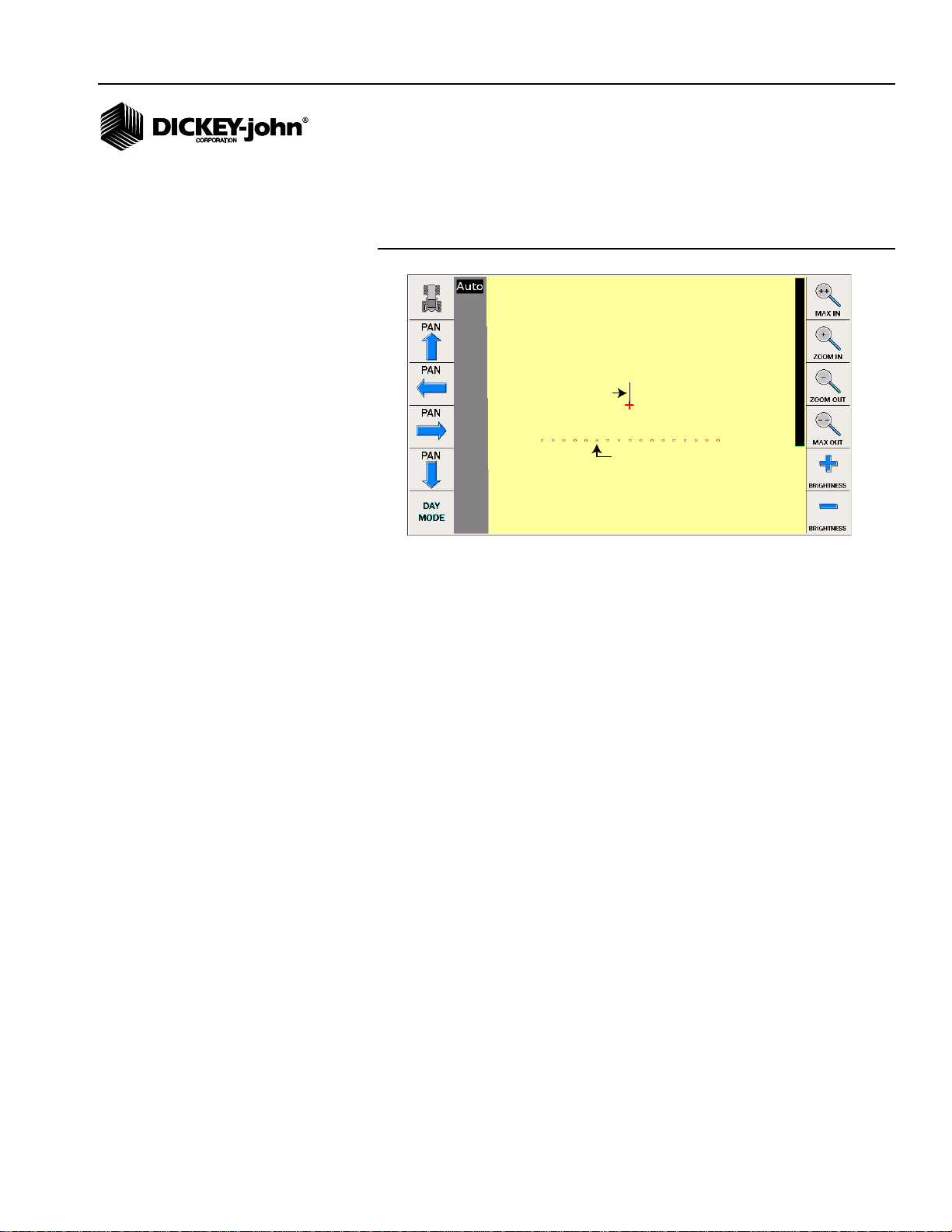

IMPORTED EXTERNAL BOUNDARY

Field maps created in a PC farm software that is compatible with the

IntelliAg Task Control application can be imported to the Auto Section

Control terminal. Automatic row shutoff occurs when any defined external

and internal boundaries are entered.

(1) External boundary - Any defined boundary outside of the field appears in

gray (day mode) or black (night mode). Rows automatically shut off if a

section extends past the external boundary.

(2) Internal boundary - Any defined boundary within the field appears in

gray (day mode) or black (night mode). Rows automatically shut off if a

section extends into the internal field boundary.

(2) Seeded area - Areas planted with seed are defined in green.

(3) Nonseeded area - Any areas not seeded remain in yellow (day mode) or

brown (night mode).

(4) Over applied area - Areas with multiple applications appears in blue.

Figure 9

External / Internal Boundary

10 / AUTO SECTION TERMINAL

Auto Section Control System

11001-1561B-201207

Page 13

OPERATOR’S MANUAL

Implement

Tractor

Direction

Indicator

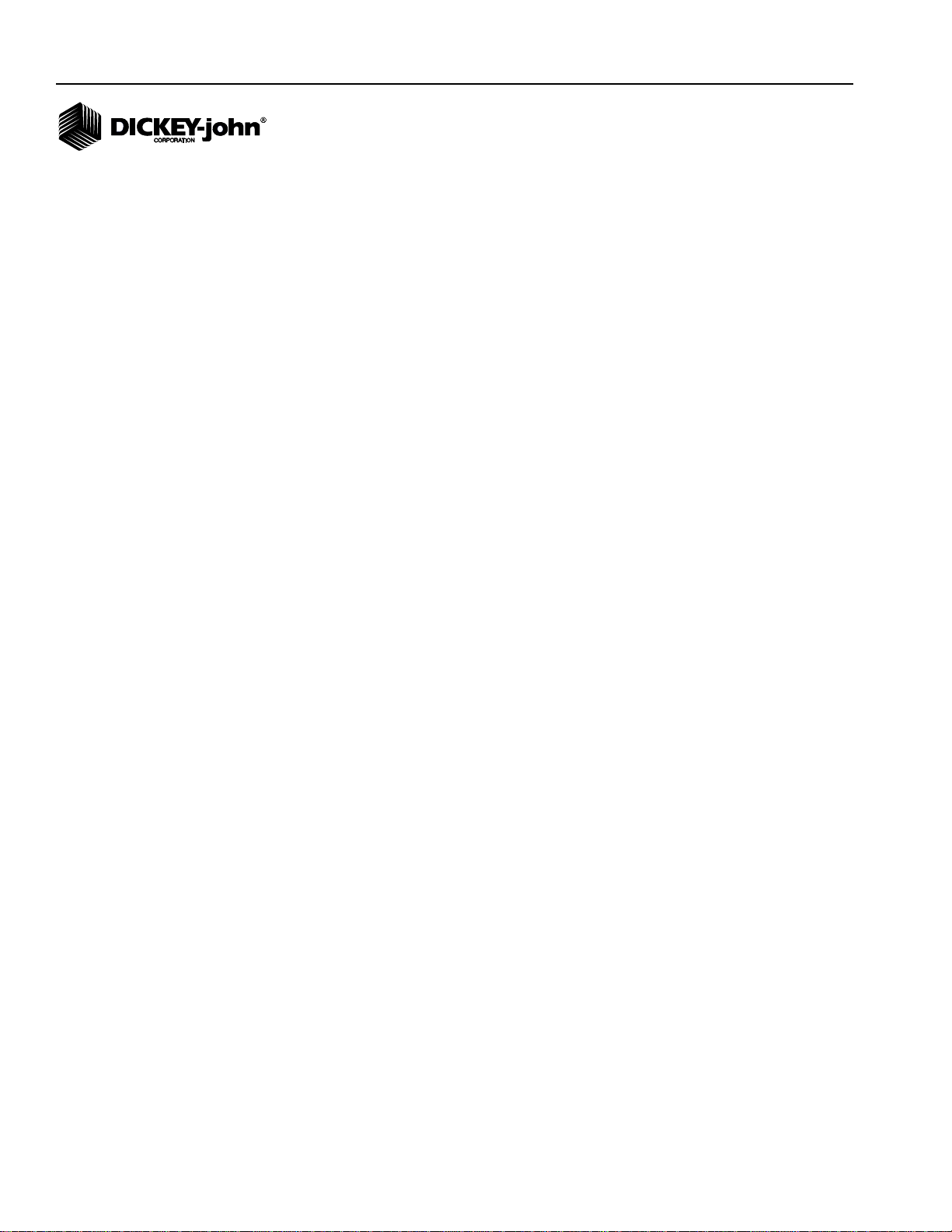

TRACTOR/IMPLEMENT POSITION

A direction indicator identifies the front of the tractor and direction the tractor

is heading.

Figure 10

Tractor Position

Auto Section Control System

11001-1561B-201207

AUTO SECTION TERMINAL / 11

Page 14

OPERATOR’S MANUAL

12 / AUTO SECTION TERMINAL

Auto Section Control System

11001-1561B-201207

Page 15

OPERATOR’S MANUAL

INTELLIAG PDC SETUP

The following IntelliAg PDC screens must be configured to communicate

with the Auto Section Control application/terminal and perform Auto Section

Control functions.

• Implement Layout

• Planter Output Module

• Clutch Module/Switch Assignment

IMPORTANT: Rows must be assigned to a channel before proceeding

to implement setup. Row assignment can be verified at

the Channel Setup screen.

NOTE: If using the IntelliAg system

prior to Auto Section Control,

some of the IntelliAg screens

may already be configured and

do not require additional setup.

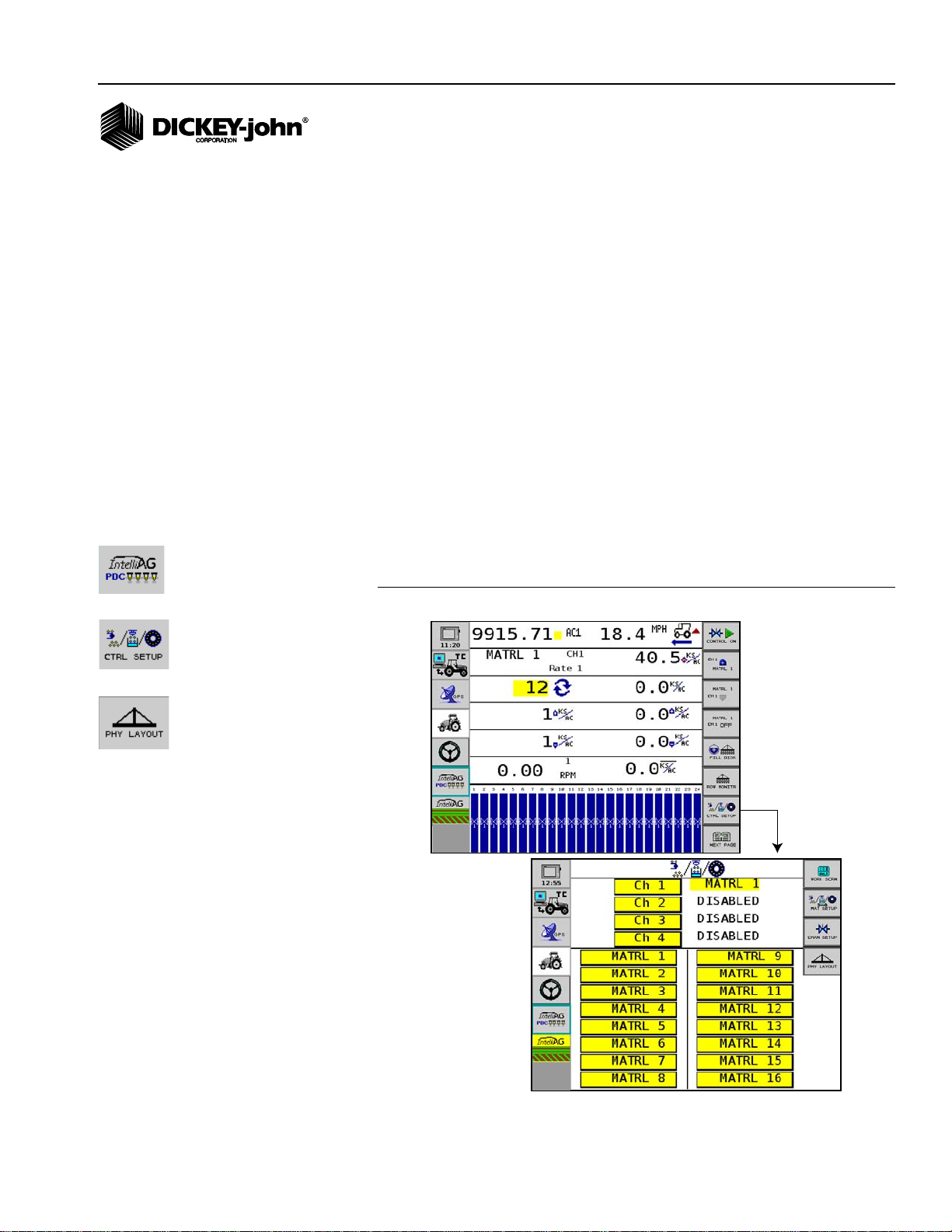

IMPLEMENT SETUP

To Enter Implement Settings:

1. Press the IntelliAg PDC button to display the IntelliAg Main Work

screen.

2. At the Main Work screen, press the Control Setup button.

3. At the Control Setup screen, press the Physical Layout button.

Figure 11

Physical Setup Screen

Auto Section Control System

11001-1561B-201207

INTELLIAG PDC SETUP / 13

Page 16

OPERATOR’S MANUAL

Implement

Center 0”

Y coordinate

-Y = center of channel 1 (rows 1-16) left of hitch

+Y= center of channel 2 (rows 17-32) right of hitch

-180

-Y

180

+Y

-X

-180

X coordinate

-X = distance from hitch to

implement center

Channel 1

Planter Ctrl

Rows 1-16

Channel 2

Planter Ctrl

Rows 17-32

Channel

Center

Implement

Center 0”

-0

-Y

+0

+Y

-X

-180

X coordinate

-X = distance from hitch to

implement center

Channel 1

Planter Ctrl

Rows 1-24

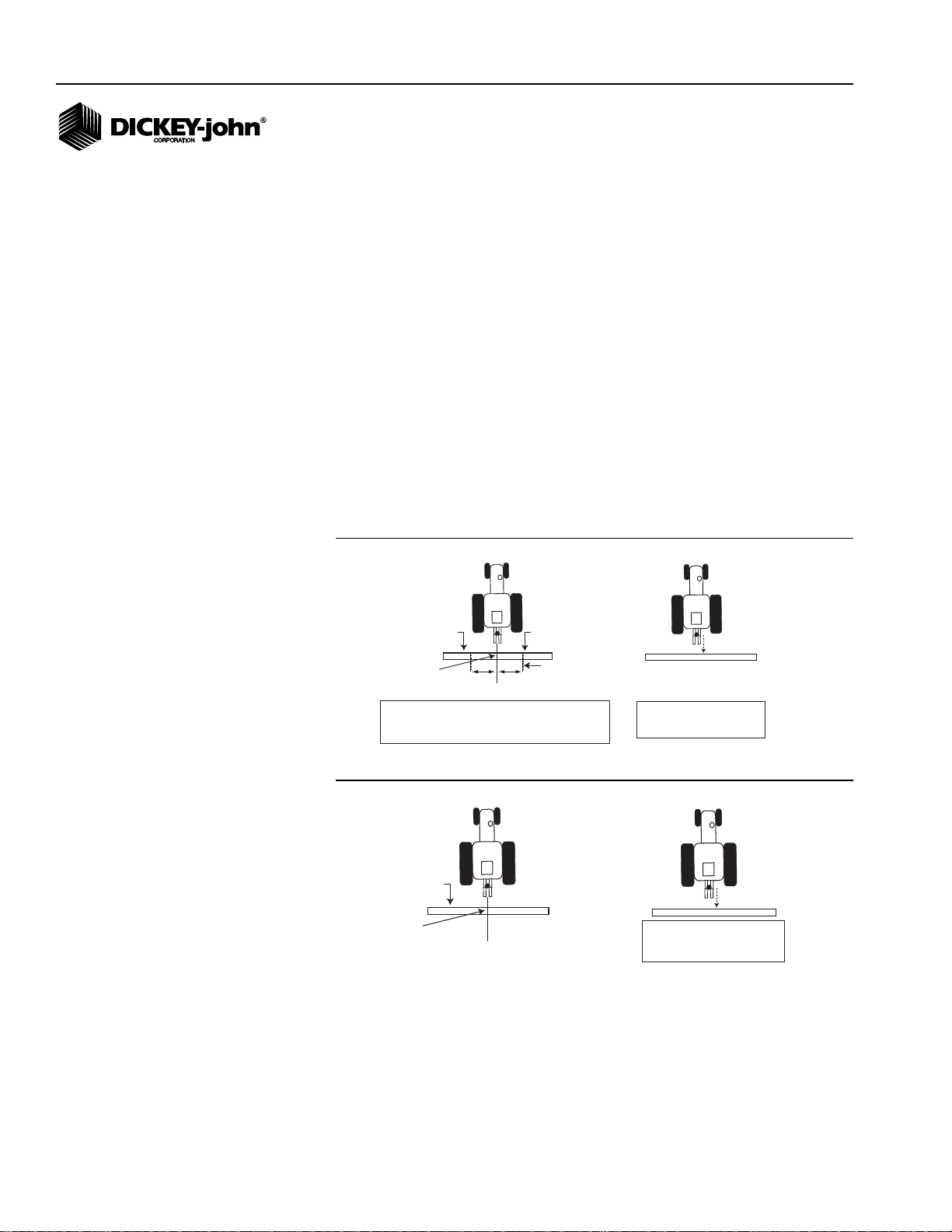

PHYSICAL LAYOUT

Physical layout of the implement is required to determine the position of the

planter control channel in the field. The physical layout of planter center is

calculated by measuring the distance from the center of the row units to the

hitch pivot point connection.

NOTE: If T ask Controller functionality is

used, these coordinates should

already be established.

To measure X/Y Coordinates:

1. Stand behind the implement facing tractor.

X coordinate:

– Measured from the hitch pivot point to where the seed is placed in

the ground, i.e. bottom of seed tube, and entered as a negative

entry (-X). This measurement should be entered for each control

channel enabled.

Y coordinate:

– Channels to the left of hitch pivot point are entered as a negative

entry (-Y).

– Channels to the right of hitch pivot point are entered as a positive

entry (Y).

Figure 12

32 Row Planter 2 Control Channels X /Y Coordinate Example

14 / INTELLIAG PDC SETUP

Figure 13

24 Row Planter 1 Control Channel X / Y Coordinate Example

IMPORTANT: It is critical to enter the exact distances required when

setting up the physical layout of the implement position.

Do not guess; use a tape measure to find exac t

measurements. Failure to enter accurate measurements

of the implement control channels will impa ct the

system’s performance to shut row sections off at the

proper location within the field.

Auto Section Control System

11001-1561B-201207

Page 17

OPERATOR’S MANUAL

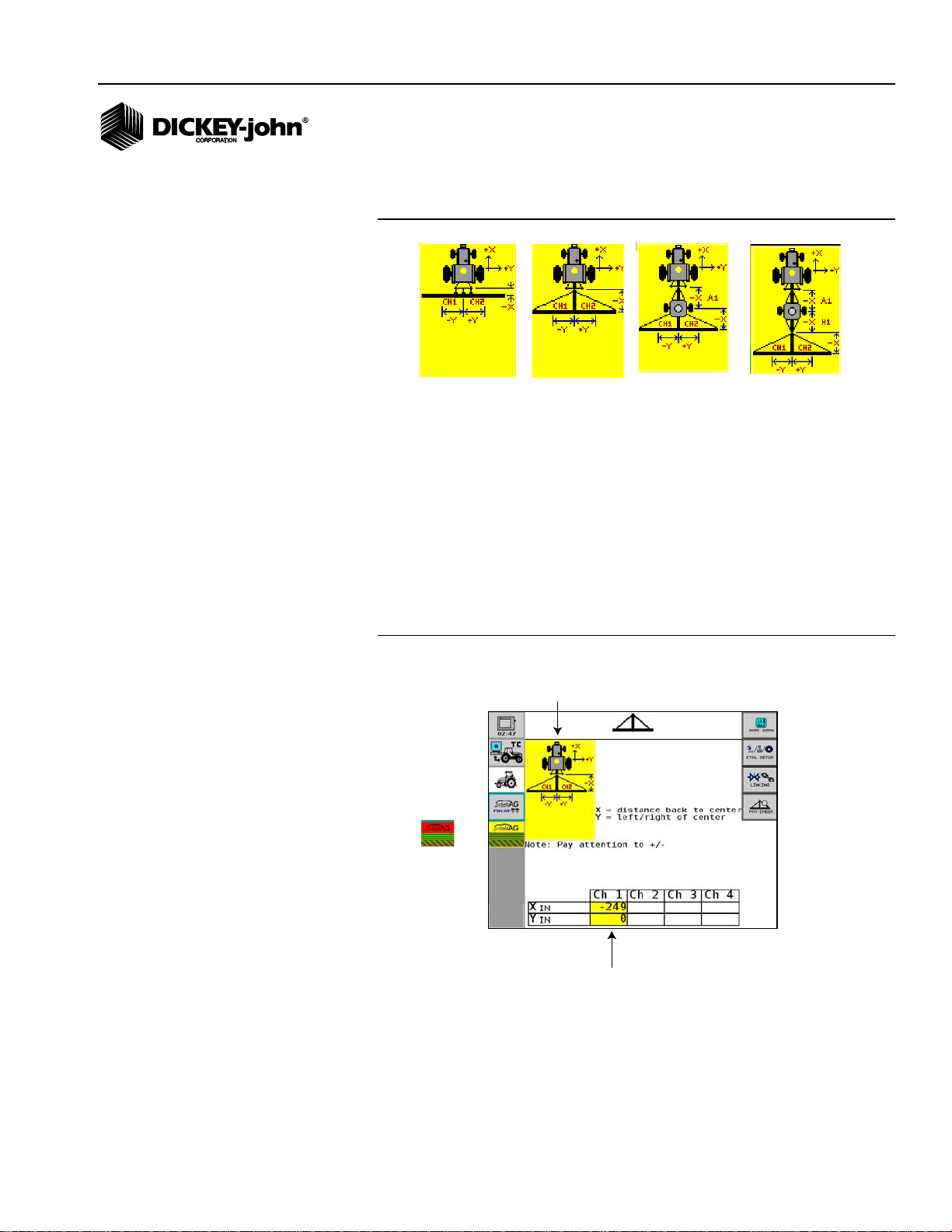

3-Point Hitch Towed Hitch Tow-Behind CartRigid-Cart Mount

Select

Implement

Type

Enter X Y Coordinates

for each enabled channel

A red button

indicates

GPS signal

is lost.

2. At the Physical Layout screen, select the appropriate implement layout

type by pressing the tractor/implement graphic.

Figure 14

Implement Layout Types

3. Enter in the table each channel’s X and Y coordinates. X and Y

coordinate measurements will vary based on the implement type

selected.

NOTE: When operating with only 1

control channel, the “Y” value

on the Physical Layout screen

should remain at 0 unless the

implement is offset left or right

of center.

NOTE: Use the gray implement table

on screen as a guide to verify

channels are aligned correctly

as X Y coordinates are entered.

IMPORTANT: If there are no rows assigned to a control channel, such

as operating in Monitor Only mode, a row column

appears on the Physical Layout screen and rows must

be assigned an offset.

3 POINT HITCH AND TOWED HITCH

Figure 15

Physical Layout Screen - 1 Channel Assignment (3 Point Hitch and Towed Hitch)

Auto Section Control System

11001-1561B-201207

INTELLIAG PDC SETUP / 15

Page 18

OPERATOR’S MANUAL

-180

Hitch to cart

axle

measurement

- 40

- 40

Control channel

over lap (Y coordinates

are not correct)

Implement

Table appears indicating

channel assignment as

X Y coordinates

are entered for two or

more channels

Correct control

channel alignment

(Y coordinates

entered correct)

-180

-180

Hitch to Cart

Axle

Measurement

Cart Axle to

Implement

Hitch

Measurement

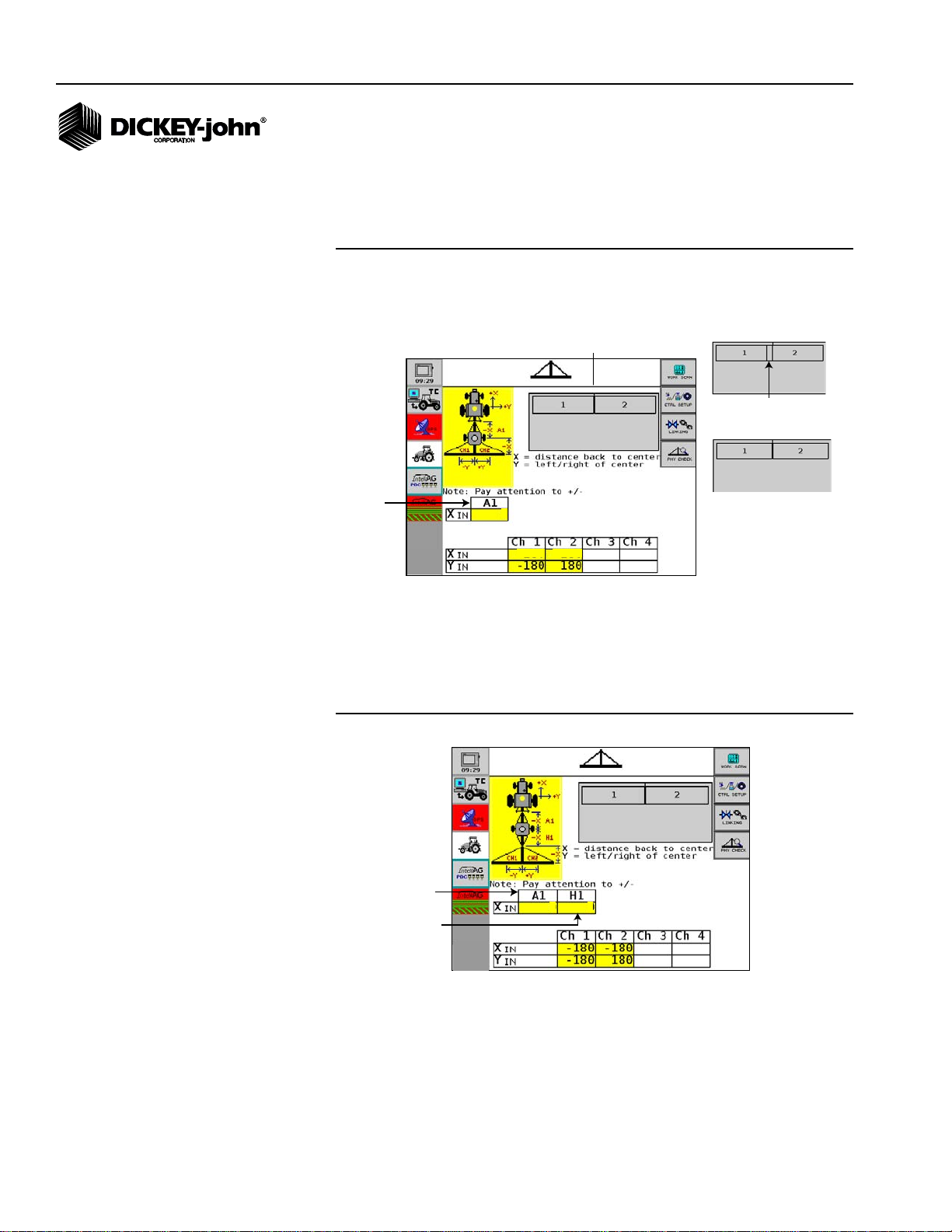

RIGID CART MOUNT

An additional -X coordinate measurement from hitch to cart axle is entered

in (A1) table.

Figure 16

Physical Layout Screen - 2 Channel Assignment (Rigid Cart Mount)

NOTE: When operating with only 1

control channel, the “Y” value

on the Physical Layout screen

should remain at 0.

16 / INTELLIAG PDC SETUP

TOW-BEHIND CART

Two additional -X and -Y coordinate measurements from hitch to cart axle

entered in (A1) and cart center to implement hitch (H1).

Figure 17

Physical Layout Screen (Tow-Behind Cart)

4. To view implement layout, press the Physical Check button.

Auto Section Control System

11001-1561B-201207

Page 19

OPERATOR’S MANUAL

Channel 1 center

(1)

(2)

(3)

OVERLAP

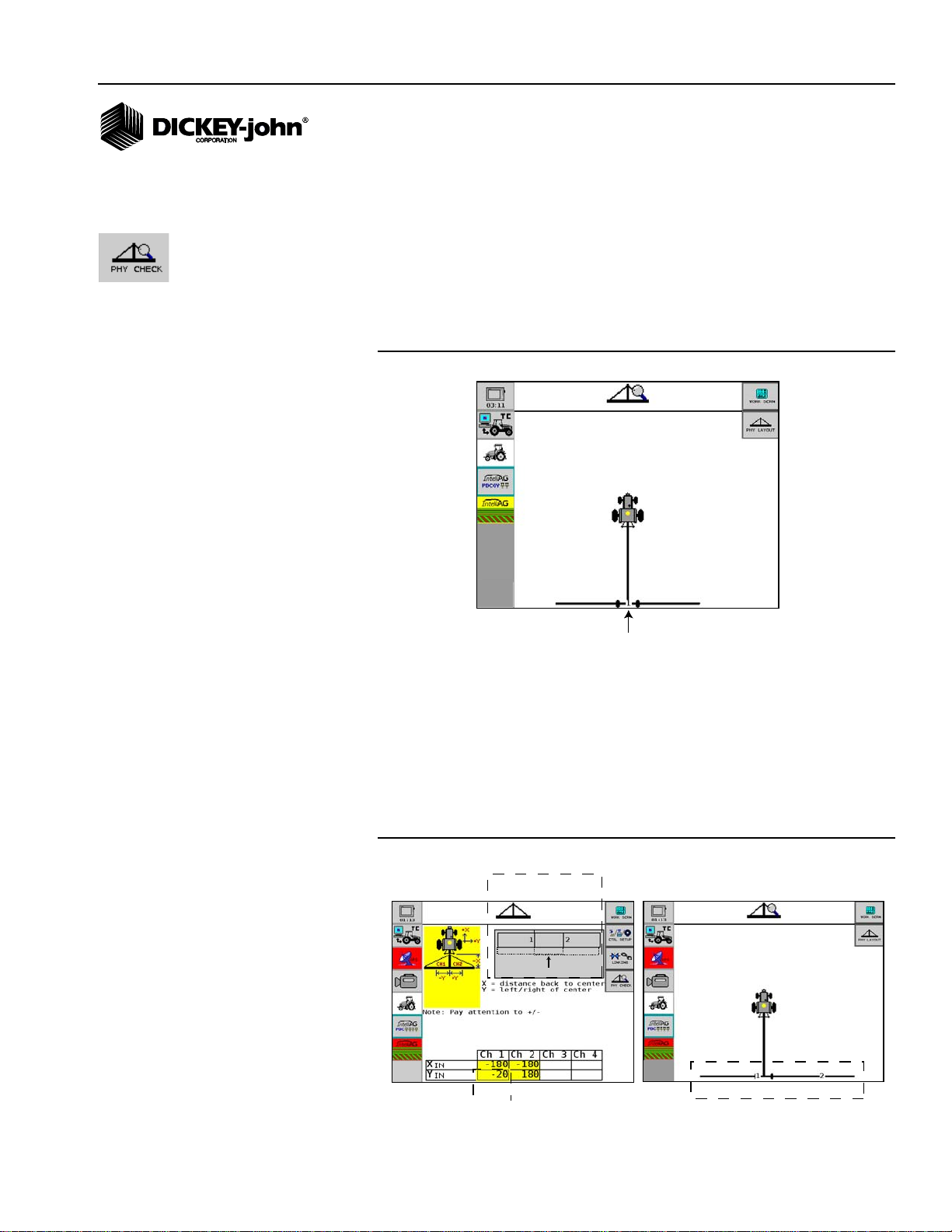

PHYSICAL CHECK

The Physical Check screen visually displays the implement layout and

control channel center as entered on the Physical Layout screen. Use this

screen to verify channels are setup correctly.

To view Physical Check screen:

1. At the Physical Layout screen, press the Physical Check button.

(Figure 18) depicts channel 1 setup in a correct format.

Figure 18

Physical Check Screen Setup Correct (Example Only)

(Figure 19) depicts an incorrect Y channel setup:

1. Y coordinate for channel 1 entered incorrectly.

2. Control channel graphic (gray box) shows that channel 1 and 2 are not

aligned correctly and are overlapping.

3. Physical check screen provides another visual of actual control

channel center for channel 1 that is incorrectly aligned and overlapping

channel 2.

Figure 19

Physical Check Screen Setup Incorrect

Auto Section Control System

11001-1561B-201207

INTELLIAG PDC SETUP / 17

Page 20

OPERATOR’S MANUAL

CLUTCH CONFIGURATION

Clutch module configuration is required to:

• Identify how many planter output modules are connected to the

IntelliAg system

• Assign how many outputs are assigned to each output module

• Assign how many rows are assigned to each output

• Assign row shutoff module switches to outputs that enable and disable

planter sections

MULTIPLE TRU COUNT OUTPUT MODULE ASSIGNMENT

Output module addresses are a critical parameter used to identify a

module’s position on the implement that will control row shutoff switches.

IMPORT ANT: If a planter uses more than one output module, modules

MUST be installed in increasing serial number order

starting on the left side and proceeding to the right so

that row assignment is configured correctly.

TRU COUNT OUTPUT MODULE ASSIGNMENT

The Clutch Module Configuration screens displays:

• Module address

• Type

• Number of outputs per module

To enter # of Outputs per Module:

1. At the IntelliAg Main Work screen, press the Module Configuration

button.

2. At the Module Configuration screen, press the Clutch Module button.

3. Enter the number of solenoid outputs connected to the specific TCOM.

Outputs do NOT always total the number of clutches but the total

number of controlled solenoids. The Output Numbers (#s) value is

automatically sequenced for each module based on the module

address value.

4. Enter the shutoff delay times for engaging and disengaging clutches.

Delay times vary based on manufacturer. Refer to (Figure 20) for

recommended clutch delay times.

Delay time defaults for both turning on and shutting off is set at 0.0 seconds

on the Clutch Configuration screen.

IMPORTANT: The shutoff delay time is a mechanical delay for

engaging and disengaging clutches. Seconds entered

at this screen will increase the look-ahead time when

shutting off and turning on rows controlled at the Auto

Section Control screens. Shutoff delay times can effect

accuracy of Run in and Run Out functionality.

18 / INTELLIAG PDC SETUP

Auto Section Control System

11001-1561B-201207

Page 21

OPERATOR’S MANUAL

Figure 20

Clutch Delay Times

Clutch Type Turn Off Turn On

TruCount 0.4 seconds 0.4 seconds

Great Plains 0.3 seconds 0.4 seconds

Contact DICKEY-john Technical Support at 1-800-637-3302 for

recommended shutoff delay times on all other clutches.

Figure 21

Clutch Configuration Screen

ASSIGNING ROWS

The Clutch Configuration screen assigns rows to outputs. As rows are

assigned to each output, row numbers automatically populate.

1. At the Clutch Module screen, press the Clutch Configuration button.

Enter number of rows to be assigned to each output.

Figure 22

Clutch Configuration

Auto Section Control System

11001-1561B-201207

INTELLIAG PDC SETUP / 19

Page 22

OPERATOR’S MANUAL

A red button

indicates

GPS signal

is lost.

ASSIGNING ROW SHUTOFF SWITCHES

The Clutch Set screen identifies what switches on the row shutoff switch

box enable and disable planter sections or outputs.

1. At the Clutch Configuration screen, press the Clutch Set button. Enter

which clutch switch will be assigned to an output module to enable and

disable planter sections.

Figure 23

Clutch Set Screen

20 / INTELLIAG PDC SETUP

Auto Section Control System

11001-1561B-201207

Page 23

OPERATOR’S MANUAL

MASTER

ROW SECTION

123

4

5

6

Rows

1-9

Rows

10-15

Rows

16-24

Master

On/Off

Not

assigned

Not

assigned

Not

assigned

1

2

3

4

TCOM

MODULE OUTPUT ASSIGNMENT EXAMPLE

1. Three solenoid outputs to be controlled by Tru Count output module.

2. Number of rows assigned to each output.

3. Row shutoff switches assigned to corresponding outputs.

4. Corresponding row shutoff switches will turn sections on and off.

Figure 24

Clutch Setup for Row Shutoff Module

Auto Section Control System

11001-1561B-201207

IMPLEMENT SECTION CHECK

IMPORTANT: After clutch row assignment, it is recommended to

perform a diagnostics check to verify the order of clutch

sections shut on and off correctly. Refer to the

Diagnostics section for section check instruction.

INTELLIAG PDC SETUP / 21

Page 24

OPERATOR’S MANUAL

22 / INTELLIAG PDC SETUP

Auto Section Control System

11001-1561B-201207

Page 25

OPERATOR’S MANUAL

AUTO SECTION CONTROL SETUP

Auto Section Control setup is entered on the IntelliAg virtual terminal. The

following Auto Section Control screens must be configured to perform Auto

Section Control functions.

• GPS Setup/Calibration

• System Setup

• Selecting a Task

GPS SETUP

GPS setup and calibration is required for the system to know implement

position in relation to the GPS receiver mounting location on the tractor and

effectively operate Auto Section control.

IMPORTANT: A minimum 5 Hz GPS receiver is required for

communication with the Auto Section Control system.

Any receiver less than 5 Hz will not provide adequate

communication to run the Auto Section Control system.

GPS SOURCE

The Auto Section Control system communicates with the GPS receiver

using either:

• CAN (GPS receiver signal broadcast over CAN)

• RS232 (GPS receiver connected to RS232 port)

If using an RS232 GPS source, the receiver must be connected to the Auto

Section Control terminal to prevent any additional system communication

delays.

GPS LAG

GPS lag time is the amount of delayed communication time in seconds that

occurs between the Auto Section Control system and the GPS receiver. A

GPS calibration is required to define the GPS lag time.

BAUD RATE AND DATA MODE (RS232 ONLY)

Baud Rate and Data Mode are communication signals as defined by the

manufacturer of the GPS receiver. Reference the receiver manual for

settings.

GPS OUTPUT

The GPS Output setting converts an RS232 output to CAN in a NMEA 2000

format and should be enabled when the following conditions occur:

Auto Section Control System

11001-1561B-201207

• Using an RS232 receiver and

• Using Task Controller functionality

The default setting is disabled.

AUTO SECTION CONTROL SETUP / 23

Page 26

OPERATOR’S MANUAL

TRACTOR SETUP (FIXED)

To determine an accurate reference point between the GPS receiver and

Auto Section Control, three distance positions are required:

• Distance from the GPS receiver antenna mounting location to the rear

axle center

• Distance from rear axle center to the implement hitch

• Distance from GPS receiver antenna mounting location to implement

hitch center of tractor

To enter GPS Setup:

1. At the Auto Section Control screen, press the System Setup button.

2. At the System Setup screen, press the GPS Setup button.

3. Select the GPS Source as RS232 or CAN.

4. Enter GPS lag time only after a calibration is performed. Refer to the

GPS Calibration section to perform test.

5. Select the Baud Rate and Data Mode if RS232 is the GPS source for

the GPS receiver. Reference the GPS receiver manual for settings.

6. If RS232, check the GPS Output input box to enable GPS messages in

NEMA 2000 format. This allows a GPS signal to be communicated

over CAN and available for use by the IntelliAg virtual terminal or Task

Controller.

7. Select Tractor Setup as Fixed.

8. Enter receiver/implement distances per below.

To determine Receiver/Implement Position (Fixed):

IMPORTANT: It is critical to enter the exact distances required when

setting up the receiver/implement position. Do not

guess; use a tape measure to find exact measurements.

Failure to enter accurate receiver and implement

positions will impact the system’s performance to shut

row sections off at the proper location with the field.

9. Place the tractor on a flat, level surface. Tractor should be straight for

accurate measurement.

10. Measure the horizontal (side-to-side) distance between the receiver

and implement hitch center. If the receiver is mounted in the center, the

value is 0. Enter the value in inches into the Receiver to Center input

box.

–Use the Left/Right button to position the blue receiver indicator to

visually represent if the antenna is located on the left or right side of

the tractor.

11. Measure the distance from the center of the receiver to the center of

the fixed axle. Enter the value in inches into the Receiver to Axle input

box.

12. Measure the distance from the center of the rear axle to the implement

hitch pin pivot point for pull-type implements. Enter the value in inches

into the Axle to Hitch input box.

24 / AUTO SECTION CONTROL SETUP

Auto Section Control System

11001-1561B-201207

Page 27

OPERATOR’S MANUAL

0.5

8

42

Figure 25

GPS Setup Screen

TRACTOR SETUP (ARTICULATED)

NOTE: Measurements entered as

inches/meters.

To determine an accurate reference point between the GPS receiver and

Auto Section Control, four distance positions are required:

• Distance from the GPS receiver antenna to the front axle center

position

• Distance from front axle center to pivot point

• Distance from pivot point to rear axle center

• Distance from rear axle center to implement hitch

To enter GPS Setup:

1. At the Auto Section Control screen, press the System Setup button.

2. At the System Setup screen, press the GPS Setup button.

3. Select the GPS Source as RS232 or CAN.

4. GPS lag time should only be entered after a calibration is performed.

Refer to the GPS Calibration section to perform test.

5. Select the Baud Rate and Data Mode if RS232 is the GPS source for

the GPS receiver. Reference the GPS receiver manual for settings.

6. If RS232, check the GPS Output input box to enable GPS messages in

NEMA 2000 format. This allows a GPS signal over CAN and available

for use by the IntelliAg virtual terminal.

7. Select Tractor Setup as Articulated.

8. Enter receiver/implement distances per below.

To determine Receiver/Implement Position (Articulated):

9. Place the tractor on a flat, level surface. Tractor should be straight for

accurate measurement.

10. Measure the horizontal (side-to-side) distance between the receiver

and implement hitch pin pivot point. If the receiver is mounted in the

center, the value is 0. Enter the value in inches into the Receiver to

Center input box.

–Use the Left/Right button to position the blue receiver indicator to

visually represent if the antenna is located on the left or right side of

the tractor.

Auto Section Control System

11001-1561B-201207

AUTO SECTION CONTROL SETUP / 25

Page 28

OPERATOR’S MANUAL

RS232

0.5

96

84

11. Measure the distance from the center of the receiver to the distance

from the center front axle. Enter the distance into the Axle to Receiver

input box.

12. Measure the distance from the center of the front axle to the center of

the tractor pivot point. Enter the distance into the Front to Pivot input

box.

13. Measure the distance from the center of the rear axle to the center of

the tractor pivot point. Enter the distance into the Pivot to Rear input

box.

14. Measure the distance from the rear axle center to the implement hitch

pivot point for pull-type implements . Enter the distance into the Axle to

Hitch input box.

Figure 26

Articulated GPS Setup Screen

GPS CALIBRATION

A GPS calibration test should be performed to determine the GPS lag time

that occurs between the Auto Section Control system and the GPS receiver.

IMPORT ANT: The most accura te calibration test is to drive over a fixed

26 / AUTO SECTION CONTROL SETUP

1. Place a fixed reference line in the field to drive over, such as a rope or

2. Drive until the front tires are sitting on the reference line.

3. At the System Setup screen, press the GPS Setup button.

4. At the GPS Setup screen, press the Calibration button.

5. With ground speed at 0, press the Set Reference button.

IMPORTANT: Ground speed must be 0 for the Set Ref er enc e b utton to

painted line.

reference line that can visually be seen from the cab

versus driving past an object.

appear.

Auto Section Control System

11001-1561B-201207

Page 29

OPERATOR’S MANUAL

in the opposite direction

SET REFERENCE LINE

Beep after

reference line

Increase Lag (+) time

When the Set Reference button is pressed, the Auto Section Control

terminal will indicate tractor position and mark a blue line on the screen

as a site of reference. It is important that the tractor be perpendicular

to the blue line to drive straight across the line.

6. Follow the onscreen instructions on the IntelliAg virtual terminal and

begin driving forward at the desired planting speed. Continue driving in

an oval until the reference line is crossed heading the same direction

that the reference line was set.

7. Redrive the same course in the same direction.

8. A beep should occur at the same spot the set reference point was set.

– If the beep occurs after the set reference point is crossed, increase

the GPS lag time on the GPS Calibration screen.

– If the beep occurs before the set reference point is crossed,

decrease the GPS lag time on the GPS Calibration screen.

–The Plus and Minus buttons adjust lag time by 0.1 seconds

entered on the GPS Calibration screen.

9. Continue to perform the test, at least three times, until the beep and

crossing the reference line occurs at the same time. If the reference

point needs adjustment, press the Cancel button to abort calibration.

NOTE: GPS lag time range is 0 to 2.5

seconds.

IMPORTANT: Take adequate time and care for proper calibration of

GPS receiver. Run this test at least 3 times after proper

calibration has been determined to verify accurate GPS

lag value has been set.

10. When the beep occurs at the reference line, perform another complete

test (3 test runs) setting a new reference line to confirm that the GPS

lag value from the previous calibration test is correct.

11. Press OK button to accept the changes.

Figure 27

GPS Lag Time Test

Auto Section Control System

11001-1561B-201207

IMPORTANT GPS CALIBRATION NOTES

• Do not manually change the GPS lag after successful calibration is

completed in attempt to correct Run In or Run out section shutoff

points.

• If accuracy of the GPS lag value is in question, complete a full GPS

calibration as described for a new GPS lag value to be calculated.

AUTO SECTION CONTROL SETUP / 27

Page 30

OPERATOR’S MANUAL

+

Tractor

position

Reference

line

Auto Section Control Terminal

IntelliAg

Virtual

Terminal

• When diagnosing system accuracy issues, it is recommended to re-run

the GPS calibration.

• In the event a new software version is loaded in the Auto Section

Control or GPS receiver, the GPS calibration should be executed as

the software update could cause the GPS lag value to change.

Figure 28

GPS Calibration Screens

28 / AUTO SECTION CONTROL SETUP

Auto Section Control System

11001-1561B-201207

Page 31

OPERATOR’S MANUAL

FIELD PREPARATION

SETTING OVERLAP

An automatic delay or advance can be configured to enable and disable

planter sections when approaching or leaving an area by setting a Run In/

Run Out Overlap or Skip and a side-to-side overlap. A distance is entered in

inches/metric to enable this feature.

RUN IN OVERLAP

A Run In Overlap sets the distance (inches) to automatically delay section

shutoff when a planted area is entered.

RUN OUT OVERLAP

A Run Out Overlap sets the distances (inches) to automatically turn on

sections before a planted area is exited.

RUN IN SKIP

A Run In Skip sets the distance (inches) to automatically shutoff sections

before a planted area is entered.

RUN OUT SKIP

A Run Out Skip sets the distance (inches) to automatically turn on sections

after a planted area is exited.

SIDE-TO-SIDE OVERLAP

When entering an angled headland, a side-to-side overlap defines the

percent of overlap to occur when the angle is crossed. A percentage

adjustment between 50% to 100% in increments of 10% is allowed. At

100%, the shutoff and turn on point is calculated as each section reaches

the angle. At 50%, the shutoff and turn on point is calculated as each

section middle crosses the angle. (Figure 29) illustration depicts a planter

configured as one entire section with a 50% and 100% overlap.

Auto Section Control System

11001-1561B-201207

FIELD PREPARATION / 29

Page 32

OPERATOR’S MANUAL

}

Overlap

}

Overlap

}

100% Overlap Adjustment

50% Overlap Adjustment

Skip

50% Overlap Adjustment

100% Overlap Adjustment

Overlap

Overlap

Skip

Figure 29

Side-to-Side Overlap Adjustment with Planter (Single Section)

Example:

One-to-One Row/Clutch Assignment

A one-to-one row/clutch assignment set at 100% turns individual rows on

and off with an overlap and no gap. As the side-to-side overlap percentage

decreases, the overlap decreases and the gap increases. As the

side-to-side overlap percentage adjustment increases, the amount of

overlap increases and the gap decreases. A 50% adjustment results in a

50% overlap and 50% gap when the section center crosses the angle.

Figure 30

One-to-One Clutch Assignment with 100% Side-to-Side Overlap

30 / FIELD PREPARATION

Auto Section Control System

11001-1561B-201207

Page 33

OPERATOR’S MANUAL

IMPORTANT FUNCTIONALITY NOTES

The below situations can effect how Run In/Run Out functionality operates

in the field. Take into account the following when determining what values

to enter on the System Setup screen.

• A Run In/Run Out value of “0” turns on and off sections as soon as the

planter rows reach an area equal to 50% of the programmed row

spacing entered on the IntelliAg PDC setup of Row I/O. Example: If the

row spacing is set at 30” a Run In value of “0” will initiate shutoff of the

planter row 15” before reaching the first inner row of the headland. A

Run In value of “15” will initiate shutoff of the planter row at the first

inner row of the headland.

• To ensure the correct Run In/Run Out settings are entered, dig and

locate seed within the furrow and then measure distance from last

seed planted in row to desired shutoff point at headland. Mechanical

delays associated with the planter (chains, drives, hydraulics) can

have a direct impact on the row unit stopped versus the last seed

placed in the furrow.

• A side-to-side overlap adjustment percentage from 50% to 100% can

be changed during operation to increase or decrease the amount of

overlap. The steeper the angle, the greater the overlap percentage

should be to minimize gap.

• Population rate can also affect Run In/Run Out accuracy. This should

be accounted for when determining Run In/Run out values due to

meter speed ramp down time, i.e., higher population requires higher

meter RPM so it can take a fraction of a second longer for seed

placement to stop compared to a lower population and meter speed.

• Do not adjust the GPS lag value to compensate for shutting off and

turning on row units.

• When using a WAAS only signal, that has +/-12” accuracy, GPS

position drift may affect shutoff points. This drift can effect how the

Auto Section Control terminal identifies planter position as it relates to

turning rows on and off outside.

• Rows can unexpectedly turn on or off due to drift while driving or the

inaccuracy of the WAAS signal on pass-to-pass and headlands can

shift in and out over time due to the inaccuracy of the WAAS signal.

Auto Section Control System

11001-1561B-201207

FIELD PREPARATION / 31

Page 34

OPERATOR’S MANUAL

Run In/

Run Out

Buttons

Amount of

Skip or Overlap

in inches

Decrease

% to increase

skip

Increase

% to decrease

skip

Actual %

overlap

Run In Button

Run Out Button

To Enter a Run In and Run Out Settings and Overlap:

1. At the Auto Section Control Main screen, press the System Setup

button.

2. Press the Run In and/or Run Out buttons to cycle between Skip or

Overlap.

3. Enter the amount of Run In and/or Run Out in inches into the

appropriate input boxes.

4. Press the Increase and Decrease % Side-to-Side buttons to adjust to

desired overlap and gap percentage from 50% to 100%.

IMPORTANT: If a Run In and Run Out Overlap or Skip do not perform

as entered at System Setup, verify that an additional

delay value is not entered at the IntelliAg Clutch

Configuration screen (Figure 14) and a GPS calibration

has been performed.

Figure 31

System Setup Screen

Increase % Side-to-Side Button

Decrease % Side-to-Side Button

32 / FIELD PREPARATION

Auto Section Control System

11001-1561B-201207

Page 35

OPERATOR’S MANUAL

SMITH

PLANTING

LOAD A TASK

A task must be created or selected first before Auto Section Control will

operate. A task can be created at the Auto Section Control menu on the

IntelliAg virtual terminal or existing tasks established in Task Controller can

be imported using an SD card.

CREATE TASK

1. At the Auto Section Control Main screen, press the Select Task

button.

2. At the Select Task screen, press the New Client button.

3. Press the New Client input box and enter name using the keypad.

4. Press the OK button to accept.

5. Continue to enter New Farm, New Field, and New Task names.

6. Press the Open Task button to select the created task.

Figure 32

Creating a Task

Auto Section Control System

11001-1561B-201207

FIELD PREPARATION / 33

Page 36

OPERATOR’S MANUAL

Auto Section Control Button

IMPORT A TASK OR FIELD BOUNDARY FILE

Client, Farm, Field, and Events created in Task Controller or a farm

management software tool can be saved and imported into the Auto Section

Control terminal eliminating the step of re-creating a task.

Tasks and boundary file data are saved to an SD card inserted into the

IntelliAg terminal and then transferred to the Auto Section Control terminal.

The Import button only appears when Task Controller is enabled on the

IntelliAg VT with an SD card.

Maps and boundaries created in a farm management software tool on a

computer can be saved as task data files with a specific file structure for

transfer to the terminal.

To Prepare a Field Boundary File for Export:

1. Within the farm management software create a file folder named

TaskData. The task data file must be contained within this folder for the

terminal to recognize the files.

2. Select the file(s) to export and save with an .xml extension within the

TaskData folder.

3. Insert SD card into computer and begin export. Verify tasks are saved

and then remove SD card from computer.

To Transfer Task and/or Boundary File Data to IntelliAg Terminal:

NOTE: Tasks created in the Auto

Section Control terminal will

NOT transfer to the IntelliAg

Task Controller application.

4. Insert SD card into IntelliAg VT.

5. Press the Auto Section Control button. At the Auto Section Control

Main screen, press the Select Task button.

Figure 33

Select Task Screen

34 / FIELD PREPARATION

6. At the Select Task screen, press the Task Control Import button. The

Import Task Control screen displays a question mark as the source

until the appropriate import source button is pressed (Figure 34).

7. Press the Task Control Import TC button to begin transfer.

Auto Section Control System

11001-1561B-201207

Page 37

OPERATOR’S MANUAL

Files

Loaded

Import

Source

11

Boundary

File Indicator

8. When transfer is complete, the number of clients, farms, fields, tasks,

and field boundaries appear on screen.

9. Press the Back button to return to the Select Task screen.

10. Select the desired client, farm, field, task, and field boundary. A

Boundary Exists icon appears when a boundary file (created with farm

management software) is available.

11. Press the Open Task button.

IMPORTANT: Depending on file size, transfer time of Task Controller

data to the Auto Section Control terminal can take

several minutes.

Figure 34

Importing Tasks

Auto Section Control System

11001-1561B-201207

FIELD PREPARATION / 35

Page 38

OPERATOR’S MANUAL

OVERWRITE FIELD BOUNDARY

An Overwrite Field Boundary screen appears if the Auto Section Control

terminal already has the existing boundary with the same file name

associated with a field.

– Press the OK button to overwrite the existing boundary.

– Press the Cancel button to retain the existing boundary.

Figure 35

Overwrite Field Boundary

AUTO SECTION CONTROL STATUS

The Auto Section Control terminal will be in ready mode at the Select Task

screen. Auto Section Control status will indicate No Field Selected until a

task is opened and the system is enabled once GPS has been acquired.

Figure 36

Auto Section Control Terminal

36 / FIELD PREPARATION

Auto Section Control System

11001-1561B-201207

Page 39

OPERATOR’S MANUAL

All

sections

ON

11

3

4

1

5

6

2

12

Section

Indicator

7

8

9

10

SYSTEM OPERATION

AUTO SECTION MAIN SCREEN

When a task is loaded, the Auto Section Control Main Menu displays on the

IntelliAg virtual terminal and provides a visual representation of implement

section status that can be controlled from this screen.

NOTE: Pressing a section indicator

button represents what action

will occur when pressed, not

the current action.

Auto Section Control System

11001-1561B-201207

Figure 37

Auto Section Control Main Screen Functions

MAIN SCREEN FUNCTIONS

1. Implement section bar

Represents the total number of sections controlled by output modules

and gives a visual indicator of which sections are turned on (green)

and off (white)

2. Manual section indicator

Defines a section area to turn on (green) and off (white)

3. Manual section On/Off buttons

Toggles sections within the defined area on or off when pressed

4. Left Section Indicator buttons define all sections in the left group to be

controlled by the left Auto On/Off button when moved. The color of the

left and right indicator identifies the action (on or off) to occur when

section indicators are moved.

5. All sections on/off

Toggles all sections to an on or off state and moves the section

indicators back to the outside of the implement section bar on screen.

6. Manual/Auto mode

Puts system in Auto and Manual mode when pressed

7. Auto Section Control internal storage

Internal storage capacity indicator of imported, created, and stored

fields

SYSTEM OPERATION / 37

Page 40

OPERATOR’S MANUAL

8. Current Task

Active task running

9. GPS signal

GPS signal strength

10. Satellites

Number of active satellites

11. System status bar

Provides current status of Auto Section Control

12. Right Section Indicator buttons define all sections in the right group to

be controlled by the right Auto/On/Off button when moved. The color of

the left and right indicator identifies the action (on or off) to occur when

section indicators are moved.

Figure 38

System Status Bar

System Status Cause Resolution

Controller Offline WSMT (PDC) not found Error 100 (See Troubleshooting section)

No Controller WSMT (PDC) not talking or incompatible version Error 100 (Contact dealer to update WSMT (PDC)

System Fault System has encountered a nonrecoverable error 1. Power cycle the system.

No GPS No data from the GPS Receiver Error 102 (See Troubleshooting section)

Controller Setup WSMT (PDC) is on a Setup screen 1. Finish setup changes on WSMT (PDC) and return to

Controller Update Need to get data from WSMT (PDC) Error 200 (See Troubleshooting section)

Controller Sync Obtaining data from WSMT (PDC) Wait. System busy.

No Outputs No outputs configured on the WSMT (PDC) Outputs not assigned or assigned incorrectly. Check

Poor GPS Quality or number of satellites is not at acceptable levels Error 102 (See Troubleshooting section)

Init Loading coverage file Wait. System busy.

Pause WSMT (PDC) is not running WSMT (PDC) system is not active.

Ready WSMT (PDC) is running

Coverage Override Pause Coverage override is on with the implement up

Coverage Override Active Coverage override is on with the implement down

software.

2. Disconnect connector on the Auto Section Control

display and reconnect.

3. Create new field or clear current task.

Main Work screen.

2. Wait for WSMT (PDC) to finish power up process.

IntelliAg Module Configuration screens.

38 / SYSTEM OPERATION

Auto Section Control System

11001-1561B-201207

Page 41

OPERATOR’S MANUAL

Auto

Auto

Section

Control

Status

Swath

ENABLE AUTO SECTION CONTROL

To enable Auto Section Control:

1. Once a task is selected, press the Open Task button.

2. At the Auto Section Control Main Menu screen enable the following

system functions:

– Lower implement into the ground

– Turn master switch on

– Verify all clutch section switches are on

IMPORTANT: Vehicle speed must be greater than the shutoff speed

set at the IntelliAg Speed Setup screen.

3. Begin driving at desired planting speed.

4. Auto swath lines will appear on the Auto Section Control screen to the

path being driven.

Figure 39

Auto Section Control

Auto Section Control System

11001-1561B-201207

DISABLE AUTO SECTION CONTROL

Auto Section Control is disabled by performing any of the following

functions:

• Lifting the implement

• Master switch is turned off

• Manual override of the system (Manual button)

• Vehicle speed is lower than the shutoff speed set at the IntelliAg Speed

Setup screen

• Master section switch is turned off on the row control module

• A lost GPS signal

SYSTEM OPERATION / 39

Page 42

OPERATOR’S MANUAL

Auto

Mode

Active

Toggles

between

Auto/Manual

modes

1

5

2

3 4

3

4

6

Implement

Bar

Sections

AUTO MODE

Auto mode automatically enables and disables individual planter sections

utilizing a GPS signal as previously planted areas or boundaries are

approached. As planted areas and boundaries are approached, the Auto

Section Control Main Menu screen indicates which outputs turn on and off

and the row control switch module/clutch folding module indicator lights

automatically turn on and off. Sections can be forced OFF in Auto mode.

IMPORTANT: If using boundary files for Auto Section Control, pay

close attention to the first pass a r ound the boundaries

to ensure outside clutches perform c orrectly. If the

boundary is drawn a little tight, outside clutches may

turn off when a percent of the section width is outside

the boundary based on the side-to-side overlap set at

the System Setup screen. To correct, run outer pass in

Manual mode and widen boundary file in PC software.

This scenario is typically prevalent when using WAAS.

NOTE: Pressing a section indicator

button represents what action

will occur when pressed not the

current action.

40 / SYSTEM OPERATION

Figure 40

Main Screen (Auto Mode)

MANUALLY FORCE SECTIONS OFF IN AUTO

Section indicators can be positioned to turn sections off while in Auto mode.

Auto Active button remains in Auto mode when sections are off.

1. Left Auto On/Off button turns all sections to the left of the section

indicator off (white) when pressed and is depicted in white on the

implement bar.

2. Right Auto On/Off button turns all sections to the right of the section

indicator off (white) when pressed and is depicted in white on the

implement bar.

3. Auto/Off buttons toggle all sections between the section indicators to

an off or Auto mode state.

Auto Section Control System

11001-1561B-201207

Page 43

OPERATOR’S MANUAL

1

2

3

4

5

On/Off button

automatically

turns sections

on and off

when section

indicators are

pressed

6

Toggles between

Auto/Manual

mode

Manual

Mode

Enabled

Implement

Bar

Sections

4. Left Section Indicator buttons define all sections in the left group

when moved. The color of the left and right indicator identifies the

action (on or off) to occur when section indicators are moved.

5. Right Section Indicator buttons define all sections in the right group

when moved. The color of the left and right indicator identifies the

action (on or off) to occur when section indicators are moved.

6. All On or All Off buttons turns all sections on or off when pressed and

moves left and right section indicators back to the outside.

MANUAL MODE

Manual mode allows the operator to manually control planter sections in the

event of a lost GPS signal or in special conditions, such as marking

headlands in Override. When the system is in manual mode, sections must

be turned on and off either on the Auto Section Control screen or the Row

Control Switch module or Clutch Fold module.

NOTE: Pressing a section indicator

button represents what action

will occur when pressed, not

the current action.

Figure 41

Section Indicators

MANUAL ON/OFF CONTROL OF SECTIONS

In manual mode, section indicators allow manual control of turning

implement sections on and off. Manual Active button must be pressed to

enable Manual mode.

1. Left On/Off button turns all sections to the left of the section indicator

on (green) or off (white) when pressed as depicted on the implement

bar.

2. Right On/Off button turns all sections to the right of the section

indicator on (green) or off (white) when pressed as depicted on the

implement bar.

3. On/off button turns all sections between the section indicators on or off

when pressed.

4. Left Section Indicator buttons define all sections in the left group to

be controlled by the left Auto/On/off button when moved. The color of

Auto Section Control System

11001-1561B-201207

SYSTEM OPERATION / 41

Page 44

OPERATOR’S MANUAL

the left and right indicator identifies the action (on or off) to occur when

section indicators are moved.

5. Right Section Indicator buttons define all sections in the right group

to be controlled by the right Auto/On/Off button when moved. The color

of the left and right indicator identifies the action (on or off) to occur

when section indicators are moved.

6. All On or All Off buttons turns all sections on or off when pressed and

moves left and right section indicators back to the outside.

ADDITIONAL OPERATING CONDITIONS

ADJUSTING IMPLEMENT POSITION

The Flip button performs a flip function that adjusts the implement to its

actual heading (North, South, East, West direction) if the initial tractor

movement is reverse, such as backing to a corner. The Flip button should

only be used after a true moving heading has been established to reposition

the implement.

The Cycle button located on the bottom of the Auto Section Control

terminal also performs the Flip functionality. Refer to (Figure 4) for Cycle

button location.

MARKING/PLANTING HEADLANDS

For use if headlands will be planted last or after all long internal areas of the

field have been planted.

IMPORTANT: Auto Section Control MUST be in Manual mode when

planting marked headlands.

The Override button allows headland swaths to be marked first and planted

last and allows for inland rows to automatically turn on and off when the

marked headland is reached.

To Mark a Headland Swath:

1. Drive to the beginning of the headland.

2. Press the Override button and put implement lift switch in down

position (hydraulic drive systems leave master switch off).

3. Start driving the headland swath to mark.

4. At the end of the headland swath, press the Override button or lift the

planter (implement lift switch in up position) to disengage override.

5. Continue to mark additional headland swaths until complete. Swaths

can be marked as follows:

– If the inner most headland is known, this is the only swath that is

required to be marked.

– If the inner most headland is not known, all swaths can be marked.

6. Ensure system is placed back in Auto mode once headland swaths

have been completed.

Planting a Marked Headland:

42 / SYSTEM OPERATION

Auto Section Control System

11001-1561B-201207

Page 45

OPERATOR’S MANUAL

Planting Marked

Headlands

(Manual Mode)

Planted in rows

(Auto Mode)

Inner

Headland

The system cannot differentiate between a marked and already planted

area. Therefore, when planting the marked headland, the section control

must be in manual. The field map planting area will appear in blue which is

the indication of overplanting. However, overplanting is not occurring since

the first pass was marked and no seeds were dropped.

If only the inner most headland is marked, this is the only headland that

requires the control to be in manual. All other headlands can be planted in

Auto mode.

Figure 42

Planting a Marked Headland

STORING HEADLANDS

The following steps should be performed to ensure that headlands are

saved:

1. At the Auto Section Main Work screen, press the Select Task button.

2. At the Select Task screen, press the Open Task button to return to the

Main Work screen.

3. No further action required.

LOST GPS SIGNAL

A NO GPS screen on the Auto Section Control terminal indicates a GPS

signal cannot be found, has been lost, or the signal quality is not at

acceptable levels.

Potential causes:

• GPS setup incorrect.

– Check GPS Setup screen for proper inputs

– Check GPS status at the Diagnostics screen

• GPS signal blocked.

– Move to a clear area

• GPS receiver failure.

– Check receiver connection

In the event of a lost GPS signal, switch Auto Section Control to Manual

mode to continue planting.

Auto Section Control System

11001-1561B-201207

SYSTEM OPERATION / 43

Page 46

OPERATOR’S MANUAL

Figure 43

Auto No GPS

OUT OF FIELD RANGE

An Out of Field screen on the Auto Section Control terminal occurs when

the field is outside of range to display on the screen.

Select the correct field or start a new task to continue.

Figure 44

Out of Field Range

44 / SYSTEM OPERATION

Auto Section Control System

11001-1561B-201207

Page 47

OPERATOR’S MANUAL

SMITH

TERMINAL STORAGE CAPACITY

All created and imported fields are stored on the Auto Section Control

terminal. Storage capacity is indicated on the Auto Section Control

terminal Main Menu screen.

When full, storage can be cleared or deleted by clearing tasks or deleting

files. Task or files cannot be exported.

TIP: It is recommended that imported and created fields are cleared

after use to avoid the system from running slow.

CLEAR TASK

1. At the Select Task screen on the IntelliAg VT, select the task to be

cleared.

2. Press the Clear Task button.

3. At the Clear Task Coverage screen, verify the correct task is selected.

4. Press the OK button to delete.

NOTE: The Clear Task button only

appears for an existing task

stored on the terminal.

IMPORTANT: Deleted tasks cannot be restored.

Figure 45

Clear Task Coverage Screen

Auto Section Control System

11001-1561B-201207

TERMINAL STORAGE CAPACITY / 45

Page 48

OPERATOR’S MANUAL

SMITH

DELETE/RENAME FILES

NOTE: Individual clients, farms, fields,

and tasks can be renamed at

the Rename/Delete screen by

pressing the appropriate yellow

selection box. Use virtual

keypad to enter new name.

Individual clients, farms, fields, and tasks can be deleted.

1. At the Select Task screen, select the desired client, farm, field, or task

to delete.

2. Press the Rename/Delete button.

3. At the Rename/Delete screen, press the appropriate Delete button.

4. Verify the appropriate data is selected and press the OK button to

delete.

IMPORTANT: Deleted files cannot be restored.

Figure 46

Delete Files Screen

46 / TERMINAL STORAGE CAPACITY

Auto Section Control System

11001-1561B-201207

Page 49

OPERATOR’S MANUAL

Average GPS

Rate must be

lower than

200 ms

200 ms

DIAGNOSTICS

The Diagnostics screen provides information about the Auto Section

Control software version and GPS status. Information on the screen cannot

be edited.

Press the Diagnostics button to access the GPS Status and System

Information screens.

GPS STATUS

The GPS Status screen provides information about the current status of the

GPS functionality used for troubleshooting. Information on the screen

cannot be edited.

1. At the Diagnostics screen, press the Status button to access the GPS

Status screen.

The average GPS Rate must be lower than 200 ms for the 5 Hz

requirement to be met.

Figure 47

GPS Status Screen

Auto Section Control System

11001-1561B-201207

DIAGNOSTICS / 47

Page 50

OPERATOR’S MANUAL

SYSTEM INFORMATION

The System Information screen provides system software version

information. Information on this screen cannot be edited.

1. At the Diagnostics screen, press the Information button to access the

System Information screen.

Figure 48

System Information Screen

48 / DIAGNOSTICS

Auto Section Control System

11001-1561B-201207

Page 51

OPERATOR’S MANUAL

Start

Test

CLUTCH SECTION CHECK

A recommended pre-test to verify correct module and clutch assignment

ensures that clutches turn on and off appropriately.

To perform test:

1. At the Diagnostics screen, press the Section Check button.

1. Enter the cycle time duration of turning clutches on and off.

2. Select the type of test to perform

– All output test

– Single output test

3. Press the Start Test button to begin test.

4. Press the Stop Test button to end test.

IMPORTANT: Master switch and all clutch switches must be ON, if

equipped.

Figure 49

Clutch Section Check

Auto Section Control System

11001-1561B-201207

Cycle Time

Desired cycle time duration of turning clutches on and off during test.

All Output Test

Turns all clutches on and off at the same time.

Single Output Test

Selects which section to perform an individual section test. Plus button

goes to next higher section. Minus button goes to next lower section.

DIAGNOSTICS / 49

Page 52

OPERATOR’S MANUAL

50 / DIAGNOSTICS

Auto Section Control System

11001-1561B-201207

Page 53

OPERATOR’S MANUAL

TROUBLESHOOTING

FIRST PASS NEXT TO BOUNDARY IS SHUTTING OFF

ROWS WHEN USING BOUNDARY FILES

• Outside clutches will turn off when a section width is outside the

boundary based on the side-to-side overlap setting. To correct, run

outer pass in Manual mode and widen boundary file in PC software to

prevent this issue next time. This scenario is typically prevalent when

using WAAS.

AUTO SECTION CONTROL TERMINAL DOES NOT POWER

ON

• Verify that the Auto Section Control terminal ignition wire is connected

to switched power source.

• Check fuse connections of Auto Section Terminal Interface harness p/n

467980458 to the Tractor VT harness p/n 467980451A and to the

Tractor Power harness p/n 467980455.

AUTO SECTION CONTROL TERMINAL READS NO GPS

SIGNAL

• Poor GPS signal. Check GPS Status on the Auto Section Control

Diagnostics screen for signal status.

• Verify that GPS RS232 receiver is connected to the Auto Section

Terminal Interface Harness p/n 467980458 and not the Tractor

Harness p/n 467980451A.

• Verify that proper settings have been entered at the GPS Setup screen

for quality of GPS signal. An average GPS Rate must be lower than

200 ms for the 5 Hz requirement to be met.

• Check GPS status at the Auto Section Control Diagnostics screen for

signal status.

• GPS may be blocked. Move to a clear area.

• Check that receiver connection is powered up and secure.

To continue planting in the event of a lost GPS signal, switch Auto Section

Control to Manual mode and use section switch on CFM module.

AUTO SECTION CONTROL SCREEN SHOWS GAPS IN

SWATH PATTERN (SIDE TO SIDE)

• Adjust the Side-to-Side overlap percentage to adjust the amount of