Great Plains CTA4000HD User Manual

Great Plains Mfg., Inc.

Installation Instructions 1

Lock Valve Kit

40ft Conventional Till Heavy Duty Air Drills

Used with:

• CTA4000HD s/n EE1130-

General Information

These instructions explain how to install a Lock Valve Kit.

This kit prevents openers from lowering during transport

or maintenance.

These instructions apply to an installation of:

Kit Kit Description

160-048A CTA4000 OPNR TRANSPRT LOCK KIT

Each kit upgrades an entire drill. All new parts are used.

Tools Required

• air cart Operator Manual:

ADC1150: 167-058M, 167-101M

ADC2220: 167-073M

ADC2350: 167-085M

• updated drill implement Operator Manual:

160-037M, dated Nov. 2008 or later, and

updated drill Parts Manual:

160-037P, dated Oct. 2008 or later.

• basic hand tools,

• cleaning rags and supplies,

• a line to temporarily secureone loose hose, and a

small amount of hydraulic fluid to replace any lost

during hose disconnection.

When you see this symbol, the subsequent instructions

and warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

U

R

F

B

L

D

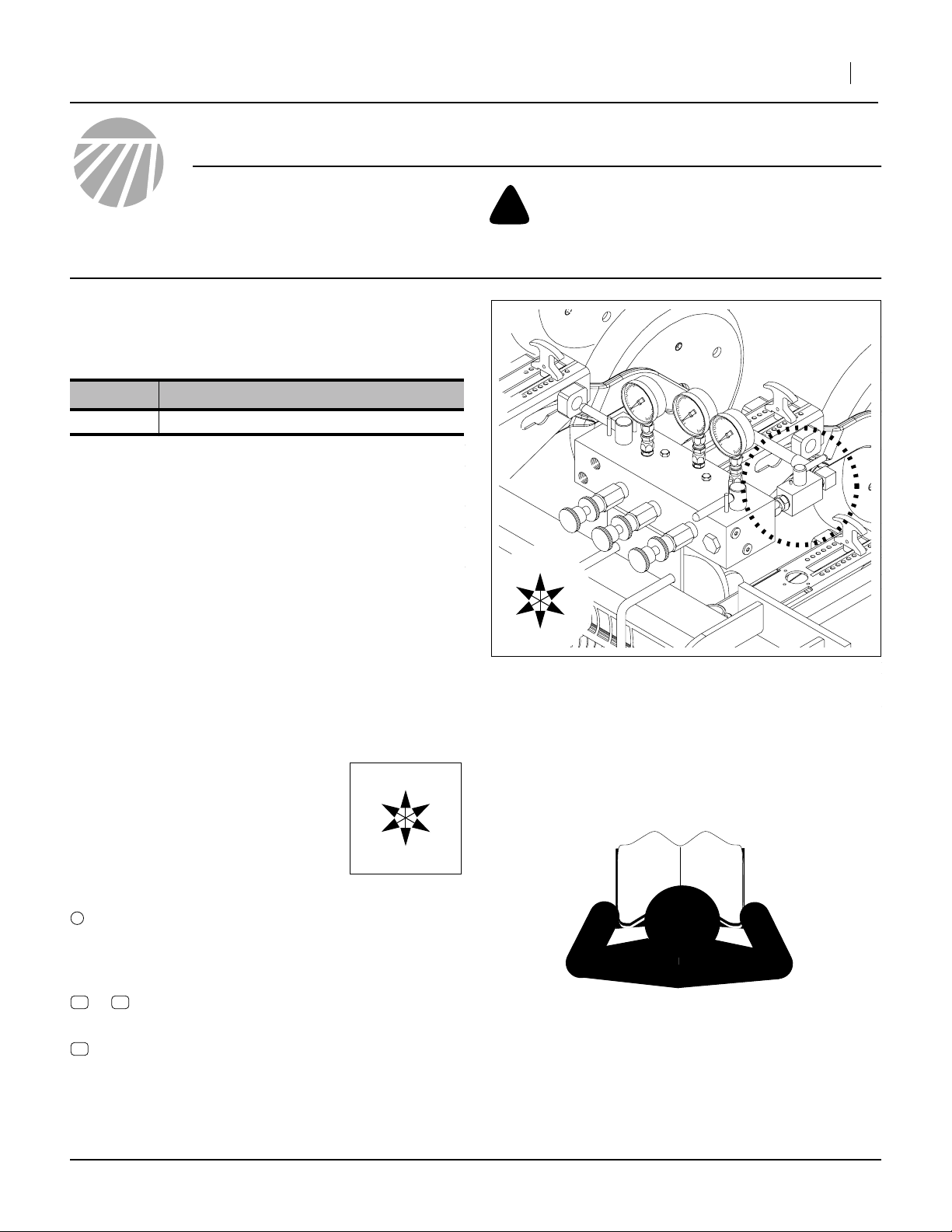

Figure 1

Lock Valve Installed

29114

Notations and Conventions

“Left” and “Right” are facing in the

direction of machine travel. An orientation rose in the line art illustrations

shows the directions of Up, Back, Left,

Down, Front, and Right.

R

F

U

B

L

D

Call-Outs

1

11 15

to

51

©Copyright 2008 Printed 11/07/2008 160-049M

Single-digit callouts identify components in

the currently referenced Figure or Figures.

These numbers may be reused for different

items from page to page.

Two-digit callouts in this range reference new

parts from the new parts list on page 6.

This callout references an affected existing

part from the table on page 6. The description matches that in your Parts Manual.

2 Lock Valve Kit

Before You Start

Review these instructions, with the following objectives at

each step:

• Need:

Inspect the drill an ensure that it does not already have

the lock valve. See page 1 for an illustration of the completed installation.

Great Plains Mfg., Inc.

Avoid High Pressure Fluids

• Safety:

Hydraulic Lines may be under pressure even with tractor circuits in Float.

Frame-mountedcoulters have sharp disk blades under

the work area.

• Inventory:

Examine any called-for items and make sure all parts

are present.

• Comprehension:

Make sure the installer understands where each part is

installed, and what tools are required for the task.

Pre-Assembly Preparation

Work Location

1. Move the drill to a location with:

• a non-flammable surface beneath, and;

• adequate illumination.

Prepare Drill

2. Unfold the drill.

Lower the openers.

3. Put tractor hydraulic circuits in Float.

Shut down tractor and remove key.

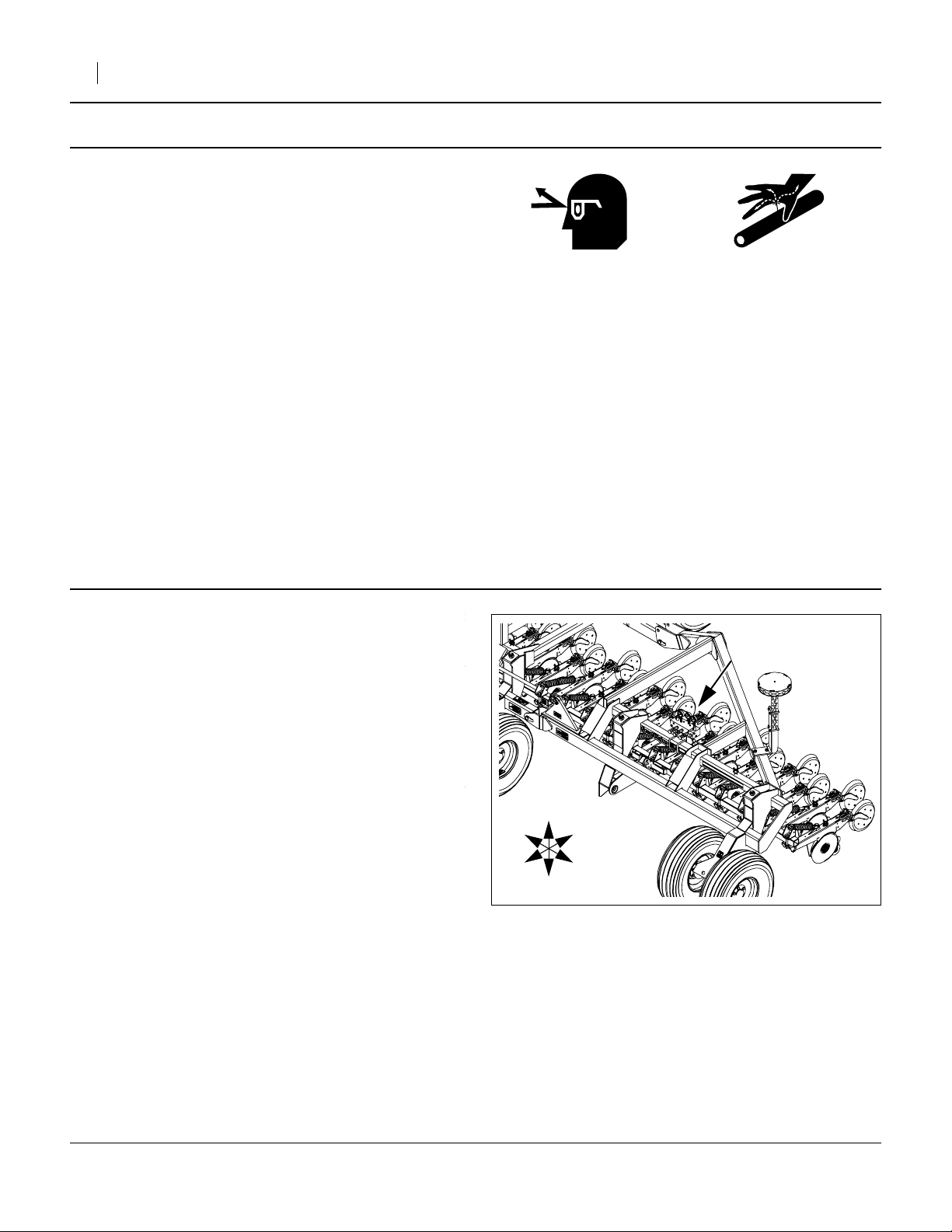

Refer to Figure 2

4. Locate the valve block to be updated.

5. Clean the valve and hose connections of any oil, dirt

or other contaminants.

Escaping fluid under pressure can penetrate the skin,

causing serious injury.

▲ Reduce the hazard by relieving pressure before disconnect-

ing hydraulic lines.

▲ Wear protective gloves and safety glasses or goggles when

working with hydraulic systems.

▲ Assume lines are pressurized until bled. Slowly open

(“crack”) fittings.

▲ Use a piece of paper or cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ If an accident occurs, seek immediate medical attention

from a physician familiar with this type of injury.

U

R

F

B

L

D

Figure 2

Valve Block Location

160-049M 11/07/2008

26377

Loading...

Loading...