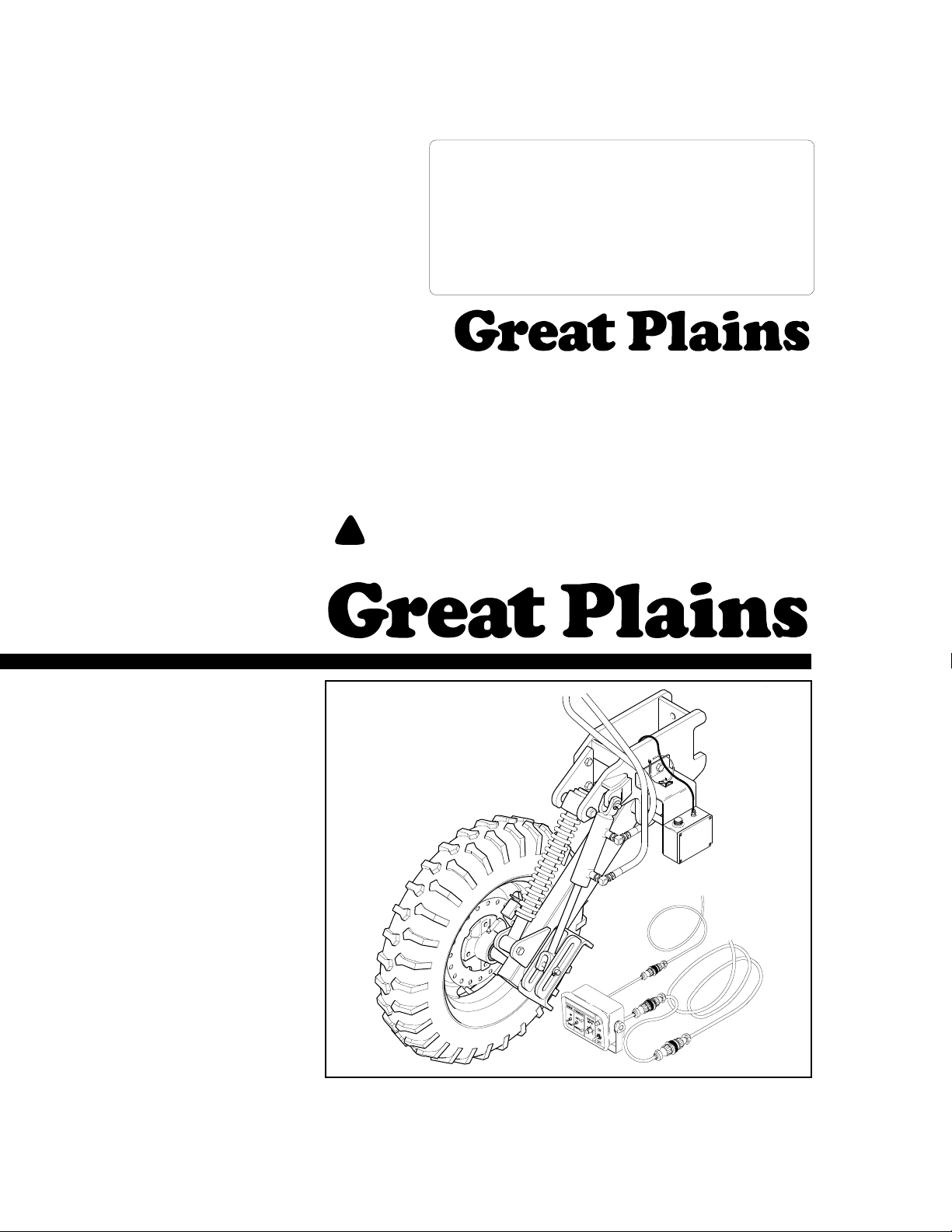

Page 1

Operator’s/Parts Manual

CPH and CP1000

Coulter Command System

Manufacturing, Inc.

P.O. Box 5060 ● Salina, Kansas 67402-5060

Read the operator’s manual entirely. When you see this symbol, the subsequent in-

!

structions and warnings are serious -follow without exception. Your life and thelivesof

others depend on it!

© Copyright 1999 Printed

2/30/2002

12611

Cover illustration may show optional equipment not supplied with standard unit.

148-258M-B

Page 2

Table of Contents

Table of Contents

Great Plains Mfg., Inc.

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

Important Safety Information . . . . . . . . . . . . . . . . . 1

Safety Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . 2

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . 2

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important Notice . . . . . . . . . . . . . . . . . . . . . . 2

Pre-Assembly Checklist. . . . . . . . . . . . . . . . . . . . 3

Coulter Command Assembly . . . . . . . . . . . . . . . . 3

Depth Sensing Wheel . . . . . . . . . . . . . . . . . . 3

Section 1 Assembly Instructions & Set-Up . . . . . . 3

Lift Switch Assembly . . . . . . . . . . . . . . . . . . . 4

Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . 6

Tongue Cylinder. . . . . . . . . . . . . . . . . . . . . . . 7

Hydraulic Control Valve . . . . . . . . . . . . . . . . . 7

Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Coulter Command Assembly Adjustments. . . . . . 9

Section 2 Operating Instructions . . . . . . . . . . . . . 10

Load Sensing Hydraulics . . . . . . . . . . . . . . . . . . 10

Hydraulic Hook-Up & Function. . . . . . . . . . . . . . 10

Closed-center hydraulic systems . . . . . . . . 10

Open center hydraulic systems. . . . . . . . . . 11

Operation of Electronic Controls . . . . . . . . . . . . 12

Field Adjustments . . . . . . . . . . . . . . . . . . . . . . . 12

Lift Switch. . . . . . . . . . . . . . . . . . . . . . . . . . .12

Speed Sensor. . . . . . . . . . . . . . . . . . . . . . . .13

Hydraulic Valve. . . . . . . . . . . . . . . . . . . . . . .13

Transport Cylinder Depth Channels . . . . . . . 13

Section 3 Troubleshooting . . . . . . . . . . . . . . . . . . . 14

System Schematics . . . . . . . . . . . . . . . . . . . . . .17

Hydraulic Schematic. . . . . . . . . . . . . . . . . . .17

Electrical Schematic. . . . . . . . . . . . . . . . . . .18

Section 4 Maintenance and Lubrication . . . . . . . .19

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Section 5 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Coulter Depth Control Hydraulics. . . . . . . . . . . .20

Coulter Command Electronics . . . . . . . . . . . . . .22

Coulter Command Gauge Wheel Assembly. . . .24

Top Link Assembly . . . . . . . . . . . . . . . . . . . . . . .26

Coulter Command Switch Mount . . . . . . . . . . . .28

Lift Circuit Manifold (810-262C) . . . . . . . . . . . . .30

Coulter Depth Control Valve (810-214C) . . . . . .32

O-Ring Identification Chart . . . . . . . . . . . . . . . . . 34

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Torque Values Chart for Common Bolt Sizes . . .36

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . .36

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

0

Page 3

Great Plains Mfg., Inc.

Important Safety Information

Important Safety Information

Foryour safety and to help in developinga better understanding of your equipment we highly recommend that

you read the operator sections of this manual. Reading

these sections not only provides valuable training but

also familiarizes you with helpful information and its location. The parts sections are for reference only and

don’trequire covertocoverreading.Afterreviewingyour

manual store it in a dry,easily accessible location for future reference.

!

The SAFETY ALERT SYMBOL indicates that there is a

potential hazard to personal safety involved and extra

safety precautions must be taken. When you see this

symbol, be alertand carefully read themessage that follows it. In addition to design and configuration of

equipment; hazard control and accident prevention are

dependentupon the awareness,concern,prudence and

proper training of personnel involved in the operation,

transport, maintenance and storage of equipment.

Watchforthe followingsafety notations through-out

your Operators Manual:

!

DANGER!

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury. This

signal word is limited to the most extreme situations.

!

WARNING!

Indicates a potentially hazardoussituation which, if not

avoided, could result in death or serious injury.

1. Escaping fluid under pressure can have sufficient force

to penetrate the skin. Check all hydraulic lines and hoses

before applying pressure. Fluid escaping from a very

small hole can be almost invisible. Use paper or cardboard, not body parts, to check for suspected leaks. If injured, seek medical assistance from a doctor that is

familiar with this type of injury. Foreign fluids in the tissue must be surgically removed within a few hours or

gangrene will result.

2. Make sure all people, animals, and objects are clear of

the coulter tool bar before switching the tongue hydrau-

lics switch to the "auto" mode.

3. Do not crawl under a raised machine without the transport lock blocks securely in place. Sudden hydraulic activation or failure could cause serious injury or death.

4. Never permit anyone to ride on hitch or planting equipment when moving.

5. Never permit anyone to ride tractor when hitch is being

moved.

6. Do not pull the Center Pivot Hitch faster than 20 miles

per hour.

7. Always set the hitch in field position before assembling,

lubrication, making adjustments, or servicing. Periodically check bolts for tightness and lubricate all fittings.

8. Shut off hydraulics valves and shut down tractor before

preforming any maintenance to the hitch or crawling under it.

9. Do not allow anyone to operate the machine who has not

been properly trained in its safe operation.

10. Do not operate equipment while under the influence of

drugs or alcohol.

11. Keep hands, feet, hair, and clothing away from all moving parts.

12. Clear the area of bystanders, especially small children

and animals before moving and operating equipment.

Review the safety instructions annually.

!

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices.

Safety Rules

Most accidents are the result of negligence and carelessness, usually caused by failure of the operator to

follow simple but necessary safety precautions. The followingsafetyprecautions are suggested to help prevent

such accidents. The safeoperation of any machinery is

a big concern to consumers and manufacturers.Your

Coulter Command System has been designed with

many built-in safety features. However, no one should

operate this product beforecarefully reading this Operator’s Manual.

9/21/05

CAUTION!

CPH and CP1000 Coulter Command System 148-258M-B

1

Page 4

Introduction

Introduction

Great Plains Mfg., Inc.

This manual applies to the following:

148-260A CPH Coulter Command

148-272A CPH Coulter Command Update

148-260A CP1000 Coulter Command

This manual has been prepared to instruct you in the

safe and efficient operation of your Coulter Command

System. Read and follow all instructions and safetyprecautions carefully.

Theparts on yourCoulter Command havebeen specially designed and should only be replaced with genuine

GreatPlains parts. Therefore, should your Coulter Commandrequirereplacement parts go toyourGreat Plains

Dealer.

Product Overview

The Coulter Command couples a microprocessor with

electro-hydraulics to provide a state-of-the-art system

formaintaining coulter depth regardless of the terrain or

soil type. It also provides coulter depth adjustment

"FromThe TractorCab". The Coulter Commandsystem

contains a depth sensing wheel, an electronic control

box, a speed sensor, a depth sensor box, a lift control

switch,a wiringharness, a top link, and a hydraulic control valve. It also uses the tongue cylinder from your

Center Pivot Hitch (CPH) or CP1000.

Definitions

The right hand and left hand as used throughout this

manual is determined by facing in the direction the machine will travel when in use unless otherwise stated.

NOTE: Indicates a special point of information

which requires your attention.

Important Notice

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either

expressed or implied, while every precaution has been

taken in the preparation of this manual, Great Plains

Manufacturing,Inc. assumesno responsibility forerrors

oromissions.Neither is any liability assumed for damages resulting from the use of the information contained

herein. Great Plains Manufacturing, Inc. reserves the

righttoreviseand improveits products asitseesfit.This

publicationdescribes the state ofthisproductat the time

of its publication, and may not reflect the product at all

times in the future.

Printed in the United States of America.

Foryour convenience, record your Serial Number, Mod-

el Number and the Date Purchased in the space

provided below. Have this information before you when

calling a Great Plains Authorized Dealer.

Using This Manual

Foryour safety and to help in developinga better understanding of your equipment we highly recommend that

you read the operator sections of this manual. Reading

these sections not only provides valuable training but

also familiarizes you with helpful information and its location. The parts sections are for reference only and

don’t require cover to cover reading. After reviewing

your manual store it in a dry, easily accessible location

for future reference.

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

2

Page 5

Great Plains Mfg., Inc.

Section 1 Assembly Instructions & Set-Up

Section 1 Assembly Instructions & Set-Up

Pre-Assembly Checklist

Check

All major components

Fasteners that were shipped with the Coulter Command

System.

NOTE: Some of the hardware from the factory has been

installed in the location where it will be used.

Have a minimum of 2 people at hand while assembling the

Coulter Command.

Have a fork lift or loader along with chains and safety

stands ready for the assembly task.

If you are unsure where a fastener is used, use the parts

section of this manual to identify it. Be sure the part gets

used in the correct location.

Coulter Command Assembly

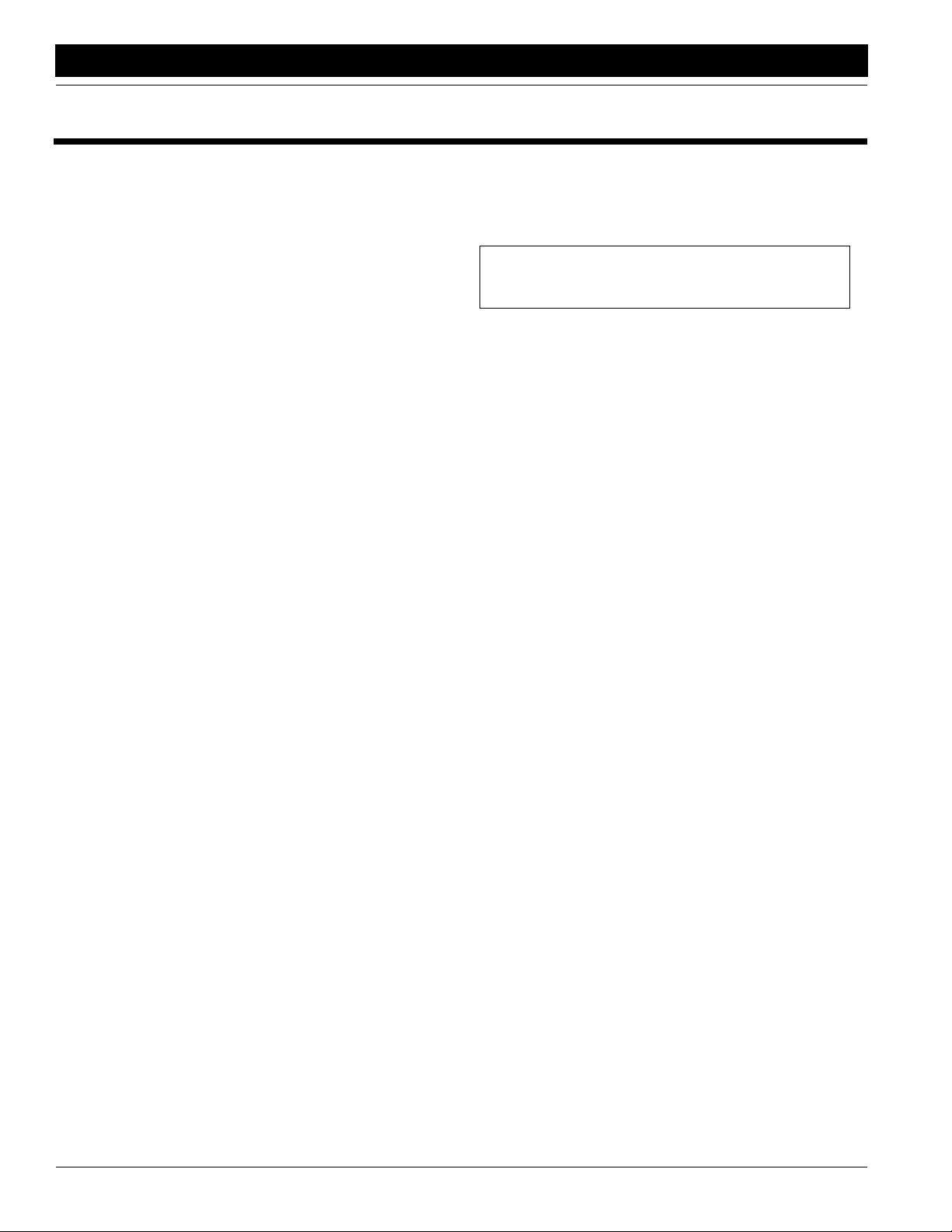

Depth Sensing Wheel

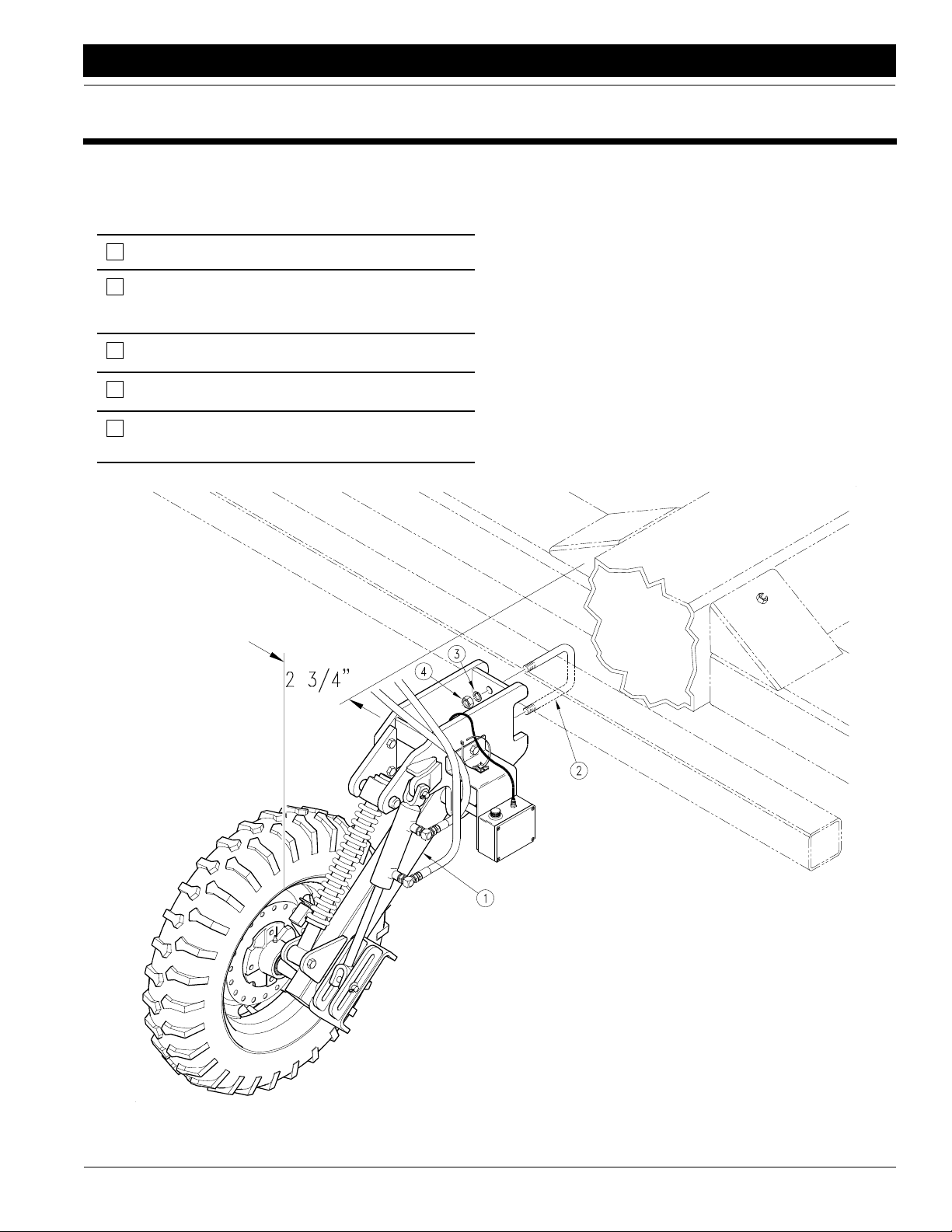

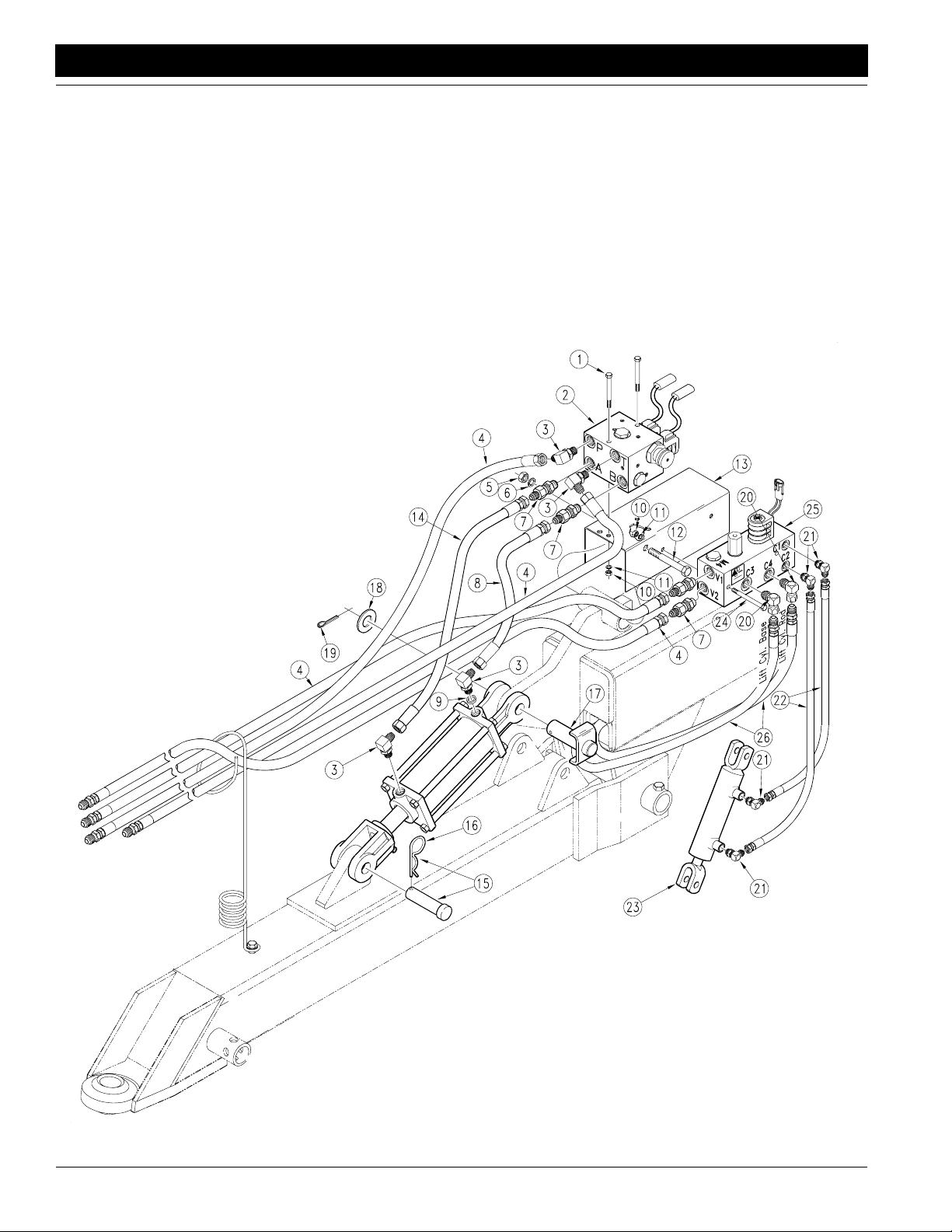

Refer to Figure1

Install the coulter depth sensingwheel assembly (#1) to

the front 4" x 4" coulter tool bar tube with the 5/8" X 6"

long U-bolt (#2), lock washers (#3), and nuts (#4). The

centerofthecoulter depth sensing wheel mount bracket

should be positioned 2 1/4" to the right of the center of

the hitch center beam. This dimension leaves about 2 3/

4"clearance between the inside edge of thedepth sensing tire and the edge of the 8" X 8" hitch center beam.

9/21/05

Figure 1

Coulter Command Assembly

CPH and CP1000 Coulter Command System 148-258M-B

12613

3

Page 6

Section 1 Assembly Instructions & Set-Up

Great Plains Mfg., Inc.

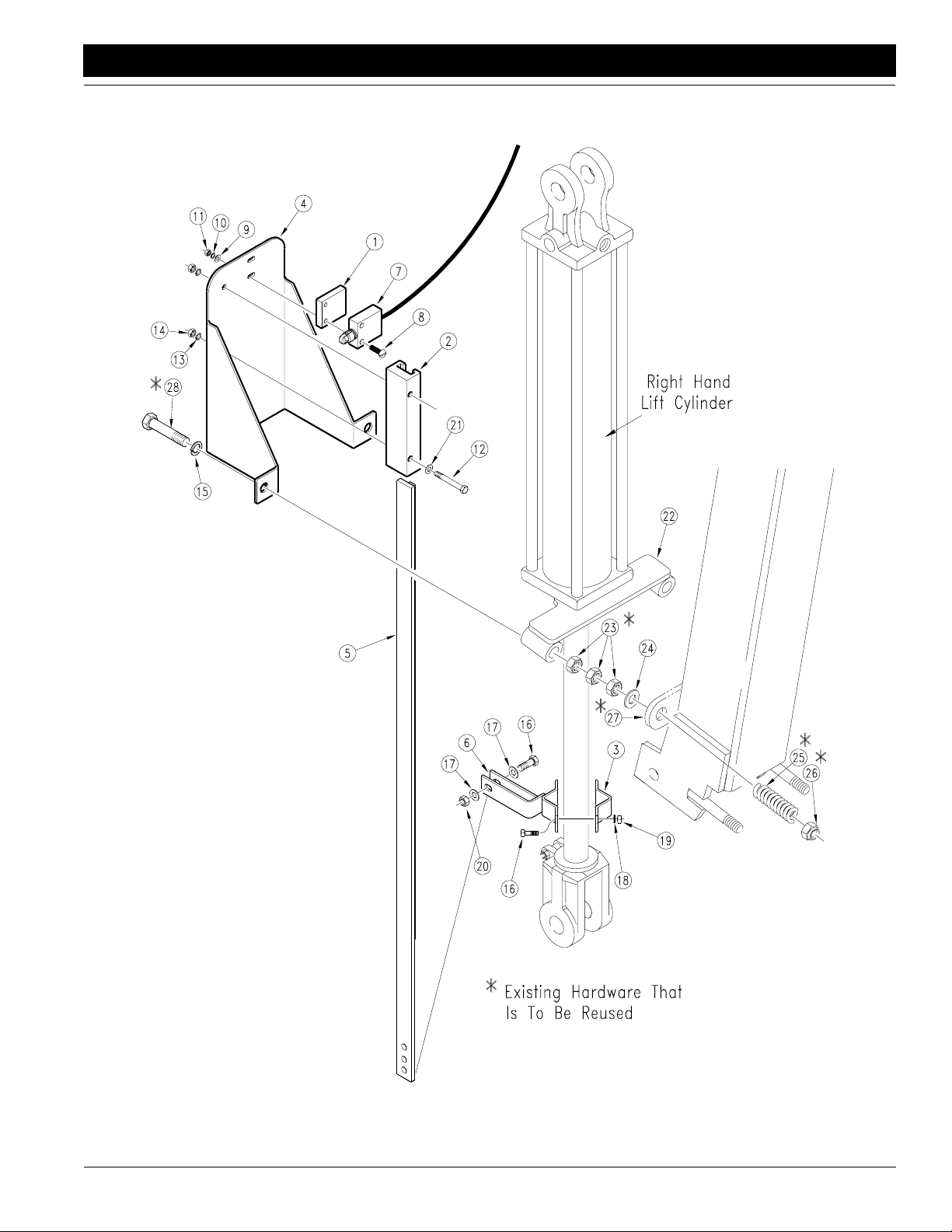

Lift Switch Assembly

Refer to Figure2

1. Remove the 1/2" x 5 1/2" long bolts (#28) nuts, flat

washers, and springs from the right hand transport

cylinderbraceand insert theswitchmount (#4),and

1/2" lock washer (#15), under the head of the bolt.

Position the mount and bolts back onto the brace

and reassemble the nuts, flat washers and springs

onto the brace. It is important that these support

braces are properly assembled to supportthe transport cylinders without binding or placing undo side

loads on the cylinders. Whenever the 5 1/2" support

bolts are removed or the inner axle slide blocks becomeworn, assemble or adjust the cylindersupport

braces as follows.

a. Assemble the 1/2" x 5 1/2" long full thread bolt

(#28), 1/2" lock washer (#15), and the switch

mount (#4) to the cylinder support brace (#22)

bolted to the rod end cylinder casting.

b. Screw on three 1/2" jam nuts (#23), and one

1/2" washer (#24) as shownin . Tighten thefirst

jam nut against the cylinder support (#22) and

run the other two jam nuts on, nearly all the way.

c. With the cylinder properly installed, the support

bolts (#28) should extend through the bracket

(#27)on the outer slide tube when thebaseend

and rod end pins are in place.

d. Screw the outer 1/2" jam nut out until the 1/2"

washer (#24) just touches the bracket on the

outer slide tube. Do not put pressure on the cylinder by tightening the 1/2" jam nut. Once the

washer touches the bracket,lock the outer 1/2"

jam nut in place with the center 1/2" jam nut.

e. Install spring (#25) and 1/2" nylock nut (#26).

Tighten nut to compress spring to a 1 1/4"

length.

Use this procedure foreach of the two supportbolts

on the transport cylinders.

2. Fastenthe cylinder rod clamps (#3 & 6) to the clevis

end of the cylinder rod with two 5/16" x 1 1/4" bolts

(#16),lockwashers(#18)andnuts(#19). The offset

of the clamp must be toward the right hand side of

the hitch as shown.

3. Withthe ramp of thepushrod(#5),facing towardthe

center of the hitch, insert it between the ears of the

cylinder rod clamp (#6), and bolt it in place with a

5/16"x 1 1/4" bolt (#16),two5/16" USS flat washers

(#17), and nylock nut (#20). It is recommended to

bolt it through the lower-most hole in the push rod.

Only run the nylock nut far enough onto the bolt to

makefull engagement of thenylon collar on the nut.

Do not cinch it down. Thebolt and push rod mustbe

free to move in the slot of the clamp.

4. Slide the switch guide block (#2), over the push rod

and fasten it to the mount with two 1/4" x 2" long

bolts (#12), flat washer (#21), lock washers (#13),

and nuts (#14).

5. Bolt the plunger activated switch (#7), to the mount

with the spacer plate (#1), under it with two #10" x

1 1/2" long round head machine screws (#8), flat

washers (#9), lock washers (#10), and nuts (#11).

Slide the plunger switch in the slots of the mount so

the plunger moves "in" about 1/8" when the cam on

the push rod activates it and tighten the screws.Do

not"bottom out" the plunger on theswitchor itcould

be damaged.

Wiring Harness

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

4

Page 7

Great Plains Mfg., Inc.

Section 1 Assembly Instructions & Set-Up

9/21/05

12612

Figure 2

Switch Assembly

CPH and CP1000 Coulter Command System 148-258M-B

5

Page 8

Section 1 Assembly Instructions & Set-Up

Great Plains Mfg., Inc.

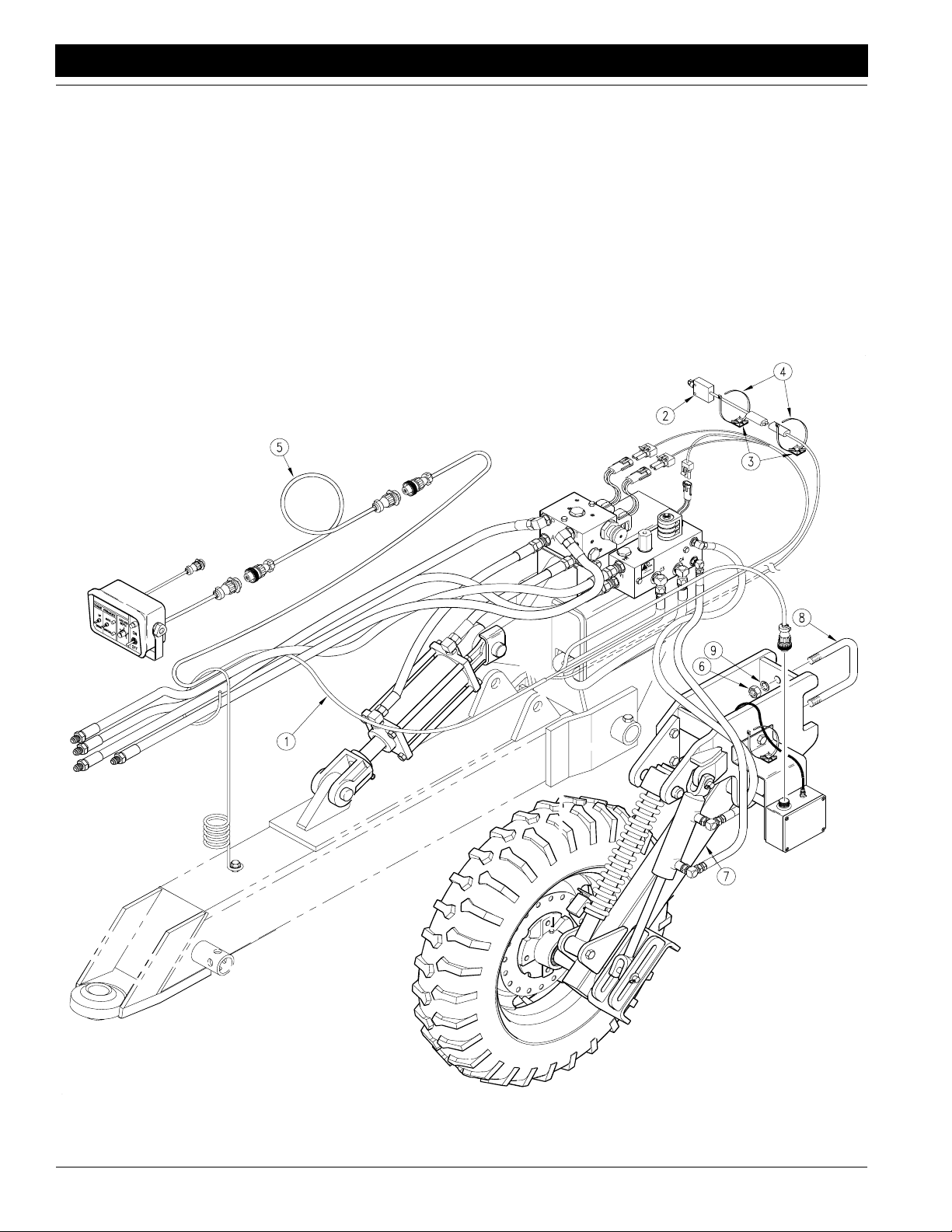

Refer to Figure3

1. Route the 156" long two wire lead of the wiring harness(#1) through the 8" x 8" hitch tube andtothelift

switch(#2) at the rear of the machine. Plug in the lift

switch and support the cable with the cable tie

mounts (#3) and releasable cable ties (#4) or strap

the cable to the hydraulic hoses.

2. Plugthe 4-Pin connector ofthewiringharnesstothe

sensor boxon the depth sensing wheel and support

the cable with the cable tie mounts (#3) and releasable cable ties (#4).

3. Route the 9-Pin connector through the spring hose

loop and to the tractor hitch. This will plug into the 9Pin Female lead from the control box extension cable (#5).

4. The other three short leads on the wiring harness

will plug into the leads from the solenoids on the hydraulic control valves after they are installed.

12617

Figure 3

Wiring Harness Assembly

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

6

Page 9

Great Plains Mfg., Inc.

Section 1 Assembly Instructions & Set-Up

Tongue Cylinder

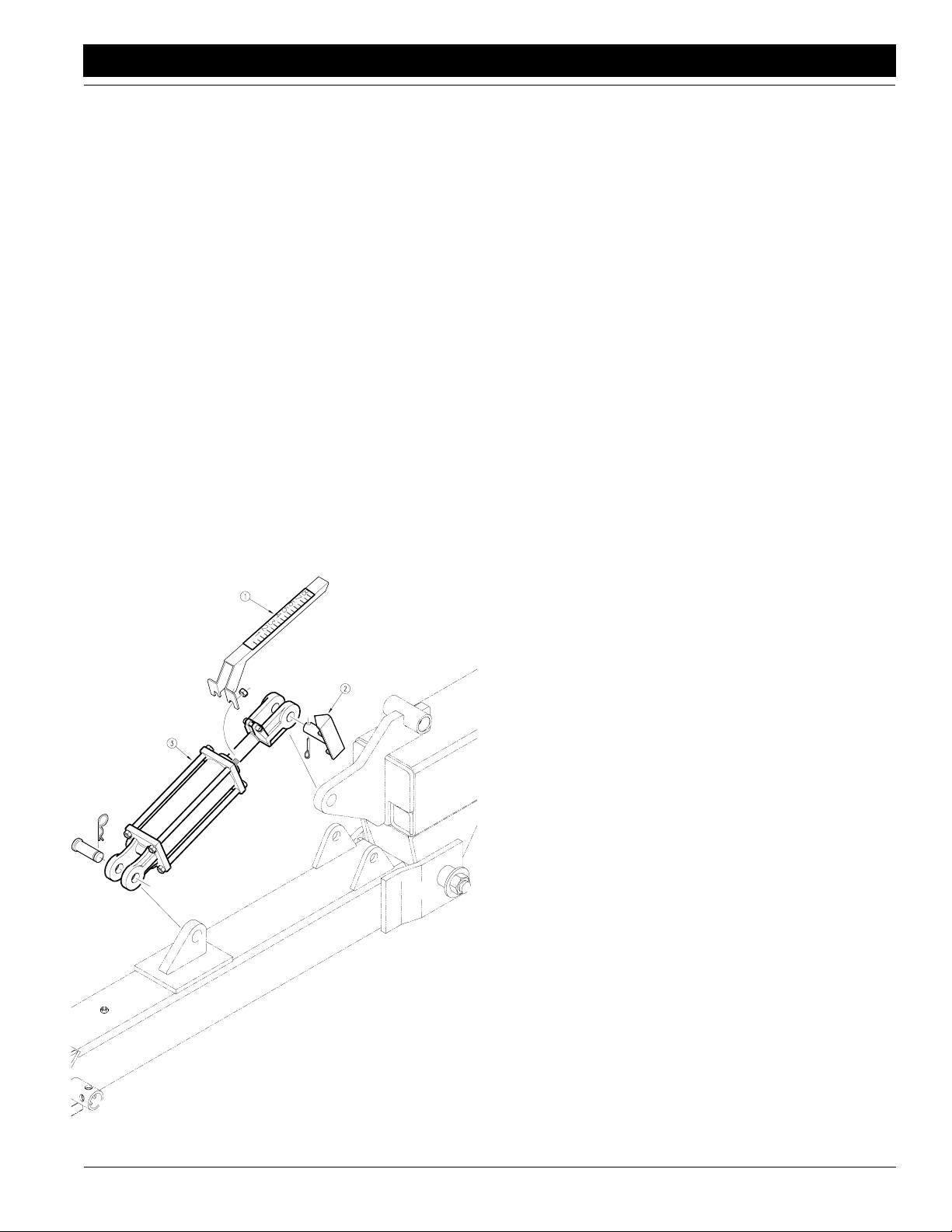

Refer to Figure4

1. Remove the stroke pointer gauge (#1) which was

bolted to the rod end of the tongue cylinder and retorque the cylinder tie rod bolts to 95 FT-LBS. Remove the stroke pointer (#2) at the cylinder rod

clevis and discard it.

Refer to Figure5

2. Turn the tongue cylinder with the rod end pointing

forwardand down,andwith the portsturned up. Use

the clevis pin (#17), flat washer (#18), and 1/4" cotterpin(#13) to replace the stroke pointer pin at what

is now the base end of the cylinder. Use the existing

clevis pin (#15) and hair pin cotter (#16) to connect

the rod end to the tongue.

3. Removethe elbow fitting (#3) at the base end of the

tongue cylinder and screw the 1/16" orifice plate

(#9)intothebaseendport. Screw the orifice plate in

far enough so it doesn't interfere with the elbow fitting and replace the fitting.

IMPORTANT: Failureto install the orifice platewill not allow coulter command to operate correctly.

12672

Figure 4

Tongue Cylinder Disassembly

Hydraulic Control Valve

Refer to Figure5

1. Boltthe 3 1/2" x 3 1/2" x 5" hydraulicvalveblock(#2)

to the top of the valve mount bracket (#13) with the

5/16" x 4" long bolts (#1), lock washers (#11), and

hex nuts (#10). Position the valve block so the solenoids set above the middle of the top surface of the

valve mount.

2. Boltthe 3" x 3 1/4" x 8" hydraulic valveblock (#25) to

the side of the valve mount bracket (#13) with the

5/16" x 3 1/2" long bolts (#24), lock washers (#11),

and hex nuts (#10). Positionthe valveblock so the

four ports point awayfrom the valvemount and the

solenoid points up.

3. Bolt the valve mount assembly to the hitch with the

1/2" x 5 1/2" long bolt (#12), lock washer (#6), and

hex nut (#5). Assemble the bolt through the pivot

tube for the levellink located just behind the tongue

cylinder. Position the valve mount so the dual solenoids face toward the rear of the machine.

4. Assemblethe 3/4" JIC elbows (#3) to the valveports

marked"P"and "T" of the top valve block.Assemble

the straight 3/4" adaptors (#7) to the valve ports

marked"A"and"B"of the top valveblock. Assemble

the straight 3/4" adaptors (#7) to the valve ports

marked "V1" and V2" of the lower valve block. Assemble the 1/2" female pipe swivel elbows (#20) to

the valveports marked "C3" and "C4" of the lower

valveblock. Assemble the 9/16" elbows (#21) to the

valveports marked "C1" and "C2" of the lowerblock.

Assemble the remaining two 9/16" elbows (#21) to

the ports on the side of the 1 1/2" x 4" gauge wheel

lift cylinder (#23).

5. Remove the 122" hoses (#4) from the tongue cylinder and assemble them to the elbows (#3) at ports

"P" and "T" on the top hydraulic valve. Connect the

20" long hose (#8) between the port "B" of the top

valveand the tongue cylinder base end fitting. Connect the 30" long hose (#14)betweenport "A"of the

top valve and the tongue cylinder rod end fitting. Assemble the other two 122" hoses (#4), from the

Coulter Command kit, to the adaptors (#7) at ports

"V1" and "V2" on the lower hydraulic valve.Remove

the quick couplers from the ends of the long transport lift hoses (#26) and assemble them to the ends

of the 122" hoses (#4) from ports "V1" and "V2". Assemble the long transport lift hoses (#26) to the elbows (#20) at ports"C3" and "C4" on the lower

hydraulicvalve.The hose coming from the base end

of the transport lift cylinders connects to the port

marked "C3" and the hose coming form the rod end

of the transport lift cylinders connects to the port

marked "C4". Slide the excess hose from the long

transport lift hoses into the 8" x 8" hitch main tube.

Connect one of the 36" long 1/4" hoses (#22) between the port "C1" of the lower valveblock and the

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

7

Page 10

Section 1 Assembly Instructions & Set-Up

1 1/2" x 4" gauge wheel lift cylinder base and elbow

fitting (#21). Connect the other 36" long 1/4" hose

(#22) between the port"C2" of the lower valve block

and the 1 1/2" x 4" gauge wheel lift cylinder rod end

elbow fitting (#21).

6. Route the three 16" wiring harness leads with the

weather-proof connectors, under the valve mount

and connect each lead to its solenoid. The lead labeled "A" should be plugged into the solenoid

marked"A",Theleadlabeled"B"shouldbeplugged

into the solenoid marked "B," and the lead labeled

"S1" should be plugged into the solenoid marked

"S1."

Great Plains Mfg., Inc.

13482

Figure 5

Hydraulic Control Valve Assembly

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

8

Page 11

Great Plains Mfg., Inc.

Section 1 Assembly Instructions & Set-Up

Control Box

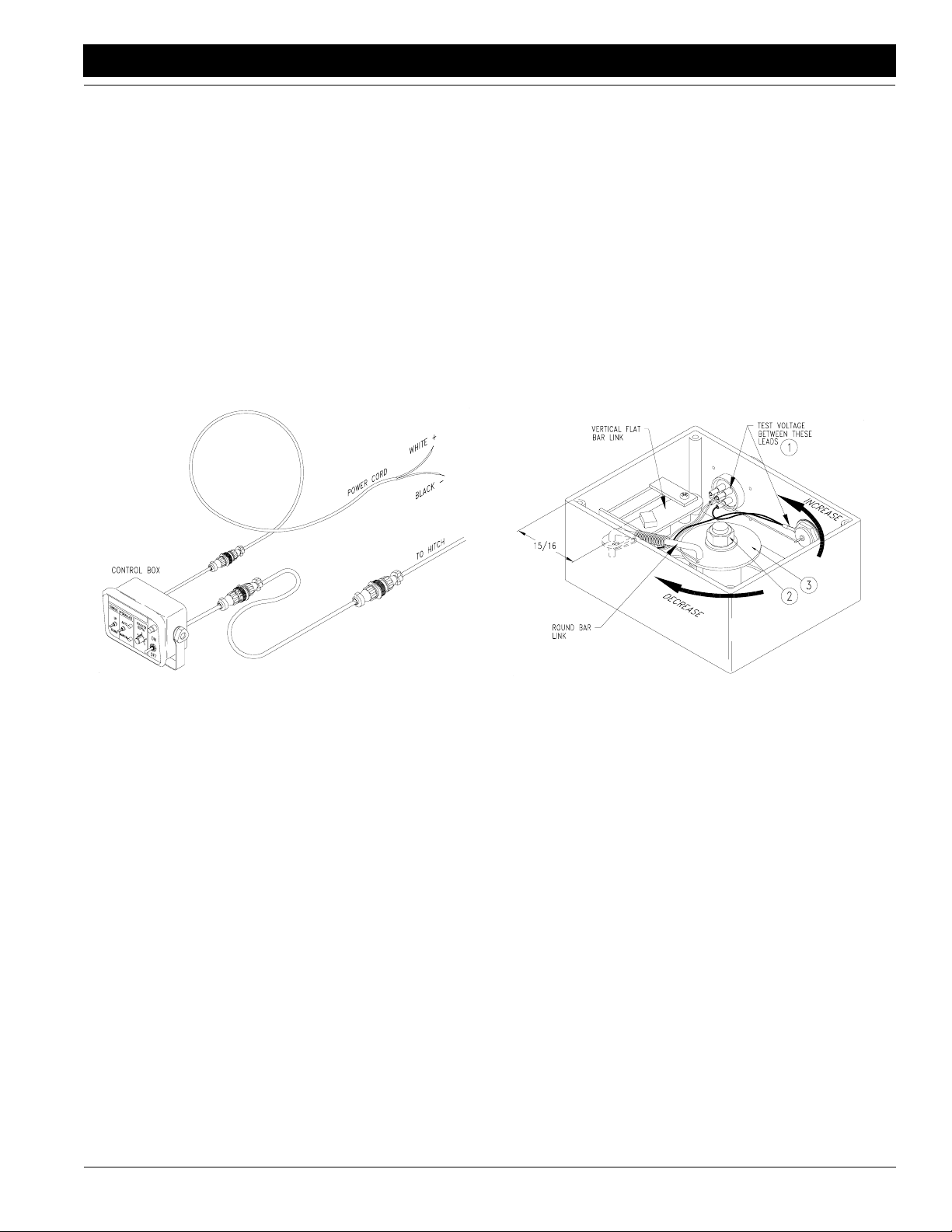

Refer to Figure6

1. Mountthe control boxata convenientlocation inthe

tractor cab. Connect the 12’ extension cable to the

9-pin connector on the back of the control box and

routethecable backtowardthe tractor drawbararea

making sure it will not get kinked or pinched.

2. Connect the power cord to a good uninterrupted 12

voltpower source on the tractor.Connecting directly

to the battery is recommended. Plug the cord into

the lead with the 2-Pin connector on the back of the

control box. The polarity of the power supply is very

important to prevent circuit damage. The white wire

of the power cord must be connected to the "+" positive battery terminal and the black wire to the "-"

negative battery terminal.

With the depth sensing wheel in the max down position, the voltage potential between the lead containing the WHITE WIRE and the ground lead (BLACK

WIRE) in the gauge wheel sensor box (#1) should

be 5 volts DC plus or minus 1/4 volt. To adjust the

gauge wheel sensor box linkage, loosen the 3/8"

hexflange nut (#2) on the sensor spindle and rotate

the circular disk (#3) until the voltage potential betweentheleadcontainingthe WHITE WIRE and the

ground lead (BLACK WIRE) (#1) is 5 volts DC plus

or minus 1/4 volt. Rotating the circular disk counterclockwise increases voltage potential, and rotating

the circular disk clockwise decreases the voltage

potential. Once the correct voltage potential is

achieved,tighten the 3/8" nut. Be careful not to rotate the circular disk as you tighten the nut. Replace

the sensor box cover.

12575

Figure 6

Coulter Command Control Box

Coulter Command

Assembly Adjustments

Refer to Figure7

Coulter command depth sensing wheel assemblies

whicharepre-assembledat the factory are pre-adjusted

and should not require further adjustment. If the sensor

boxat the depth sensing wheel has been field installed,

or if its linkage gets out of adjustment, it must be adjusted using one of the following two procedures:

1. The best and most accurate means of adjusting the

linkage inside the sensor box makes use of a voltmeterwhich reads 0-12 voltsDC.TheControlBoxin

the tractor must be properly connected to a power

source and the POWER switch must be ON. The

TONGUE HYDRAULICS switch should be in the

MANUAL mode. The wiring harness must be connected to the control box and the sensor box. The

depth sensing wheel should be off the ground with

the arm rotated down as far as its spring-loaded

down-pressure link will allow. Remove the cover

from the sensor box and inspect theinternal linkage

for proper assembly.

12619

Figure 7

Sensor Box Adjustments

2. The second means of adjusting the linkage inside

the sensor box involvesmeasuring from the inside

edge of the boxto the left pivot of the formed roundbar link. The depth sensing wheel should be off the

ground and rotated downas far as its spring-loaded

down-pressure link will allow. Remove the cover

from the sensor box and inspect theinternal linkage

for proper assembly.

With the depth sensing wheel in the max down position, the pivot between the vertical flat-bar link and

the formed round-bar link should be 15/16" from the

front inside edge of the sensor box.

With the sensor box linkage properly assembled,

loosen the 3/8" hex flange nut on the sensor spindle

androtatethecirculardiskuntilthepivotbetween the

vertical flat-bar link and the formed round-bar link is

15/16" + or - 1/16" from the front inside edge of the

box. Be careful not to rotate the circular disk as you

retighten the nut. Replace the sensor box cover.

3. Some models of the sensor box have a mark on the

vertical flat-bar link which should line up with a mark

on the link’sslotted mount plate at the correct preset

voltage. With the depth sensing wheel in the max

down position, the marks should line up at a voltage

of5 voltsDC+ or-1/4volt.Aligningthe marks is more

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

9

Page 12

Section 2 Operating Instructions

Section 2 Operating Instructions

Great Plains Mfg., Inc.

The Coulter Command couples a microprocessor with

electro-hydraulics to provide a state-of-the-art system

formaintaining coulter depth regardless of the terrain or

soil type. It also provides coulter depth adjustment

"FromThe Tractor Cab". A manual feature allows manual control of the front hydraulic tongue cylinder for

hitching, unhitching, or making adjustments. To understand the Coulter Command system, one must be

familiarwith the functions of the hydraulics and the electronic controls.

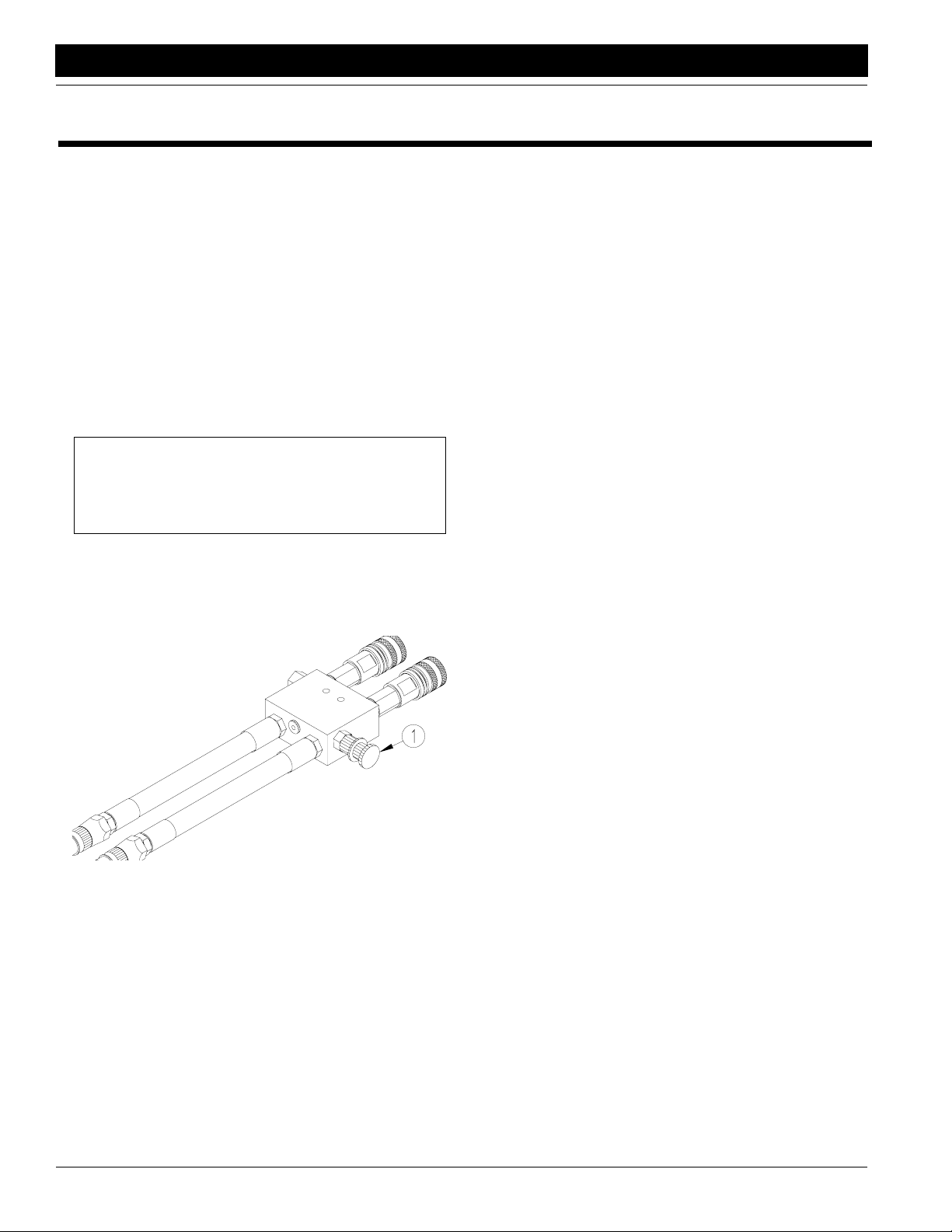

Load Sensing Hydraulics

To operate Coulter Command, some tractors with loadsensing or constant-flow hydraulics require a bypass

valve,GreatPlains partnumber810-400C.Contact your

Great Plains dealer to order the bypass valve.

NOTE: Failure to install a bypass valve on load-sensingtractorsmaycause major tractor damage. Consult

yourtractor dealertoverifyif the bypass valveis needed.

After installing the bypass valve,set valve as follows:

Refer to Figure8

1. Closebypassvalvefor no oilflowbyturning knob (1)

on valveclockwise.

17987

Figure 8

Bypass Valve

2. Adjust flow-control valvefor tractor to a maximum of

10 gpm. If youdo not have a flowmeter, hook a standard8-inch stroke,4-inchbore cylinder tothecircuit.

At 10 gpm, the cylinder will take about 2.6 seconds

to extend.

3. Engage tractor hydraulics for Coulter Command.

4. Using a pressure gauge, turnknob on bypass valve

counterclockwiseuntilpressure gauges reads 1800

psi. Lock bypass valve at this setting.

Hydraulic Hook-Up & Function

Tractors with closed-center hydraulic systems and

variable displacement hydraulic pumps.

(If you are not familiarwith your tractor's hydraulics, consult your tractor dealer.)

For tractors with closed-center hydraulics or pressure/

flow compensated hydraulics which are powered by a

variable displacement hydraulic pump, turn the knurled

control knob on the left side of the hydraulic valve completelyclockwise and lockit in placewiththecircular lock

disk. Do not apply any torque to the control knob after it

bottoms out or valve damage may occur. Be sure the

lock disk is snugged to prevent the control knob from vibrating loose in field operation.

The tongue cylinder hydrauliccircuit consists of the hosesfromports "P" and "T". Once the hydraulicvalveis set

forCLOSED CENTER operation, the Coulter Command

tongue cylinder circuit requires live hydraulic power supplied to the port labeled "P". This is accomplished by

pushing FORWARD on the tractor remote hydraulic lever and LOCKING IT OPEN in this position.

• On John Deere tractors equipped with SOUND-

GUARDRBody you must use the LEVERLOCKCLIP

John Deere Part No. R52667 to lock the lever in the

forward position. See your tractor dealer for purchase

and installation of this clip.

• On John Deere 7000 Series tractors, rotate valve de-

tentselector to MOTOR POSITION to lock the lever in

the forward position.

• On Case-IHMagnumtractorsusethecircuitdesigned

for HYDRAULIC MOTOR CONTROL and lock the leverforwardin the detent position. The detent pressure

will probably have to be turned up to its maximum setting.DONOTtie the hydraulic lever on past the detent

positionwith a strap. This could shift the spool beyond

its designed operating position and cause system

damage. See your tractor dealer for hydraulic system

details.

• On other model tractors use the circuit designed for

HYDRAULIC MOTOR CONTROL and lock the lever

forwardinthe detent position. The detent pressure will

probably have to be turned up to its maximum setting

orsome other mechanicaldetentholder willhavetobe

usedto hold the lever forward.See your tractor dealer

for the proper means of providing constant pressure/

flow to the tongue cylinder circuit.

The Coulter Command hydraulic circuit requires a flow

rate of 8 to 12 gallons per minute forefficient operation.

On high flow rate tractors, the flow control on the tractor

remote mayhaveto be turned down soas not to exceed

12gallons per minute. Flow rates higher than 12 gallons

per minute will not damage the valve, but may cause

poor Coulter Command performance.

The remote tractor hydraulic leverwill have to be locked

in position to supply oil to the "P" port of the hydraulic

control valve, regardless of whether you want to control

the tongue hydraulic cylinder manually or automatically.

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

10

Page 13

Great Plains Mfg., Inc.

Section 2 Operating Instructions

The CPH transport hydraulic circuit contains the hoses

from the ports marked "V1" and "V2". This circuit must

be connected to one of the remaining circuits for raising

and lowering the transport system. This circuit must receive hydraulic pressure for raising the machine even

while the hydraulictongue circuit is "locked in" for continuoususe. Ifthemachine will notraisewhen the hydraulic

tongue circuit is "locked in," consult your tractor dealer.

You may need to run the transport hydraulic circuit on a

"priority circuit" and the hydraulic tongue circuit on an alternate remote if the tractor hydraulics allows live

hydraulic power to other remotes. If the "priority circuit"

is the only circuit suitable for HYDRAULIC MOTOR

CONTROL, then run the transport hydraulic circuit on

the "priority circuit" and run the hydraulic tongue circuit

onan alternate remote with theCoulter Command valve

inthe OPENCENTERMODE.See "Tractors with open

center hydraulic systems or fixed displacement hydraulic pumps" below.

Tractors with open center hydraulic systems or

fixed displacement hydraulic pumps.

(If you are not familiarwith your tractor's hydraulics, consult your tractor dealer.)

For tractors with open-center hydraulics or on tractors

with fixed displacement hydraulic pumps turn the

knurled control knob on the left side of the hydraulic

valve completely counterclockwise and lock it in place

with the circular lock disk. Be sure the lock disk is

snuggedto preventthecontrolknobfromvibrating loose

in field operation.

The CPH transport hydraulic circuit contains the hoses

from the ports marked "V1" and "V2". This circuit must

be connected to tractor's "priority circuit" to supply hydraulic pressure for raising the machine even while the

hydraulictongue circuit is"lockedin" for continuous use.

The"No.1"hydrauliccircuiton mostopen-centertractors

is the priority circuit.

The tongue cylinder hydrauliccircuit consists of the hosesfrom ports"P"and"T".Connect "P" and"T"to a circuit

other than the "prioritycircuit". Once the hydraulic valve

is set for OPEN CENTER operation, the Coulter Command tongue cylinder circuit requires live hydraulic

power supplied to the port labeled "P". This is accomplished by pushing FORWARDon the tractor remote

hydraulic lever and LOCKING IT OPEN in this position.

The remote tractor hydraulic leverwill have to be locked

in position to supply oil to the "P" port of the hydraulic

control valve, regardless of whether you want to control

the tongue hydraulic cylinder manually or automatically.

The Coulter Command tongue hydraulic circuit requires

a flow rate of 8 to 12 gallons per minute for efficient operation. On high flow rate tractors, turn down the flow

rate on the tractor remote, if possible, so as not to exceed 12 gallons per minute. Flow rates higher than 12

gallons per minute will increase the heat generated by

the Coulter Command circuit when it circulates this high

flow of oil.

Refer to Figure9

WhenoperatingtheCoulterCommandtonguehydraulic

circuit in the OPEN CENTER mode, use poppet style

quick couplers on the hoses connecting to the tractor.

These quick couplers allow better flow through some

tractor remotes and may produce less heat when circulating continuous hydraulic flow through them. Parker

Hannifin offersthe poppet style Pioneer quickcoupler in

their 8010 Series couplers. For tractors with Pioneer

quick couplers use Pioneer 8010-4P poppet style male

couplers when operating in the OPEN CENTER mode.

Poppet Style Ball Style

Figure 9

Quick Couplers

16316

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

11

Page 14

Section 2 Operating Instructions

Great Plains Mfg., Inc.

Operation of Electronic Controls

1. Connect the power cord to a good uninterrupted 12

voltpower source on the tractor.Connecting directly

to the battery is recommended. Plug the cord into

the lead with the 2-Pin connector on the back of the

control box. The polarity of the power supply is very

important to prevent circuit damage. The white wire

of the power cord must be connected to the "+" positive battery terminal and the black wire to the "-"

negative battery terminal.

2. With the remote tractor hydraulic lever locked in position to supply oil to the "P" port of the hydraulic

control valve, turn the power switch on.

a. Formanual tongue hydrauliccylinder operation,

simply moveUP-DOWN switch. Moving the

switch to the UP position extends the tongue

cylinder, and moving the switch to the DOWN

position retracts the tongue cylinder. If UP retracts the cylinder, then your remote hydraulic

leveris not supplying oil to the "P" portof the hydraulic control valve, or the wires going to the

solenoids A and B are reversed. By moving the

UP-DOWN switch, the AUTO-MANUAL switch

automatically switchesto the MANUALmode.If

you are in the AUTO mode and you want to

manually hold the tongue hydraulic cylinder in

the position set by the automatic controls, just

switch the AUTO-MANUAL switch to MANUAL.

b. For automatic coulter depth control, simply

switchthe AUTO-MANUAL switch to AUTO and

dial in the desired coulter depth you wish to

maintainwith the coulter depth controlknob.

!

Make sure all people, animals, and objects are clear of the

coulter tool bar before switching the tongue hydraulics

switch to the "auto" mode. Sudden automatic lowering of the

coulter tool bar could cause serious personal injury or death.

WARNING!

Turning the coulter depth switch clockwise makes

thecoulters run shallower.Turningthe coulter depth

switch counterclockwise makes the coulters run

deeper.If the hitch is not moving or is on a hard surface,turning thecoulterdepthswitchmaynot cause

thetonguecylinder to retract to the desired position.

The coulters may not penetrate to the desireddepth

until the hitch is moving. The coulter depth setting

can alwaysbe changed "on-the-go" if you desire.

With the AUTO-MANUAL switch in the AUTOmode,

the coulters should maintain a constant depth regardless of terrain, soil type or speed. When lifting

and turning in the field, the tongue cylinder will remainin its last automatically setmid strokeposition.

When the machine is lowered, the coulters will automatically return to their preset depth.

Field Adjustments

Lift Switch

The switch at the transportlift cylinder of the Center PivotHitch determines thepoint in the lift cycle atwhich the

automatic feature of the Coulter Command will be interrupted and the depth sensing gauge wheel will be lifted

offthe ground forturning around. Since theCenter Pivot

Hitch transport tires can be lowered duringoperation to

provideflotation forthedrillinsoftsoil conditions, coulter

command should not beinterrupted and the depth sensing gauge wheel should not be lifted until after the

transport tiresareloweredto the point wheretheyare no

longerused forsystem flotation. This is usually thepoint

inthelift cycle when the drill openers are justbeinglifted

out of the ground.

A 3/8" x 3/8" square ramp attached to a sliding push rod

on the right transport lift cylinder activates a plunger

switchwhich causestheautomaticfeatureof theCoulter

Command to be interrupted and the depth sensing

gauge wheel to be lifted off the ground for turning the

Center Pivot Hitch around in the field.

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

12

Page 15

Great Plains Mfg., Inc.

Section 2 Operating Instructions

1. To adjust the lift switchtiming, assemble the push rod

tothe cylinder rod clamp using one of thethreeadjustment holes at the bottom of the push rod. When tightening up the 5/16" nylock nut on the pivot bolt, DO

NOT TIGHTEN IT DOWN TIGHT. The bolt and push

rod must be free to move in the slot of the clamp. It is

recommended to assemble the push rod through its

lower-most hole. BE CAREFUL NOT TO "BOTTOM

OUT" THE LIFT SWITCHPLUNGER when the plunger roller climbs the surface of the 3/8" square ramp.

2. To adjust the lift switch position, loosen the two #10

screws and slide it forward or backward in the slotted

switch mount holes so the plunger moves "in" only

about 1/8" when the cam activates it. DO NOT "BOTTOM OUT" THE LIFT SWITCH PLUNGER.

!

Shut the tractor off and put all hydraulic valve levers in neutral

position before attempting to work on or crawl under the machine. Do not crawl under a raised machine without the transport lock pins securely in place. Sudden hydraulic activation or

failure could cause serious injury or death.

Aproperly adjusted lift switchallows the automatic coulter

depth feature to be interrupted early in the lift cycle. This

providedthefastestlift cycle timeswhenturning around in

thefield. Operatingthe lift switchearly in the lift cycle, also

provides the maximum amount of time for the depth sensing gauge wheel cylinder to completely extend as the

machine is lowered back to field position. It is important

thatthe depth sensing gauge wheel cylinder always be fully extendedwhen the Center Pivot Hitch isin field position

toallowthedepth sensing gauge wheel to float through its

full range of motion.

Speed Sensor

The Coulter Command depth control system automatically compensates for changes in ground speed. A speed

sensor and speed sensor plate mounted behind the

coulter depth sensing wheel monitors the ground speed

so the Coulter Command can adjust for it. This sensor

should be in close proximity to the speed sensor plate. In

general, it should never need adjustment. If the sensor

WARNING!

does get moved, it should be adjusted against the speed

sensor plate until is just touches the plate in the closest

part of the rotation. A bent speed sensor plate should be

straightenedorreplaced immediately. Toadjust the speed

sensor,loosen the two #6 screws on the sensor and slide

ittowardthe speed sensorplate.Rotate the depth sensing

wheelto the position where the speedsensorplate is closest to the sensor mount, and retighten the sensor mount

screws where the sensor just touches the speed sensor

plate.

Hydraulic Valve

All adjustable valve cartridges on the hydraulic valve

blocks are preset at the manufacturer and should not be

tampered with. Tamperingwith a cartridge valve could result in decreased lift cycle times forthe Center Pivot Hitch.

The only required adjustment is on the upper hydraulic

control valve.This valve contains a rotaryknob for setting

the Coulter Command to be used with either OPEN CENTERED or CLOSED CENTERED tractor hydraulics.

Check the owners manual of your tractor to determine

what type of hydraulic system you have.

Referto “Hydraulic Hook-Up & Function” on page 10 of

this manual for setting the hydraulic control valve for your

style of tractor.

Transport Cylinder Depth Channels

Whenplanting in soft soil conditions wheresinking of your

drillgaugewheelsmaybe a problem, a cylinder stop channel package (GP# 148-181A) is available to allow your

transport tires to run on the ground and assist in the supporting the drill and hitch weight. The 148-181A cylinder

stopchannel packagecontainstwo cylinder stopchannels

(one for each transport cylinder). Since the transport hydraulics is a master-slave system, it is only necessary to

useone cylinder stopchannelon the masterliftcylinderon

the left side of the Center Pivot Hitch. The other cylinder

stop channel will not workon the slavecylinder located on

theright side of the Center PivotHitch because the lift control switch for the Coulter Command mounts to that

cylinder.Useonlyonecylinder stop channel onthemaster

lift cylinder (left side) on Center Pivot Hitches equipped

with Coulter Command.

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

13

Page 16

Section 3 Troubleshooting

Section 3 Troubleshooting

Problem Possible Cause Solution

Great Plains Mfg., Inc.

Coulters move up when the

down switch is operated and

down when the up switch is

operated.

Automatic coulter depth control stops adjusting coulter

depth.

T urningthe coulter depth knob

does not set coulters deep

enough.

Not supplying oil to the "P" port of the

hydraulic valve.

Solenoids wired backward or hoses from

port "A" and port "B" reversed at the

hydraulic valve.

tongue hydraulics switch bumped to

"manual" mode.

Tractor remote hydraulic lever not locked

for constant oil supply to valve.

System variables out of adjustment Turn power switch OFF and back on again

If the tongue cylinder runs completely

retracted, the tractor drawbar is to high.

In extremely hard conditions with the

machine standing the tongue cylinder

pulses but does not retract.

If the coulter depth knob is turned to "A"

and the tongue cylinder will not completely retract when moving through the

field then the internal sensor box linkage is

not set correctly.

Reverse the remote hydraulic lever in the

tractor.

Reverse the hoses at the quick couplers.

Unplug solenoids and swap wire leads to

them.

Flip tongue hydraulics switch back to

"auto" mode.

Lock Tractor remote hydraulic lever with

rubber tarp strap or other means.

so the system variables can reset. Then

flip AUTO-MANUAL switch to AUTO.

Use a straight drawbar or one which

sweeps down.

This is perfectly normal.The cylinder will

not penetrate the coulters on a stationary

machine in hard conditions.Pull forward

and check coulter depth on a moving

machine.

Adjust the sensor box internal linkage. See

"Coulter Command Assembly Adjust-

ments" on page 9.

The hydraulic valve constantly

pulses when you are stopped

to refill or adjust something.

T urningthe coulter depth knob

to "E" does not allow the

coulters to run shallow

enough.

Depth sensing gauge wheel

not lifting off the ground when

Center Pivot Hitch is raised.

If the sensor box linkage is properly

adjusted and tongue cylinder constantly

pulses while moving through the field but

the front tongue cylinder will not retract,

you do not have enough system weight.

Hard soil conditions are hindering coulter

penetration while stopped.

The internal sensor box linkage is not set

correctly.

Coulter Command power is OFF or 12 volt

power has been interrupted.

The lift switchhas become disconnected or

the lift switch cam on the right transport lift

cylinder has been damaged.

Add weights to the pull hitch frame weight

brackets. Add tool bar weight brackets to

coulter tool bars.

Flip tongue hydraulicsswitch to "manual"

mode while you are stopped or turncoulter

command power "off". Pulsing does not

hurt the valve, but can be annoying.

Adjust the sensor box internal linkage. See

"Coulter Command Assembly Adjust-

ments" on page 9.

Coulter Command must be connected and

the power must be ON for the depth sensing gauge wheel to raise when the All

Seeds Hitch is raised. The depth sensing

gauge wheel should raise with the transport lift circuit with Coulter Command in

either the AUTO or MANUAL mode is long

as the power is ON.

Inspect and adjust the lift switch and push

rod cam. See "Lift Switch" under Section

2 "Operating Instructions" on page 12.

Check cable connections on lift switch

lead.

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

14

Page 17

Great Plains Mfg., Inc.

Section 3 Troubleshooting

Problem Possible Cause Solution

Depth sensing gauge wheel

not lowering to the ground

when Center Pivot Hitch is lowered, or depth sensing gauge

wheel cylinder not fully extending when the machine is lowered.

Coulterdeptherraticorwillnot

adjust when you turn the

"DEPTH CONTROL" dial.

The lift switchhas become disconnected or

the lift switch cam on the right transport lift

cylinder has been damaged.

Relief valve "M3" is set too low. Turn valve adjustment screw on top of

Moisture present in the master control

box.

Hydraulic flow rates of more than 12

gallons per minute to the hydraulic control valvewhen operating in the

CLOSED-CENTER mode.

Inspect and adjust the lift switch and push

rod cam. See "Lift Switch" under Section

2 "Operating Instructions" on page 12.

Check cable connection on lift switch lead.

valve"M3" one eighth turn clockwise.Valve

"M3" is preset to relieve at 600 psi. Turning

the adjustment screw one eighth turn

clockwise increases the relief setting by

approximately 75 psi.

!

Any attempt to set valve "M3" above 1200

psi could result in system malfunction. Setting the valve "M3" above 750 psiwill slow

down the lift cycle time.

The master control box in the tractor

mustbe keptdry.Moisture on thecircuit

board or in the control terminals will

cause false readings.

Turn down the flow rate on the tractor

remote which is providing oil to the

tongue hydrauliccircuit.

CAUTION!

System generating excess

heat when operating in the

OPEN CENTER MODE.

Inconsistent 12-volt power supply.

The OPEN CENTER - CLOSED CENTER control knob is not turned

completely counterclockwise.

Ball style quick couplers may produce

more heat when circulating continuous

hydraulic flow through them.

Connect the power cord directly to the

battery. The Coulter Command electrical circuit must have a good uninterrupted power supply. Fluctuations in

the power supply will cause inconsistent electrical readings.

Turn theknurledcontrolknob on the left

side of the hydraulic valvecompletely

counterclockwise and lock it in place

with the circular lock disk.

Use poppet style male quick couplers.

Fortractorswith Pioneerquickcouplers

usePioneer8010-4Ppoppet stylemale

couplers when operating in the OPEN

CENTER mode. See Figure 8, page

10.

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

15

Page 18

Section 3 Troubleshooting

Problem Possible Cause Solution

Great Plains Mfg., Inc.

T ransport lift cylinders will not

lift the Center Pivot Hitch for

transport.

OPEN-CENTER tractors with multiple

sets of hydraulic outlets use the #1 circuit for priority flow which slows down

orcutsoffflow to the other circuits. This

problemwill occur if Coulter Command

ports "P" and "T" are plugged into the

#1 circuit.

On CLOSED-CENTER tractors the

Coulter Command should be connected to a circuit capable of HYDRAULIC

MOTOR CONTROL for supplying constantpressure/flowtoremote locations.

If the machine will not raise when the

hydraulic tongue circuit is "locked in,"

consult your tractor dealer. You may

need to run the transport hydraulic circuit on a "priority circuit" and the

hydraulictongue circuit on an alternate

remote if the tractor hydraulics allows

live hydraulic power to other remotes.

Connect transport lift circuit ports "V1" and

"V2" to the #1 hydraulic circuit on OPENCENTER tractors. Ports "P" and "T" of the

Coulter Command hydraulics should connect to another circuit other than the #1 circuit on OPEN-CENTER tractors.

On CLOSED-CENTER tractors, if the

"priority circuit" is the only circuit suitable for HYDRAULIC MOTOR

CONTROL or supplying constant pressure/flow to remote locations, then run

the transport hydraulic circuit on the

"priority circuit" and run the hydraulic

tongue circuit on an alternate remote

with the Coulter Command valvein the

OPENCENTER MODE.See "Tractors

with open center hydraulic systems

or fixed displacement hydraulic

pumps," page 11.

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

16

Page 19

Great Plains Mfg., Inc.

Section 3 Troubleshooting

System Schematics

If problems occur in the hydraulic or electric systems,

refer to the schematics below and on page 18 to help

locate the problem.

Hydraulic Schematic

16313

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

17

Page 20

Section 3 Troubleshooting

Electrical Schematic

Great Plains Mfg., Inc.

16314

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

18

Page 21

Great Plains Mfg., Inc.

Section 4 Maintenance and Lubrication

Section 4 Maintenance and Lubrication

Maintenance

The Coulter Command is relatively maintenance free.

The switches,sensors, and linkages should not need

any routine adjustment unless they are moved or

damaged.

Lubrication

Lubrication Symbols

50

As

Required

Lubrication is required every 50 hours of operation.

10

12620

Use a multipurpose spray lube. Use as required.

Do not over lubricate.

Seasonally

Lubrication is requiredLubrication is required every 10 hours of operation.

2 - 3 Years

Axle Bearings

Repack

Type of Lubrication: Wheel Bearing Grease

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

19

Page 22

Section 5 Parts

Section 5 Parts

Coulter Depth Control Hydraulics

Great Plains Mfg., Inc.

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

20

16317

Page 23

Section 5 Parts

Ref. Part No. Part Description

1. 802-279C Bolt, Hex Head 5/16"-18 x 4"

2. 810-214C Valve, Electronic Depth Control

3. 811-063C Fitting, Hydraulic Elbow 3/4" JIC Male x 3/4" O-Ring Male

4. 811-383C Hose, Hydraulic 1/2" R1 x 122" Long x 1/2" NPT Male x 3/4" JIC Female

5. 803-020C Nut, Hex 1/2"-13

6. 804-015C Washer, Lock Spring 1/2"

7. 811-088C Fitting, Hydraulic Adaptor 3/4" O-Ring Male x 3/4" JIC Male

8. 811-331C Hose, Hydraulic 1/2" R2 x 020 3/4" JIC Female

9. 811-172C Orifice Plate /16" x 3/4"

10. 803-008C Nut, Hex 5/16"-18

11. 804-009C Washer, Lock Spring 5/16"

12. 802-046C Bolt, Hex Head 1/2"-13 x 5 1/2" Long

13. 148-415D Hydraulic Valve Mount

14. 811-340C Hose, Hydraulic 1/2" R2 x 030 3/4" JIC Female

15. 805-004C Pin Clevis 1" x 2 3/4" Usable Long

16. 805-010C Pin Hair Cotter.094

17. 148-283H Cylinder Pin

18. 804-029C Washer, Flat 1" SAE

19. 805-021C Pin, Cotter 1/4" x 2" Long

20. 811-280C Hydraulic Fitting, Elbow 1/2" NPT Female x 3/4" O-Ring Male

21. 811-065C Hydraulic Fitting, Elbow 9/16" JIC Male x 9/16" O-Ring Male

22. 811-443C Hydraulic Hose 1/4" R2 x 036 9/16" JIC Female

23. 810-259C Cylinder 1.50" x 4.0" x 0.75" Weld 1" Pin

24. 802-333C Bolt, Hex Head 5/16"-18 x 3 1/2" Long

25. 810-262C Lift Circuit Manifold

9/21/05 Great Plains Mfg., Inc. CPH and CP1000 Coulter Command System 148-258M-B

-21

Page 24

Section 5 Parts

Coulter Command Electronics

12623

22

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

Great Plains Mfg., Inc.

Page 25

Section 5 Parts

Ref. Part No. Part Description

1. 823-103C Control Box

2. 823-110C Power Cord

3. 823-108C Control Box Cable

4. 823-104C Wire Harness

9/21/05 Great Plains Mfg., Inc. CPH and CP1000 Coulter Command System 148-258M-B

-23

Page 26

Section 5 Parts

Coulter Command Gauge Wheel Assembly

12594

24

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

Great Plains Mfg., Inc.

Page 27

Section 5 Parts

Ref. Part No. Part Description

1. 823-105C Gauge Wheel Sensor Box

2. 803-068C Nut, Hex Flange 3/8"-16

3. 804-012C Washer, Flat 3/8" SAE

4. 803-008C Nut, Hex 5/16"-18

5. 804-009C Washer, Lock Spring 5/16"

6. 148-507D Gauge Wheel Sensor Mount

7. 804-004C Washer Internal Star #10

8. 801-051C Screw, Cross Recess Pan Head Machine #10-24 x 7/16" Long

9. 802-091C Bolt, Hex Head 1/2"-13 x 1 1/2" Long

10. 800-148C Cable Tie Mount

11. 800-149C Cable Tie 6" Long Releasable

12. 822-041C Flangette 47 MST

13. 822-040C Bearing 3/4"bore 47mm Sphere OD

14. 802-092C Bolt, Round Head Square Neck 5/16"-18 x 3/4" Long

15. 148-382D Coulter Command Gauge Wheel Mount Pin

16. 806-105C U-Bolt 5/8"-11 x 4 1/32" x 6 Long

17. 804-022C Washer, Lock Spring 5/8"

18. 803-021C Nut, Hex 5/8"-11

19. 148-199H CPH Gauge Wheel Mount

20. 804-015C Washer, Lock Spring 1/2"

21. 803-020C Nut, Hex 1/2"-13

22. 802-128C Bolt, Hex Head 1/2"-13 x 2 Long

23. 148-381D CPH Gauge Wheel Mount Ear

24. 148-197H Gauge Wheel Spring

25. 817-129C Flng Bushing 1 1/8" x 1 3/4"

26. 805-146C Pin, Roll 1/4" x 2 Long

27. 817-084C Parallel Arm Pivot Bushing

28. 148-413D Gauge Wheel Spring Spacer Tube

29. 822-091C Bearing Cone 15123

30. 816-098C Seal, 1 3/8" ID x 2.441 OD X.313

31. 802-041C Bolt, Hex Head 1/2"-13 x 3 1/2" Long

32. 804-109C Washer, Flat #6

33. 804-050C Washer, Lock #6 SS

34. 801-017C Screw, Pan Head 6-32 x 1/2" SS

35. 823-106C Speed Sensor

36. 148-177H Gauge Wheel Arm

37. 802-104C Bolt, Lug 1/2"-20 x 1" Long

38. 816-035C Valve Stem

39. 814-115C Tire, 5.00-15SL 4-Ply

40. 814-116C Wheel, 15" Dia X 4 1/2" Wide x 4-Bolt

41. 148-246S 5.00-15 SL 4-Ply Wheel & Tire Assembly

42. 148-426D Speed Sensor Plate

43. 200-001D Hub Grease Cap

44. 805-016C Pin, Cotter 3/16" x 1 x 1/4"

45. 803-029C Nut, Hex Slotted 7/8"-14

46. 804-055C Washer, Spindle - 7/8"

47. 312-151S 120 Pull Hub & Cups Assembly

48. 822-092C Bearing Cup 15245

49. 312-106D 4-Bolt Hub

50. 800-001C Grease Zerk Straight 1/4"-28

51.

52. 04003013 Clevis Pin

53. 805-067C Pin, Cotter 1/8" x 3/4"

54. 810-259C Cylinder 1.50" x 4.0" x 0.75" Weld 1" Pin

55. 804-017C Washer, Flat 1/2" USS

56. 805-128C Pin Clevis 1/2" x 2 3/4"

816-193C Gauge Wheel Sensor Box Gasket

9/21/05 Great Plains Mfg., Inc. CPH and CP1000 Coulter Command System 148-258M-B

-25

Page 28

Section 5 Parts

Top Link Assembly (Jan. 1, 2001)

12601

26

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

Great Plains Mfg., Inc.

Page 29

Section 5 Parts

Ref. Part No. Part Description

1. 148-217V 94 All Seeds Top Link Tube Assembly (Includes 1 Each Of Items #2 Through 7)

2. 148-085H Level Link Adjuster

3. 803-034C Nut, Hex 1 1/4"-7

4. 148-198H Top Link

5. 802-059C Bolt, Hex Head 5/8"-11 x 3" Long

6. 803-024C Nut, Lock 5/8"-11

7. 148-084H Level Link Lock Plate

8. 807-063C Spring, Level Link Lock

9. 802-073C Bolt, Hex Head 1"-8 x 4" Long

10. 804-027C Washer, Lock Spring 1"

11. 803-031C Nut, Hex 1"-8

9/21/05 Great Plains Mfg., Inc. CPH and CP1000 Coulter Command System 148-258M-B

-27

Page 30

Section 5 Parts

Coulter Command Switch Mount

12603

28

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

Great Plains Mfg., Inc.

Page 31

Section 5 Parts

Ref. Part No. Part Description

1. 148-500D Switch Spacer

2. 817-170C Switch Guide Block

3. 148-510D Cylinder Rod Clamp

4. 148-502D Switch Mount

5. 148-247H Push Rod

6. 148-264H Cylinder Rod Clamp

7. 823-107C Lift Switch

8. 801-085C Screw, Round Head #10-24 x 1 1/2" Long

9. 804-046C Washer, Flat #10

10. 804-054C Washer, Lock #10

11. 803-001C Nut, Hex #10-24

12. 802-152C Bolt, Hex Head 1/4"-20 x 2" Long

13. 804-006C Washer, Lock Spring 1/4"

14. 803-006C Nut, Hex 1/4"-20

15. 804-015C Washer, Lock Spring 1/2"

16. 802-010C Bolt, Hex Head 5/16"-18 x 1 1/4" Long

17. 804-010C Washer, Flat 5/16" USS

18. 804-009C Washer, Lock Spring 5/16"

19. 803-008C Nut, Hex 5/16"-18

20. 803-084C Nut, Hex Nylock 5/16"-18

21. 804-007C Washer, Flat 1/4" SAE

9/21/05 Great Plains Mfg., Inc. CPH and CP1000 Coulter Command System 148-258M-B

-29

Page 32

Section 5 Parts

Lift Circuit Manifold (810-262C)

13479

30

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

Great Plains Mfg., Inc.

Page 33

Section 5 Parts

Ref. Part No. Part Description

1. 34702171 Orifice Disk.031

2. 39680008 Coil, 12VDC

3. 86020224 NC Bi-Directional

4. 61000000 1/16" NPTF Plug

5. 30102663 Manifold

6. 34952061 Piston Assembly

7. 86020028 Check Valve

8. 87410001 Super Check

9. 62010018 Manifold Tag

10. 33702007 Cavity Plug

11. 85002929 P.O. Relief

12. 10000001 Hydraulic Fitting #4 SAE Male x #6 SAE Female (Only on some models)

13. Seal Kit For Cartridge Valves (Refer To The Illustrations Below

For Proper Seal Kit Identification.)

NOTE: Each o-ring kit contains all of the o-rings for the series of valve on

which it is used. Not all of the seals will be used on every valve.

Each kit also contains a packet of sealant which is to be used on the threads

of the valve when it is re-installed into the manifold.

Seal Kits For Cartridges in Lift Circuit Manifold 810-262C

Refer to Page 34 For Full Scale O-Ring/Back-up Ring Identification Chart

Relief Valve

Use Seal Kit 810-228C

(Ref. Item #11)

13634

"A" size

o-ring

"B" size

thick

back-up

"B" size

o-ring

NC Bi-Dir

Use Seal Kit 810-271C

(Ref. Item #3)

"B" size

o-ring

13637

"A" size

"A" size

o-ring

"B" size

thin

back-up

Super Check

Use Seal Kit 810-235C

(Ref. Item #8)

o-ring

"B" size

o-ring

"B" size

thick

back-up

12589

Piston Assy.

Use Seal Kit 810-271C

(Ref. Item #6)

"B" size

thin back-up

13636

"B" size

o-ring

Check Valve

Use Seal Kit 810-272C

(Ref. Item #7)

"A" size

o-ring

"B" size

o-ring

12589

"B" size

thick

back-up

Cavity Plug

Use Seal Kit 810-228C

(Ref. Item #10)

"A" size

o-ring

"B" size

thin

back-up

"B" size

o-ring

13635

"B" size

thin

back-up

9/21/05 Great Plains Mfg., Inc. CPH and CP1000 Coulter Command System 148-258M-B

-31

Page 34

Section 5 Parts

Coulter Depth Control Valve (810-214C)

12292

32

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

Great Plains Mfg., Inc.

Page 35

Section 5 Parts

Ref. Part No. Part Description

1. 39680008 Delta Coil 12VDC With Connector

2. 85002279 Delta 3W2P Valve

3. 810-265C Delta Shuttle Valve

4. 61000000 Delta 1/16" NPT Plug

5. 85002006 Delta Check Valve

6. 34952104 Delta Piston Assembly

7. 87410043 Delta PCR Valve

8. 30102610 Delta Coulter Command Manifold

9. 62010056 Delta PCR Sticker

10. 62010053 Delta Notice Tag

11. Seal Kit For Cartridge Valves (Refer To The Illustrations Below

For Proper Seal Kit Identification.)

NOTE: Each o-ring kit contains all of the o-rings for the series of valve on

which it is used. Not all of the seals will be used on every valve.

Each kit also contains a packet of sealant which is to be used on the threads

of the valve when it is re-installed into the manifold.

3W2P Valve

Use Seal Kit 810-228C

(Ref. Item #2)

"C" size

o-ring

"B" size

o-ring

12587 12590

Seal Kits For Coulter Depth Control Valves

Refer to Page 34 For Full Scale O-Ring/Back-up Ring Identification Chart

Shuttle Valve

Use Seal Kit 810-228C

(Ref. Item #3)

"B" size

o-ring

12588

"A" size

o-ring

"C" size

thin

"B" size

thin

back-up

"A" size

o-ring

"C" size

thick

back-up

"C" size

o-ring

"B" size

thick

back-up

Piston Valve

Use Seal Kit 810-228C

"B" size

thick back-up

Check Valve

Use Seal Kit 810-228C

(Ref. Item #5)

12589

(Ref. Item #6)

"B" size

o-ring

PCR Valve

Use Seal Kit 810-235C

(Ref. Item #7)

"A" size

o-ring

"B" size

o-ring

"B" size

thick

back-up

"C" size

o-ring

"E" size

o-ring

12591

"A" size

o-ring

"C" size

back-up

"E" size

back-up

9/21/05 Great Plains Mfg., Inc. CPH and CP1000 Coulter Command System 148-258M-B

-33

Page 36

Section 5 Parts

O-Ring Identification Chart

(Match o-rings and back-up rings to full size illustrations below for identification.)

810-228C For

7/8"-14 Series Valves

A

OD .949

ID .754

B

OD .629

ID .489

C

OD .691

ID .551

810-235C For

1 5/16"-12 Series Valves

A

OD 1.403

ID 1.170

B

OD 1.129

ID .989

C

OD 1.126

ID .924

810-271C For

3/4"-16 Series Valves

A

OD .818

ID .644

B

OD .504

ID .364

C

OD .566

ID .426

D

OD .629

ID .489

D

OD .754

ID .614

Scale: 1=1

D

OD 1.068

ID .862

E

OD 1.002

ID .798

810-272C For

5/8"-18 Check Valves

OD .694

ID .530

OD .504

ID .364

F

OD 1.193

ID .987

34

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

Great Plains Mfg., Inc.

A

B

Page 37

Section 5 Parts

Kit No. Description

810-228C For 7/8"-12 Series Valves

Includes: 2 Each Of The Thin Back-Up Rings, Sizes B, C, And D

1 Each of The Thick Back-Up Rings, Sizes C and D.

2 Thick "B" Size Back-Up Rings

1 Each Of O-Rings Sizes A, B, C, And D

810-235C For 1 5/16"-12 Series Valves

Includes: 1 Each of Sizes A, B, C, D, E, And F

2 Each of Back-Up Rings Sizes B, C, D, E, And F

810-271C For 3/4"-16 Series Valves

Includes: 2 Each Of The Thin Back-Up Rings, Sizes B, C, And D

1 Each of The Thick Back-Up Rings, Sizes B.

1 Each Of O-Rings Sizes A, B, C, And D

810-272C For 5/8"-18 Check Valves

Includes:

1 Each of The Thick Back-Up Rings, Sizes B.

1 Each Of O-Rings Sizes A, And B.

9/21/05 Great Plains Mfg., Inc. CPH and CP1000 Coulter Command System 148-258M-B

-35

Page 38

Appendix

Appendix

Torque Values Chart for Common Bolt Sizes

Great Plains Mfg., Inc.

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 436597

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16 - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 2 Grade 5

N · m2ft-lb3N · m ft-lb N · m ft-lb mm x pitch

Grade 8

Bolt Size

(Metric)

4

N · m ft-lb N · m ft-lb N · m ft-lb

1

in-tpi = nominal thread dia.in inches-threads per inch

2

N· m = newton-meters

3

ft-lb= foot pounds

4

mm x pitch = nominal thread dia. in millimeters x thread pitch

Bolt Head Identification

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

Tire Inflation Chart

Tire Size Inflation PSI Tire Size Inflation PSI

7.50 x 20" 4-Ply Drill Rib 28 11L x 15" 6-Ply Rib Implement 28

9.0 x 22.5 10-Ply Highway Service 70 70 11L x 15" 12-Ply Rib Implement 52

9.0 x 24" 8-Ply Rib Implement 40 12.5L x 15" 8-Ply Rib Implement 36

9.5L x 15" 6-Ply Rib Implement 32 12.5L x 15" 10-Ply Rib Implement 44

9.5L x 15" 8-Ply Rib Implement 44 16.5L x 16.1" 10-Ply Rib Implement 36

9.5L x 15" 12-Ply Rib Implement 60 41 x 15" x 18 - 22-Ply Rib Implement 44

CPH and CP1000 Coulter Command System 148-258M-B 9/21/05

36

Page 39

Great Plains Mfg., Inc.

Appendix

Warranty

Great Plains Manufacturing, Incorporated warrants to the original purchaser that this seeding equipment will be free from defects in material

and workmanship for a period of one year from the date of original purchasewhen used as intended and undernormal service and conditions

for personal use; 90 days for commercial or rental purposes. This Warranty is limited to the replacement of any defective part by Great Plains

Manufacturing, Incorporated and the installation by the dealer of any

such replacement part. Great Plains reserves the right to inspect any

equipment or part which are claimed to have been defective in material

or workmanship.

This Warranty does not apply to any part or product which in Great

Plains’ judgement shall have been misused or damaged by accident or

lack of normal maintenance or care, or which has been repaired or altered in a way which adversely affects its performance or reliability, or

which has been used for a purpose for which the product is not designed. This Warranty shall not apply ifthe product is towed at a speed

in excess of 20 miles per hour.

Claims under this Warranty must bemade to the dealer whichoriginally

sold the product and all warranty adjustments must by made through

such dealer. Great Plains reserves the right to make changes in materials or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for

damages of any kind, direct, consequential, or contingent, to property.

Furthermore,GreatPlainsshallnot be liable for damages resulting from

any cause beyond its reasonable control. This Warranty does not extend to loss of crops, losses caused by harvest delays or any expense

or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, expressed or implied,

is made with respect to this sale; and all implied warranties of

merchantability and fitness for a particular purpose which exceed the obligations set forth in this written warranty are hereby

disclaimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains Manufacturing, Incorporated within 10 days from the date of original purchase.

9/21/05

CPH and CP1000 Coulter Command System 148-258M-B

37

Page 40

Great Plains Manufacturing, Inc.

Corporate Offices: P.O. Box 218

Assaria, Kansas 67416 USA

Loading...

Loading...