Great Plains Contact Drive Wheel Update User Manual

Great Plains Mfg., Inc.

Contact Drive Wheel Update Kit

Yield-Pro Ground Drive Planters

Used with:

• Pre-2007 12- and 16-row Yield-Pro Planters with ground drive

General Information

Installation Instructions 1

These instructions explain how to install the Contact

Drive Wheel Update Kit. This feature is now standard on

new products, and is available as an upgrade to provide

more consistent ground-drive performance in unusually

challenging conditions.

These instructions apply to:

401-462A Contact Drive Wheel Update Kit

Before You Start

Each kit converts an entire planter. Inventory the contents per the “Parts List” on page 4. You may want to

check tire pressure on the new tire before installation.

Raise and fold the planter. Install lift cylinder locks

Installation

Install New Sprocket

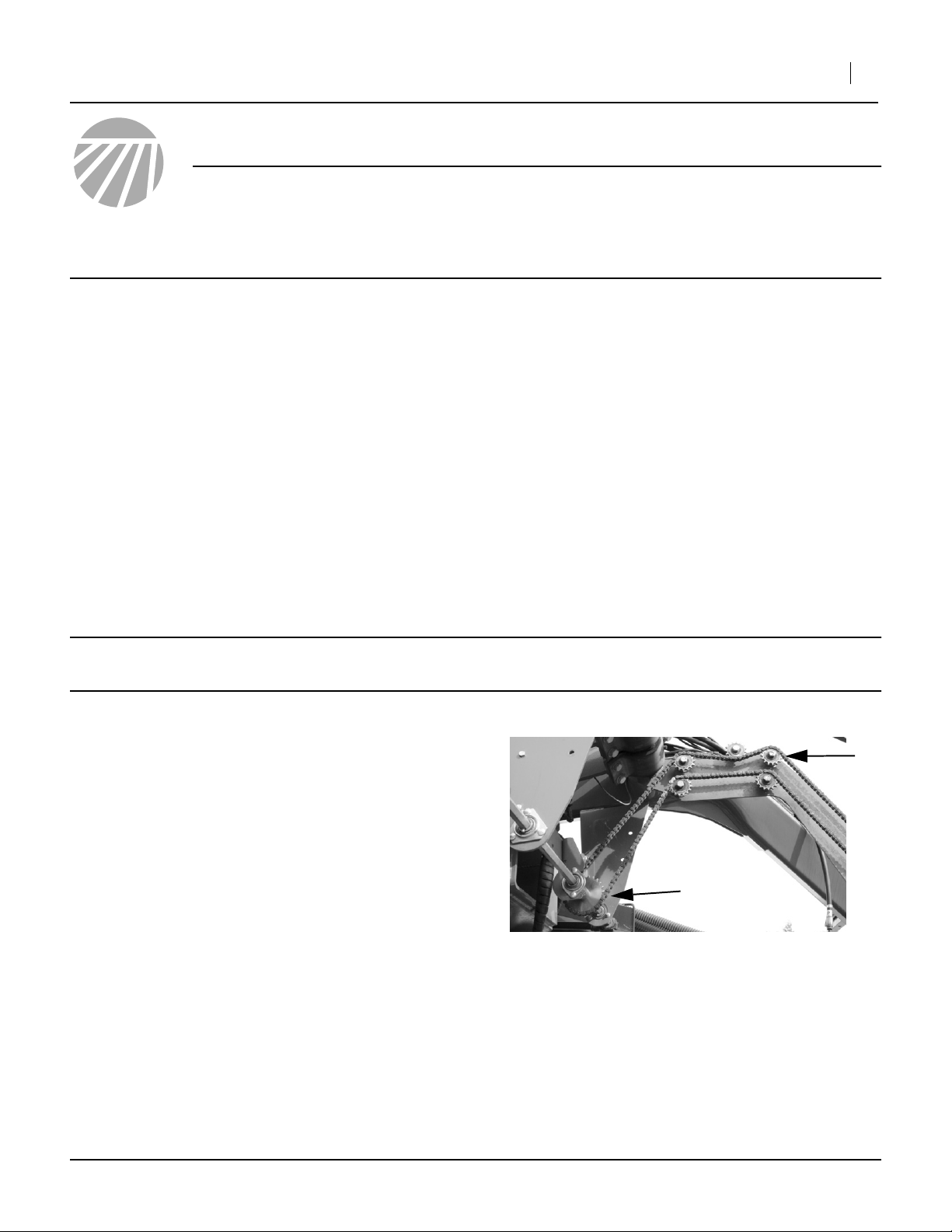

The contact drive wheel sprocket ➀ to be replaced is

located at the center of the planter, beneath the peak of

the overhead frame tubes.

Refer to Figure 1

1. Loosen idler ➁, and lift the drive chain off the old

sprocket ➀.

Note: Although this update can be performed with the

planter unfolded, it is much more complicated that

way. These instructions assume a folded planter.

If necessary, move the implement to a dry well-lighted

location suitable for disassembly.

Park and secure the implement. Secure the tractor if left

connected. Disconnect any hydraulic and electrical

power to the implement.

“Left” and “Right” are facing in the direction of machine

travel.

Have the following tools at hand:

• Basic hand tools (including an assortment of roll-pin

punches)

Also have an assistant for the wheel assembly portion of

this upgrade. Removing the old wheel and installing the

new wheel is not easily done by one person.

➁

➀

Figure 1

Remove Old Sprocket

©Copyright 2006 Printed 12/21/2006 401-465M

25146

2 Contact Drive Wheel Update Kit

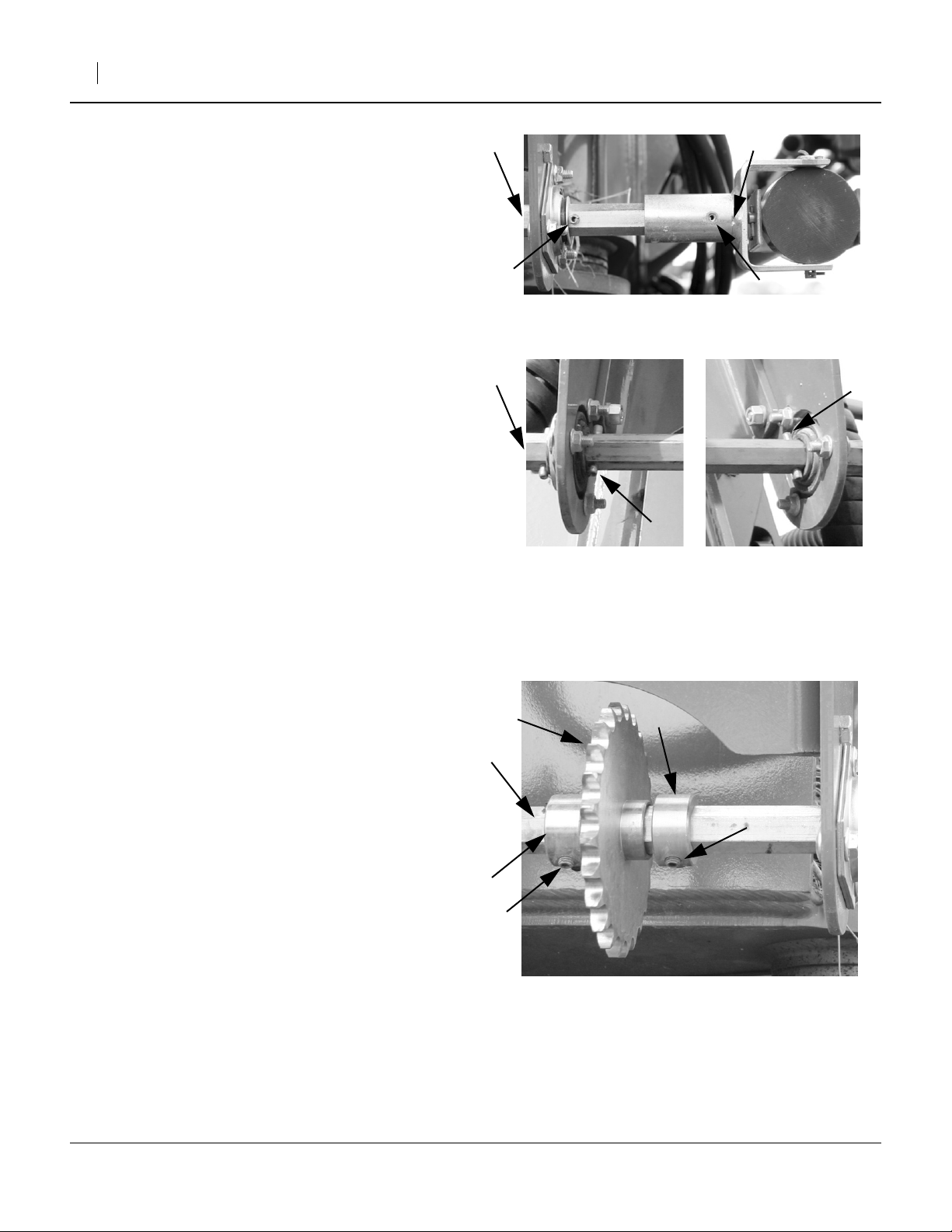

Refer to Figure 2

2. Drive out the roll pin ➀ that attaches the right side

drive shaft U-joint ➁ to the center drive shaft ➂.

Save the pin, unless also performing the drive shaft

update.

3. Slide the U-joint ➁ off the right end of the center

shaft ➂.

4. If a second pin ➃ is installed outside the bearing,

remove it as well. Save this pin.

Refer to Figure 3

5. If pins ➀➁ are present at the insides of the center

shaft brackets, remove and save them.

Refer to Figure 4

6. Loosen the set screws ➀ on the retaining collar ➁

to the right of the sprocket ➂ to be removed.

7. Slide the drive shaft ➃ to the left, until the locking

collar ➁, and then the sprocket ➂, are off the end of

the shaft. Save the locking collar. The old sprocket

is not reused.

Note: If it is not possible to slide the drive shaft ➃ far

enough to remove the collar and sprocket:

a. Mark the shaft location of the left collar ➄

b. Loosen that collar’s set screws ➅

c. Remove the sprocket and right collar (only)

➂

➂

➃

➁

Figure 2

Disconnect Right U-Joint

➁

Figure 3

Remove Pins

Great Plains Mfg., Inc.

➀

25142

➀

➂

25147

8. Slide the new sprocket, and then the locking collar

➁ onto the shaft. If it was necessary to loosen the

left collar ➄, re-position it to the mark and tighten its

set screws.

9. Re-insert the shaft ➃ through all bearings and

brackets.

10. Firmly slide the locking collar ➁ against the new

sprocket. Tighten its set screws.

11. Re-install any pins removed in steps 4 and 5.

➃

➄

Refer to Figure 1

12. Remount the chain.

13. Tighten idler ➂ (previous page) until there is3⁄4in

slack in the longest chain span.

14. Skip this next step if also installing the drive shaft

update.

15. Re-insert the roll pin in the right drive shaft universal joint.

➂

➅

➁

Figure 4

Loosen Collar

➀

➂

25148

401-465M 12/21/2006

Loading...

Loading...