Page 1

Operator’s Manual

CF500 and CF600

Hydraulic Cross-Fold Boom

Manufacturing, Inc.

Read the operator’s manual entirely. When you see this symbol, the subsequent

instructions and warnings are serious - follow without exception. Your life and

!

the lives of others depend on it!

Cover illustration may show optional equipment not supplied with standard unit.

© Copyright 2012 Printed 2012-04-20 506-582M

Page 2

Table of Contents

Important Safety Information. . . . . . . . . . . . . . . 1

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . 8

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Description of Unit . . . . . . . . . . . . . . . . . . . . 13

Intended Usage . . . . . . . . . . . . . . . . . . . 13

Using This Manual . . . . . . . . . . . . . . . . . . . . 13

Definitions . . . . . . . . . . . . . . . . . . . . . . . 13

Owner Assistance . . . . . . . . . . . . . . . . . . . . 14

Preparation and Setup . . . . . . . . . . . . . . . . . . . 15

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . 15

Hitching Tractor to Boom . . . . . . . . . . . . . . . 15

Leveling Boom . . . . . . . . . . . . . . . . . . . . . . . 17

Operating Instructions . . . . . . . . . . . . . . . . . . . 18

Prestart Checklist . . . . . . . . . . . . . . . . . . . . . 18

Field Operation. . . . . . . . . . . . . . . . . . . . . . . 18

Electric-Hydraulic Control. . . . . . . . . . . . . . . 20

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Hydraulic Elevator . . . . . . . . . . . . . . . . . . . . 23

Boom Height . . . . . . . . . . . . . . . . . . . . . . . . 23

Leveling Boom . . . . . . . . . . . . . . . . . . . . . . . 23

Locking System . . . . . . . . . . . . . . . . . . . . . . 24

Break Away Spring. . . . . . . . . . . . . . . . . . . . 24

Spring Arm Tension . . . . . . . . . . . . . . . . . . . 25

Wing Folding . . . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance and Lubrication . . . . . . . . . . . . . 27

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . 27

Cables and Rollers. . . . . . . . . . . . . . . . . 28

Optional Hydraulic Elevator . . . . . . . . . . 28

Optional Electric-Hydraulic Control . . . . 28

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Center Section Pivots . . . . . . . . . . . . . . 30

Wing Joint Pivots . . . . . . . . . . . . . . . . . . 30

Swing Plates . . . . . . . . . . . . . . . . . . . . . 30

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Electric-Hydraulic Control. . . . . . . . . . . . . . . 31

Specifications and Capacities . . . . . . . . . . . . . 32

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Torque Values Chart. . . . . . . . . . . . . . . . . . . 33

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

© Copyright 1999, 2003, 2006, 2012 All rights Reserved

Great Plains Manufacturing, Inc. provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution

has been taken in the preparation of this manual, Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any

liability assumed for damagesresulting from the use of the information contained herein. Great Plains Manufacturing, Inc. reserves the right to revise

and improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product

in the future.

Trademarks of Great Plains Manufacturing, Inc. include: Singulator Plus, Swath Command, Terra-Tine.

Registered Trademarks of Great Plains Manufacturing, Inc. include:

Air-Pro, Clear-Shot, Discovator, Great Plains, Land Pride, MeterCone, Nutri-Pro, Seed-Lok, Solid Stand,

Terra-Guard, Turbo-Chisel, Turbo-Chopper, Turbo Max, Turbo-Till, Ultra-Till, Ver ti-Till, Whirlfilter, Yield-Pro.

Brand and Product Names that appear and are owned by others are trademarks of their respective owners.

Printed in the United States of America

506-582M 2012-04-20

Page 3

Important Safety Information

Look for Safety Symbol

The SAFETY ALERT SYMBOL indicates there is

a potential hazard to personal safety involved and

extra safety precaution must be taken. When you

see this symbol, be alert and carefully read the

message that follows it. In addition to design and

configuration of equipment, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

Important Safety Information

!

1

Be Aware of Signal Words

Signal words designate a degree or level of hazard seriousness.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. This signal word is limited to the

most extreme situations, typically for machine

components that, for functional purposes, cannot

be guarded.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury, and includes hazards that are exposed when guards are removed. It may also be

used to alert against unsafe practices.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

DANGER!

!

WARNING!

!

CAUTION!

!

2012-04-20

506-582M

Page 4

CF500 and CF600

2

Be Familiar with Safety Decals

Read and understand “Safety Decals,” page 8,

thoroughly. Read all instructions noted on the

decals.

Keep Riders Off Machinery

Riders obstruct the operator’s view. Riders could

be struck by foreign objects or thrown from the

machine.

▲ Never allow children to operate equipment.

▲ Keep all bystanders away from machine dur-

ing operation.

Shutdown and Storage

▲ Park boom in the unfolded position.

▲ Lower boom, put tractor in park, turn off

engine, and remove the key.

▲ Detach and store boom in an area where chil-

dren normally do not play. Secure boom using

blocks and supports provided.

Use Safety Lights and Devices

▲ Slow-moving tractors and towed implements

can create a hazard when driven on public

roads. They are difficult to see, especially at

night.

▲ Flashing warning lights and turn signals are

recommended whenever driving on public

roads. Use lights and devices provided with

implement.

OFF

506-582M

2012-04-20

Page 5

Transport Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for implement is 20

mph. DO NOT EXCEED. Never travel at a

speed which does not allow adequate control

of steering and stopping. Some rough terrains

require a slower speed.

▲ Sudden braking can cause a towed load to

swerve and upset.

▲ Do not tow a sprayer that, when fully loaded,

weighs more than 1.5 times the weight of the

towing vehicle.

▲ Do not transport sprayer when filled with

chemicals.

▲ Carry reflectors or flags to mark boom and

sprayer in case of breakdown on the road.

Important Safety Information

3

▲ Keep clear of overhead power lines and other

obstructions when transporting. Refer to transport dimensions under “Specifications and

Capacities,” page 32.

▲ Do not fold or unfold the boom while the trac-

tor is moving.

Avoid High Pressure Fluids

▲ Escaping fluid under pressure can penetrate

the skin, causing serious injury.

▲ Avoid the hazard by relieving pressure before

disconnecting hydraulic lines.

▲ Use a piece of paper or cardboard, NOT

BODY PARTS, to check for suspected leaks.

▲ Wear protective gloves and safety glasses or

goggles when working with hydraulic systems.

▲ If an accident occurs, see a doctor immedi-

ately. Any fluid injected into the skin must be

surgically removed within a few hours or gangrene may result.

2012-04-20

506-582M

Page 6

CF500 and CF600

4

Practice Safe Maintenance

▲ Understand procedure before doing work. Use

proper tools and equipment. Refer to this manual for additional information.

▲ Work in a clean, dry area.

▲ Lower the boom, put tractor in park, turn off

engine, and remove key before performing

maintenance.

▲ Make sure all moving parts have stopped and

all system pressure is relieved.

▲ Allow sprayer to cool completely.

▲ Do not work on hoses, nozzles or plumbing

components (with the exception of throttling

valve and chemical inductor) while pump is

running or hoses are pressurized. Disengage

pump and release hose pressure by turning

boom section switches on before working on

individual components.

▲ Do not grease or oil sprayer while it is in oper-

ation.

▲ Disconnect battery ground cable (-) before

servicing or adjusting electrical systems or

before welding on sprayer.

▲ Inspect all parts. Make sure parts are in good

condition and installed properly.

▲ Remove buildup of grease, oil or debris.

▲ Remove all tools and unused parts from

sprayer before operation.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire extinguisher handy.

▲ Keep emergency numbers for doctor, ambu-

lance, hospital and fire department near

phone.

911

506-582M

2012-04-20

Page 7

Important Safety Information

5

Handle Chemicals Properly

▲ Read and follow chemical manufacturer’s

instructions.

▲ Wear protective clothing.

▲ Handle all chemicals with care.

▲ Agricultural chemicals can be dangerous.

Improper use can seriously injure persons,

animals, plants, soil and property.

▲ Inhaling smoke from any type of chemical fire

is a serious health hazard.

▲ Store or dispose of unused chemicals as

specified by the chemical manufacturer.

▲ Before adding chemical to the tank, make

sure tank is at least half full. Do not pour concentrate into an empty tank.

▲ Never leave fill hose attached to the sprayer

after filling tank. Chemicals in tank can siphon

out of tank and contaminate freshwater

source.

▲ Always keep hand-wash tank filled with clean

water and have soap available in case of an

emergency. Immediately and thoroughly flush

any area of the body that is contaminated by

chemicals.

▲ Spray only with acceptable wind conditions.

Wind speed must be below 5 mph. Make sure

wind drift of chemicals will not affect any surrounding land, people or animals.

▲ Never wash out the sprayer tank within 100

feet of any freshwater source or in a car wash.

▲ Rinse out the tank. Spray rinse water on last

field sprayed.

▲ Do not touch sprayer components with mouth

or lips.

▲ If chemical is swallowed, carefully follow the

chemical manufacturer’s recommendations

and consult with a doctor.

▲ If persons are exposed to a chemical in a way

that could affect their health, consult a doctor

immediately with the chemical label or container in hand. Any delay could cause serious

illness or death.

▲ Dispose of empty chemical containers prop-

erly. By law rinsing of the used chemical container must be repeated three times. Puncture

the container to prevent future use. An alternative is to jet-rinse or pressure rinse the container.

▲ Wash hands and face before eating after

working with chemicals. Shower as soon as

spraying is completed for the day.

2012-04-20

506-582M

Page 8

CF500 and CF600

6

Safety at All Times

Thoroughly read and understand the instructions

in this manual before operation. Read all instructions noted on the safety decals.

▲ Be familiar with all sprayer and boom func-

tions.

▲ Operate machinery from the driver’s seat only.

▲ Do not leave sprayer or boom unattended with

tractor engine running.

▲ Use only water without pesticides added to

calibrate the sprayer.

▲ Do not exceed the calibrated sprayer speed

and pressure when operating.

▲ Do not dismount a moving tractor. Dismount-

ing a moving tractor could cause serious injury

or death.

▲ Do not stand between the tractor and boom

during hitching.

▲ Keep hands, feet and clothing away from

power-driven parts.

▲ Wear snug-fitting clothing to avoid entangle-

ment with moving parts.

▲ Watch out for wires, trees, etc., when folding

and raising boom. Make sure all persons are

clear of working area.

▲ Turning tractor too tight may cause sprayer to

ride up on wheels. This could result in injury or

equipment damage.

▲ When using a PTO pump, be sure that PTO

shield is in place on the tractor, PTO coupler

bolts are torqued to the correct specification,

and torque bar is properly chained to tractor

drawbar.

▲ Spray with the boom in the unfolded position

only.

▲ Do not modify the boom for use with sprayers

other than Great Plains units. Do not modify

boom for use with tillage attachments. Do not

mount the boom on a tandem-axle sprayer.

▲ The boom has many pinch points during field

operation and folding. Keep all bystanders

away.

506-582M

2012-04-20

Page 9

Wear Protective Equipment

Great Plains advises all users of chemical pesticides or

herbicides to use the following personal safety

equipment.

▲ Waterproof, wide-brimmed hat

▲ Waterproof apron

▲ Face shield, goggles or full face respirator.

▲ Goggles with side shields or a full face respirator is

required if handling or applying dusts, wettable powders, or granules or if being exposed to spray mist.

▲ Cartridge-type respirator ap-proved for pesticide

vapors unless label specifies another type of respirator.

▲ Waterproof, unlined gloves. Neoprene gloves are

recommended.

Important Safety Information

7

▲ Cloth coveralls/outer clothing changed daily; water-

proof items if there is a chance of becoming wet with

spray

▲ Waterproof boots or foot coverings

▲ Do not wear contaminated clothing. Wash protective

clothing and equipment with soap and water after

each use. Personal clothing must be laundered separately from household articles.

▲ Clothing contaminated with certain pesticides must

be destroyed according to state and local regulations. Read chemical label for specific instructions.

▲ Wear clothing and equipment appropriate for the job.

Avoid loose-fitting clothing.

▲ Prolonged exposure to loud noise can cause hear-

ing impairment or loss. Wear suitable hearing protection such as earmuffs or earplugs.

▲ Avoid wearing radio headphones while operating

machinery. Operating equipment safely requires the

full attention of the operator.

2012-04-20

506-582M

Page 10

CF500 and CF600

8

Safety Decals

Your implement comes equipped with all safety

decals in place. They were designed to help you

safely operate your implement.

1. Read and follow decal directions.

2. Keep all safety decals clean and legible.

3. Replace all damaged or missing decals. Order new decals from your Great Plains dealer.

Refer to this section for proper decal placement.

4. When ordering new parts or components,

also request corresponding safety decals.

5. To install new decals:

a. Clean the area on which the decal is to be

placed.

b. Peel backing from decal. Press firmly on

surface, being careful not to cause air

bubbles under decal.

818-055C

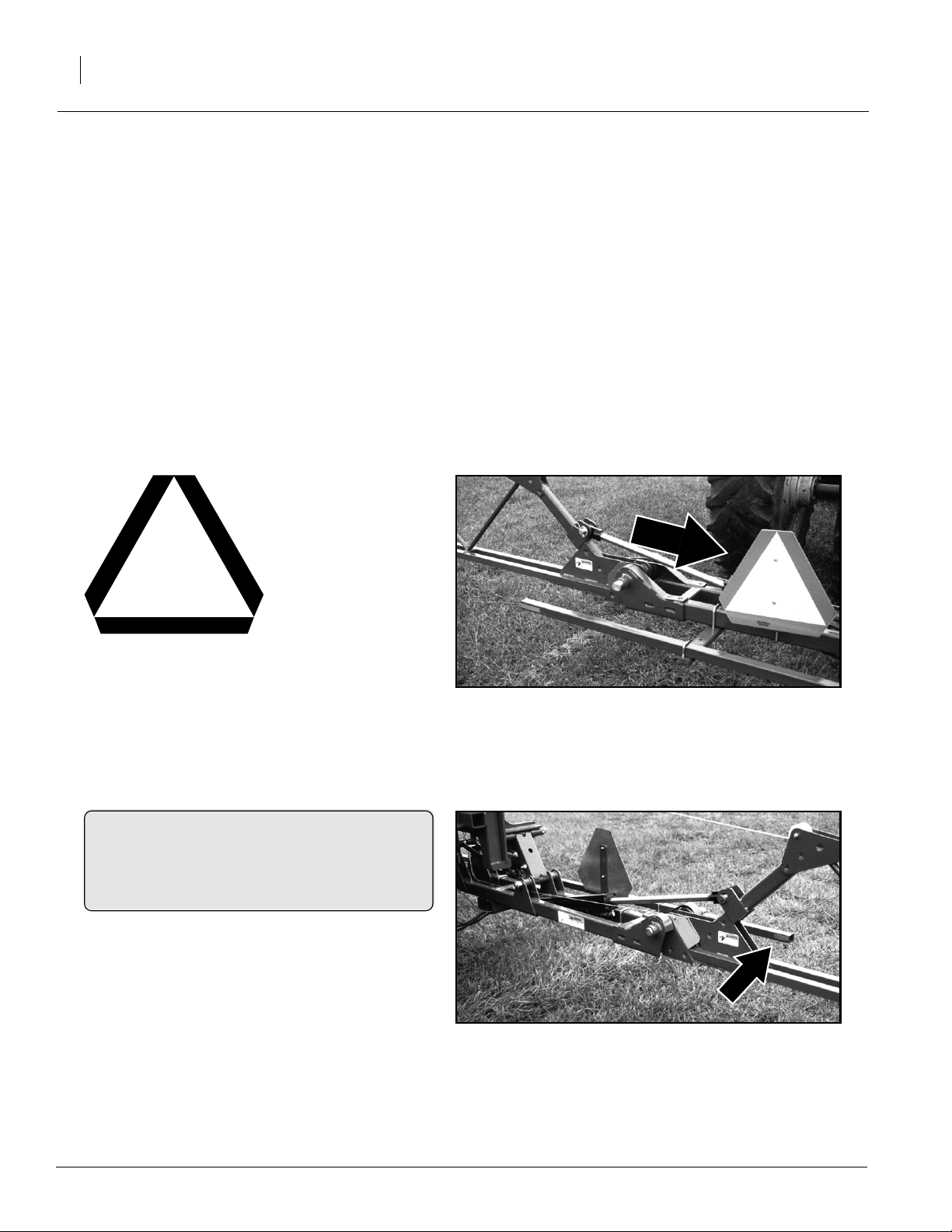

Slow Moving Vehicle Label

838-265C

Amber Reflectors

Front of nozzle tube, both ends of tube; two reflectors total

16921

506-582M

2012-04-20

Page 11

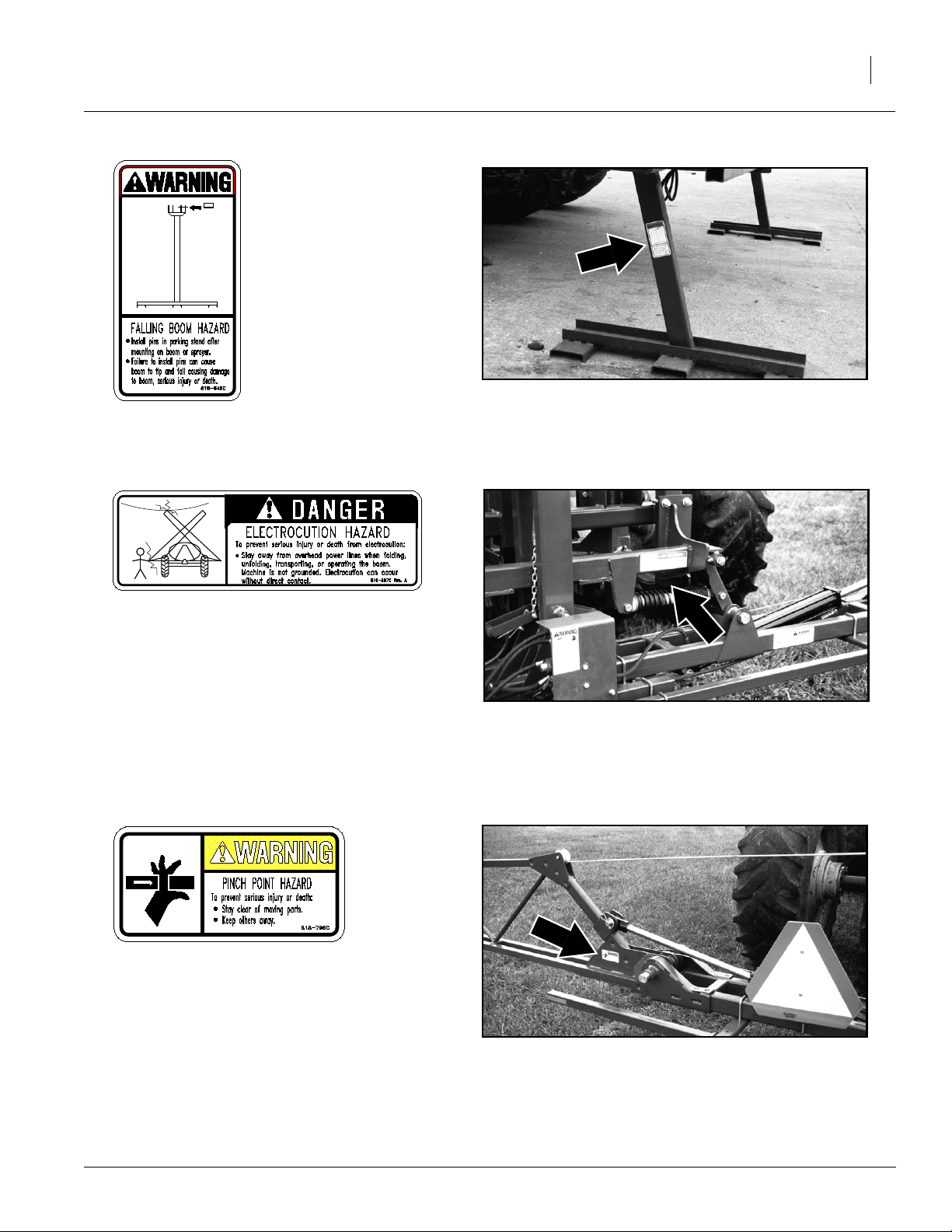

818-648C

Warning Boom Parking Pin

One decal on each parking

stand (Stands sold with

3P300 and three-point

mounts only.)

Important Safety Information

16918

9

818-367C

Danger Power Line Hazard

818-798C

Warning Pinch Point

Decals at wing hinge points, front and back of

boom; eight decals total

17008

17007

2012-04-20

506-582M

Page 12

CF500 and CF600

10

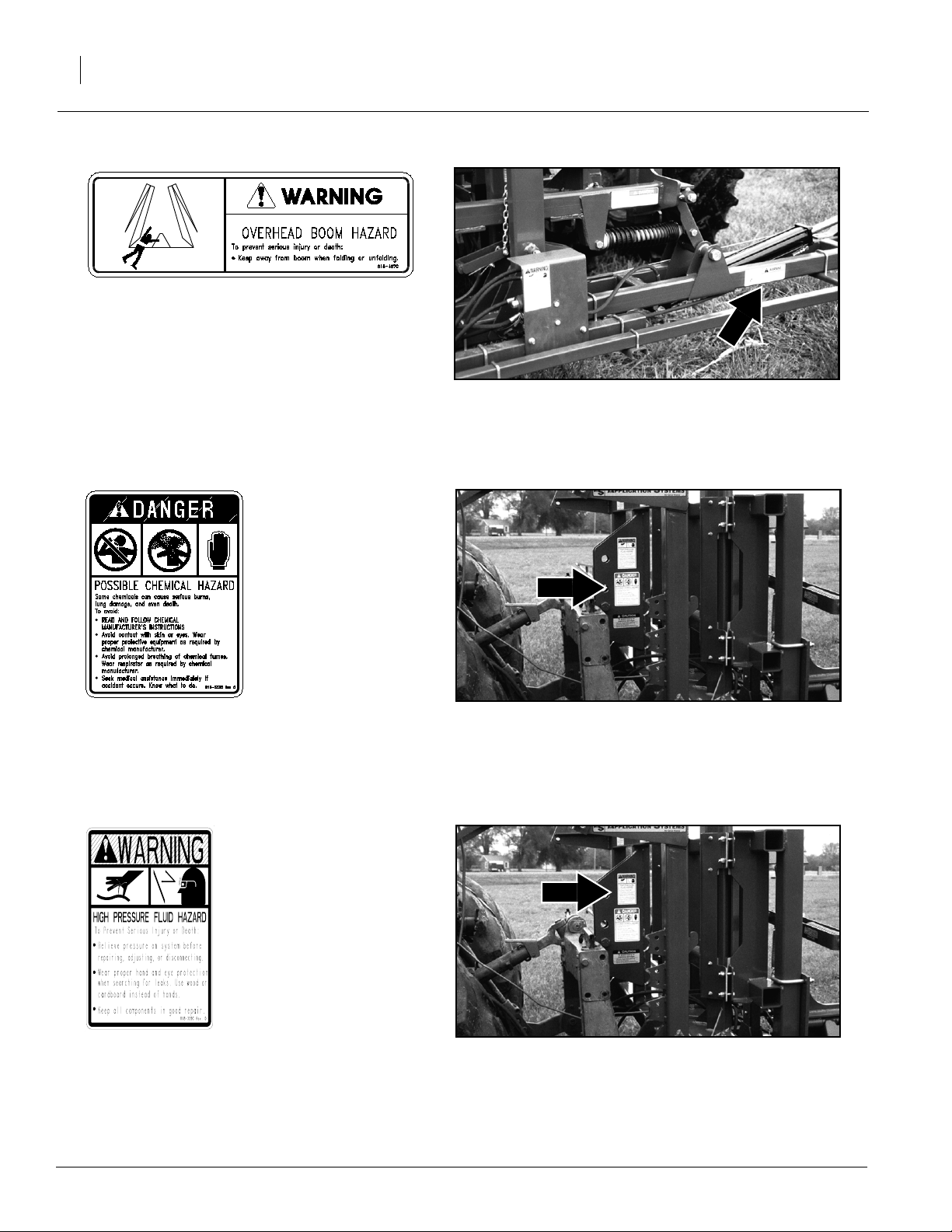

818-467C

Warning Overhead Boom

Front and rear of boom; two decals total

818-323C

Danger Chemical

Hazard

16920

818-339C

Warning High Pressure

SML

16922

16922

506-582M

2012-04-20

Page 13

Important Safety Information

11

818-466C

Caution Hitching Sprayer

818-648C

Warning Boom Parking Pin

One decal on each parking

stand

16922

818-367C

Danger Power Line Hazard

2012-04-20

506-582M

Page 14

CF500 and CF600

12

818-647C

Warning Unfold Boom

818-864C

Danger Crushing Hazard

818-339C

Warning High Pressure SML

Optional Elevator

16919

17008

506-582M

2012-04-20

Page 15

Introduction

Great Plains welcomes you to its growing family of

new product owners. This boom has been designed with care and built by skilled workers using

quality materials. Proper setup, maintenance and

safe operating practices will help you get years of

satisfactory use from the machine.

Description of Unit

The CF500 and CF600 are non-turf type, crossfolding sprayer booms. The booms hydraulically

unfold to an operating width of 50 or 60 feet. The

booms can be mounted on an Great Plains trailer

sprayer, three-point sprayer or three-point mount.

Introduction

13

Intended Usage

Use these booms as part of a pressurized sprayer

system to apply liquid pesticides, herbicides or

fertilizers to production-agriculture crops only.

Mount booms on Great Plains trailer sprayers,

three-point sprayers or three-point hitches only.

Do not modify the boom or use the boom with any

tillage attachments.

Using This Manual

This manual will familiarize you with safety, assembly, operation, adjustments, troubleshooting

and maintenance. Read this manual and follow

the recommendations to help ensure safe and efficient operation.

The information in this manual is current at printing. Some parts may change to assure top

performance.

Definitions

Right-hand and left-hand as used in this manual

are determined by facing the direction the machine will travel while in use unless otherwise

stated.

2012-04-20

IMPORTANT: A crucial point of information related to the preceding topic. For safe and correct operation, read and follow the directions

provided before continuing.

NOTE: Useful information related to the preceding topic.

506-582M

Page 16

CF500 and CF600

14

Owner Assistance

If you need customer service or repair parts, contact your Great Plains dealer. They have trained

personnel, repair parts and equipment specially

designed for Great Plains products.

Refer to Figure 1

Your boom’s parts were specially designed and

should only be replaced with Great Plains parts.

Always use the serial and model number when ordering parts from your Great Plains dealer.

Your Great Plains dealer wants you to be satisfied

with your new machine. If you do not understand

any part of this manual or are not satisfied with the

service received, please take the following

actions.

1. Discuss the matter with your dealership service manager. Make sure they are aware of

any problems so they can assist you.

16972

Figure 1

Serial Number Plate

2. If you are still unsatisfied, seek out the owner

or general manager of the dealership.

3. For further assistance write to:

Product Support

Service Department

Great Plains Mfg. Inc.

PO Box 5060

Salina, KS 67402-5060

506-582M

2012-04-20

Page 17

Preparation and Setup

This section will help you prepare your boom for

use with your tractor andsprayer. Before using the

boom in the field, you must hitch your tractor to

your sprayer or three-point mount and check that

the boom is level.

Read and understand the operator’s manual for

the sprayer you will be using with the boom.

Prestart Checklist

Perform these checks before setting up your

cross-fold boom.

4. Read and understand “Important Safety Information,” beginning on page 1.

Preparation and Setup

15

5. Check that all working parts are moving freely, bolts are tight, and cotter pins are spread.

6. Check that all grease fittings are in place and

lubricated. Refer to “Lubrication,” page 30.

7. Check that all safety decals and reflectors are

correctly located and legible. Replace if damaged. Refer to “Safety Decals,” page 8.

Hitching Tractor to Boom

!

DANGER!

Electrocution hazard. To prevent serious injury or

death from electric shock, keep clear of overhead power lines when transporting, folding or unfolding boom.

Boom is not grounded. Electrocution can occur without direct contact. Refer to transport dimensions under

“Specifications and Capacities”, page 32. Do not fold

or unfold boom while tractor is moving.

!

WARNING!

You could be seriously injured or killed by being

crushed between the tractor and boom. Do not stand

or place any body part between the tractor and boom

while the tractor is in motion. Stop and shut off tractor

before inserting hitch pins.

18098

2012-04-20

506-582M

Page 18

CF500 and CF600

16

!

WARNING!

Hitch the CF500 or CF600 to an Great Plains trailer,

single-axle or three-point sprayer or a three-point

mount only. Hitching the boom to any other sprayer

can result in negative tongue weight which can lead to

serious injury or death.

If your cross-fold boom is mounted on an Great

Plains sprayer, refer to your sprayer operator’s

manual for hitching instructions.

Refer to Figure 2

If your cross-fold boom is mounted on a threepoint mount, attach three-point mount to tractor

with correct pinmountings determined from figure

2.

IMPORTANT: Adjust top three-point link so

boom frame is level. If frame is not level boom

may hit tractor cab when folded.

NOTE: The category IV narrow hitch (CAT IV-N)

spacers are not standard boom equipment.

Figure 2

11939

Pin and Spacer Configurations

506-582M

2012-04-20

Page 19

Leveling Boom

!

WARNING!

Pinch point hazard. Your fingers, hands or arms could

be severely injured or severed if caught in the folding

boom sections. Shut off tractor and remove key before

adjusting shims.

The boom sections must be level across the span

for even spraying.

Refer to Figure 3

To adjust an inner arm, fold boom and loosen

bolts (A) holding shims (B). Add or remove shims

as necessary.

Preparation and Setup

Figure 3

Level Inner Arm

17

16916

Refer to Figure 4

To expose shims for outer arm, fold wings and

band together arms, then disconnect cable from

spring arm and unfold wings while arms are still

banded together. Add or remove shims (A) by

loosening bolt (B).

NOTE: Boom arms are disassembled in figures

for illustration purposes only.

16917

Figure 4

Level Outer Arm

2012-04-20

506-582M

Page 20

CF500 and CF600

18

Operating Instructions

This section covers general operating procedures. Experience, machine familiarity and the

following information will lead to efficient operation and good working habits. Always operate

farm machinery with safety in mind.

Prestart Checklist

1. Read and follow “Important Safety Information,” beginning on page 1.

2. Read and follow the chemical manufacturer’s

instructions. Consider how you will store and

dispose of the chemical.

3. When working with agricultural chemicals, alwayswear protective, waterproof clothing that

covers the body.

4. Have soap and water available to wash any

exposed areas. Check that hand-wash tank is

full of clean water.

5. Lubricate boom as indicated under “Lubrication,” page 30.

6. Check boom for loose bolts, pins and hose

clamps. Check hoses, pumps, valves and fittings for leaks. Tighten all bolts as specified

under “Torque Value Chart,” page 33.

Field Operation

!

DANGER!

Electrocution hazard. To prevent serious injury or

death from electric shock, keep clear of overhead power lines when transporting, folding or unfolding boom.

Boom is not grounded. Electrocution can occur without direct contact. Refer to transport dimensions under

“Specifications and Capacities,” page 32. Do not fold

or unfold boom while tractor is moving.

18098

506-582M

2012-04-20

Page 21

!

WARNING!

Crushing and pinching hazard. During folding, the

boom has many pinch points. Bystanders could be injured by the moving sections. Hydraulic failure could

cause the boom to fall on bystanders. To eliminate the

hazard, keep all bystanders awayduring boomfolding.

Fold the boom only when the tractor is parked. Do not

allow riders on the boom.

!

WARNING!

Escaping fluid under pressure can penetrate the skin

causing serious injury. Check all hydraulic lines and

fittings before applying pressure.Use paper or cardboard, NOT BODY PARTS, to check for suspected

leaks. Wear protective gloves and safety glasses or

goggles when working with hydraulic systems. If an

accident occurs, see a doctor immediately. Any fluid

injected into the skin must be surgically removed within a few hours or gangrene will result.

18107

Operating Instructions

17273

19

!

CAUTION!

Operate boom only whenboom is unfolded completely.

Spraying chemicals with the boom partially folded increases the risk of sprayer and chemical-exposure accidents.

1. Remove parking stands before folding, transporting or operating boom.

2. Fill sprayer tank half full with water.

3. Unfold boom in field where you will spray.

4. Check nozzles for streaks and non-uniformity.

Clean or replace nozzles as necessary.

5. Calibrate sprayer. Refer to calibration procedures in the Application Guide.

6. Adjust boom to proper height. For proper nozzle height, refer to nozzle tables in the Appli-

cation Guide.

7. Add chemicals to sprayer and finish filling with

water. Never open chemical containers with

bare hands.

8. Rinse chemical container three times. Puncture containers to prevent future use. Dispose

of containers as recommended by the chemical manufacturer.

2012-04-20

506-582M

Page 22

CF500 and CF600

20

9. Start sprayer pressurizing system to work up

to desired pressure.

10. When applying chemicals in the field, your

goals are accuracy, efficiency and safety. To

reduce expenses and risks to human health:

• Apply spray when wind is 5 mph or less.

• Take note of adjoining crops, houses or

persons.

• Minimize drift by using nozzle tips with the

largest practical opening and by operating

boom at the lowest practical height.

• Work crosswise to the wind. Start from the

down-wind side of the field to avoid heading

directly into chemical fumes.

• When turning at the end of field, make sure

boom will not overlap previously sprayed

crop.

• While spraying, monitor pressure closely.

Maintain a constant tank pressure for even

and accurate spraying.

• Periodically check hoses, connections and

nozzles. Release pressure before working

on sprayer or boom. Always wear rubber

gloves when making repairs or adjustments.

11. When finished spraying, empty tank and flush

sprayer with water, including the pump, nozzles and valve-bypass line. Store or dispose

unused chemicals as recommended by the

chemical manufacturer.

Electric-Hydraulic Control

Refer to Figure 5

The optional electric-hydraulic valve allows you to

control boom folding and elevator lift on the same

hydraulic circuit. To select a hydraulic function,

depress its colored button on the joystick controller or flip its switch on the control box. Hydraulic

functions are coded as follows.

• Yellow Button or Light: Elevator

• Green Button or Light: Left Wing

• Red Button or Light: Right Wing

For more information on the optional electric-hydraulic control, refer to “Troubleshooting,” page

26, and “Maintenance and Lubrication,” page 27.

Figure 5

Electric-Hydraulic Control

506-582M

18114

2012-04-20

Page 23

Transporting

!

DANGER!

Electrocution hazard. To prevent serious injury or

death from electric shock, keep clear of overhead power lines when transporting, folding or unfolding boom.

Boom is not grounded. Electrocution can occur without direct contact. Refer to transport dimensions under

“Specifications and Capacities,” page 32.

!

WARNING!

Crushing and pinching hazards. During folding, the

boom has many pinch points. Bystanders could be injured by the moving sections. Hydraulic failure could

cause the boom to fall on bystanders. To eliminate the

hazard, keep all bystanders awayduring boomfolding.

Fold the boom only when the tractor is parked.

18107

Operating Instructions

17273

21

Before transporting boom, check and practice

these items:

No chemicals. Do not transport sprayer with

chemicals in tank.

Remove parking stands. Remove parking

stands from boom before transporting.

Maximum Speed. Do not exceed 20 mph when

transporting.

Bystanders. Check that no one is in the way

before moving tractor. Do not allow anyone to

ride on boom or sprayer.

Clearance. Know dimensions of folded boom.

Refer to “Specification and Capacities,” page

32. Follow a route that provides adequate clearance from all obstructions. Be especially observant of low overhead power lines.

Road Rules. Comply with all federal, state and

local laws when transporting on public roads.

2012-04-20

506-582M

Page 24

CF500 and CF600

22

Parking

!

WARNING!

Crushing hazard. The parked boom could fall and

cause serious injury or death. Always park boom in

unfolded position. Always secure parking stands under

three-point mount and boom when parking boom.

If parking a boom that is mounted on an Great

Plains sprayer, refer to your sprayer manual for

parking instructions. For information on long-term

storage, refer to “Storage,” page 29.

Refer to Figure 6

To park a three-point boom, follow these steps:

1. Flush sprayer with water in last field sprayed.

Flush pump, nozzles and bypass line from

valves.Store or dispose unused chemicalsas

recommended by the chemical manufacturer.

2. Park boom on a level, flat area that is protected from wind gusts and direct sunlight. Park

boom in an area where children do not play. If

possible, store boom inside for longer machine life.

3. Unfold boom.

4. Position parking stands under three-point

mount and center section of boom frame.

Make sure parking stands are positioned over

level, firm ground so boom will be stable from

front to rear. If the groundis soft, place boards

under parking stands to increase ground-contact area.

5. Lower tractor hitch so mount and boom rest

on parking stands. Secure stands to mount

and boom with wire pins.

6. Unhook PTO pump or unplug hydraulic lines

from hydraulic pump.

7. Unhook cam-lock connectors and hydraulic

hoses from boom and position on frame.

8. Remove three-point pins from tractor. Pull

away from boom.

17615

Figure 6

Position Stands Under Parked Boom

506-582M

2012-04-20

Page 25

Adjustments

!

WARNING!

Crushing hazard. The boom could fall and cause serious injury or death. Before performing any maintenance, secure boom to parking stands if provided.

Hydraulic Elevator

Refer to Figure 7

Periodically check the slide pads (A) for wear. As

the pads wear, tighten 1/2-inch bolts (B) on both

sides of elevator frame (C) until pads just touch

frame.

Adjustments

23

Boom Height

After calibrating sprayer for your nozzles, desired

pressure and tractor speed, the main field adjustment is boom height. Set boom height to achieve

correct overlap for your nozzle. If the crop canopy

is taller in some fields than others, adjust boom

height accordingly.

Refer to nozzle tables in the Application Guide to

determine correct boom height.

Leveling Boom

For even application, the sprayer boom must be

level across the span. The boom is initially leveled

during assembly. After a period of normal use, you

may need to level the boom.

If necessary, refer to “Leveling Boom,” page 17.

17000

Figure 7

Hydraulic Elevator

2012-04-20

506-582M

Page 26

CF500 and CF600

24

Locking System

Refer to Figure 8

The CF500 and CF600 have a locking system for

automatic boom locking during folding and transport. For proper folding, the boom-lock cable must

be tight enough that the lock arms (A) just clear

their stops when unfolded (B) and rest secure

against the stop when folded (C).

A

Refer to Figure 9

To adjust the tension on the boom-lock cable,

loosen jam nut and turn clevis.

B

Locking System

Boom-Lock Cable

C

Figure 8

Figure 9

17003

17614

Break Away Spring

Refer to Figure 10

Periodically check that break-away springs are

compressed to 6 inches. Adjust spring by turning

mounting nut under spring.

Figure 10

Break-Away Spring

506-582M

17001

2012-04-20

Page 27

Spring Arm Tension

Refer to Figure 11

Periodically check that spring is compressed to a

length of 10 1/4 inches. Check spring compression with boom unfolded. To compress spring,

tighten spring nut (A). Lock with second nut (B).

Adjustments

25

Wing Folding

Refer to Figure 12

Normal boom use may cause wing misalignment.

If the inner- and outer-arm sections are out of

alignment, the outer arm (A) will miss the fold

bracket (B) on the inner arm when boom is folded.

To realign wing sections, loosen 1/2-inch bolts at

arm joint. Swing outer-arm section until it is

aligned with inner-arm section. Retighten bolts.

Normal boom use may also shift the folding brackets along the inner-arm section. When properly

adjusted, the outer arm will meet the fold bracket

at the stop (C). Loosen u-bolts and reposition

brackets as necessary.

Figure 12

Aligning Wing Sections

16946

Figure 11

Spring-Arm Tension

2012-04-20

16997

506-582M

Page 28

CF500 and CF600

26

Troubleshooting

Problem Solution

Excessive cable wear

Pressure increases

Optional electric-hydraulic control not

working

Restricted oil flow to optional electrichydraulic control

No oil flow and no clicking sound

from valve on optional electrichydraulic control

Check cable and roller for obstruction or wear. Remove obstructions.

Check that roller is turning properly. Replace roller or roller bushing if

necessary.

If necessary, replace worn cable.

Check for clogging in boom hoses. Remove obstruction.

Check if boom hoses are pinched. Use cable ties to keep hoses from

kinking.

If valve does not work and indicator lights are not lit, check for a blown

fuse, damaged wiring or a bad switch.

If valve does not work but indicator lights are lit, check that system is

properly grounded. Ground valve by running a wire from the tractor

frame to the coil nut on top of the valve.

Do not mix and match styles of tips and couplers.

Check that hydraulic hoses are not blocked, damaged or kinked.

Check valve cartridge for internal contamination. Before removing cartridge, relieve all hydraulic pressure and remove all hydraulic hoses

from ports. Contact your Great Plains dealer for cartridge-cleaning

instructions.

506-582M

2012-04-20

Page 29

Maintenance and Lubrication

Maintenance

!

DANGER!

Some chemicals will cause serious burns, lung damage

and death. Avoid contact with skin or eyes. Wear proper protective equipment as required by chemical manufacturer. Avoid prolonged breathing of chemical

fumes. Wear respirator as required by chemical manufacturer. Seek medical assistance immediately if accident occurs. Know what to do in case of an accident.

!

WARNING!

Crushing hazard. The boom could fall and cause serious injury or death. Before performing any maintenance, secure boom to parking stands if provided.

Maintenance and Lubrication

18108

18109

27

!

WARNING!

Crushing and pinching hazards. During boom folding,

the boom has many pinch points. Bystanders could be

injured by moving sections. Hydraulic failure could

cause boom to fall on bystanders. To eliminate the hazards, keep all bystanders away during boom folding.

Fold boom only when the tractor is parked.

!

WARNING!

Escaping fluid under pressure can penetrate the skin

causing serious injury. Check all hydraulic lines and

fittings before applying pressure.Use paper or cardboard, NOT BODY PARTS, to check for suspected

leaks. Wear protective gloves and safety glasses or

goggles when working with hydraulic systems. If an

accident occurs, see a doctor immediately. Any fluid

injected into the skin must be surgically removed within a few hours or gangrene will result.

Proper service and maintenance is the key to long

implement life. With careful and systematic inspection, you can avoid costly maintenance,

downtime and repair.

17273

18107

2012-04-20

506-582M

Page 30

CF500 and CF600

28

Always turn off and remove the tractor key before

making any adjustments or performing any

maintenance.

1. Release system pressure by flipping boomsection switches on and off without pump running.

2. Clean nozzles with an air hose with less than

30 psi. Periodically replace nozzles.

3. Check hoses, pumps, valves and fittings for

leaks. Always wear rubber gloves when making repairs or adjustments.

4. Check sprayer for loose bolts, pins and hose

clamps.

Cables and Rollers

Refer to Figure 13

Inspect cables and rollers for proper rolling. If a

roller does not turn, inspect roller for dirt or other

imperfections on bearing surface.

Rollers have a self-lubricating bearing. Do not lubricate bearings with oil. Lubricating bearing with

oil may cause dirt accumulation that jams roller.

Keep cables tight and spring compressed to

10 1/4 inches. See “Spring Arm Tension,” page

25.

Optional Hydraulic Elevator

Keep slide pads properly adjusted as explained

under “Hydraulic Elevator,” page 23. Do not

grease slide pads. Lubricating slide pads with

grease may cause dirt accumulation that jams elevator. If necessary, use silicone spray on slide

pads.

Optional Electric-Hydraulic Control

Periodically inspect electrical connections for corrosion, wear or damage. Replace terminals as

necessary.

Inspect control harness for damage. Make sure

the harness has not shifted into a position where it

could be damaged by boom or elevator operation.

Inspect hydraulic hoses and fittings for leaks. Replace any hoses that show signs of failure.

Tighten any leaking fittings.

17007

Figure 13

Cable and Roller

506-582M

2012-04-20

Page 31

Storage

Store boom where children do not play. If possible, store boom inside for longer life.

1. Empty solution from sprayer tank and store or

dispose chemicals as recommended by the

chemical manufacturer.

2. Change filters in tractor cab.

3. Wash boom exterior thoroughly using a safe

solvent or soap and water.

4. Flush out boom with antifreeze to prevent

freeze damage.

5. Inspect all parts for wear and rust.

6. Repair and paint parts as necessary.

7. Park boom in a dry area away from direct sunlight.

Maintenance and Lubrication

29

8. Follow instructions for parking boom as listed

under “Parking,” page 22.

9. Make sure all personal safety equipment is

stored in an easily accessible place and protected from potential contamination from dust

or chemicals.

2012-04-20

506-582M

Page 32

CF500 and CF600

30

Lubrication

Multipurpose

spray lube

Multipurpose

grease lube

30

Center Section Pivots

Both ends of center section – four zerks total.

Type of Lubrication: Grease

Quantity = Until resistance is felt

30

Multipurpose

oil lube

50

Intervals at which

lubrication is required

17002

Wing Joint Pivots

One zerk on each wing – two zerks total

Type of Lubrication: Grease

Quantity = Until resistance is felt

10

Swing Plates

Zerks on each end of plates – four zerks total

Type of Lubrication: Grease

Quantity = Until resistance is felt

17001

16998

506-582M

2012-04-20

Page 33

Options

Electric-Hydraulic Control

With the optional electric-hydraulic control, you

can operate boom folding and elevator lift on the

same hydraulic circuit. The controller mounts in

your tractor cab for convenient switching between

hydraulic functions.

The control is available with a joystick controller

for tractors with hydraulic levers or a switch-box

controller for tractors with hydraulic switches.

To order the electric-hydraulic control, contact

your Great Plains dealer.

Electric-Hydraulic Control Part Number

Options

17608

31

with Joystick Controller 506-584A

with Switch-Box Controller 506-585A

2012-04-20

506-582M

Page 34

CF500 and CF600

32

Specifications and Capacities

CF500 CF600

Nozzle Spacing

Nozzles Per Boom

Weight

Working Width

Transport Width (Folded)

Transport Height (Folded)

Tractor Requirements

20 inches 30 inches 20 inches 30 inches

30 21 36 25

895 pounds 935 pounds

50 feet 60 feet

12 feet 9 inches 12 feet 9 inches

12 feet 2 inches 12 feet 2 inches

Two remote valves; Category II, III or IV-N for three-point-mounted

booms

506-582M

2012-04-20

Page 35

Appendix

Torque Values Chart

Appendix

33

Bolt

Size

in-tpi

1

⁄4-20

1

⁄4-28

5

⁄16-18

5

⁄16-24

3

⁄8-16

3

⁄8-24

7

⁄16-14

7

⁄16-20

1

⁄2-13

1

⁄2-20

9

⁄16-12

9

⁄16-18

5

⁄8-11

5

⁄8-18

3

⁄4-10

3

⁄4-16

7

⁄8-9

7

⁄8-14

1-8

1-12

1

⁄8-7

1

1

1

⁄8-12

1

1

⁄4-7

1

1

⁄4-12

3

⁄8-6

1

3

1

⁄8-12

1

1

⁄2-6

1

1

⁄2-12

Bolt Head Identification

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

a

b

d

ft-lb

N-m

7.4 11 16

8.5 13 18

15 24 33

17 26 37

27 42 59

31 47 67

43 67 95

49 75 105

66 105 145

75 115 165

95 150 210

105 165 235

130 205 285

150 230 325

235 360 510

260 405 570

225 585 820

250 640 905

340 875 1230

370 955 1350

480 1080 1750

540 1210 1960

680 1520 2460

750 1680 2730

890 1990 3230

1010 2270 3680

1180 2640 4290

1330 2970 4820

N-m N-m

5.6 8 12

61014 5 811

11 17 25 12 19 27

13 19 27 13 21 29

20 31 44 24 39 53

22 35 49 29 45 62

32 49 70 42 67 93

36 55 78 44 70 97

49 76 105 66 77 105

55 85 120 68 105 150

70 110 155 73 115 160

79 120 170 105 165 230

97 150 210 115 180 245

110 170 240 145 230 300

170 265 375 165 260 355

190 295 420 205 325 450

165 430 605 230 480 665

185 475 670 355 560 780

250 645 910 390 610 845

275 705 995 705 1120 1550

355 795 1290 785 1240 1710

395 890 1440 1270 1950 2700

500 1120 1820 1380 2190 3220

555 1240 2010

655 1470 2380

745 1670 2710

870 1950 3160

980 2190 3560

Bolt Head Identification

Bolt

Size

ft-lb ft-lb ft-lb ft-lb ft-lb

mm x pitch

M 5 X 0.8

M 6 X 1

M 8 X 1.25

M 8 X 1

M10 X 1.5

M10 X 0.75

M12 X 1.75

M12 X 1.5

M12 X 1

M14 X 2

M14 X 1.5

M16 X 2

M16 X 1.5

M18 X 2.5

M18 X 1.5

M20 X 2.5

M20 X 1.5

M24 X 3

M24 X 2

M30 X 3.5

M30 X 2

M36 X 3.5

M36 X 2

a. in-tpi = nominal thread diameter in inches-threads per inch

b. N· m = newton-meters

c. mm x pitch = nominal thread diameter in mm x thread pitch

d. ft-lb = foot pounds

c

5.8 8.8 10.9

N-m N-m N-m

357

71115

17 26 36

18 28 39

33 52 72

39 61 85

58 91 125

60 95 130

90 105 145

92 145 200

99 155 215

145 225 315

155 240 335

195 310 405

220 350 485

280 440 610

310 650 900

480 760 1050

525 830 1150

960 1510 2100

1060 1680 2320

1730 2650 3660

1880 2960 4100

946

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

2012-04-20

25199

506-582M

Page 36

CF500 and CF600

34

Warranty

Great Plains Manufacturing, Incorporated warrants to the original purchaser that this spraying equipment will be free from defects in material

and workmanship for a period of one year from the date of original purchase when used as intended and under normal service and conditions

for personal use; 90 days for commercial or rental purposes. This Warranty is limited to the replacement of any defective part by Great Plains

Manufacturing, Incorporated and the installation by the dealer of any

such replacement part. Great Plains reserves the right to inspect any

equipment or part which are claimed to have been defective in material

or workmanship.

This Warranty does not apply to any part or product which in Great

Plains’ judgement shall have been misused or damaged by accident or

lack of normal maintenance or care, or which has been repaired or altered in a way which adversely affects its performance or reliability, or

which has been used for a purpose for which the product is not designed. This Warranty shall not apply if the product is towed at a speed

in excess of 20 miles per hour.

Claims under this Warranty must be made to the dealer which originally

sold the product and all warranty adjustments must by made through

such dealer. Great Plains reserves the right to make changes in materials or design of the product at any time without notice.

This Warranty shall not be interpreted to render Great Plains liable for

damages of any kind, direct, consequential, or contingent, to property.

Furthermore, Great Plains shall not be liable for damages resulting from

any cause beyond its reasonable control. This Warranty does not extend to loss of crops, losses caused by harvest delays or any expense

or loss for labor, supplies, rental machinery or for any other reason.

No other warranty of any kind whatsoever, express or implied, is

made with respect to this sale; and all implied warranties of merchantability and fitness for a particular purpose which exceed

the obligations set forth in this written warranty are hereby disclaimed and excluded from this sale.

This Warranty is not valid unless registered with Great Plains Manufacturing, Incorporated within 10 days from the date of original purchase.

506-582M

2012-04-20

Page 37

Page 38

Great Plains Manufacturing, Inc.

Corporate Office: P.O. Box 5060

Salina, Kansas 67402-5060 USA

Loading...

Loading...