Page 1

NGP SERIES PISTON

METERING PUMP

PARTS AND

INSTRUCTION MANUAL

NGP-6055 Shown

CDS-JOHN BLUE COMPANY

DIVISION OF ADVANCED SYSTEMS TECHNOLOGY, INC.

290 Pinehurst Drive - Huntsville, Alabama 35806

P.O. Box 1607 - Huntsville, Alabama 35807

Telephone: (256) 721-9090 - FAX: (256) 721-9091 - Toll Free: 1-800-253-2583

Printed in U.S.A. 12-M-43 Rev 08/13

Page 2

SAFETY PRECAUTIONS

Equipment should be operated only by responsible people.

A careful operator is the best insurance against an accident.

Fill system with WATER first and check output.

Check all valves, fittings, hose clamps, etc. for wear / leaks before admitting process fluid to the system.

Replace hoses when worn, cracked, or if leaking.

WARNING: USE OF THIS PRODUCT FOR ANY PURPOSES OTHER THAN ITS ORIGINAL INTENT, ABUSE

OF THE PRODUCT, AND/OR MODIFICATION TO THE ORIGINAL PRODUCT IS STRICTLY PROHIBITED BY

CDS-JOHN BLUE COMPANY. CDS-JOHN BLUE COMPANY RESERVES THE RIGHT TO DENY

WARRANTY OR LIABILITY CLAIMS IN ANY/ALL SITUATIONS INVOLVING MISUSE, ABUSE OR

MODIFICATION.

THE ORIGINAL INTENT OF THIS PRODUCT DOES NOT INCLUDE USE WHERE THE MAXIMUM

ALLOWED SPEED, PRESSURE, OR TEMPERATURE IS EXCEEDED, AND IT DOES NOT INCLUDE

APPLICATIONS UTILIZING FLUIDS THAT ARE NOT COMPATIBLE WITH THE PRODUCT’S COMPONENT

MATERIALS. DO NOT USE THIS PRODUCT WITH FLAMMABLE OR COMBUSTIBLE FLUIDS SUCH AS

GASOLINE, KEROSENE, DIESEL, ETC…, AND DO NOT USE IN EXPLOSIVE ATMOSPHERES. FAILURE

TO FOLLOW THIS NOTICE MAY RESULT IN SERIOUS INJURY AND/OR PROPERTY DAMAGE AND WILL

VOID THE PRODUCT WARRANTY. IF IN DOUBT ABOUT YOUR APPLICATION, CONTACT YOUR

STOCKING DEALER OR THE CDS-JOHN BLUE TECHNICAL STAFF AT 1-800-253-2583.

Important Message to Owners / Operators of Pumps

Equipped with Lever Actuated Throw Out Clutches

When using a pump operated by a lever actuated throw out clutch, the rope must be routed by use of eyelet

pulleys such that the rope cannot become entangled with or come in contact with any moving parts of the tractor

or the applicator such as PTO shafts, tractor tires, ground drive units, etc. If eyelet pulleys are not found packed

in with the pump, please contact your selling agent or CDS – John Blue Company (1-800-253-2583)

immediately before any operations are undertaken.

Verification must be made prior to any operation that the rope is clear of any moving parts while not only driving

straight but when making turns either right or left. Verification must be made prior to any operation that the

properly routed rope contains no loops, which might become entangled with any part of the equipment or

operator.

At no time should the rope be attached to any clothing worn by or to any body parts of the operator

such as hands, arms, legs, etc.

We fully understand these are normal precautions owners / operators should take prior to and while operating

equipment. However, we wish to remind you that failure to comply with all safety regulations regarding

instructing operators in the use of moving equipment and actual operation of the equipment may lead to serious

injury and possible death.

This manual has been prepared and illustrated to assist you in the maintenance of your CDS – JOHN BLUE

PUMP. Enter your serial number and the date of the purchase in the space provided below for future reference

in service information or for ordering parts. Because our engineering department is constantly improving

products, we reserve the right to make design and specification changes without notice.

Model Number: ________________ Serial Number: ________________ Purchase Date: ____ ____________

To The Owner

© 2013 CDS-John Blue Co.

2

Page 3

TABLE OF CONTENTS

Safety Precautions …………………………………………………………………………………… …………… 2

Note to the Owner ………………………………………………………………………………… ………………. 2

Table of Contents …………………………………………………………………………………………….……. 3

Pump Specifications …………………………………………………………………………………… ….……… 3

Introduction ………………………………………………………………………………………………….……… 4

Installation …………………………………………………………………………………………………..……… 5

Pump Setting ……………………………………………………..………………………………………….....…. 6

Initial Start-Up of Pump ……………………………………………….…………………………………….……. 8

Pump Calibration …………………………………………………….………………………………………….... 8

Pump Accuracy ………………………………………………………………………………………… …………. 8

Maintenance ……………………………………………………………………………..……………………..….. 9

Storage …………………………………………………………………………..…………………………………. 9

Service Maintenance ………………………………………………………………..………………… ………..… 10

Crankcase Disassembly ………………………………………………………… ………….………………..…… 12

Parts List NGP-6050 & NGP-7050 [Single Piston] ………………………………………………………….…. 14

Parts List NGP-8050 & NGP-9050 [Double Piston] ……………………………………………..…………….. 16

Parts List for Double Adjustable Double Piston ………………...………………………………..…………….. 18

Parts List Optional Clutch ……………………………………………………………………………………...…. 19

Dimensional Footprints …………………………………………………………… …………………….………… 22

Trouble Shooting …………………………………………………………………………………………....…….. 23

Warranty ……………………………………………………………………………………………………....……. 24

PUMP SPECIFICATIONS

Universal Specifications

Operating Pressure: MAX 120 PSI

Operating Speed: MAX 450 RPM

Rotation: Clockwise or Counter-clockwise

Drive: No. 50 Roller Chain

Crankcase Lubrication: SAE 90 Gear Oil

Grease Zerks: Multipurpose Grease

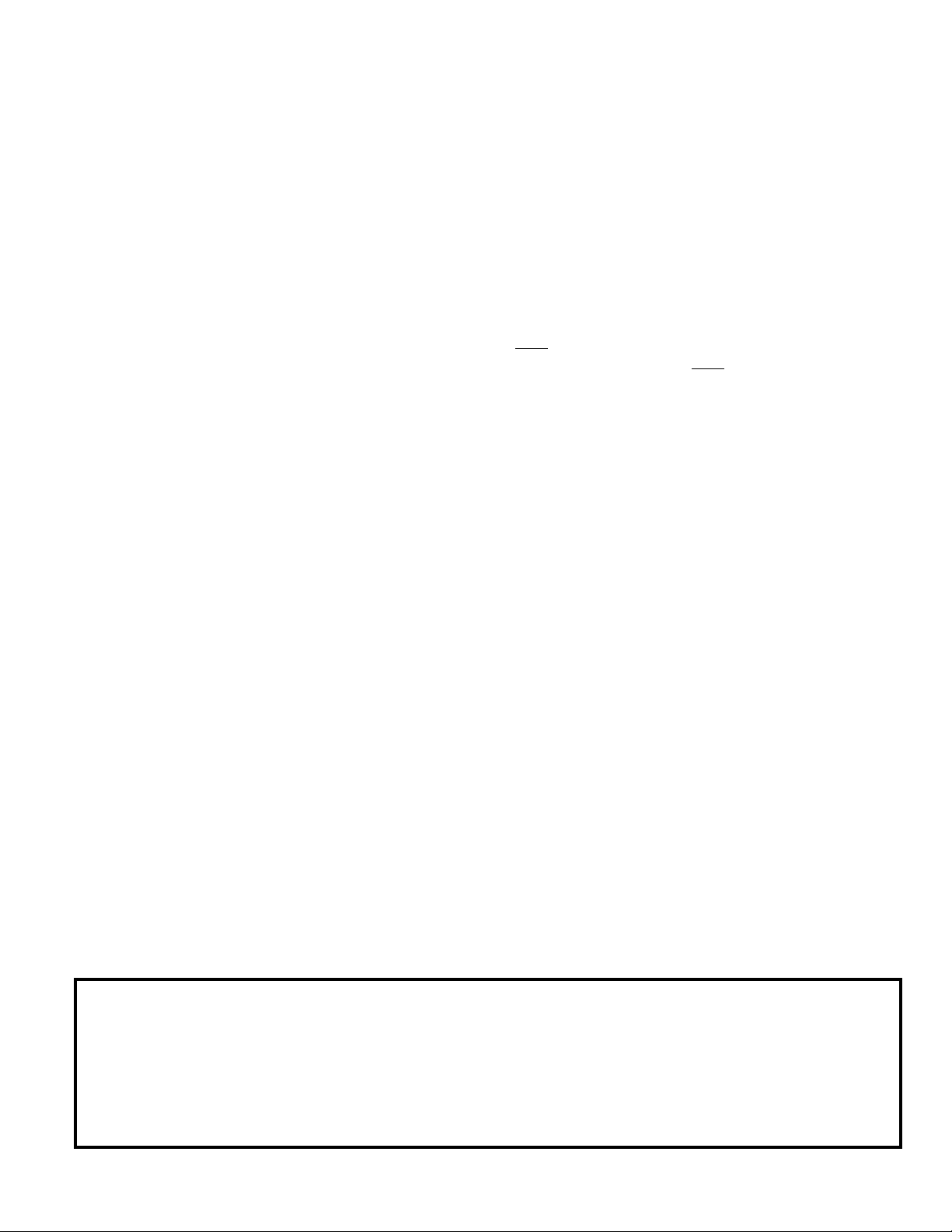

Model Specifications

Pump Series: NGP-4055 NGP-5055 NGP-6050 NGP-7050 NGP-8050 NGP-9050

Output Volume 10.2 20.4 21.0 34.2 42.0 68.4 Max Gal/Min

Output Disp. .023 .046 .047 .076 .093 .152 Max Gal/Rev

Required H.P. __ __ 2.25 3.00 4.50 6.00 Theoretical

Physical Dims. 10x16x9 14x16x9 10x15x9 10x19x11 14x15x11 14x19x13 W x L x H (in.)

Weight __ __ 65 105 125 155 Lbs.

Crankcase Oil Cap. 0.5 2.5 0.5 1.5 2.5 5.4 Pints

Inlet/Outlet Ports 1” 1” 1-1/2” 1-1/2” 1-1/2” 1-1/2” Female Pipe Thd

Optional Flanges 200 200 220 220 220 220 Flange Size

W

L

H

© 2013 CDS-John Blue Co.

3

Page 4

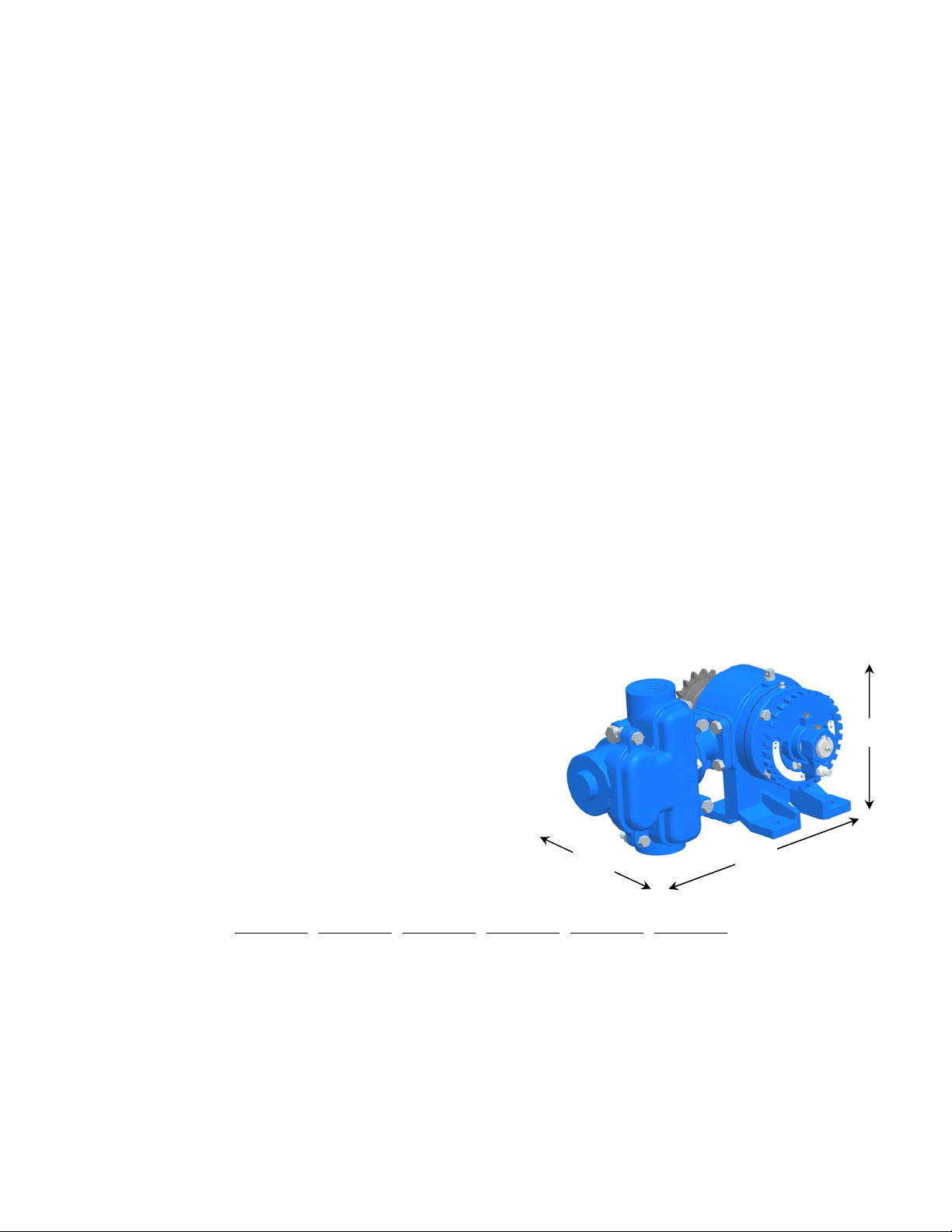

INTRODUCTION

The NGP series pump is a positive displacement variable stroke metering pump. It is specifically designed to

accurately meter liquid fertilizer solutions. The pump’s construction is of rigid thick walled cast iron cylinders

and manifolds for durability and long life. The check valves, piston, and rod are constructed of stainless steel for

improved corrosion resistance. Optionally, the pump may be purchased with stainless cylinders and manifolds.

The NGP series pump functions as a positive displacement metering device which operates in direct relati on to

the ground speed through a ground drive system (model number DRV-3xxx). The application rate can be set

(covered under the “Pump Setting” section) before application begins and the GPA (gallons per acre ) application

will be accurate regardless of the varying speeds of the drive mechanism.

The NGP series pump may also be used with one of our hydraulic drive kits (model number VRH-xxx-xx) to

provide variable rate application when used with one of many different control systems. The pump provides

several advantages over other types of pumps such as: suction capability from saddle tanks, stable settings that

do not vary with temperature, and proven durability and longevity.

The NGP series pump is designed to control the overall gallons of solution metered over an acre, independent

of downstream discharge pressure (120 psi max). The only function of the flow divider or row orifices in a CDS

– John Blue pump system is to divide liquid accurately row to row - not to meter the overall application rate.

Optional 220 size

Flanges Shown

Rod Packing

Piston

Discharge Valves

Top Position

(Stiff Spring,

Flat Side In)

Not Visible

Piston

Packing

Discharge Port

1-1/2” NPT

Suction Valves

Bottom Position

(Weak Spring,

Flat Side Out)

Suction Port

1-1/2” NPT

Sprocket

Valve Access

Cover

Oil Fill Plug

Vent Plug

Oil Level Plug

Rear - Not Shown

Oil Drain Plug

Rear - Not Shown

Pump Setting

Hub & Pointer

Packing Grease Zerk

© 2013 CDS-John Blue Co.

4

Page 5

INSTALLATION

MOUNTING

The NGP pump should be mounted on a rigid base in a horizontal position.

The mount position should allow for a straight drive chain and proper tightness.

Chain idlers should be installed on the slack side of the drive chain.

The supplied rubber washers are installed between the pump and mount.

Caution should be exercised on implements with wings or folding members to assure that sufficient area is

allowed around the pump and plumbing to not cause contact or binding.

Verify that the rear tractor wheel will clear the pump during sharp turns.

The oil vent plug should be installed in the oil fill located on top of crankcase.

SUCTION PLUMBING

An adequately sized 30 mesh strainer should be installed on the suction side of

the pump and should be checked at each tank filling for debris, which could

cause suction restriction, starving the pump of flow.

The NGP pump does produce suction to pull fluid from the tank; however, it is

recommended to mount the pump level or below the tank, if possible, to assure the most effective and

quickest prime.

Install the process fluid suction line as straight as possible avoiding restrictions from kinks or e x tremely

sharp turns. This will ensure even flow during maximum pump output.

Quick connect fittings should be checked and double checked to verify that no leakage is present. Quick

connects, although commonly necessary, quite often can produce a suction leak if installed in a bind

allowing air to enter the pump, causing loss of prime and / or reduction in pump output.

It is recommended that suction line hoses be double clamped. Again, this is an area that can produce a

suction air leak into the pump, even if no drip from the hose is present.

DISCHARGE PLUMBING

It is not recommended to install a discharge strainer as these could clog with debris causin g significant

discharge pressure and possible system damage in positive displacement pump applications.

Flow dividers may be installed either directly on top of the discharge port or remote mounted.

Orifice applications must pay particular attention for proper orifice sizing for the specified application rate.

It is recommend that applications using a double piston pump with two flow dividers remove the common

manifold and plumb each flow divider independently to each piston to assure accuracy.

On – The – Go Variable Rate applications require that a CDS – John Blue Co. flow divider distribution

manifold be used that will automatically and accurately adjust for varying on the go rate changes.

WARNING: The flow range of a NGP pump far exceeds the flow curve of a single orifice operating below

120 psi. For Example: An orifice application at 30 psi discharge pressure for a rate of 20 GPA @ 4 mph will

produce 422 psi when the rate is adjusted to 50 GPA and ground speed increased to 6 mph.

© 2013 CDS-John Blue Co.

5

Page 6

PUMP SETTING

The NGP pump output is determined by the drive sprocket ratio and the stroke setting. There are two ways to

find the proper setting for your pump:

1. Using the online flow rate calculator at www.cds-johnblue.com .The icon is on the

right-hand side of the page, and there is a mobile version available here:

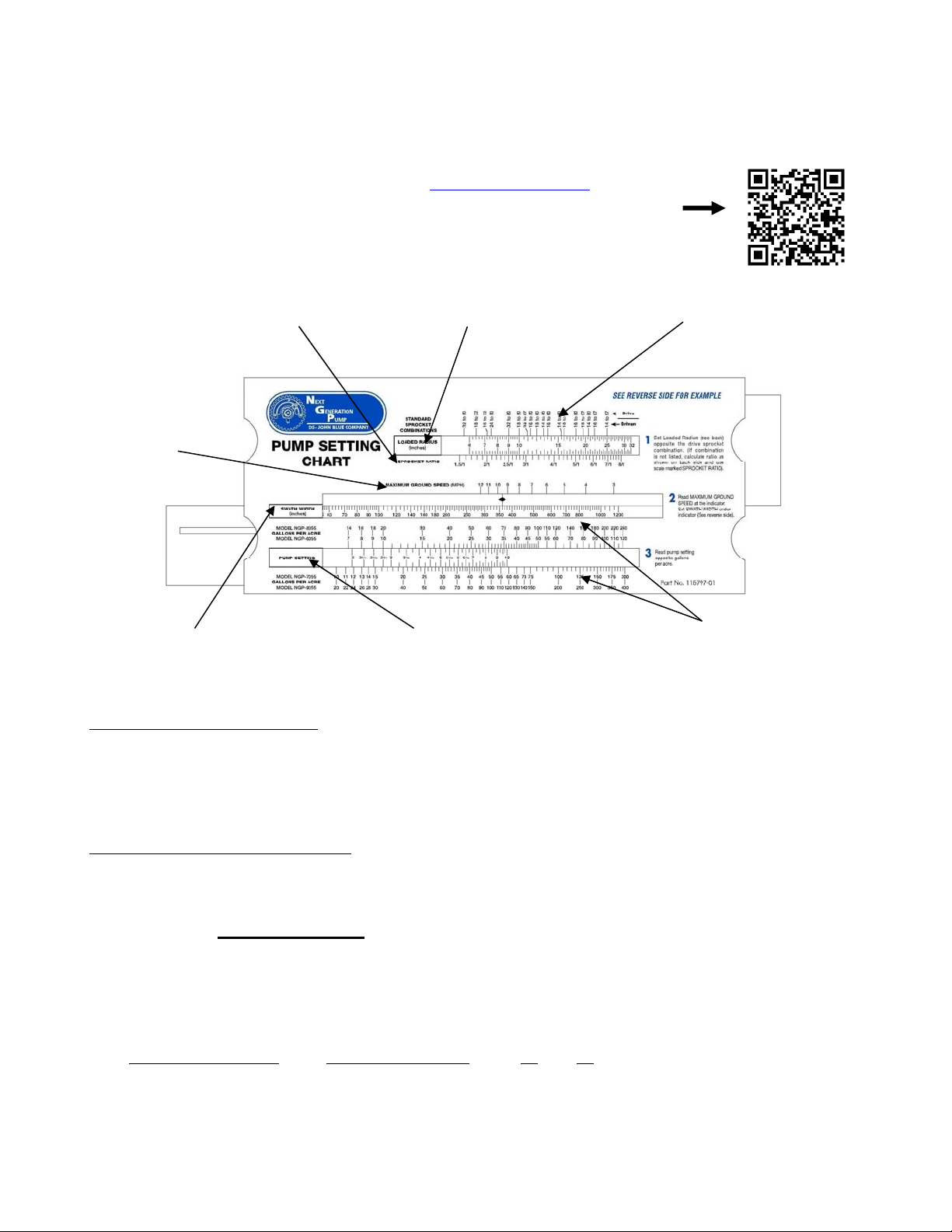

2. Using the slide chart (115698-91) supplied with the pump – follow the example below:

MAXIMUM

GROUND

SPEED

SPROCKET

RATIO

LOADED RADIUS

STANDARD SPROCKET

COMBINATIONS

SPROCKET RATIO

Standard Sprocket Combinations

Standard sprocket combinations may be used for equipment with only one chain from the ground or press wheel

sprocket to the pump sprocket. For example: an applicator with a 60 tooth drive sprocket on the tire driving a

16 tooth driven sprocket on the pump can use the 16 to 60 mark on the slide chart.

Non-Standard Sprocket Combinations

If you are using sprocket combinations with multiple sprockets, such as with a jack shaft, use the following

formula to determine sprocket ratio:

For example: an applicator with a 50 tooth on the drive wheel, driving to a 24 tooth on the jack shaft, then a 36

tooth on the jack shaft driving up to a 16 tooth pump driven sprocket, would yield a 4.69 drive ratio.

Set the sprocket ratio on the slide chart using the 4.69 calculation for the example above.

SWATH WIDTH

Drive Sprocket

Driven Sprocket

50 T (@ Drive Wheel) 36 T (@ Drive Shaft) 50 36

24 T (@ Driven Shaft) 16 T (@ Driven Pump) 24 16

X X

PUMP SETTING

= Sprocket Ratio

=

= 4.69 Sprocket Ratio

GALLONS PER ACRE

© 2013 CDS-John Blue Co.

6

Page 7

LOADED RADIUS

The measurement for the loaded radius must be from the Manufacturer of the tire or be measured under loaded

conditions. The loaded radius tire is always the tire that has the first drive sprocket attached to its hub.

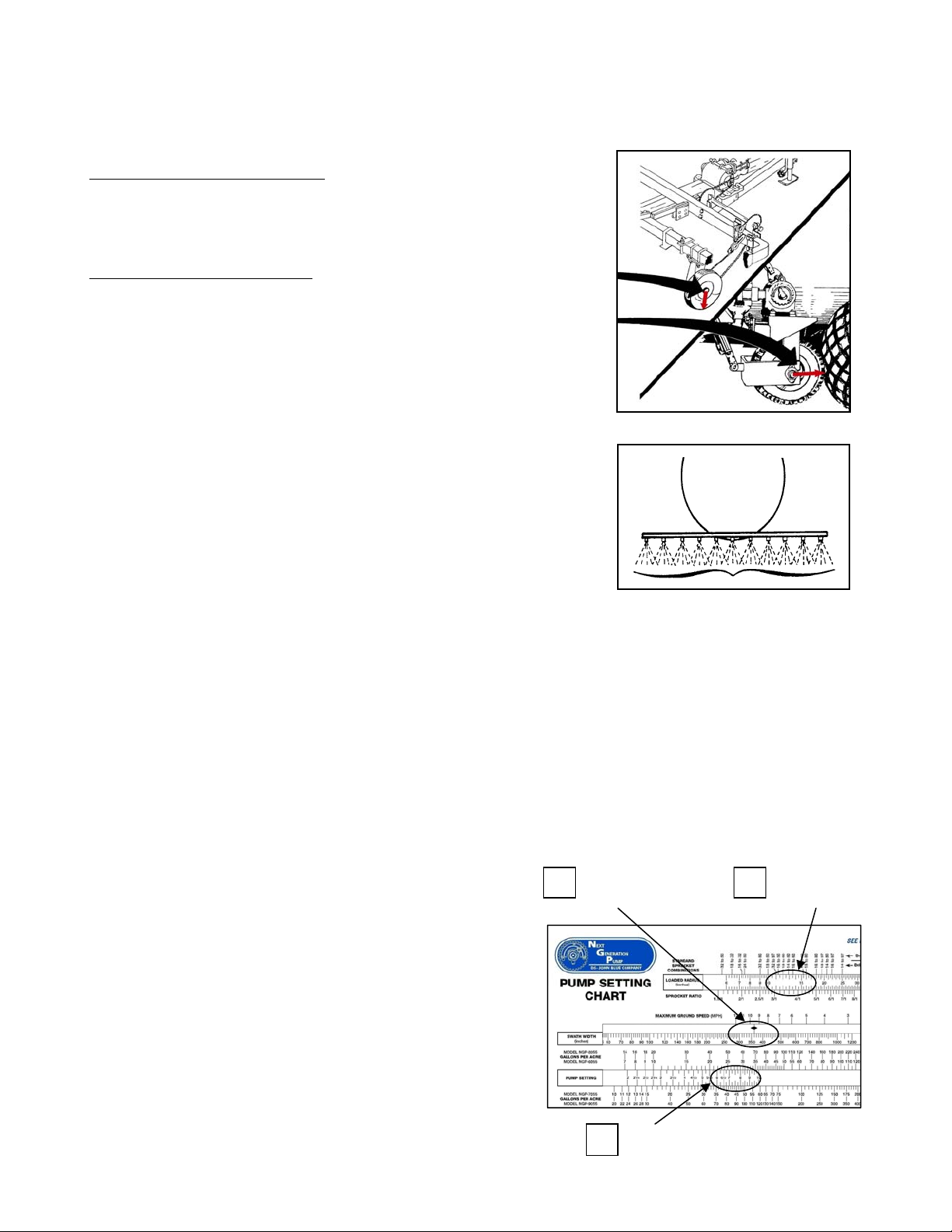

Ground Wheel Drive Arrangement

Measure the loaded radius from the center of the hub to the bottom of the

tire where it rests on the ground.

Press Wheel Drive Arrangement

Measure the loaded radius from the center of the press wheel shaft to

where the wheel rests against the tire. The press wheel must be engaged

for normal operation to give an accurate reading.

SWATH WIDTH

To determine the swath width, count the number of outlets and multiply by

the distance (inches) between any two outlets, nozzles, or shanks. This

assumes that all outlets are equally spaced, if outlets are not evenly

spaced, figure the entire length of the boom or toolbar from end nozzle

to end nozzle and allow for coverage beyond the ends.

For example, an 11 row boom at 30” would have a swath width of 330”

SETTING THE PUMP

Read the desired pump setting from the bottom scale on the pump setting chart. Loosen the setting pointer nut

and rotate the setting hub until the setting pointer is over the desired setting. The setting wrench will facilitate

rotation of the setting hub. Once proper pump setting is achieved, tighten the setting pointer nut.

EXAMPLE:

An applicator is equipped with a NGP-6050 series pump, 11L x 15” tires, a 60 tooth drive sprocket, and a 16

tooth pump driven sprocket. It is desired to apply 33 gallons per acre on a 360” swath. The following steps will

determine correct pump setting:

SET SWATH WIDTH

AT DIAMOND

SET LOADED RADIUS

1 2

AT SPROCKET RATIO

1. Set loaded radius of tire (13.5”) under the sprocket

combination of 16 to 60 in the top window.

2. Set the swath width (360”) under the diamond in the middle

window.

3. Read that the pump setting is approx. 9 at 33 gallons per

acre on the NGP-6055 scale in the bottom window.

4. Set the pump to setting 9 to achieve 33 gallons per acre

Note: The max. ground speed is read above the diamond as

READ PUMP

approx. 9 mph to avoid exceeding 450 pump rpm.

© 2013 CDS-John Blue Co.

7

3

SETTING

Page 8

INITIAL PUMP START UP

Verify that all installation guidelines have been followed as outlined in the installation section of this manual.

Fill the tank full of water to test for leaks in the plumbing system and output of the pump.

Fully open the valve at the tank allowing water to fill the suction line and check for leaks.

Set the pump to pump setting 10.

Before installing nozzles or orifices (if used), prime the pump and purge the system of air and foreign

material by slowly pulling the applicator 100 to 200 yards.

Turn off the valve at the tank, open strainer, check for foreign material and clean the screens.

The CDS – John Blue flow divider is automatic and requires no calibration; however, if nozzles or orifices

are used, verify that the orifices are sized properly as to not produce high discharge pressure.

Pull the machine over known acreage and verify the application accuracy with water prior to field

application of chemical. Note that tank level marks can give false readings if read on uneven ground.

PUMP CALIBRATION

The NGP pump is calibrated from the factory; however, if the setting scale, hub, or pointer is replaced, use the

following procedure to calibrate the pump output with scale readings.

Remove the valve cover and outboard cylinder (see maintenance section).

Set the pump on pump setting 5 for all pump sizes.

Rotate the crankshaft until the piston is as far in as it will go. Measure the distance from the end of the

piston to the inboard cylinder flange. Rotate the crankshaft until the piston is as far out as it will go and

measure again to the same place. The difference in length is the stroke length, which at pump setting

5 should be 9/16” for the NGP-4050, 5050, 6050, & 8050, or 15/16” for the NGP-7050 & 9050.

If the distance is less than the required amount, reset the pointer at a higher setting, if it is greater; reset

the pointer at a lower setting. Repeat this procedure to obtain the required measurement.

Once accomplished, loosen the setting scale screws until the 5 is directly under the pointer and secure the

scale in position with the three scale screws.

Replace the outboard cylinder and valve cover, making sure that the valves are in their proper orientation

as covered under the maintenance section.

PUMP ACCURACY

A catch test may be performed to verify accuracy (not as a calibration method) by priming the pump and

catching all of the pumped fluid from the discharge for a known number of revolutions. See chart below:

Pump Series Pump Setting # of Revolutions Total Pump Output

NGP-4050 8-1/4 10 1-1/2 Pints

NGP-5050 8-1/4 10 3 Pints

NGP-6050 8 10 3 Pints

NGP-7050 8-1/4 10 5 Pints

NGP-8050 8 10 6 Pints

NGP-9050 8-1/4 10 10 Pints

© 2013 CDS-John Blue Co.

8

Page 9

MAINTENANCE

Check oil daily and fill crankcase with a quality grade SAE 90 weight gear oil. Oil level must be visible at oil

level check plug on back of crankcase. The level plug is located at same height as the crankshaft.

Lubricate all grease zerks on roller chain sprocket spacer, outboa rd cover plate, crankshaft end, and at

stuffing box flange daily. Fill zerks until grease is visibly seen seeping from mating parts. For the stuffing

box flange zerk, grease will be seen seeping from the vent on the opposite side of the flange.

Pump oil should be changed seasonal or in extreme use conditions.

Visually inspect sprocket and drive chain daily for excessive wear or corrosion. Lubricate chain regularly to

reduce corrosion. Chain alignment must be straight.

STORAGE

IMPORTANT – KEEP AIR OUT AND KEEP FROM FREEZING

Keep air out of the pump! This is the only way to prevent corrosion. Even for short periods of storage, the

entrance of air into the pump causes RAPID and SEVERE CORROSION. Freezing temperatures can cause the

fluid or water to freeze internally to the pump, which can cause severe damage to the wet-end castings.

OVERNIGHT

Suspension fertilizer must be flushed from the pump for ANY storage period. For Clear Liquids:

1. Steady or rising temperatures: leave pu mp and hoses filled with solution. DO NOT DRAIN nor admit air

to the pumps.

2. Cooling weather: (solution likely to salt out), fill pump with water and leave filled. DO NOT admit air.

3. Freezing temperature: fill pump with RV-antifreeze and leave filled, DO NOT admit air.

ONE TO TWO WEEKS

ACCEPTABLE: Flush pump thoroughly with 5 to 10 gallons of a solution that will neutralize the liquid last

pumped (refer to that manufacturer’s instructions). Fill with clean water and DO NOT DRAIN.

Keep pump sealed to exclude air. If freezing temperatures are remotely possible, the winter

storage procedure (see below) must be used to avoid damage to the pump castings.

PREFERRED: Flush pump as detailed above. IMMEDIATELY fill all passages in pump with straight RV-

antifreeze which contains a rust inhibitor. Place 1-1/2” NPT PVC plugs in the suction and

discharge fittings to keep pump full and exclude air.

WINTER STORAGE

1. Flush pump as detailed above.

2. With pump set on 10, draw in straight RV-antifreeze until the discharge is clean. If system

utilizes a flow divider (FD), pump the RV-antifreeze through the FD manifold until it is seen in the

discharge lines. Fill pump and plug suction and discharge fittings of pump to retain RV-antifreeze.

© 2013 CDS-John Blue Co.

9

Page 10

SERVICE MAINTENANCE

Proper maintenance of the NGP pump will ensure a service life for many years. Rebuilding and / or servicing

check valves, piston flange packing, piston rod packing, and crankcase compone nts is an economical way to

ensure optimum service. This type of service is simple, and can be done by almost all end users. The parts list

and schematic section shows the position of all service kit items, which includes all seals, packing, and gaskets.

Gasket kits and component parts can be ordered through any authorized CDS – John Blue distributor.

CLEAN AND INSPECT CHECK VALVES

Remove the valve cap exposing all 4 check valves. Take care in

removal to notice the orientation of the valves. Discharge valves

use a tighter spring and are on top, flat side in. Suction valves use

a weaker spring and in the bottom, flat side out.

Valves should be removed by hand, do not use a screw driver or

pry-bar as damage can result. Push each valve disc off its o-ring

seat ensuring that the spring reseats each disc evenly and that no

debris is present. Inspect the o-rings for cuts or cracks which

could allow air to enter or cause the discs to not seat properly.

Check the port o-rings positioned near the top and bottom of the

inboard cylinder in an oval shaped groove. This o-ring should not

be removed unless visible damage is present. The o-rings should

be fully installed in the groove with no cuts or cracks. Once all valves are checked for debris or damage and

o-rings are in position, re-install valves in proper orientation, replace the cover, an d tighten the bolts evenly.

PISTON PACKINGS

With valve cover removed, remove the ½” long bolts securing the

outboard cylinder. Remove the outboard cylinder exposing the

piston – gaskets, washer, and packing.

Remove the first piston – packing, gasket, and washer; notice the

orientation of the packing lip. Remove the second piston gasket

and packing from the inboard cylinder; again noticing the

orientation of the packing lip.

Inspect the packing and replace if necessary, gaskets should

always be replaced once removed. The piston - packing should

be pliable and without cracks or nicks to perform properly.

Clean the cavities of both the inboard and outboard cylinder as

well as the valve cap while disassembled. Discoloration of the

plunger and / or lateral scoring of the piston can be deceiving, but

not necessarily detrimental.

Inspect piston for deep grooves, radial scoring, or severe abrasion. The best method is by feel.

Assemble in reverse manner taking care for proper orientation of the piston – packing, gaskets, and washer.

Suction Valves

Discharge Valve

Piston – packing

Piston – gasket

Piston – washer

Piston – gasket

Piston - packing

© 2013 CDS-John Blue Co.

10

Page 11

PISTON ROD PACKINGS

The rod packing consists of 2 sets of self-tightening ‘V’ rings which seal around the piston rod to prevent

pumped fluid from leaking and protect the crankcase from contamination. Virtually any leakage of the pumped

fluid through the vent in the side of the stuffing box is an indication that these rod packing need replacement.

However, it is not uncommon for oil to drip form this drain.

Removal of rod packing:

With the valve cap and cylinders removed, remove the piston nut

and piston by rotating piston counter-clockwise, use a belt wrench

Piston Rod Packing

or cloth nearest to the nut end to prevent damage to the piston.

Remove the stuffing box and gasket which house the wet-end

piston rod packing.

Remove the snap ring from the end of the stuffing box, allowing

the washer, spring, and washer to slip out. The L-1031-2 insert

should not be removed from the stuffing box. The rod packing set

can be removed with a hook or screwdriver by prying the multipiece rod packing set out of the cavity. Once removed it must be

replaced with a new service rod packing set.

There is no snap ring on the second set closest to the crankcase

located in the crosshead guide. This set may be removed in the

same manner as the first set. There is a secondary o-ring rod seal

located at the bottom of the set which also should be replaced.

Inspect the piston rod for any deep scoring and replace if necessary. A polished wear pattern may be

evident and is not detrimental; however, deep grooves indicate the piston rod assembly should be replaced.

The crosshead guide may be removed from crankcase to allow for inspection of the connecting rod bu shing.

If damaged or slop is present, this should be replaced.

Re-assembly and replacement of rod packing:

Carefully re-install the crosshead guide and gasket and bolt to

crankcase, if removed.

Lubricate piston rod and install o-ring first, then carefully install the

first ‘V’ ring packing set. The set consists of a bottom adapter, 4

rings, and a top adapter. Each component should be inserted one

at a time and pressed firmly in place. The 4 rings have a ‘V’ shape

and are oriented so as the ‘V’ point is pointed towards the

crankcase, for both sets. Install the washer and spring.

Install second set in the stuffing box in a similar manner, there is

no secondary o-ring required in this set. Install the washer, spring,

then washer and hold in place with snap ring.

Lubricate piston rod and stuffing box, then slide stuffing box carefully back over rod, being extremely careful

to push straight on the piston rod so as the rods threads do not damage the ‘V’ ring set.

Re-assemble piston, inboard, and outboard cylinder in reverse manner. Continue with valves in proper

orientation, valve cover, and secure all bolts evenly.

Finally, lubricate the stuffing box grease zerk until grease seeps out of the stuffing box vent hole.

© 2013 CDS-John Blue Co.

11

Page 12

CRANKCASE DISASSEMBLY

Major pump repair requires some in-depth knowledge on working tolerances for internal parts. We recommend

that you contact your nearest CDS-John Blue sales and service dealer for best results in major pump repair.

Shaft oil seals have been upgraded from previous L & LM series pumps to include a wiper ring. The oil seals

are enclosed in a greaseable cavity to flush debris from around the seal, which is a contributing factor to premature oil seal failure. The oil seals may be replaced by following the OUTBOARD & INBOARD

COMPONENTS section below. All instruction and visual representation in this section is shown with wet-end

components removed which is covered in the maintenance sections preceding this section.

OUTBOARD COMPONENTS

Remove the retaining ring, pump setting hub, and pointer.

Remove the flange cover exposing the oil seal in its cavity.

Remove the oil seal which may be done with a screw

driver, taking care not to scar the internal shaft or housing.

Inspection of the stroke setting sleeve should be made for

wear at the seal location as well as the flange gasket for

tears prior to re-assembly.

INBOARD COMPONENTS

Remove the sprocket from shaft and sprocket spacer,

inspecting the o-ring and thrust washer for wear, cuts, or

damage and replace as necessary.

Remove the cover plate. It may be necessary to remove

any marks in the crankshaft from the sprocket / spacer

set-screws with a light emery cloth in order for the cover

plate to slip off with the bearing.

Remove the oil seal with a screw driver, taking care not to

scar the housing or shaft.

If only the oil seal is being replaced, the cover plate should be re-installed first, then the oil seal. Inspect

the shaft for wear at the seal location, as well as the cover plate gasket for tears, replace as necessary.

INTERNAL COMPONENTS

The following inspection points should be made prior to disassembly if required:

With inboard and outboard components removed, examine for sediment in the crankcase. A small

amount of metal wear and ‘grit’ in the oil is normal, large sediment may require further disassembly.

Check for metal and/or fertilizer discoloration to the oil. If fertilizer is present, the crankcase should be

disassembled and each component examined for rust pitting or deterioration.

Holding the crankcase firmly, take hold of the connecting rod and push / pull. If you feel obvious end

play, disassemble all components and inspect for wear, particularly the eccentrics and connecting rod.

© 2013 CDS-John Blue Co.

12

Page 13

INTERNAL DISASSEMBLY

Reference to the schematic section is recommended prior to disassembly of the internal crankcase components

to familiarize yourself with components. The wet-end components, inboard, and outboard components should

be removed prior to internal disassembly as outlined in previous sections of this manual.

Supporting the piston rod with a wood block, locate the

crosshead pin, which connects the piston rod and connecting

rod and carefully drive pin out with a hammer and punch.

Inspect the connecting rod bushing for damage and replace as

necessary during re-assembly.

Slide the outer eccentric and eccentric pin out of the crankcase.

The connecting rod can then be removed by carefully sliding it

out the side of the pump at an angle.

The shaft can then be removed as shown with the inner

eccentric still in place.

Note: Double piston pumps will require the stroke transfer

sleeve to be removed with the shaft exposing the

second piston eccentric and connecting rod for removal.

The stroke setting sleeve is then removed.

The eccentric pins may slide out during any

part of this process and should be

accounted for, single pumps utilize 1,

double pumps utilize 3 [ref schematic].

Examine all components, giving more

attention to ones showing “galling” than to

ones which are undersize, yet smooth.

CRANKCASE RE-ASSEMBLY

All components in the gasket kit should be used during re-assembly.

Reassemble the crankcase in reverse order.

When assembling the shaft, oil the shaft o-ring and carefully insert into stroke setting sleeve.

It is extremely important that all eccentric pins engage appropriate mating slots.

Coat all bolts threads with gasket sealant before installing in crankcase.

© 2013 CDS-John Blue Co.

13

Page 14

PARTS LISTING – NGP- 405x / 605x / 705x Series

NGP-4050 NGP-6050 NGP-7050 NGP-4050 NGP-6050 NGP-7050

ITEM

1 KEY L-1020 L-1020 L-1020 55 STUFFING BOX 116070-01 115790-01 115690-01

2 SPROCKET RC50-18T 112661-01 112661-01 112661-01 -S STAINLESS N/A 115790-01S 115690-01S

3 5/16x3/8 SETSCREW 90532 90532 90532 57 STUFF. BOX INSERT 116068-01 L-1031-2 L-1031-2

4 GREASE FITTING H-28 H-28 H-28 -S STAINLESS NOT USED NOT USED NOT USED

5 5/16x3/8 SETSCREW 90532 90532 90532 58 PACKING - SNAP RING 112698-01 L-1042 L-1042

6 SPROCKET SPACER 115625-01 115625-01 115625-01 59 O-RING S-316 S-316 115604-01

7 O-RING S-316 S-316 S-316 -S STAINLESS N/A 104824-01 115612-01

8 THRUST WASHER 115626-01 115626-01 115626-01 -U FUMIGANT N/A 104824-01 115612-01

9 5/16x1 HEX BOLT 90637 90637 90637 60 O-RING S-316 L-3031 A-2848

10 OIL SEAL 115621-01 115621-01 115621-01 -S STAINLESS N/A 114768-01 114870-01

11 COVER PLATE 115723-01 115723-01 115623-01 -U FUMIGANT N/A 114768-01 114870-01

12 BEARING L-3019 L-3019 L-3019 61 DISCHARGE VALVE 116127-91 115707-91 115607-91

13 CONNECTING ROD L-1008-A L-1008-A 113630-01 62 SUCTION VALVE 116126-91 115706-91 115606-91

14 JOURNAL BEARING L-928 L-928 113629-01 63 INBOARD CYLINDER N/A 115701-02 115601-02

15 ROD BUSHING 113588-01 113588-01 113588-01 -F FLANGED 116071-01

16 ROD PIN 105895-01 105895-01 105895-01 -S STAINLESS N/A 115701-02S 115601-02S

17 ECCENTRIC - OUTER L-1013-A L-1013-A 113633-01 64 3/8 LOCK WASHER 93024 93024 93024

18 ECCENTRIC - INNER L-1015 L-1015 L-3017 -S STAINLESS N/A 93025 93025

19 TRANSFER SLEEVE NOT USED NOT USED NOT USED 65 3/8 HEX NUT 92024 92024 92024

20 PISTON ROD ASM 116078-91 115712-91 105900-91 66 PLUNGER – PACKING 112696-01 L-1045-V L-1045-V

21 ECCENTRIC PIN L-3004 L-3004 L-3004 -B BUNA PACKING N/A L-1045-A L-1045-A

22 WOODRUFF KEY 108093-01 108093-01 A-4333 67 PLUNGER – GASKET 112712-01 L-1098 L-1098

23 CRANKSHAFT 115614-01 115614-01 115614-01 -U FUMIGANT N/A 114769-01 114769-01

24 O-RING L-1022 L-1022 L-1022 68 PLUNGER – WASHER 112695-01 L-1044-A L-1044-A

25 GREASE ZERK 115647-01 115647-01 115647-01 69 PLUNGER 112700-91 103290-91 112816-91

26 SETTING SLEEVE 115718-01 115718-01 115618-01 70 PLUNGER – LOCKNUT 92125 L-1047 L-1047

27 BEARING L-1007-A L-1007-A L-1007-A 71 VALVE COVER 116073-01 115703-01 115603-01

28 GASKET L-1006 L-1006 L-3002 -S STAINLESS N/A 115703-01S 115603-01S

29 VENT PLUG S-350 S-350 S-350 72 NOT USED

30 NAME PLATE 111958-01 111958-01 111958-01 NOT USED

31 DRIVE SCREW A-3557 A-3557 A-3557 73 3/8 X 1-1/2 HEX BOLT 90911 90911 90911

32 OIL PLUG C-431-B C-431-B C-431-B -S STAINLESS N/A 90654 90654

33 FLANGE COVER 115724-01 115724-01 115724-01 74 OUTBOARD CYL. 116072-01 115702-01 115602-01

34 5/16 X 1 HEX BOLT 90637 90637 90637 -S STAINLESS N/A 115702-01S 115602-01S

35 SETTING HUB 115627-01 115627-01 115627-01 75 1/2 HEX BOLT 90704 90704 90705

36 SCREW A-368 A-368 A-368 -S STAINLESS (2 BOLTS) N/A 90693/90687 90693/90687

37 SNAP RING 115791-01 115791-01 115791-01 76 NOT USED

38 3/8 SELF-LOCK NUT A-3097 A-3097 A-3097 NOT USED

39 SETTING POINTER 115628-01 115628-01 115628-01 77 NOT USED

40 SETTING SCALE 115645-01 115645-01 115645-01 NOT USED

41 3/8x2-1/4 CARR.BOLT 115646-01 115646-01 115646-01 NOT USED

42 OIL SEAL 115622-01 115622-01 115622-01 78 NOT USED

43 CRANKCASE 115720-01 115720-01 115620-01 NOT USED

44 CROSSHEAD GASK. 115711-01 115711-01 115611-01 79 SPROCKET KEY 106493-01 106493-01 106493-01

45 1/2 HEX NUT 92029 92029 92029 A RC50-18T SPRKT ASM 106532-01 106532-01 106532-01

46 NOT USED -R RC40-18T SPRKT ASM 113907-01 113907-01 113907-01

47 HEX BOLT 90637 90637 90860 B SPRKT. SPACER ASM 115624-91 115624-91 115624-91

48 CROSSHEAD GUIDE 116069-01 115700-01 115600-01 C CONN. ROD ASM L-1008-B L-1008-B 113645-91

49 STUFF. BOX GASK. 116075-01 115610-01 115610-01 D FLANGE COVER ASM 115725-91 115725-91 115725-91

50 O-RING 116074-01 111943-01 111943-01 F SET POINTER ASM 115630-91 115630-91 115630-91

51 PACKING 'V' SET L-1113 L-1109 L-1109 G GASKET KIT 116134 115788 115688

52 PACKING WASHER 112694-01 L-1041 L-1041 H OPERATORS KIT 115787 115787 115787

53 PACKING SPRING 112697-01 L-1063 L-1063 N/S SLIDE CHART 115698-91 115698-91 115698-91

54 GREASE ZERK H-30 H-30 H-30 N/S SETTING WRENCH 115631-01 115631-01 115631-01

PART DESCRIPTION PART # PART # PART #

-K NO SPROCKET NOT USED NOT USED NOT USED 56 INBOARD CYL. GASK. 116076-01 115710-01 115710-01

-R SPROCKET RC40-18T 113905-01 113905-01 113905-01 -U FUMIGANT N/A 104826-02 104826-02

-S STAINLESS N/A 92030 92030 -K NO SPROCKET NOT USED NOT USED NOT USED

-U FUMIGANT N/A 104828-02 104828-02 E SET HUB ASM 115629-91 115629-91 115629-91

@ CROSSHD GUIDE USE 4 “V”s N/A N/A -S GASKET KIT - SS N/A 115788-S 115688-S

-U FUMIGANT N/A L-1109-U L-1109-U -U GASKET KIT - FUM N/A 115788-U 115688-U

ITEM

PART DESCRIPTION PART # PART # PART #

115701-02FLG 115601-02FLG

© 2013 CDS-John Blue Co.

14

Page 15

NGP- 405x / 605x / 705x SERIES

220 FLANGE ADAPTERS:

- CAST IRON PUMPS USE 115701-02FLG OR 115601-02FLG

- STAINLESS USE 116083-01S SCREWIN ADAPTERS

© 2013 CDS-John Blue Co.

15

Page 16

PARTS LISTING – NGP- 505x / 805x / 905x SERIES

NGP-5050 NGP-8050 NGP-9050 NGP-5050 NGP-8050 NGP-9050

ITEM

1 KEY L-1020 L-1020 L-1020 55 STUFFING BOX 116070-01 115790-01 115690-01

2 SPROCKET RC50-18T 112661-01 112661-01 112661-01 -S STAINLESS N/A 115790-01S 115690-01S

3 5/16x3/8 SETSCREW 90532 90532 90532 57 STUFF. BOX INSERT 116068-01 L-1031-2 L-1031-2

4 GREASE FITTING H-28 H-28 H-28 -S STAINLESS NOT USED NOT USED NOT USED

5 5/16x3/8 SETSCREW 90532 90532 90532 58 PACKING - SNAP RING 112698-01 L-1042 L-1042

6 SPROCKET SPACER 115625-01 115625-01 115625-01 59 O-RING S-316 S-316 115604-01

7 O-RING S-316 S-316 S-316 -S STAINLESS N/A 104824-01 115612-01

8 THRUST WASHER 115626-01 115626-01 115626-01 -U FUMIGANT N/A 104824-01 115612-01

9 5/16x1 HEX BOLT 90637 90637 90637 60 O-RING S-316 L-3031 A-2848

10 OIL SEAL 115621-01 115621-01 115621-01 -S STAINLESS N/A 114768-01 114870-01

11 COVER PLATE 115723-01 115723-01 115623-01 -U FUMIGANT N/A 114768-01 114870-01

12 BEARING L-3019 L-3019 L-3019 61 DISCHARGE VALVE 116127-91 115707-91 115607-91

13 CONNECTING ROD L-1008-A L-1008-A 113630-01 62 SUCTION VALVE 116126-91 115706-91 115606-91

14 JOURNAL BEARING L-928 L-928 113629-01 63 INBOARD CYLINDER N/A 115701-02 115601-02

15 ROD BUSHING 113588-01 113588-01 113588-01 -F FLANGED 116071-01

16 ROD PIN 105895-01 105895-01 105895-01 -S STAINLESS N/A 115701-02S 115601-02S

17 ECCENTRIC - OUTER L-1013-A L-1013-A 113633-01 64 3/8 LOCK WASHER 93024 93024 93024

18 ECCENTRIC - INNER L-1015 L-1015 L-3017 -S STAINLESS N/A 93025 93025

19 TRANSFER SLEEVE 115783-01 115783-01 115683-01 65 3/8 HEX NUT 92024 92024 92024

20 PISTON ROD ASM 116078-91 115712-91 105900-91 66 PLUNGER – PACKING 112696-01 L-1045-V L-1045-V

21 ECCENTRIC PIN 112686-01 112686-01 L-3004 -B BUNA PACKING N/A L-1045-A L-1045-A

22 WOODRUFF KEY 108093-01 108093-01 A-4333 67 PLUNGER – GASKET 112712-01 L-1098 L-1098

23 CRANKSHAFT 115681-01 115681-01 115681-01 -U FUMIGANT N/A 114769-01 114769-01

24 O-RING L-1022 L-1022 L-1022 68 PLUNGER – WASHER 112695-01 L-1044-A L-1044-A

25 GREASE ZERK 115647-01 115647-01 115647-01 69 PLUNGER 112700-91 103290-91 112816-91

26 SETTING SLEEVE 115718-01 115718-01 115618-01 70 PLUNGER – LOCKNUT 92125 L-1047 L-1047

27 BEARING L-1007-A L-1007-A L-1007-A 71 VALVE COVER 116073-01 115703-01 115603-01

28 GASKET L-1006 L-1006 L-3002 -S STAINLESS N/A 115703-01S 115603-01S

29 VENT PLUG S-350 S-350 S-350 72 1/2 FLAT WASHER N/A NOT USED NOT USED

30 NAME PLATE 111958-01 111958-01 111958-01 -DR DUAL RATE (CYLS) N/A NOT USED NOT USED

31 DRIVE SCREW A-3557 A-3557 A-3557 73 3/8 X 1-1/2 HEX BOLT 90911 90911 90911

32 OIL PLUG C-431-B C-431-B C-431-B -S STAINLESS N/A 90654 90654

33 FLANGE COVER 115724-01 115724-01 115724-01 74 OUTBOARD CYL. 116072-01 115702-01 115602-01

34 5/16 X 1 HEX BOLT 90637 90637 90637 -S STAINLESS N/A 115702-01S 115602-01S

35 SETTING HUB 115627-01 115627-01 115627-01 75 1/2 HEX BOLT 90704 90704 90705

36 SCREW A-368 A-368 A-368 -S STAINLESS (2 BOLTS) N/A 90693/90687 90693/90687

37 SNAP RING 115791-01 115791-01 115791-01 76 MANIFOLD GASKET N/A 112696-01 112696-01

38 3/8 SELF-LOCK NUT A-3097 A-3097 A-3097 -DR DUAL RATE (CYLS) N/A NOT USED NOT USED

39 SETTING POINTER 115628-01 115628-01 115628-01 77 MANIFOLD N/A 115796-01 115696-01

40 SETTING SCALE 115645-01 115645-01 115645-01 -S STAINLESS N/A 115796-01S 115696-01S

41 3/8x2-1/4 CARR.BOLT 115646-01 115646-01 115646-01 -DR DUAL RATE (CYLS) N/A NOT USED NOT USED

42 OIL SEAL 115622-01 115622-01 115622-01 78 ½ HEX BOLT N/A 115793-01 115693-01

43 CRANKCASE 115780-01 115780-01 115680-01 -DR DUAL RATE (CYLS) N/A NOT USED NOT USED

44 CROSSHEAD GASK. 115711-01 115711-01 115611-01 79 SPROCKET KEY 106493-01 106493-01 106493-01

45 1/2 HEX NUT 92029 92029 92029 A RC50-18T SPROCKET 106532-01 106532-01 106532-01

46 NOT USED -R RC40-18T SPROCKET 113907-01 113907-01 113907-01

47 HEX BOLT 90637 90637 90860 B SPRKT. SPACER ASM 115624-91 115624-91 115624-91

48 CROSSHEAD GUIDE 116069-01 115700-01 115600-01 C CONN. ROD ASM L-1008-B L-1008-B 113645-91

49 STUFF. BOX GASK. 116075-01 115610-01 115610-01 D FLANGE COVER ASM 115725-91 115725-91 115725-91

50 O-RING 116074-01 111943-01 111943-01 F SET POINTER ASM 115630-91 115630-91 115630-91

51 PACKING 'V' SET L-1113 L-1109 L-1109 G GASKET KIT 116135 115789 115689

52 PACKING WASHER 112694-01 L-1041 L-1041 H OPERATORS KIT 115787 115787 115787

53 PACKING SPRING 112697-01 L-1063 L-1063 N/S SLIDE CHART 115698-91 115698-91 115698-91

54 GREASE ZERK H-30 H-30 H-30 N/S SETTING WRENCH 115631-01 115631-01 115631-01

PART DESCRIPTION PART # PART # PART #

-K NO SPROCKET NOT USED NOT USED NOT USED 56 INBOARD CYL. GASK. 116076-01 115710-01 115710-01

-R SPROCKET RC40-18T 113905-01 113905-01 113905-01 -U FUMIGANT N/A 104826-02 104826-02

-S STAINLESS N/A 92030 92030 -K NO SPROCKET NOT USED NOT USED NOT USED

-U FUMIGANT N/A 104828-02 104828-02 E SET HUB ASM 115629-91 115629-91 115629-91

@ CROSSHD GUIDE USE 4 “V”s N/A N/A

-U FUMIGANT N/A L-1109-U L-1109-U

ITEM

PART DESCRIPTION PART # PART # PART #

115701-02FLG 115601-02FLG

-S GASKET KIT - SS N/A 115789-S 115689-S

-U GASKET KIT - FUM N/A 115789-U 115689-U

© 2013 CDS-John Blue Co.

16

Page 17

NGP- 505x / 805x / 905x SERIES

A

220 FLANGE ADAPTERS:

- CAST IRON PUMPS USE 115701-02FLG OR 115601-02FLG

ON “DR” PUMPS WITHOUT MANIFOLD

- STAINLESS AND MANIFOLDS USE 116083-01S SCREWIN

DAPTERS

© 2013 CDS-John Blue Co.

17

Page 18

PARTS LISTING – DOUBLE ADJUSTABLE PUMPS

Parts unique to the NGP-5655-ARF, NGP-8055-AR, and NGP 9055-AR assemblies

(refer to the NGP-505x / 805x / 905x chart for common/shared parts)

ITEM PART DESCRIPTION PART # PART #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SPROCKET KEY

SPROCKET

KEY

SETTING POINTER

SETTING SCALE

5/16 X 3/8 SET SCREW

3/8 X 2-1/4 CAR BOLT

3/8 SELF LOCKING NUT

THRUST WASHER

5/16” X 1 BOLT

GREASE FITTING

COVER PLATE

O-RING

GASKET

NGP-8050-AR NGP-9050-AR

106493-01 106493-01 15 BEARING L-1007-A L-1007-A

116055-01 116055-01 16 CRANKCASE INSERT BLOCK 116049-01 N/A

L-1020 L-1020 17 SHORT SETTING SLEEVE 116052-01 116154-01

115628-01 115628-01 18 ECCENTRIC PIN L-3004 L-3004

L-1002 L-1002 19 SPACER SLEEVE 116051-01 116155-01

90532 90532 20 CRANKCASE 116048-01 115680-01

115646-01 115646-01 21 #10-32 X 1/4 SET SCREW 90502 90502

A-3097 A-3097 22 SEAL COVER 116054-01 116054-01

115626-01 115626-01 23 OIL SEAL 115622-01 115622-01

90637 90637 24 SNAP RING 115791-01 115791-01

H-28 H-28 25 GREASE ZERK 115647-01 115647-01

116053-01 116153-01 26 MAIN SHAFT 116050-01 116050-01

L-1022 l-1022

L-1006 L-3002

NGP-5655-ARF

DIMENSIONS

NGP-8055-AR

DIMENSIONS

ITEM PART DESCRIPTION

NGP-9055-AR

DIMENSIONS

NGP-8055-AR NGP-9050-AR

PART # PART #

Note: Apply gasket

sealant along sides of

part #16 at assembly

© 2013 CDS-John Blue Co.

18

Page 19

NGP Clutch Kit Assembly (optional)

Universal Clutch Components

- Assemble as shown in the first schematic figure, and ensure that the clutch yoke 21 is installed against

the clutch jaw

19

according to the schematic for each assembly (either tight or with a 5/16” gap).

- It may be necessary to loosen the set screws on the pump’s stroke adjustment pointer to slide the

main shaft over to allow clutch spacer

- Grease all fittings

3

daily during seasonal usage.

Manual Clutch: NGP-xxxx-050

Conversion Kit # 115670

- Assemble as shown in the second schematic figure, and ensure that the shift rod

assembly

- Place one end of the torsion spring

mounting plate

34-38

are aligned with throw out cam 29 so that the clutch is smoothly engaged/disengaged.

27

and the other end against the ear on the throw out bracket 28.

Electric Clutch: NGP-xxxx-058

Conversion Kit # 115672

- Assemble as shown in the third schematic figure – be sure to note the required 5/16” gap between the

yoke and clutch jaw when retracted.

- A double pole / double throw (DPDT) switch must be obtained and wired to the actuator

should be rated for 10A min., and can be either a sustaining or a momentary centering type.

- A 10 Amp fuse must be installed before the switch – see the diagram below for connecting the

switch and actuator.

4

to fit correctly. Be sure to re-tighten the set screws.

23

and pin

27

over the 5/16” x 1-1/2” bolt

57

after assembling the bolts to the

48

. The switch

Electric Actuator/Switch Wiring Diagram:

Hydraulic Clutch: NGP-xxxx-059

Conversion Kit # 115671

- Assemble as shown in the fourth schematic figure, and ensure that the jam nut

the shifter rod

23

.

22

is fully threaded onto

© 2013 CDS-John Blue Co.

19

Page 20

Clutch Kit

Parts List

ITEM PART DESCRIPTION PART #

1 WASHER 115626-01 X X X

2 O-RING S-316 X X X

3 GREASE FITTING H-28 X X X

4 CLUTCH SPACER 115639-01 X X X

5 3” DOWEL PIN 115640-01 X X X

6 SHAFT EXTENSION 115638-01 X X X

7 THRUST WASHER 115651-01 X X X

8 ¼-20 X 1” SOCKET CAP SCREW 90512 X X X

9 SPROCKET RETAINER 115632-01 X X X

10 CLUTCH SPROCKET 18T-RC50 115637-01 X X X

11 CLUTCH BEARING 115650-01 X X X

12 CLUTCH CARRIER ASSY 115663-91 X X X

13 SPROCKET CARRIER ASSEMBLY 115664-91 X X X

14 2” DOWELL PIN 115194-01 X X X

15 CLUTCH COLLAR 115641-01 X X X

16 3/8” SQ KEY 115642-01 X X X

17 CLUTCH SPRING 108907-01 X X X

18 HAND WHEEL A-50 X X X

19 CLUTCH JAW ASSEMBLY 115662-91 X X X

20 KEY RETAINER – ROLL PIN S-4248 X X X

21 CLUTCH YOKE 115635-01 X X X

22 5/8” JAM NUT 92037 X X X

23 SHIFTER ROD 115643-01 X X X

24 CLUTCH MOUNTING PLATE 115993-91 X X X

25 5/16 X 1 HEX BOLT 90637 X X X

26 3/8 X 1-1/4 HEX BOLT 90653 X X X

27 TORSION SPRING 114165-01 X X X

28 BRACKET - THROW OUT L-3007 X

29 CAM - THROW OUT A-2757-A X

30 PAWL - THROW OUT A-2758-A X

31 SPRING – THROW OUT F-48 X

32 COTTER PIN 5/32” X 1” 94010 X

33 LEVER - THROW OUT L-3064 X

34 # 10 SQ NUT 92014 X

35 WASHER A-697 X

36 CAM ROLLER A-2762 X

37 ROLL PIN A-2763 X

38 2-1/4 RD HEAD SCREW 90953 X

39 3/8 NUT 92024 X

40 HANDLE SUPPORT 115661-01 X

41 5/16 – 18 HEX NUT 92020 X X X

42 5/16 LOCK WASHER 93023 X X X

43 5/16 FLAT WASHER 93010 X

44 MOUNT - ACTUATOR 115995-91 X

45 1-3/4” PIN 114002-01 X

46 COTTER PIN 1/16 X ½” 94002 X

47 BRACKET - SHIFTER 114001-01 X

48 ELECTRIC ACTUATOR 114003-01 X

49 2” PIN 114594-01 X

50 BRACKET - CYLINDER 115998-01 X

51 5/8 SAE FLAT WASHER 93016 X

52 PISTON 105463-01 X

53 CYLINDER 105449-01 X

54 HOUSING 105447-01 X

55 HYD CYLINDER REPAIR KIT 106531 KIT

56 HYD CYLINDER ASSEMBLY 113557-91 KIT

57 5/16 X 1-1/2 HEX BOLT 115158-01 X

58 3/8 X 1 HEX BOLT 90860 X

59 3/8 LOCK WASHER 93024 X X

60 3/8 X 4-1/2 HEX BOLT 90667 X

61 3/8 X 1-1/2 HEX BOLT 90655 X

62 5/16 X 1-3/4 SQ. HD BOLT 90554 X

N/S PULLEY A-2765 X

N/S ROPE – 12’ A-2766 X

-X050

MANUAL

-X058

ELEC.

-X059

HYD.

© 2013 CDS-John Blue Co.

20

Page 21

Clutch Kit Schematics

UNIVERSAL COMPONENTS: (FOR ALL KITS)

NGP-x050 MANUAL SHIFT COMPONENTS

NGP-x058 ELECTRIC SHIFT COMPONENTS

NGP-x059 HYDRAULIC SHIFT COMPONENTS

© 2013 CDS-John Blue Co.

21

Page 22

DIMENSIONAL FOOTPRINTS

© 2013 CDS-John Blue Co.

22

Page 23

TROUBLE SHOOTING

ISSUE PROBABLE CAUSE

Pump hard or impossible to prime Valves damaged or in wrong place

Debris lodged in valves

Suction line leaks or restriction

Pump set too low

Packing worn

Tank Valve Closed

Clogged suction strainer

Pump building too much pressure Boom orifices / nozzles wrong size

Debris lodged in discharge lines

Excessive ground speed

Low / Under Metering Valves damaged or in wrong place

Debris lodged in valves

Suction line leaks or restriction

Pump set too low

Excessive tire slippage

Clogged suction strainer

High / Over Metering Valves damaged or in wrong place

Debris lodged in valves

Excessive suction head pressure

Pump set too high

Fluid leaks through when stopped Valves damaged

Excessive suction head pressure

Debris lodged in valves

Fertilizer leaks out stuffing box vent hole Rod packing worn out

Pump using excessive oil Oil seals or o-rings worn / leaking

Pump leaking oil around oil seals Vent plug not installed or plugged

Pump turns hard or skids ground tire Excessive pressure or speed

Clutch Models

ISSUE PROBABLE CAUSE

Clutch face contact showing excessive wear Yoke position on shifter rod is too far out

Clutch won’t disengage Yoke position on shifter rod is too far in

Clutch won’t engage Check main spring for breakage

Check jaws for severe wear / non-engagement

Clutch doesn’t engage / disengage Manual – Check all manual components for operation

Electric – Check all wiring and actuator for operation

Hydraulic – Check hydraulics and cylinder for operation

© 2013 CDS-John Blue Co.

23

Page 24

LIMITED WARRANTY

THIS WARRANTY IS IN LIEU OF ALL OTHER WRITTEN OR EXPRESS WARRANTIES AND

REPRESENTATIONS. ANY IMPLIED WARRANTIES INCLUDING MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE ARE EXPRESSLY LIMITED TO THIS WRITTEN WARRANTY. CDS-JOHN BLUE

COMPANY SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES.

Use of this product for any purpose other than its original intent, abuse of the product, and/or any modification to

the original product is strictly prohibited by the manufacturer, CDS-John Blue Company. Any modification to the

product should be approved by CDS-John Blue Company prior to use. CDS-John Blue Company will deny

Warranty claims and liability in any situation involving misuse, abuse or modification.

Each new machine or component manufactured by CDS-John Blue Company through original buyer is warranted

by CDS-John Blue Company to buyer and to any party or parties to whom buyer may resell, lease or lend the

equipment to be free from defects in material and workmanship under normal use and service. This obligation of

CDS-John Blue Company under this warranty is limited to the repair or replacement of defective parts or

correction of improper workmanship of any parts of such equipment which shall within one year from the date of

CDS-John Blue’s original delivery thereof, be returned to CDS-John Blue’s factory, transportation charges prepaid

and which CDS-John Blue Company shall determine to its satisfaction upon examination thereof to have been

thus defective. When it is impractical to return the defective parts of such equipment to CDS-John Blue’s factory,

then CDS-John Blue shall have no liability for the labor cost involved in repairing or replacing any such parts and

shall be liable solely for supplying the material necessary to replace or repair the defective parts, provided that

prior thereto CDS-John Blue Company shall have determined to its satisfaction that any such parts are thus

defective.

This warranty shall not apply to any equipment which shall have been repaired or altered outside CDS-John

Blue’s factory in any way so as to affect its durability, nor which has been subjected to misuse, abuse, negligence

or accident, or operated in any manner other than in accordance with operating instructions provided by CDSJohn Blue Company. This warranty does not extend to repairs made necessary by the use of inferior or

unsuitable parts or accessories, or parts or accessories not recommended by CDS-John Blue Company.

CDS-John Blue Company makes no warranties in respect to parts, accessories or components not manufactured

by CDS-John Blue Company, same ordinarily being warranted separately by their respective manufacturers.

DIVISION OF ADVANCED SYSTEMS TECHNOLOGIES HUNTSVILLE, AL (256) 721-9090

Division of Advanced Systems Technology

Telephone: (256) 721-9090 - Fax (256)-721-9091 - Toll Free 1-800-253-2583

© 2013 CDS-John Blue Co.

CDS-John Blue Company

290 Pinehurst Dr. Huntsville AL 35806

PO Box 1607 Huntsville AL 35807

www.cds-johnblue.com

YOUR LOCAL DEALER

24

Loading...

Loading...