Page 1

Chariot

GDRZ25KAE, GDRZ25KHE, GDRZ26KHE

D02-105

GD10001

B2

OPERATOR’S MANUAL

c WARNING: The Engine Exhaust

from this product contains chemicals known

to the State of California to cause cancer,

birth defects or other reproductive harm.

California Proposition 65 Warning

OMGD10001 B2

North American Version

Litho in U.S.A.

Page 2

INTRODUCTION

Introduction

Using Your Operator’s Manual

This manual is an important part of your machine and

should remain with the machine when you sell it.

An engine manufacturer’s owner’s manual has been

provided with your machine. This will provide maintenance

and troubleshooting information for the engine installed in

your machine.

Reading your operator’s manual will help you and others

avoid personal injury or damage to the machine.

Information given in this manual will provide the operator

with the safest and most effective use of the machine.

Sections in your operator’s manual are placed in a specific

order to help you understand all the safety messages and

learn the controls so you can operate this machine safely.

You can also use this manual to answer any specific

operating or servicing questions.

The machine shown in this manual may differ slightly from

your machine, but will be similar enough to help you

understand our instructions.

RIGHT-HAND and LEFT-HAND sides are determined by

facing in the direction the machine will travel when going

forward. When you see a broken line (------), the item

referred to is hidden from view.

GDRZ26KHE Serial No. (459000 - 460999)

If you need to contact an Authorized Service Center for

information on servicing, always provide the product model

and serial numbers.

You will need to locate the model and serial numbers for

the machine and for the engine of your machine and record

the information in the spaces provided.

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

B

Special Messages

Your manual contains special messages to bring attention

to potential safety concerns, machine damage as well as

helpful operating and servicing information. Please read all

the information carefully to avoid injury and machine

damage.

c CAUTION: Avoid injury! This symbol and text

highlight potential hazards or death to the

operator or bystanders that may occur if the

hazards or procedures are ignored.

IMPORTANT: Avoid damage! This text is used to tell

the operator of actions or conditions that might

result in damage to the machine.

NOTE: General information is given throughout the

manual that may help the operator in the operation or

service of the machine.

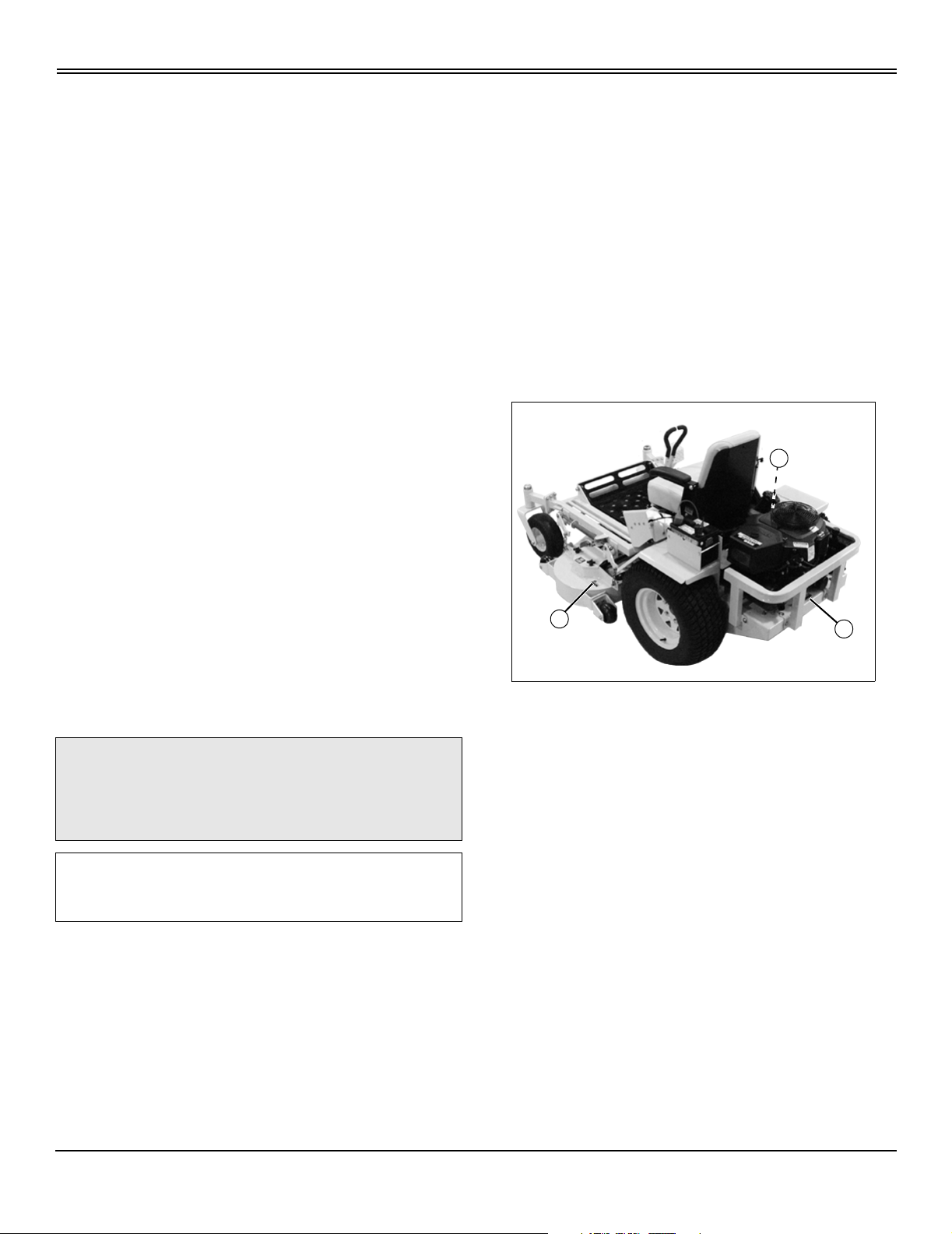

Record Identification Numbers

Chariot

GDRZ25KAE Serial No. (455000 - 455999)

C

MODEL NUMBER (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

SERIAL NUMBER (POWER UNIT) (B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER (B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SPECIFICATION NUMBER (C):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

A

MX9204

GDRZ25KHE Serial No. (457000 - 458999)

Introduction

Page 3

TABLE OF CONTENTS

Table of Contents

Safety .....................................................................................................................................................................................1

Operating................................................................................................................................................................................ 6

Replacement Parts ...............................................................................................................................................................10

Service Intervals...................................................................................................................................................................11

Service Lubrication...............................................................................................................................................................12

Service Engine .....................................................................................................................................................................13

Service Transmission............................................................................................................................................................15

Service Mower......................................................................................................................................................................18

Service Electrical..................................................................................................................................................................23

Service Miscellaneous..........................................................................................................................................................26

Troubleshooting ....................................................................................................................................................................28

Storage.................................................................................................................................................................................31

Assembly..............................................................................................................................................................................32

Specifications .......................................................................................................................................................................34

Index.....................................................................................................................................................................................35

Service Record GD ..............................................................................................................................................................36

All information, illustrations and

specifications in this manual are based

on the latest information at the time of

publication. The right is reserved to

make changes at any time without

John Deere Worldwide Commercial and

Consumer Equipment Division

notice.

COPYRIGHT© 2002

Deere & Co.

All rights reserved

Previous Editions

COPYRIGHT© 2001

OMGD10001 B2 - English

Table of Contents

Page 4

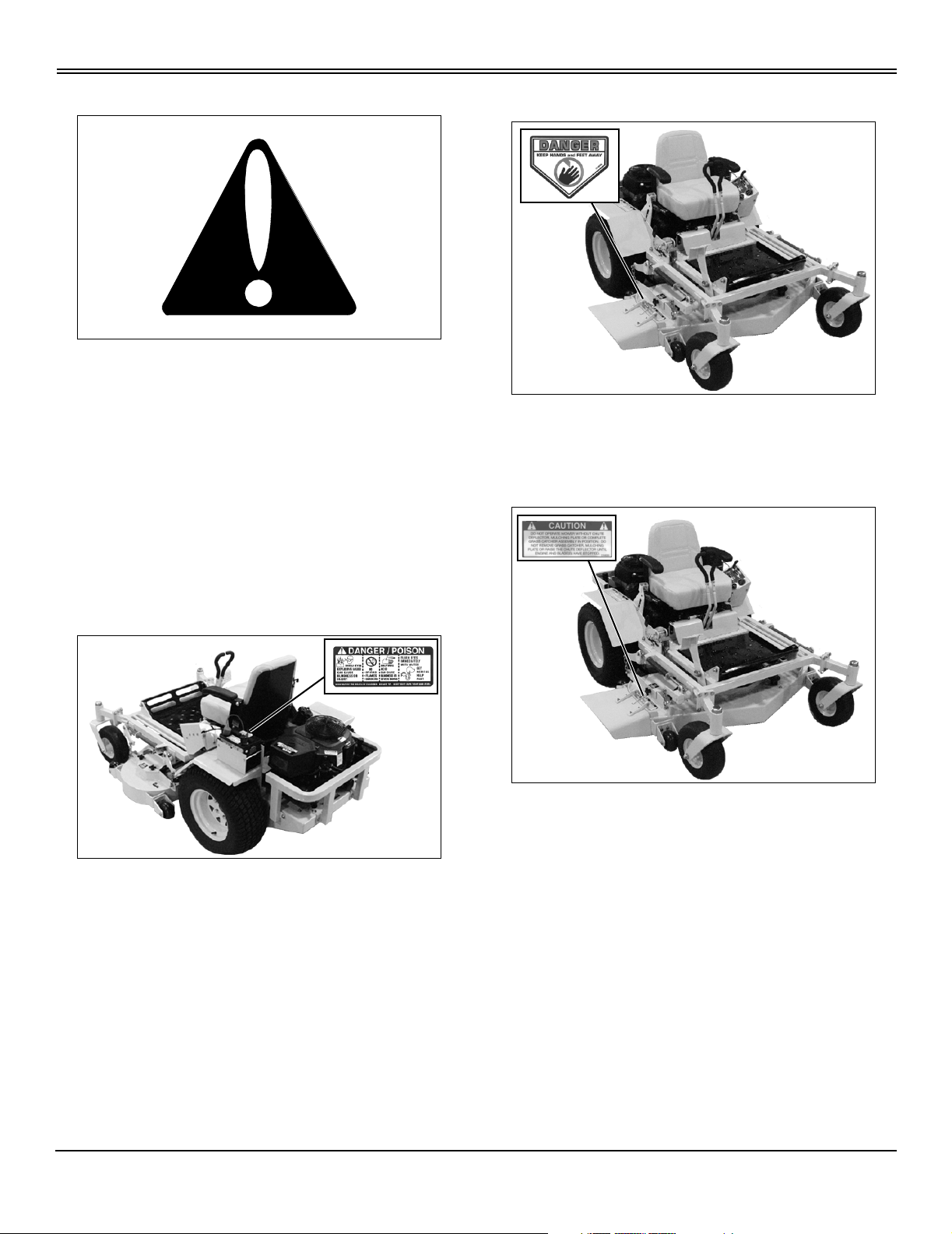

SAFETY

Safety

Understanding The Machine Safety Labels

MIF

The machine safety labels shown in this section are placed

in important areas on your machine to draw attention to

potential safety hazards.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-alert

symbol. DANGER identifies the most serious hazards.

The operator’s manual also explains any potential safety

hazards whenever necessary in special safety messages

that are identified with the word, CAUTION, and the safetyalert symbol.

DANGER

MX9293 MX9214

• Keep hands and feet away.

CAUTION

DANGER/POISON

MX9292 MX9204

• Shield eyes, explosive gases can cause blindness or

injury.

• No sparks, flames, smoking.

• Sulfuric acid can cause blindness or severe burns.

• Flush eyes immediately with water, get medical help

fast.

• Keep out of the reach of children.

MX9294 MX9214

• Do not operate mower without chute deflector, mulching

plate or complete grass catcher assembly in position.

• Do not remove grass catcher, mulching plate or raise

the chute deflector until engine and blade(s) have stopped.

• Do not tip.

• Keep vent caps tight and level.

Safety - 1

Page 5

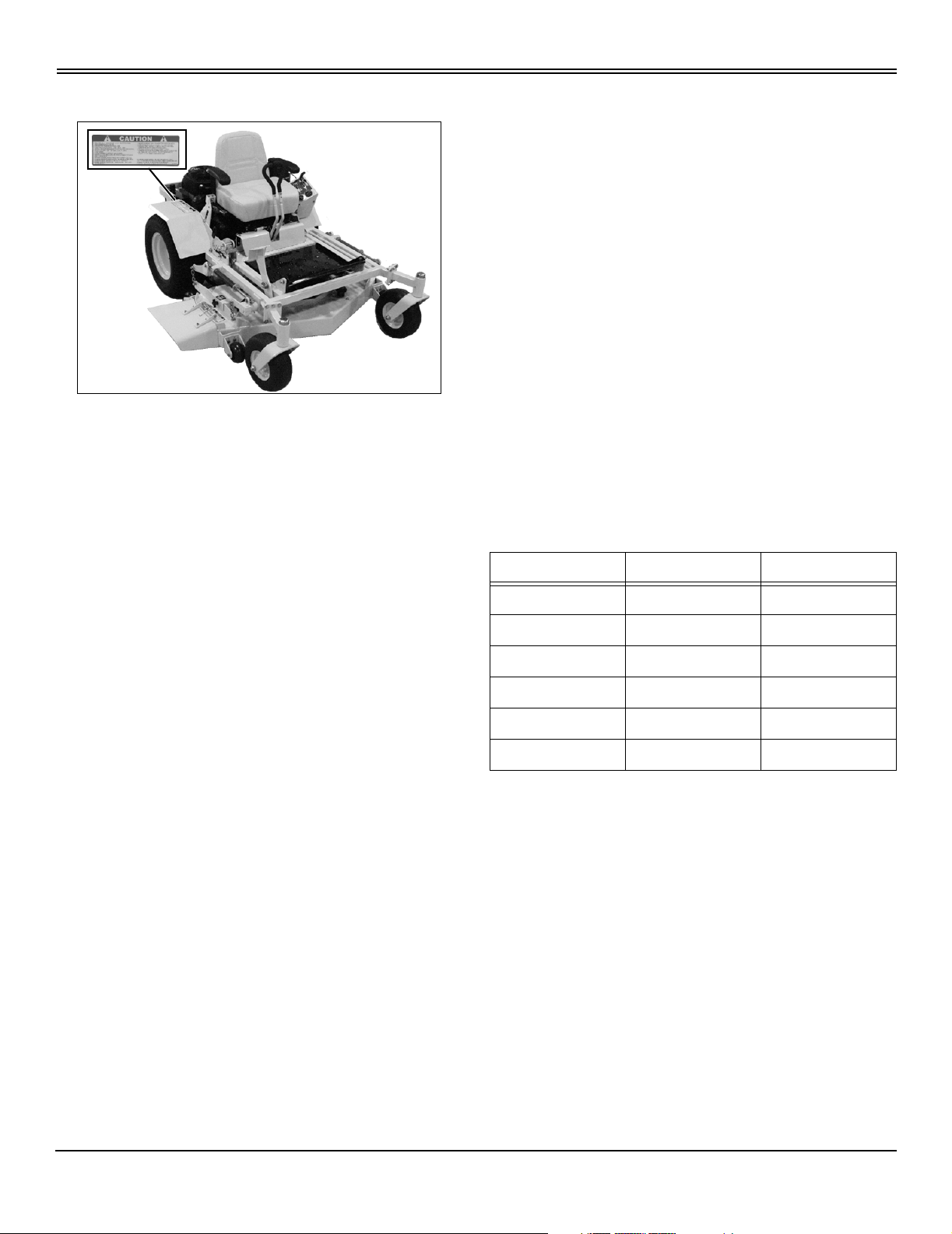

SAFETY

CAUTION

MX9295 MX9214

• This product is designed for professional and

commercial users.

• Operation training is required.

• Carefully read safety instructions.

• Know function of controls before operating.

• Practice with cutter blades off until confident.

• Clear mowing area of all debris.

• Keep all guards, covers and shields in place while

working.

• Do not disable or bypass any safety device.

• Always wear safety goggles while operating.

• Always park machine on level surface.

• Avoid contact with cutter blades. They may be rotating.

• Keep children and others clear from area.

• Set ground speed control to safe speed.

• Slowly and smoothly move speed control levers to start

and stop machine.

• Reduce speed and avoid sharp turns.

• Be careful on slopes, do not mow where stability or

traction is in doubt.

• To obtain additional operator manual and safety

instructions, contact your Great Dane dealer or write Great

Dane Power Equipment, 4700 New Middle Rd.,

Jeffersonville, IN 47130, USA.

Emission Control System Certification Label (Small Off-Road Gas Engines)

NOTE: Tampering with emission controls and

components by unauthorized personnel may result in

severe fines or penalties. Emission controls and

components can only be adjusted by EPA and/or

CARB authorized service centers. Contact your Great

Dane Equipment Retailer concerning emission

controls and component questions.

The presence of an emissions label signifies that the

engine has been certified with the United States

Environmental Protection Agency (EPA) and/or California

Air Resources Board (CARB).

The emissions warranty applies only to those engines

marketed by Great Dane that have been certified by the

EPA and/or CARB; and used in the United States and

Canada in off-road mobile equipment.

Emission Compliance Period (Small Off-Road Gas Engines)

If your engine has the emission compliance category listed

on the emission control system certification or air index

label, this indicates the number of operating hours for

which the engine has been certified to meet EPA and/or

CARB emission requirements. The following table provides

the engine compliance period in hours associated with the

category found on the certification label.

Agency Category Hours

EPA C 250

EPA B 500

EPA A 1000

CARB Moderate 125

CARB Intermediate 250

CARB Extended 500

Operating Safely

• Inspect machine before you operate. Be sure hardware

is tight. Repair or replace damaged, badly worn, or missing

parts. Be sure guards and shields are in good condition

and fastened in place. Make any necessary adjustments

before you operate.

• Do not operate mower without discharge chute or entire

grass catcher in place.

• Check before each use that operator presence controls

are functioning correctly. Test safety systems. Do not

operate unless they are functioning correctly.

• Do not change the engine governor setting or

overspeed the engine.

• Check brake action before you operate. Adjust or

service brakes as necessary.

Safety - 2

Page 6

SAFETY

• Stop machine if anyone enters the area.

• Never raise mower decks when blades are running.

• If you hit an object, stop and inspect the machine. Make

repairs before you operate. Keep machine and

attachments properly maintained and in good working

order.

• Do not leave machine unattended when it is running.

• Only operate during daylight or with good artificial light.

• Slow down and be careful of traffic when operating near

or crossing roadways. Stop blades before crossing roads

or sidewalks. Use care when approaching blind corners,

shrubs, trees, or other objects that may obscure vision.

• Be aware of the mower discharge direction and make

sure that no one is in the path of the discharge direction.

• Use only accessories and attachments approved by the

manufacturer of the machine.

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Always wear safety goggles or safety glasses with side

shields when operating the mower.

• Wear a suitable protective device such as earplugs.

Loud noise can cause impairment or loss of hearing.

• Do not wear radio or music headphones. Safe service

and operation requires your full attention.

Checking Mowing Area

Rotating Blades are Dangerous

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

MIF

• Rotating blades can cut off arms and legs.

• Keep hands, feet and clothing away from mower deck

when engine is running.

• Be alert at all times, drive forward carefully. People,

especially children can move quickly into the mowing area

before you know it.

• Before backing up, shut off PTO and look down and

behind the machine carefully, especially for children.

• Do not mow in reverse.

• Shut off blades when you are not mowing.

• Do not operate machine if you are under the influence of

drugs or alcohol.

• Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform the

job.

• Clear mowing area of objects that might be thrown.

Keep people and pets out of mowing area.

• Study mowing area. Set up a safe mowing pattern. Do

not mow where traction or stability is doubtful.

• Test drive area with mower lowered but not running.

Slow down when you travel over rough ground.

Parking Safely

1. Stop machine on a level surface, not on a slope.

2. Disengage PTO.

3. Lower attachments to the ground.

4. Lock park brake.

5. Stop engine.

6. Remove key.

7. Wait for engine and all moving parts to stop before you

leave the operator’s station.

• Park machine safely before inspecting or unplugging

mower or bagger.

PROTECT CHILDREN:

• Never assume that children will remain where you last

saw them. Children are attracted to mowing activity, stay

alert to the presence of children.

• Keep children indoors when you are mowing. Turn the

machine off if a child enters the mowing area.

• Use extra care when you come to blind corners, shrubs,

trees, or other objects that may block your vision.

• Do not let children or an untrained person operate the

machine.

• Do not carry or let children ride on any attachment or

machine even with the blades off. Do not tow children in a

cart or trailer.

Avoid Tipping

• Slopes are a major factor related to loss-of-control and

tip-over accidents, which can result in severe injury or

death.

Safety - 3

Page 7

SAFETY

• Drive across a hill - not up and down. If necessary, turn

slowly and in the downhill direction. Do not shift to neutral

and coast downhill.

• Avoid starting and stopping on a slope. If machine

stops, disengage mower blades and back down slowly.

• Do not drive where machine could slip or tip.

• Stay alert for holes and other hidden hazards in the

terrain.

• Keep away from drop-offs, ditches, and embankments.

• Slow down before you make a sharp turn or operate on

a slope. On gear models, choose a low gear so that shifting

and stopping will not be necessary while on the slope.

• Transport machine with decks lowered to improve

stability.

• Drive machine very slowly and avoid quick stops when

attachment is removed.

• Mowing when grass is wet can cause reduced traction

and sliding.

Keep Riders Off

• Only allow the operator on the machine. Keep riders off.

• Riders on the machine or attachment may be struck by

foreign objects or thrown off the machine causing serious

injury.

• Riders obstruct the operator’s view resulting in the

machine being operated in an unsafe manner.

Checking Wheel Bolts

• A serious accident could occur causing serious injury if

wheel bolts are not tight.

• Check wheel bolt tightness often during the first 100

hours of operation.

• Wheel hardware must be tightened to specified torque

using the proper procedure anytime it is loosened.

Driving Safely on Public Roads

Avoid personal injury or death resulting from a collision with

another vehicle on public roads:

• Use safety lights and devices. Slow moving machines

when driven on public roads are hard to see, especially at

night.

• Use extra care when loading or unloading the machine

into a trailer or truck.

• Whenever driving on public roads, use flashing warning

lights and turn signals according to local regulations. Extra

flashing warning lights may need to be installed.

Practice Safe Maintenance

• Only qualified, trained adults should service this

machine.

• Understand service procedure before doing work. Keep

area clean and dry.

• Never lubricate, service, or adjust machine while it is

moving. Keep safety devices in place and in working

condition. Keep hardware tight.

• Keep hands, feet, clothing, jewelry, and long hair away

from any moving parts, to prevent them from getting

caught.

• Lower attachments to the ground before servicing

machine. Disengage all power and stop the engine. Lock

park brake and remove the key. Let machine cool.

• Disconnect battery or remove spark plug wire before

making any repairs.

• Before servicing machine, carefully release pressure

from components with stored energy such as hydraulic

components.

• Keep all nuts and bolts tightened, especially blade

attachment bolts.

• Securely support any machine elements that must be

raised for service work. Lock service latches before

working on machine with raised attachments.

• Never run engine unless park brake is locked.

• Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Replace all worn or damaged safety and instruction decals.

• To prevent fires, remove any buildup of grease, oil, or

debris from the machine, especially the engine

compartment.

• Charge batteries in an open, well-ventilated area, away

from sparks. Unplug battery charger before connecting or

disconnecting from the battery. Wear protective clothing

and use insulated tools.

• Do not modify machine or safety devices. Unauthorized

modifications may impair its function and safety.

• Do not wear radio or music headphones while servicing

the machine. Safe service requires your full attention.

Avoid High Pressure Fluids

• Hydraulic hoses and lines can fail due to physical

damage, kinks, age, and exposure. Check hoses and lines

regularly. Replace damaged hoses and lines.

• Hydraulic fluid connections can loosen due to physical

Safety - 4

Page 8

SAFETY

damage and vibration. Check connections regularly.

Tighten loose connections.

• Escaping fluid under pressure can penetrate the skin

causing serious injury. Avoid the hazard by relieving

pressure before disconnecting hydraulic or other lines.

Tighten all connections before applying pressure.

• Search for leaks with a piece of cardboard. Protect

hands and body from high pressure fluids.

• If an accident occurs, see a doctor immediately. Any

fluid injected into the skin must be surgically removed

within a few hours or gangrene may result. Doctors

unfamiliar with this type of injury should reference a

knowledgeable medical source.

Prevent Fires

• Never remove fuel cap, or add fuel with engine running

or hot. Allow engine to cool for several minutes.

• Never store equipment with fuel in the tank inside a

building where fumes may reach an open flame or spark.

• Allow engine to cool before storing in any enclosure.

• To reduce fire hazard, keep engine free of grass,

leaves, or excessive grease.

running.

• Never fill fuel tank or drain fuel from a machine in an

enclosed area. Fill fuel tank outdoors.

• Prevent fires. Clean up spilled fuel immediately.

• Do not store machine with fuel in tank in a building

where fumes may reach an open flame or spark.

• Prevent fire and explosion caused by static electric

discharge. Use only non-metal, portable fuel containers

approved by the Underwriter’s Laboratory (U.L.) or the

American Society for Testing & Materials (ASTM). If using

a funnel, make sure it is plastic and has no screen or filter.

Tire Safety

Explosive separation of a tire and rim parts can cause

serious injury or death:

• Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

• Always maintain the correct tire pressure. Do not inflate

the tires above the recommended pressure. Never weld or

heat a wheel and tire assembly. The heat can cause an

increase in air pressure resulting in a tire explosion.

Welding can structurally weaken or deform the wheel.

• When inflating tires, use a clip-on chuck and extension

hose long enough to allow you to stand to one side and not

in front of or over the tire assembly.

• Check tires for low pressure, cuts, bubbles, damaged

rims or missing lug bolts and nuts.

Handling Fuel Safely

Fuel and fuel vapors are highly flammable and explosive:

• Do not refuel machine while you smoke, when machine

is near an open flame or sparks, or when engine is running.

Stop engine and allow to cool before filling.

• Never remove the fuel cap or add fuel with the engine

MIF

• Static electric discharge can ignite gasoline vapors in an

ungrounded fuel container. Remove the fuel container from

the bed of a vehicle or the trunk of a car and place on the

ground away from the vehicle before filling. Keep nozzle in

contact with container opening while filling.

• When practical, remove equipment from trailers or truck

beds and refuel them on the ground. If this is not possible,

use a portable, plastic fuel container to refuel equipment on

a truck bed or trailer.

• For gasoline engines, do not use gas with methanol.

Methanol is harmful to your health and to the environment.

Safety - 5

Page 9

OPERATING

Operating

Daily Operating Checklist

❏ Test safety systems.

❏ Check tire pressure.

❏ Check fuel level.

❏ Check engine oil level.

❏ Remove and clean engine air filter.

❏ Check transmission oil reservoir level.

❏ Remove grass and debris from machine.

❏ Clean engine cooling air intake screen and cooling fins.

❏ Inspect all belts for damage.

❏ Sharpen and balance mower blades.

❏ Check area below machine for any fuel or oil leaks.

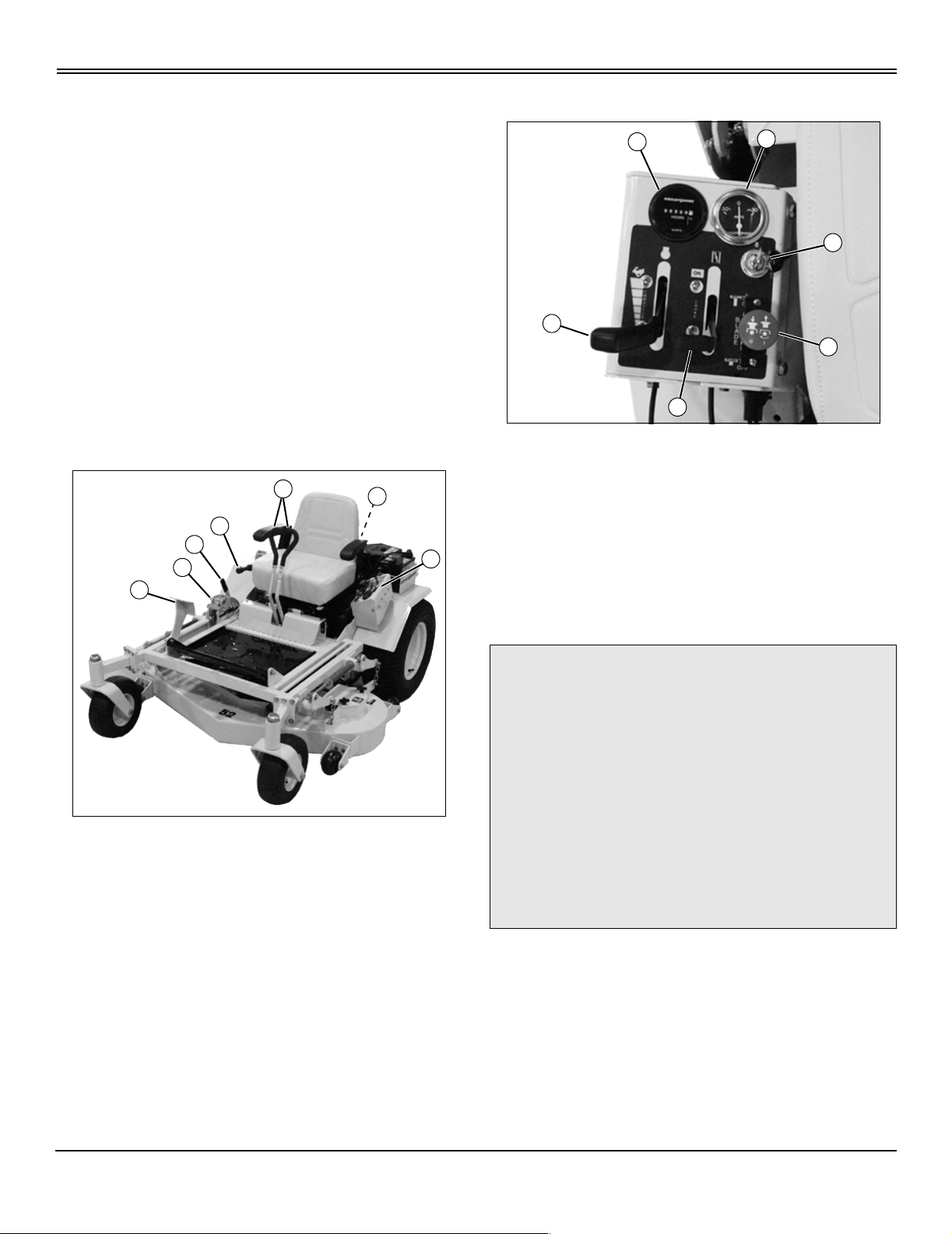

Operating Controls

F

A

D

B

C

E

G

Console Controls

A

A - Throttle Lever

B - Key Switch

C - Choke Lever

D - PTO/Clutch Switch

E - Hourmeter

F- Ammeter

E

C

F

B

D

MX9205

MX9206

A - Park Brake Lever

B - Height-of-Cut (HOC) Adjustment Pin

C - Mower Deck Lift/Lower Pedal

D - Mower Deck Transport Position Lock Lever

E - Fuel Shutoff Valve

F - Steering Control Levers

G - Console

Testing Safety Systems

c CAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause

serious illness or death.

Move the vehicle to an outside area before

running the engine.

Do not run an engine in an enclosed area

without adequate ventilation.

• Connect a pipe extension to the engine

exhaust pipe to direct the exhaust fumes out of

the area.

• Allow fresh outside air into the work area to

clear the exhaust fumes out.

Use the following checkout procedure to check for normal

operation of machine.

If there is a malfunction during one of these procedures, do

not operate machine. See your Great Dane dealer for

service.

Perform these tests in a clear open area. Keep bystanders

away.

Operating - 6

Page 10

OPERATING

Testing Park Brake Safety Switch

1. Operator must be seated in the seat (seat safety switch

engaged).

2. Move control levers to neutral position.

3. Move PTO/clutch switch to off position.

4. Unlock park brake.

5. Turn key switch to start position.

Result: The engine must not crank.

Testing Park Brake

Stop the machine on a maximum 17° slope. Stop the

engine and lock the park brake.

Result: Park brake must hold the machine stationary. If the

machine moves more than 61 cm [24 in.] in one hour,

brakes need to be adjusted. See your Great Dane dealer.

Testing Neutral Start Safety Switch

1. Operator must be seated in the seat (seat safety switch

engaged).

2. Move control levers to forward travel position.

3. Move PTO/clutch switch to off position.

4. Lock park brake.

5. Turn key switch to start position.

Result: The engine must not crank.

Testing Seat Safety Switch

1. Operator must be seated in the seat (seat safety switch

engaged).

2. Move control levers to neutral position.

3. Start the engine.

2. Unlock park brake.

3. Move PTO/clutch switch to on position (mower deck

drive engaged).

4. Turn key switch to start position.

Result: The engine must not crank.

Using the Park Brake

Move park brake lever to the raised (locked) position to

lock the park brake. This will also engage the park brake

safety switch.

Starting the Engine

c CAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause

serious illness or death.

Move the vehicle to an outside area before

running the engine.

Do not run an engine in an enclosed area

without adequate ventilation.

• Connect a pipe extension to the engine

exhaust pipe to direct the exhaust fumes out of

the area.

• Allow fresh outside air into the work area to

clear the exhaust fumes out.

1. Open the fuel shutoff valve.

2. Operator must be seated in the seat (seat safety switch

engaged).

3. Lock park brake.

4. Move control levers to neutral position.

5. Move PTO/clutch switch to off position.

6. Move throttle lever to half-speed position.

c CAUTION: Avoid injury! Before engaging

mower, clear area of bystanders, especially

children.

4. Move PTO/clutch switch to on position.

5. Operator rises slightly off the seat.

Result: The engine must stop.

Testing PTO/Clutch Safety Switch

1. Operator must be seated in the seat (seat safety switch

engaged).

Operating - 7

7. Adjust choke as required.

IMPORTANT: Avoid damage! Starter may be

damaged if starter is operated for more than 20

seconds at a time:

• Wait 2 minutes before trying again if the engine

does not start.

8. Turn key switch to start position for no more than 5

seconds. Release key to the run position when engine

starts.

• If the engine does not start, wait 10 seconds.

• Turn key to start position again for no more than 5

Page 11

OPERATING

seconds.

• Repeat the procedure if necessary.

IMPORTANT: Avoid damage! Unnecessary engine

idling may cause engine damage. Excessive idling

can cause engine overheating, carbon build-up and

poor performance.

9. Let the engine run at half-speed position for several

minutes to warm up before operating the machine. Reduce

choke setting as the engine warms up.

Operating the Machine

c CAUTION: Avoid injury! Learn the use of the

control levers. Practice at half throttle until

becoming proficient and comfortable with the

operation of the machine.

Do not move control levers from forward to

reverse or reverse to forward position rapidly.

Sudden direction changes could cause loss of

control or damage the machine.

1. Adjust mower deck to desired cutting height.

2. Start and warm up engine at half throttle.

3. Move PTO/clutch switch to on position.

4. Move throttle lever to wide open position.

5. Unlock park brake.

NOTE: The travel speed and turn rate will vary with the

amount that the control levers are moved.

neutral position.

To drive the machine in reverse: Pull both control levers

back evenly.

Stopping the Machine

NOTE: If the operator leaves the seat without placing

the PTO switch in the off position, the mower blades

will stop as soon the operator leaves the seat.

1. Move the PTO/clutch switch to the off position.

2. Return both control levers to the neutral position.

c CAUTION: Avoid injury! Children or bystanders

may attempt to move or operate an unattended

machine.

Always lock the park brake and remove the

key before leaving the machine unattended.

3. Lock park brake.

4. Move the throttle lever to the half-speed position, and let

the engine run at low throttle for a few seconds.

5. Turn the key switch to the stop position.

6. Remove key.

Adjusting Cutting Height

Cutting height can be adjusted from approximately 25-152

mm (1-6 in.). Each hole adjusts the height of cut (HOC) in

13 mm (1/2 in.) increments.

The deck can also be raised and locked in a transport

position to provide maximum ground clearance when

moving the machine from one area to another.

MX9220

6. Drive the machine:

To drive the machine forward: Push both control levers

forward smoothly and evenly.

To turn the machine: Pull the control lever back on the

same side as the direction of the desired turn. Push the

other lever forward.

To stop the machine: Return both control levers to the

Operating - 8

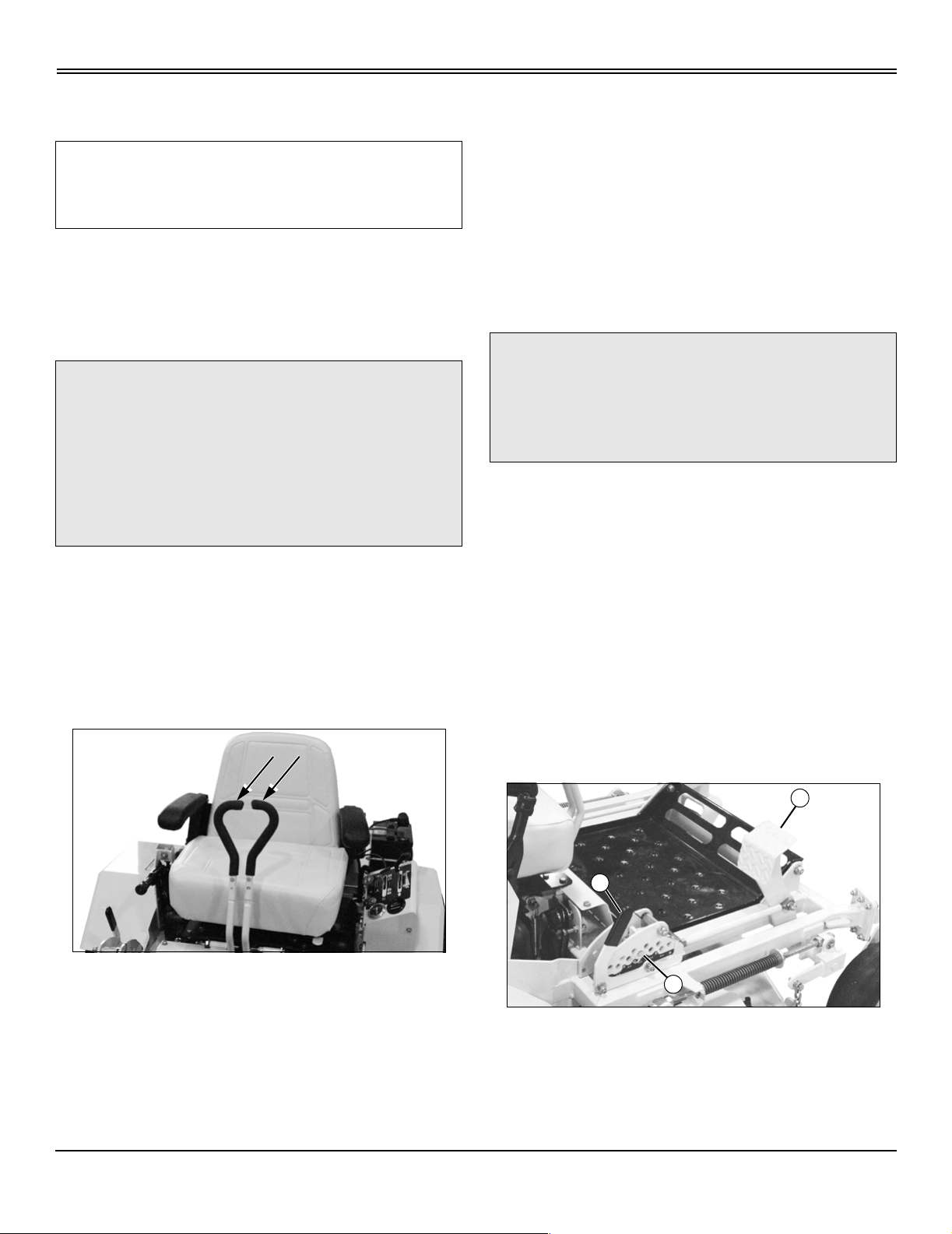

A

C

B

MX9215

1. Push the mower deck lift/lower pedal (A) forward to

raise and latch the deck in the transport position.

2. Position the HOC adjustment pin (B) in the proper hole

for the desired height of cut.

Page 12

OPERATING

3. Depress and hold the mower deck lift/lower pedal (A)

and release the transport position lock lever (C).

4. Release the mower deck lift/lower pedal (A) and allow

the pedal to rest against the HOC pin.

Using the Fuel Shutoff Valve

A

MX9409

Move the fuel shutoff valve (A) to the on position for normal

operation. Move the valve to the off position when the

machine is not in use and during transport.

Moving the Machine Manually

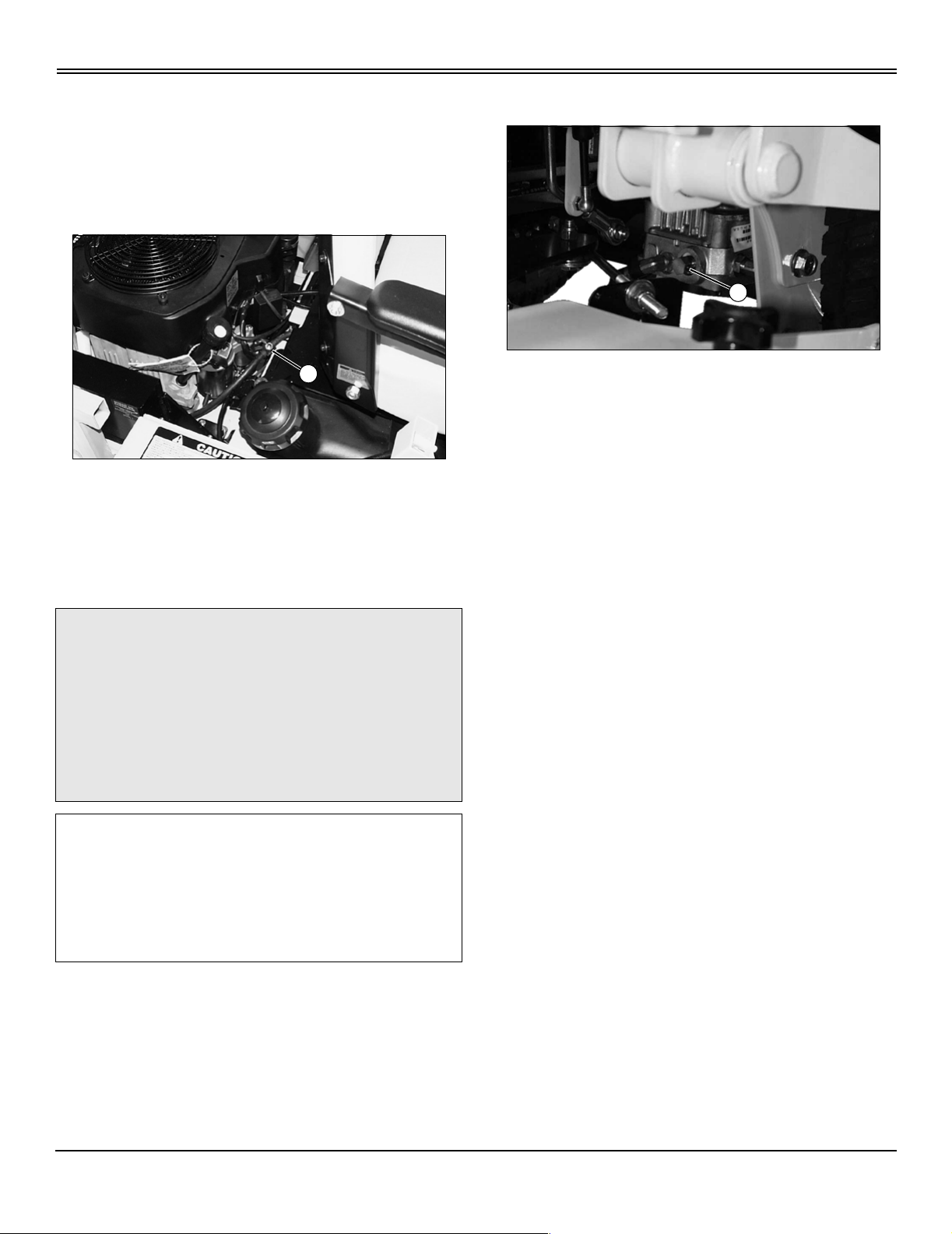

NOTE: The pumps are located under the machine,

behind the mower deck.

A

MX9226

Picture Note: Left pump shown.

2. Turn free-wheeling valves (A) on both pumps one full

turn counterclockwise (open position).

3. Unlock park brake.

4. Push machine to desired location. Due to internal

hydraulic system resistance, the machine will move slowly.

5. Turn free-wheeling valves (A) on both pumps one full

turn clockwise (closed position). Tighten the valves to 9-14

N•m (80-120 lb-in.).

6. Lock park brake.

c CAUTION: Avoid injury! With the free-wheeling

valve open, the machine will have unrestricted

motion.

• The machine may free-wheel out of control if

the free-wheeling valve is opened with the

machine on an incline.

• Park the machine on a level surface before

opening the free-wheeling valve.

IMPORTANT: Avoid damage! Transmission damage

may occur if the machine is moved or towed

incorrectly:

• Move unit by hand only.

• Do not use another vehicle to move unit.

• Do not tow unit.

1. Park machine safely. (See Parking Safely in the Safety

section.)

Operating - 9

Page 13

REPLACEMENT PARTS

Replacement Parts

Parts

We recommend Great Dane quality parts available at your

Great Dane dealer.

Part numbers may change. Use part numbers listed below

when you order. If a number changes, your dealer will have

the latest number.

When you order parts, your Great Dane dealer needs your

machine model and serial numbers and engine serial

number. These are the numbers that you recorded in the

Product Identification section of this manual.

Part Numbers

Item Part Number

Battery D18169

Fuel Tank Cap D18097

Oil Reservoir Cap D18081

Oil Filter (Hydraulic System) D18094

Traction (Hydro) Drive Belt D28030

Engine to Blade Belts:

• 1,32 m (52 in.) Deck

• 1,55 m (61 in.) Deck

Mower Deck Drive Belts:

• 1,32 m (52 in.) Deck

• 1,55 m (61 in.) Deck

Mower Blades:

• 53 cm (21 in.)

• 45 cm (18 in.)

(Part numbers are subject to change without notice. Part

Numbers may be different outside the U.S.A.)

D28032

D28029

D28031

D28028

D18036

D18037

Replacement Parts - 10

Page 14

SERVICE INTERVALS

Service Intervals

Servicing Your Machine

IMPORTANT: Avoid damage! Operating in extreme

conditions may require more frequent service

intervals:

• Engine components may become dirty or

plugged when operating in extreme heat, dust or

other severe conditions.

• Engine oil and spark plugs may lose efficiency if

vehicle is operated constantly at slow or low engine

speeds or with frequent short trips.

Please use the following timetables to perform routine

maintenance on your machine.

NOTE: The following initial break-in items must be

performed and verified to validate the warranty (dealer

service invoice accepted).

Break-In (After First 8 Hours of Operation)

Change engine oil and filter.

Check drive belt tension.

Check transmission neutral adjustment.

Check wheel nut torque.

Break-In (After First 24 Hours of Operation)

Check drive belt tension.

Break-In (After First 40 Hours of Operation)

Change transmission oil and filter.

Check wheel nut torque.

Every 160 Hours

Clean and inspect spark plugs.

Change engine oil filter.

Check transmission oil level.

Lubricate mower deck idler pulley pivots (three places).

Lubricate seat platform hinges (two places)

Lubricate pump control arms (five places).

Lubricate control lever pivot shafts (two places).

Lubricate throttle cable.

Lubricate choke control cable.

Every 500 Hours

Change transmission oil and filter.

Annually

Replace all spindle bearings (6).

Replace all mower deck idler pulleys (3).

Remove caster wheel roller bearings, clean and lubricate.

Replace drive belts. Run-in and adjust tension.

Clean power unit.

Replace hydraulic oil filter.

Check all bolts and nuts; tighten as needed.

Remove battery. Clean battery and holder.

Replace spark plugs.

Every 40 Hours

Change engine oil.

Grease HOC shafts (five places).

Grease caster wheel pivot bearings (two places).

Grease caster wheel bearings (two places).

Grease mower deck thrust arms (two places).

Grease mower deck spindle bearings (three places) if

equipped.

Remove debris from the underside of the mower deck.

Check drive belt tension.

Check tire pressure.

Check battery electrolyte level.

Clean engine air filter.

Service Intervals - 11

Page 15

SERVICE LUBRICATION

Service Lubrication

Grease

IMPORTANT: Avoid damage! If operating outside

that temperature range, contact your Servicing

dealer for a special-use grease.

Use a general all-purpose grease with an NLGI grade No.2

rating.

Wet or high speed conditions may require use of a specialuse grease. Contact your Servicing dealer for information.

Spray Lubricant

Use a general-purpose petroleum-based spray lubricant.

Lubrication Points

D

E

D

B

C

A

E

A

B

• Grease caster wheel bearings (A).

• Grease caster wheel pivot bearings (B).

• Grease HOC shafts (C).

• Grease mower deck thrust arms (D), located at the rear

of the mower deck.

• Grease mower deck spindle bearings (E) if equipped.

E

MX9206

NOTE: Use spray lubricant to lubricate the following

items:

A

B

D

C

MX9252

• Lubricate mower deck idler pulleys (A-D).

E

C

B

D

A

MX9408

• Lubricate hydraulic pump control arms (A).

• Lubricate control lever pivot shaft (B).

• Lubricate seat platform hinges (C).

• Lubricate throttle control cable (D).

• Lubricate choke control cable (E).

Service Lubrication - 12

Page 16

SERVICE ENGINE

Service Engine

Avoid Fumes

c CAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause

serious illness or death.

Move the vehicle to an outside area before

running the engine.

Do not run an engine in an enclosed area

without adequate ventilation.

• Connect a pipe extension to the engine

exhaust pipe to direct the exhaust fumes out of

the area.

• Allow fresh outside air into the work area to

clear the exhaust fumes out.

Engine Oil

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

Use oil that meets the following specification:

• API Service Classification SG or higher

Checking Engine Oil Level

overfill.

6. Install and tighten dipstick.

Changing Engine Oil and Filter

A

MX9413

NOTE: An oil drain tube is provided with your machine.

Attach the tube to the oil drain fitting on your engine,

and open the valve (A) to drain the used oil. Close the

valve, and remove the drain tube from the fitting after

the oil has been drained. Store the drain tube after use.

Change engine oil and filter at the intervals recommended

in the Service Intervals section. See the engine

manufacturer’s owner’s manual provided with your

machine for the complete procedure.

IMPORTANT: Avoid damage! Failure to check the oil

level regularly could lead to serious engine

problems if oil level is low:

• Check oil level before operating.

• Check oil level when the engine is cold and not

running.

• Keep level between the FULL and the ADD marks.

• Shut off engine before adding oil.

NOTE: Check oil twice a day if you run engine over 4

hours in a day.

Make sure engine is cold when checking engine oil

level.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Clean area around dipstick to prevent debris from falling

into crankcase.

3. Remove dipstick. Wipe with a clean cloth.

4. Install and tighten dipstick.

5. Remove dipstick and check oil level on dipstick. Oil must

be between ADD and FULL marks. If oil is low, add oil to

bring oil level no higher than FULL mark on dipstick. Do not

Cleaning Air Intake Screen and Engine Fins

IMPORTANT: Avoid damage! The engine is aircooled and requires a large amount of air intake

when running. Reduced air intake can cause

overheating:

• Keep air intake screen and cooling fins clean.

• Keep covers and screens in place.

Keep air intake screens and engine cooling fins clear of

debris to ensure proper cooling. See the engine

manufacturer’s owner’s manual provided with your

machine for the complete procedure.

Checking and Cleaning Air Filter Elements

c CAUTION: Avoid injury! Touching hot surfaces

can burn skin. The engine and components will

be hot if the engine has been running. Allow

the engine to cool before servicing.

Service Engine - 13

Page 17

SERVICE ENGINE

IMPORTANT: Avoid damage! Dirt and debris can

enter the engine through a damaged filter element:

• Do not wash paper element.

• Do not attempt to clean paper element by tapping

against another object.

• Do not use pressurized air to clean element.

• Replace element only if it is very dirty, damaged

or the seal is cracked.

Check and clean air filter elements at the intervals

recommended in the Service Intervals section. See the

engine manufacturer’s owner’s manual provided with your

machine for the complete procedure.

Checking Spark Plug

c CAUTION: Avoid injury! Touching hot surfaces

can burn skin. The engine and components will

be hot if the engine has been running. Allow

the engine to cool before servicing.

Check spark plugs at the intervals recommended in the

Service Intervals section. See the engine manufacturer’s

owner’s manual provided with your machine for the

complete procedure.

Replacing Fuel Filter

c CAUTION: Avoid injury! Fuel vapors are

explosive and flammable:

• Do not smoke while handling fuel.

• Keep fuel away from flames or sparks.

• Shut off engine before servicing.

• Cool engine before servicing.

• Work in a well-ventilated area.

• Clean up spilled fuel immediately.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Turn fuel shutoff valve to off position.

3. Disconnect the fuel hose from the outlet side of the fuel

filter, and drain gasoline into a properly marked container.

4. Remove the fuel filter from the inlet fuel hose. Discard

filter.

IMPORTANT: Avoid damage! When installing a new

fuel filter, the filter arrow must be pointing in the

direction of fuel flow.

5. Connect a new fuel filter to hoses.

6. Turn fuel shutoff valve to ON position.

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine

manufacturer and is not adjustable.

If engine is operated at altitudes above 1829 m (6,000

ft), some carburetors may require a special high

altitude main jet.

If engine is hard to start or runs rough, see the

troubleshooting section of the engine manufacturer’s

owner’s manual provided with your machine.

Possible engine surging will occur at high throttle with

transmission in “N” neutral and mower disengaged. This is

a normal condition due to the emission control system.

After performing the checks in the troubleshooting section

and your engine is still not performing correctly, contact the

local engine manufacturer’s authorized servicing dealer.

Service Engine - 14

Page 18

SERVICE TRANSMISSION

Service Transmission

Avoid Fumes

c CAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause

serious illness or death.

Move the vehicle to an outside area before

running the engine.

Do not run an engine in an enclosed area

without adequate ventilation.

A

• Connect a pipe extension to the engine

exhaust pipe to direct the exhaust fumes out of

the area.

• Allow fresh outside air into the work area to

clear the exhaust fumes out.

Transmission Oil

Use only Quaker State® 5W-50 or Mobil-1® 15W-50 all

synthetic oil.

Checking Transmission Oil Level

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove the hydraulic reservoir cap. The oil level should

be 76 mm (3 in.) from the top of the filler pipe. Add oil as

needed.

Changing Transmission Oil and Filter

IMPORTANT: Avoid damage! Contamination of

hydraulic fluid could cause transmission damage or

failure. Do not open oil reservoir cap unless

absolutely necessary.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Allow engine and hydraulic reservoir to cool.

3. Clean area around the reservoir filler cap, and remove

the filler cap from the reservoir.

MX9233

4. Turn hydraulic filter (A) counterclockwise to remove, and

drain oil into a properly marked container with a capacity of

at least 7.5 L (2.0 gal).

5. Apply a film of clean oil to gasket of new filter.

6. Install filter. Turn filter clockwise until gasket makes

contact with the mounting surface. Tighten 1/2 to 3/4 turn

after contact.

7. Fill reservoir with approximately 2.8 L (3 qt) (low-profile

tank) or 3.8 L (4 qt) (high-profile tank) of oil.

8. Install reservoir cap.

9. Bleed air from hydraulic system.

Adjusting Transmission Neutral Position

1. Park machine safely. (See Parking Safely in the Safety

section.)

c CAUTION: Avoid injury! Machine must be

safely supported on jackstands before

removing or installing wheels. Do not use a

hoist or floor jack to support the machine.

2. Raise drive wheel off the ground and securely support

the machine, and block caster wheels.

3. Start and run the engine until it reaches normal

operating temperature.

4. Observe wheel movement as control levers are moved

back and forth. The wheels should travel in the correct

direction as the levers are moved.

Service Transmission - 15

Page 19

SERVICE TRANSMISSION

A

MX9244

5. Move control levers to neutral position. The wheels

should stop rotating. If the wheels continue to rotate, adjust

the neutral adjustment knob(s) (A), located on each side of

the seat, until wheel(s) stop rotating.

B

B

A

MX9216

Picture Note: Drive belt routing as viewed from the

top of machine.

3. Disconnect tension spring (A) from the anchor pin.

4. Remove drive belt (B).

5. Install new drive belt (B).

6. Connect tension spring (A) to anchor pin.

7. Install mower deck drive belt.

MX9250

6. Adjust neutral switch activator bolt(s) (B) as needed.

The switches should be engaged when the control levers

are in the neutral position.

7. Shut engine off.

8. Lower the machine to the ground.

Removing and Installing Traction Drive Belt

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove mower deck drive belt.

Bleeding Hydraulic System

c CAUTION: Avoid injury! Escaping fluid under

pressure can penetrate the skin causing

serious injury. Avoid the hazard by relieving

pressure before disconnecting hydraulic or

other lines. Tighten all connections before

applying pressure. Search for leaks with a

piece of cardboard. Protect hands and body

from high pressure fluids.

Use caution when filling and draining hydraulic

oil. During periods of machine operation, the

hydraulic oil reservoir can get hot. Allow

engine and oil reservoir to cool before

servicing.

IMPORTANT: Avoid damage! Contamination of

hydraulic fluid could cause transmission damage or

failure. Do not open oil reservoir cap unless

absolutely necessary.

Severe or unusual conditions may require a more

frequent service interval.

NOTE: Whenever hydraulic components are removed

from the system, hoses are disconnected, or the

system has been drained, trapped air must be removed

from the hydraulic system.

Service Transmission - 16

Page 20

SERVICE TRANSMISSION

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Check hydraulic oil level. Adjust as necessary.

c CAUTION: Avoid injury! Machine must be

safely supported on jackstands before

removing or installing wheels. Do not use a

hoist or floor jack to support the machine.

3. Raise drive wheels off the ground and block caster

wheels.

NOTE: The pumps are located under the machine,

behind the mower deck.

A

MX9226

Picture Note: Left pump shown.

4. Open free-wheeling valves (A) one full turn

counterclockwise and start engine.

5. Slowly move the control levers in both forward and

reverse directions five to six times. As the air is purged

from the unit, the oil level will drop.

6. Turn off engine and check oil level. Adjust as necessary.

7. Close the free-wheeling valves and tighten to 9-14 N•m

(80-120 lb-in.).

8. Start engine and slowly move the control levers in both

forward and reverse directions five to six times.

9. Turn off engine and lower machine to ground. Check oil

level and adjust as necessary. Mower should move in

forward and reverse at normal speed, if not, repeat

procedure.

Service Transmission - 17

Page 21

SERVICE MOWER

Service Mower

Adjusting Mower Level

c CAUTION: Avoid injury! Mower blades are

sharp. Always wear gloves when handling

mower blades or working near blades.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Inflate drive (rear) tires to 69-83 kPa (10-12 psi), and

caster (front) tires to 110-139 kPa (16-20 psi).

3. Adjust cutting height to 50 mm (2 in.), and lower mower

to cutting position.

D

C

B

A

• If no adjustment is required, proceed to Step 8.

H

G

I

J

MX9221

7. Loosen jam nuts (G) and (H) on the swivel adjuster rod.

Turn the jam nuts as required to obtain the desired height

of position D.

8. Measure the distance from the top of the mower deck to

the ground at positions C and D. The height at position C

must be 3-6 mm (1/8-1/4 in.) higher than position D.

• If adjustment is required, proceed to Step 9.

• If no adjustment is required, proceed to Adjust

Cutting Height.

MX9288

4. Measure the distance from the top of the mower deck to

the ground at positions A and B. The height at position A

must be 3-6 mm (1/8-1/4 in.) higher than position B.

• If adjustment is required, proceed to Step 5.

• If no adjustment is required, proceed to Step 6.

E

F

MX9284

5. Loosen jam nuts (E) and (F) on the swivel adjuster rod.

Turn the jam nuts as required to obtain the desired height

of position A.

6. Measure the distance from the top of the mower deck to

the ground at positions B and D. The heights of position B

and D should be equal, ±3 mm (1/8 in.).

• If adjustment is required, proceed to Step 7.

9. Loosen the nut (I), and slide cap screw (J) in the slot

until the desired height at position C is obtained. Tighten

the nut.

Adjust Cutting Height

1. Set the cutting height to 89 mm (3-1/2 in.), and lower

mower to cutting position.

A

MIF

2. Turn right blade (A) so that the blade tip is pointing out

of the middle of the discharge chute.

3. Measure from outside blade tip to flat ground surface. If

the blade height (A) is not 89 mm (3-1/2 in.), adjust the

cutting height.

Service Mower - 18

Page 22

SERVICE MOWER

B

C

MX9285

4. Loosen the jam nut (B) on the link rod assembly, and

turn the sleeve (C) until the blade height is 89 mm (3-1/2

in.). Tighten the jam nut.

Checking and Adjusting Mower Deck Drive Belt Tension

counterclockwise.

Removing and Installing Mower Deck Drive

Belts

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Raise foot platform.

3. Remove mower deck drive belt covers.

B

A

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Adjust the mower deck for the lowest cutting height, and

lower the deck.

A

C

B

D

MX9217

3. Check the mower deck drive (A) and spindle drive (B)

belt tension. The belts should deflect a maximum of 13 mm

(1/2 in.) when a force of 4.5 kg (10 lb) is applied to the

center of the longest span.

• To Increase Belt Tension: Turn nut (C - mower

deck drive belt) or (D - spindle drive belt) clockwise.

D

C

MX9217

4. Release mower deck drive belt tension, by turning the

tension adjuster nut (A) counterclockwise.

5. Remove mower deck drive belt (B).

6. Release spindle drive belt tension by turning tension

adjustment nut (C) counterclockwise.

7. Remove spindle drive belt (D).

8. Install new spindle drive belt (D) and adjust drive belt

tension.

9. Install new mower deck drive belt (B) and adjust drive

belt tension.

10.Install mower deck drive belt covers.

11.Lower foot platform.

• To Decrease Belt Tension: Turn nut (C - mower

deck drive belt) or (D - spindle drive belt)

Service Mower - 19

Page 23

SERVICE MOWER

Checking for Bent Mower Blades

c CAUTION: Avoid injury! Mower blades are

sharp. Always wear gloves when handling

mower blades or working near blades.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Lower mower deck to mowing position.

A

MIF

3. Measure distance (A) between blade tip and flat ground

surface.

4. Turn blade 180°. Measure distance between the other

blade tip and flat ground surface.

A

C

B

D

MX9231

2. Remove nut (A), blade (B), blade washers (C), and bolt

(D).

3. Install blade (B), blade washers (C), bolt (D) and secure

using nut (A). Tighten nut to 80 N•m (60 lb-ft).

Balancing Mower Blades

1. Clean blade.

5. Install a new blade if the difference between the two

measurements is more than 3 mm (1/8 in.).

Servicing Mower Blades

c CAUTION: Avoid injury! Mower blades are

sharp. Always wear gloves when handling

mower blades or working near blades.

Removing and Installing Mower Blades

1. Park machine safely. (See Parking Safely in the Safety

section.)

M61524

2. Put blade on nail in a vise. Turn blade to horizontal

position.

3. Check balance. If blade is not balanced, heavy end of

blade will drop.

4. Grind bevel of heavy end. Do not change blade bevel.

Sharpening Blades

c CAUTION: Avoid injury! Always wear safety

eye protection when grinding.

• Sharpen blades with grinder, hand file, or electric blade

sharpener.

Service Mower - 20

Page 24

SERVICE MOWER

A

B

M61830

• Keep original bevel (A) when grinding.

• Blade should have 0.40 mm (1/64 in.) cutting edge (B)

or less.

• Balance blades before installing.

Replacing Mower Spindle Bearings

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove mower deck drive and spindle drive belt.

A

B

C

K

J

I

D

E

F

3. Remove mower blade.

H

G

MX9222A

4. Remove upper pulleys:

• Side Spindles: Remove nut (A), spacer (B) and

pulley (C).

• Center Spindle: Remove nut (D), drive pulley (E)

and spindle pulley (F).

5. Remove spindle shaft (G), lower bearing (H) and spacer

(I) from spindle housing (J). Discard bearing.

6. Remove and discard upper bearing (K).

7. Clean entire assembly.

8. Install a new lower bearing (H) and spacer (I) on the

spindle shaft (G).

IMPORTANT: Avoid damage! The clearance between

the lower bearing and the housing is only 0.05 mm

(0.002 in.). Do not force bearing into housing.

9. Install the spindle shaft (G), lower bearing (H) and

spacer (I) into the spindle housing (J).

10.Install the upper bearing (K).

Service Mower - 21

Page 25

SERVICE MOWER

11.Install upper pulleys:

• Side Spindles: Install pulley (C), spacer (B) and nut

(A). Tighten nut to 80 N•m (60 lb-ft).

• Center Spindle: Install spindle pulley (F), drive

pulley (E) and nut (D). Tighten nut to 80 N•m (60 lb-ft).

12.Install mower blade. Tighten nut to 80 N•m (60 lb-ft).

Replacing Mower Deck Idler Pulleys

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove the mower deck drive and spindle drive belts.

A

B

D

C

MX9252

3. Remove mower deck drive tension idler pulleys (A) and

(B), mower deck drive fixed idler pulley (C) and spindle

drive tension idler pulley (D).

4. Install new idler pulleys.

5. Install spindle drive and mower deck drive belts.

6. Adjust belt tension.

Service Mower - 22

Page 26

SERVICE ELECTRICAL

Service Electrical

WARNING: Battery posts, terminals and related

accessories contain lead and lead components, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

Removing and Installing the Battery

c CAUTION: Avoid injury! The battery produces a

flammable and explosive gas. The battery may

explode:

• Do not smoke near battery.

• Wear eye protection and gloves.

• Do not allow direct metal contact across

battery posts.

• Remove negative cable first when

disconnecting.

• Install negative cable last when connecting.

Removing:

1. Park the vehicle safely. (See Parking Safely in the

safety section.)

C

D

A

B

F

battery tray.

3. Tighten the cap screws and nuts (E) to secure the

battery in the battery tray. Do not overtighten.

4. Connect the positive (+) battery cable (D) first, then the

negative (-) cable (B).

5. Apply general purpose grease or silicone spray to the

terminals to prevent corrosion.

6. Slide covers (A and C) over battery terminals.

Checking Battery Electrolyte Level

c CAUTION: Avoid injury! Battery electrolyte

contains sulfuric acid. It is poisonous and can

cause serious burns:

• Wear eye protection and gloves.

• Keep skin protected.

• If electrolyte is swallowed, get medical

attention immediately.

• If electrolyte is splashed into eyes, flush

immediately with water for 15-30 minutes and

get medical attention.

• If electrolyte is splashed onto skin, flush

immediately with water and get medical

attention if necessary.

NOTE: Add only distilled water to replace normal

electrolyte loss.

1. Park the vehicle safely. (See Parking Safely in the

safety section.)

2. Remove battery from vehicle and set it on a level

surface.

E

G

MX9209

2. Slide black cover (A) away from the negative (-) battery

terminal and disconnect the negative (-) battery cable (B).

3. Slide red cover (C) away from the positive (+) battery

terminal and disconnect the positive (+) battery cable (D).

4. Loosen the cap screws and nuts (E) on both sides of the

battery tray.

5. Remove battery (F) and isolator pad (G).

Installing:

1. Place isolator pad (G) in the battery tray.

2. Install battery (F) in the battery tray, making sure that

the isolator pad (G) is between the bottom and sides of the

Service Electrical - 23

3. Remove battery cell caps. Make sure cap vents are not

plugged.

B

A

C

MIF

4. Check electrolyte level. Electrolyte (A) should be

Page 27

SERVICE ELECTRICAL

approximately halfway between bottom of filler neck (B)

and top of plates (C).

IMPORTANT: Avoid damage! Do not overfill battery.

Electrolyte can overflow when battery is charged

and cause damage.

5. Add only distilled water if necessary.

6. Install battery cell caps.

7. Install battery.

Cleaning Battery and Terminals

c CAUTION: Avoid injury! The battery produces a

flammable and explosive gas. The battery may

explode:

• Do not smoke near battery.

• Wear eye protection and gloves.

• Do not allow direct metal contact across

battery posts.

• Remove negative cable first when

disconnecting.

• Install negative cable last when connecting.

1. Disconnect and remove battery.

2. Wash battery with a solution of four tablespoons of

baking soda to one gallon of water. Be careful not to get the

soda solution into the battery cells.

3. Rinse the battery with plain water and dry.

4. Clean terminals and battery cable ends with wire brush

until bright.

5. Install battery.

6. Attach cable clamps to battery posts.

7. Apply petroleum jelly or silicone spray to terminal to

prevent corrosion.

Replacing Fuses

IMPORTANT: Avoid damage! When replacing fuses use only 20-amp fuses or you may damage the

circuit.

A

B

MX9245

1. Remove defective fuse (A - electric start circuit) or (B charging circuit) from socket.

2. Check metal clip in fuse window and discard fuse if clip

is broken.

3. Install new fuse into socket.

Check and Adjust PTO Clutch Air Gap

NOTE: If clutch is not equipped with adjusting nuts (B),

no adjustment is required.

1. Park the vehicle safely. (See Parking Safely in the

safety section.)

B

A

2. Check the air gap at the three openings (A) around the

clutch, using a feeler gauge. The air gap should be within

0.012-0.584 mm (0.005-0.023 in.). If the gap is not within

specifications, adjust the air gap.

3. Adjust the air gap to 0.34 mm (0.12 in.), by tightening or

loosening the three adjustment nuts (B).

B

MX9290

Two 20-amp fuses to protect the electric start and charging

circuit are located behind the seat area.

Service Electrical - 24

Page 28

Kohler Wiring Schematic

SERVICE ELECTRICAL

MX9299A

Service Electrical - 25

Page 29

SERVICE MISCELLANEOUS

Service Miscellaneous

Filling Fuel Tank

Use regular grade 87 octane unleaded fuel.

Add fuel stabilizer to fuel before using it in your machine to

prevent engine damage due to stale fuel. Follow directions

on stabilizer container.

c CAUTION: Avoid injury! Fuel vapors are

explosive and flammable:

• Shut engine off before filling fuel tank.

• Do not smoke while handling fuel.

• Keep fuel away from flames or sparks.

A

B

C

E

F

• Fill fuel tank outdoors or in well-ventilated

area.

• Clean up spilled fuel immediately.

• Use clean, approved non-metal container to

prevent static electric discharge.

• Use clean, approved plastic funnel without

screen or filter to prevent static electric

discharge.

IMPORTANT: Avoid damage! Dirt and water in fuel

can cause engine damage:

• Clean dirt and debris from the fuel tank opening.

• Use clean, fresh, stabilized fuel.

• Fill the fuel tank at the end of each day’s

operation to keep condensation out of the fuel tank.

• Use a non-metallic funnel with a plastic mesh

strainer when filling the fuel tank or container.

Checking Wheel Nuts

Tighten rear wheel nuts in an alternating pattern to 68 N•m

(50 lb-ft.).

G

F

E

C

D

MX9223

3. Remove lock nut (A), bolt (B), two spacers (C) and

wheel assembly (D).

4. Remove seals (E), bearings (F) and spacer tube (G)

from wheel.

5. Clean and inspect bearings (F) and pack with clean

grease. Replace bearings as needed.

6. Install spacer tube (G), bearings (F) and new seals (E).

7. Install wheel assembly (D), two spacers (C), bolt (B) and

lock nut (A).

Servicing Caster Pivot Bearings

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Raise and securely support the front of the mower deck.

Servicing Caster Wheel Roller Bearings

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Raise and securely support the front of the mower deck.

Service Miscellaneous - 26

Page 30

SERVICE MISCELLANEOUS

A

B

C

J

F

L

G

I

H

E

D

MX9224

3. Remove cap (A), cotter pin (B), castle nut (C), caster

yoke and wheel assembly (D) and caster bushing (E).

NOTE: It is not necessary to remove the bearing races

(F) and (G), unless the bearings need to be replaced.

4. Remove seal (H) and lower bearing (I).

5. Remove upper bearing (J).

6. Clean and inspect bearings (I) and (J); pack with clean

grease. Replace bearings if needed.

7. Install lower bearing (I) and a new seal (H).

8. Install upper bearing (J).

NOTE: Do not overtighten castle nut (C). Tighten castle

nut only enough to remove excess play from bearings.

Align crossdrill and nut to allow installation of the

cotter pin (B). The caster wheel yoke assembly must be

free to rotate.

9. Install caster bushing (E) on yoke shaft, and install

caster yoke and wheel assembly (D), castle nut (C), and

cotter pin (B).

10.Apply grease to lubrication fitting (L) until you can see

grease at the top bearing (J). Install grease cap (A).

Service Miscellaneous - 27

Page 31

TROUBLESHOOTING

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this

chart, see your Great Dane dealer for service.

When you have checked all the possible causes listed and

you are still experiencing the problem, see your Great

Dane dealer.

Engine

NOTE: This engine troubleshooting chart covers items

that are unique to the machine operation. See the

engine manufacturer’s owner’s manual provided with

your machine for detailed engine troubleshooting

procedures.

If Check

Poor Engine Performance Dirt in fuel system or fuel is old; obtain fresh fuel from another

supplier before suspecting machine problems. Suppliers blend fuels

differently and changing suppliers will generally solve any

performance problems.

Fuel blended with alcohol or ether may contribute to performance

problems by causing gum and varnish deposits, especially if fuel is

stored for several weeks or more. Obtain fresh fuel.

Engine Will Not Start Park brake not locked.

Control levers are not in neutral position.

PTO/clutch switch is in on position.

Fuel shutoff valve in off position.

Spark plug wire(s) loose or disconnected.

Improper fuel.

Plugged fuel filter.

Electrical problem. (See Electrical Troubleshooting section)

Engine Will Not Idle Operator rising off the seat.

Engine Stops Or Misses When Operating On

Hillsides

Engine Backfires Operator rising off of the seat.

Fuel tank less than half full of fuel.

Operator rising off of the seat.

Troubleshooting - 28

Page 32

TROUBLESHOOTING

Electrical

If Check

Starter Does Not Work Or Will Not Turn Engine Park brake is not locked.

PTO/clutch switch is in on position.

Battery terminals are corroded.

Battery not charged.

20-amp fuse is blown.

Battery Will Not Charge Dead cell in the battery.

Battery cables and terminals are dirty.

Low engine speed or excessive idling.

Machine Operation

If Check

Machine Vibrates Too Much Or Rattles Excessively Attachment drive belts worn or damaged.

Traction drive belt damaged or worn.

Dirt on drive sheaves.

Machine Will Not Move With Engine Running Park brake locked.

Transmission hydraulic oil level low.

Free-wheeling valves are open.

Traction drive belt damaged or worn.

Machine Will Not Follow a Straight Path Steering tracking out of adjustment.

Machine Moves To The Left Or Right With Engine

Running And Transmission In Neutral

Pump linkage (neutral position) out of adjustment.

Mower

If Check

Discharge Chute Plugged Travel speed too fast.

Grass too long.

Grass too wet.

Engine rpm not at wide open throttle.

Restricted air flow.

Belt installed incorrectly.

Patches Of Grass Uncut Travel speed too fast.

Engine rpm not at wide open throttle.

Mower deck needs cleaning.

Troubleshooting - 29

Page 33

TROUBLESHOOTING

If Check

Belt Slipping Debris in sheaves.

Worn belt.

Too Much Vibration Debris on mower deck or in sheaves.

Damaged sheaves or sheaves out of alignment.

Damaged drive belt.

Blades out of balance.

Blades Scalping Grass Cutting too low.

Mower wheels not adjusted correctly.

Turning speed too fast.

Ridges in terrain.

Rough or uneven terrain.

Low tire pressure.

Mower Loads Down Engine Engine rpm too low.

Travel speed too fast.

Debris wrapped around mower spindles.

Uneven Cut Mower deck not leveled properly.

Travel speed too fast.

Blades dull.

Mower wheels not adjusted correctly.

Tire pressure unequal.

Grass Tips Are Jagged And Turn Grayish Brown

After Mowing

Dull mower blades.

Mower deck not leveled properly.

Troubleshooting - 30

Page 34

STORAGE

Storage

Storing Safety

c CAUTION: Avoid injury! Fuel vapors are

explosive and flammable. Engine exhaust

fumes contain carbon monoxide and can cause

serious illness or death:

• Run the engine only long enough to move

the machine to or from storage.

• Do not store vehicle with fuel in the tank

inside a building where fumes may reach an

open flame or spark.

• Allow the engine to cool before storing the

machine in any enclosure.

Preparing Machine for Storage

1. Repair any worn or damaged parts. Replace parts if

necessary. Tighten loose hardware.

2. Repair scratched or chipped metal surfaces to prevent

rust.

3. Clean under the deck and remove grass and debris

from inside chute and bagger.

4. Wash the machine and apply wax to metal and plastic

surfaces.

5. Run machine for five minutes to dry belts and pulleys.

6. Apply light coat of engine oil to pivot and wear points to

prevent rust.

circulate through carburetor.

Engine:

Engine storage procedure should be used when vehicle is

not to be used for longer than 60 days.

1. Change engine oil and filter while engine is warm.

2. Service air filter if necessary.

3. Clean debris from engine air intake screen.

4. Remove spark plugs. Put 30 mL (1 oz.) of clean engine

oil in cylinders.

5. Crank the engine five or six times to allow oil to be

distributed.

6. Install spark plugs.

7. Clean the engine and engine compartment.

8. Remove battery.

9. Clean the battery and battery posts. Check the

electrolyte level.

10.Move fuel shut-off valve to off position.

11.Store the battery in a cool, dry place where it will not

freeze.

NOTE: The stored battery should be recharged every

90 days.

12.Charge the battery.

13.Store the vehicle in a dry, protected place. If vehicle is

stored outside, put a waterproof cover over it.

Preparing Fuel and Engine for Storage

Fuel:

If you have been using “Stabilized Fuel”, add stabilized fuel

to tank until the tank is full.

NOTE: Filling the fuel tank reduces the amount of air in

the fuel tank and helps reduce deterioration of fuel.

If you are not using “Stabilized Fuel”:

1. Park machine safely in a well-ventilated area.

NOTE: Try to anticipate the last time the machine will

be used for the season so very little fuel is left in the

fuel tank.

2. Turn on engine and allow to run until it runs out of fuel.

3. Turn key to off position.

4. Mix fresh fuel and fuel stabilizer in separate container.

Follow stabilizer instructions for mixing.

5. Fill fuel tank with stabilized fuel.

6. Run engine for a few minutes to allow fuel mixture to

Removing Machine From Storage

1. Check tire pressure.

2. Check engine oil level.

3. Check battery electrolyte level. Charge battery if

necessary.

4. Install battery.

5. Check spark plug gap. Install and tighten plugs to

specified torque.

6. Lubricate all grease points.

7. Turn fuel shut-off valve to on position.

8. Run the engine 5 minutes without the mower or any

attachments running to allow oil to be distributed

throughout engine.

9. Be sure all shields and guards or deflectors are in place.

Storage - 31

Page 35

ASSEMBLY

Assembly

Install Seat and Control Lever Handles

1. Install seat on platform and secure using nuts provided

in small parts bag.

2. Connect seat safety switch to wiring harness.

3. Install handles on control levers and secure using

sleeves, cap screws and nuts provided in small parts bag.

Activate and Charge Battery

c CAUTION: Avoid injury! Battery electrolyte

contains sulfuric acid. It is poisonous and can

cause serious burns:

• Wear eye protection and gloves.

• Keep skin protected.

• If electrolyte is swallowed, get medical

attention immediately.

• If electrolyte is splashed into eyes, flush

immediately with water for 15-30 minutes and

get medical attention.

• If electrolyte is splashed onto skin, flush

immediately with water and get medical

attention if necessary.

1. Park the vehicle safely. (See Parking Safely in the

Safety section.)

2. Remove battery from machine and set it on a level

surface.

3. Remove battery cell caps. Make sure cap vents are not

plugged.

be 6 mm (1/4 in.) above plates (B), but NO HIGHER

than 6 mm (1/4 in.) from the bottom of the filler neck (C).

5. Install the battery caps before charging the battery.

IMPORTANT: Avoid damage! Wait 20 minutes before

charging the battery to allow the plates to “absorb”

the acid, so they will take a charge well.

Battery must be charged before operation. Adding

acid without charging will result in battery damage.

6. Charge the battery for a minimum of 30 minutes at 5-10

amps. If your battery charger has a Deep Cycle or

Maintenance Free setting, use this setting to charge the

battery. Failure to charge the battery before use will reduce

battery performance and life.

7. Install the battery in the machine.

Check Fluid Levels

IMPORTANT: Avoid damage! Check all fluid levels

before attempting to start the machine. Machine

should be parked on a hard, level surface with the

key switch in the STOP position.

Check Engine Oil Level

Oil level should be between the ADD and FULL marks on

the dipstick. Add oil as necessary.

Check Transmission Oil Level

Hydraulic oil level should be to the top of the FULL COLD

mark on the reservoir dipstick. Add oil as necessary.

If your mower has no dipstick, make sure that oil is 76 mm

(3 in.) from the top of the filler pipe.

C

A

B

4. Fill the battery:

• Only use battery acid with a 1.265 specific gravity.

• Slowly add acid (A) to each cell. The solution should

Lubricate Machine

Lubricate all moving parts before operating the machine,

see Lubrication Points in Service Lubrication section.

Check Safety System

For a complete checkout procedure of the safety interlock

system, see Testing the Safety Interlock System in the

Operating section.

MIF

Assembly - 32

Page 36

ASSEMBLY

Check Tire Pressure