Page 1

Scamper HG

GDB10025, GDB10026, GDB10027,

GDB10028, GDB10029, GDB10030

GD10003

B3

OPERATOR’S MANUAL

c WARNING: The Engine Exh aust

from this product contains chemicals known

to the State of California to cause cancer,

birth defects or other reproductive harm.

California Proposition 65 Warning

OMGD10003 B3

North American Version

Litho in U.S.A.

Page 2

INTRODUCTION

Introduc tion

Using Your Operator’s Manual

This manual is an important part of your machine and

should remain with the machine when you sell it.

An engine manufacturer’s owner’s manual has been

provided with your machine. This will provide maintenance

and troubleshooting information for the engine installed in

your machine.

Reading your operator’s manual will help you and others

avoid personal injury or damage to the machine.

Information given in this manual will provide the operator

with the safest and most effective use of the machine.

Sections in your operator’s manual are placed in a specific

order to help you understand all the safety messages and

learn the controls so you can operate this machine safely.

You can also use this manual to answer any specific

operating or servicing questions.

The machine shown in this manual may differ slightly from

your machine, but will be similar enough to help you

understand our instr uctions.

RIGHT-HAND and LEFT-HAND sides are determined by

facing in the direction the machine will travel when going

forw ard. When you see a broken line (------), the item

referred to is hidden from view.

GDB10026 (15 hp, Recoil, 48-Inch Deck) Serial No.

(TCHR15W010001-

GDB10027 (17 hp, Recoil, 48-Inch Deck) Serial No.

(TCHR17W010001-

GDB10028 (17 hp, Electric, 48-Inch Deck) Serial No.

(TCHE17W010001-

GDB10029 (17 hp, Recoil, 52-Inch Deck) Serial No.

(TCHR17W010001-

GDB10030 (17 hp, Electric, 52-Inch Deck) Serial No.

(TCHE17W010001-

If you need to contact an Authorized Service Center for

information on servicing, always provide the product model

and serial numbers.

You will need to locate the model and serial numbers for the

machine and for the engine of your machine and record the

information in the spaces provided below.

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

Special Messages

Your manual contains special messages to bring attention

to potential safety concerns, machine damage as well as

helpful operating and servicing information. Please read all

the information carefully to avoid injury and machine

damage.

c CAUTION: Avoid injury! This symbol and text

highlight potential hazards or death to the

operator or bystanders that may occur if the

hazards or procedures are ignored.

IMPORTANT: Avoid damage! This text is us ed t o tell

the operator of actions or conditions that might

result in damage to the machine.

NOTE: General information is given throughout the

manual that may help the operator in the operation or

service of the machine.

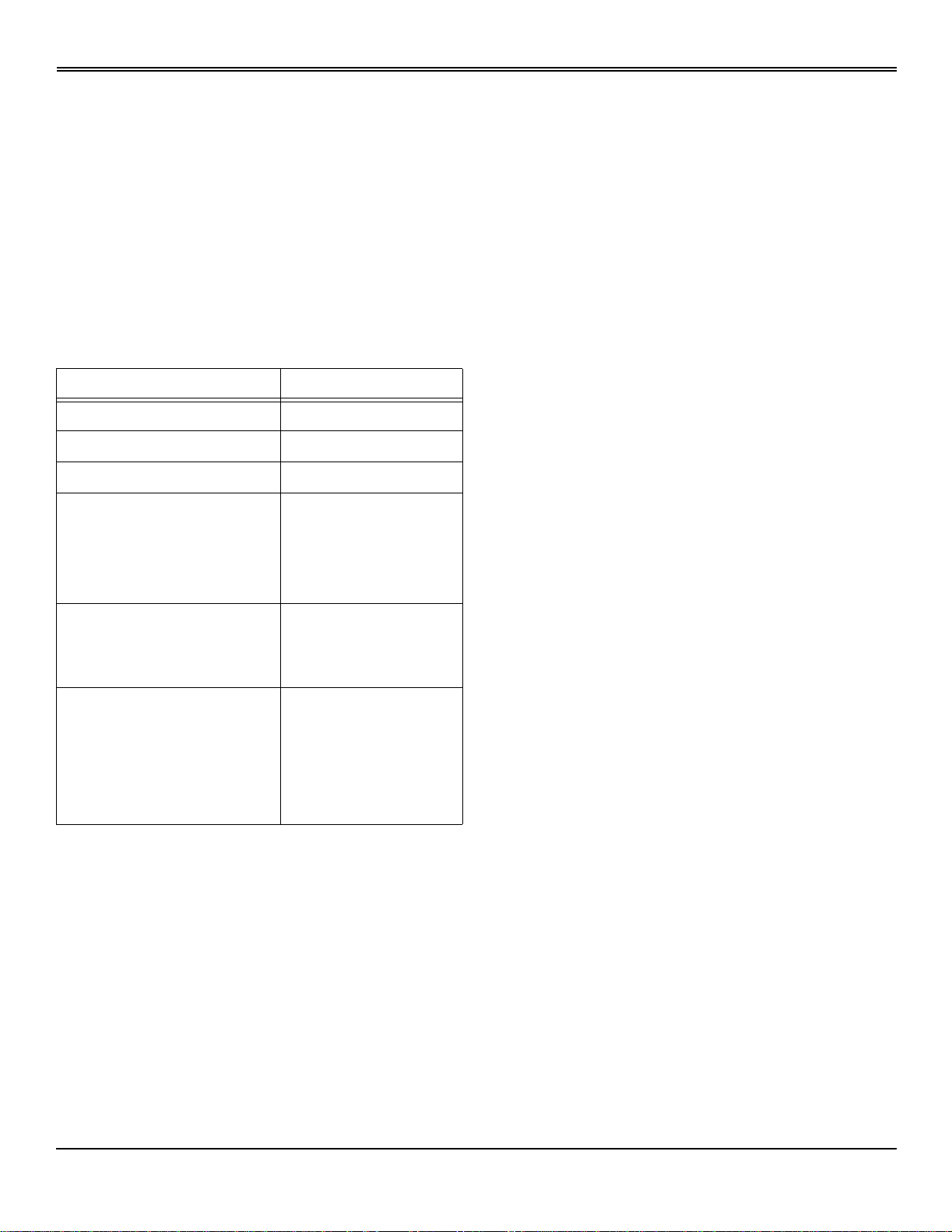

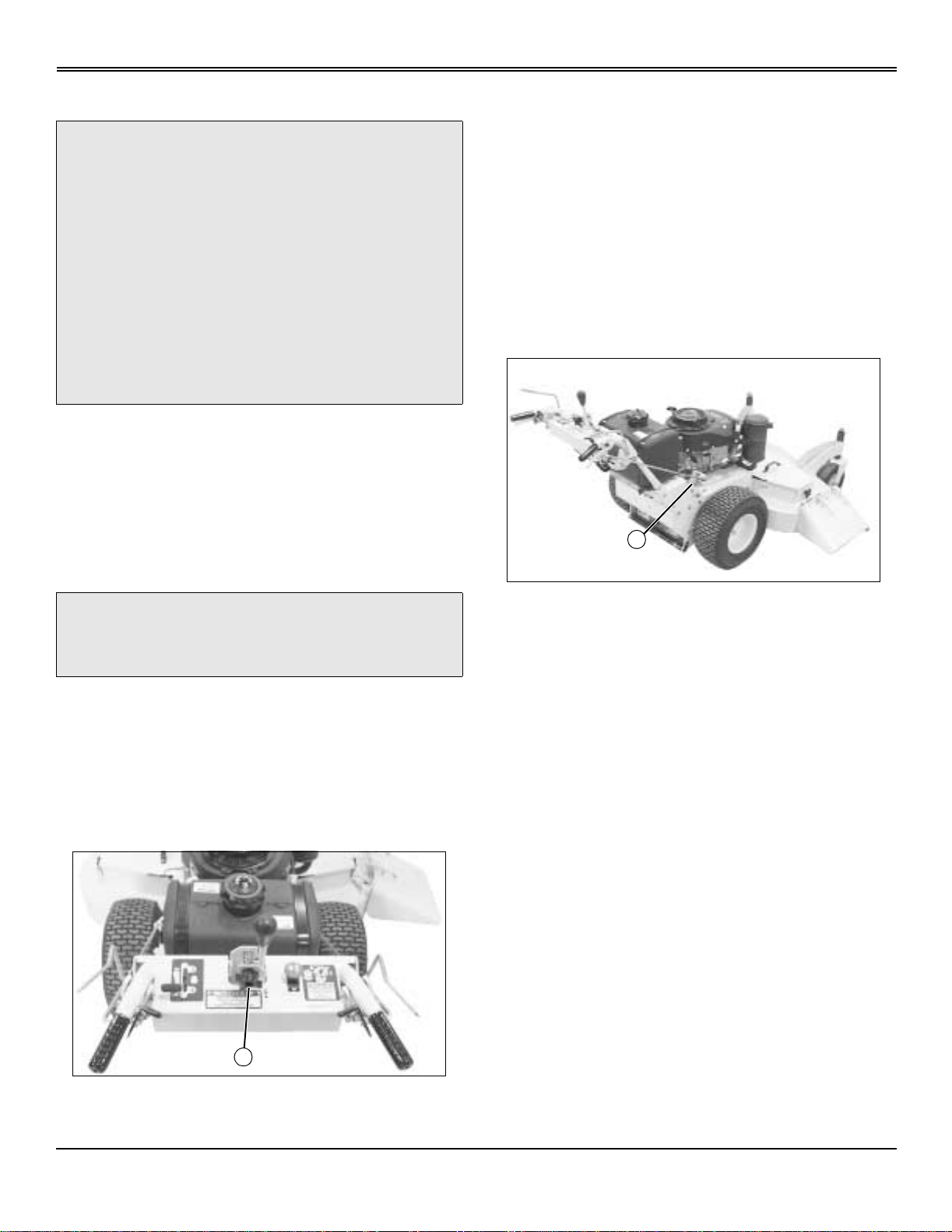

Record Identification Numbers

Scamper HG

B

A

MX18836

MODEL NUMBER (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

SERIAL NUMBER (POWER UNIT) (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER (B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SPECIFICATION NUMBER (B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

GDB10025 (15 hp, Recoil, 36-Inch Deck) Serial No.

(TCHR15W010001-

Introduction

Page 3

TABLE OF CONTENTS

Table of Contents

Safety .....................................................................................................................................................................................1

Operating................................................................................................................................................................................7

Replacement Parts................................ .............................................. ...... ...........................................................................11

Service Intervals...................................................................................................................................................................12

Service Lubrication...............................................................................................................................................................13

Service Engine .....................................................................................................................................................................14

Service Tr ansmission............................................................................................................................................................16

Service Mower......................................................................................................................................................................18

Service Electrical..................................................................................................................................................................22

Service Miscellaneous..........................................................................................................................................................25

Troubleshooting ....................................................................................................................................................................27

Storage.................................................................................................................................................................................32

Assembly..............................................................................................................................................................................33

Specifications .......................................................................................................................................................................35

Index.....................................................................................................................................................................................36

Service Record GD ..............................................................................................................................................................37

All information, illustrations and

specifications in this manual are based

on the latest information at the time of

publication. The right is reserved to

make changes at any time without

John Deere Worldwide Commercial and

Consumer Equipment Division

notice.

COPYRIGHT© 2003

Deere & Co.

All rights reserved

Previous Editions

COPYRIGHT© 2002

OMGD10003 B3 - English

Table of Contents

Page 4

SAFETY

Safety

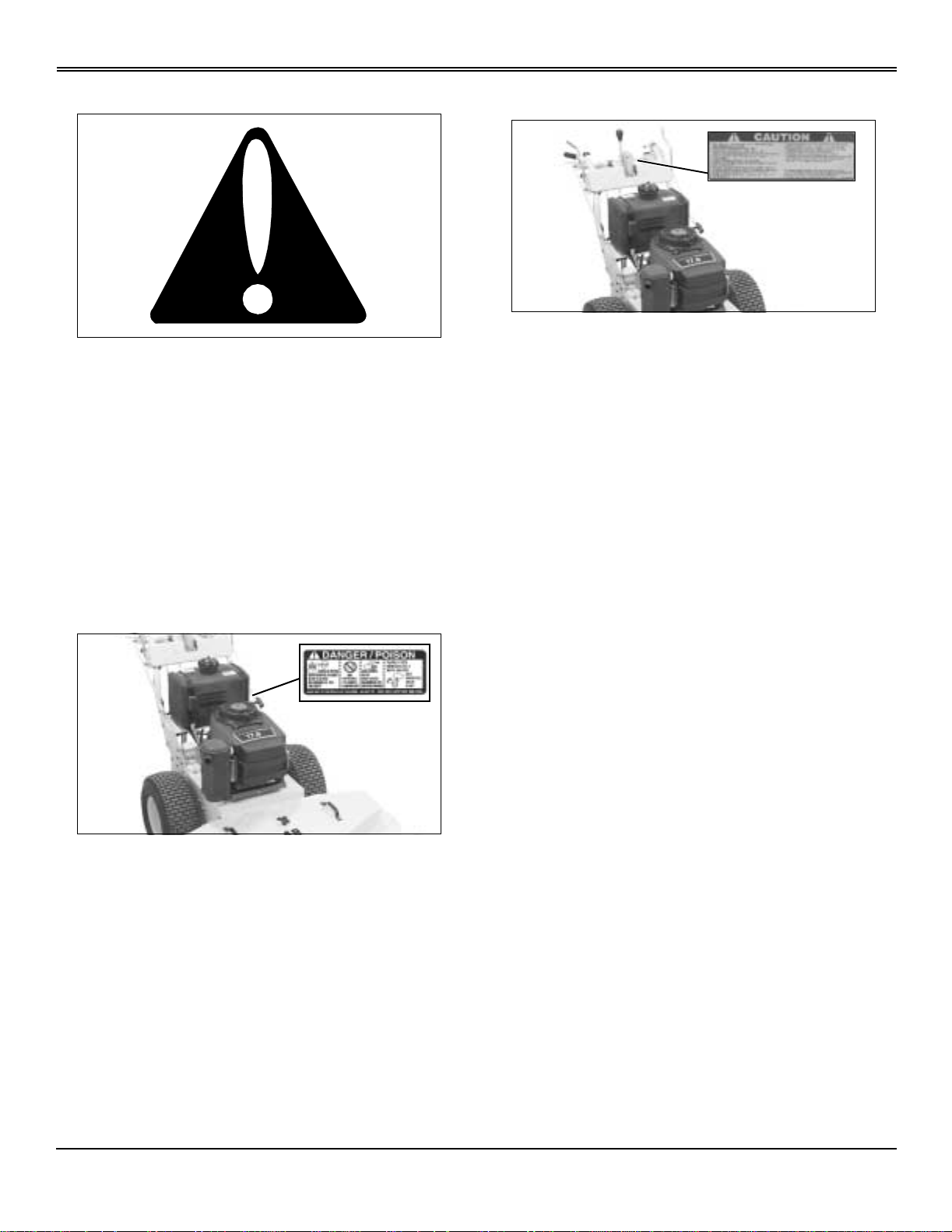

Understanding The Machine Safety Labels

Safety-Alert Symbol

The machine safety labels shown in this section are placed

in important areas on your machine to draw attention to

potential safety hazards.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-alert

symbol. DANGER identifies the most serious hazards.

The operator’s manual also explains any potential safety

hazards whenever necessary in special safety messages

that are identified with the word, CAUTION, and the safetyalert symbol.

CAUTION

MX9295 M9261

• This product is designed for professional and

commercial users.

• Operation training is required.

• Carefully read safety instructions.

• Know function of controls before operating.

• Practice with cutter blades off until confident.

• Clear mowing area of all debris.

• Keep all guards, covers and shields in place while

working.

• Do not disable or bypass any safety device.

DANGER/POISON

MX9292 MX9261

• Shield eyes, explosive gases can cause blindness or

injury.

• No sparks, flames, smoking.

• Sulfuric acid can cause blindness or severe burns.

• Flush eyes immediately with water, get medical help

fast.

• Keep out of the reach of children.

• Do not tip.

• Always wear safety goggles while operating.

• Always park machine on level surface.

• Avoid contact with cutter blades. They may be rotating.

• Keep children and others clear from area.

• Set ground speed control to safe speed.

• Slowly and smoothly move speed control levers to start

and stop machine.

• Reduce speed and avoid sharp turns.

• Always hold on to safety bar while operating.

• Be careful on slopes, do not mow where stability or

traction is in doubt.

• To obtain additional operator manual and safety

instructions, contact Great Dane dealer or write to: Great

Dane Power Equipment, P.O. Box 33009, Raleigh, NC

27636-3009, USA.

• Keep vent caps tight and level.

Safety - 1

Page 5

SAFETY

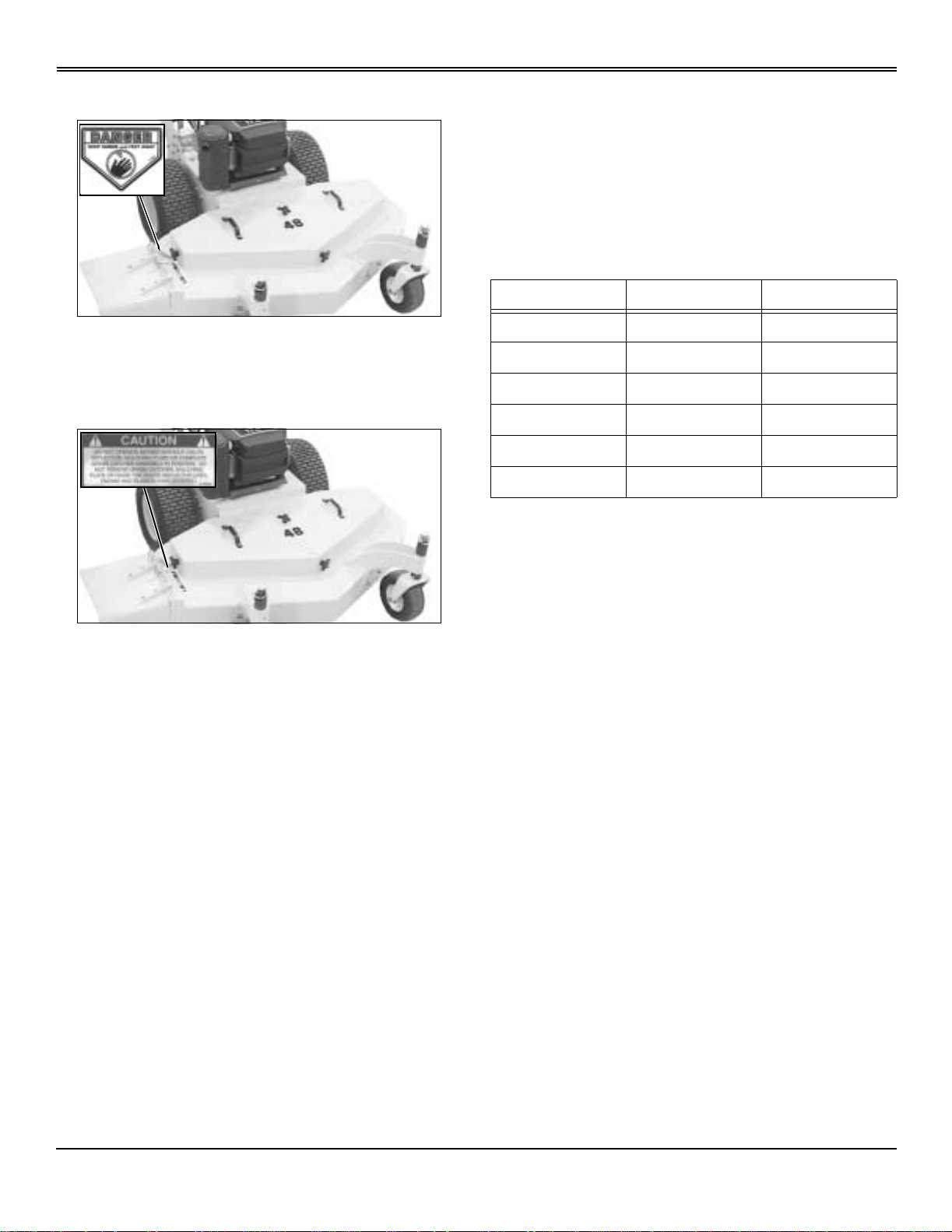

DANGER

• Keep hands and feet away.

CAUTION

MX9293 MX9261

Emission Compliance Period (Small Off-Road Gas Engines)

If your engine has the emission compliance category listed

on the emission control system certification or air index

label, this indicates the number of operating hours for which

the engine has been certified to meet EPA and/or CARB

emission requirements. The following table provides the

engine compliance period in hours associated with the

category found on the certification label.

Agency Category Hours

EPA C 250

EPA B 500

EPA A 1000

CARB Moderate 125

CARB Intermediate 250

CARB Extended 500

Operating Safely

MX9294 MX9261

• Do not operate mower without chute deflector, mulching

plate or complete grass catcher assembly in position.

• Do not remove grass catcher, mulching plate or raise the

chute deflector until engine and blade(s) have stopped.

Emission Control System Certification Label (Small Off-Road Gas Engines)

NOTE: Tampering with emission controls and

components by unauthorized personnel may result in

severe fines or penalties. Emission controls and

components can only be adjusted by EP A and/or CARB

authorized service centers. Contact your Great Dane

Equipment Retailer concerning emission controls and

component questions.

The presence of an emissions label signifies that the

engine has been certified with the United States

Environmental Protection Agency (EPA) and/or California

Air Resources Board (CARB).

The emissions warranty applies only to those en gines

marketed by Great Dane that have been certified by the

EPA and/or CARB; and used in the United States and

Canada in off-road mobile equipment.

• Do not allow operation or service of the machine by

children or untrained adults.

• Read the operator’s manual and study the safety and

operation sections before operating the machine.

• Operate the machine in an open, unobstructed area

under the direction of an experienced operator.

• Learn the use of all controls.

• Operator experience is required to learn the moving,

stopping, turning and other operating characteristics of the

machine.

• Inspect machine before you operate. Be sure hardware

is tight. Repair or replace damaged, badly worn, or missing

parts. Be sure guards and shields are in good condition

and fastened in place. Make any necessary adjustments

before you operate.

• Do not operate mower without discharge chute or entire

grass catcher in place.

• Check before each use that operator presence controls

are functioning correctly. Test safety systems. Do not

operate unless they are functioning correctly.

• Do not change the engine governor setting or overspeed

the engine.

• Check park brake function before operating. Adjust or

service park brake as necessary.

• Stop machine if anyone enters the area.

• Never raise mower decks when blades are running.

Safety - 2

Page 6

SAFETY

• If you hit an object, stop and inspect the machine. Make

repairs before you operate. Keep machine and attachments

properly maintain ed and in goo d wor king or der.

• Do not leave machine unattended when it is running.

• Only operate during daylight or with good artificial light.

• Slow down and be careful of traffic when operating near

or crossing roadways. Stop blades before crossing roads or

sidewalks. Use care when approaching blind corners,

shrubs, trees, or other objects that may obscure vision.

• Be aware of the mower discharge direction and make

sure that no one is in the path of the discharge direction.

• Use only accessories and attachments approved by the

manufacturer of the machine.

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Always wear safety goggles or safety glasses with side

shields and a hard hat when operating the mower.

• Wear a suitable protective device such as earplugs.

Loud noise can cause impairment or loss of hearing.

• Do not wear radio or music headphones. Safe service

and operation requires your full attention.

Slow down when you travel over rough ground.

Parking Safely

1. Stop machine on a level surface, not on a slope.

2. Disengage PTO.

3. Lock park brake.

4. Stop engine.

5. Remove key.

6. Wait for engine and all moving parts to stop before you

leave the operator’s station.

Rotating Blades are Dangerous

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

Using a Spark Arrestor

The engine in this machine is not equipped with a spark

arrestor muffler. It is a violation of California Public

Resource Code Section 4442 to use or operate this engine

on or near any forest-covered, brush-covered or grasscovered land unless the exhaust system is equipped with a

spark arrestor meeting any applicable local or state laws.

Other states or federal areas may have similar laws.

A spark arrestor for your machine may be available from

your authorized dealer. An installed spark arrestor must be

maintained in good working order by the operator.

Checking Mowing Area

• Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform the

job.

• Clear mowing area of objects that might be thrown.

Keep people and pets out of mowing area.

• Low-hanging branches and similar obstacles can injure

the operator or interfere with mowing operation. Before

mowing, identify potential obstacles such as low-hanging

branches, and trim or remove those obstacles.

• Study mowing area. Set up a safe mowing pattern. Do

not mow where traction or stability is doubtful.

• Test drive area with mower lowered but not running.

MIF

• Rotating blades can cut off arms and legs.

• Keep hands, feet and clothing away from mower deck

when engine is running.

• Be alert at all times, drive forward carefully. People,

especially children can move quickly into the mowing area

before you know it.

• Before backing up, shut off PTO and look down and

behind the machine carefully, especially for children.

• Do not mow in reverse.

• Shut off blades when you are not mowing.

• Do not operate machine if you are under the influence of

drugs or alcohol.

• Park machine safely before inspecting or unplugging

mower or bagger.

PROTECT CHILDREN:

• Never assume that children will remain where you last

saw them. Children are attracted to mowing activity; stay

alert to the presence of children.

• Keep children indoors when you are mowing. Turn the

Safety - 3

Page 7

SAFETY

machine off if a child enters the mowing area.

• Use extra care when you come to blind corners, shrubs,

trees, or other objects that may block your vision.

• Do not let children or an untrained person operate the

machine.

• Do not carry or let children ride on any attachment or

machine even with the blades off. Do not tow children in a

cart or trailer.

Avoid Tipping

• Slopes are a major factor related to loss-of-control and

tip-over accidents, which can result in severe injury or

death.

• Drive across a hill - not up and down. If necessary, turn

slowly and in the downhill direction. Do not shift to neutral

and coast downhill.

• Avoid starting and stopping on a slope. If machine

stops, disengage mower blades and back down slowly.

• Do not drive where machine could slip or tip.

• Stay alert for holes and other hidden hazards in the

terrain.

• Keep away from drop-offs, ditches, and embankments.

• Slow down before you make a sharp turn or operate on

a slope.

• Mowing when grass is wet can cause reduced traction

and sliding.

Keep Rider s Off

• Only allow the operator on the machine. Keep riders off.

• Riders on the machine or attachment may be struck by

foreign objects or thrown off the machine causing serious

injury.

• Riders obstruct the operator’s view resulting in the

machine being operated in an unsafe manner.

Practice Safe Maintenance

• Only qualified, trained adults should service this

machine.

• Understand service procedure before doing work. Keep

area clean and dry.

• Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

• Never lubricate, service, or adjust machine while it is

moving. Wait for all movement to stop on machine before

adjusting, cleaning or repairing.

• Keep safety devices in place and in working condition.

Keep hardware tight.

• On multi-bladed machines, be aware that rotating one

blade can cause other blades to rotate.

• Keep hands, feet, clothing, jewelry, and long hair away

from any moving parts, to prevent them from getting

caught.

• Disengage all power and stop the engine. Lock park

brake and remove the key. Let machine cool.

• Disconnect battery or remove spark plug wire (for

gasoline engines) before making any repairs.

• Before servicing machine, carefully release pressure

from any components with stored energy , such as hydraulic

components.

• Keep all nuts and bolts tightened, especially blade

attachment bolts.

• Securely support any machine elements that must be

raised for service work. Use jack stands or lock service

latches to support components when needed.

• Never run engine unless park brake is locked.

• Use care when checking blades. Wrap blades or wear

gloves and use caution when servicing them. Only replace

blades. Never straighten or weld them.

• Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Replace all worn or damaged safety and instruction decals.

Checking Whe el Bolts

• A serious accident could occur causing serious injury if

wheel bolts are not tight.

• Check wheel bolt tightness often during the first 100

hours of operation.

• Wheel hardware must be tightened to specified torque

using the proper procedure anytime it is loosened.

Safety - 4

• Grass catcher components are subject to wear,

damage, and deterioration which could expose moving

parts or allow objects to be thrown. Check components

frequently and replace with manufacturer’s recommended

parts when necessary.

• Charge batteries in an open, well-ventilated area, away

from sparks. Unplug battery charger before connecting or

disconnecting from the battery. W ear protective clothing

and use insulated tools.

• Do not modify machine or safety devices. Unauthorized

modifications may impair its function and safety.

• Check park brake function frequently. Adjust and service

Page 8

SAFETY

as needed.

Prevent Fires

• Remove grass and debris from engine compartment

and muffler area, before and after operating machine,

especially after mowing or mulching in dry conditions.

• To reduce fire hazard, keep engine and engine

compartment free of grass, leaves, or excessive grease.

• Clean up oil or fuel spillage.

• Allow engine to cool before storing in any enclosure.

• Never remove fuel cap, or add fuel with engine running

or hot. Allow engine to cool for several minutes.

• Never store equipment with fuel in the tank inside a

building where fumes may reach an open flame or spark.

• Always shut off fuel when storing or transporting

machine.

Tire Safety

Explosive separation of a tire and rim parts can cause

serious injury or death:

• Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

• Always maintain the correct tire pressure. Do not inflate

the tires above the recommended pressure. Never weld or

heat a wheel and tire assembly. The heat can cause an

increase in air pressure resulting in a tire explosion.

Welding can structurally weaken or deform the wheel.

• When inflating tires, use a clip-on chuck and extension

hose long enough to allow you to stand to one side and not

in front of or over the tire assembly.

• Check tires for low pressure, cuts, bubbles, damaged

rims or missing lug bolts and nuts.

Handling Fuel Safely

Fuel and fuel vapors are highly flammable:

• Do not refuel machine while you smoke, when machine

is near an open flame or sparks, or when engine is running.

Stop engine and allow to cool before filling.

• Never remove the fuel cap or add fuel with the engine

running.

• Replace all fuel tanks and container caps securely.

• Never fill fuel tank or drain fuel from a machine in an

enclosed area. Fill fuel tank outdoors.

• Prevent fires. Clean up spilled fuel immediately . If fuel is

spilled on clothing, change clothing immediately. Do not

attempt to start the engine but move the machine away

from the area of spillage and avoid creating any source of

ignition until fuel vapors have dissipated.

• Do not store fuel in container or machine with fuel in

tank in a building where fumes may reach an open flame or

spark.

• Prevent fire and explosion caused by static electric

discharge. Use only non-metal, portable fuel containers

approved by the Underwriter’s Laboratory (U.L.) or the

American Society for Testing & Materials (ASTM). If using a

funnel, make sure it is plastic and has no screen or filter.

Safety - 5

Page 9

SAFETY

• Static electric discharge can ignite gasoline vapors in an

ungrounded fuel container. Remov e the fuel container from

the bed of a machine or trailer or the trunk of a car and

place on the ground away from the machine before filling.

Keep nozzle in contact with container opening while filling.

Do not use a nozzle lock-open device.

The seller of the chemical products used with your machine

is responsible for providing the MSDS for that product.

• When practical, remove equipment from trailers or truck

beds and refuel them on the ground. If this is not possible,

use a portable, plastic fuel container to refuel equipment on

a truck bed or trailer.

• For gasoline engines, do not use gas with methanol.

Methanol is harmful to your health and to the environment.

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant, brake fluid,

and batteries, can harm the environment and people:

• Do not use beverage containers for waste fluids someone may drink from them.

• See your local Recycling Center or authorized dealer to

learn how to recycle or get rid of waste products.

• A Material Safety Data Sheet (MSDS) provides specific

details on chemical products: physical and health hazards,

safety procedures, and emergency response techniques.

Safety - 6

Page 10

OPERATING

Operating

Daily Operating Checklist

❏ Test safety systems.

❏ Check tire pressure.

❏ Check fuel level.

❏ Check engine oil level.

❏ Remove grass and debris from machine.

❏ Clean air intake screen.

❏ Check area below machine for leaks.

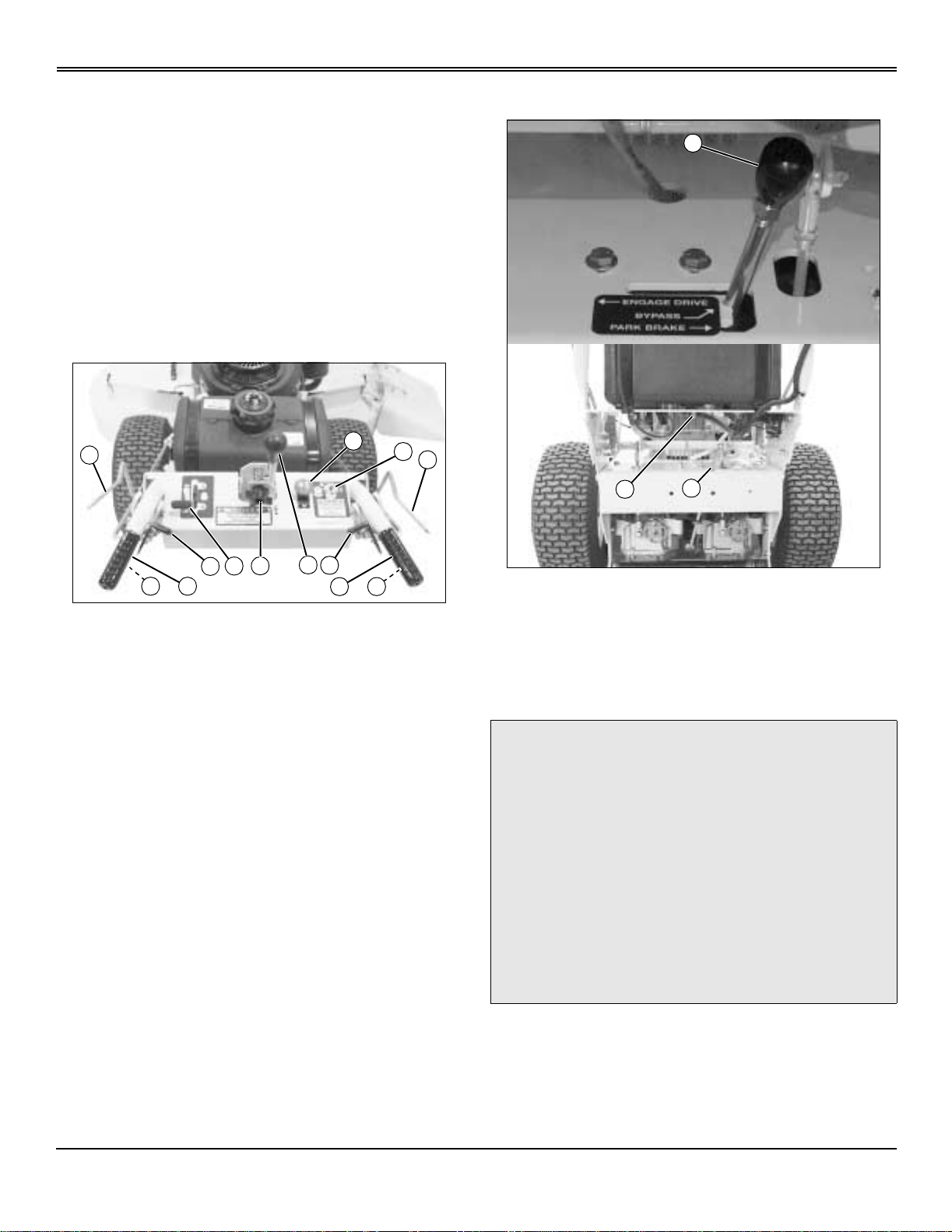

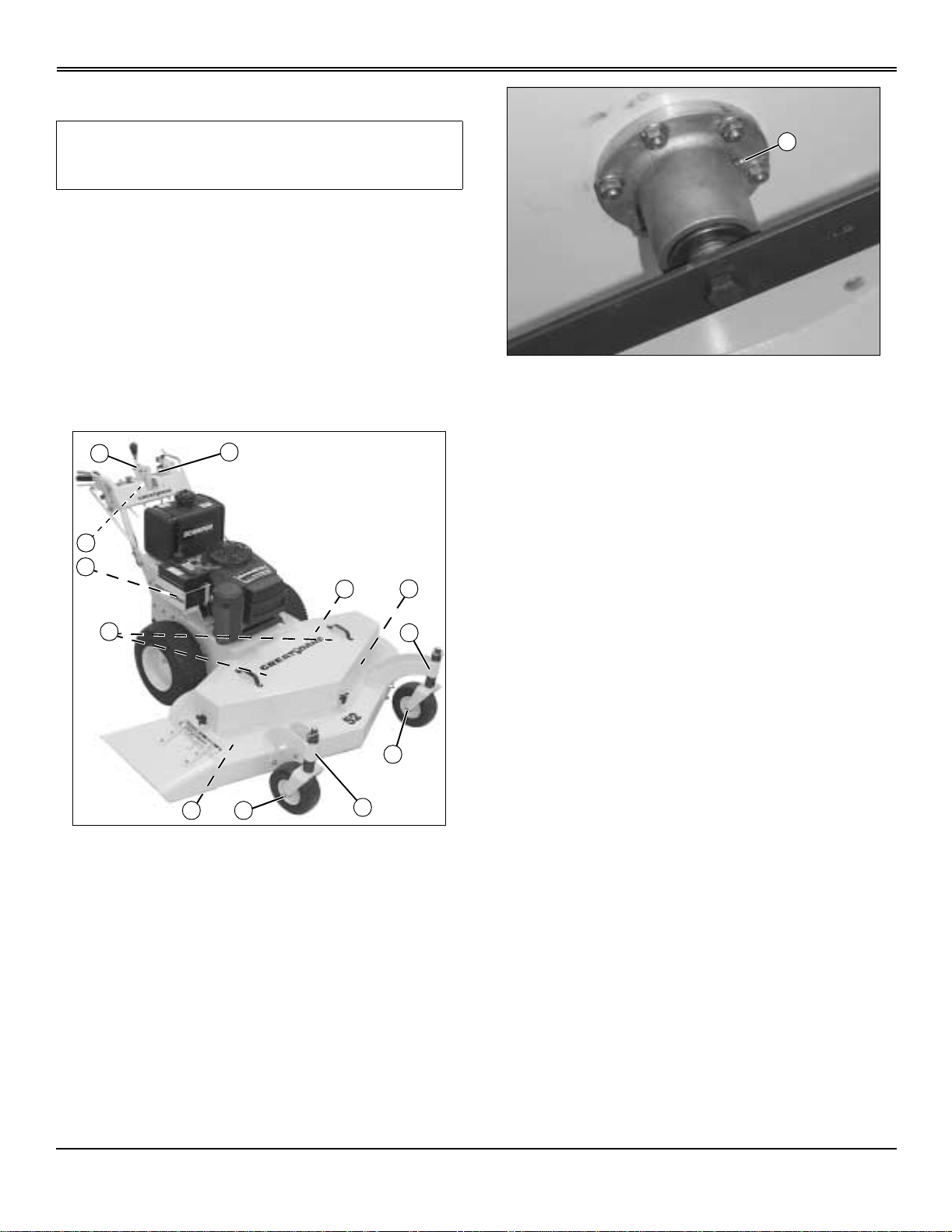

Console Controls

C

Miscellaneous Controls

A

H

I

C

B

A

A

B

G

D

FFE

A - Speed Control Lever

B - Tracking Adjustment Knob

C - Operator Presence Control Lever

D - Neutral Lock Lever

E - Handlebar Grip

F - Steering/Reverse Control Grip Lever

G - Throttle Lever/Choke Control (choke may be

individual control on some models)

H - PTO/Clutch Switch

I - Key Switch

D

E

MX9263

MX18837 MX9264

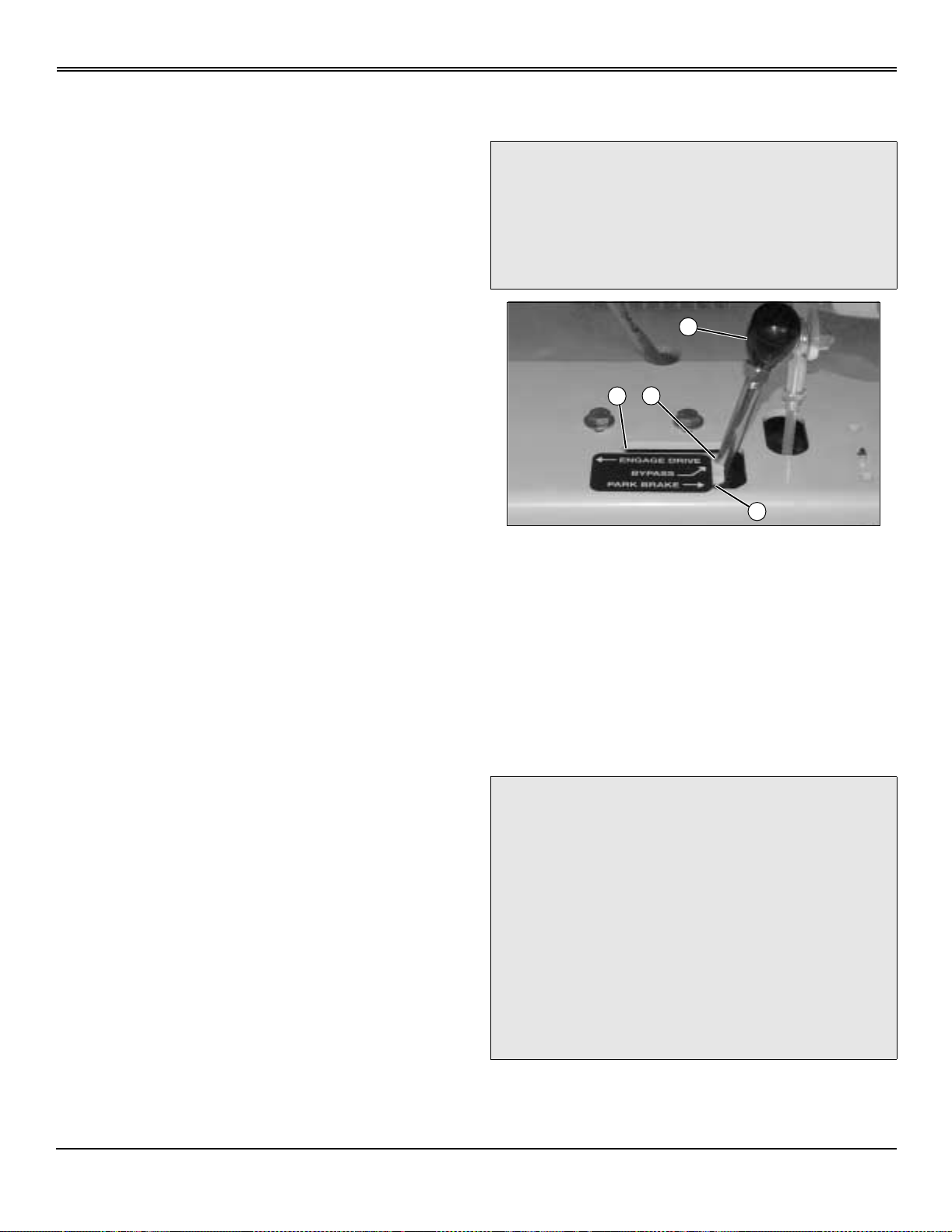

A - Transmission Drive/Bypass/Park Brake

Selector

B - Fuel Shutoff Valve

Testing Safety Systems

c CAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause

serious illness or death.

Move the vehicle to an outside area before

running the engine.

Do not run an engine in an enclosed area

without adequate ventilation.

• Connect a pipe extension to the engine

exhaust pipe to direct the e xhaust f umes out of

the area.

• Allow fresh outside air into the work area to

clear the exhaust fumes out.

Use the following checkout procedure to check for normal

operation of machine.

If there is a malfunction during one of these procedures, do

not operate machine. See your Great Dane dealer for

service.

Operating - 7

Page 11

OPERATING

Perform these tests in a clear open area. Keep bystanders

away.

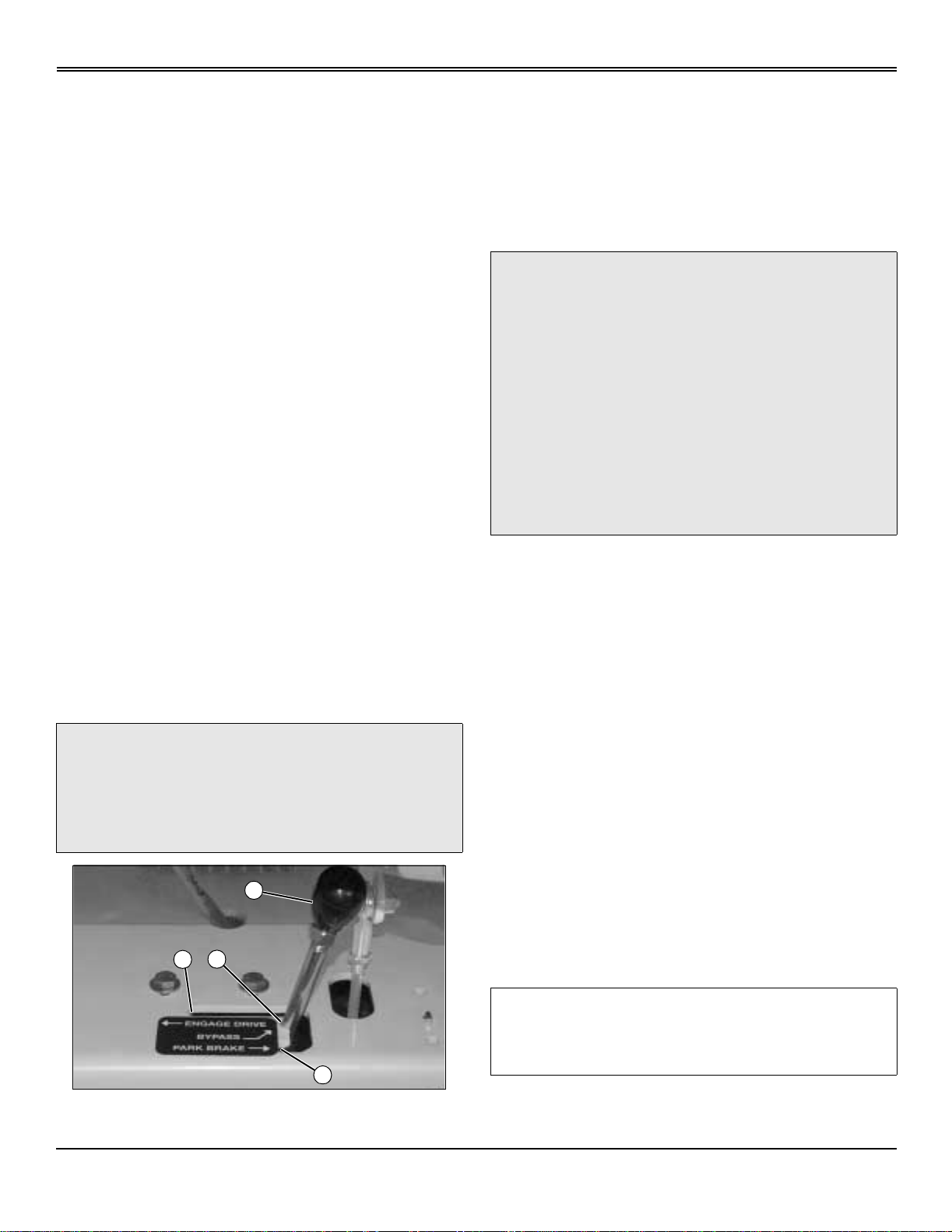

Testing Transmission Drive/Bypass/Park Brake Selector - Park Function

Stop the machine on a maximum 17° slope. Stop the

engine and lock the park brake.

Result: Park brake must hold the machine stationary. If the

machine moves more than 61cm (24 in.) in one hour,

brakes need to be adjusted. See your Great Dane dealer.

Testing Operator Presence Safety Interlock System

1. Move transmission drive/bypass/park brake selector into

park brake position.

2. Move control levers to neutral position.

3. Move PTO/clutch switch to off position.

4. Start engine.

5. Move transmission drive/bypass/park brake selector into

drive position.

6. Do not depress operator presence levers.

7. Move speed control lever forward.

drive/bypass/park brake selector lever (A) back firmly until it

locks into park position (B).

2. To disengage park brake function, move control lever to

the right and then forward, locking into bypass (C) or drive

(D) position.

Starting the Engine

c CAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause

serious illness or death.

Move the vehicle to an outside area before

running the engine.

Do not run an engine in an enclosed area

without adequate ventilation.

• Connect a pipe extension to the engine

exhaust pipe to direct the e xhaust f umes out of

the area.

• Allow fresh outside air into the work area to

clear the exhaust fumes out.

1. Open the fuel shutoff valve.

2. Move transmission drive/bypass/park brake selector into

park position.

Result: Engine must shut off immediately.

Using the Transmission Drive/Bypass/Park Brake Selector

c CAUTION: A v oid injury! Children or bystanders

may attempt to move or operate an unattended

machine.

Always lock the park brake and remove the key

before leaving the machine unattended.

A

C

D

B

MX18837

1. To engage park brake function, move transmission

3. Engage neutral lock levers.

4. Move speed control lever to neutral position.

5. Move PTO/clutch switch to off position.

6. Move throttle lever to half-speed position and set choke

(separate choke control models). Move throttle lever into

choke position on models with choke incorporated into

throttle lever.

7. Manual Start Engines Only: Turn key s witch to run

position. Pull recoil starter until the engine starts.

8. Electric Start Engines Only: Turn key switch to start

position for no more than five seconds. Release key to the

run position when engine starts.

• If the engine does not start, wait 10 seconds.

• Turn key to start position again for no more than 5

seconds.

• Repeat the procedure if necessary.

IMPORTANT: Avoid damage! Unnecessary engine

idling may cause engine damage. Excessive idling

can cause engine overheating, carbon build-up and

poor performance.

9. Let the engine run at half-speed position for several

minutes to warm up before operating the machine. Reduce

Operating - 8

Page 12

OPERATING

choke setting as the engine warms up.

Stopping the Engine

1. Move the throttle lever to the half-speed position, and let

the engine run at low throttle for a few seconds.

2. Turn the key switch to the stop position.

3. Remove key.

4. Move transmission drive/bypass/park brake selector into

park position.

5. Close the fuel shutoff valve.

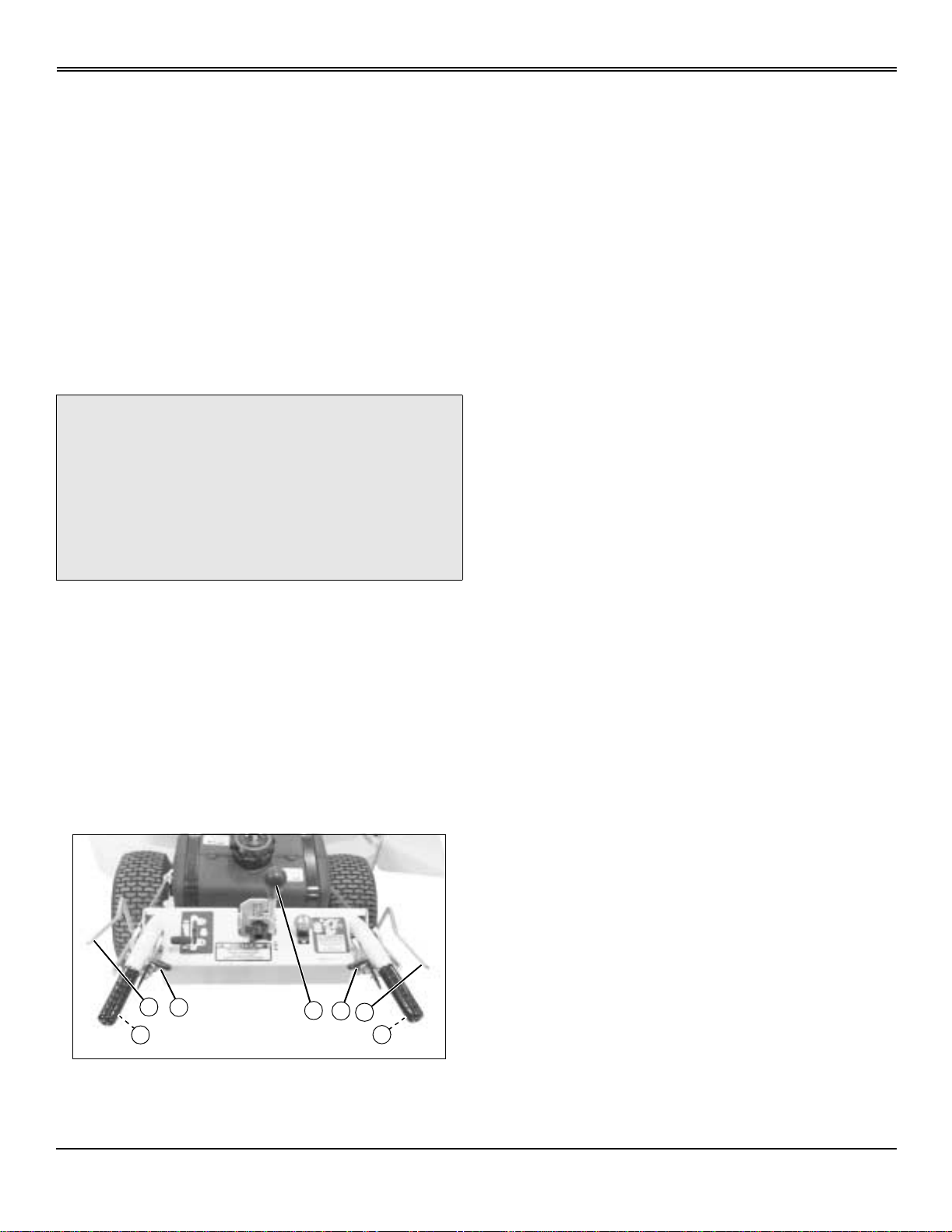

Operating the Machine

c CAUTION: Avoid injury! Learn the use of the

control levers. Practice at half throttle until

becoming proficient and comfortable with the

operation of the machine.

Do not move control levers from forward to

reverse or reverse to forward position rapidly.

Sudden direction changes could cause loss of

control or damage the machine.

1. Verify mower deck is adjusted to desired cut height.

2. Start and warm-up engine.

NOTE: The travel speed and turn rate will vary with the

amount that the control lever is moved.

3. Move transmission drive/bypass/park brake selector into

drive position.

4. Move throttle lever to wide open position.

5. Depress operator presence control levers and grasp

handlebar grips with both hands.

6. Move PTO/clutch switch to on position.

push the neutral lock levers (A) forward.

To drive the machine forward: Push speed control lever

(B) forward smoothly and evenly to desired forward speed.

To turn the machine: Squeeze steering control grip lever

(D) on the same side as the direction of the desired turn.

To stop the machine: Return speed control lever to the

neutral position and set thumb locks.

To drive the machine in reverse: Squeeze both steering/

reverse control grip levers (D) evenly.

Stopping the Machine

NOTE: For emergency stop of blades and unit drive,

release operate presence control levers.

1. Return steering/reverse control levers to the neutral

position and set thumb locks. Move speed control lever to

neutral position.

2. Move the PTO/clutch switch to the off position.

3. Move the throttle lever to the half-speed position, and let

the engine run at low throttle for a few seconds.

4. Turn the key switch to the stop position.

5. Move transmission drive/bypass/park brake selector into

park position.

6. Remove key.

Adjusting Cut Height

NOTE: The cut heights listed reflect the three blade

spacers being on the top side of blade. An additional

19mm (0.75 in.) of adjustment can be made in 6.3mm

(0.25 in.) increments by moving the spacers to the top

side of the spindle assembly.

Cutting height can be changed by adjusting the machine at

the traction deck and the front casters. The traction deck

allows for 51mm (2 in.) of height adjustment and the front

casters allow for up to 76mm (3 in.) of height adjustment.

C

A

D

7. Place palms on operator’s presence controls (C) and

fingers on steering/reverse control levers (D). With thumbs,

B

A

C

D

MX9263

Operating - 9

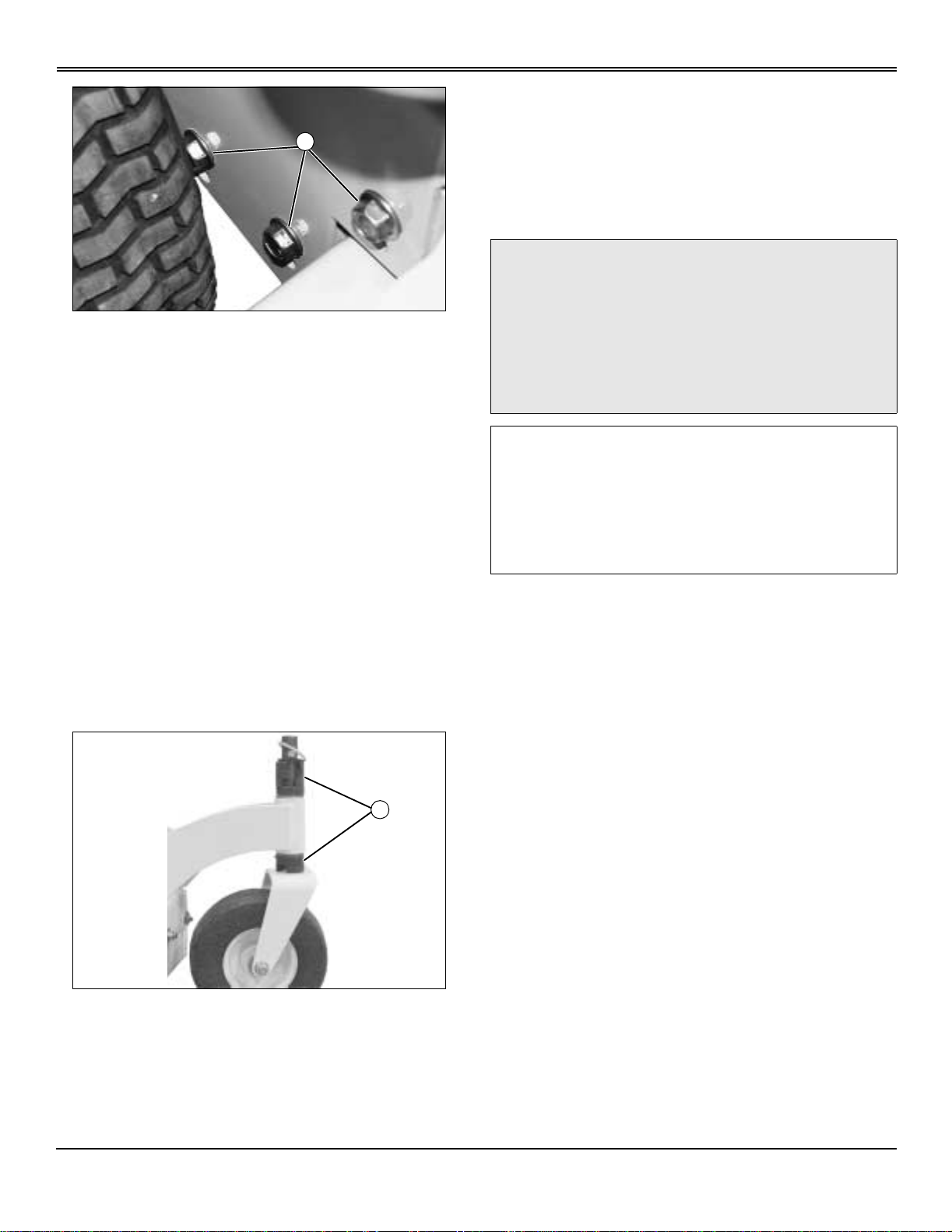

1. Check tire pressure. Inflate front caster wheels to 6983kPa (10-12 psi). Inflate rear tires to 172-207kPa (25-30

psi).

2. Place blocks at the rear of the mower deck, beyond the

outside edge of each tire.

Page 13

OPERATING

A

MX9269

3. With a second person holding the handlebar grips firmly,

loosen and remove bolts (A) from both sides of machine.

4. With bolts removed from machine, tilt rear of machine up

or down by handlebar grips to accommodate height

desired.

NOTE: The c ut height r ange is set b y t he wa y the upper

traction deck is bolted to the mower deck.

• Bolting the upper traction deck holes to the lower

mower deck holes sets the cut height range at 89108mm (3.5-4.25 in.).

• Bolting the upper traction deck holes to the upper

mower deck holes sets the cut height range at 6483mm (2.5-3.25 in.).

• Bolting the lower traction deck holes to the upper

mower deck holes sets the cut height range at 3857mm (1.5-2.25 in.).

5. Insert bolts into desired holes and tighten to 81-109N•m

(60-80 lb-ft).

Using the Fuel Shutoff Valve

Move the fuel shutoff valve to the on position for normal

operation. Move the fuel shutoff valve to the off position

when the machine is not in use, transported or trailered.

Moving the Machine Manually

c CAUTION: Avoid injury! With the machine in

neutral, the machine will have unrestricted

motion.

• The machine may free-wheel out of control

when in neutral position and on an incline.

• Park the machine on a level surface before

moving machine into neutral position.

IMPORTANT: Avoid damage! Transmission damage

may occur if the machine is moved or towed

incorrectly:

• Move unit by hand only.

• Do not use another vehicle to move unit.

• Do not tow unit.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Move transmission drive/bypass/park brake selector into

neutral position.

3. Push machine to desired location. Due to internal

hydraulic system resistance, the machine will move slowly.

4. Move transmission drive/bypass/park brake selector into

park brake position.

B

MX9257

6. Front mower deck height can be adjusted by moving

shims (B). Each shim is equal to 13mm (0.5 in.) of

adjustment.

Operating - 10

Page 14

REPLACEMENT PARTS

Replacement Parts

Parts

We recommend Great Dane quality parts available at your

Great Dane dealer.

Part numbers may change, use part numbers listed below

when you order. If a number changes, your dealer will have

the latest number.

When you order parts, your Great Dane dealer needs your

machine serial number and engine serial number. These

are the numbers that you recorded in the Product

Identification section of this manual.

Part Numbers

Item Part Number

Battery T425221

Fuel Tank Cap D18097

Traction (Hydro) Drive Belt D18388

Engine to Blade Belts:

• 92cm (36 in.) Deck

• 1.22m (48 in.) Deck

• 1.32m (52 in.) Deck

Mower Deck Drive Belts:

• 1.32m (48 in.)

• 1.55m (52 in.)

Mower Blades:

• 48-Inch Mower Deck: 42cm

(16.5 in.) Blade

• 36 and 52-Inch Mower

Decks: 45cm (18 in.) Blade

(Part numbers are subject to change without notice. Part

numbers may be different outside the U.S.A.)

D38163

D38131

D38162

D18007

D38163

D18086

D18037

Replacement Parts - 11

Page 15

SERVICE INTERVALS

Service Intervals

Servicing Your Machine

IMPORTANT: Avoid damage! Operating in extreme

conditions may require more frequent service

intervals:

• Engine components may become dirty or

plugged when operating in extreme heat, dust or

other severe conditions.

• Engine oil and spark plugs may lose efficiency if

vehicle is operated constantly at slow or low engine

speeds or with frequent short trips.

Please use the following timetables to perform routine

maintenance on your machine.

NOTE: The following initial break-in items must be

performed and verified to validate the warranty (dealer

service invoice accepted).

Break-In (After First 8 Hours of Operation)

Change engine oil and filter.

Check drive belt tension.

Check mower deck drive belt tension (36-Inch Mower

Deck).

Check engine-to-deck drive belt tension (48 and 52-Inch

Mower Deck).

Check spindle drive belt tension (48 and 52-Inch Mower

Deck).

Check transmission neutral adjustment.

Check wheel nut torque.

Check and adjust (as needed) park brake.

Remove debris from the underside of the mower deck.

Every 25 Hours or Weekly (Whichever Comes First)

Grease caster wheel spindle bearings (two places).

Grease lower control arms (two places).

Remove debris from the underside of the mower deck.

Check drive belt tension.

Check tire pressure.

Clean engine air filter.

Check wheel nut torque.

Every 160 Hours or Monthly (Whichever Comes First)

Check transmission oil level.

Lubricate mower deck idler pulley pivots (three places).

Lubricate seat platform hinges (two places)

Lubricate pump control arms (five places).

Lubricate control lever pivot shafts (two places).

Lubricate throttle cable.

Lubricate choke control cable (Carbureted Engines Only).

Annually

Inspect all spindle bearings (6). Replace as needed.

Inspect all mower deck idler pulleys. Replace as needed.

Remove and inspect caster wheel roller bearings; clean

and pack with grease. Replace as needed.

Inspect drive belts. Replace as needed. Run-in and adjust

tension.

Clean power unit.

Check all bolts and nuts; tighten as needed.

Remove battery. Clean battery and holder (electric start).

Replace spark plugs.

Grease spindle bearings (three places).

Lubricate spindle drive belt tension arms.

Lubricate front caste r wheels.

Lubricate front caste r wheel spi ndl es.

Remove debris from the underside of the mower deck.

Every 50 Hours or Weekly (Whichever Comes First)

Change engine oil and filter. See the engine manufacturer’s

owner’s manual provided with your machine for the

complete procedure.

Service Intervals - 12

Page 16

Service Lubrication

Grease

SERVICE LUBRICATION

IMPORTANT: Avoid damage! If operating outside

that temperature range, contact your Servicing

dealer for a special-use grease.

Use a general all-purpose grease with an NLGI grade No.2

rating.

Wet or high speed conditions may require use of a specialuse grease. Contact your Servicing dealer for information.

Spray Lubricant

Use a general-purpose petroleum-based spray lubricant.

Lubrication Points

H

H

J

I

F

D

E

MX15287

• Apply grease to three spindle bearings (E), until grease

is expelled from vent on spindle housings.

• Lubricate mower deck idler pulleys (F).

NOTE: Use spray lubricant to lubricate the following

items:

• Lubricate speed control lever pivot shaft (G).

• Lubricate throttle control cable (H).

• Lubricate choke control cable (I) if independent.

• Lubricate hydro pump lower control arms on both sides

(J).

C

AD

B

B

A

MX18835

• Grease caster wheel bearings (A).

• Grease caster wheel pivot bushings (B).

• Grease cutter housings (C) (two on 36-Inch mower

deck, three on 48 and 52-inch mower decks).

• Grease idler arm bushings ( D).

Service Lubrication - 13

Page 17

SERVICE ENGINE

Service Engine

Avoid Fumes

c CAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause

serious illness or death.

Move the vehicle to an outside area before

running the engine.

Do not run an engine in an enclosed area

without adequate ventilation.

• Connect a pipe extension to the engine

exhaust pipe to direct the exhaust f umes out of

the area.

IMPORTANT: Avoid damage! To prevent extensive

engine wear or damage, always maintain the proper

engine oil level. Never operate the engine with the oil

level below the ADD mark or over the FULL mark.

6. Remove dipstick and check oil level on dipstick. Oil must

be between the ADD and FULL marks.

• If oil is low, add oil to bring oil level no higher than the

FULL mark on dipstick.

• If oil level is above the FULL mark, drain to proper

level.

7. Install and tighten dipstick.

• Allow fresh outside air into the work area to

clear the exhaust fumes out.

Engine Oil

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

Use oil that meets the following specification:

• See the engine manufacturer’s owner’s manual provided

with your machine for the correct specifications.

Checking Engine Oil Level

IMPORTANT: Avoid damage! Failure to check the oil

level regularly could lead to serious engine

problems if oil level is low:

• Check oil level before operating.

• Check oil level when the engine is cold and not

running.

• Keep level between the FULL and the ADD marks.

• Shut off engine before adding oil.

Changing Engine Oil and Filter

A

MX9414

NOTE: An oil drain tube is provided with this machine.

Attach the tube to the oil drain fitting on the engine,

and open valve (A) to drain the used oil. Close the

valve, and remove the drain tube from the fitting after

the oil has been drained. Store the drain tube after use.

Change engine oil and filter at the intervals recommended

in the Service Intervals section. See the engine

manufacturer’s owner’ s manual provided with your machine

for the complete procedure.

NOTE: Check oil twice a day if the engine runs over

four hours in a day.

Make sure engine is cold when checking engine oil

level.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Allow engine to cool.

3. Clean area around dipstick to prevent debris from falling

into crankcase.

4. Remove dipstick (A). Wipe with a clean cloth.

5. Install dipstick and allow the cap to rest on the end of the

tube. Do not tighten the cap.

Service Engine - 14

Cleaning Air Intake Screen and Engine Fins

IMPORTANT: Avoid damage! The engine is aircooled and requires a large amount of air intake

when running. Reduced air intake can cause

overheating:

• Keep air intake screen and cooling fins clean.

• Keep covers and screens in place.

Keep air intake screens and engine cooling fins clear of

debris to ensure proper cooling. See the engine

manufacturer’s owner’ s manual provided with your machine

for the complete procedure.

Page 18

SERVICE ENGINE

Checking and Cleaning Air Filter Elements

c CAUTION: Avoid injury! Touching hot surfaces

can burn skin. The engine and components will

be hot if the engine has been running. Allow

the engine to cool before servicing.

IMPORTANT: Avoid damage! Dirt and debris can

enter the engine through a damaged filter element:

• Do not wash paper element.

• Do not attempt to clean paper element b y tapping

against another object.

• Do not use pressurized air to clean element.

• Replace element only if it is very dirty, damaged

or the seal is cracked.

Check and clean air filter elements at the intervals

recommended in the Service Intervals section. See the

engine manufacturer’s owner’s manual provided with your

machine for the complete procedure.

Checking Spark Plugs

your dealer.

Replacing Fuel Filter

c CAUTION: Avoid injury! Fuel vapors are

explosive and flammable:

• Do not smoke while handling fuel.

• Keep fuel away from flames or sparks.

• Shut off engine before servicing.

• Cool engine before servicing.

• Work in a well-ventilated area.

• Clean up spilled fuel immediately.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Turn fuel shutoff valve to off position.

3. Disconnect the fuel hose from the outlet side of the fuel

filter, and drain gasoline into a properly marked container.

4. Remove the fuel filter from the inlet fuel hose. Discard

filter.

c CAUTION: Avoid injury! Touching hot surfaces

can burn skin. The engine and components will

be hot if the engine has been running. Allow

the engine to cool before servicing.

Check spark plugs at the intervals recommended in the

Service Intervals section. See the engine manufacturer’s

owner’s manual provided with your machine for the

complete procedure.

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine

manufacturer and is not adjustable.

If engine is operated at altitudes above 1829 m (6,000

ft), some carburetors may require a special high

altitude main jet.

If engine is hard to start or runs rough, see the

troubleshooting section of the engine manufacturer’s

owner’s manual provided with your machine.

Possible engine surging will occur at high throttle with

transmission in “N” neutral and mower engagement lever

disengaged. This is a normal condition due to the emission

control system.

After performing the checks in the troubleshooting section

and your engine is still not performing correctly, contact

IMPORTANT: Avoid damage! When installing a new

fuel filter, the filter arrow must be pointing in the

direction of fuel flow.

5. Connect a new fuel filter to hoses.

6. Turn fuel shutoff valve to on position.

Service Engine - 15

Page 19

SERVICE TRANSMISSION

Service Transmission

Avoid Fumes

c CAUTION: Avoid injury! Engine exhaust fumes

contain carbon monoxide and can cause

serious illness or death.

Move the vehicle to an outside area before

running the engine.

Do not run an engine in an enclosed area

without adequate ventilation.

• Connect a pipe extension to the engine

exhaust pipe to direct the exhaust f umes out of

the area.

• Allow fresh outside air into the work area to

clear the exhaust fumes out.

Transmission Oil

The Hydro-Gear transaxle units used in this machine are

designed to be maintenance free. If service is required,

contact a Great Dane dealer.

Adjusting Transmission Tracking

c CAUTION: Avoid injury! Clear area of all

bystanders before performing this service

procedure.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Start and run the engine until it reaches normal

operating temperature.

3. Move machine to an open area for operation.

adjustment knob (A) to compensate.

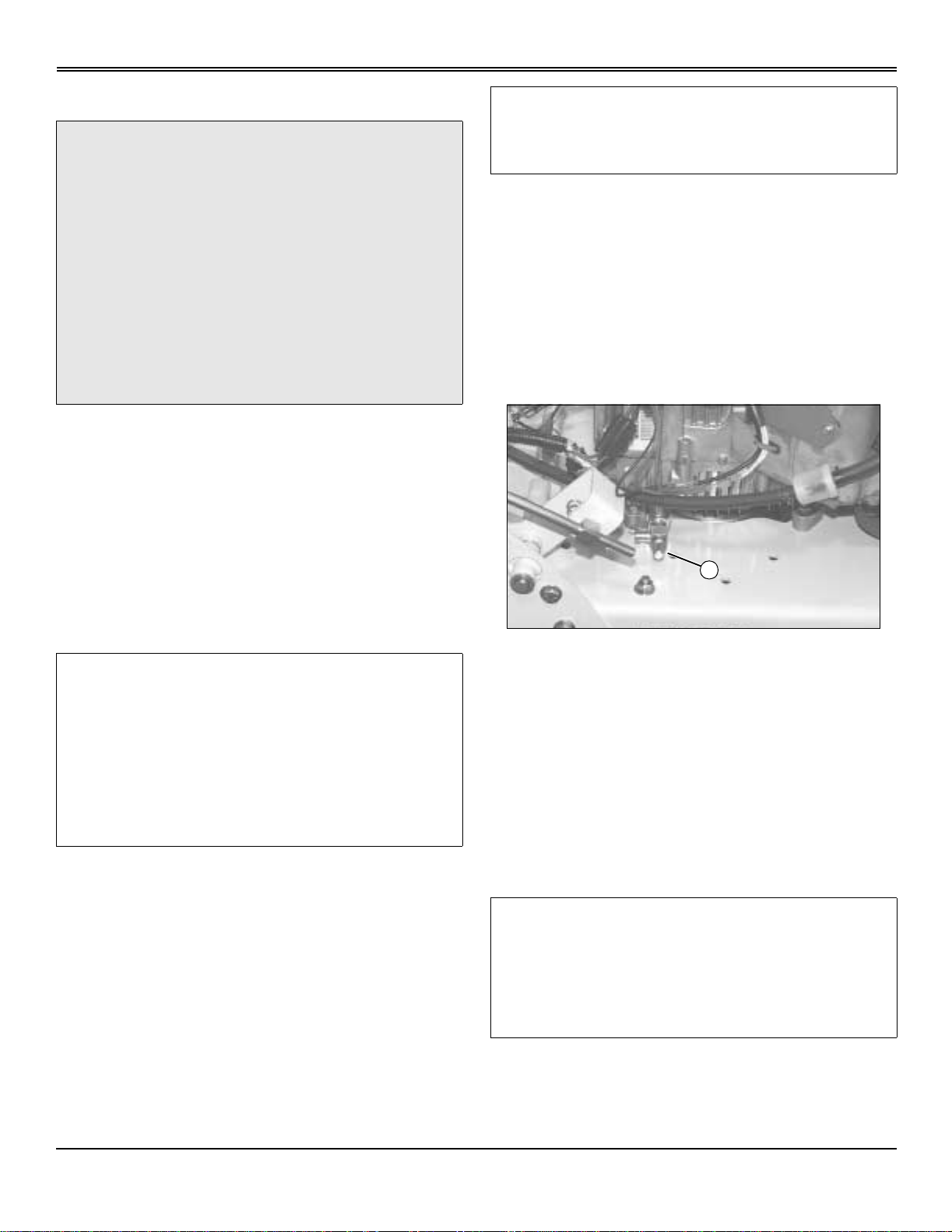

Adjusting Transmission Neutral Position

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Raise drive wheels off the ground, securely support the

machine and block caster wheels.

3. Move speed control lever to neutral position.

4. Start and run the engine until it reaches normal

operating temperature.

5. Observe wheel movement. Wheels should not rotate.

A

MX9262

6. Determine which drive motor is in need of adjustment.

7. Remove retaining clip, control rod and swivel from drive

arm (A).

8. Adjust accordingly by turning swivel up or down con trol

rod.

9. Install control rod, swivel and retaining clip in drive arm.

NOTE: If additional adjustment is needed, see your

Great Dane dealer.

4. Drive machine forward by pushing speed control lever

forward slowly.

A

MX9263

5. If machine does not drive in a straight line, turn tracking

Service Transmission - 16

Removing and Installing Drive Belt

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove mower deck belt guard.

Page 20

SERVICE TRANSMISSION

B

A

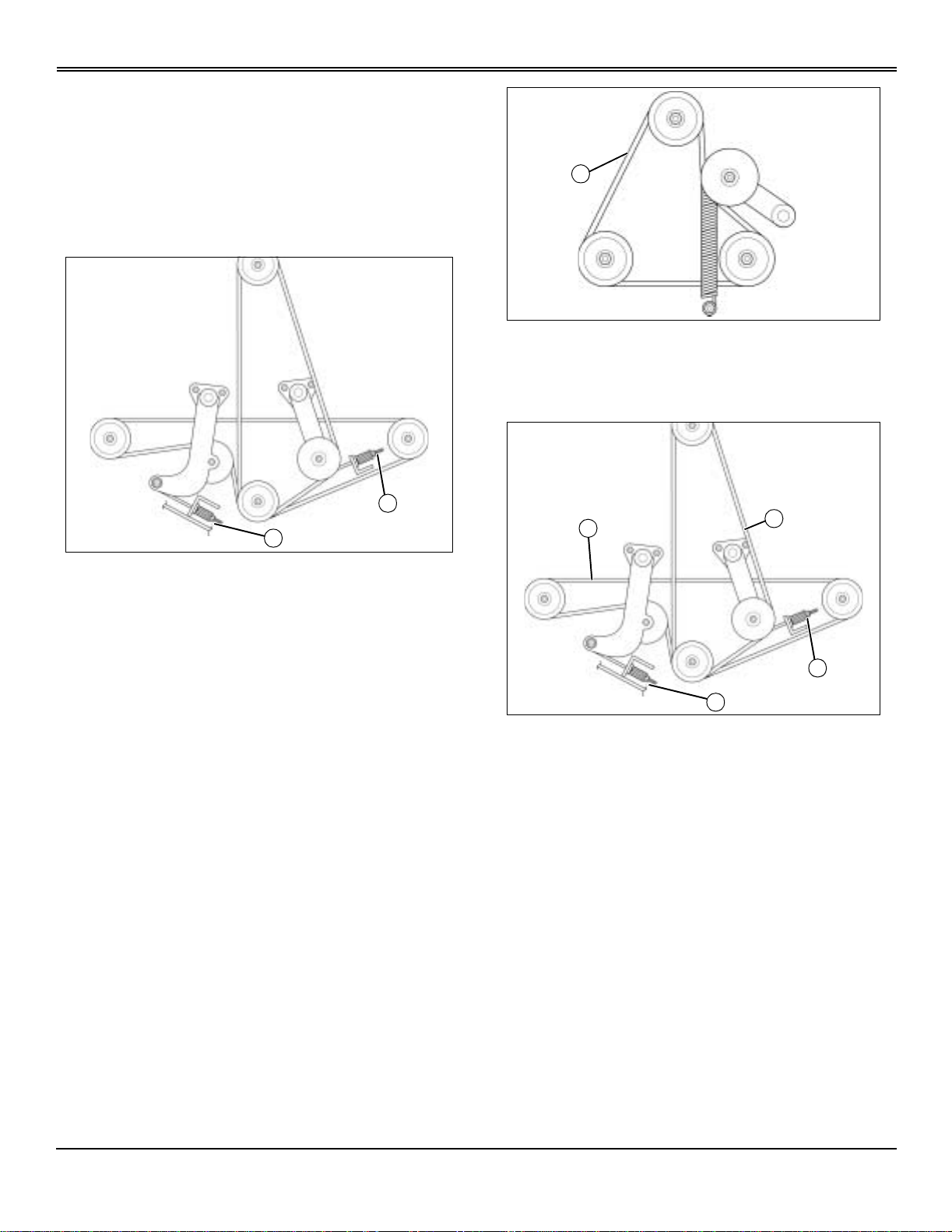

Picture Note: Drive belt routing as viewed from the

top of machine.

3. Disconnect tension spring (A) from anchor pin.

4. Remove drive belt (B).

5. Install new drive belt (B).

6. Connect tension spring (A) to anchor pin.

MX9291

7. Install mower deck belt guard.

Service Transmission - 17

Page 21

SERVICE MOWER

Service Mower

Adjusting Belt Tension

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove belt covers.

3. Adjust to proper tension. The belt should deflect a

maximum of 13mm (0.5 in.) when a force of 4.5kg (10 lb) is

applied to the center of the longest span.

A

B

MX9238

4. To Increase Belt Tension: Turn nut (A - main mower

deck drive belt) or (B - spindle drive belt) clockwise.

A

MX9291

Picture Note: Drive belt routing as viewed from the

top of machine.

3. Remove pump drive belt (A) as previously described.

E

C

T o Decrease Belt Te nsion: Turn nut (A - main mower deck

drive belt) or (B - spindle drive belt) counterclockwise.

Removing and Installing Mower Deck Drive Belts

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove mower deck belt covers.

B

D

MX9238

4. Release mower deck drive belt tension by turning the

tension adjuster nut (B) counterclockwise.

5. Remove mower deck drive belt (C).

6. Release spindle drive belt tension by turning the

tensioner adjuster nut (D) counterclockwise.

7. Remove spindle drive belt (E).

8. Install the new spindle drive belt (E) and adjust the drive

belt tension.

9. Install new mower deck drive belt (C) and adjust the

drive belt tension.

10.Install pump drive belt (A).

11.Install mower deck drive belt covers.

Service Mower - 18

Page 22

SERVICE MOWER

Checking for Bent Mower Blades

c CAUTION: Avoid injury! Mower blades are

sharp. Always wear gloves when handling

mower blades or working near blades.

1. Park machine safely. (See Parking Safely in the Safety

section.)

A

MIF

2. Measure distance (A) between blade tip and flat ground

surface.

3. Turn blade 180°. Measure distance between other blade

tip and flat ground surface.

4. Install new blade, if the difference between the two

measurements is more than 3mm (0.13 in.).

Replacing Mower Blades

2. Remove nut (A), blade bolt (B), three 1/4 in. washers (C)

and blade (D).

3. Install replacement blade:

• Blade wing must face toward top of mower deck.

IMPORTANT: Avoid damage! When installing the

blade:

• Make sure the blade is properly seated on the

spindle.

• Make sure the concave side of the large washer

faces toward the blade.

• Install blade bolt (B), blade (D), three 1/4 in. washers

(C) and nut (A) .

• Tighten blade nut to 81 N•m (60 lb-ft).

4. Lower machine.

5. Adjust mower deck to a desirable cutting height.

Sharpening Blades

c CAUTION: Avoid injury! Mower blades are

dangerous!

• Always wear gloves while working on

blades.

• Always wear safety eye protection when

grinding.

c CAUTION: Avoid injury! Mower blades are

sharp. Always wear gloves when handling

mower blades or working near blades.

A

C

D

B

MX15357

1. Use two long-handled 15/16 in. wrenches to loosen nut

(A).

• Sharpen blades with grinder, hand file or electric blade

sharpener.

A

B

MX8333

• Keep original bevel (A) when grinding.

• Blade should have 0.40 mm (1/64 in.) cutting edge (B)

or less.

• Balance blades before installing.

Service Mower - 19

Page 23

SERVICE MOWER

Balancing Blades

c CAUTION: Avoid injury! Mower blades are

sharp. Always wear gloves when handling

mower blades or working near blades.

1. Clean blade.

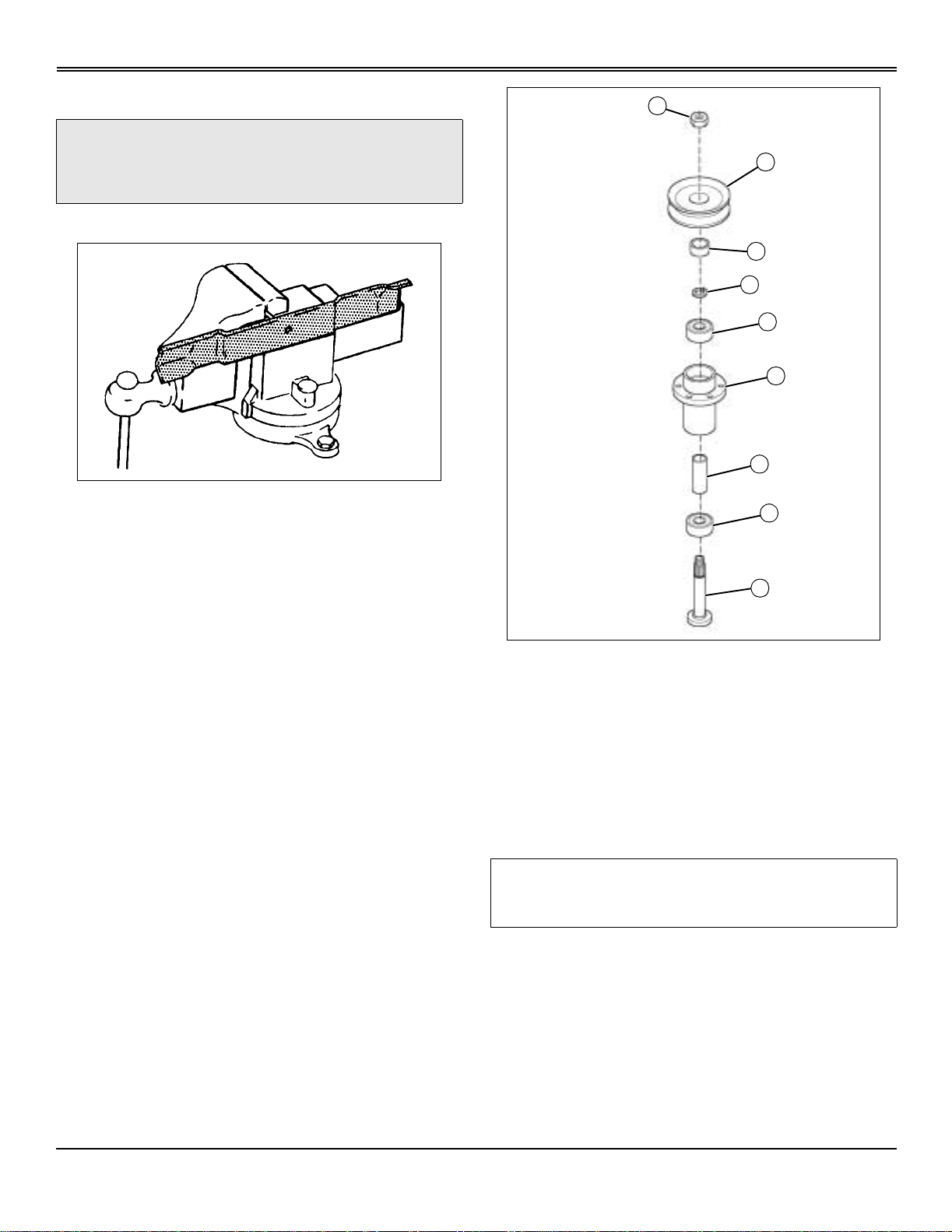

M61524

2. Put blade on nail in a vise. Turn blade to horizontal

position.

A

B

C

D

I

H

G

F

3. Check balance. If blade is not balanced, heavy end of

blade will drop.

4. Grind bevel of heavy end. Do not change blade bevel.

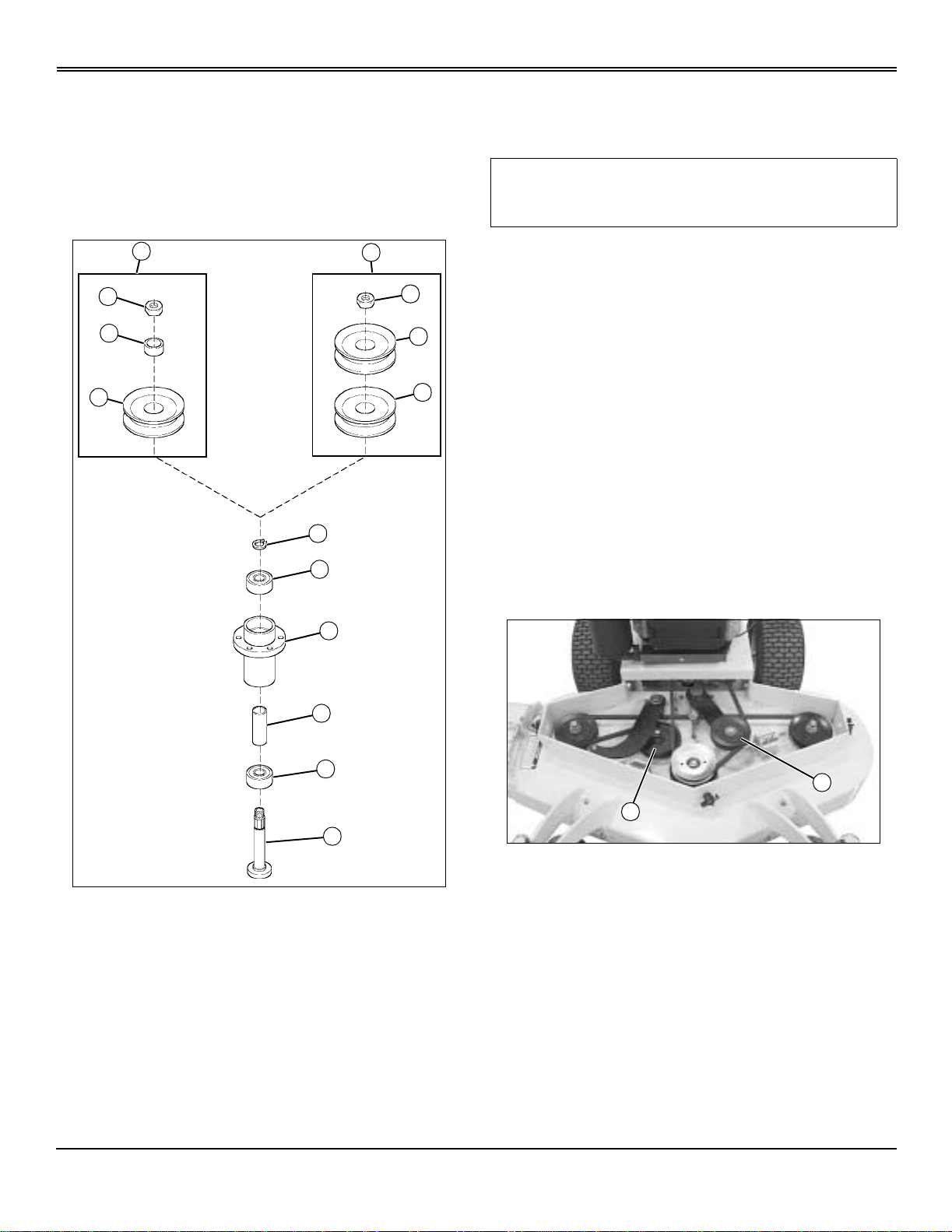

Replacing Mower Spindle Bearings - 36-Inch

Mower Deck

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove mower blade. (See Replacing Mower Blades.)

E

MX15354

3. Remove nut (A), pulley (B) and spacer (C).

4. Remove retaining ring (D), spindle shaft (E), lower

bearing (F) and spacer (G) from spindle housing (H).

Discard bearing.

5. Remove and discard upper bearing (I).

6. Clean entire assembly.

7. Install a new lower bearing (F) and spacer (G) on the

spindle shaft (E).

IMPORTANT: Avoid damage! The clearance between

the lower bearing and the housing is only 0.05 mm

(0.002 in.). Do not force bearing into housing.

8. Install the spindle shaft (E), lower bearing (F) and

spacer (G) into the spindle housing (H).

9. Install the upper bearing (I) and retaining ring (D).

10.Install spacer (C).

11.Install pulley (B) and nut (A). Tighten nut to 61 N•m (50

lb-ft).

12.Install mower blade, blade washers and blade bolt

assembly. Tighten nut to 81 N•m (60 lb-ft). (See Checking

and Replacing Mower Blades.)

Service Mower - 20

Page 24

SERVICE MOWER

Replacing Mower Spindle Bearings - 48 and 52-Inch Mower Decks

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Remove engine-to-deck drive and spindle drive belts.

3. Remove mower blade. (See Replacing Mower Blades.)

A

B

C

D

I

N

E

F

G

H

7. Clean entire assembly.

8. Install a new lower bearing (K) and spacer (L) on the

spindle shaft (J).

IMPORTANT: Avoid damage! The clearance between

the lower bearing and the housing is only 0.05 mm

(0.002 in.). Do not force bearing into housing.

9. Install the spindle shaft (J), lower bearing (K) and spacer

(L) into the spindle housing (M).

10.Install the upper bearing (N) and retaining ring (I).

11.Install upper pulleys:

• Right and Left Spindles (A): Install pulley (D),

spacer (C) and nut (B). Tighten nut to 68 N•m (50 lb-ft).

• Center Spindle (E): Install spindle pulley (H), drive

pulley (G) and nut (F). Tighten nut to 68 N•m (50 lb-ft).

12.Install mower blade, blade washers and blade bolt

assembly. Tighten nut to 81 N•m (60 lb-ft). (See Checking

and Replacing Mower Blades.)

Replacing Mower Deck Idler Pulleys

1. Park machine safely. (See Parking Safely in the Safety

section.)

M

L

K

J

MX9222

4. Remove pulleys:

• Right and Left Spindles (A): Remove nut (B),

spacer (C) and pulley (D).

• Center Spindle (E): Remove nut (F), drive pulley (G)

and spindle pulley (H).

5. Remove retaining ring (I), spindle shaft (J), lower

bearing (K) and spacer (L) from spindle housing (M).

Discard bearing.

2. Remove the mower deck drive and spindle drive belts.

A

B

MX9267

3. Remove the mower deck drive tension idler pulley (A)

and the mower and spindle drive tension idler pulley (B).

4. Install new idler pulleys.

5. Install spindle drive and mower deck drive belts.

6. Adjust belt tension.

6. Remove and discard upper bearing (N).

Service Mower - 21

Page 25

SERVICE ELECTRICAL

Service Electrical

WARNING: Battery posts, terminals and related

accessories contain lead and lead components, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

Removing and Installing the Battery

c CAUTION: A v oid injury! The batt ery produces a

flammable and explosive gas. The battery may

explode:

• Do not smoke near battery.

• Wear eye protection and gloves.

• Do not allow direct metal contact across

battery posts.

• Remove negative cable first when

disconnecting.

• Install negative cable last when connecting.

Removing:

1. Park the vehicle safely . (See P arking Safely in the Safety

section.)

2. Slide black cover away from the negative (-) battery

terminal and disconnect the negative (-) battery cable.

3. Slide red cover away from the positive (+) battery

terminal and disconnect the positive (+) battery cable.

4. Loosen the cap screws and nuts on both sides of the

battery tray.

Cleaning Battery and Terminals

c CAUTION: A v oid injury! The batt ery produces a

flammable and explosive gas. The battery may

explode:

• Do not smoke near battery.

• Wear eye protection and gloves.

• Do not allow direct metal contact across

battery posts.

• Remove negative cable first when

disconnecting.

• Install negative cable last when connecting.

1. Disconnect and remove battery.

2. Wash battery with a solution of four tablespoons of

baking soda to one gallon of water. Be careful not to get the

soda solution into the battery cells.

3. Rinse the battery with plain water and dry.

4. Clean terminals and battery cable ends with wire brush

until bright.

5. Install battery.

6. Attach cable clamps to battery posts.

7. Apply petroleum jelly or silicone spray to terminal to

prevent corrosion.

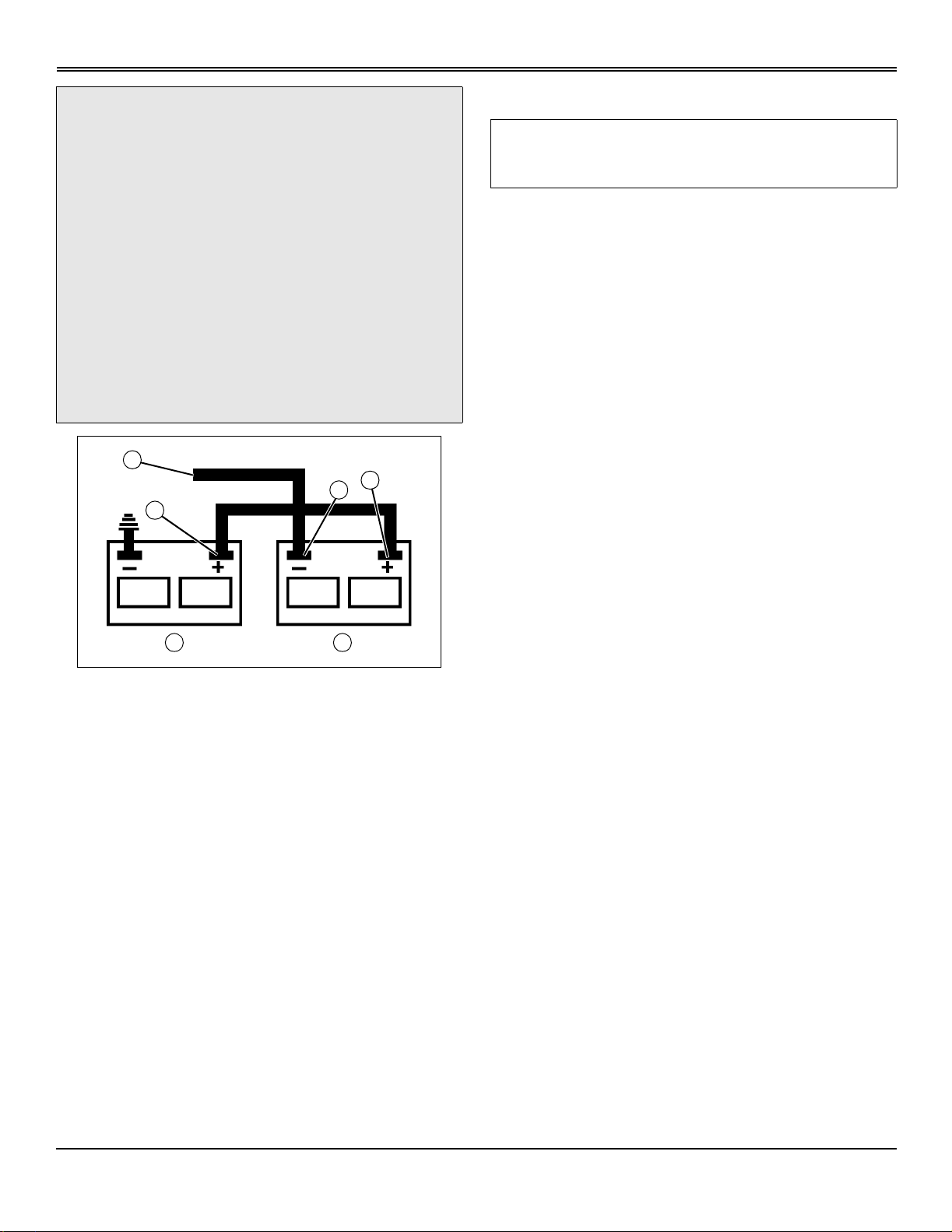

Using Booster Battery

5. Remove battery and isolator pad.

Installing:

1. Place isolator pad in the battery tray .

2. Install battery in the battery tray, making sure that the

isolator pad is between the bottom and sides of the battery

tray.

3. Tighten the cap screws and nuts to secure the battery in

the battery tray. Do not overtighten.

4. Connect the positive (+) battery cable first, then the

negative (-) cable.

5. Apply general purpose grease or silicone spray to the

terminals to prevent corrosion.

6. Slide covers over battery terminals.

Service Electrical - 22

MIF TS204

Page 26

SERVICE ELECTRICAL

c CAUTION: A v oid injury! The batt ery produces a

flammable and explosive gas. The battery may

explode:

• Do not attempt to jump start a frozen battery .

Warm to 16 degrees C (60 degrees F).

• Do not smoke near battery.

• Wear eye protection and gloves.

• Keep sparks and flames away.

• Do not connect the negative (-) booster

cable to the negative (-) terminal of the

discharged battery. Connect at a good ground

location away from the discharged battery.

• Do not cross jump the battery, damage to

electronic modules will result.

F

C

E

D

Replacing Fuses

IMPORTANT: Avoid damage! When replacing fuses use only 20-amp fuses or you may damage the

circuit.

The machine is equipped with two 20-amp fuses (electric

start units) and one 20-amp fuse (manual start units) to

protect the electric start and/or charging circuit. These

fuses are located under the control panel area.

1. Remove defective fuse from socket.

2. Check metal clip in fuse window and discard fuse if clip

is broken.

3. Install new fuse into socket.

B A

M71044

A - Booster Battery

B - Disabled Vehicle Battery

1. Connect positive booster cable to booster battery (A)

positive post (C).

2. Connect the other end of positive booster cable to the

disabled vehicle battery (B) positive post (D).

3. Connect negative booster cable to booster battery

negative post (E).

4. Connect the other end (F) of negative booster cable to a

unpainted metal part of the disabled machine’s engine,

away from battery.

5. Start the engine of the disabled machine and run

machine for several minutes.

6. Carefully disconnect the booster cables in the exact

reverse order: negative cable first and then the positive

cable.

Service Electrical - 23

Page 27

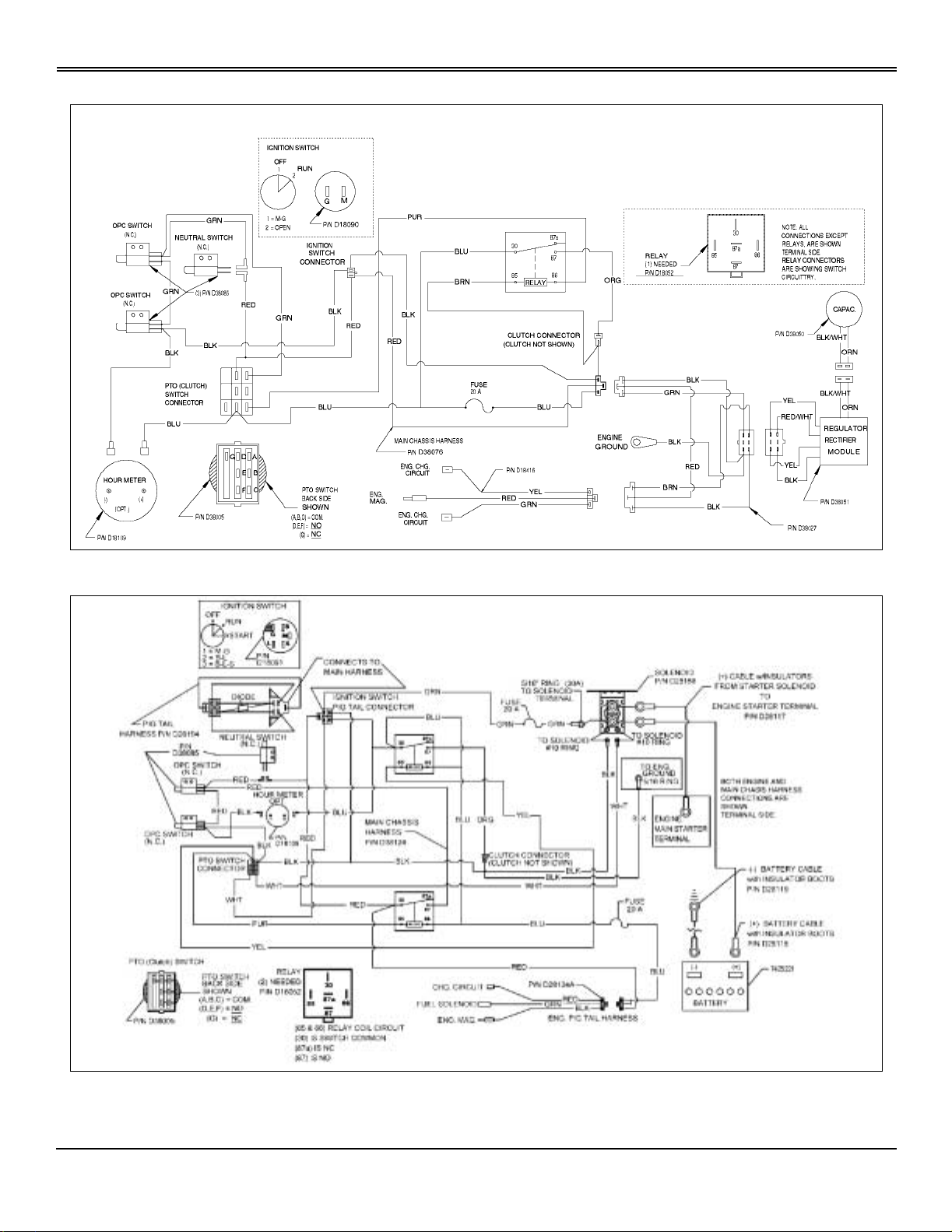

Wiring Schematics

SERVICE ELECTRICAL

MX9418a

Picture Note: Kawasaki Manual Start Shown Above

MX18838

Picture Note: Kawasaki Electric Start Shown Above

Service Electrical - 24

Page 28

SERVICE MISCELLANEOUS

Service Miscellaneous

Filling Fuel Tank

Use regular grade 87 octane unleaded fuel.

Add fuel stabilizer to fuel before using it in your machine to

prevent engine damage due to stale fuel. Follow directions

on stabilizer container.

c CAUTION: Avoid injury! Fuel vapors are

explosive and flammable:

C

E

F

D

A

• Shut engine off before filling fuel tank.

• Do not smoke while handling fuel.

• Keep fuel away from flames or sparks.

• Fill fuel tank outdoors or in well-ventilated

area.

• Clean up spilled fuel immediately.

• Use clean, approved non-metal container to

prevent static electric discharge.

• Use clean, approved plastic funnel without

screen or filter to prevent static electric

discharge.

IMPORTANT: Avoid damage! Dirt and water in fuel

can cause engine damage:

• Clean dirt and debris from the fuel tank opening.

• Use clean, fresh, stabilized fuel.

• Fill the fuel tank at the end of each day’s

operation to keep condensation out of the fuel tank.

• Use a non-metallic funnel with a plastic mesh

strainer when filling the fuel tank or container.

B

MX15717

3. Remove nut (A), bolt (B) and wheel assembly (C).

4. Remove bushing (D), bearing retainer (E), roller bearing

(F) from wheel.

5. Clean bushing and roller bearing; and pack with clean

grease.

6. Install wheel assembly (C), roller bearing (F), bearing

retainer (E), bushing (D), bolt (B) and nut (A).

Replacing Caster Pivot Bearing Bushings

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Raise and securely support the front of the mower deck.

A

B

Servicing Caster Wheel Roller Bearings

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Raise and securely support the front of the mower deck.

Service Miscellaneous - 25

E

G

F

C

B

D

MX15717

3. Remove lynch pin (A), spacer bushings (B), washer (C)

Page 29

SERVICE MISCELLANEOUS

and caster yoke and wheel assembly (D).

4. Remove and discard upper (E) and lower (F) bushings.

5. Install new bushings (E and F).

6. Install caster yoke and wheel assembly (D), washer (C),

spacer bushings (B) and lynch pin (A).

7. Apply grease to lubrication fitting (G).

Checking Whe el Nut s

Tighten rear wheel nuts in an alternating pattern to 68N•m

(50 lb-ft).

Service Miscellaneous - 26

Page 30

TROUBLESHOOTING

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this

chart, see your Great Dane servicing dealer for service.

When you have checked all the possible causes listed and

you are still experiencing the problem, see your Great Dane

servicing dealer.

Engine

If Check

Engine Will Not Start or Is Hard to Start Motion control levers not in the neutral detent (or neutral lock)

position.

Speed control lever not in the neutral position.

Key s witch not in proper position.

PTO engaged.

Loose or corroded starter cable connections.

Stale or improper fuel/fuel level.

Plugged fuel filter.

Fuel shutoff valve in off position.

Plugged air intake filter.

Spark plug wire is loose or disconnected.

Spark plug not gapped correctly.

Blown 20-amp fuse (main power circuit).

Electrical problem - dead battery.

Choke adjusted incorrectly. See your Great Dane servicing dealer.

Engine Will Not Slow Idle Bent or kinked throttle cable.

Bent governor control.

Incorrect governor idle control.

Carburetion problems. See your Great Dane servicing dealer.

Engine Runs Rough or Stalls Plugged fuel filter.

Plugged air intake system.

Fuel cap vent dirty.

Stale or improper fuel/fuel level.

Spark plug not gapped correctly.

Replace spark plug.

Choke adjusted incorrectly. See your Great Dane servicing dealer.

Engine Knocks Engine oil level low.

Reduce load. (Slower ground speed.)

Fuel is bad. Fill tank with fresh fuel, correct octane.

Idle speed too slow.

Troubleshooting - 27

Page 31

TROUBLESHOOTING

If Check

Engine Overheats Clean cooling fins.

Low oil level.

Do not operate at slow idle. Operate at full-throttle setting.

Cooling air intake screen is dirty.

Plugged air intake filter.

Operating at too fast ground speed for conditions.

Engine Lacks Power Plugged air intake system.

Plugged fuel filter.

Improper type of fuel. Drain tank and fill with correct fuel.

Clean cooling fins to help prevent overheating.

Replace spark plug.

Engine Uses Too Much Oil Find and correct oil leaks.

Incorrect engine oil.

Plugged oil filter.

Plugged air intake filter.

Engine Backfires Through Muffler Throttle should be at low idle for several seconds before turning off

machine.

Leaking/damaged exhaust manifold gasket.

High Fuel Consumption Improper type of fuel.

Plugged air intake system.

Operating at too fast ground speed for conditions.

Improper valve clearance. See your Great Dane servicing dealer.

Restricted air intake system.

Electrical System

If Check

Starter Will Not Work Dead battery.

Blown 20-amp fuse (main power circuit).

Loose or corroded battery or ground connections.

Loose or corroded starter cable connections.

Neutral start switches faulty or not adjusted properly. See your

Great Dane servicing dealer.

Key switch or starter faulty. See your Great Dane servicing dealer.

PTO engaged.

Motion control levers not in proper position.

Speed control lever not in proper position.

Steering/reverse levers not in locked proper position.

Troubleshooting - 28

Page 32

TROUBLESHOOTING

If Check

Battery Will Not Charge Loose or corroded battery or ground connections.

Blown fusible link (charging circuit).

Battery cables and terminals are dirty.

Dead cell in battery.

PTO Clutch Does Not Engage Blown 20-amp fuse (main power circuit).

Faulty PTO switch.

Faulty PTO clutch.

Loose PTO clutch connections.

Starter Turns Slowly Loose or corroded battery or ground connections.

Low battery power - charge battery.

Engine oil viscosity too heavy.

Transaxle linkages failed and are engaged.

Machine

If Check

Excessive Machine Vibration Engine speed too slow.

Deck drive belts worn or damaged.

Traction drive belt worn or damaged.

Dirt or debris on drive sheaves.

Loose or damaged electric PTO or drive sheave.

Bent or damaged cutting blades.

Machine Will Not Move With Engine Running Park brake locked.

Transmission hydraulic oil level low.

Transmission oil cold - allow engine to warm.

Traction drive belt slipping.

Transaxle free-wheel valves open.

Traction drive belt damaged or worn.

Transaxle and/or wheel motor problems. See your Great Dane

servicing dealer.

Machine Creeps With Engine Running and Motion

Control Levers in a Neutral Position

Needs shift control linkage adjustment.

Park Brake

If Check

Park Brake Not Working Correctly Brakes out of adjustment - adjust linkage.

Brake linkage or components damaged.

Troubleshooting - 29

Page 33

TROUBLESHOOTING

Steering

If Check

Steering Not Working Park brake locked.

Transaxle free-wheel valves partially open.

Improper tire Inflation.

Hydrostatic transmission oil low.

Traction drive belt slipping.

Traction drive belt damaged or worn.

Machine Will Not Follow a Straight Path Steering tracking out of adjustment.

Machine Moves to the Left or Right With Engine

Running and Transmission in Neutral

Pump linkage (neutral position) out of adjustment.

Mower Deck

If Check

Discharge Chute Plugged Grass is wet - mow grass only when dry.

Raise cutting height.

Mow at full throttle.

Ground speed too fast for conditions.

Correct installation of deck drive belt.

Mower Deck Vibrates Run engine at full throttle.

Loose hardware.

Check/replace mower deck drive belt.

Check/replace spindle drive belt.

Blades bolts are loose.

Blades are bent or worn.

Sharpen and balance blades.

Remove belt shields and check for debris on sheaves.

Check sheaves for proper alignment or damage. See your Great

Dane servicing dealer.

Mower Blades Do Not Engage Mower deck drive belt slipping or broken.

Spindle drive belt slipping or broken.

Mower deck belt tension spring not installed or broken.

PTO switch failure.

20-amp fuse is blown (main power circuit).

Loose electrical connections.

Faulty PTO clutch.

Troubleshooting - 30

Page 34

TROUBLESHOOTING

If Check

Mower Mows Unevenly Mower deck not properly leveled.

Ground speed too fast for conditions.

Run engine at full throttle.

Reduce ground speed when making turns.

Blades are bent or worn.

Sharpen or replace blades.

Change mowing pattern.

Check tire pressure.

Troubleshooting - 31

Page 35

STORAGE

Storage

Storing Safety

c CAUTION: Avoid injury! Fuel vapors are

explosive and flammable. Engine exhaust

fumes contain carbon mono xide and can cause

serious illness or death:

• Run the engine only long enough to move

the machine to or from storage.

• Do not store vehicle with fuel in the tank

inside a building where fumes may reach an

open flame or spark.

• Allow the engine to cool before storing the

machine in any enclosure.

Preparing Machine for Storage

1. Repair any worn or damaged parts. Replace parts if

necessary. Tighten loose hardware.

2. Repair scratched or chipped metal surfaces to prevent

rust.

3. Clean under the deck and remove grass and debris from

inside chute.

4. Wash the machine and apply wax to metal surfaces.

5. Run machine for five minutes to dry belts and pulleys.

6. Apply light coat of engine oil to pivot and wear points to

prevent rust.

Engine:

Engine storage procedure should be used when vehicle is

not to be used for longer than 60 days.

1. Change engine oil and filter while engine is warm.

2. Service air filter if necessary.

3. Clean debris from engine air intake screen.

4. Remove spark plugs. Put 30 mL (1 oz.) of clean engine

oil in cylinders.

5. Crank the engine five or six times to allow oil to be

distributed.

6. Install spark plugs.

7. Clean the engine and engine compartment.

8. Remove battery.

9. Clean the battery and battery posts.

10.Store the battery in a cool, dry place where it will not

freeze.

NOTE: The stored battery should be recharged every

90 days.

11.Charge the battery.

12.Store the machine in a dry, protected place. If machine

is stored outside, put a waterproof cover over it.

Removing Machine From Storage

1. Check tire pressure.

2. Check engine oil level.

Preparing Fuel and Engine for Storage

Fuel:

If you have been using “Stabilized Fuel”, add stabilized fuel

to tank until the tank is full.

NOTE: Filling the fue l tank reduces the amount o f air in

the fuel tank and helps reduce deterioration of fuel.

If you are not using “Stabilized Fuel”:

1. Park machine safely in a well-ventilated area.

NOTE: Try to anticipate the last time the machine will

be used for the season so very little fuel is left in the

fuel tank.

2. Turn on engine and allow to run until it runs out of fuel.

3. Turn key to off position.

4. Mix fresh fuel and fuel stabilizer in separate container.

Follow stabilizer instructions for mixing.

5. Fill fuel tank with stabilized fuel.

6. Run engine for a few minutes to allow fuel mixture to

circulate through fuel system.

3. Charge battery if necessary.

4. Install battery.

5. Check spark plug gap. Install and tighten plugs to

specified torque.

6. Lubricate all grease points.

7. Run the engine 5 minutes without the mower or any

attachments running to allow oil to be distributed

throughout engine.

8. Be sure all shields and guards or deflectors are in place.

Storage - 32

Page 36

Assembly

Bag of Parts

ASSEMBLY

Tire Size Pressure

Qty. Description

1Key

1 Operator’s Manual

1 PDR Check List

Check Engine Oil Level

Remove dipstick from tube by unscrewing it. Wipe it clean.

9. Install dipstick and allow the cap to rest on the end of the

tube. Do not tighten the cap.

10.Remove dipstick. Check oil level on dipstick; oil level

should be between the ADD and FULL marks.

• If oil is low, add oil to bring oil level no higher than the

FULL mark on dipstick.

• If oil level is above the FULL mark, drain to proper

level.

11.Install and tighten dipstick.

Check Tire Pressure

Front: 9 x 3.5-4 172

Rear: 16 x 6.5-8 69

-207kPa (25-30 psi)

-83kPa (10-12 psi)

Lubricate Machine

Lubricate all moving parts before operating the machine.

See Lubrication Points in the Service Lubrication section.

Check Mower Deck Level

The mower deck is assembled and adjusted at the factory.

After machine is completely assembled, check the mower

front-to-rear and side-to-side deck level.

Check Safety System

For a complete checkout procedure of the safety interlock

system, see Testing the Safety Interlock System in the

Operating section.

Initial Adjustments

c CAUTION: A v oid injury! Explosive separation of

a tire and rim parts can cause serious injury or

death:

• DO NOT attempt to mount a tire without the

proper equipment and experience to perform

the job.

• Always maintain the correct tire pressure. DO

NOT inflate the tires above the recommended

pressure. Never weld or heat a wheel and tire

assembly. The heat can cause an increase in

air pressure resulting in a tire explosion.

Welding can structurally weaken or deform the

wheel.

• When inflating tires, use a clip-on chuck and

extension hose long enough to allow you to

stand to one side and NOT in front of or over

the tire assembly.