Page 1

®

®

Chariot

GCBR2652S, GCBR2661S, GCKA1948S,

GCKA1952S, GCBV2348S, GCBV2361S,

GCKH2348S,GCKH2352S,

GCKH2361S

TCU20866

C5

OPERATOR’S MANUAL

200964 06/17/2007

Page 2

Page 3

INTRODUCTION

WARNING: The Engine Exhaust

from this product contains chemicals known

to the State of California to cause cancer,

birth defects or other reproductive harm.

California Proposition 65 Warning

Introduction

Using Your Operator’s Manual

This manual is an important part of your machine and should remain with

the machine when you sell it.

Use the safety and operating information in the machine operator’s

manual to operate and service the machine safely and correctly.

An engine manufacturer’s owner’s manual has been provided with your

machine. This will provide maintenance and troubleshooting information

for the engine installed in your machine.

Specifications and design are subject to change without notice.

Special Messages

Your manual contains special messages to bring attention to potential

safety concerns, machine damage as well as helpful operating and

servicing information. Please read all the information carefully to avoid

injury and machine damage.

CAUTION: Avoid injury! This symbol and text highlight

potential hazards or death to the operator or bystanders that

may occur if the hazards or procedures are ignored.

All information, illustrations and

specifications in this manual are based on

the latest information at the time of

publication. The right is reserved to make

changes at any time without notice.

COPYRIGHT© 2007

Auburn Consolidated Industries Inc.

All rights reserved

COPYRIGHT© 2006

IMPORTANT: Avoid damage! This text is used to tell the operator

of actions or conditions that might result in damage to the

machine.

NOTE: General information is given throughout the manual that may

help the operator in the operation or service of the machine.

Product Identification

Record Identification Numbers

Chariot

GCBR2652S S/N 637910001

GCBR2661S S/N 638910001

GCBV2348S S/N 638510001

GCBV2361S S/N 639610001

GCKA1948S S/N 638710001

GCKA1952S S/N 638810001

GCKH2348S S/N 641010001

GCKH2352S S/N 641110001

GCKH2361S S/N 641210001

If you need to contact an Authorized Service Center for information on

servicing, always provide the product model and serial numbers.

You will need to locate the model and serial numbers for the machine and

for the engine of your machine and record the information in the spaces

provided.

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

Introduction - 1

Page 4

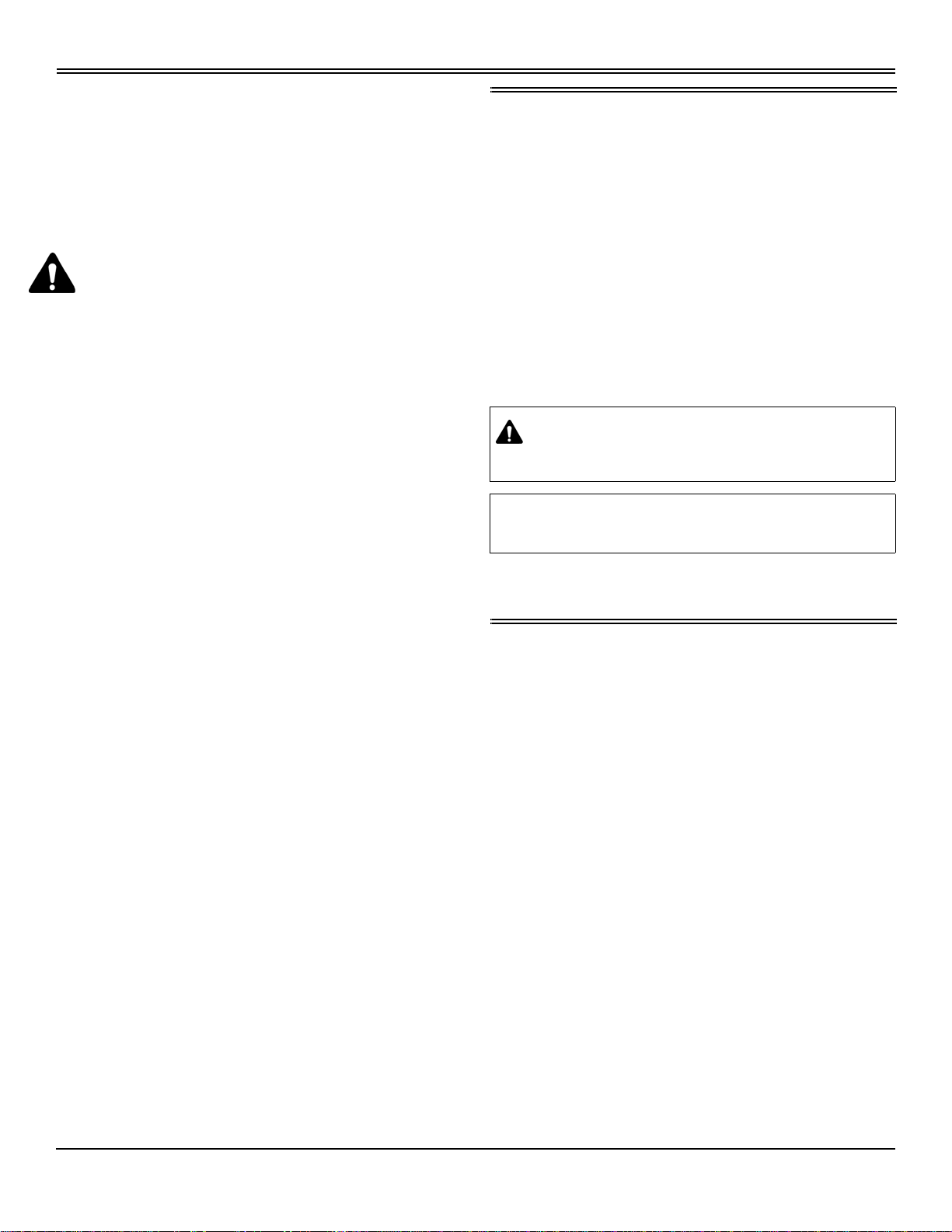

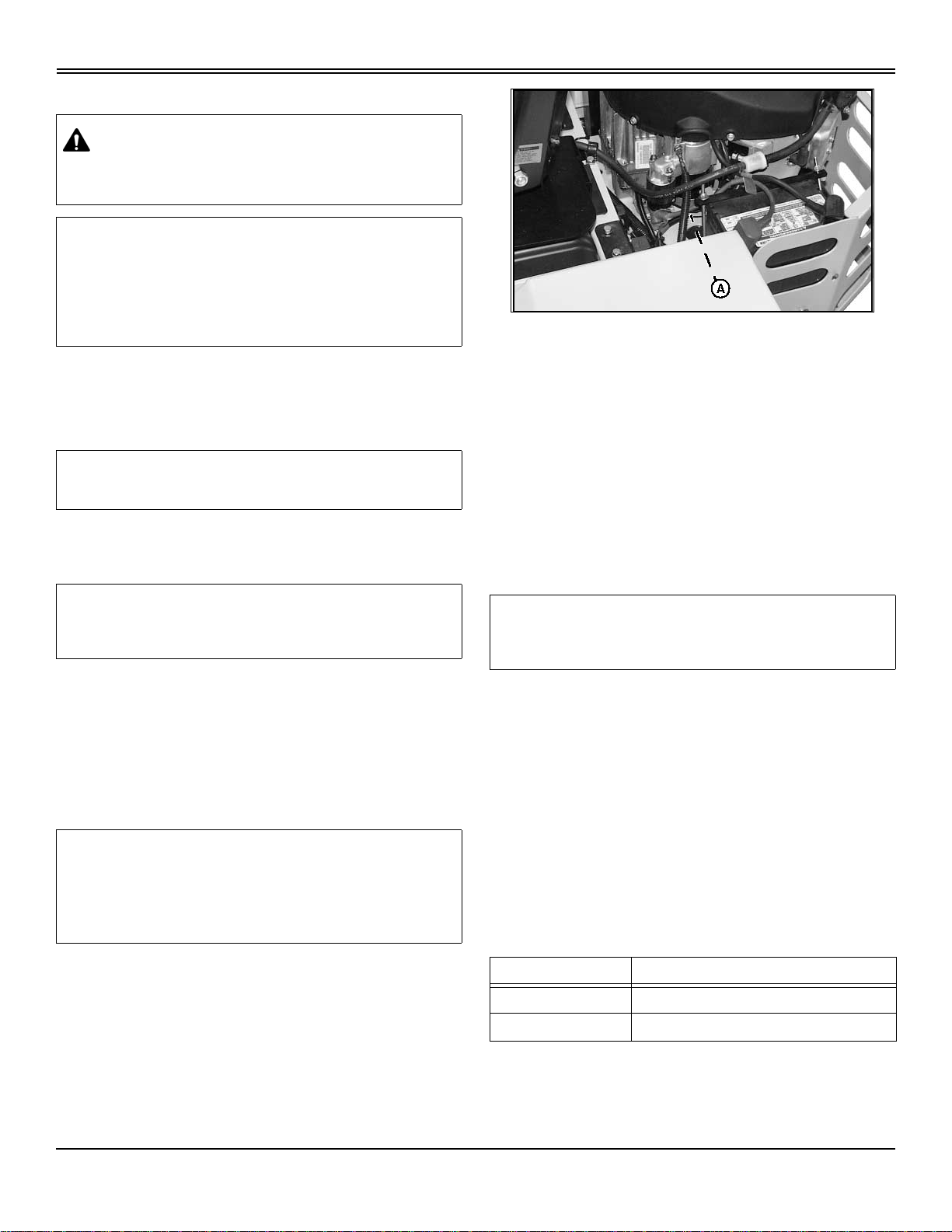

MODEL NUMBER (POWER UNIT) (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

SERIAL NUMBER (POWER UNIT) (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE MODEL NUMBER(B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SERIAL NUMBER (B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

ENGINE SPECIFICATION NUMBER (B):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

MOWER DECK MODEL NUMBER (C):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

MOWER DECK SERIAL NUMBER (C):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

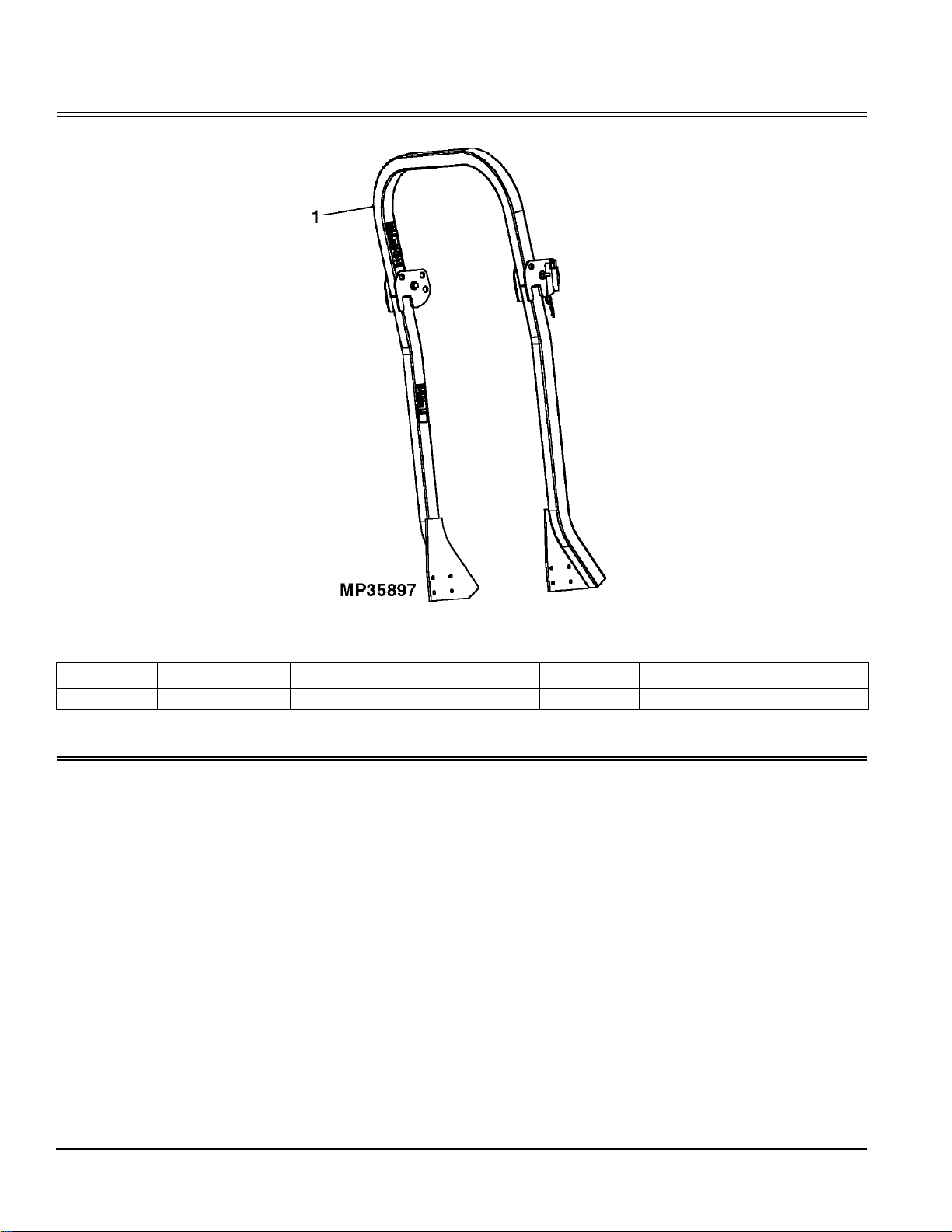

ROPS SERIAL NUMBER (D):

SAFETY LABELS

The operator’s manual also explains any potential safety hazards

whenever necessary in special safety messages that are identified with

the word, CAUTION, and the safety-alert symbol.

DANGER

To avoid injury from rotating blades, stay clear of deck edge.

Safety Labels

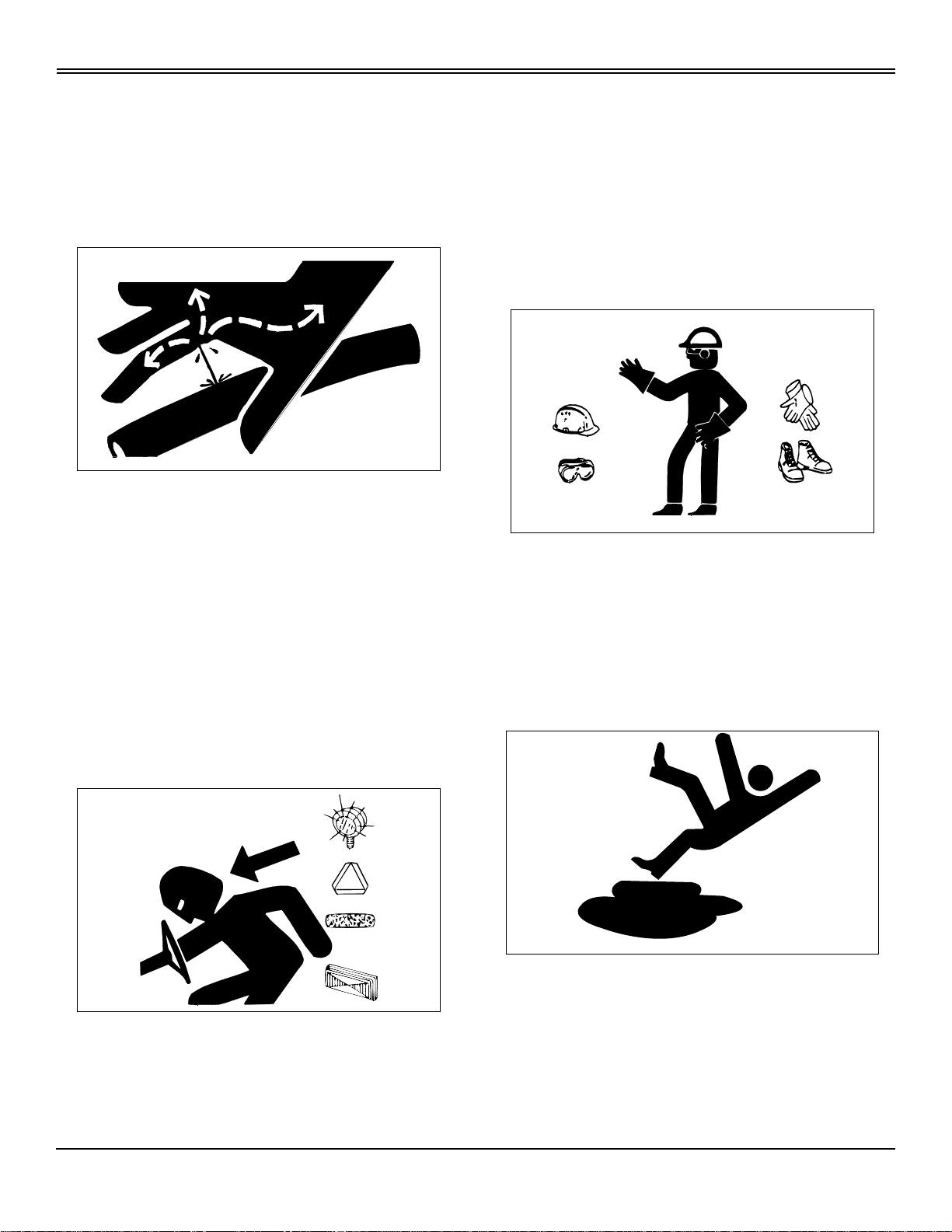

Understanding The Machine Safety Labels

The machine safety labels shown in this section are placed in important

areas on your machine to draw attention to potential safety hazards.

On your machine safety labels, the words DANGER, WARNING, and

CAUTION are used with this safety-alert symbol. DANGER identifies the

most serious hazards.

Safety Labels - 2

Page 5

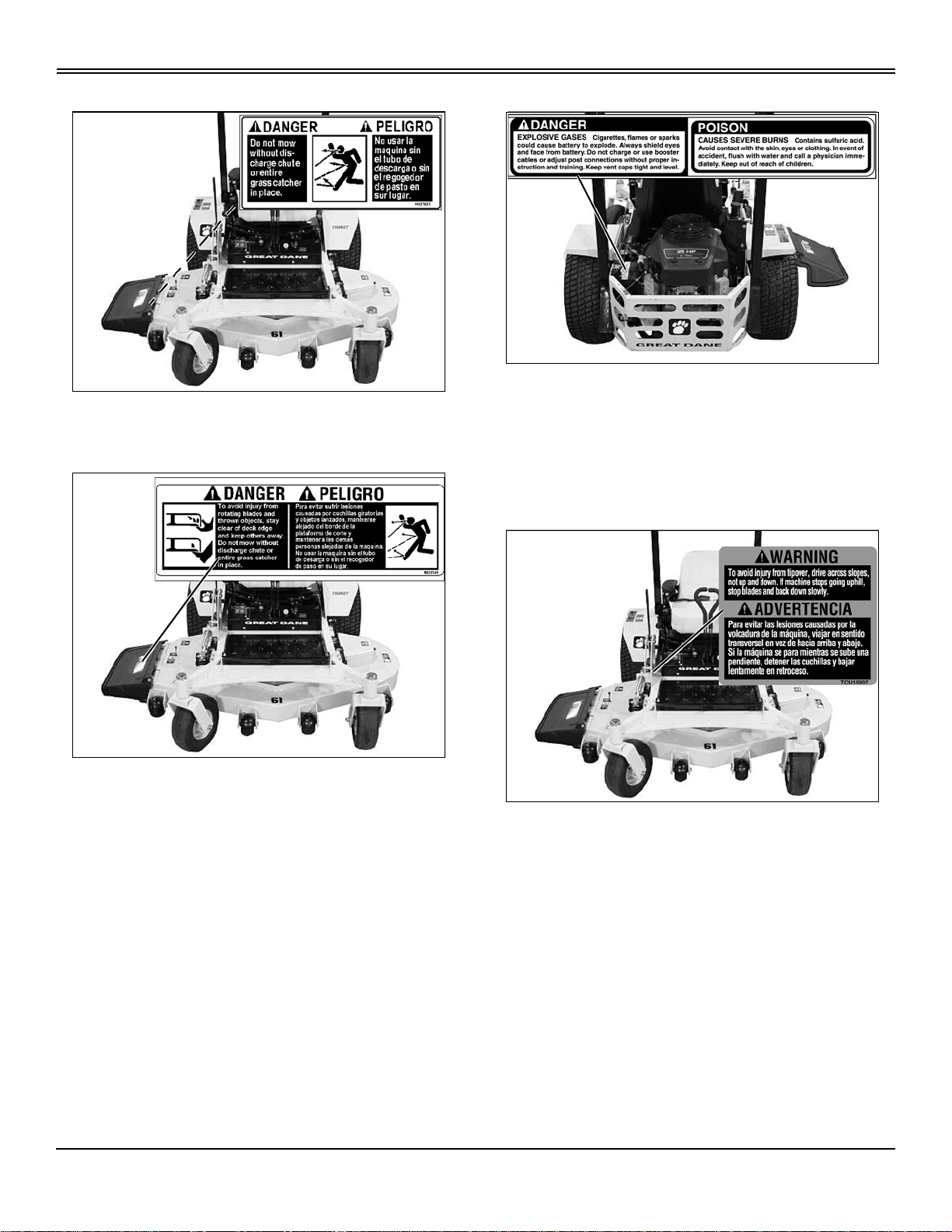

SAFETY LABELS

DANGER

Do not mow without discharge chute or entire grass catcher in place.

DANGER

DANGER

• Cigarettes, flames or sparks could cause battery to explode. Always

shield eyes and face from battery. Do not charge or use booster cables or

adjust post connections without proper instruction and training.

• Contains sulfuric acid. Avoid contact with the skin, eyes or clothing. In

event of accident, flush with water and call a physician immediately. Keep

out of reach of children.

WARNING

To avoid injury from rotating blades and thrown objects, stay clear of deck

edge and keep others away. Do not mow without discharge chute or entire

grass catcher in place.

Safety Labels - 3

To avoid injury from tipover, drive across slopes, not up and down. If

machine stops going uphill, stop blades and back down slowly.

Page 6

SAFETY LABELS

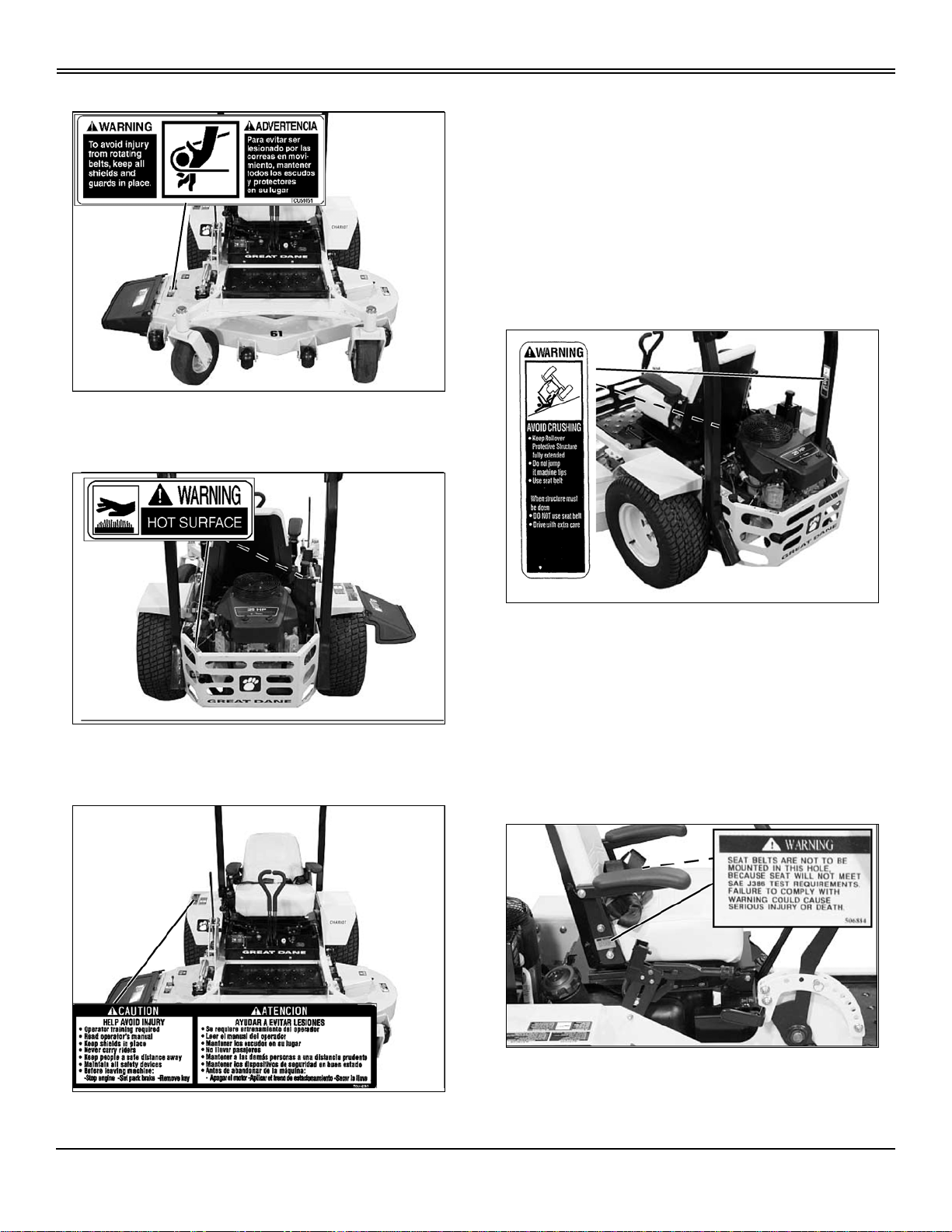

WARNING

To avoid injury from rotating belts, keep all shields and guards in place.

WARNING

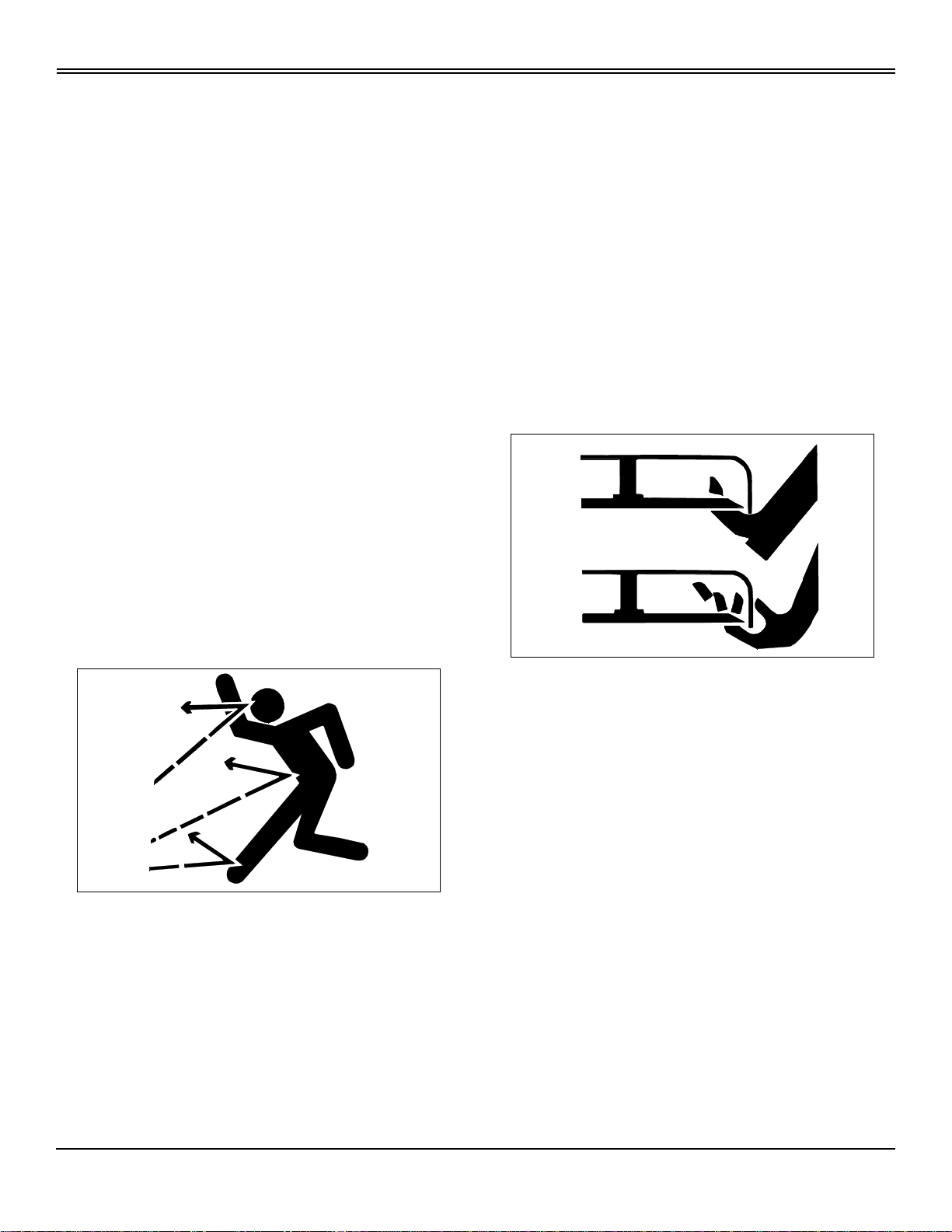

• Read operator’s manual

• Keep shields in place

• Never carry riders

• Keep people a safe distance away

• Maintain all safety devices

• Before leaving machine:

• Stop engine

• Set park brake

• Remove key

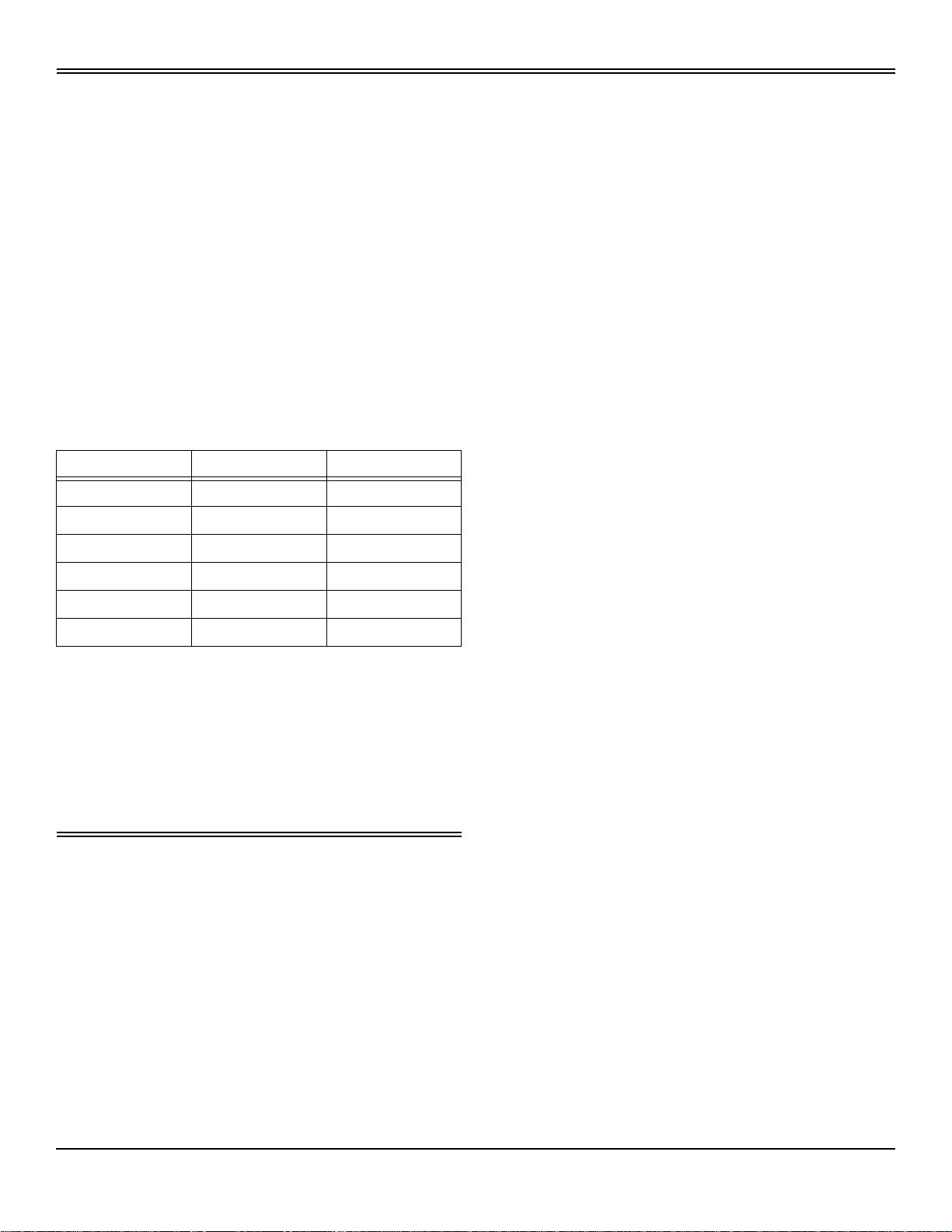

WARNING

Hot surface

CAUTION

• Operator training required

AVOID CRUSHING

• Keep Rollover Protective Structure fully extended

• Do not jump if machine tips

• Use seat belt

When Structure must be down

• DO NOT use seat belt

• Drive with extra care

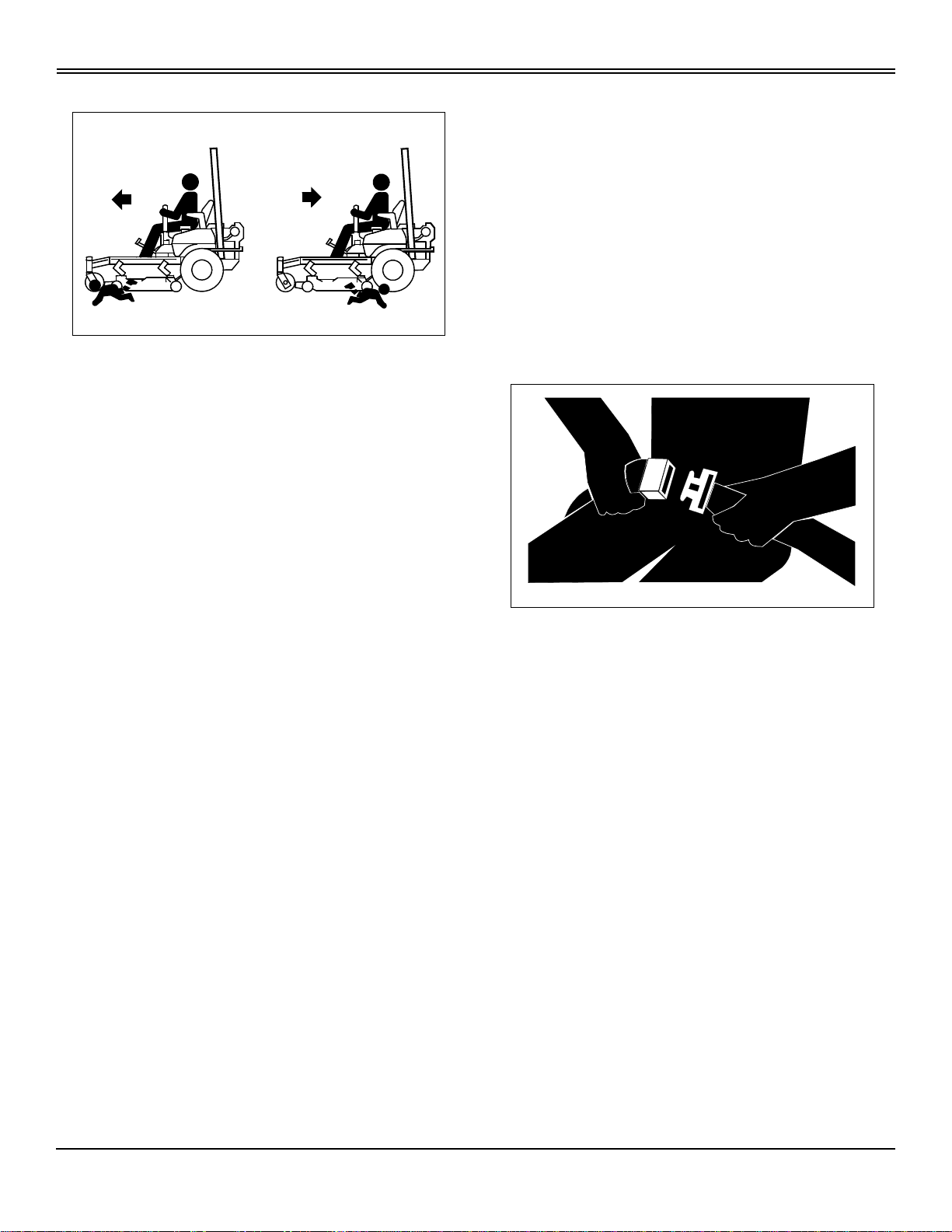

WARNING

Seat belts are not to be mounted in this hole, because seat will not meet

SAE J386 test requirements. Failure to comply with warning could cause

serious injury or death.

Safety Labels - 4

Page 7

SAFETY

Emission Control System Certification Label

NOTE: Tampering with emission controls and components by

unauthorized personnel may result in severe fines or penalties.

Emission controls and components can only be adjusted by EPA

and/or CARB authorized service centers. Contact your Great Dane

Equipment Retailer concerning emission controls and component

questions.

The presence of an emissions label signifies that the engine has been

certified with the United States Environmental Protection Agency (EPA)

and/or California Air Resources Board (CARB).

The emissions warranty applies only to those engines marketed by Great

Dane that have been certified by the EPA and/or CARB; and used in the

United States and Canada in off-road mobile equipment.

Emission Compliance Period

If your engine has the emission compliance category listed on the

emission control system certification or air index label, this indicates the

number of operating hours for which the engine has been certified to meet

EPA and/or CARB emission requirements. The following table provides

the engine compliance period in hours associated with the category found

on the certification label.

Agency Category Hours

EPA C 250

EPA B 500

EPA A 1000

CARB Moderate 125

CARB Intermediate 250

CARB Extended 500

Certification

Your product has been tested and evaluated by the manufacturer and

conforms with American National Standard B-71.4, “Safety Specifications”

for commercial turf care equipment.

Canadian Electromagnetic Compatibility (EMC)

Compliance

This spark ignition system complies with Canadian ICES-002.

Safety

Operator Training Required

• Read the operator’s manual and other training material. If the operator

or mechanic cannot read English, it is the owner’s responsibility to explain

this material to them. This publication is available in other languages.

• Become familiar with the safe operation of the equipment, operator

controls, and safety signs.

• All operators and mechanics should be trained. The owner of the

machine is responsible for training the users.

• Never let children or untrained people operate or service the equipment.

Local regulations may restrict the age of the operator.

• The owner/user can prevent and is responsible for accidents or injuries

occurring to themselves, other people, or property.

• Operate the machine in an open, unobstructed area under the direction

of an experienced operator.

Preparation

• Evaluate the terrain to determine what accessories and attachments are

needed to properly and safely perform the job. Only use accessories and

attachments approved by the manufacturer.

• Wear appropriate clothing including hard hat, safety glasses and

hearing protection. Long hair, loose clothing or jewelry may get tangled in

moving parts.

• Inspect the area where the equipment is to be used and remove all

objects such as rocks, toys and wire which can be thrown by the machine.

• Use extra care when handling gasoline and other fuels. They are

flammable and vapors are explosive.

a.Use only an approved container.

b.Never remove gas cap or add fuel when engine is running. Do not

smoke.

c.Never refuel or drain the machine indoors.

• Check that the operator’s presence controls, safety switches and shields

are attached and functioning properly. Do not operate unless they are

functioning properly.

Operating Safely

• Never run an engine in an enclosed area where dangerous carbon

monoxide fumes can collect.

• Only operate in good light, keeping away from holes and hidden

hazards.

• Be sure all drives are in neutral and parking brake is engaged before

starting engine. Only start engine from the operator’s position. Use seat

belts if provided.

• Slow down and use extra care on hillsides. Be sure to travel in the

recommended direction on hillsides. For this machine, drive across

hillsides, not up and down. Turf conditions can affect the machine’s

stability. Use caution while operating near drop-offs.

• Slow down and use caution when making turns and when changing

directions on slopes.

• Never raise deck with the blades running.

• Never operate with the PTO shield, or other guards, not securely in

place. Be sure all interlocks are attached, adjusted properly, and

functioning properly.

• Never operate with the discharge deflector raised, removed or altered,

unless using a grasscatcher. Do not operate mower without discharge

chute or entire grasscatcher in place.

• Do not change the engine governor setting or overspeed the engine.

Operating the engine at excessive speed can increase the hazard of

personal injury.

• Stop on level ground, lower implements, disengage drives, engage

parking brake, and shut off engine before leaving the operator’s position

for any reason including emptying the grasscatchers or unclogging the

chute.

• Stop equipment and inspect blades after striking objects or if an

abnormal vibration occurs. Make necessary repairs before resuming

operations.

• Keep hands and feet away from the cutting units.

• Look behind and down before backing up to be sure of a clear path.

• Never carry passengers and keep pets and bystanders away.

• Slow down and use caution when making turns and crossing roads and

sidewalks. Stop blades if not mowing. Watch for traffic when operating

near or crossing roadways.

Safety - 5

Page 8

SAFETY

• Be aware of the mower discharge direction and do not point it at anyone.

• Do not operate the machine while under the influence of alcohol or

drugs.

• Use care when loading or unloading the machine into or off of a trailer or

truck.

• Use care when approaching blind corners, shrubs, trees, or other

objects that may obscure vision.

• Inspect machine before you operate. Be sure hardware is tight. Repair

or replace damaged, badly worn, or missing parts. Be sure guards and

shields are in good condition and fastened in place. Make any necessary

adjustments before you operate.

• Before using, always visually inspect to see that the blades, blade bolts

and the mower assembly are not worn and damaged. Replace worn and

damaged blades and bolts in sets to preserve balance.

• Keep safety labels visible when installing accessories and attachments.

• Do not wear radio or music headphones. Safe service and operation

require your full attention.

• When machine is left unattended, stored, or parked, lower the mower

deck unless a positive mechanical lock is used.

Using a Spark Arrestor

The engine in this machine is not equipped with a spark arrestor muffler. It

is a violation of California Public Resource Code Section 4442 to use or

operate this engine on or near any forest-covered, brush-covered or

grass-covered land unless the exhaust system is equipped with a spark

arrestor meeting any applicable local or state laws. Other states or federal

areas may have similar laws.

A spark arrestor for your machine may be available from your authorized

dealer. An installed spark arrestor must be maintained in good working

order by the operator.

Parking Safely

1.Stop machine on a level surface, not on a slope.

2.Move motion control levers out to the neutral lock position.

3.Disengage mower blades.

4.Lower attachments to the ground.

5.Lock the park brake.

6.Stop the engine.

7.Remove the key.

8.Wait for engine and all moving parts to stop before you leave the

operator’s seat.

9.Close fuel shut-off valve, if your machine is equipped.

10.Disconnect the negative battery cable or remove the spark plug wire

(for gasoline engines) before servicing the machine.

Rotating Blades are Dangerous

HELP PREVENT SERIOUS OR FATAL ACCIDENTS:

Checking Mowing Area

• Clear mowing area of objects that might be thrown. Keep people and

pets out of mowing area.

• Low-hanging branches and similar obstacles can injure the operator or

interfere with mowing operation. Before mowing, identify potential

obstacles such as low-hanging branches, and trim or remove those

obstacles.

• Study mowing area. Set up a safe mowing pattern. Do not mow where

traction or stability is doubtful.

• Test drive area with mower lowered but not running. Slow down when

you travel over rough ground.

• Rotating blades can cut off arms and legs, and throw objects. Failure to

observe safety instructions could result in serious injury or death.

• Keep hands, feet and clothing away from mower deck when engine is

running.

• Be alert at all times, drive forward carefully. People, especially children

can move quickly into the mowing area before you know it.

• Do not mow in reverse.

• Shut off blades when you are not mowing.

• Park machine safely before leaving the operator station for any reason

including emptying the catchers or unplugging the chute.

Safety - 6

Page 9

SAFETY

Protect Children

• Death or serious injury can occur when young children associate having

fun with a lawn mowing machine simply because someone has given

them a ride on a machine.

• Children are attracted to lawn mowing machines and mowing activities.

They don’t understand the dangers of rotating blades or the fact that the

operator is unaware of their presence.

• Children who have been given rides in the past may suddenly appear in

the mowing area for another ride and be run over or backed over by the

machine.

• Tragic accidents with children can occur if the operator is not alert to the

presence of children, especially when a child approaches a machine from

behind. Before and while backing up, stop mower blades and look down

and behind the machine carefully, especially for children.

• Never carry children on a machine or attachment, even with the blades

off. Do not tow children in a cart or trailer. They can fall off and be

seriously injured or interfere with safe machine operation.

• Never use the machine as a recreational vehicle or to entertain children.

• Never allow children or an untrained person operate the machine.

Instruct all operators not to give children a ride on the machine or in an

attachment.

• Keep children indoors, out of the mowing area, and in the watchful eye

of a responsible adult, other than the operator, when a mower is being

operated.

• Stay alert to the presence of children. Never assume that children will

remain where you last saw them. Turn the machine off if a child enters the

work area.

Avoid Tipping

• Slopes are a major factor related to loss-of-control and tip-over

accidents, which can result in severe injury or death. Operation on all

slopes requires extra caution.

• If you feel uneasy on a hillside, do not mow it.

• Mow across slopes, not up and down.

• Watch for holes, ruts, bumps, rocks, or other hidden objects. Uneven

terrain could overturn the machine. Tall grass can hide obstacles.

• Choose a low ground speed so you will not have to stop or shift while on

a slope.

• Do not mow or operate machine on wet grass. Tires may lose traction.

Tires may lose traction on slopes even though the brakes are functioning

properly.

• Avoid starting, stopping or turning on a slope. If the tires lose traction,

disengage the blades and proceed slowly, straight down the slope.

• Keep all movement on slopes slow and gradual. Do not make sudden

changes in speed or direction, which could cause the machine to roll over.

• Use extra care while operating machine with grasscatchers or other

attachments, they can affect stability of the machine. Do not use on steep

slopes.

• Do not mow near drop-offs, ditches, embankments, or bodies of water.

The machine could suddenly roll over if a wheel goes over the edge or the

edge caves in.

• Follow the manufacturer’s recommendations for wheel weights or

counterweights for added stability when operating on slopes or using front

or rear mounted attachments. Remove weights when not required.

• Drive machine very slowly and avoid quick stops when attachment is

removed.

• Transport machine with decks lowered to improve stability.

Use Seat Belt Properly

• Use a seat belt when operating with the folding Roll-Over Protective

Structure (ROPS) in the upright position to minimize chance of injury from

an accident, such as an overturn.

• Do not use a seat belt when operating with the folding ROPS in the

folded position. Return the folding ROPS to the upright position as soon as

possible.

• Never modify, disassemble or attempt to repair the seat belt.

• Replace entire seat belt if mounting hardware, buckle, belt, or retractor

show signs of damage.

• Inspect seat belt and mounting hardware at least once a year. Look for

signs of loose hardware or belt damage, such as cuts, fraying, extreme or

unusual wear, discoloration, or abrasion. Replace only with replacement

parts approved by your Great Dane.

• Layers of heavy clothing can interfere with proper positioning of the seat

belt and can reduce the effectiveness of the seat belt.

Keep ROPS Installed Properly

• Make certain all parts of the ROPS are installed correctly if the ROPS

structure is loosened or removed for any reason. All ROPS hardware

should be tightened to the proper torque per manufacturer’s

recommendations.

• Any alteration of the ROPS must be approved by the manufacturer. The

protection provided by the ROPS will be impaired if the ROPS is subjected

to structural damage, is involved in an overturn incident, or is in any way

altered by welding, bending, drilling, or cutting.

• Never attempt to repair a damaged or altered ROPS. It must be

replaced to maintain the manufacturer’s certification of the structure.

Safety - 7

Page 10

SAFETY

Keep Riders Off

• Only allow the operator on the machine. Keep riders off.

• Riders on the machine or attachment may be struck by foreign objects

or thrown off the machine causing serious injury.

• Riders obstruct the operator’s view resulting in the machine being

operated in an unsafe manner.

Avoid High Pressure Fluids

• Hydraulic hoses and lines can fail due to physical damage, kinks, age,

and exposure. Check hoses and lines regularly. Replace damaged hoses

and lines.

• Hydraulic fluid connections can loosen due to physical damage and

vibration. Check connections regularly. Tighten loose connections.

• Escaping fluid under pressure can penetrate the skin causing serious

injury. Avoid the hazard by relieving pressure before disconnecting

hydraulic or other lines. Tighten all connections before applying pressure.

• Search for leaks with a piece of cardboard. Protect hands and body from

high pressure fluids.

• If an accident occurs, see a doctor immediately. Any fluid injected into

the skin must be surgically removed within a few hours or gangrene may

result. Doctors unfamiliar with this type of injury should reference a

knowledgeable medical source.

signals according to local regulations. Extra flashing warning lights may

need to be installed.

Checking Wheel Hardware

• A serious accident could occur causing serious injury if wheel hardware

is not tight.

• Check wheel hardware tightness often during the first 100 hours of

operation.

• Wheel hardware must be tightened to specified torque using the proper

procedure anytime it is loosened.

Wear Appropriate Clothing

• Always wear safety goggles, or safety glasses with side shields, and a

hard hat when operating the machine.

• Wear close fitting clothing and safety equipment appropriate for the job.

• While mowing, always wear substantial footwear and long trousers. Do

not operate the equipment when barefoot or wearing open sandals.

• Wear a suitable protective device such as earplugs. Loud noise can

cause impairment or loss of hearing.

Maintenance and Storage

Driving Safely on Public Roads

Avoid personal injury or death resulting from a collision with another

vehicle on public roads:

• Use safety lights and devices. Slow moving machines when driven on

public roads are hard to see, especially at night.

• Whenever driving on public roads, use flashing warning lights and turn

Safety - 8

• Never operate machine in a closed area where dangerous carbon

monoxide fumes can collect.

• Disengage drives, lower implement, lock parking brake, stop engine and

remove key or disconnect spark plug (for gas engines). Wait for all

movement to stop before adjusting, cleaning or repairing.

• Clean grass and debris from cutting units, drives, mufflers, and engine to

help prevent fires. Clean up oil or fuel spillage.

• Let engine cool before storing and do not store near flame.

Page 11

SAFETY

• Shut off fuel while storing or transporting. Do not store fuel near flames

or drain indoors.

• Park machine on level ground. Never allow untrained personnel to

service machine. Understand service procedure before doing work.

• Use jack stands or lock service latches to support components when

required. Securely support any machine elements that must be raised for

service work.

• Before servicing machine or attachment, carefully release pressure from

any components with stored energy, such as hydraulic components or

springs.

• Release hydraulic pressure by lowering attachment or cutting units to

the ground or to a mechanical stop and move hydraulic control levers back

and forth.

• Disconnect battery or remove spark plug (for gas engines) before

making any repairs. Disconnect the negative terminal first and the positive

last. Reconnect positive first and negative last.

• Use care when checking blades. Wrap the blades or wear gloves, and

use caution when servicing them. Only replace blades. Never straighten

or weld them.

• Keep hands, feet, clothing, jewelry and long hair away from moving

parts. If possible, do not make adjustments with the engine running.

• Charge batteries in an open well ventilated area, away from spark and

flames. Unplug charger before connecting or disconnecting from battery.

Wear protective clothing and use insulated tools.

• Keep all parts in good working condition and all hardware tightened.

Replace all worn or damaged decals.

• Check grasscatcher components and the discharge guard frequently

and replace with manufacturer’s recommended parts, when necessary.

Grasscatcher components are subject to wear, damage, and deterioration

which could expose moving parts or allow objects to be thrown.

• Keep all nuts and bolts tight, especially blade attachment bolts, to be

sure the equipment is in safe working condition.

• Check brake operation frequently. Adjust and service as required.

• On multi-bladed machines, take care as rotating one blade can cause

other blades to rotate.

Prevent Fires

• Do not store machine near an open flame or source of ignition, such as

a water heater or furnace.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks.

Replace if necessary.

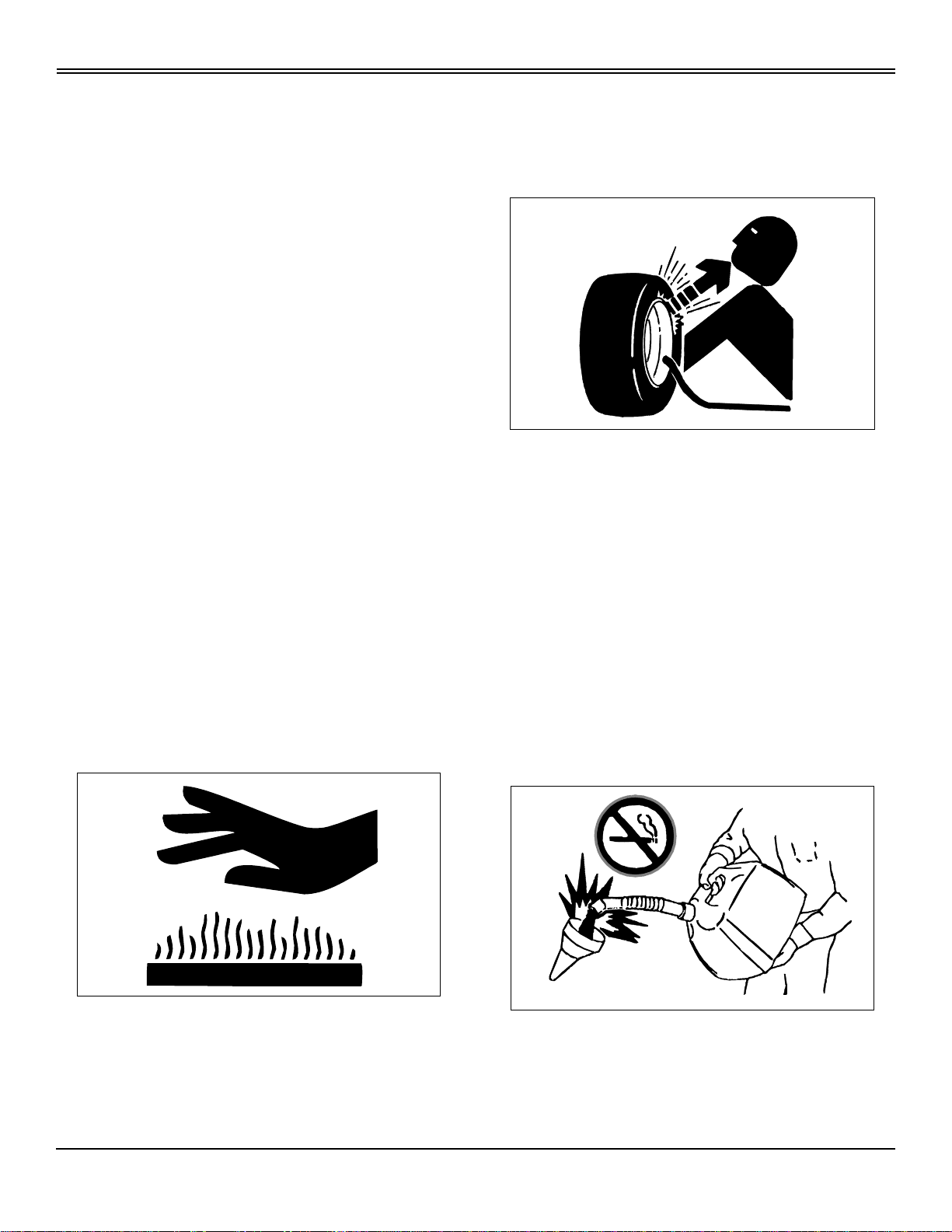

Tire Safety

Explosive separation of a tire and rim parts can cause serious injury or

death:

• Do not attempt to mount a tire without the proper equipment and

experience to perform the job.

• Always maintain the correct tire pressure. Do not inflate the tires above

the recommended pressure. Never weld or heat a wheel and tire

assembly. The heat can cause an increase in air pressure resulting in a

tire explosion. Welding can structurally weaken or deform the wheel.

• When inflating tires, use a clip-on chuck and extension hose long

enough to allow you to stand to one side and NOT in front of or over the

tire assembly.

• Check tires for low pressure, cuts, bubbles, damaged rims or missing

lug bolts and nuts.

Handling Fuel Safely

To avoid personal injury or property damage, use extreme care in

handling fuel. Fuel is extremely flammable and fuel vapors are

explosive:

• Remove grass and debris from engine compartment and muffler area,

before and after operating machine, especially after mowing or mulching

in dry conditions.

• Empty the grasscatcher completely before storing.

• Always shut off fuel when storing or transporting machine, if the

machine has a fuel shutoff.

Safety - 9

• Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

• Use only an approved fuel container. Use only non-metal, portable fuel

containers approved by the Underwriter’s Laboratory (U.L.) or the

American Society for Testing & Materials (ASTM). If using a funnel, make

sure it is plastic and has no screen or filter.

Page 12

OPERATING

• Never remove the fuel tank cap or add fuel with the engine running.

Allow engine to cool before refueling.

• Never add fuel to or drain fuel from the machine indoors. Move machine

outdoors and provide adequate ventilation.

• Clean up spilled fuel immediately. If fuel is spilled on clothing, change

clothing immediately. If fuel is spilled near machine, do not attempt to st art

the engine but move the machine away from the area of spillage. Avoid

creating any source of ignition until fuel vapors have dissipated.

• Never store the machine or fuel container where there is an open flame,

spark, or pilot light such as on a water heater or other appliance.

Handling Waste Product and Chemicals

Waste products, such as, used oil, fuel, coolant, brake fluid, and batteries,

can harm the environment and people:

• Do not use beverage containers for waste fluids - someone may drink

from them.

• See your local Recycling Center or authorized dealer to learn how to

recycle or get rid of waste products.

• A Material Safety Data Sheet (MSDS) provides specific details on

chemical products: physical and health hazards, safety procedures, and

emergency response techniques. The seller of the chemical products

used with your machine is responsible for providing the MSDS for that

product.

• Prevent fire and explosion caused by static electric discharge. Static

electric discharge can ignite fuel vapors in an ungrounded fuel container.

• Never fill containers inside a vehicle or on a truck or trailer bed with a

plastic liner. Always place containers on the ground away from your

vehicle before fueling.

• Remove fuel-powered equipment from the truck or trailer and refuel it on

the ground. If this is not possible, then refuel such equipment with a

portable container, rather than from a fuel dispenser nozzle.

• Keep the nozzle in contact with the rim of the fuel tank or container

opening at all times until the fueling is complete. Do not use a nozzle lockopen device.

• Never overfill fuel tank. Replace fuel tank cap and tighten securely.

• Replace all fuel container caps securely after use.

• For gasoline engines, do not use gas with methanol. Methanol is

harmful to your health and to the environment.

Operating

Daily Operating Checklist

oMake sure all necessary guards and shields are safely and securely

attached. Check for loose, missing, or damaged parts.

oRemove mower deck belt shields. Clean grass and debris from belt

area.

oRemove grass and debris from machine and mower deck.

oTest park brake.

oTest safety systems.

oInspect battery terminals and hold-downs.

oInspect for oil leaks.

oCheck engine and hydraulic oil levels.

oInspect all belts for damage or cracking.

oInspect engine air filter.

oInspect mower level.

oAdjust cutting height if necessary.

oInspect wheel bolt torque. Tighten if necessary.

oCheck tire air pressure. Check tires for damage or cracking.

oInspect front caster spindles/wheels.

Avoid Damage to Plastic and Painted Surfaces

• Do not wipe plastic parts unless rinsed first.

• Insect repellent spray may damage plastic and painted surfaces. Do not

spray insect repellent near machine.

Operating - 10

Page 13

OPERATING

• Be careful not to spill fuel on machine. Fuel may damage surface. Wipe

up spilled fuel immediately.

• Prolonged exposure to sunlight will damage the hood surface.

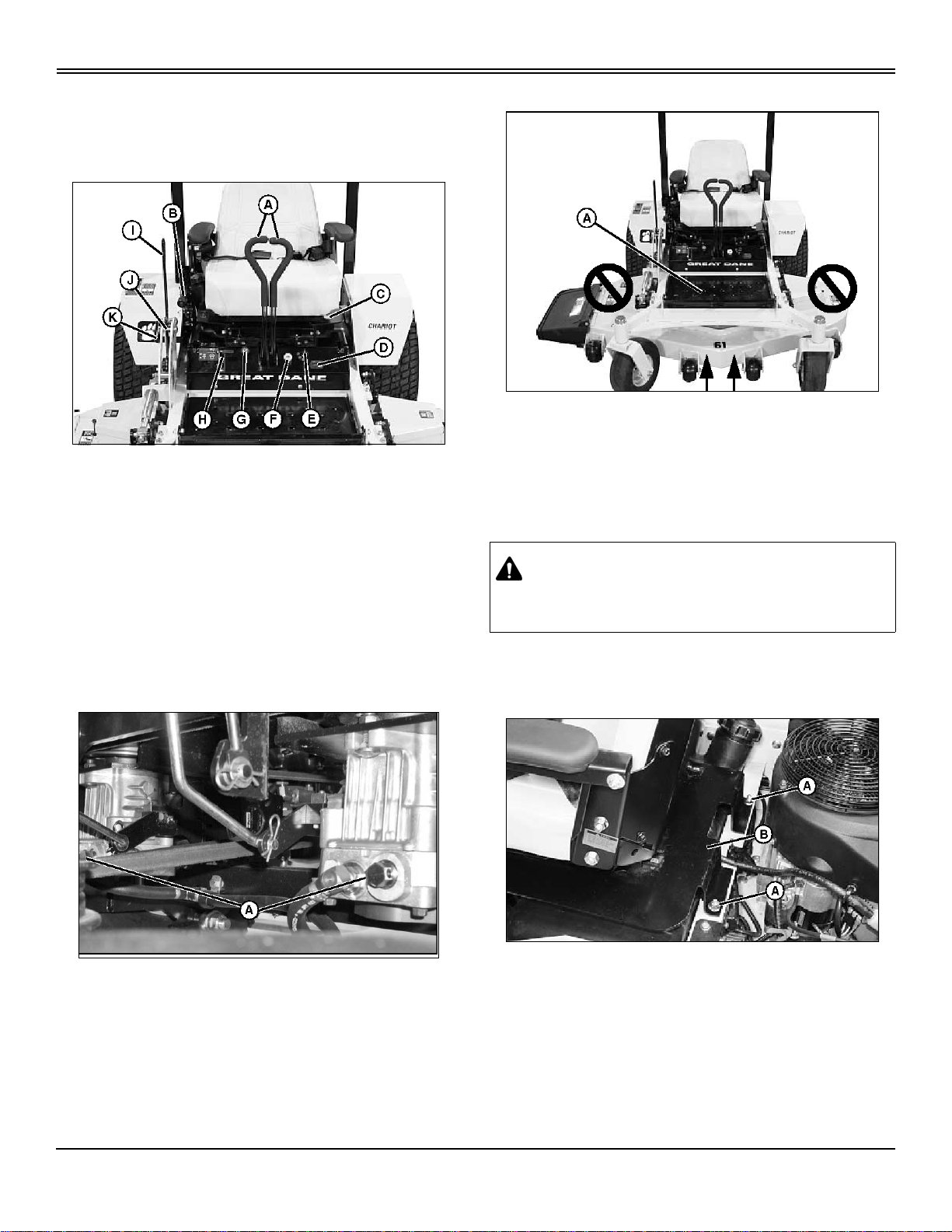

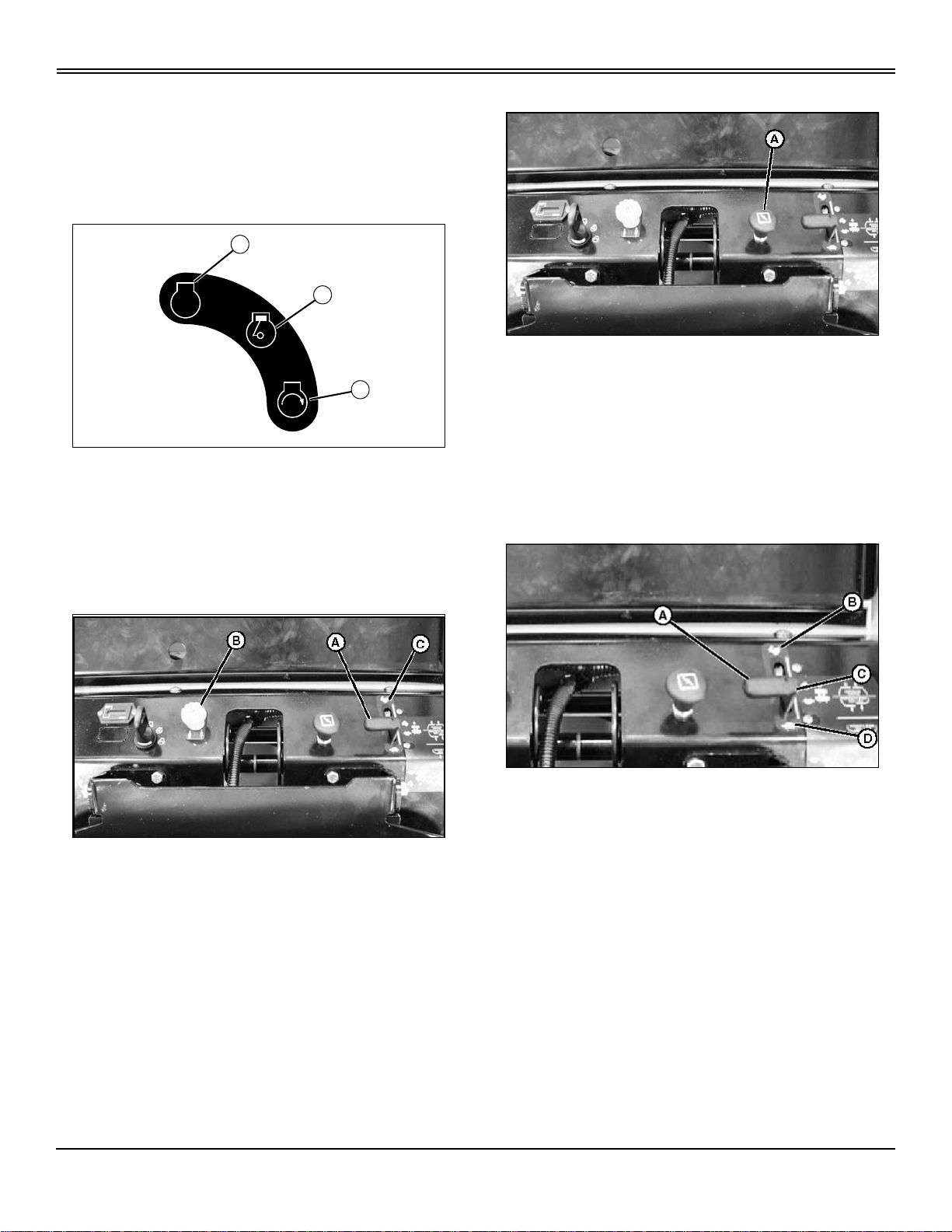

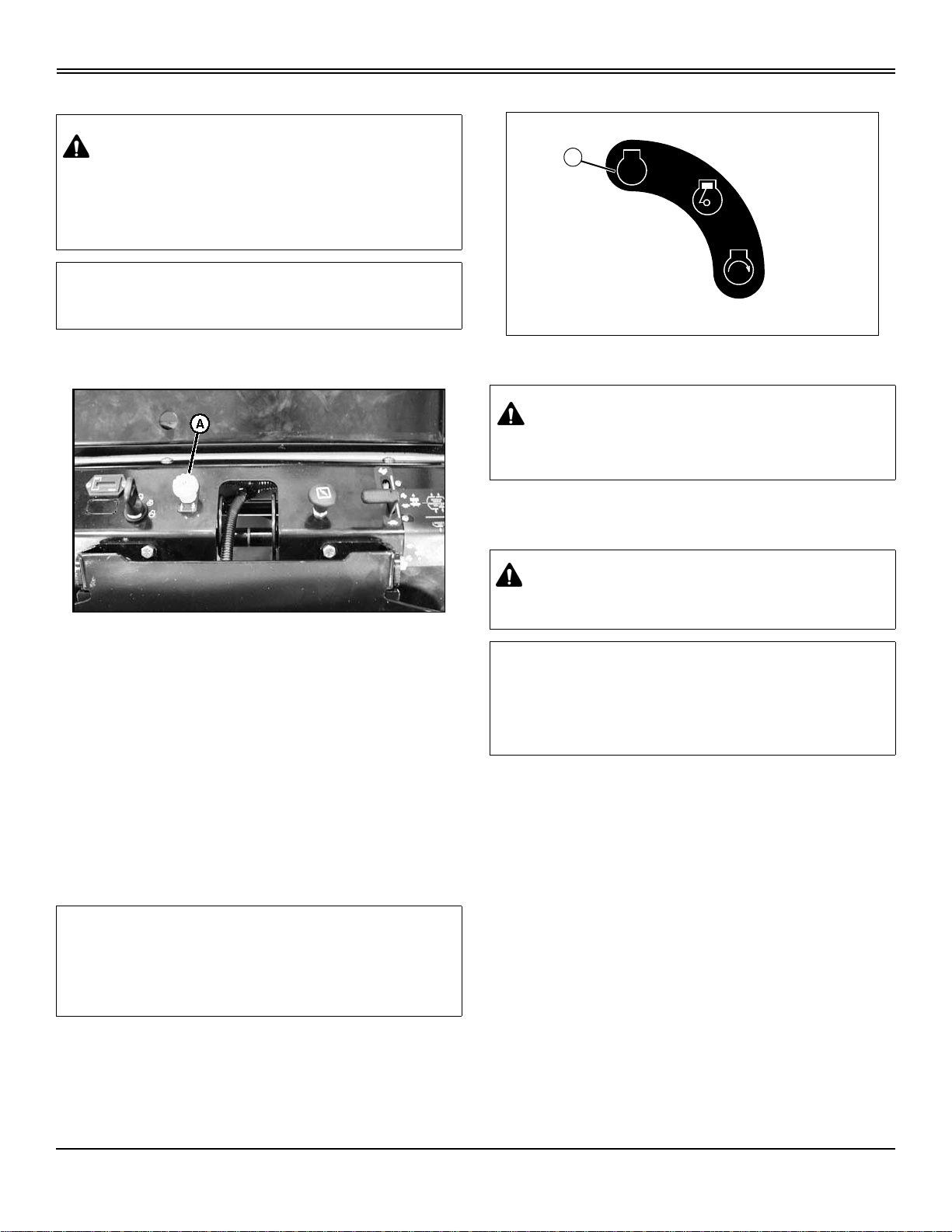

Operator Station Controls

A- Motion Control Levers

B- Park Brake Lever

C- Seat Adjustment Lever

D- Hourmeter

E- Ignition Key Switch

F- PTO Knob

G- Choke (Carbureted Engines Only)

H- Throttle Lever

I - Mower Deck Lift/Lower Lever

J- Height-of-Cut (HOC) Adjustment Pin

K- Mower Deck Transport Position Lock Lever

Miscellaneous Controls

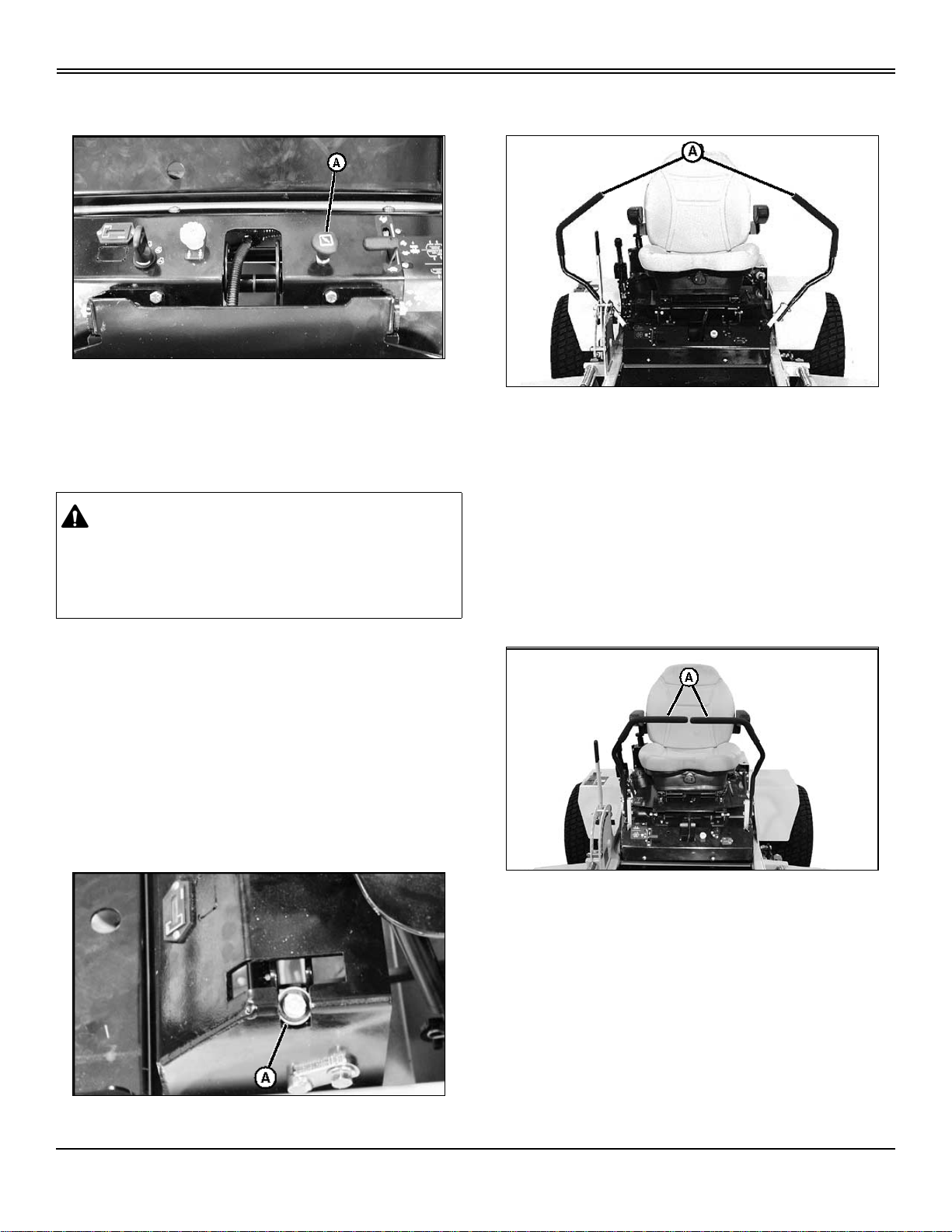

Mounting and Dismounting Machine Safely

Do not step on the mower deck when mounting and dismounting the

machine. Mount the machine from the front using the foot plate (A). Park

machine safely (See Parking Safely in the SAFETY section) before

dismounting.

Keep the foot plate clean.

Raising and Lowering Operator Seat

CAUTION: Avoid injury! The seat is heavy and can cause

injury if it falls. When performing any service function under

the operator seat, make sure the seat is tilted forward and

rests against the hinge stops.

Raising the Seat:

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2.Slide seat to full rear position.

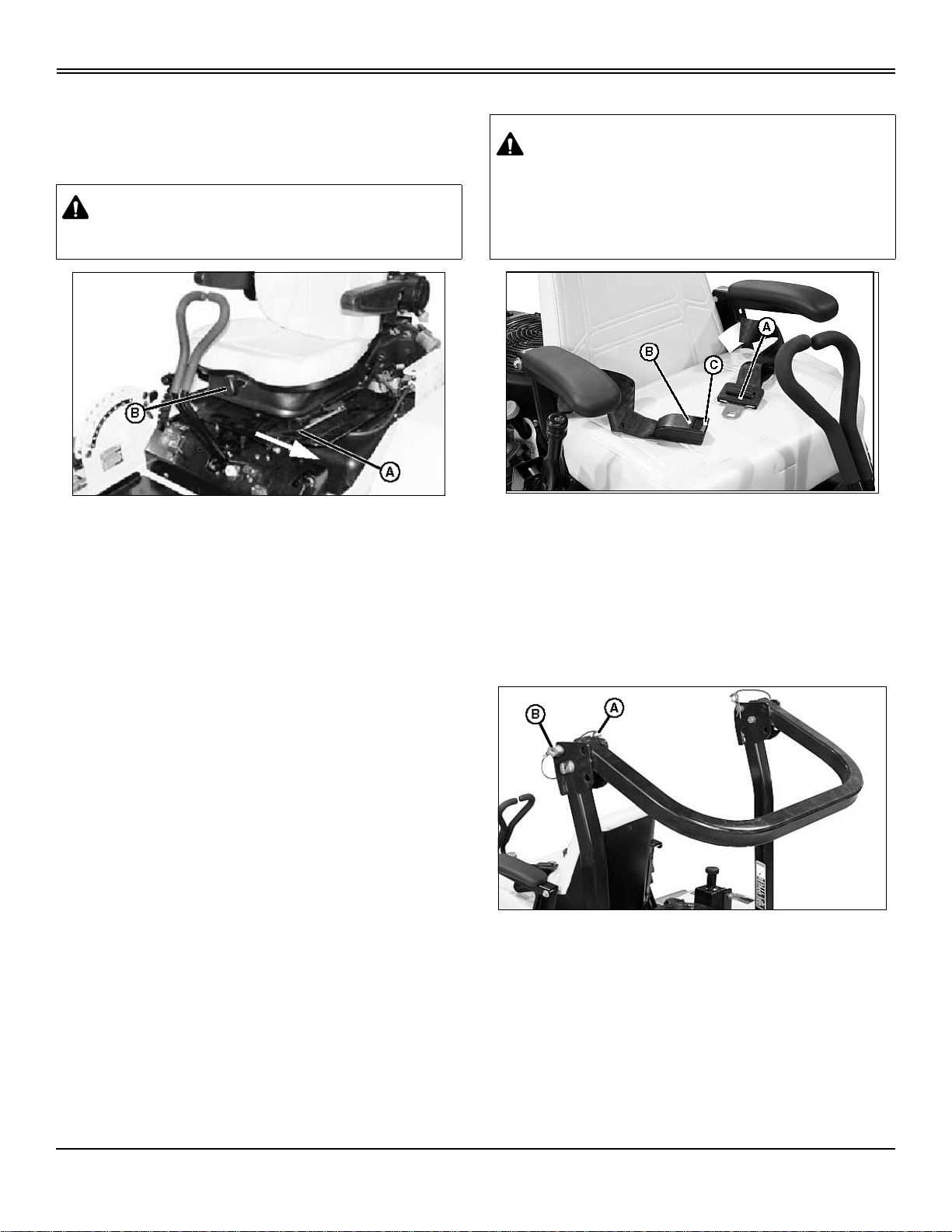

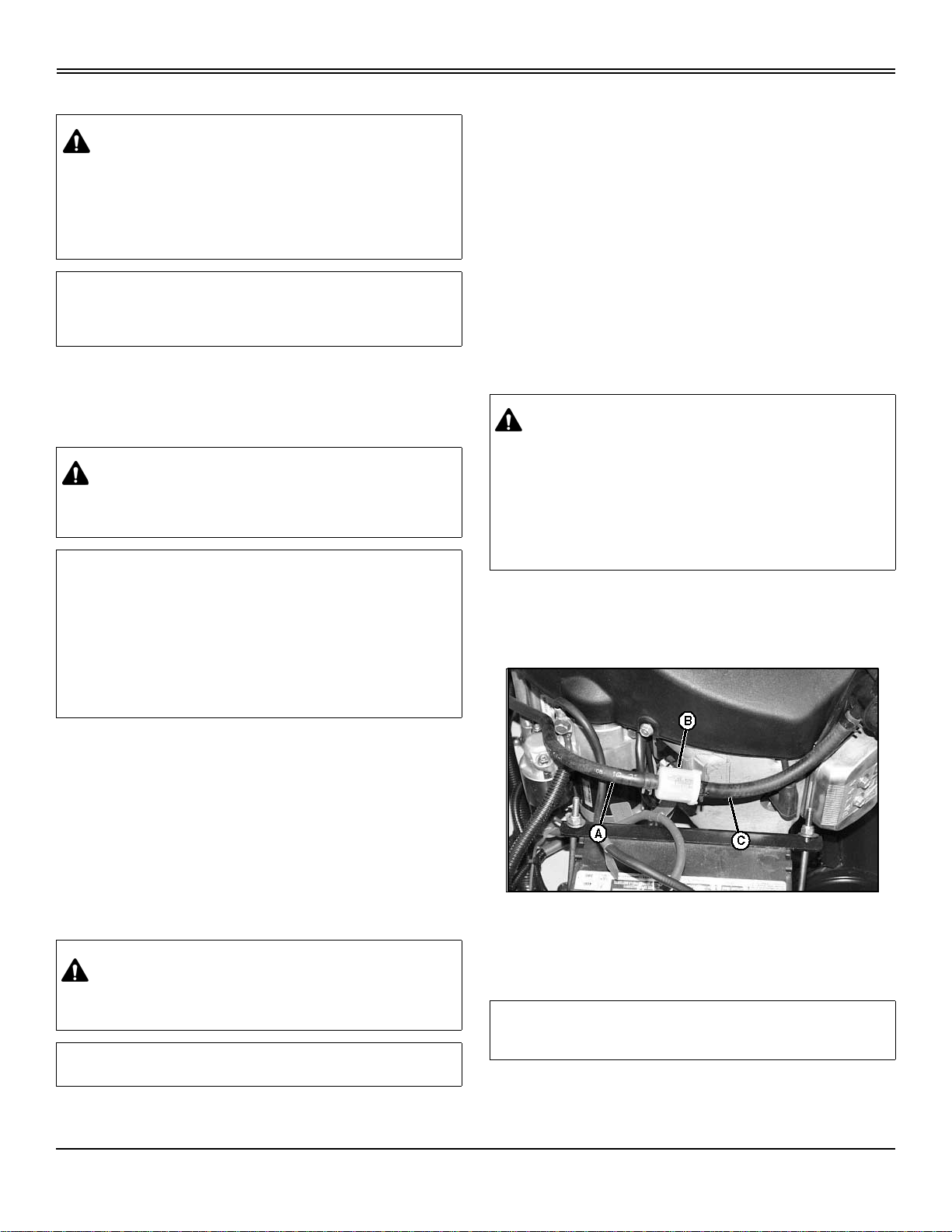

A- Hydraulic Pump Free-Wheel Valves

3.Remove two locknuts (A) and capscrews securing the flanges at the

rear of the seat frame (B) to the machine.

4.Lift seat frame and tilt forward until it rests against the hinge stops.

Lowering the Seat:

1.Stand on the side of the machine.

2.Slowly lower seat frame. Secure with cap screws and locknuts, removed

earlier.

3.Adjust seat as necessary for operator comfort.

Operating - 11

Page 14

OPERATING

Adjusting Seat

Front-to-Back Adjustment

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2.Sit on the operator seat.

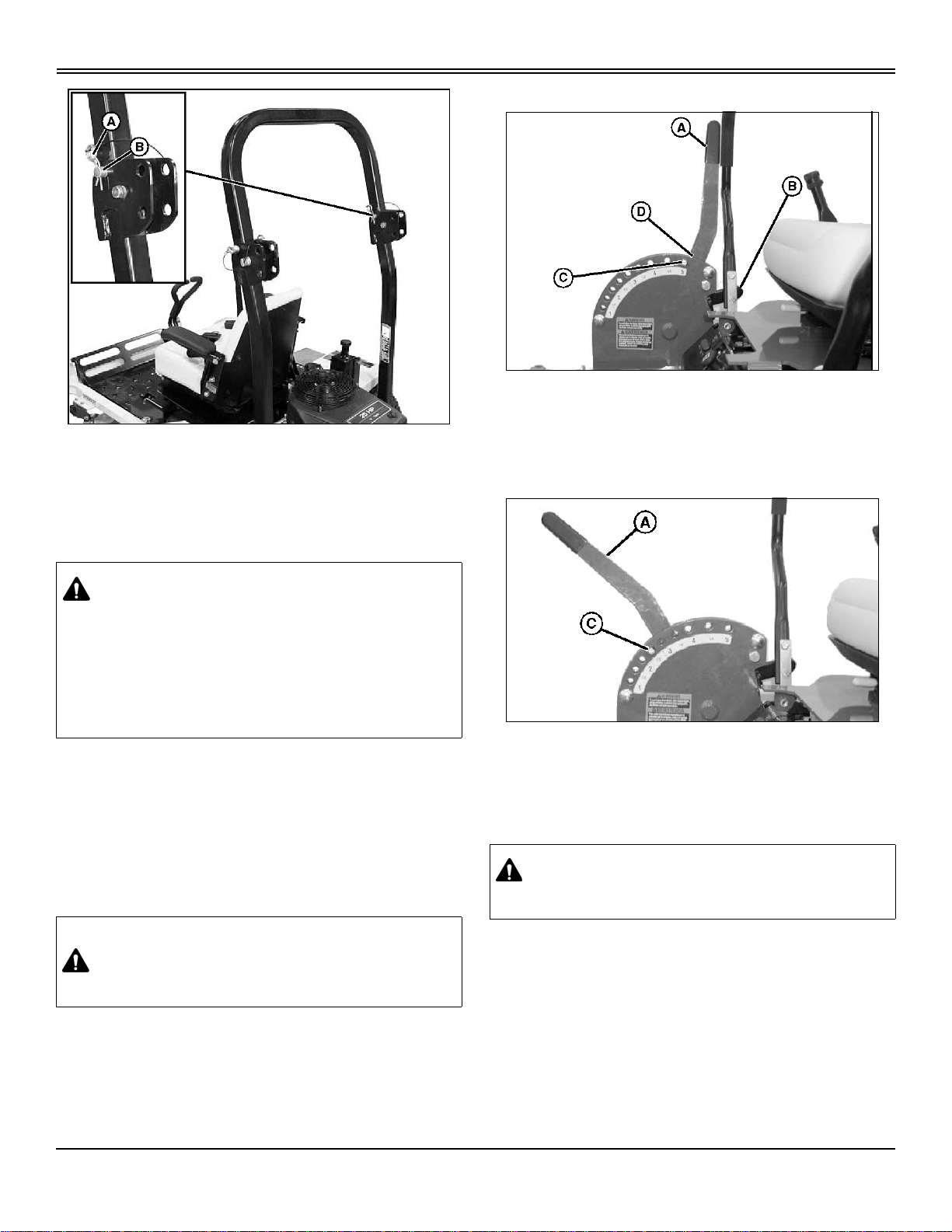

CAUTION: Avoid injury! Never adjust seat while machine is

moving. Stop machine before adjusting seat to prevent loss of

machine control.

3.T o adjust the seat front to back, push and hold the seat adjustment lever

(A) away from the seat.

4.Slide forward or backward to desired position.

5.Release lever.

Seat Height Adjustment

1.Sit on the operator seat.

2.To lower the seat, turn knob (B) counterclockwise.

3.To raise the seat, turn knob (B) clockwise.

Using Seat Belt

CAUTION: Avoid injury! Always wear seat belt when

operating machine with non-folding Roll-Over Protective

Structure (ROPS) or folding ROPS in upright position. Do not

jump from machine if machine tips.

•If folding ROPS must be folded to operate in a low

clearance area, do not use seat belt. Raise ROPS and use

seat belt as soon as conditions permit.

1.Sit in seat.

2.Pull belts across your lap and insert seat belt buckle (A) into latch (B)

until it locks.

3.T o release seat belt, press red button (C) until buckle comes out of latch.

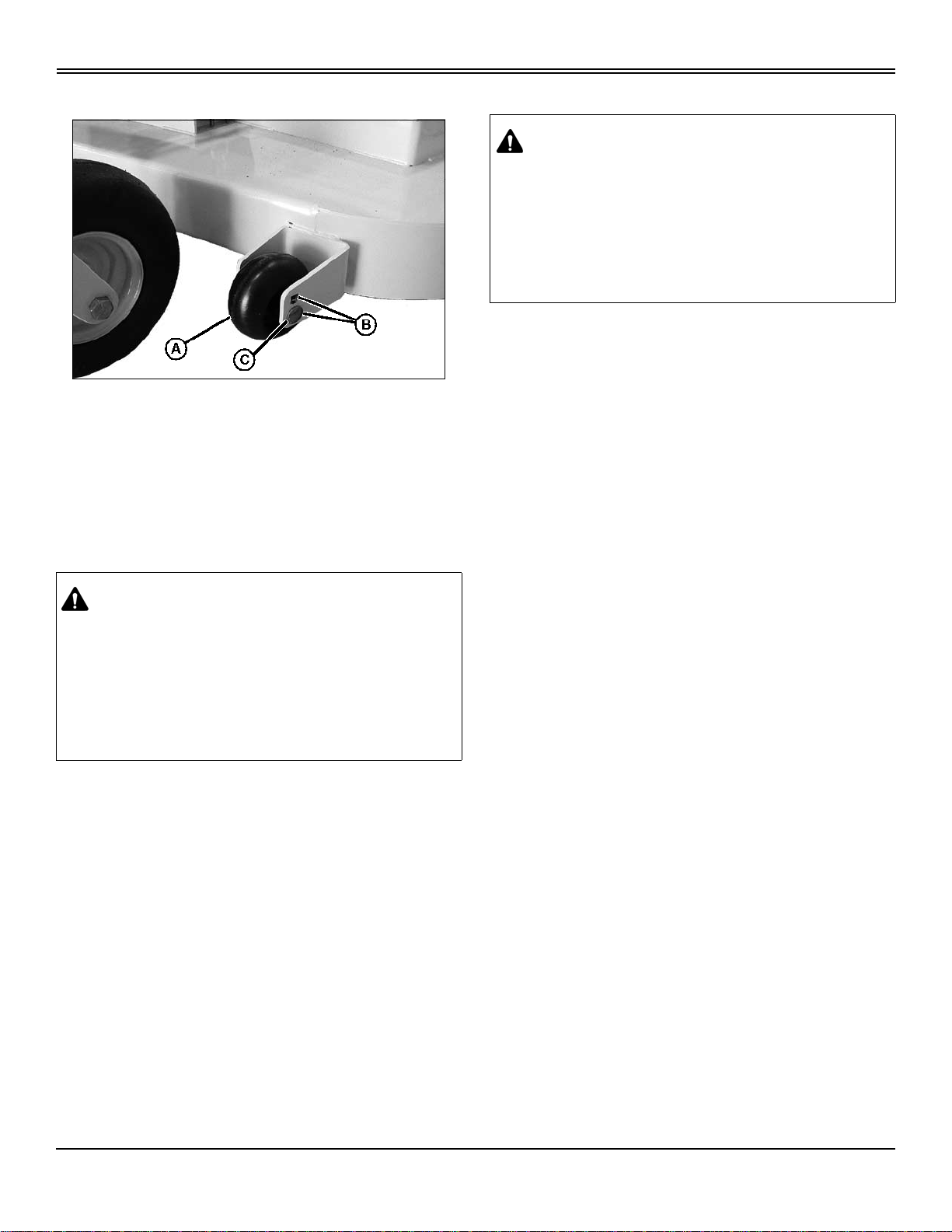

Raising and Lowering ROPS

Raising ROPS

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2.Remove spring pin (A) from drilled pin (B) on left and right side of ROPS.

3.Remove drilled pin from left and right side of ROPS.

Operating - 12

Page 15

OPERATING

4.Push ROPS into upright position.

5.Install drilled pin (B) into holes on left and right side of ROPS, and

secure in place with spring pins (A).

6.Check the ROPS bolt torque if the ROPS is loose.

Lowering ROPS

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2.Move the mower deck lift lever (A) to the transport position (D).

3.Position the HOC adjustment pin (C) in the proper hole for the desired

height-of-cut.

4.Pull back and hold the mower deck lift lever (A) and release the

transport position lock lever (B).

CAUTION: Avoid injury! Use roll-over protection system

(ROPS) in lowered position only when low clearance

operation is necessary.

•Do not use seat belt when ROPS is in lowered position.

•Do not operate machine on slope with ROPS in folded

position.

•Raise ROPS and fasten seat belt as soon as conditions

permit.

1.Park machine safely. (See Parking Safely in the SAFETY section).

2.Remove spring pin (A) from drilled pin (B) on left and right side of ROPS.

3.Remove drilled pin from left and right side of ROPS.

4.Pull ROPS rearward to lower.

5.Install drilled pins and spring pins back into hole in ROPS to secure in

place.

Adjusting Mower Deck Cutting Height

CAUTION: Avoid injury! Rotating blades are dangerous and

can cut fingers and toes. Stop engine, lock the park brake,

and wait for blade to stop rotating before adjusting cutting

height.

Cutting height can be adjusted from approximately 25-125 mm (1-5 in.).

Each hole adjusts the height-of-cut (HOC) in approximately 12 mm (1/2

in.) increments.

The deck can also be raised and locked in a transport position, to provide

maximum ground clearance when moving the machine from one area to

another.

5.Allow the mower deck lift lever (A) to rest against the HOC adjustment

pin (C).

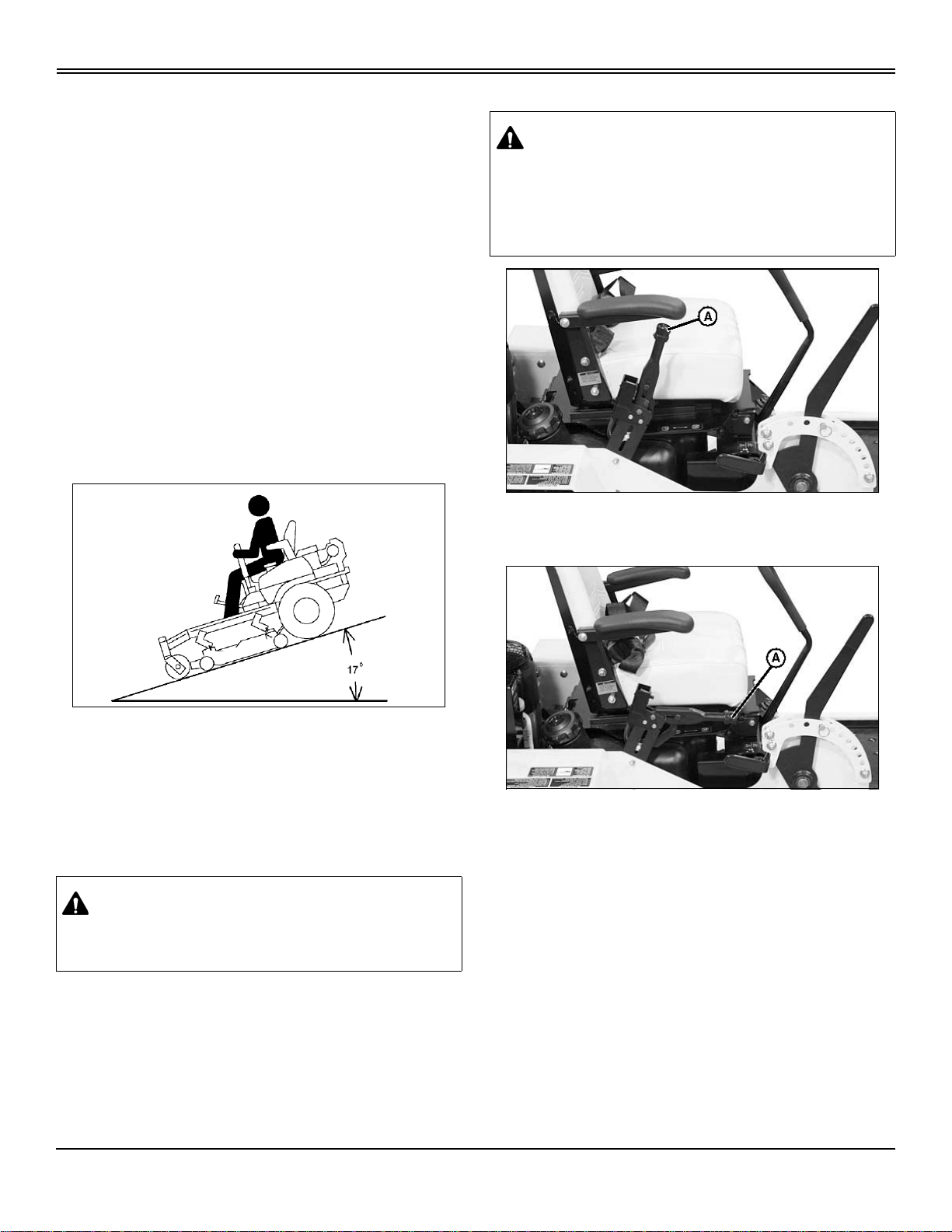

Adjusting Mower Deck Anti-Scalp Wheels

1.Park machine safely. (See Parking Safely in the SAFETY section.)

CAUTION: Avoid injury! Fingers and loose clothing can get

caught in rotating parts. Do not operate machine without all

mower deck belt shields installed.

NOTE: The flattest cut can be achieved by having all anti-scalp

wheels adjusted off the ground. Check anti-scalp wheel adjustments

each time the mower deck cutting height is changed.

It is recommended that all anti-scalp wheels be kept off the ground to

minimize scuffing.

2.Inflate tires to correct pressure.

3.Adjust mower deck to desired cutting height.

Operating - 13

Page 16

OPERATING

NOTE: The rear anti-scalp wheels are located under the rear of the

mower deck.

4.Adjust anti-scalp wheel (A) to one of two positions (B).

• Remove screw (C), nut and washer.

• Adjust wheel up or down so it is approximately 6-13 mm (1/4-1/2 in.)

above mowing surface.

5.Install wheel with attaching hardware.

6.Adjust all wheels to same height.

Testing Safety Systems

CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Move the machine to an outside area before running the

engine.Do not run an engine in an enclosed area without

adequate ventilation.•

•Connect a pipe extension to the engine exhaust pipe to

direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the

exhaust fumes out.

The safety systems installed on your machine should be checked before

each machine use. Be sure you have read the machine operator manual

and are completely familiar with the operation of the machine before

performing these safety system checks.

Use the following checkout procedures to check for normal operation of

machine.

If there is a malfunction during one of these procedures, do not operate

machine. See your authorized dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Testing Safety Systems

CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Move the machine to an outside area before running the

engine.Do not run an engine in an enclosed area without

adequate ventilation.•

•Connect a pipe extension to the engine exhaust pipe to

direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the

exhaust fumes out.

The safety systems installed on your machine should be checked before

each machine use. Be sure you have read the machine operator manual

and are completely familiar with the operation of the machine before

performing these safety system checks.

Use the following checkout procedures to check for normal operation of

machine.

If there is a malfunction during one of these procedures, do not operate

machine. See your authorized dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Testing PTO Switch

1.Sit on the operator seat with the motion control levers in the neutral

detent position (standard levers) or neutral lock position (optional “over the

lap” levers).

2.Lock the park brake.

3.Pull PTO knob up to engage.

4.Turn key switch to the start position.

Result: The engine must not crank.

Testing Park Brake Switch

1.Sit on the operator seat with the motion control levers in the neutral

detent position (standard levers) or neutral lock position (optional “over the

lap” levers).

2.Push PTO knob down to disengage.

3.Unlock the park brake.

4.Turn key switch to the start position.

Result: The engine must not crank.

Testing Neutral Start Switch

NOTE: Repeat this test three times, with the motion control levers in

the following positions:

• Right side motion control lever inward.

• Left side motion control lever inward.

• Both motion control levers inward.

1.Move motion control lever(s) out of the neutral detent position (standard

levers) or neutral lock position (optional “over the lap” levers).

2.Lock the park brake.

3.Push PTO knob down to disengage.

4.Turn key switch to the start position.

Result: The engine must not crank.

Operating - 14

Page 17

OPERATING

Testing Seat Switch

Procedure 1:

1.Sit on the operator seat with the motion control levers in the neutral

detent position (standard levers) or neutral lock position (optional “over the

lap” levers).

2.Unlock the park brake.

3.Push PTO knob down to disengage.

4.Turn key switch to the start position.

5.Raise slightly off the seat.

Result: The engine must stop.

Procedure 2:

1.Start engine.

2.Lock the park brake.

3.Pull PTO knob up to engage.

4.Raise slightly off the seat.

Result: The engine must stop.

Testing the Park Brake

Locking Park Brake:

CAUTION: Avoid injury! If the engine should stop while

operating on an incline, the mower can free wheel. If this

should occur:•lock the park brake,

•start the engine,

•unlock the park brake,

•resume operation.

• Raise and pull rearward park brake lever (A) to lock the park brake.

Unlocking Park Brake:

1.Stop machine on a 17° slope (30% grade). Stop the engine and lock the

park brake.

Result: Park brake must hold the machine stationary. (Machine should

move no more that 61 cm (24 in.) in one hour.) If machine moves more

than that, brakes need to be adjusted. See Adjusting Park Brake in the

Service Steering & Brakes section.

Using the Park Brake

CAUTION: Avoid injury! Children or bystanders may attempt

to move or operate an unattended machine.

Always lock the park brake and remove the key before leaving

the machine unattended.

Operating - 15

• Lower park brake lever (A) forward to unlock the park brake.

Page 18

OPERATING

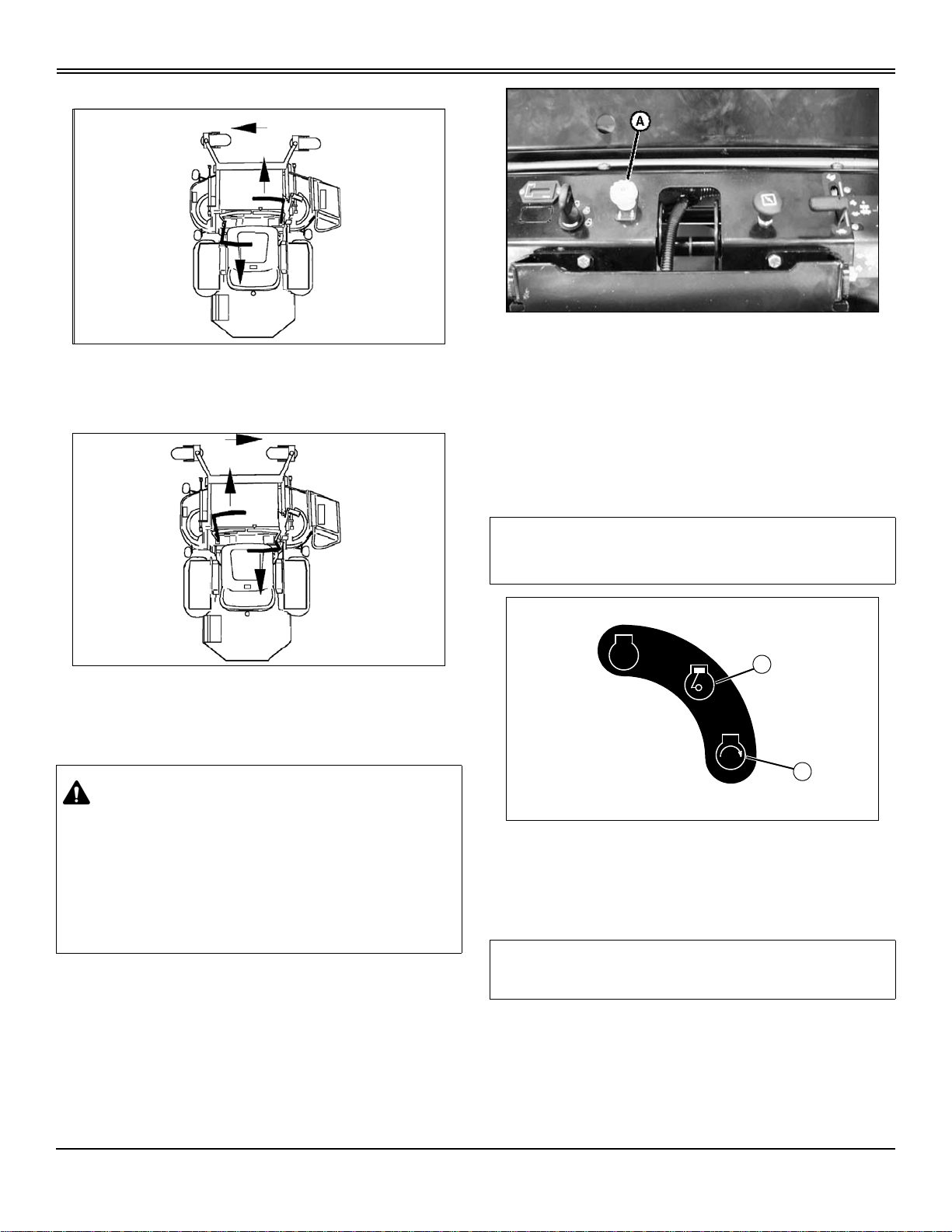

Using the Key Switch

NOTE: Machine will only start if the following conditions exist:

• Park brake is locked.

• PTO is disengaged.

• Motion control levers are in the neutral detent position (standard

levers) or neutral lock position (optional “over the lap” levers).

A

STOP

• To turn ignition off, turn key to the STOP position (A).

• To turn ignition on, turn key to the run position (B).

• To start engine, turn key to the start position (C). Once engine begins to

run, release key back to the run position.

B

C

Using the Throttle Lever

• Push throttle lever (A) all the way forward to the full-throttle detent

position (B) when mowing.

• Move throttle lever (A) to the 1/2-throttle position (C) when starting and

warming the engine.

• Pull throttle lever (A) rearward to the slow position (D) to idle engine. Do

not run engine at slow idle any longer than necessary.

Using the Hourmeter

NOTE: The machine is equipped with an electric start. The hourmeter

will continue to run with the key switch left in the run position.

Using the PTO

Engage PTO:

1.Move throttle lever (A) to the 1/2- to 3/4-throttle position.

2.Pull PTO knob (B) up to engage mower deck.

3.Move throttle lever (A) forward to the fast detent position (C) for mowing.

Disengage PTO:

• Push PTO knob (B) down.

• The hourmeter (A) shows the number of hours the machine has run.

• The service interval chart gives necessary service intervals. Use the

hourmeter and service interval chart in the Service Intervals section to

determine when machine will need service.

See the service interval chart in the engine manufacturer’s owners manual

supplied with your machine to determine when the engine will need

service.

Operating - 16

Page 19

OPERATING

Using the Choke

Engage Choke:

• Pull choke knob (A) out.

Disengage Choke:

• Push choke knob (A) in.

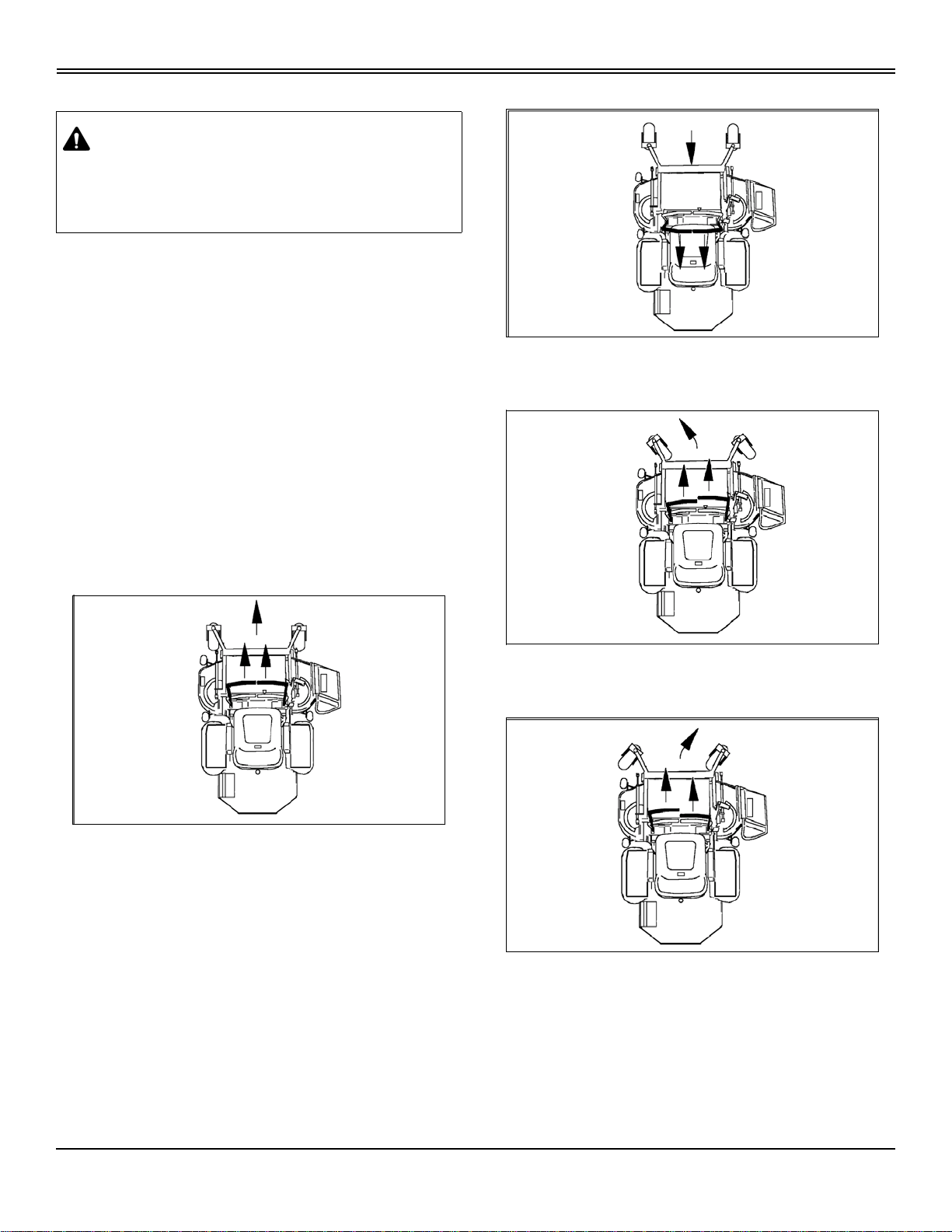

Using the Motion Control Levers

CAUTION: Avoid injury! Learn use of the motion control

levers and practice at half throttle until becoming proficient

and comfortable with the operation of the machine.

Do not move motion control levers from forward to reverse or

reverse to forward position rapidly. Sudden direction changes

could cause loss of control or damage the machine.

NOTE: Two types of control levers are available - standard “center

steer” levers and optional “over the lap” levers. The operation of

both styles of levers is the same except as noted.

The functions of the motion control levers are:

• Dual function neutral position.

•Steering.

• Acceleration.

•Braking.

Neutral Detent Position - Standard “Center Steer” Levers

NOTE: When the control levers are in the neutral detent position, the

control lever rollers (A) located on each side of the control console

will be seated in the notches in the console.

switch disengaged and the park brake locked to start the engine.

Neutral Lock Position - Optional “Over the Lap” Levers

Picture Note: Motion control levers (A) shown in the neutral lock

position.

• Motion control levers must be in the neutral lock position, the PTO

switch disengaged and the park brake locked to start the engine.

• Forward and reverse movement of the motion control levers is

prevented when levers are moved to the neutral lock position.

• Operator can exit mower with the engine running when the PTO switch

is disengaged, the motion control levers are in the neutral lock position

and the park brake is locked.

• Motion control levers must be in the neutral lock position to safely enter

and exit the operator seat.

Neutral Position - Optional “Over the Lap” Levers

• Motion control levers must be in the neutral detent position, the PTO

Operating - 17

Picture Note: Motion control levers (A) shown in the neutral

position.

• Machine speed, motion, and direction can be controlled when the

engine is running, operator is on the seat and the park brake is unlocked.

Page 20

OPERATING

Forward and Reverse Motion:

CAUTION: Avoid injury! Children or bystanders can be

injured or killed by moving machine and rotating blades.

Before traveling forward or rearward:•

•Carefully check area around machine.

•Disengage mower before backing up.

1.Move throttle lever to the full-throttle position.

2.Unlock the park brake.

3.Optional “over the lap” levers: Move both motion control levers from the

neutral lock position inward to the neutral position.

4.Push the control levers forward to begin forward motion.

• The farther forward the control levers are moved, the faster the

machine will travel.

• Forward speed range: 0-14 km/h (0-9 mph).

5.Pull both control levers rearward at the same time to begin reverse

motion.

• Reverse speed range: 0-6 km/h (0-4 mph).

6.To stop motion, move both motion control levers forward or rearward

until the machine comes to a stop.

NOTE: The motion control linkages are adjustable. If adjustment is

required, see Checking and Adjusting Motion Control Linkages in

the Service Transmission section.

Reverse:

• Pull both control levers past center rearward at the same time.

Gentle Left Turn:

Forward:

• Push both motion control levers forward at the same time.

• Push right control lever farther forward than the left control lever.

Gentle Right Turn:

• Push left control lever farther forward than the right control lever.

Operating - 18

Page 21

OPERATING

Sharp Left Turn:

• Push right control lever forward and pull left control lever rearward at the

same time.

Sharp Right Turn:

4.Push PTO knob (A) down to disengage PTO.

5.Move throttle lever to set engine speed:

• Cold engine: Set throttle lever at the 1/2- to 3/4-throttle position.

• Warm/Hot engine: Set throttle lever to the 1/2-throttle position.

6.Position choke knob (D):

• Cold engine: Pull knob up and hold in choke position.

• Warm/Hot engine: If necessary, pull knob up and hold in choke

position.

• Push left control lever forward and pull right control lever rearward at the

same time.

Starting the Engine

CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Move the machine to an outside area before running the

engine.Do not run an engine in an enclosed area without

adequate ventilation.

•Connect a pipe extension to the engine exhaust pipe to

direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the

exhaust fumes out.

1.Sit on the operator seat.

2.Lock the park brake.

3.Move both motion control levers to the neutral detent position (standard

levers) or neutral lock position (optional “over the lap” levers).

IMPORT AN T: Avoid damage! Starter may be damaged if starter is

operated for more than 20 seconds at a time:

• Wait two minutes before trying again if engine does not start.

STOP

7.Turn key switch to start position (B).

If the engine does not start, wait 10 seconds.

• Turn key to start position again for no more than 5 seconds.

• Repeat the procedure if necessary.

IMPORTANT: Avoid damage! Unnecessary engine idling can

cause engine overheating, carbon build-up, and poor

performance.

8.Release key to run position (C) when engine starts.

9.With engine started:

• Push choke knob to off position.

• Move throttle lever to full-throttle position.

• Unlock the park brake.

C

B

Operating - 19

Page 22

OPERATING

Engaging Mower

CAUTION: Avoid injury! Clear mowing area of all bystanders

when operating this machine.

Thrown objects could cause serious injury or death.

Keep hands and feet away from blades and discharge

opening.

Do not mow in reverse unless absolutely necessary.

IMPORTANT: Avoid damage! To help prevent damage to PTO

clutch:

• Do not engage PTO with throttle in the fast position.

1.Adjust mower deck to desired cutting height.

2.Start engine.

move throttle to slow position.

A

STOP

5.Turn key switch to STOP position (A).

CAUTION: Avoid injury! Children or bystanders may attempt

to move or operate an unattended machine.

Always lock the park brake and remove the key before leaving

the machine unattended.

6.Remove key.

Transporting Machine

3.Move throttle lever to the 1/2 - 3/4 throttle position.

4.Unlock the park brake.

5.Move both motion control levers to the neutral position.

NOTE: In cold weather or with a new machine, it may be necessary to

engage the choke at the same time as the PTO knob to prevent the

engine from stalling.

6.Pull PTO knob (A) up to engage mower deck.

7.Move throttle lever to full-throttle position.

NOTE: The travel speed and turn rate will vary with the amount that

the control levers are moved.

8.Push motion control levers forward slowly. Mow at a safe travel speed.

Stopping the Engine

IMPORTANT: Avoid damage! To help prevent engine backfiring,

throttle lever should be set at the 1/4 throttle position and run for

30 seconds prior to stopping the engine.

Do not stop engine when mower is on a slope of more than 30° for

an extended period of time. Oil may run through valve train into

carburetor and muffler.

1.Move the motion control levers to the neutral detent position (standard

levers) or neutral lock position (optional “over the lap” levers).

2.Lock the park brake.

3.Push PTO switch down to disengage.

4.Move throttle lever to 1/4-throttle position and run for 30 seconds, then

CAUTION: Avoid injury! Use extra care when loading or

unloading the machine into a trailer or truck.

Close fuel shut-off valve, if your machine is equipped.

IMPORTANT: Avoid damage! Transmission damage may occur if

the machine is moved or towed incorrectly:

• Move unit by hand only.

• Do not use another vehicle to move unit.

• Do not tow unit.

Use a heavy-duty trailer to transport your machine. Trailer must have

signs and lights required by law.

1.Raise the mower deck lift lever to the transport position.

2.Drive machine on trailer.

3.Stop engine and lock the park brake.

4.Remove key.

5.Fasten machine to trailer with heavy-duty straps, chains or cables. Both

front and rear straps must be directed down and outward from machine.

Mowing Tips

• Mow grass with throttle lever in the full fast position.

• Cut grass when it is dry.

• Keep mower deck and discharge chute clean.

• Mow with sharp blades.

• Properly level mower deck for a smooth cut.

• Mow grass high and often.

• Use a travel speed that fits the conditions:

Operating - 20

Page 23

SERVICE INTERVALS

• Mow tall or wet grass twice. Cut grass at half desired height – then cut

at desired height.

• Travel slow when mowing tall, thick or wet grass.

• Avoid damaging grass by slipping or skidding machine drive wheels.

Practice smooth control lever movements.

• When performing sharp turns, do not allow inside machine drive wheel

to stop and twist on grass.

Mowing Travel Speeds

Use slow travel speed for:

• Trimming.

• Working in close quarters.

• Mowing tall grass.

Use faster travel speeds for:

• Normal mowing on level ground.

Dismounting to Inspect Mower

CAUTION: Avoid injury! Help prevent serious injury. Keep

hands and feet away from blades and the discharge opening.

Do not step on either side of the mower deck when mounting

and dismounting the machine. Mount and dismount the

machine using the front foot plate.

1.Park machine on a hard, level surface.

2.Push PTO knob down to disengage mower.

3.Move motion control levers to the neutral detent position (standard

levers) or neutral lock position (optional “over the lap” levers).

4.Lock the park brake.

5.Stop engine and remove key. Always wait for mower blades to stop

turning before leaving operator seat.

Service Intervals

Servicing Your Machine

IMPORTANT: Avoid damage! Operating in extreme conditions

may require more frequent service intervals:

• Engine components may become dirty or plugged when

operating in extreme heat, dust or other severe conditions.

• Engine oil may lose efficiency if vehicle is operated constantly

at slow or low engine speeds or with frequent short trips.

Please use the following timetables to perform routine maintenance on

your machine.

Break-In (After First 8 Hours of Operation)

NOTE: The following initial break-in items must be performed and

verified to validate the warranty (dealer service invoice accepted).

• Change engine oil and filter.

• Check drive belt tension.

• Check mower deck drive belt tension.

• Check transmission neutral adjustment.

• Check wheel nut torque.

• Check and adjust (as needed) park brake.

• Remove debris from the underside of the mower deck.

Every 25 Hours or Weekly (Whichever Comes First)

• Grease mower deck thrust arms (two places).

• Grease mower deck thrust arms (two places).

• Grease traction drive belt tension arm.

• Grease mower deck drive belt tension arm.

• Grease HOC shafts (four places).

• Lubricate front caster wheel spindles.

• Remove debris from the underside of the mower deck.

Every 50 Hours or Weekly (Whichever Comes First)

• Change engine oil and filter. See the engine manufacturer’s owner’s

manual provided with your machine for the complete procedure.

• Grease caster wheel spindle bearings (two places).

• Grease mower deck thrust arms (two places).

• Remove debris from the underside of the mower deck.

• Check drive belt tension.

• Check tire pressure.

• Clean engine air filter.

• Check wheel nut torque.

Every 160 Hours or Monthly (Whichever Comes First)

• Grease mower spindle bearings (three places).

• Check transmission oil level.

• Check transmission oil level.

• Lubricate mower deck idler pulley pivots (three places).

• Lubricate seat platform hinges (two places)

• Lubricate pump control arms (five places).

• Lubricate control lever pivot shafts (two places).

• Lubricate throttle cable.

• Lubricate choke control cable.

Annually

• Inspect all spindle bearings (6). Replace as needed.

• Inspect all mower deck idler pulleys (3). Replace as needed.

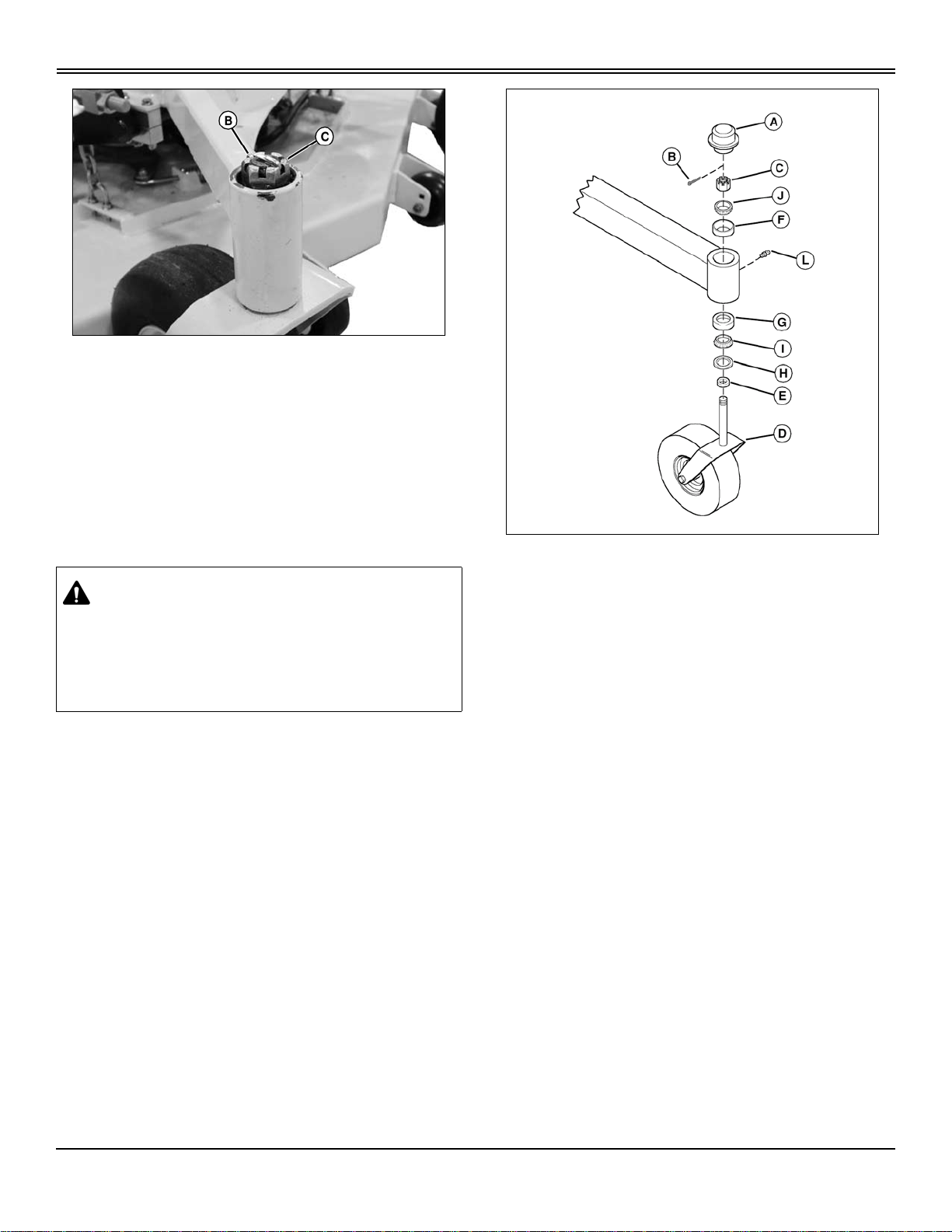

• Remove and inspect caster wheel roller bearings; clean and pack with

grease. Replace as needed.

• Remove and inspect caster pivot bearings; clean and pack with grease.

Replace as needed.

• Inspect drive belts. Replace as needed. Run-in and adjust tension.

• Change hydraulic oil and filter (annually or 500 hours whichever comes

first).

• Check all bolts and nuts; tighten as needed.

• Remove battery. Clean battery and holder.

• Replace spark plugs.

Service Intervals - 21

Page 24

SERVICE LUBRICATION

Service Lubrication

Grease

IMPORTANT: Avoid damage! The recommended grease is

effective within an average air temperature range of -29 to 135

degrees C (-20 to 275 degrees F).

If operating outside that temperature range, contact your

servicing dealer for a special-use grease.

Use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease.

Contact your Servicing dealer for information.

Spray Lubricant

Use a general-purpose petroleum-based spray lubricant.

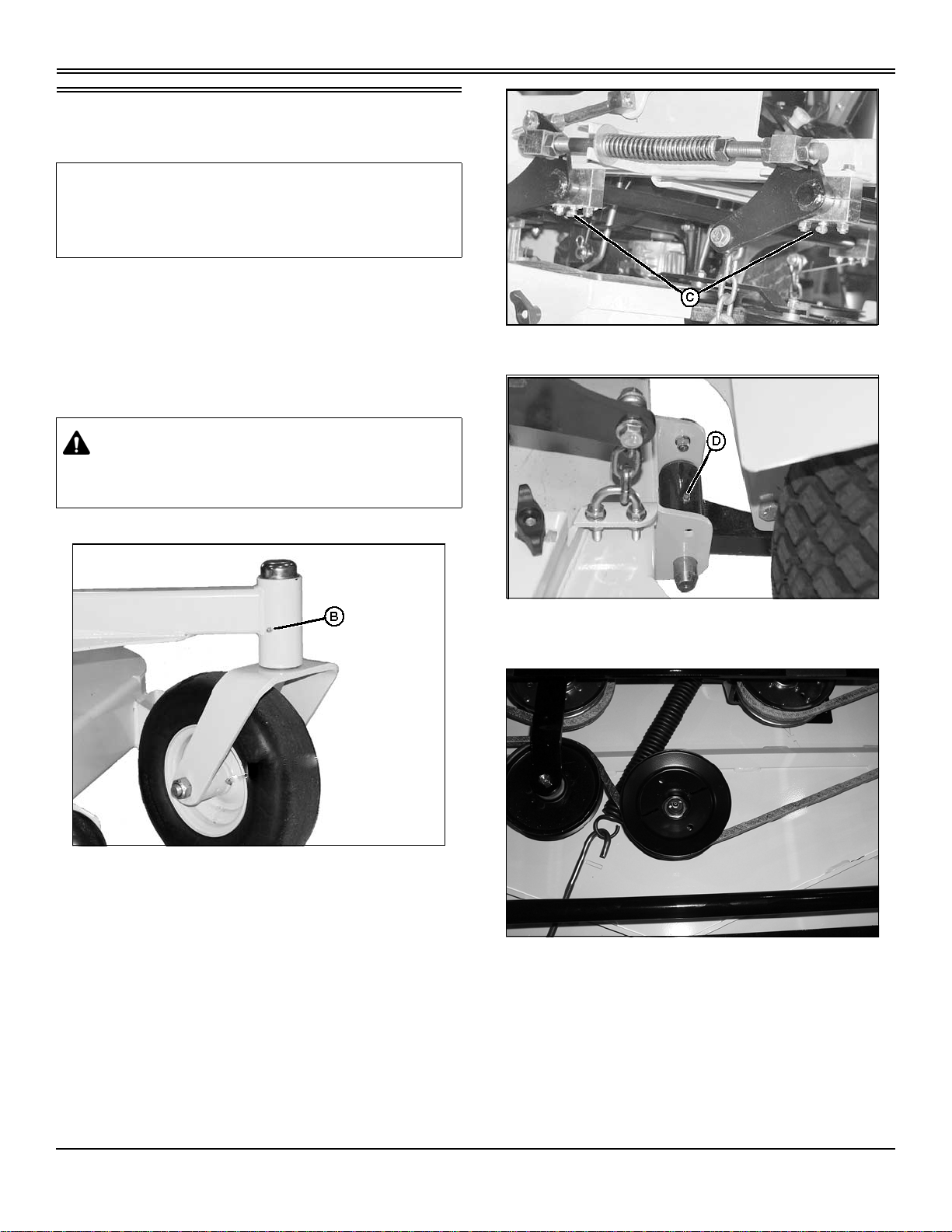

Lubrication Points

CAUTION: Avoid injury! Rotating parts can catch fingers,

loose clothing, or long hair. Wait for engine and all moving

parts to stop before leaving operator’s station to adjust or

service machine.

1.Park machine safely. (See Parking Safely in the SAFETY section.)

3.Grease HOC shafts (C) (two points on each side of the machine).

4.Grease mower deck thrust arms (D), located at the rear of the mower

deck.

2.Grease caster wheel spindle bearings (B).

5.Apply grease to three spindle bearings.

Service Lubrication - 22

Page 25

SERVICE ENGINE

6.Grease traction drive belt tension arm pivot (G).

7.Grease mower deck drive belt tension arm (H).

NOTE: Use spray lubricant to lubricate the following items:

9.Lubricate hydraulic pump control arms (N).

10.Lubricate control lever pivot shaft (O).

11.Lubricate seat platform hinges (P).

12.Lubricate throttle control cable (Q).

13.Lubricate choke control cable (R).

Service Engine

Engine Warranty Maintenance Statement

Maintenance, repair, or replacement of the emission control devices and

systems on this engine, which are being done at the customer’s expense,

may be performed by any non-road engine repair establishment or

individual. Warranty repairs must be performed by an authorized servicing

dealer.

Avoid Fumes

CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Move the machine to an outside area before running the

engine.Do not run an engine in an enclosed area without

adequate ventilation.•

•Connect a pipe extension to the engine exhaust pipe to

direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the

exhaust fumes out.

8.Lubricate mower deck idler pulleys (K-M).

Engine Oil

Use oil viscosity based on the expected air temperature range during the

period between oil changes.

Use oil that meets the following specification:

• See the engine manufacturer’s owner’s manual provided with your

machine for the correct specifications.

Service Engine - 23

Page 26

SERVICE ENGINE

Checking Engine Oil Level

CAUTION: Avoid injury! Touching hot surfaces can burn

skin. The engine, components, and fluids will be hot if the

engine has been running. Allow the engine to cool before

servicing or working near the engine and components.

IMPORTANT: Avoid damage! Failure to check the oil level

regularly could lead to serious engine problems if oil level is low:

• Check oil level before operating.

• Keep oil level between the FULL and the ADD marks.

• Check oil level when engine is stopped, level, and is cooled so

oil has had time to drain into the sump.

NOTE: Check oil twice a day if you run engine over 4 hours in a day.

Make sure engine is cool when checking engine oil level.

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2.Allow engine to cool.

IMPORTANT: Avoid damage! Dirt and debris in oil may cause

damage to the engine. Clean area around opening before

removing plug or dipstick.

3.Remove dipstick (A). Wipe with a clean cloth.

4.Install dipstick and allow the cap to rest on the end of the tube. Do not

tighten the cap.

IMPORTANT: Avoid damage! To prevent extensive engine wear or

damage, always maintain the proper engine oil level. Never

operate the engine with the oil level below the add mark or over

the full mark.

5.Remove dipstick and check oil level on dipstick. Oil must be between the

ADD and FULL marks.

• If oil is low, add oil to bring oil level no higher than the FULL mark on

dipstick.

• If oil level is above the FULL mark, drain to proper level.

6.Install and tighten dipstick.

Changing Engine Oil and Filter

IMPORTANT: Avoid damage! Change the oil more often if the

vehicle is used in extreme conditions:

• Extremely dusty conditions.

• Frequent slow or low-speed operation.

• Frequent short trips.

3.Put container under drain tube.

4.Open drain valve (A) using a 10 mm socket, 1 ft extension, swivel and 3/

8 in. drive ratchet.

5.Allow oil to drain into an oil drain pan.

6.After oil drains, close drain valve.

7.Remove oil filter using an appropriate filter wrench. Turn filter

counterclockwise to remove.

8.Apply a film of clean engine oil on gasket of new filter.

9.Install filter. Turn filter clockwise until gasket makes contact with

mounting surface. Tighten 1/2 to 3/4 turn after gasket contact.

10.Clean area around the dipstick.

11.Unscrew and remove dipstick.

IMPORTANT: Avoid damage! To prevent extensive engine wear or

damage, always maintain the proper engine oil level. Never

operate the engine with the oil level below the add mark or over

the full mark.

12.Add approximately 1.4 L (1.5 qt) of oil.

13.Install and tighten dipstick.

14.Start engine and run at slow throttle for approximately two minutes.

Check for leaks around filter and drain valve.

15.Stop engine.

16.Check oil level:

• Remove dipstick. Wipe with a clean cloth.

• Install dipstick and allow the cap to rest on the end of the tube. Do not

tighten the cap.

• Remove dipstick and check oil level on dipstick. Oil level should be

between the ADD and FULL marks. Add oil if needed.

17.Install and tighten dipstick.

1.Run engine to warm oil.

2.Park machine safely. (See Parking Safely in the SAFETY section).

Service Engine - 24

MODEL Oil Capacity With Filter (Dry)

Kawasaki Engines 1.8 L (1.9 qt)

Kohler Engines 2.0 L (2.1 qt)

Page 27

SERVICE ENGINE

Cleaning Engine Air Intake Screen and Fan

CAUTION: Avoid injury! Compressed air can cause debris to

fly a long distance.•

•Clear work area of bystanders.

•Wear eye protection when using compressed air for

cleaning purposes.

•Reduce compressed air pressure to 210 kPa (30 psi).

IMPORTANT: Avoid damage! An obstructed air intake screen can

cause engine damage due to overheating. Keep air intake screen

and other external surfaces of the engine, including cooling fins,

clean at all times to allow adequate air intake.

Keep air intake screens and engine cooling fins clear of debris to ensure

proper cooling. See the engine manufacturer’s owner’s manual provided

with your machine for the complete procedure.

Checking and Cleaning Air Filter Elements

CAUTION: Avoid injury! Touching hot surfaces can burn

skin. The engine, components, and fluids will be hot if the

engine has been running. Allow the engine to cool before

servicing or working near the engine and components.

IMPORTANT: Avoid damage! Dirt and debris can enter the engine

through a damaged filter element:

• Do not wash paper element.

• Do not attempt to clean paper element by tapping against

another object.

• Do not use pressurized air to clean element.

• Replace element only if it is very dirty, damaged or the seal is

cracked.

your machine for the complete procedure.

Adjusting Carburetor

NOTE: Carburetor is calibrated by the engine manufacturer and is

not adjustable.

If engine is operated at altitudes above 1829 m (6,000 ft), some

carburetors may require a special high altitude main jet. See your

authorized dealer.

If engine is hard to start or runs rough, check the TROUBLESHOOTING

section of this manual.

Possible engine surging will occur at high throttle with transmission in “N”

neutral and mower engagement lever disengaged. This is a normal

condition due to the emission control system.

After performing the checks in the troubleshooting section and your

engine is still not performing correctly, contact your authorized dealer.

Replacing Fuel Filter

CAUTION: Avoid injury! Fuel vapors are explosive and

flammable:•Do not smoke while handling fuel.

•Keep fuel away from flames or sparks.

•Shut off engine before servicing.

•Cool engine before servicing.

•Work in a well-ventilated area.

•Clean up spilled fuel immediately.

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2.Allow engine to cool.

3.Place a drain pan under hoses to catch any fuel that may be left in

hoses.

NOTE: It may be necessary to check the air filter more frequently if

operating machine in dusty conditions.

Check and clean air filter elements at the intervals recommended in the

Service Intervals section. See the engine manufacturer’s owner’s manual

provided with your machine for the complete procedure.

Cleaning Engine Oil Cooler - Kohler Engines

Keep engine oil cooler fins clear of debris to ensure proper cooling. See

the engine manufacturer’s owner’s manual provided with your machine for

the complete procedure.

Checking Spark Plug

CAUTION: Avoid injury! Touching hot surfaces can burn

skin. The engine, components, and fluids will be hot if the

engine has been running. Allow the engine to cool before

servicing or working near the engine and components.

IMPORTANT: Avoid damage! Do not clean spark plugs with

abrasives.

Check spark plugs at the intervals recommended in the Service Intervals

section. See the engine manufacturer’s owner’s manual provided with

Service Engine - 25

Picture Note: Kawasaki engine shown.

4.Locate fuel hose (A) coming from fuel tank, disconnect it from the inlet

side of fuel filter (B) and drain gasoline into a properly marked container.

5.Remove fuel filter from fuel hose (C) going to engine. Discard filter.

IMPORTANT: Avoid damage! When installing a new fuel filter, the

filter arrow must be pointing in the direction of fuel flow. Make

sure clamps are installed properly.

6.Connect a new fuel filter to hoses. Make sure fuel filter is installed with

arrow pointing in direction of fuel flow.

Page 28

SERVICE TRANSMISSION

Service Transmission

Hydraulic Oil

Use only 5W-50 or 15W-50 all synthetic oil.

Checking Hydraulic Oil Level

IMPORTANT: Avoid damage! Check oil level in reservoir tank

when oil is cold.

Do not overfill oil reservoir tank. Oil will expand during operation

and could overflow.

1.Park machine safely. (See Parking Safely in the SAFETY section.)

IMPORTANT: Avoid damage! Dirt and debris in oil may cause

damage to the transaxle. Clean area around opening before

removing dipstick.

IMPORTANT: Avoid damage! Contamination of hydraulic fluid

could cause transmission damage or failure. Do not open oil

reservoir cap unless absolutely necessary.

Severe or unusual conditions may require a more frequent

service interval.

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2. Allow engine and hydraulic oil reservoir to cool.

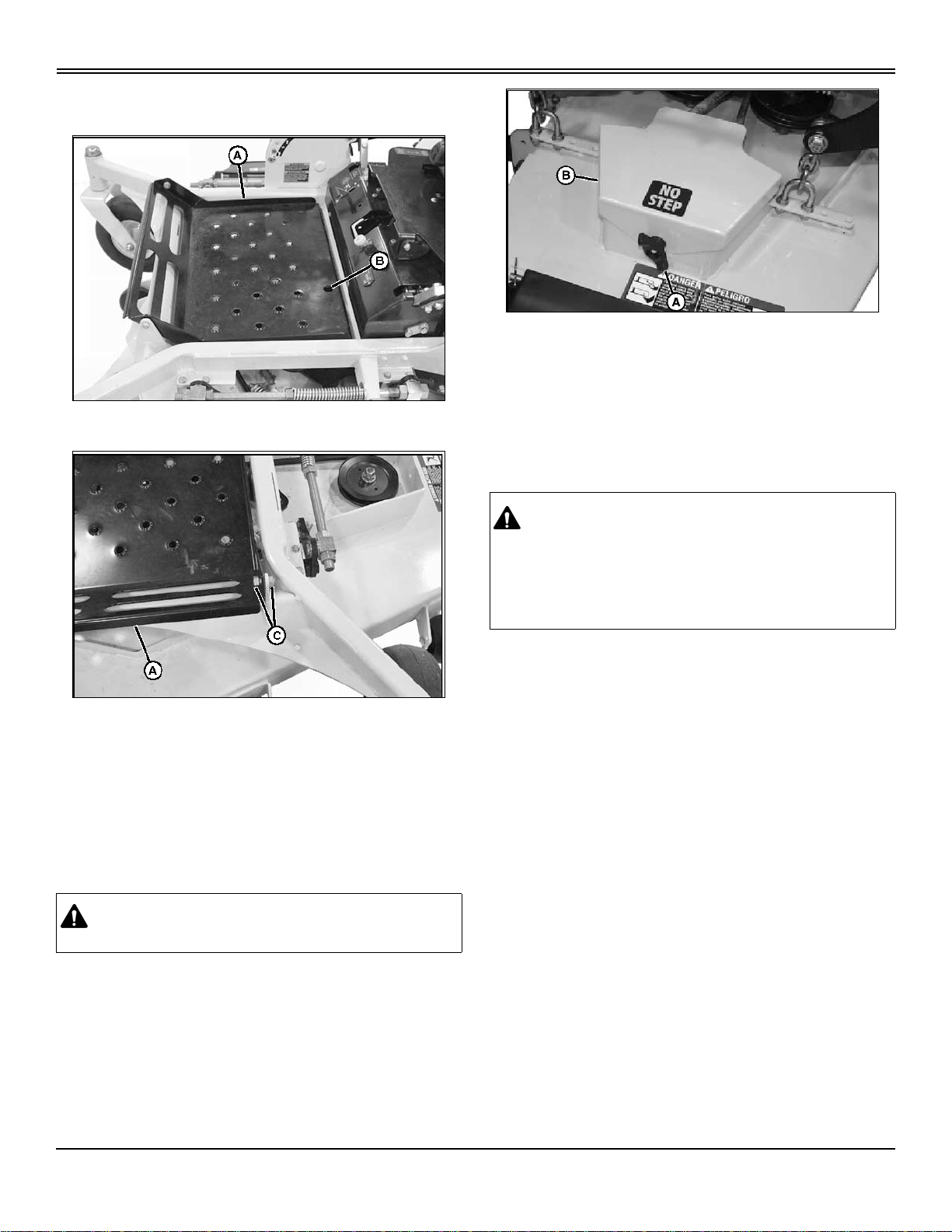

3.Clean area around reservoir filler cap, and remove filler cap from

reservoir.

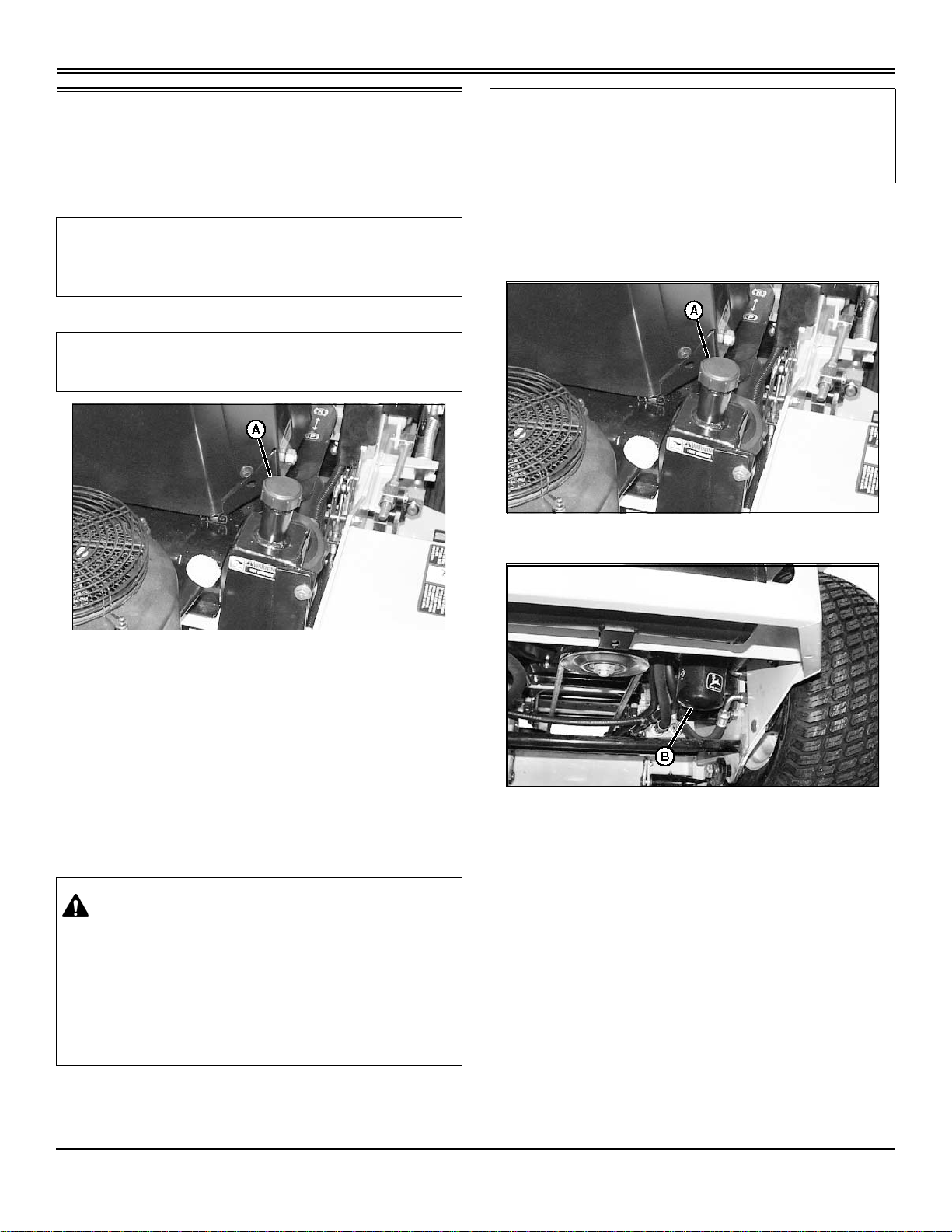

4.Remove cap (A) from oil reservoir tank filler neck.

2.Unscrew and remove hydraulic reservoir cap/dipstick (A) from hydraulic

oil reservoir.

3.Wipe dipstick with a clean cloth.

4.Install dipstick and allow the cap to rest on the end of the tube. Do not

tighten the cap.

5.Remove dipstick and check oil level. Oil level should be at top mark on

dipstick.

6.If necessary, add oil through oil reservoir filler neck.

7.Install cap on filler neck.

Changing Hydraulic Oil and Filter

CAUTION: Avoid injury! Escaping fluid under pressure can

penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic or other

lines. Tighten all connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands and

body from high pressure fluids.

Use caution when filling and draining hydraulic oil. During

periods of machine operation the hydraulic oil reservoir can

get hot. Allow engine and oil reservoir to cool before

servicing.

5.Turn hydraulic oil filter (B) counterclockwise to remove.

6.Allow hydraulic oil to drain into a drain pan with at least a 3.8 L (1.0 gal)

capacity.

7.Apply a film of clean oil on gasket of new filter.

8.Install filter. Turn filter clockwise until gasket makes contact with

mounting surface. Tighten 1/2 to 3/4 turn after gasket contact.

NOTE: Reservoir capacity is approximately 1.9 L (2.0 qt). Total

system capacity is approximately 3.5 L (3.75 qt).

9.Fill oil reservoir with approximately 1.9 L (2.0 qt) of oil.

10.Install reservoir cap.

Service Transmission - 26

Page 29

SERVICE TRANSMISSION

CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Move the machine to an outside area before running the

engine.Do not run an engine in an enclosed area without

adequate ventilation.

•Connect a pipe extension to the engine exhaust pipe to

direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the

exhaust fumes out.

11.Start engine.

12.Move throttle lever to 3/4-throttle position.

13.Unlock the park brake.

CAUTION: Avoid injury! Help prevent serious bodily injury.

Remain alert to other people and the surroundings when

operating the machine.

14.Run engine in full forward position for several minutes and then cycle

motion control levers forward and rearward several times. Check for leaks

around filter.

15.Stop engine. Check oil level. Add oil as necessary.

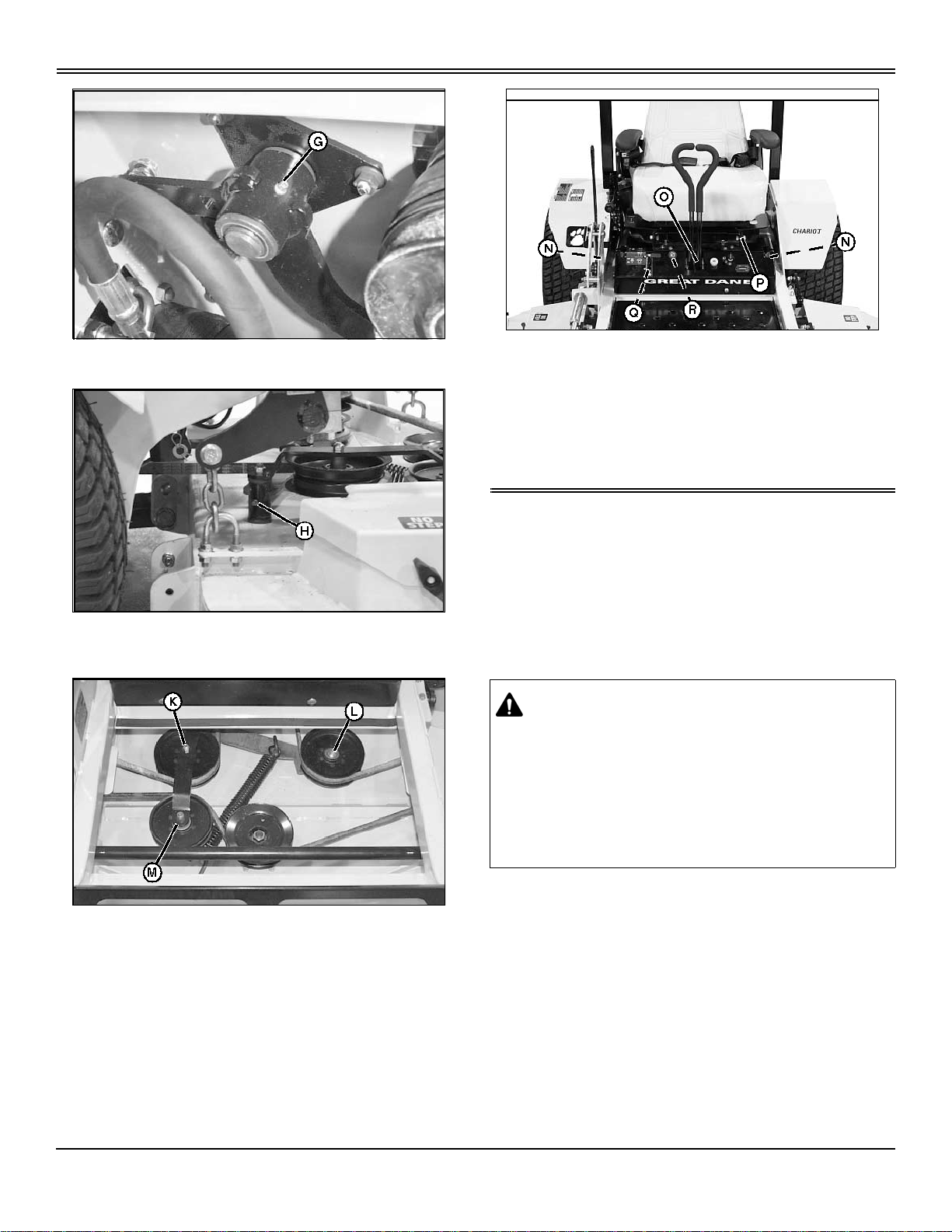

Removing and Installing Traction Drive Belt

1.Park machine safely. (See Parking Safely in the SAFETY section.)

2.Remove mower deck drive belt.

CAUTION: Avoid injury! Fingers and hands can be pinched or

crushed. Keeps hands clear of sheave and belt pinch points

when servicing belt.

Cleaning Hydraulic Pump Cooling Fins

CAUTION: Avoid injury! Compressed air can cause debris to

fly a long distance.

•Clear work area of bystanders.

•Wear eye protection when using compressed air for

cleaning purposes.

•Reduce compressed air pressure to 210 kPa (30 psi).

IMPORTANT: Avoid damage! To ensure proper cooling, keep the

cooling fins clean at all times. Operating the machine with

obstructed cooling fins could cause damage due to overheating.

1.Park machine safely. (See Parking Safely in the SAFETY section.)

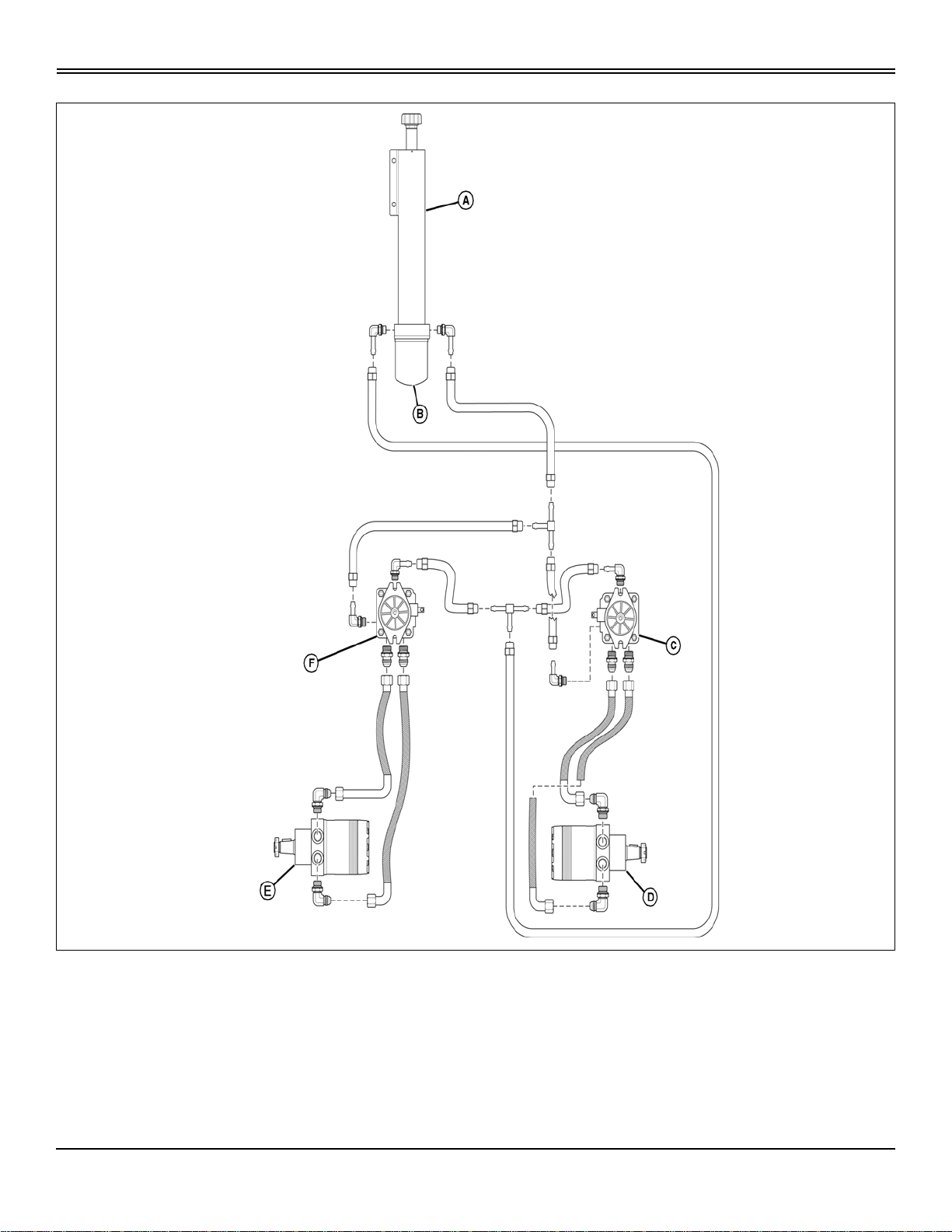

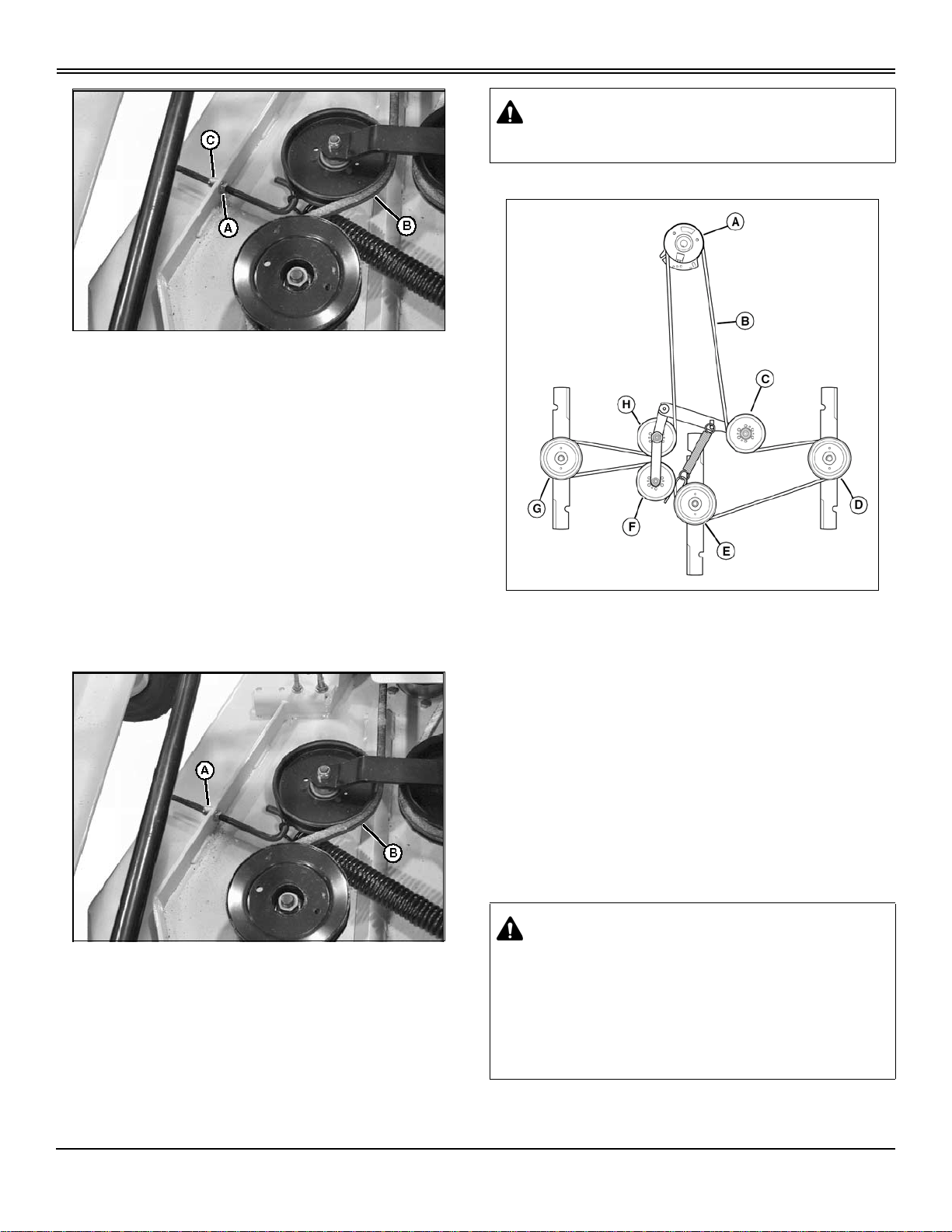

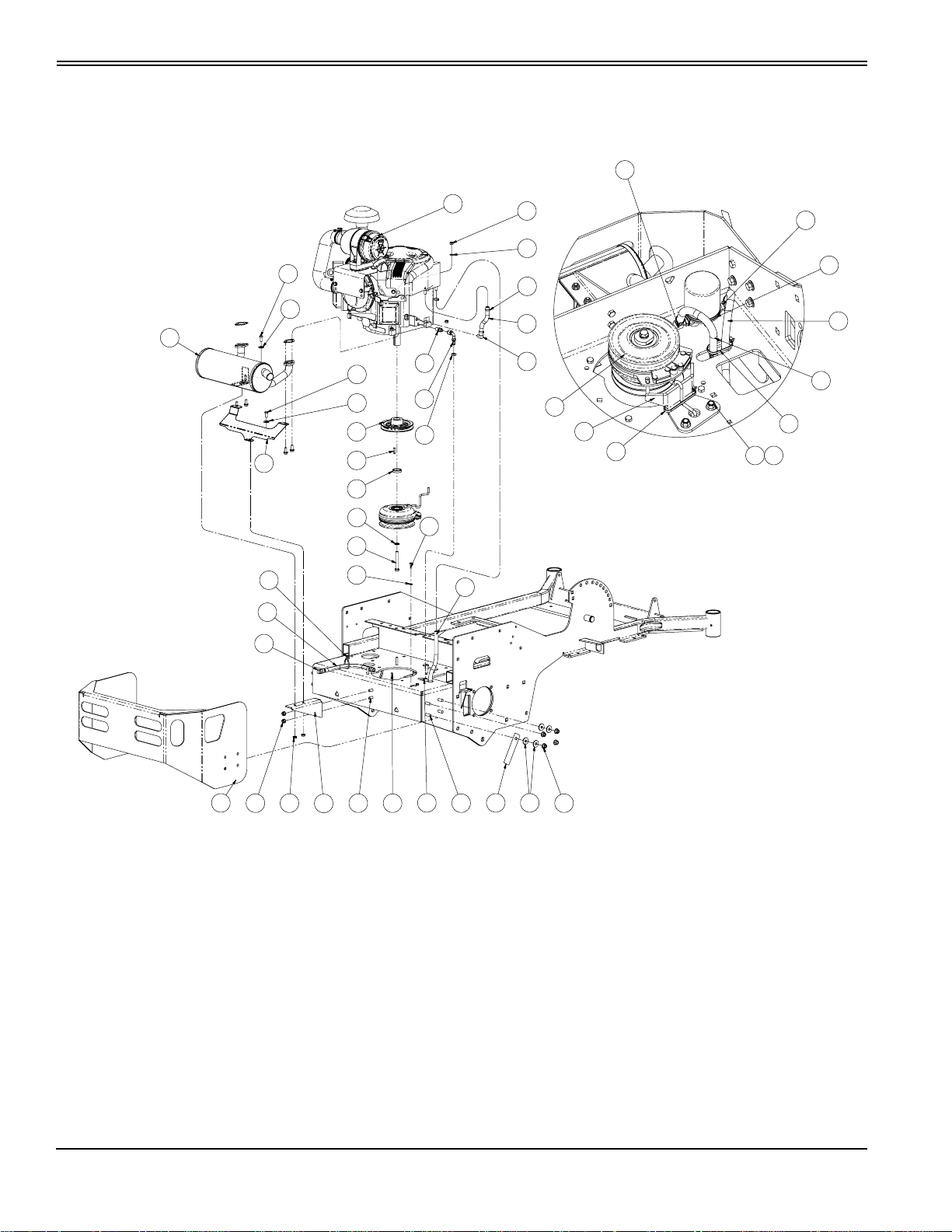

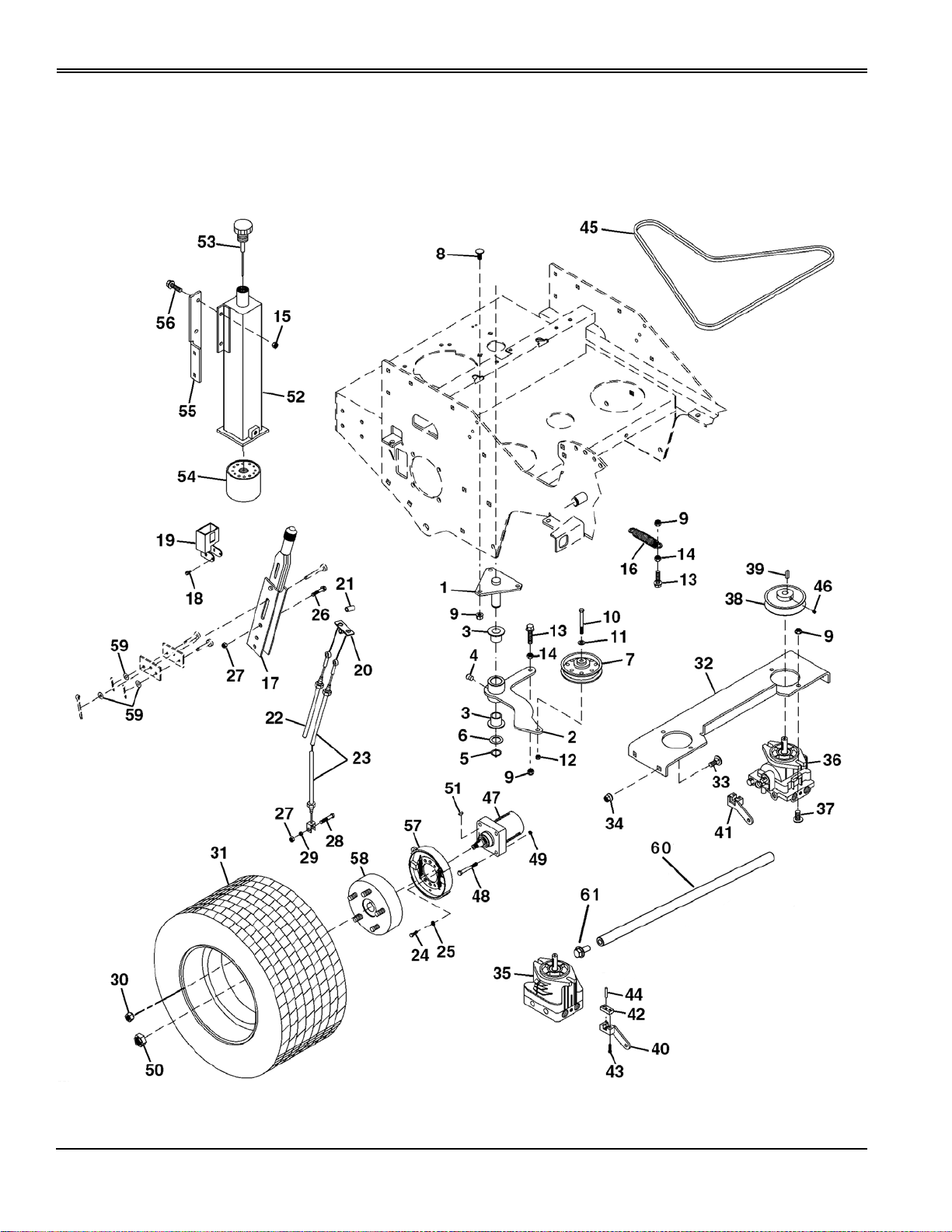

Picture Note: Drive belt routing as viewed from top of machine.

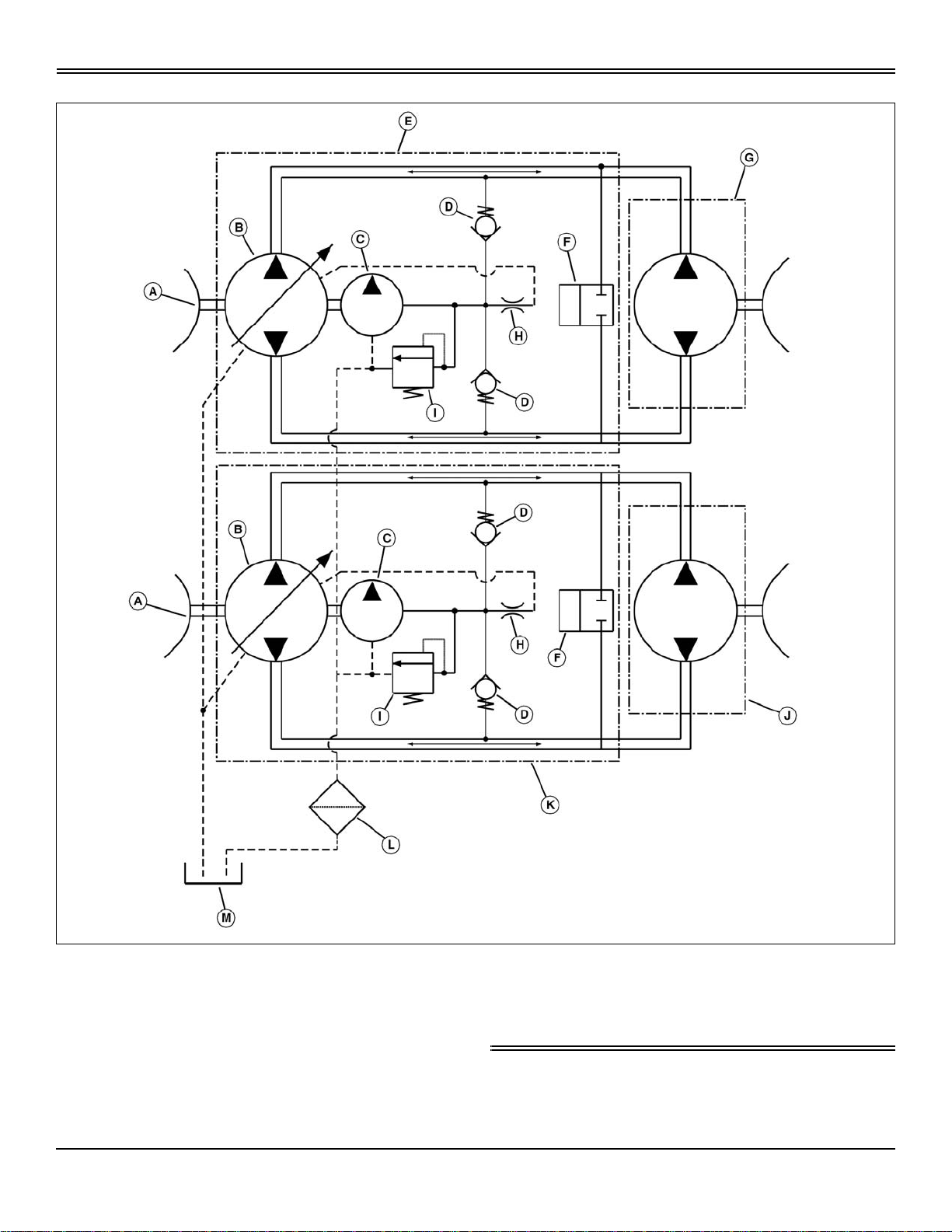

A- 1/2 in. Square Opening

B- Tension Arm

C- Traction Drive Belt

D- Engine Drive Sheave

E- Tension Idler Sheave

F- Hydraulic Pump Sheave

3.Using a 1/2 in. drive breaker bar and extension, insert end of extension

in 1/2 in. drive square opening (A) in tension arm, and carefully move

tension arm (B) counter-clockwise to release belt tension.

4.Remove drive belt (C).

5.Install new drive belt.

6.Install mower deck drive belt as shown.

Checking and Adjusting Motion Control Linkages

CAUTION: Avoid injury! Do not attempt this adjustment

unless you are a qualified and properly trained technician.

Improper adjustment can result in an unsafe machine.

2.Clean hydraulic oil cooler fins (A) on each hydraulic pump with a rag,

brush, or compressed air.

Service Transmission - 27

Page 30

SERVICE TRANSMISSION

Check Neutral Creep

CAUTION: Avoid injury! Engine exhaust fumes contain

carbon monoxide and can cause serious illness or death.

Move the machine to an outside area before running the

engine.

Do not run an engine in an enclosed area without adequate

ventilation.

•Connect a pipe extension to the engine exhaust pipe to

direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the

exhaust fumes out.

NOTE: Check and adjust motion control linkages with the machine

parked on a hard, level surface.

1.Start engine.

2.Set throttle lever to full-throttle position.

3.Unlock the park brake.

4.If the rear drive wheels begin to creep, an adjustment is required.

Neutral Creep Adjustment

1.Stop engine and lock the park brake.

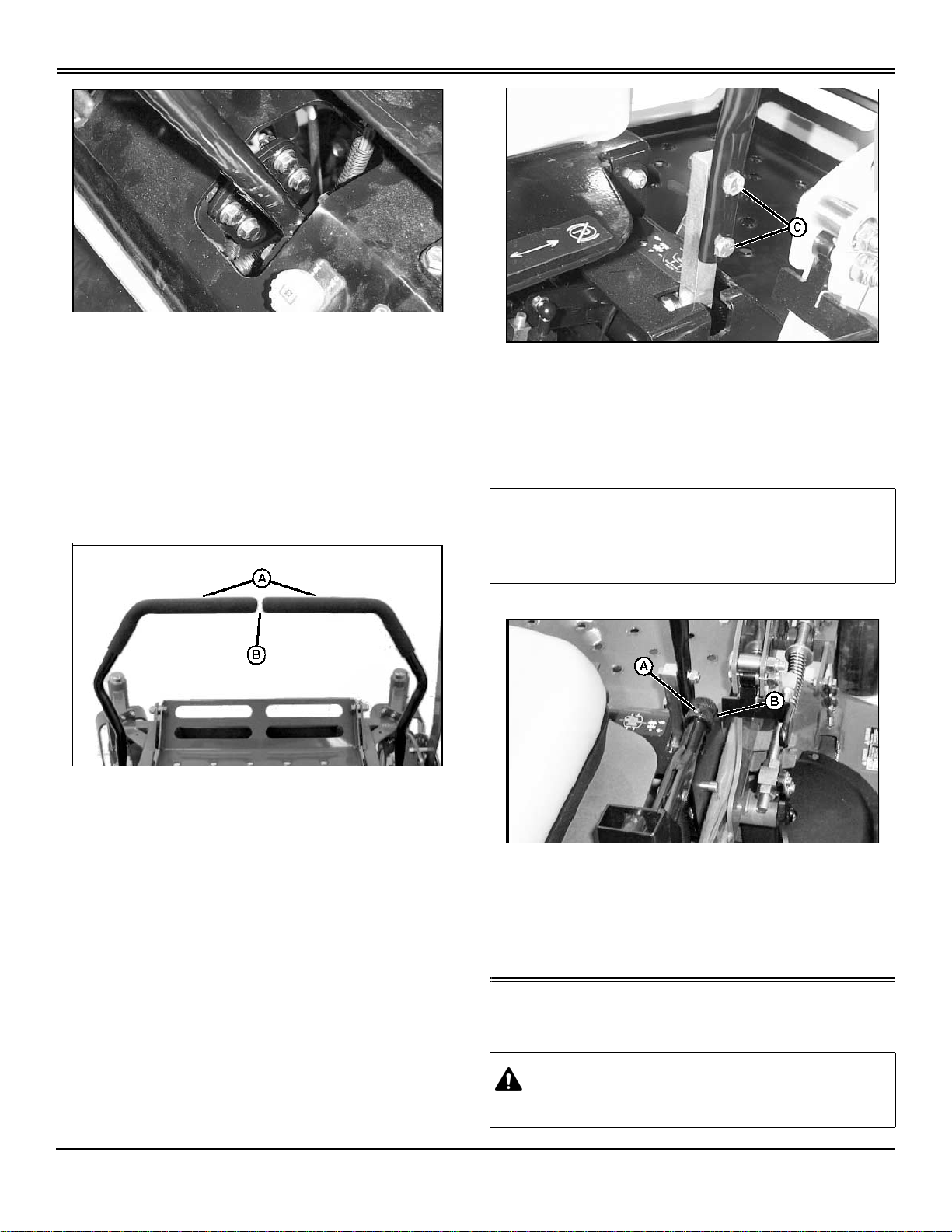

2.Move both motion control levers to neutral detent position (standard

levers) or neutral lock position (optional “over the lap” levers).

3.Raise the rear wheels off the ground and securely support the rear of

the machine.

NOTE: When tilting the seat forward, do not tilt the seat so far

forward that it moves the motion control levers out of the neutral

detent position.

4.Tilt operator seat forward and support the seat frame.

7.Remove pin (C) and disconnect swivel (D) from each traction control rod

(E), and rotate the swivel.

8.Rotate swivel (D) to adjust:

• To stop forward creep, rotate each swivel (D) counterclockwise one

rotation.

• To stop rearward creep, rotate each swivel (D) clockwise one rotation.

9.Connect swivel to traction control rod.

10.Repeat as needed to stop machine creep.

11.Lower seat.

12.Lower the rear of the machine to the ground.

13.Check maximum speed drift.

Check Maximum Speed Drift

1.Check neutral creep, and adjust as needed.

2.Sit on the seat, and start the engine.

3.Operate machine to bring the hydraulic oil to normal operating

temperature.

4.Move the machine in a level, wide-open area, such as an empty parking

lot.

5.Run the engine at full throttle.

6.Move and hold both control levers to the full forward position. Observe