TM

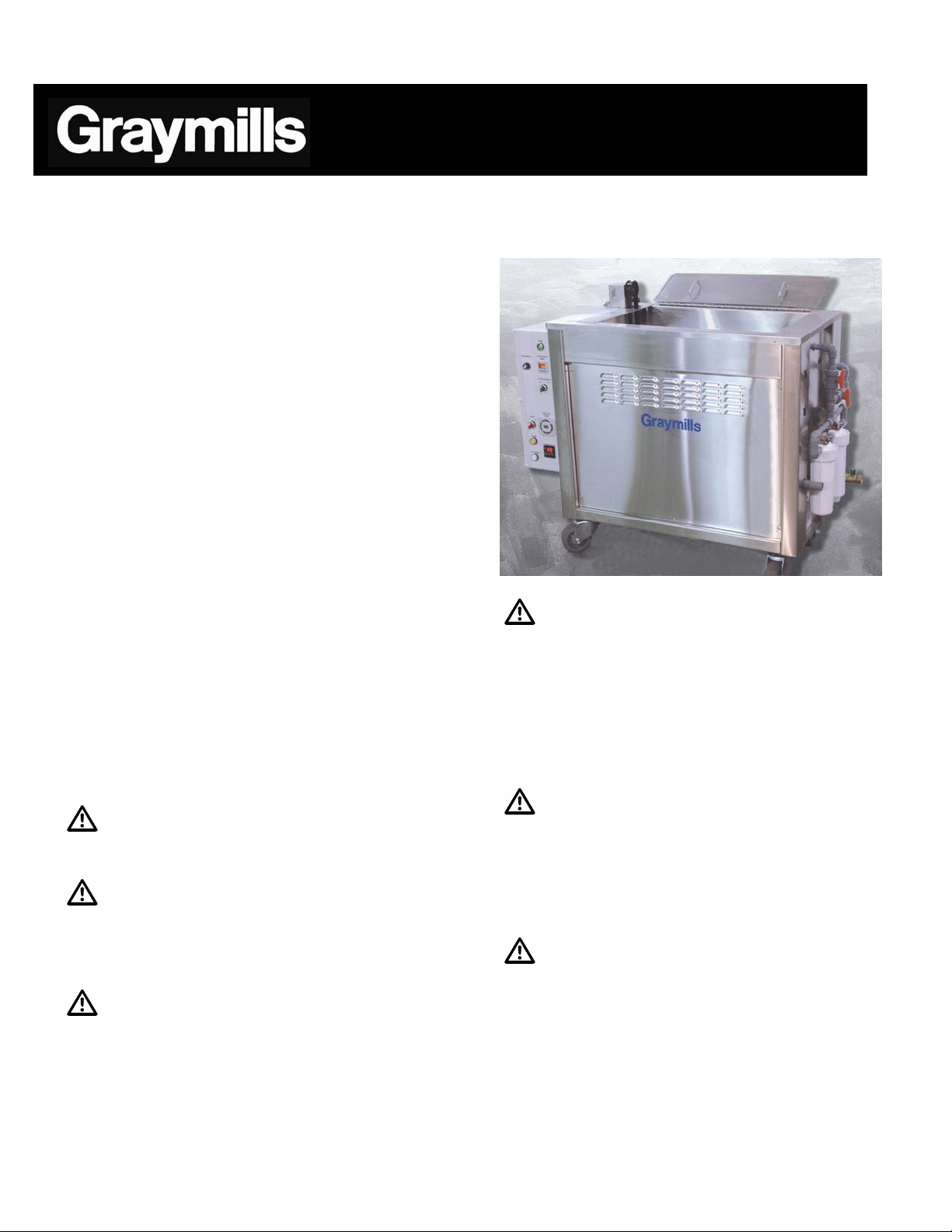

SonicMax

39-Gallon

Ultrasonic Cleaning

System

Operations and Maintenance

Instructions

795-91800

www.graymills.com

2-07

WARNINGS/CAUTIONS

Read all of these SAFETY INSTRUCTIONS and those

in the manual BEFORE installing or using this

equipment. Keep this manual handy for

reference/training

SAFETY

You will find various types of safety information on the

following pages and on the labels attached to Graymills

equipment. The following Safety Statements explain

their meaning:

The Safety Alert Symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER The DANGER Symbol means that

failure to follow this safety statement WILL result in

serious personal injury or death.

.

CAUTION The CAUTION Symbol means

failure to follow this safety statement might result in

personal injury or property damage.

NOTE The NOTE Symbol means that failure to follow

these instructions could cause damage to the

equipment or cause it to operate improperly

CAUTION

Never work with equipment you feel may be unsafe.

Contact your Supervisor immediately if you feel a piece

equipment is in an unsafe condition.

of

DANGER

.

WARNING The WARNING Symbol means that

failure to follow this safety statement might result in

serious personal injury or death.

- 1 -

Never use a flammable or combustible fluid in this unit.

Use only nonflammable, non-combustible, waterbased, low foaming cleaning compounds in this

machine.

Contact Graymills for specific details on the formula

best suited for your application.

We recommend our low foaming Aquatene.

WARNING

Do NOT contaminate cleaning fluid with any flammable

or combustible material such as gasoline, alcohol,

mineral spirits, etc. Drain parts to be cleaned of any

flammable material or combustible material before

placing inside cleaning tank. Even small quantities can

create a dangerous fire hazard.

Follow all directions, Warnings and Cautions for the

cleaning material being used. If any cleaning solutions

are splashed on clothing, remove wet clothing promptly

and thoroughly wash body areas that have been in

contact with the solution. Do NOT permit saturated

clothing to remain in contact with skin. Industrial

cleaners can cause irritation to some individuals.

Cleaning solutions may irritate skin and eyes

splashed in eyes, flush thoroughly with water. Consult

Material Safety Data Sheet (MSDS) and a physician.

Always wear appropriate safety items such as gloves,

apron, safety glasses or goggles when loading or

unloading unit.

. If

If you have any questions regarding the

correct cleaning fluids to use in this unit, call

Graymills at 773-248-6825 and ask for

Customer Service.

POWER SUPPLY, WIRING AND

GROUNDING

WARNING

Install ground and wiring according to local and

National Electrical Code requirements.

Install a fused disconnect switch on all power legs

near the unit

Disconnect and lockout electrical supply before

installing or servicing unit.

DANGER

Failure to permanently ground the unit and

controls before connecting to electrical power can

cause shock, burns or death.

Unit must be properly grounded to prevent electric

shock hazard. Connect only to three prong outlet.

Should cord become cracked, frayed or damaged in

any way, it should be repaired/replaced immediately by

a qualified electrician. Never use an extension cord.

Since operator safety is at all times a priority, this unit

is equipped with a Ground Fault Interrupter (GFI).

Should plug or cord require replacement, it should be

wired by a licensed electrician to the GFI in the control

box. All electrical connections should conform to

national/local codes and be made by qualified

personnel.

Prior to changing cleaning fluid or servicing the unit,

make sure that that heating element and cleaning

solution have cooled.

WARNING

Keep pump and motor clean and free of all

contaminates. Never allow any liquids to come

contact with motor or electrical systems as an electric

shock hazard could result. Care should be taken to

avoid clogging the air intake for the ultrasonic

generators, located on the bottom of the unit, with dust

or dirt. Do NOT add any additional screens or filters to

the air intake.

Excessive ambient temperature (over 105

permanently damage the ultrasonic generator circuits.

0

F) can

into

DESCRIPTION/SPECIFICATIONS

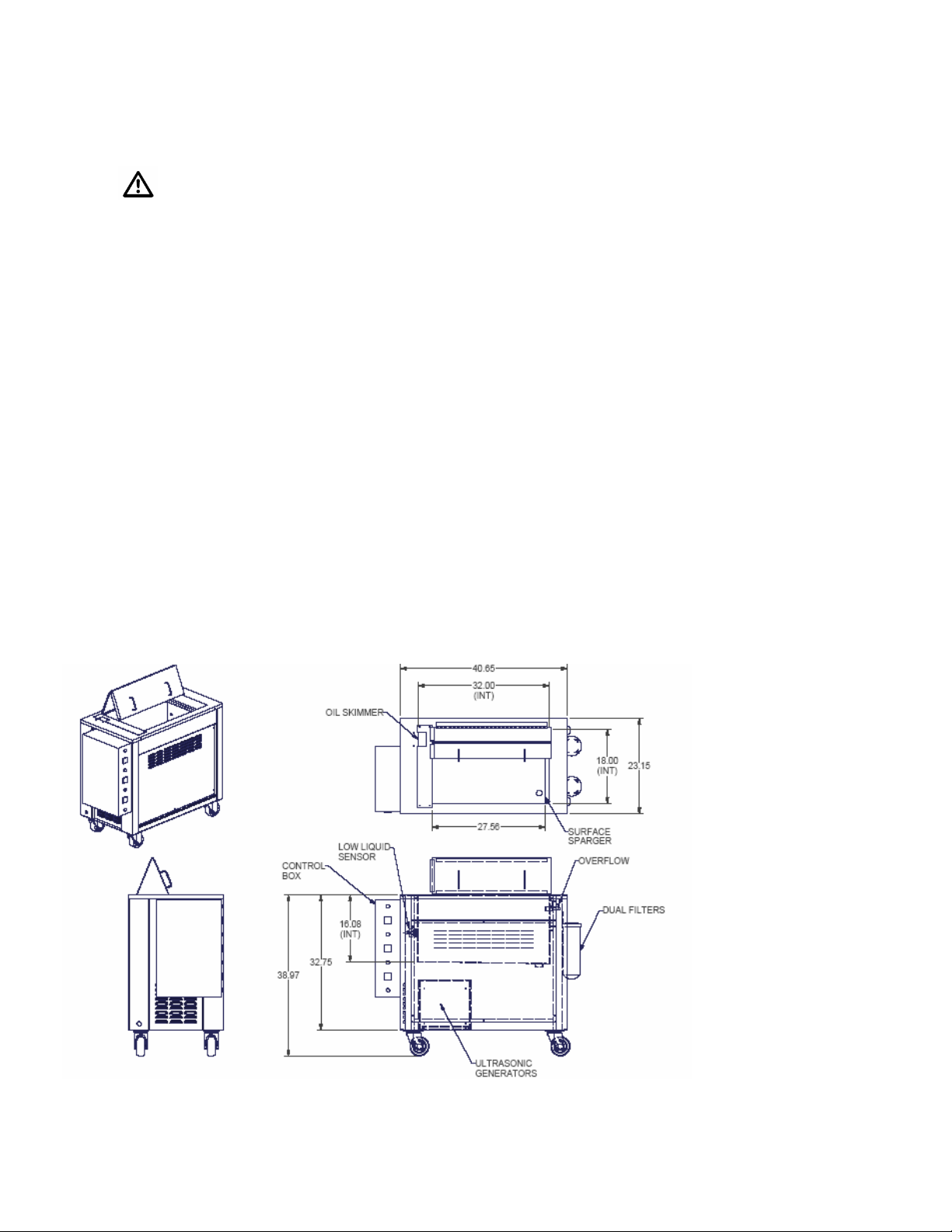

The ultrasonic cleaning system described in the

following sections has been designed for a wide variet y

of applications including both maintenance and

production applications. The information contained

herein will assist the machine operator/technician to

get the system’s maximum cleaning potential.

The system is comprised of one portable, self

contained, all stainless steel console. The system’s

ultrasonic power is supplied by one (1) 500 watt, and

(1) 1000W, 40 kHz ultrasonic generator circuits within

the console.

The Ultrasonic cleaning tank is 32” by 18” by 16”. Filled

to the top, this tank will hold 39 gallons.

In a typical cleaning application, the unit will be filled

with about 25 to 30 gallons of water and detergent.

This is approximately 13 to 14 inches of water.

INSTALLATION AND OPERATION

SITE PREPARATION

Before installing, careful consideration should be given

to the place of operation. Place unit on a smooth, level

surface.

- 2 -

CAUTION

r

r

f

The work area should be well ventilated.

Provide adequate lighting in the work area to permit

viewing of the cleaning process and of the floor area

around the machine. Be sure to allow adequate room

to bring work to and from the machine. Use flooring or

floor covering that does not become slippery when wet.

Provide sufficient clearance around the machine for

fluid changeovers and servicing.

INSTALLATION

UNPACKING

Check containers for any sign of external damage.

Carefully unpack cartons. If any damage is determined,

immediately notify carrier.

LOCATING THE MACHINE

The machine should be placed in a dry location free

from water mist or spray. The internal electronic

components can be damaged by high humidity or

water spray. When filling the machine and rinsing any

parts after ultrasonic cleaning avoid

water spray on the intake lovers, back

and underside of the ultrasonic

cleaning system.

M

AIN POWER

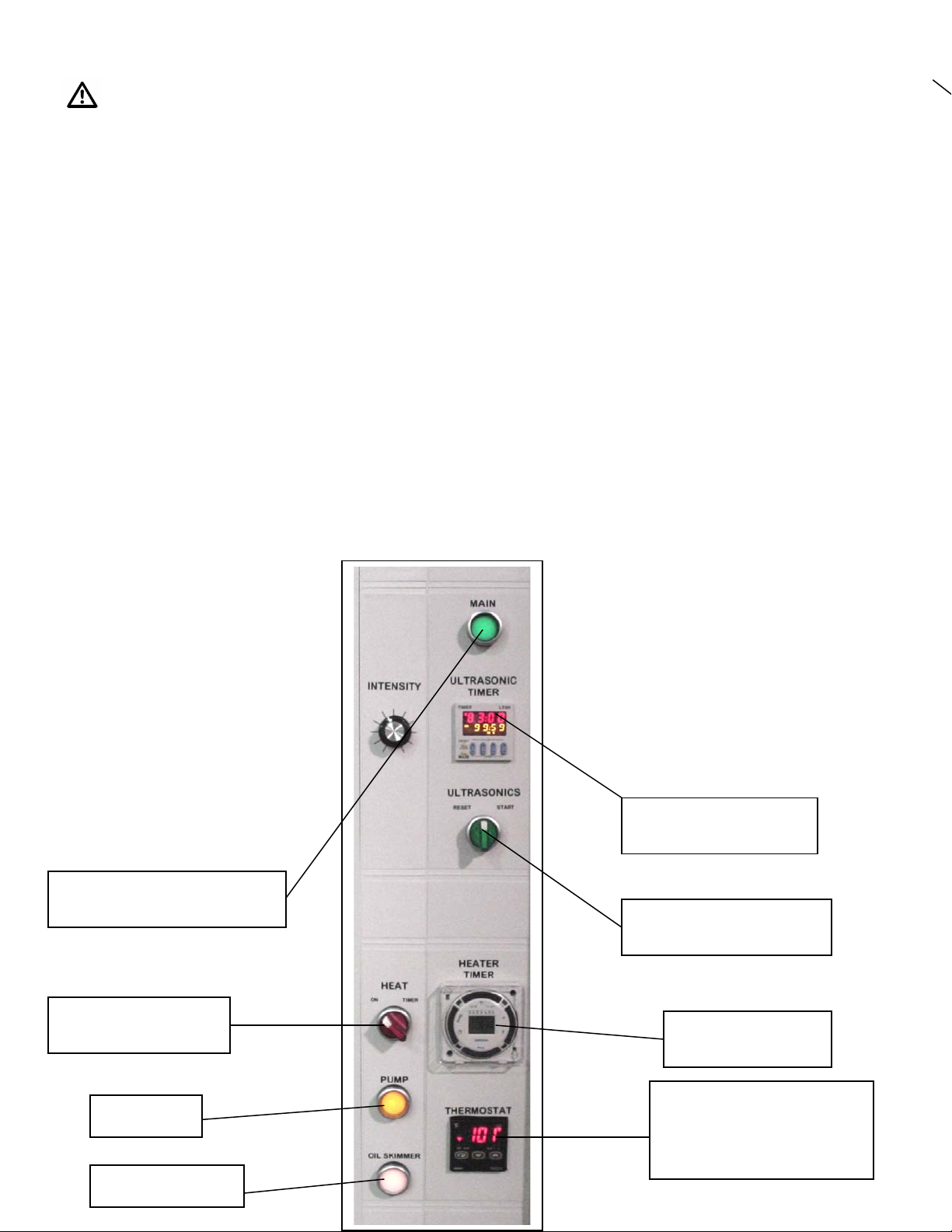

There is one (1) main power switch that allows power

to the machine.

ULTRASONICS

Ultrasonics provides scrubbing cavitation for precision

cleaning. This system features ultrasonic generators

and employs transducers immersed in the fluid. On the

control panel, there is one (1) switch that controls the

timer for the ultrasonics. Start, starts the timer cycle

and reset stops and resets the time on the timer. See

section on timer for explanation on how to set the

timer.

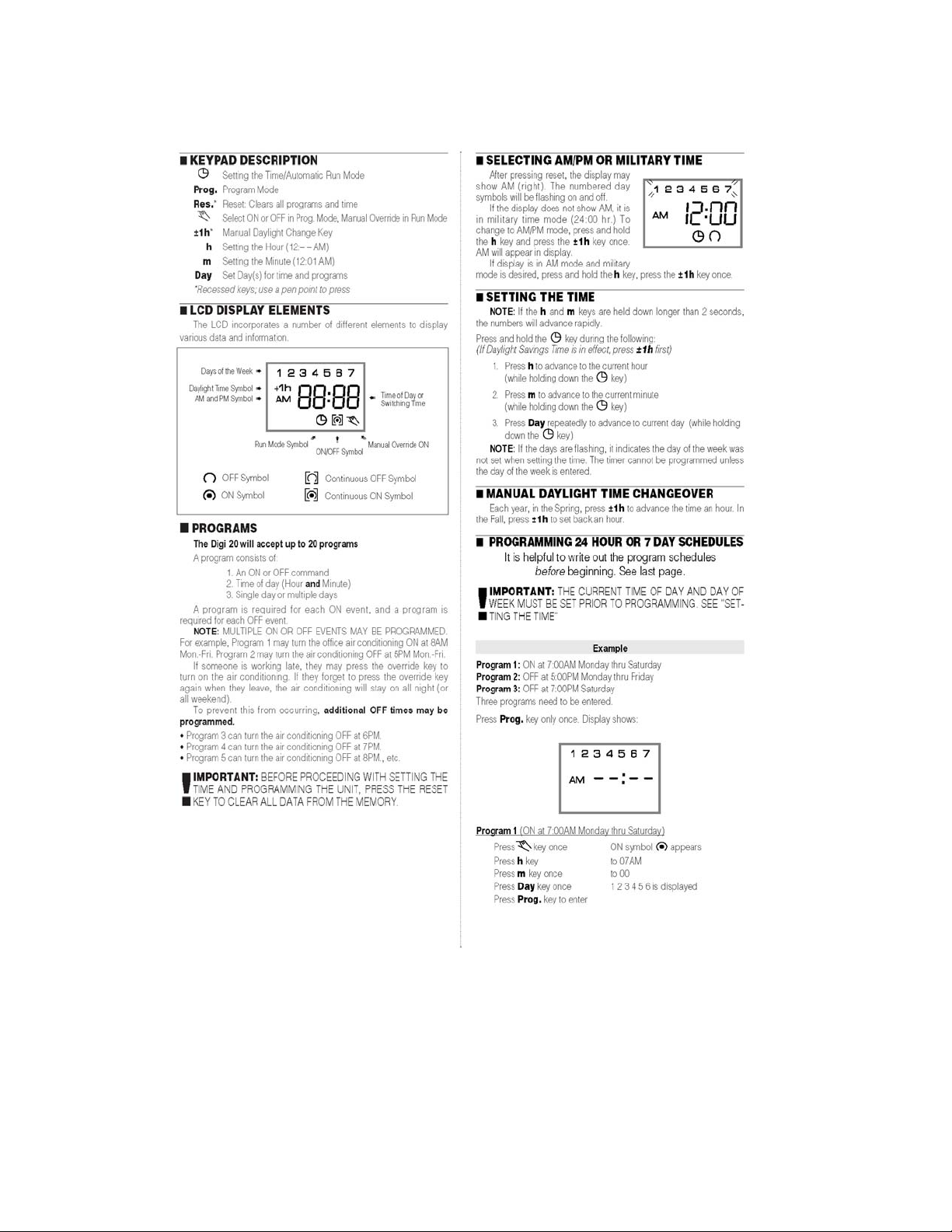

HEATER

There are four (4) 500-watt (120V) heaters attached to

the side of the ultrasonic tank. The temperature control

thermostat controls the temperature. See section on

digital thermostat on an explanation on how to set the

thermostat. The switch on the control panel turns on

the heater. Turning the switch to the right activates the

heater timer; turning to the left overrides the timer and

continuously activates the heater. See section on

heater timer

set the day timer.

(Appendix A) for an explanation on how to

PUMP

There is one (1) switch on the control panel

that controls the pump and filtering of the

system. A valve by the filter housings will

control the flow. Too much flow when using

the ultrasonics as the flow will impede the

ultrasonic's capacity to clean

.

OIL SKIMMER

There is one (1) switch on the control panel

that controls the oil skimmer

.

Ultrasonic Time

Main (Power) Switch

Ultrasonic On/Of

Heat On/Off

Heater Time

Heater

Pump

- 3 -

(Temperature)

Controller

Oil Skimmer

ULTRASONIC CLEANING SETUP

WARNING

DO NOT OPERATE THE ULTRASONIC GENERATOR WITHOUT LIQUID IN THE ULTRASONIC TANK. PERMANENT

DAMAGE WILL RESULT IF THE SYSTEM IS RUN DRY

PROTECT THE HEATERS AND ULTRASONIC TRANSDUCERS

Filling the Unit - Check to be sure the drain valve (located on the inside the drain access door) to insure it is tightly

closed. Fill the tank with 13” (approximately 24 gallons) of warm to hot water. Warm water increases the efficiency of

the cleaning process; with the optimum water temperature being 90 - 100° F some chemicals will require higher

temperatures for proper cleaning.

Adding Chemicals - Depending upon the chemical makeup of the water supply in your area, you may start by

adding a slightly reduced amount of chemical as recommended by the manufacturer. After cleaning one or two items,

you may choose to increase the chemical ratio. The amount of chemical will be based on the condition of the water

being used and how much contamination is to be removed. Detergents that are used in this ultrasonic cleaning system

must be compatible with 304 and 316L stainless steel. You will void the warranty if chemical attack to the

stainless steel occurs.

Power On - Engage the ultrasonic start switch. The ultrasonic generators will start the ultrasonic action in the tank.

Both generator circuits are controlled by switch on the control panel.

System Degassing – At startup or after fluid changes, the unit has to be run to eliminate air in the fluid before parts

washing. The system should be run for approximately 10 minutes with the ultrasonic generators at full power an tank

termperature at 100 F to allow the water in the cleaning tank to properly degas. Typically, the sound of the unit in

operation will change from a high pitch “squeal” to a lower tone when de-gassing is completed. (The de-gassing

process removes unwanted air molecules from the cleaning tank, thus maximizing the efficiency of the

cavitation/cleaning process.)

Cleaning - Place materials to be cleaned into the degassed cleaning tank. Be sure that all parts and components are

fully submerged into the cleaning solution. Check to be sure that no air pockets are present on the item(s) being

cleaned, as the cavitation process will only operate in the liquid solution. Some initial testing will allow you to determine

the proper settings for the optimum time and temperature. Also discuss the application with the chemical supplier.

Typically, due to the extreme efficiency of the unit, only 2 to 3 minutes of immersion time is required to thoroughly

clean the average job.

. THIS SYSTEM REQUIRES A MINIMUM OF 12 INCHES OF LIQUID TO

.

WARNING

When first learning the capabilities of this system, do not leave items unattended in the wash tank for periods

longer than four (4) minutes! The system may damage surfaces if allowed to remain in the ultrasonic bath for

extended periods of time! Longer cleaning times can be used after thorough testing has been completed.

Do not place items to be cleaned directly on the tank bottom. Always suspend parts or use baskets that place the

weight of the parts on the edges of the ultrasonic tank. Do not attempt to clean aluminum in a caustic solution. Do not

use bleach or ammonia as a cleaning chemical.

- 4 -

MAINTENANCE

WARNING

Before performing any maintenance on this unit, be

sure to disconnect electric power.

This unit utilizes high voltage to operate the

ultrasonic transducers. Only qualified

trained personnel should attempt any

repairs or servicing of the ultrasonic

components.

Several routine maintenance procedures

should be followed to enhance the

performance of the equipment and to ensure

long term reliability.

ULTRASONIC GENERATOR

The ultrasonic generators have fans to cool the

electronic components. These fans may

become blocked with lint or debris that will

inhibit the free flow of air. Periodically (every 1

to 3 months) under normal conditions, the

generator

inspected (for debris build-up), cleaned

placed back into the housing. Access to the

generators is via a screen inside the underside

intake grill/screen should be

and

of the machine. Should it be necessary to

remove the ultrasonic generator there are

several connections from the generator to the

system. If any connections are disconnected

be sure all connections are re-connected prior

to restarting the machine. Only a qualified

technician should perform this maintenance.

The ultrasonic generator utilizes high voltage.

While the unit is out of the housing, the

electronics can be visually inspected to

determine any areas of abnormality

(discoloration etc.). At this time, any build-up of

dust or debris on the electronics should be

gently brushed off or removed by using a

gentle blast of air.

GENERAL CLEANING

To prevent build-up of contamination on tank

walls, it is advisable to periodically drain the

tank solution and wash out the tank.

Be careful when cleaning the ultrasonic tank to

not scratch or abrade the ultrasonic radiating

surface, as this will reduce the life of the

radiating surface.

- 5 -

Graymills Corporation warra nts that the equipment manufactured and delivered, when properly installed and

maintained, shall be free from defects in workmanship and will function as quoted in the published specification.

Graymills does not warrant process performance, nor assume any liability for equipment selection, adaptation, or

installation.

Warranty does not apply to damages or defects caused by shipping, operator carelessness, misuse, improper

application or installation, abnormal use, use of add-on-parts or equipment which damages or impairs the proper

function of the unit, and modifications made to the unit. Warranty does not apply to expendable parts needing

replacement periodically due to normal wear and tear.

A new Warranty period shall not be established for repaired or replaced materials or products. Such items shall rem ain

under Warranty for only the remainder of the Warranty period of the original material or product.

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, WHETHER ORAL, WRITTEN,

EXPRESSED, IMPLIED OR STATUTORY. GRAYMILLS CORPORATION MAKES NO OTHER WARRANTY OF

ANY KIND, EXPRESS OR IMPLIED. ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WHICH EXCEED THE AFORESTATED OBLIGATION ARE HEREBY DISCLAIMED BY

GRAYMILLS CORPORATION AND EXCLUDED FROM THIS SALE. Graymills warranty obligation s a nd Buyer

remedies (except to title), are solely and exclusively stated herein. In no case will Graymills be liable for

consequential damages, loss of production, or any other loss incurred due to interruption of service.

Graymills' obligation u nder this Warranty shall be limited to:

1. Repairing or replacing (at Graymills sole discretion) any non-conforming or defective component within

one year from the date of shipment from Graymills.

2. ULTRASONIC EQUIPMENT – On parts cleaners equipped with ultrasonics, the ultrasonic transducers are

guaranteed against cracking, depolarizing or becoming detached from the radiating surface for a period of

ten (10) years from the date of shipment from Graymills. This warranty does not cover transducer failure

that results from operating the equipment with insufficient liquid in the tank as evidenced by inspection by

Graymills.

3. Repairing or replacing (at Graymills sole discretion), components supplied by, but not manufactured by

Graymills, to the extent of the warranty given by the original manufacturer.

4. This warranty does not cover rusting of a mild-steel parts cleaner u s ed with aqueous (water-based)

materials. On ultrasonic equipment, the finish of the stainless steel tank interior or the immersible

transducer radiating surface is excluded from this warranty as erosion of these surfaces occurs normally

during the course of operation.

Buyer must give Graymills prompt notice of any defect or failure.

If you believe you have a Warranty claim, contact Graymills at (773) 248-6825. Any return material must have an

RMA number on the outside of the package and shipping prepaid or shipment will be refused. Graymills will

promptly examine the material and determine if it is defective and within the Warranty period.

Graymills® 3705 N. Lincoln Ave. Chicago, IL 60613

773-248-6825 1-888-GRAYMILLS

www.graymills.com ©2007 Graymills Corporation

Specifications may change without notice

- 6 -

Loading...

Loading...