Graymills QC User Manual

795-91382

02-10

Graymills

QC Series Pumps

In order to ensure the safe operation, never operate pump without motor installed snugly against the

flange. Read all warnings and cautions in OMI #795-08260 before any service work.

For proper pump cleaning and maximum bearing life, both motor and bearing cartridge should be

removed from housing.

Removing/Installing Motor

To remove: Make sure motor is cool.

a. QC Models- Remove pin clips from retaining screws below mating flange of bearing housing.

b. QCE Models- Remove pin clip from the retaining screw above mating flange of bearing

housing.

c. Using handle, lift motor away from mating flange. DO NOT USE ELECTRICAL

CONNECTIONS FOR LIFTING.

To install motor:

1. QC Models- If installing motor on bearing housing for first time, install threaded retaining

screws to proper depth. Place the motor on top of bearing housing so retaining screws

protrude below bearing housing flange. Adjust retaining screws so hole in screw protrudes just

below housing flange.

2. QCE Models- If installing motor on bearing housing for the first time, thread retaining screws

into bearing housing flange. Place motor on top of the bearing housing so retaining screws

protrude above motor flange. Adjust retaining screws until hole in screw just protrudes above

motor flange.

3. Both Models- Insert pin clip into the retaining screw. Twist clip in a ratcheting motion, tighten

retaining screw down until flanges on motor and bearing housing are mated tightly.

Removing Bearing Cartridge from Housing- QC and QCE Series

To obtain ultimate bearing life, bearing cartridge should be removed before cleaning pump

body.

Tools Required: 4mm hex key and two 5/8” open-end wrenches

1. Remove Motor as described above.

2. Remove (2) 4mm screws located inside bearing housing with hex key. This will allow shaft to

“float” and makes bearing cartridge removal easier.

3. Place (2) 5/8” open end wrenches on straddle-milled slots on the upper and lower sections of

the pump shaft. NOTE: Shafts are threaded with a left-hand thread, thus loosening

requires turning clockwise

Graymills Corporation – 3705 N. Lincoln Ave. – Chicago, IL USA – www.graymills.com

795-91382

02-10

4. Holding lower section stationary, rotate upper shaft clockwise to unlock sections and then

continue to loosen by hand. Once loose, you can also rotate bearing cartridge to separate the

upper and lower sections of the shaft.

5. Remove bearing cartridge and upper shaft by pushing up from shaft end. The upper shaft is

retained in bearing cartridge.

Installing Bearing Cartridge- QC and QCE versions

1. Place bearing cartridge containing upper section of shaft into bearing housing

2. Holding upper shaft stationary using one 5/8” open end wrench on the straddle-milled slot,

tighten the lower section using second open end wrench on its straddle-milled slot. NOTE:

Shafts are threaded with a left-hand thread, thus tightening requires turning counterclockwise.

3. Install (2) 4mm screws inside bearing housing and tighten with hex key.

NOTE: A 3-phase motor can be wired to run in reverse; however, this will cause the shaft to

loosen during operation, due to the left-hand thread of the shaft. Flow will also be reduced by

90%

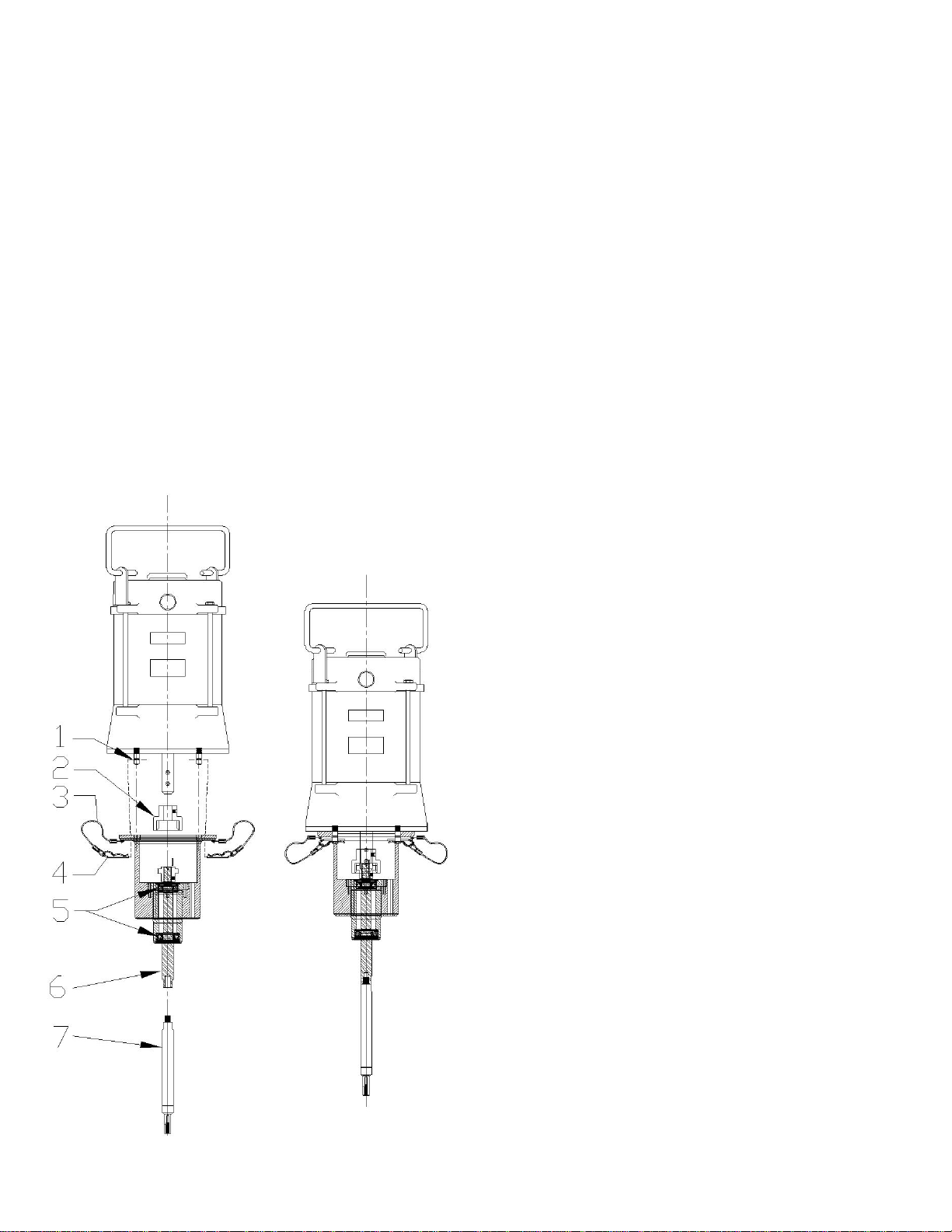

QC and QCE Versions

Part Numbers

1. Retaining Pin 568-38859-88

2. Coupling Set

QC Models C-37717

QCE Models C-37718

3. Lanyard 765-91349-13

4. Hair Pin Clip 756-91348

5. Bearing Service Kit

QC Models C-38983

QCE Models C-38984

6. Upper Pump Shaft

QC Models 560-38821-86

QCE Models 560-38814-86

7. Lower Pump Shaft

QCM3 (before 5/1/06) 560-38820-86

QCM3 (after 5/1/06) 560-39534-86

QC4000 560-38954-86

QC3 560-39174-86

QCME3 (before 5/1/06) 560-38820-86

QCME3 (after 5/1/06) 560-39534-86

QCE4000 560-39534-86

QCE3 560-39174-86

QCWE2 560-41020-86

QCGE2 560-41020-86

Graymills Corporation – 3705 N. Lincoln Ave. – Chicago, IL USA – www.graymills.com

Loading...

Loading...