Graymills PH822-A User Manual

795-92072

05/08

Graymills

Model PH822-A Heated Handi-Kleen®

Recirculating Parts Cleaner

Operations and Maintenance Instructions

Be sure anyone operating this unit reads and understands all warnings and instructions. Keep this

manual available for reference/training.

SAFETY WARNINGS

You will find various types of safety information on the following pages and on the labels attached to Graymills equipment. The following

Safety Statements explain their meaning:

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid personal injury or

READ BEFORE OPERATING

death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION, without the safety alert symbol, is used to address practices not related to

personal injury.

• Never use a flammable or combustible fluid in this

unit. Use only nonflammable, non-combustible,

water-based, low foaming cleaning compounds in this

machine. For best results, Graymills’ recommends

using Aquatene 330, Super Aquatene 360, or

Aquatene 571.

• Do NOT contaminate cleaning fluid with any

flammable or combustible material such as gasoline,

alcohol, mineral spirits, etc. Drain parts to be cleaned

of any flammable material or combustible material

before placing inside cleaning tank. Even small

quantities can create a dangerous fire hazard.

• Never work with equipment you feel may be unsafe.

Contact your supervisor immediately if you feel a

piece of equipment is in an unsafe condition.

• Cleaning solutions may be irritating to skin and eyes.

Always wear gloves, apron and safety glasses when

using. If splashed in eyes, flush thoroughly with water

and follow directions on cleaning solution MSDS.

• Install machine in a well ventilated area to avoid possible

buildup of cleaning solution fumes.

1

• Cleaning fluids should have a pH under 12.5.

• This is a heated system. Always use caution when first

putting hand into cleaning solution. Higher temperatures

can cause burns to skin and will damage pump. This

unit's thermostat has a maximum temperature of 120ºF.

Do NOT attempt to exceed thermostat setting.

• Should cleaning solution become uncomfortably hot

despite adjusting thermostat to a lower temperature

and/or the heat light is on continuously, unplug

machine and discontinue use. For instructions on

changing the thermostat, please see the Troubleshooting

section.

• If any cleaning solutions are splashed on clothing, change

promptly and thoroughly wash any body areas which have

been in contact with solution. Apply lotion. Do NOT

permit saturated clothing to remain in contact with

skin.

• After extended use, the gas-spring used to assist in

opening and closing the lid may lose its ability to keep the

lid open. At the first sign of this, replace the gas-spring

immediately. (See Spare Parts List)

• Automatic Safety Cover. Since certain soils may be

combustible, e.g., oils, greases. This unit is equipped with

a fusible safety link cover mechanism designed to support

the open cover at a slightly forward angle. In the event of

a fire, the fusible link will melt at 165ºF permitting the

cover to slam shut, cutting off oxygen supply to the fire.

(See Spare Parts List)

• Failure to keep proper liquid level will result in

burning out the pump and heater coil, creating a

potential fire hazard. To help prevent this, this unit is

equipped with a low liquid level device which will shut off

the pump and heater. If solution stops circulating and the

red “FAULT” light becomes illuminated, immediately turn

off and unplug unit. For instructions on filling the reservoir,

please see the Troubleshooting section.

• Do not leave the unit unattended with parts in the tank

which would prevent the cover from closing

completely in the event of a fire. Keep cover closed

when unit is not in use. If the fusible link breaks, do

not operate the unit until a replacement link is

installed. (See Spare Parts List)

• Turn heater and pump off when unit is to be idle for

extended periods (overnight and weekends).

• Maximum shelf capacity 150 pounds.

• Maximum fluid capacity 30 gallons.

795-92072

05/08

POWER SUPPLY, WIRING AND

GROUNDING

• Failure to permanently ground the unit and controls

before connecting to electrical power can cause

shock, burns or death.

• Install ground and wiring according to local and

national electrical code requirements.

• Install a fused disconnect switch on all power legs near

the unit

• Disconnect and lockout electrical supply before installing

or servicing unit.

• Unit must be properly grounded to prevent electric shock

hazard. Connect only to three-prong outlet. Should cord

become cracked, frayed or damaged in any way, it should

be repaired/replaced immediately by a qualified

electrician. Never use an extension cord. (See Spare

Parts List)

• The full-load amperage draw for this machine is 12 amps.

MACHINE INSTALLATION

1. Unit is shipped fully assembled.

2. Place unit on smooth, level surface in a well-ventilated

area.

3. Close drain valve before filling tank.

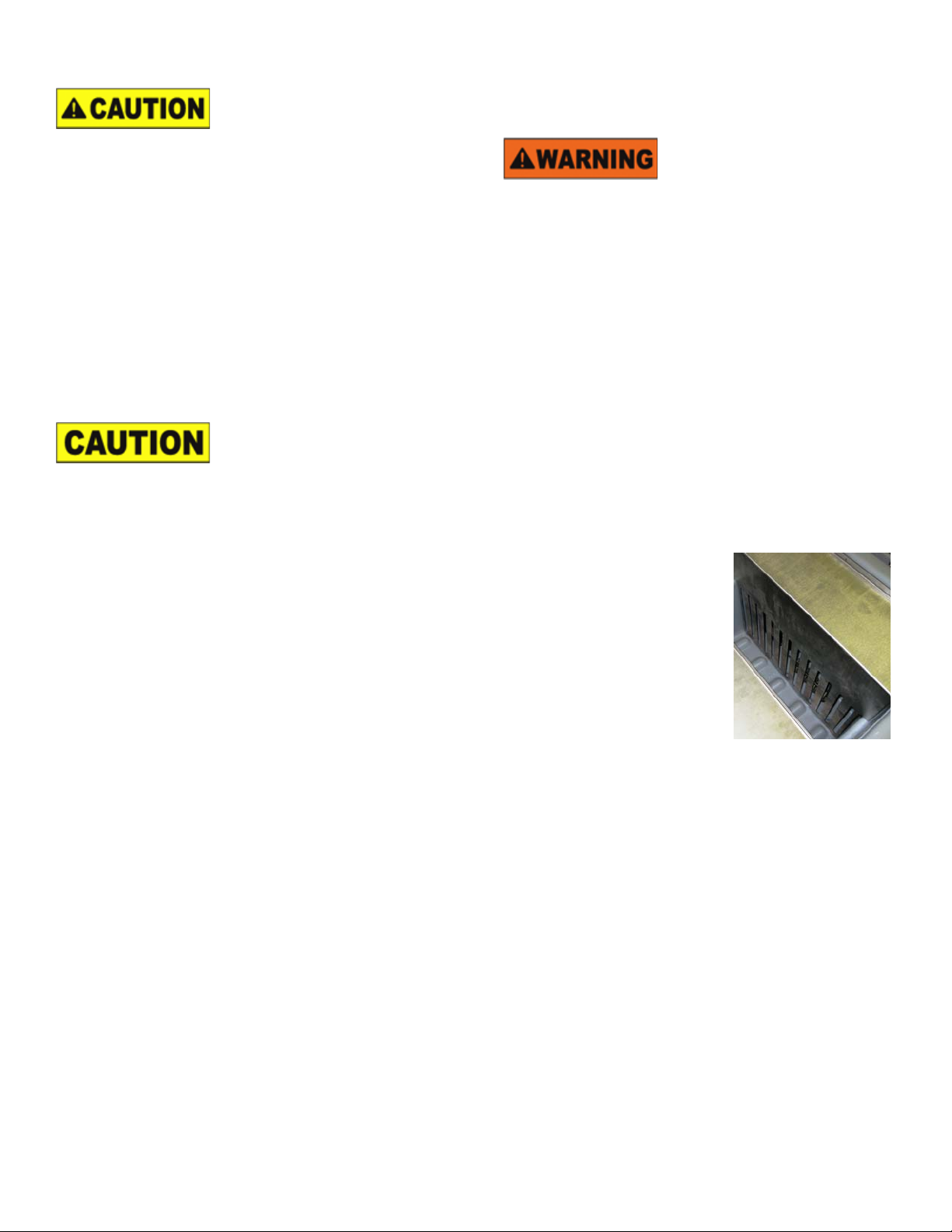

4. Fill tank with 30 gallons of

aqueous cleaning solution

according to solution

manufacturers’ suggested

dilution instructions. For best

results, Graymills

recommends Aquatene 330,

Super Aquatene 360, or

Aquatene 571. Maximum

fluid level is equal to the tops

of the slots in the baffle

screen (Right). Fluid level

must be maintained above

pump and heater coil.

5. Open lid and read warnings on inside left hand portion of

lid.

6. Place stainless steel shelf on mounting rid ges inside tank.

Flow-Thru brush rests on shelf.

7. Plug cord into properly-grounded three pron g 120V, 60 Hz

single-phase outlet.

Max-Fill Slots

2

Loading...

Loading...