Multi-Stage

Centrifugal

MVP Pumps

Operations and Maintenance

Instructions

WARNINGS/CAUTIONS

Read all these SAFETY INSTRUCTIONS BEFORE

installing or using this equipment. Keep this

manual handy for reference/training.

Inspect unit for damage. Report any damage to

carrier/dealer immediately.

Pump may be heavy. If in doubt, take appropriate

precautions.

Motor must be grounded and suitable for the

environment in which it is used. Do not use where

explosion-proof motors are required.

Do not allow liquids to come into contact with the

motor, or any electrical components.

Never attempt any service work while the unit is

still connected to any electrical power source.

This pump contains rotating parts. Use caution.

When working on or around pump, be aware of

what liquid is/has been pumped. If liquid is

potentially harmful, take appropriate precautions.

Never use any part of the wiring/electrical system

to lift or move the equipment. This could cause a

failure of the electrical system, resulting in severe

shock or death.

Do not operate this pump or allow others to

operate it until the instructions and warnings have

been read and are understood by all involved.

Never work with equipment you feel may be unsafe.

Contact your Supervisor immediately.

DESCRIPTION/SPECIFICATIONS

The Graymills MVP Series pumps are multi-stage

centrifugal pumps designed to handle clean, water and

water-based coolants.

795-91725

3-07

www.graymills.com

Minimum and maximum liquid temperature range: -

0

C to 930C(500F to 2000 )

10

Maximum Air Temperature 40

Maximum viscosity 500 SSU

Maximum On/Off Cycles per hour: 100

Maximum inlet pressure 100 psi.

Pipe connections are 1" NPT for both inlet and

discharge.

Bypass kit is included and should be used for

applications where low flow conditions can exist.

See Installation Section, Page 2.

Rotation: left hand, ie, COUNTERCLOCKWISE

when viewed from motor end.

0

C (1040 F)

POWER SUPPLY, WIRING AND

GROUNDING

WARNING

Install ground and wiring according to local and

National Electrical Code requirements.

Install a disconnect switch on all power legs near

the pump.

Disconnect and lockout electrical supply before

installing or servicing pump.

230/460V, 3 phase, 60 cycle AC circuit rated for a

minimum of 10 amps. Refer to motor nameplate for

instructions.

- 1 -

Electrical supply MUST match pump’s name plate

specifications. Incorrect voltage can cause fire

and/or damage to the motor and voids warranty.

Motor overload protection standard on three-phase

motors.

Use only stranded copper wire to motor and

ground. The ground wire MUST be at least as

large as the wire to the motor. Wires should be

color coded for ease of maintenance.

Follow motor manufacturer’s wiring diagram on the

motor nameplate or terminal cover carefully.

WARNING

Failure to permanently ground the pump, motor

and controls before connecting to electrical power

can cause shock, burns or death.

ROTATION

Incorrect rotation may cause damage to pump in

and will void the warranty.

Correct rotation is left-hand,

COUNTERCLOCKWISE when viewed from the

motor end.

Rotation can be verified by quickly energizing the

pump for an instant with a quick on/off motion.

To reverse three phase motor rotation interchange

any two power supply leads.

PIPING

Piping should be no smaller than the pump

discharge. Piping should be kept as short as

possible, avoiding unnecessary fittings to minimize

friction losses.

All piping MUST be independently supported and

MUST NOT place any piping loads on the pump. It

should “line up” naturally.

All joints MUST be airtight. Use 3 - 4 wraps of

Teflon™ tape to seal threaded connections.

CAUTION

Never draw piping into place by forcing the pump

discharge connections.

Bypass Kit (included)

Figure 1

INSTALLATION

WARNING

Multi-stage pumps produce considerable shut-off

pressure. Hoses and associated plumbing used with

these pumps should be rated for a minimum working

pressure of 350 PSI. Failure to heed this warning could

result in ruptured lines and possible injury to personnel.

Minimum and maximum liquid levels must be

maintained for proper pump operation.

See Figure 1.

Allow adequate space for servicing and ventilation.

Protect from freezing and flooding

The pump must be installed in a ventilated area,

and the ambient temperature must not exceed 40

C (104

Before installation, verify that motor and pump are

rotating well by rotating the motor fan.

0

F)

.

0

- 2 -

WARNING

Graymills recommends the use of an inlet strainer

to minimize the size and amount of debris that

enters the pump. Contamination drawn into the

pump can cause internal damage and is not

covered under warranty. Consult factory for

recommendations as to the appropriate size and

type of strainer to use.

High Pressure Filters for keeping fluid clean should

be used. Graymills can provide a filter to trap

particles, scale and contaminants to prevent costly

damage. Filter collects up to 20 cu. in. of material

(HPFB20) without pressure drop. Available in 14"

length single cartridge model (HPFB10) or 24"

length dual cartridge model (HPFB20). All models

are 304 stainless steel for use with water-soluble

and corrosive liquids. Reusable stainless steel

cartridges available in 10, 50, and 100 mesh.

OPERATION

CAUTION

Before starting, pump must be primed (free of air) and

discharge valves partially open.

Do not run pump dry; damage to mechanical seal

will result.

Use a Check valve on plumbing if pump is

mounted horizontally or if the potential to lose

prime can occur.

On-Off Cycling must be limited to under 100 times

per hour, because excessive starting cycles may

harm the windings of the motor.

Do not run against closed nozzles or damage to

pump and piping will result. Use Bypass as

described below.

Do not operate at or near zero flow.

If operating at or below 8 gpm or where valves may

be opened and closed periodically, you must use a

bypass. This kit (Bypass Kit C-39695),See Figure

1, installs in the side of the discharge head and

provides a fluid bypass when the pump is operated

against a closed discharge thus preventing

excessive heat build-up which will damage the

pump.

After stabilizing the system at normal operating

conditions, check the piping. If necessary, adjust

the pipe supports.

To ensure proper suction, fluid level should cover

first two impellers (5" from the suction end of the

pump). See Figure 1.

Pump may be mounted horizontally with optional

horizontal mounting bracket. However, care must

be taken to ensure that prime is not lost.

If pump is not generating enough pressure or flow,

see “TROUBLESHOOTING GUIDE”.

MAINTENANCE

WARNING

Failure to disconnect and lockout electrical power

before attempting any maintenance can cause shock,

burns or death.

Motors have permanently lubricated bearings. No

lubrication is possible or necessary.

Depending upon conditions and operating time, it

is important to perform regular inspections of the

pump. Items to inspect are as follows:

o Performance-Head, Pressure and

Flow

o Noise Level and Leakage

o Filter Cleanliness

The mechanical seal used is cooled and lubricated

using liquid within the pump. Separate lubrication

is unnecessary

To REMOVE pump from service, drain all fluid

from pump and piping.

To RETURN pump to service, replace all plugs and

piping using Teflon™ tape or equivalent on male

threads.

Disassembly

In most cases, the only maintenance necessary will be

replacement of the mechanical seal on the shaft. The

procedure below describes the process of

disassembling the pump’s stages to replace the seal.

Remove stay bolts on outside of pump column by

removing nuts on bottom end of bolts. Bolts can

then be unscrewed from motor bracket.

Remove suction cover from bottom of pump.

Remove O-Ring and Outer Chamber Sleeve. The

sleeve may need to be tapped and rotated to break

if free from the motor housing. There is an O-Ring

on both top and bottom of Outer Chamber Sleeve.

Inspect both after removal and replace if they show

signs of deterioration.

Remove nut and lock washer from shaft. The nut

has a left-hand thread to prevent loosening during

rotation of the pump. Each stage is a two-piece

construction of impeller and bowl/diffuser. The first

stage after the suction head will have a special

seal. During re-assembly make sure it occupies the

same position. The procedure should be the same

regardless of the number of stages in your pump.

Each stage is removed in the same manner as the

first. A screwdriver blade and application of mild

force might be needed to separate the sections.

DO NOT DEFORM OR BEND THE STAGES. Note

carefully the system of spacers. Each stage has a

spacer that prevents the impeller from contacting

the bowl/diffuser.

Once the stages have been removed, take the

circlip below the mechanical seal off the shaft.

Slide the seal off the shaft. Examine the seal for

damage or wear. If necessary, replace the seal.

If necessary to remove entire shaft from pump, it

will require the coupling guard, coupling and pin to

be removed. Remove the two fasteners that hold

the guard in place. Remove the four Allen-head

- 3 -

bolts, two on each side, from the coupling. The

shaft pin should then be accessible and the shaft

can be removed from the pump.

The seal face is pressed into the pump housing.

Inspect for damage. If necessary replace by prying

out with a screwdriver. Inspect O-Ring that

surrounds seal face. Replace O-Ring if damaged.

Replace seal face by pressing in a new face in the

housing.

Reassembly

With new seal face installed in housing, replace shaft

and pin and secure coupling with four Allen-head bolts.

Replace coupling guard and screws.

Replace mechanical seal on shaft. Replace circlip

on shaft below seal.

Reinstall stages in the reverse order of removal.

Stages should not be warped, bent or damaged.

Note carefully how spacers are used to prevent

impeller from contacting the bowl/diffuser. Replace

nut and lock washer on shaft to retain stages.

Replace O-Ring in pump housing and fit

intermediate chamber sleeve into pump housing.

Install stay bolts into motor casing. Place O-Ring

into suction cover and place suction cover over

intermediate chamber cover. Thread nuts onto end

of stay bolts and tighten to retain suction cover.

Troubleshooting Guide

Problem Probable Cause

Pump Head Leakage

Leakage between pump body, upper cover and/or casing Damaged O-ring, replace the O-Ring

Mechanical Seal Wear; replace Mechanical Seal

Low power during output during peak Overload protector frequently trips during operation

Unstable voltage supply

Odd noise and vibration

Water is not coming out

Pump is operating, but not normally

Pump cavitation

Damaged motor bearing

Pump and piping not anchored properly

Pump not primed properly

Excessive head requirement from too much piping

Check for restrictions in plumbing

Release air from, or reconfigure intake pipe

Clean out clogged impeller

Check motor rotation to verify if pump is operating

properly

- 4 -

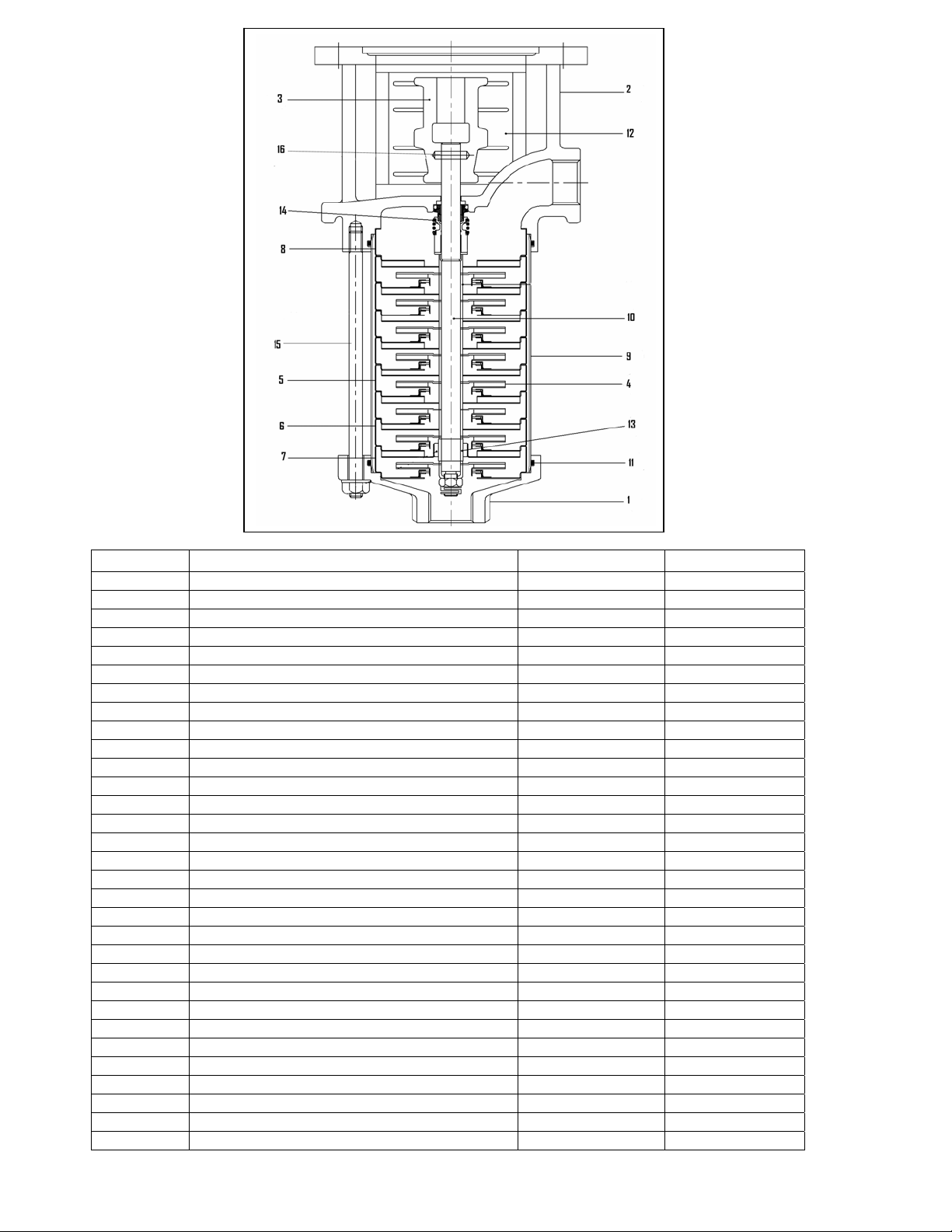

Replacement Parts

Ref Description Material Part Number

1 Suction Cover Stainless Steel 793-91748

2 Motor Bracket Gray Cast Iron 793-91749

3 Coupling Gray Cast Iron 793-91750

4 Impeller Stainless Steel 793-91751

5 Intermediate Chamber Stainless Steel 793-91752

6 Intermediate Chamber with Bearing Stainless Steel 793-91753

7 Intermediate Chamber without guide vane Stainless Steel 793-91754

8 Intermediate Chamber without neck ring Stainless Steel 793-91755

9 Outer Sleeve-MVP4(95mm) Stainless Steel 793-91727

9 Outer Sleeve-MVP6(135mm) Stainless Steel 793-91728

9 Outer Sleeve-MVP8 (175mm) Stainless Steel 793-91729

9 Outer Sleeve-MVP12 (255mm) Stainless Steel 793-91730

9 Outer Sleeve-MVP16 (335mm) Stainless Steel 793-91731

9 Outer Sleeve-MVP20 (415mm) Stainless Steel 793-91732

10 Shaft-MVP4 Stainless Steel 793-91733

10 Shaft-MVP6 Stainless Steel 793-91734

10 Shaft-MVP8 Stainless Steel 793-91735

10 Shaft-MVP12 Stainless Steel 793-91736

10 Shaft-MVP16 Stainless Steel 793-91737

10 Shaft-MVP20 Stainless Steel 793-91738

11 O-Ring Viton 793-91756

12 Coupling Guard Stainless Steel 793-91757

13 Bearing sleeve Tungsten Carbide 793-91758

14 Mechanical Seal Viton 793-91759

15 Stay Bolt-MVP4 Stainless Steel 793-91763

15 Stay Bollt-MVP6 Stainless Steel 793-91764

15 Stay Bolt-MVP8 Stainless Steel 793-91765

15 Stay Bolt-MVP12 Stainless Steel 793-91766

15 Stay Bolt-MVP16 Stainless Steel 793-91767

15 Stay Bolt-MVP20 Stainless Steel 793-91768

16 Coupling Pin Stainless Steel 793-91762

- 5 -

WARRANTY

Graymills Corporation warrants that the equipment

manufactured and delivered hereunder when properly

installed and maintained, shall be free from defects in

workmanship.This warranty does not apply to damages

or defects caused by operator carelessness, misuse,

abuse, improper application, or abnormal use; the use

of add-on parts or equipment which damages or

impairs the proper function of the unit and

modifications made by Buyer. Graymills’ obligation

under this Warranty shall be limited to: 1. Replacing or

repairing tank and structural parts within one year from

the date of installation or 13 months from the date of

shipment whichever occurs first. The decision to

replace rather than repair shall be made by Graymills

Corporation; 2. Replacing or repairing components

supplied but not manufactured by Graymills, such as

pneumatic cylinders, controls, pneumatic systems,

motors, heater controls and heaters to the extent such

components are warranted by the original

manufacturer’s warranty, provided that Buyer gives

Graymills prompt notice of any defect or failure and

satisfactory proof thereof. Before Graymills can repair

or replace a defective part under warranty, call

Graymills for a Return Merchandise Authorization

number (RMA number must appear on outside English

of package or it will be refused and returned). Upon

prepaid return to Graymills’ factory, Graymills’

examination must disclose such part to be defective.

This warranty does not apply to expendable parts such

as rollers, bearings, cylinder packings and any other

parts which need replacement periodically due to

normal wear nor to rusting of a mild steel heated unit

used with aqueous (water) based cleaning solutions. A

new warranty period shall not be established for

repaired or replaced materials, or products. Such items

shall remain under warranty for only the remainder of

the warranty period of the original materials or

products.

Graymills warrants that the equipment will function

mechanically as quoted in the published specification.

Graymills does not warrant process performance nor

does Graymills assume liability for equipment

selection, adaption or installation. The foregoing

warranties are in lieu of all other warranties whether

oral, written, expressed, implied or statutory. Implied

warranties of fitness for a particular purpose and

merchantability shall not apply. Graymills’ warranty

obligations and Buyer’s remedies thereunder (except

as to title) are solely and exclusively as stated herein.

In no case will Graymills be liable for consequential

damages, loss of production or any other loss incurred

because of interruption of service.

Graymills® 3705 N. Lincoln Ave. Chicago, IL 60613 773-248-6825 1-888-GRAYMILLS

www.graymills.com ©2007 Graymills Corporation

Specifications may change without notice

- 6 -

Loading...

Loading...