Graymills MSPR User Manual

WARNINGS/CAUTIONS

Read all these SAFETY INSTRUCTIONS BEFORE

installing or using this equipment. Keep this manual

handy for reference/training.

• Inspect unit for damage. Report any damage to carrier/dealer

immediately.

• Pump may be heavy. If in doubt, take appropriate precautions.

• Motor must be grounded and suitable for the environment in

which it is used. Do not use where explosion-proof motors

are required.

• Do not allow liquids to come into contact with the motor, or

any electrical components.

• Never attempt any service work while the unit is still connected to any electrical power source.

• This pump contains rotating parts. Use caution.

• When working on or around pump, be aware of what liquid

is/has been pumped. If liquid is potentially harmful, take

appropriate precautions.

• Never use any part of the wiring/electrical system to lift or

move the equipment. This could cause a failure of the electrical system, resulting in severe shock or death.

• Do not operate this pump or allow others to operate it until

the instructions and warnings have been read and are understood by all involved.

Never work with equipment you feel may be unsafe.

Contact your Supervisor immediately.

DESCRIPTION/SPECIFICATIONS

The Graymills MSPR Series pumps are multi-stage centrifugal

pumps designed to handle water-based coolants and water.

• Maximum liquid temperature 160°F (72°C).

• Maximum viscosity 300 SSU.

• Maximum suction pressure 75psi.

• Pipe connections are 1" NPT suction and discharge. 1/4"

NPT Bypass is included.

• Rotation: left hand, ie, COUNTERCLOCKWISE when

viewed from motor end.

POWER SUPPLY, WIRING AND

GROUNDING

WARNING

Install ground and wiring according to local and

National Electrical Code requirements.

• Install a disconnect switch on all power legs near

the pump.

• Disconnect and lockout electrical supply before

installing or servicing pump.

• 230/460V, 3 phase, 60 cycle AC circuit rated for a minimum

of 10 amps. Refer to motor nameplate for instructions.

• Electrical supply MUST match pump’s name plate specifications. Incorrect voltage can cause fire and/or damage to the

motor and voids warranty.

• All three phase motors not protected for overload conditions

MUST be provided with a starter which includes heaters.

• Use only stranded copper wire to motor and ground. The

ground wire MUST be at least as large as the wire to the

motor. Wires should be color coded for ease of maintenance.

• Follow motor manufacturer’s wiring diagram on the motor

nameplate or terminal cover carefully.

WARNING

Failure to permanently ground the pump, motor and

controls before connecting to electrical power can

cause shock, burns or death.

Multi-Stage

Centrifugal MSPR

Pumps

Operations and

Maintenance

Instructions

795-07945

GM02-05

ROTATION

NOTICE: Incorrect rotation may cause damage to pump

in as little as 5 seconds and will void the warranty.

• Correct rotation is left-hand, COUNTERCLOCKWISE when

viewed from the motor end.

• Rotation can be verified by quickly energizing the pump for

an INSTANT with a quick on/off motion.

• To reverse three phase motor rotation interchange any two

power supply leads.

PIPING

• Piping should be no smaller than the pump discharge. Piping

should be kept as short as possible, avoiding unnecessary fittings to minimize friction losses.

• All piping MUST be independently supported and MUST

NOT place any piping loads on the pump. It should “line up”

naturally.

• All joints MUST be airtight. Use 3 - 4 wraps of Teflon™

tape to seal threaded connections.

CAUTION

Never draw piping into place by forcing the pump

discharge connections.

INSTALLATION

WARNING

Multi-stage pumps produce considerable shut-off

pressure. Hoses and associated plumbing used with

these pumps should be rated for a minimum working

pressure of 180 psi. Failure to heed this warning

could result in ruptured lines and possible injury to

personnel.

• Maximum operating pressure: 175psig at 200°F

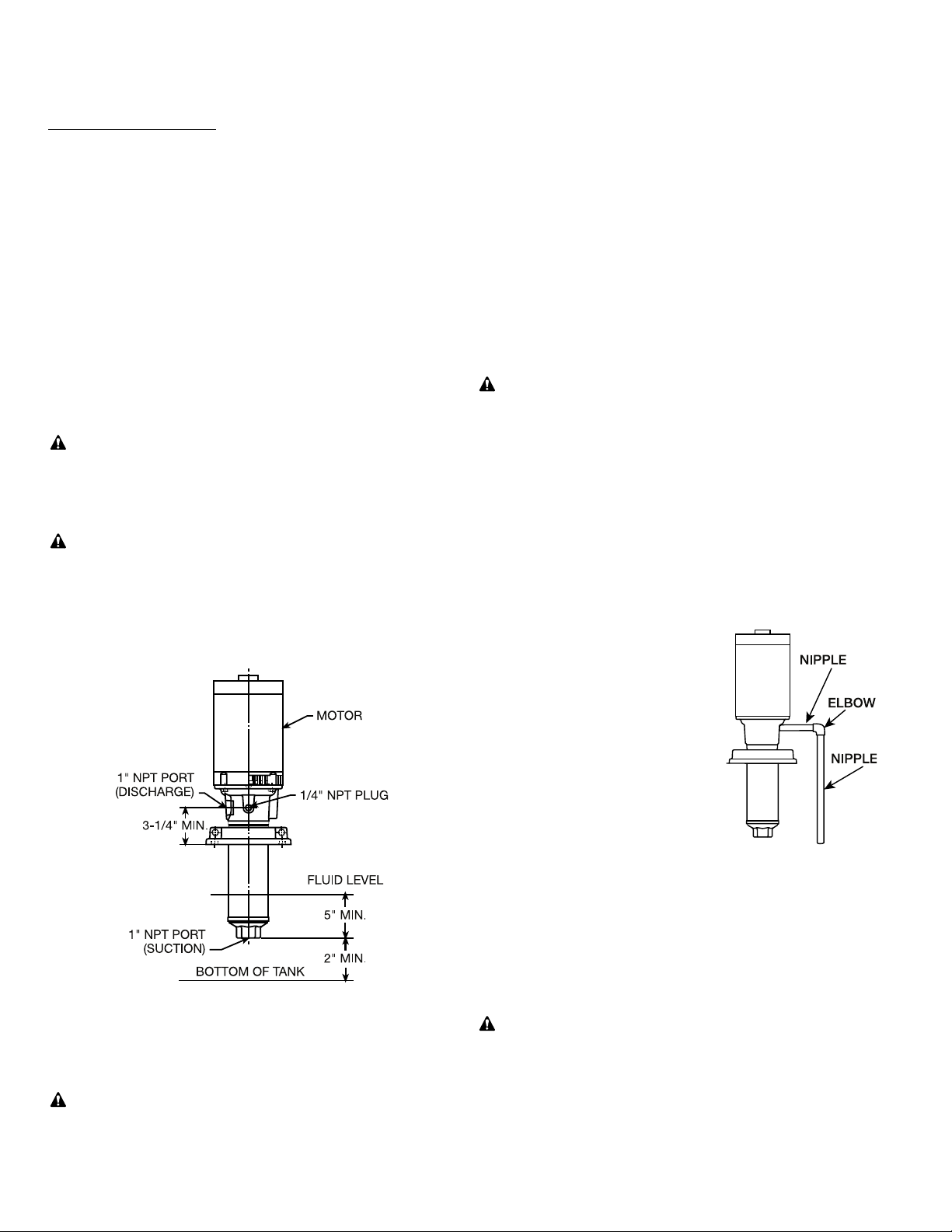

• Minimum and maximum liquid levels must be maintained for

proper pump operation. See Figure 1.

• Allow adequate space for servicing and ventilation. Protect

from freezing and flooding.

WARNING

• Use clean fluids only; no chips, grit or other foreign

particles.

• Graymills recommends the use of an inlet strainer

to minimize the size and amount of debris that

enters the pump. Contamination drawn into the

pump can cause internal damage and is not covered under warranty. Consult factory for recommendations as to the appropriate size and type of

strainer to use.

• High Pressure Filters for keeping fluid clean must be used.

Graymills can provide the filter to trap particles, scale and

contaminants to prevent costly damage. Filter collects up to

20 cu. in. of material (HPFB20) without pressure drop.

Available in 14" length single cartridge model (HPFB10) or

24" length dual cartridge model (HPFB20). All models are

304 stainless steel for use with water-soluble and corrosive

liquids. Reusable stainless steel cartridges available in 10, 50,

and 100 mesh.

OPERATION

CAUTION

• Before starting, pump must be primed (free of air)

and discharge valves partially open.

• Do not run pump dry; damage to mechanical seal

will result.

• Use a Check valve on plumbing if pump is mounted

horizontally or if the potential to lose prime can

occur.

• Do not run against closed nozzles or damage to

pump and piping will result. Use Bypass as

described below.

• Do not operate at or near zero flow.

• If operating at or below 8 GPM or

where valves may be opened and

closed periodically, you must use a

bypass. This kit (Bypass Kit

C-32450) installs in the side of the

discharge head and provides a fluid

bypass when the pump is operated

against a closed discharge thus

preventing excessive heat build-up

which will damage the pump.

• After stabilizing the system at

normal operating conditions, check

the piping. If necessary, adjust the

pipe supports.

• To ensure proper suction, fluid level should cover first two

impellers (5" from the suction end of the pump).

• Pump may be mounted horizontally with included horizontal

mounting bracket.

• If pump is not generating enough pressure or flow, see

“TROUBLESHOOTING GUIDE”.

MAINTENANCE

WARNING

Failure to disconnect and lockout electrical power

before attempting any maintenance can cause shock,

burns or death.

• Motors have permanently lubricated bearings. No lubrication

is possible or necessary. Follow the motor manufacturer’s

recommendations for maintenance.

• To REMOVE pump from service, drain all fluid from pump

and piping.

Figure 1

Bypass Kit Diagram

Loading...

Loading...