795-92152

07/16/08

Graymills

Model DH436R-A and DH536R-A Heated,

Drum-Mounted Recirculating Parts Cleaner

Operations and Maintenance Instructions

Be sure anyone operating this unit reads and understands all warnings and instructions. Keep this

manual available for reference/training.

SAFETY WARNINGS

You will find various types of safety information on the following pages and on the labels attached to Graymills equipment. The following

Safety Statements explain their meaning:

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid personal injury or

READ BEFORE OPERATING

death.

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if

not avoided, could result in minor or moderate injury.

CAUTION, without the safety alert symbol, is used to address practices not related to

personal injury.

• Use only AquateneTM 330 or Super AquateneTM 360

cleaning solution. Do NOT use solvents, gasoline,

etc., as they will create an extremely hazardous

situation.

• Do NOT contaminate cleaning fluid with any

flammable or combustible material such as gasoline,

alcohol, mineral spirits, etc. Drain parts to be cleaned

of any flammable material or combustible material

before cleaning. Even small quantities can create a

dangerous fire hazard.

Graymills Corporation – 3705 N. Lincoln Ave. / Chicago, IL 60613 – Phone: 773.477.4100 Fax: 773.477.8673 – www.graymills.com

• Never work with equipment you feel may be unsafe.

Contact your supervisor immediately if you feel a

piece of equipment is in unsafe condition.

• Cleaning solutions may be irritating to skin and eyes.

Always wear gloves, apron and safety glasses when

using. If splashed in eyes, flush thoroughly with

water and follow directions on cleaning solution

MSDS. See “USE OF INDUSTRIAL CLEANING

SOLUTIONS” on page 2.

• Install machine in a well ventilated area.

– 1

• The unit has been factory set to maintain an

approximate optimal temperature of 105°. Do NOT

attempt to change thermostat setting.

• This is a heated system. Always use caution when

first putting hand under liquid stream to prevent injury

from heated solution. If the liquid feels uncomfortably

hot, discontinue use, unplug machine and call

Graymills Customer Service.

• Failure to keep proper liquid level will result in

burning out the pump and heater coil, creating a

potential fire hazard. To help prevent this, this unit is

equipped with a low liquid level device which will shut

off the pump and heater. If solution stops circulating

and the red “RESET” light becomes illuminated,

immediately turn off and unplug unit. For instructions

on filling the reservoir, please see “INSTALLATION

AND OPERATION” steps 6 through 8.

DH436R Only

• After extended use, the gas-spring used to assist in

opening and closing the lid may lose its ability to keep

the lid open. At the first sign of this, replace the gasspring immediately.

• Automatic Safety Cover. Since certain soils may be

combustible, e.g., oils, greases, this unit is equipped

with a fusible safety link cover mechanism designed

to support the open cover at a slightly forward angle.

In the event of a fire, the fusible link will melt at 165ºF

permitting the cover to slam shut, limiting oxygen

supply to the fire.

• Do not leave the unit unattended with parts in the tank

which would prevent the cover from closing

completely in the event of a fire. Keep cover closed

when unit is not in use. If the fusible link breaks, do

not operate the unit until a replacement link is

installed.

• Turn pump and/or power off if unit is to be idle for

extended periods (overnight and weekends).

795-92152

07/16/08

POWER SUPPLY, WIRING AND

GROUNDING

• Failure to permanently ground the unit and controls

before connecting to electrical power can cause

shock, burns or death.

• Install ground and wiring according to local and

national electrical code requirements.

• Install a fused disconnect switch on all power legs

near the unit

• Disconnect and lockout electrical supply before

installing or servicing unit.

• Unit must be properly grounded to prevent electric

shock hazard. Connect only to three-prong outlet.

Should cord become cracked, frayed or damaged in

any way, it should be repaired/replaced immediately

by a qualified electrician. Never use an extension

cord. (See Spare Parts List)

• The full-load amperage draw for this machine is 12

amps.

USE OF INDUSTRIAL CLEANING

SOLUTIONS

• Always wear the recommended safety apparel and

glasses.

• Adequate ventilation should be provided when

operating this unit.

• When making an initial batch of cleaning solution or

when adding compound, follow cleaning solution’s

directions exactly.

• Industrial cleaning solutions may be irritating to some

individuals. Be certain to consult the MSDS for the

cleaning solution you are using before filling or using

parts washer.

• If splashed in the eyes, follow cleaning solution MSDS

instructions.

• If cleaning solution is splashed on clothing, remove

promptly and thoroughly wash any body areas which

have been in contact with solution. DO NOT permit

saturated clothing to remain in contact with skin.

Consult cleaning solution’s MSDS instructions.

• Clean up fluid spills immediately. Cleaning solutions

can create a slippery surface and could damage floor

coverings or painted surfaces.

• Graymills strongly recommends that federal, state and

local authorities be consulted before proceeding with

discarding and handling of used materials. Graymills

Corporation accepts no responsibility for user’s

failure to comply with regulations.

• For best results, Graymills’ recommends using only

Aquatene

Graymills Corporation – 3705 N. Lincoln Ave. / Chicago, IL 60613 – Phone: 773.477.4100 Fax: 773.477.8673 – www.graymills.com

TM

330 or Super AquateneTM 360.

– 2

MACHINE INSTALLATION AND OPERATION

1. Place unit on a smooth, level surface in a well ventilated area.

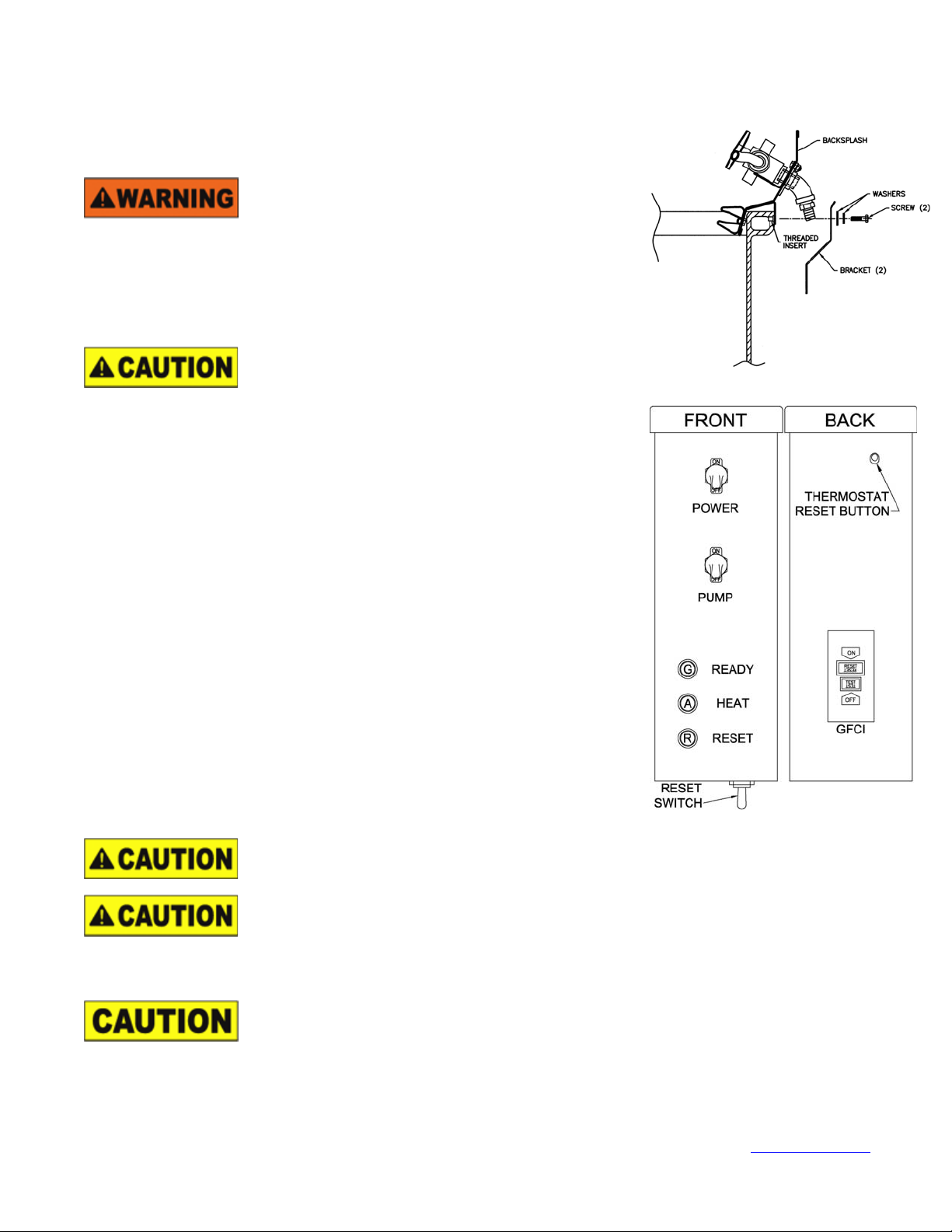

2. Install backsplash as show to the right (DH536R only).

3. Read all warnings posted on machine.

4. Inspect electrical control box, cord and plug for wear or damage.

795-92152

07/16/08

Do not use machine or add fluid if any wear or damage is noticed until impaired

components are repaired or replaced.

5. Install filter cartridge:

a. Unscrew filter cartridge bowl.

b. Remove clear plastic packaging from filter cartridge. Remove and discard BIO-

POUCH from hollow center of cartridge.

c. Install new filter cartridge in the cartridge bowl.

d. Re-attach filter cartridge bowl to filter body.

Be sure electrical cord is unplugged and cleaning solution and heater co il is cool

before adding cleaning solution or performing any maintenance.

6. Remove center sink drain (stainless steel strainer basket, mesh strainer assembly).

7. Add 30-gallons of Aquatene

reservoir tank.

8. Put center sink drain assembly back into sink drain opening.

9. Plug power cord into properly grounded 115V, 15 amp circuit. Full load amp-draw of unit

is 12 amps.

10. Press TEST button on GFCI on rear of control (right) to ensure switch is operating

properly. Press RESET button on GFCI to prepare unit for operation.

11. Air pump will begin operation immediately upon power being app lied to the machine and

the red “RESET” light will illuminate.

12. Toggle RESET switch located under the electrical box to begin operation. If the unit has

an adequate level of cleaning solution in the tank, the green “READY” light will illuminate

and the red “RESET” light will extinguish.

13. The amber “HEAT” light indicates power to the heater.

14. If cleaning solution is not at the appropriate temperature and heat is required you should

hear the thermostat engage with a “CLICK” and the amber “HEAT” light will illuminate.

Should this not happen, press the red thermostat reset button on the rear of the control

box (right). Should this problem persist: unplug machine and call factory.

15. When the unit reaches its predetermined temperature, the “HEAT” light will extinguish,

indicating the cleaning solution is at the proper temperature to obtain maximum cleaning

efficiency. For maximum cleaning efficiency, allow heater to warm solution for 2 to 4

hours before use.

16. To operate the fluid pump, toggle PUMP switch on front of electrical box to the “ON”

position.

17. For fluid via the flexible hose turn the directional valve counterclockwise to the left.

18. For fluid via the flow-thru brush turn the directional valve clockwise to the right.

When not in use return flow-thru brush to brush clip holder to holder to avoid obstructing lid closure (DH436R only).

TM

330 or Super AquateneTM 360 solution to the base

Backsplash Assembly for DH536R-A

Operator Interface

DH436R-A and DH536R-A

Front and Back

19. Failure to keep proper liquid level will result in burning out the pump and heater coil, creating a potential fire hazard. To

prevent this, this unit is equipped with a low liquid level device which will shut off the pump and heater. If solution stops circulating

and the red “RESET” light becomes illuminated, immediately turn off and unplug unit. Follow steps 6 through 8 above for

instructions on refilling unit.

20. When finished, turn pump off and close lid to minimize liquid loss due to evaporation (DH436R only).

Graymills Corporation – 3705 N. Lincoln Ave. / Chicago, IL 60613 – Phone: 773.477.4100 Fax: 773.477.8673 – www.graymills.com

– 3

RECOMMENDED NORMAL MAINTENANCE

795-92152

07/16/08

Be sure electrical cord is unplugged and cleaning solution and heater coil is cool before performi ng any maintenance.

1. Check fluid level in unit daily.

2. Due to evaporation and drag-out, fluid should be topped off with Aquatene

needed.

3. Inspect strainer basket daily. Remove and dispose of solid waste accumulation. To assure proper drainage rinse out vapor barrier

filter daily.

4. Check operation of liquid level control. Make sure that float switch moves freely up and down.

5. Unit is equipped with a blue temperature-sensitive label on the front of the reservoir. When solution is heated, the temperature

change will cause the label to change from blue to pink. The change will occur only at or below the liquid level, allowing the level to

be determined without having to look through the drain or remove the sink.

When control assembly is removed from reservoir, care must be taken not to damage components.

6. Inspect heating coil monthly, remove any deposits or build up with a soft wire brush.

Deposits and build up can cause premature failure of the heating coil.

7. Filter cartridge will require periodic replacement depending on the volume and types of soils involved. A significant reduction in the

flow through the flexible hose signals the need to replace the cartridge (see RECOMMENDED ANNUAL MAINTENANCE). Order

replacement cartridges, part number BIOFL1, from either your Graymills distributor or the factory.

8. After extended use, the gas spring used to assist in opening and closing the lid on model DH436R may lose its ability to keep the

lid open. At the first sign of this, replace the gas spring immediately. Order part number 765-09631.

TM

330 or Super AquateneTM 360 cleaning solution as

RECOMMENDED ANNUAL MAINTENANCE

Graymills recommends that the entire system be inspected and cleaned annually. To perform this maintenance:

Be sure electrical cord is unplugged and cleaning solution and heater coil is cool before performi ng any maintenance.

1. Remove sink drain filters and rinse.

2. Clean filter cartridge assembly:

a. Unscrew filter cartridge bowl.

b. Pour liquid from filter bowl into reservoir.

c. Remove filter cartridge and di spose of in proper manner.

d. Remove clear plastic packaging from filter cartridge. Remove and discard BIO-POUCH from hollow center of cartridge.

e. Install new filter cartridge in the cartridge bowl.

f. Re-attach filter cartridge bowl to filter body.

3. Unscrew sink hold downs.

4. Lift sink straight up until mounting ring clears reservoir and set to the side.

5. Lift off control assembly being careful not to damage heater, float switch or pump.

When control assembly is removed from reservoir, care must be taken not to damage components.

6. Visually inspect pump, pump inlet filter, heater float switch, and tubing for damage or wear.

7. Replace all parts as necessary. Make sure all “tie-offs” for pump, heater and float switch are still in place insuring proper separation

and alignment of these components.

8. Clean excess accumulation off heater coil with a soft wire brush.

9. Inspect surface of cleaning solution and skim to remove any oil or debris.

10. Pump cleaning solution into acceptable container for future reuse.

11. Rinse inside of reservoir tank with clean water.

12. Refill reservoir tank with saved solution from step 10.

13. If necessary, top-off cleaning solution with enough fresh of Aquatene

reservoir up to 30-gallon mark.

14. Replace control assembly and sink.

15. Follow steps 8 through 12 in MACHINE INSTALLATION AND OPERATION to complete annual maintenance.

Save this manual for future training. Do not allow operation without reading and understanding these instructions.

TM

330 or Super AquateneTM 360 cleaning solution to bring

Graymills Corporation – 3705 N. Lincoln Ave. / Chicago, IL 60613 – Phone: 773.477.4100 Fax: 773.477.8673 – www.graymills.com

– 4

TROUBLESHOOTING

Problem Probable Cause Suggested Remedy

Machine unplugged Plug machine into appropriate wall socket

No Machine Function

Heat Not Working

Red “RESET” Light ON

Little or No Fluid Flow

If your problem is not listed above or problems persist, please contact Graymills for further assistance. 1-888-472-9645

GFCI tripped Press RESET button on GFCI

No power at outlet Consult plant electrician

Thermostat tripped Press red thermostat reset button

Heater malfunction Contact Graymills for more information 1-888-472-9645

Heater coil dirty Clean heater coil (see Recommended Maintenance)

Machine needs to be reset Toggle RESET switch

Low solution level Add cleaning solution

Float sensor or control relay

malfunction

Valve shut off Turn valve fully to the left or right to open valve

Clogged filter Replace filter cartridge (Part #BIOFL1)

Cracked or broken hose Inspect and replace hose (See parts list)

Contact Graymills for more information 1-888-472-9645

795-92152

07/16/08

Graymills Corporation – 3705 N. Lincoln Ave. / Chicago, IL 60613 – Phone: 773.477.4100 Fax: 773.477.8673 – www.graymills.com

– 5

795-92152

07/16/08

DRAWINGS AND PARTS LISTS

DH436R-A

DH536R-A

Graymills Corporation – 3705 N. Lincoln Ave. / Chicago, IL 60613 – Phone: 773.477.4100 Fax: 773.477.8673 – www.graymills.com

REF DESCRIPTION PART NO.

Complete Electrical Control Ass’y 457-40313

Toggle Switch (Pump) 770-09192

Toggle Switch (Reset) 770-92011

Toggle Switch Boot 770-08481

Indicator Light – Green 772-92079

Indicator Light – Amber 772-92078

Indicator Light – Red 772-92080

GFCI – 115V 777-09499

Float Switch 770-90167

Heater 780-90166

Pump 390-09663

Tube Bulkhead Compression Fitting 735-91249

¼” Air Tubing 729-90678

8’ Power Cord and Plug 777-04152

Relay 782-92066

Relay Socket 782-92126

Rubber Condensation Guard 744-37878

Electrical Control Assembly Components (Not Shown)

Polyurethane Foam Filter 742-90883

3/8” Trim Bulb 603-37983

15 Tank 727-37995-GRAY

16 Drum 727-37883-GRAY

17 Ring 727-37995R-GRAY

18 Black Neoprene Hose 729-90327

19 Lockline Adapter 728-90796

20 Gripper Clip 769-90170

Items common to both the DH436R-A and the DH536R-A

21 3-Way Fluid Valve 738-90795

22 Flex Hose and Nozzle Assembly 728-90951

23 Strainer 715-26971-81

24 Vapor Barrier 742-90144

25 Filter Cup 742-34222-81

26 Ring Mounting Thumb Screws 753-04325-81

27 Flow-Thru Brush with Hose 749-09925

28 Filter Housing 742-90186

29 Filter Cartridge BIOFL1

30 Filter O-Ring 744-90187

31 Lid 727-34157-GRAY

32 Gas Spring Assembly 765-09361

33 Fuse Link Assembly Bracket 432-34800-81

Only

34 Linkage Bracket 435-39511-81

DH436R-A

35 Fuse Link Assembly 451-23482

N/A DH536R-A Backsplash Assembly 402-38092

– 6

ELECTRICAL SCHEMATIC

795-92152

07/16/08

WARRANTY INFORMATION

Graymills Corporation warrants that the equipment manufactured and delivered, when properly installe d and mai ntained, shall b e

free from defects in workmanship and will function as qu oted in the published specification. Graymills does not warrant process

performance, nor assume any liability for equipment selection, adaptation, or installation.

Warranty does not apply to damages or defects caused by shipping, operator carelessness, misuse, improper applic ation or installation,

abnormal use, use of add-on-parts or equipment which damages or impairs the proper function of the unit, and modifi cations made to

the unit. Warranty does not apply to expendable parts needing replacement periodically due to normal wear and tear.

A new Warranty period shall not be established for repaired or replaced materials or products. Such items shall remain under Warranty

for only the remainder of the Warranty period of the original material or product.

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, WHETHER ORAL, WRITTEN, EXPRESSED,

IMPLIED OR STATUTORY. GRAYMILLS CORPORATION MAKES NO OTHER WARRANTY OF ANY KIND, EXPRESS OR

IMPLIED. ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED

THE AFORESTATED OBLIGATION ARE HEREBY DISCLAIMED BY GRAYMILLS CORPORATION AND EXCLUDED FROM THIS

SALE. Graymills warranty obligations and Buyer remedies (except to title), are solely and exclusivel y stated herein. In no case will

Graymills be liable for consequential damages, loss of production, or any other loss incurred due to interruption of service.

Graymills' obligation under this Warranty shall be limited to:

1. Repairing or replacing (at Graymills sole discretion) any non-conforming or defective component within one year from

the date of shipment from Graymills.

2. Repairing or replacing (at Graymills sole discretion), components supplied by, but not manufactured by Graymills, to

the extent of the warranty given by the original manufacturer.

Buyer must give Graymills prompt notice of any defect or failure.

If you believe you have a Warranty claim, contact Graymills at (773) 248-6825. Any return material must have an RMA number on

the outside of the package and shipping prepaid or shipment will be refused. Graymills will promptly examine the material and

determine if it is defective and within the Warranty period.

Graymills Corporation – 3705 N. Lincoln Ave. / Chicago, IL 60613 – Phone: 773.477.4100 Fax: 773.477.8673 – www.graymills.com

– 7

Loading...

Loading...