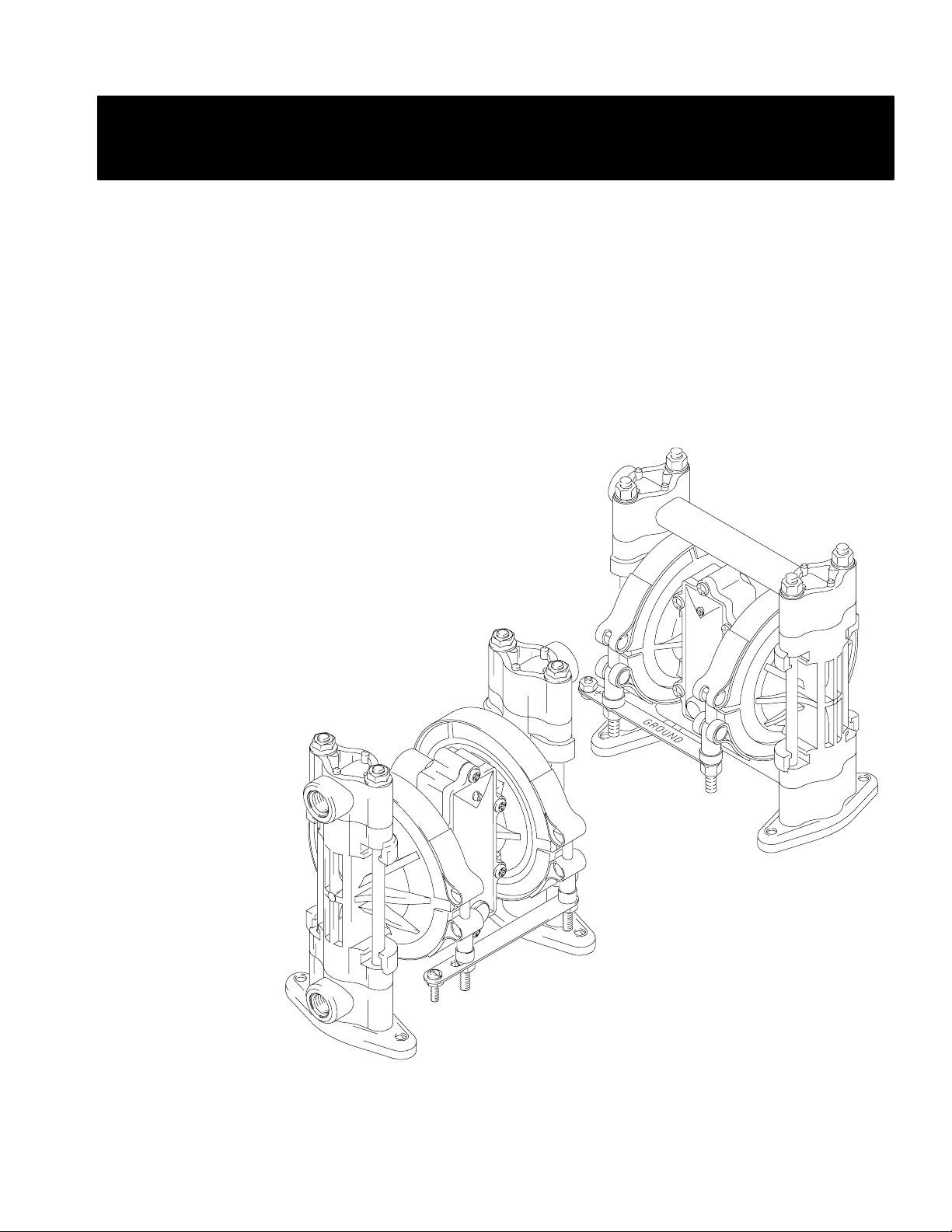

Graymills DDP-375 User Manual

Graymills

POLYPROPYLENE

Air Operated

Double Diaphragm Pumps

3/8" Model

Operations and Maintenance Instructions

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure

795–90857

GM 6–02

Polypropylene Pumps, Series E

US and Foreign Patents Pending

WARNING/CAUTIONS

Read all these SAFETY INSTRUCTIONS

BEFORE installing or using this equipment. Keep this manual handy for reference/training.

Graymills Corporation 3705 N. Lincoln Avenue Chicago, Illinois 60613

773/248–6825 FAX 773/477–8673 www.graymills.com

Table of Contents

Safety Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service

Replacing the Air Valve 16. . . . . . . . . . . . . . . . . . . . . . .

Repairing the Air Valve 18. . . . . . . . . . . . . . . . . . . . . . .

Ball Check Valves 21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diaphragm Repair 23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Charts 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graymills Standard Warranty 32. . . . . . . . . . . . . . . . . . . . .

Graymills Information 32. . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious injury or

death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to or

destruction of equipment if you do not follow the instructions.

Safety Alert Symbol

SAFETY ALERT

The safety Alert Symbol means ATTENTION! BECOME

ALERT! YOUR SAFETY IS INVOLVED!

WARNING

HAZARDOUS FLUIDS

Improper handling of hazardous fluids or inhaling toxic vapors can cause extremely serious injury or death

from splashing in the eyes, ingestion, or bodily contamination. Observe all the following precautions when

you handle hazardous or potentially hazardous fluids.

D Know what fluid you are pumping and its specific hazards. Take precautions to avoid a toxic fluid spill.

D Always wear appropriate clothing and equipment, such as eye protection and breathing apparatus, to

protect yourself.

D Store hazardous fluid in an appropriate, approved container. Dispose of it according to all Local, State,

and Federal guidelines for hazardous fluids.

D Secure the fluid outlet hose tightly into the receiving container to prevent it from coming loose and

improperly draining the fluid.

D Pipe and dispose of the exhaust air safely, away from people, animals, and food handling areas. If the

diaphragm fails, the fluid is exhausted along with the air. See Air Exhaust Ventilation on page 10.

D Use static wire hoses when pumping flammables.

D Keep containers closed when not in use.

2

WARNING

EQUIPMENT MISUSE HAZARD

Any misuse of the equipment or accessories, such as overpressurizing, modifying parts, using incompatible

chemicals and fluids, or using worn or damaged parts, can cause them to rupture and result in splashing in

the eyes or on the skin, other serious injury, or fire, explosion or property damage.

D This equipment is for professional use only. Observe all warnings. Read and understand all instruction

manuals, warning labels, and tags before you operate this equipment. If you are not sure, or if you have

questions about installation or operation, call Graymills Corporation.

D Never alter or modify any part of this equipment; doing so could cause it to malfunction.

D Check all equipment regularly and repair or replace worn or damaged parts immediately.

D Never exceed the recommended working pressure or the maximum air inlet pressure stated on your pump

or in the Technical Data on page 4.

D Do not exceed the maximum working pressure of the lowest rated component in your system. This

equipment has a 100 psi (0.7 MPa, 7 bar) maximum working pressure at 100 psi (0.7 MPa, 7 bar, )

maximum incoming air pressure.

D Be sure that all fluids and solvents used are chemically compatible with the wetted parts shown in the

Technical Data on page 4. Always read the manufacturer’s literature before you use fluid or solvent in

the pump.

D Never move or lift a pump under pressure. If dropped, the fluid section may rupture. Always follow the

Pressure Relief Procedure on page 11 before you move or lift the pump.

FIRE AND EXPLOSION HAZARD

Static electricity is created by the flow of fluid through the pump and hose. If the equipment is not properly

grounded, sparking may occur. Sparks can ignite fumes from solvents and the fluid being pumped, dust

particles, and other flammable substances, whether you are pumping indoors or outdoors, and can cause a

fire or explosion and serious injury and property damage.

D To reduce the risk of static sparking, ground the pump and all other equipment used or located in the

work area. Check your local electrical code for detailed grounding instructions for your area and type of

equipment. See Grounding on page 6.

D If you experience any static sparking or even a slight shock while using this equipment, stop pumping

immediately. Check the entire system for proper grounding. Do not use the system again until you have

identified and corrected the problem.

D Pipe and dispose of the exhaust air safely, away from all sources of ignition. If the diaphragm fails, the

fluid is exhausted along with the air. See Air Exhaust Ventilation on page 10.

D Do not smoke in the work area. Do not operate the equipment near a source of ignition or an open flame,

such as a pilot light.

3

SAFETY PRECAUTIONS

CAUTION

D Verify the chemical compatibility of the pump wetted parts and the substance being pumped, flushed or

recirculated. Chemical compatibility may change with temperature and concentration of the chemical(s)

within the substance being pumped, flushed or recirculated.

D The pump should not be used for the structural support of the piping system. Be certain system compo-

nents are properly supported to prevent stress on the pump parts.

D Do not allow pump to operate dry for long periods of time; this may cause unnecessary wear or damage

to the pump.

D Maximum temperature limits are based upon mechanical stress only. Certain chemicals will significantly

reduce maximum safe operating temperatures. Consult Graymills for chemical compatibility and temperature limits.

United States Government safety standards have been adopted under the Occupational Safety and Health Act. You should

consult these standards—particularly the General Standards, Part 1910, and the Construction Standards, Part 1926.

Technical Data For Pumps with Teflonr Diaphragms

Maximum fluid working pressure 100 psi (0.7 MPa, 7 bar). . . . . .

Air pressure operating range . . . 20 to 100 psi (0.14 to 0.7 MPa, .

1.4 to 7 bar ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum air consumption 5.5 scfm (see chart). . . . . . . . . . . . . .

Maximum free flow delivery 6.5 gpm (24.6 lpm). . . . . . . . . . . . .

Maximum pump speed 330 cpm. . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum suction lift 7 ft (2.1 m) dry, 12 ft (3.7 m) wet. . . . . . . .

Maximum size pumpable solids 1/16 in. (1.6 mm). . . . . . . . . . . .

Sound power level,

at full flow at 100 psi (0.7 MPa, 7 bar) 85 dBa. . . . . . . . . . . . .

Sound power level,

at 70 psi (0.48 MPa, 4.8 bar) and 1 gpm (3.8 lpm) 78 dBa. . .

Operating temperature range 40 to 150_ F (4.4 to 65.5_ C). . . . . . . .

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4 npt(f)

Fluid inlet and outlet size . . . . . . . . . . . . . . . . . . . 3/8” npt(f)

Wetted parts vary by models See pages 28 and 30. . . . . . .

Non-wetted external parts polyester (labels) glass–filled. .

polypropylene with conductive SST fibers

Weight (approximate) . . . . . . . . . . . . . 4.75 lb (2.2 kg). . . . .

Sound power level measured per ISO standard 9614–2.

VitonR, Teflon

DuPont Co.

Loctite

r is a registered trademark of the Loctite Corporation.

Santoprener is a registered trademark of the Monsanto Company.

Technical Data For Pumps with Hytrelr Diaphragms

Maximum fluid working pressure . . . . 100 psi (0.7 MPa, 7 bar)

Air pressure operating range . . . . 20 to 100 psi(0.14 to 0.7 MPa,

. . . . . . . . . . . . . . . . . . 1.4 to 7 bar). . . . . . . . . . . . . . . . . . . . . . .

Maximum air consumption . . . . . . . . . . . . 5.5 SCFM (see chart)

Maximum free flow delivery . . . . . . . . . . . . . 7 gpm (26.5 lpm)

Maximum pump speed . . . . . . . . . . . . . . . . . . . . . 330 cpm. . . .

Maximum suction lift 12 ft (3.7 m) dry; 21 ft (6.4 m) wet. . . . .

Maximum size pumpable solids . . . . . . . . . . . .1/16 in. (1.6 mm)

Sound power level,

at full flow at 100 psi (0.7 MPa, 7 bar) . . . . . . . . . . . . . 85

dBa

Sound power level,

at 70 psi (0.48 MPa, 4.8 bar) and 1 gpm (3.8 lpm) . . 78 dBa

Operating temperature range. 40 to 150_ F (4.4 to 65.5_ C)

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4 npt(f)

Fluid inlet and outlet size. . . . . . . . . . . . . . . . . . . . .3/8 npt(f)

Wetted Parts vary by model. . . . . . . . . See pages 27 and NO TAG.

Non-wetted external parts polyester (labels) glass–filled. .

polypropylene with conductive SST fibers

Weight (approximate) . . . . . . . . 4.75 lb (2.2 kg). . . . . . . . . . . . .

Sound power level measured per ISO standard 9614–2.

VitonR, Teflon

DuPont Co.

Loctiter is a registered trademark of the Loctite Corporation.

Santoprene

pany.

r, and Hytrelr are registered trademarks of the

r, and Hytrelr are registered trademarks of the

r is a registered trademark of the Monsanto Com-

4

Installation

General Information

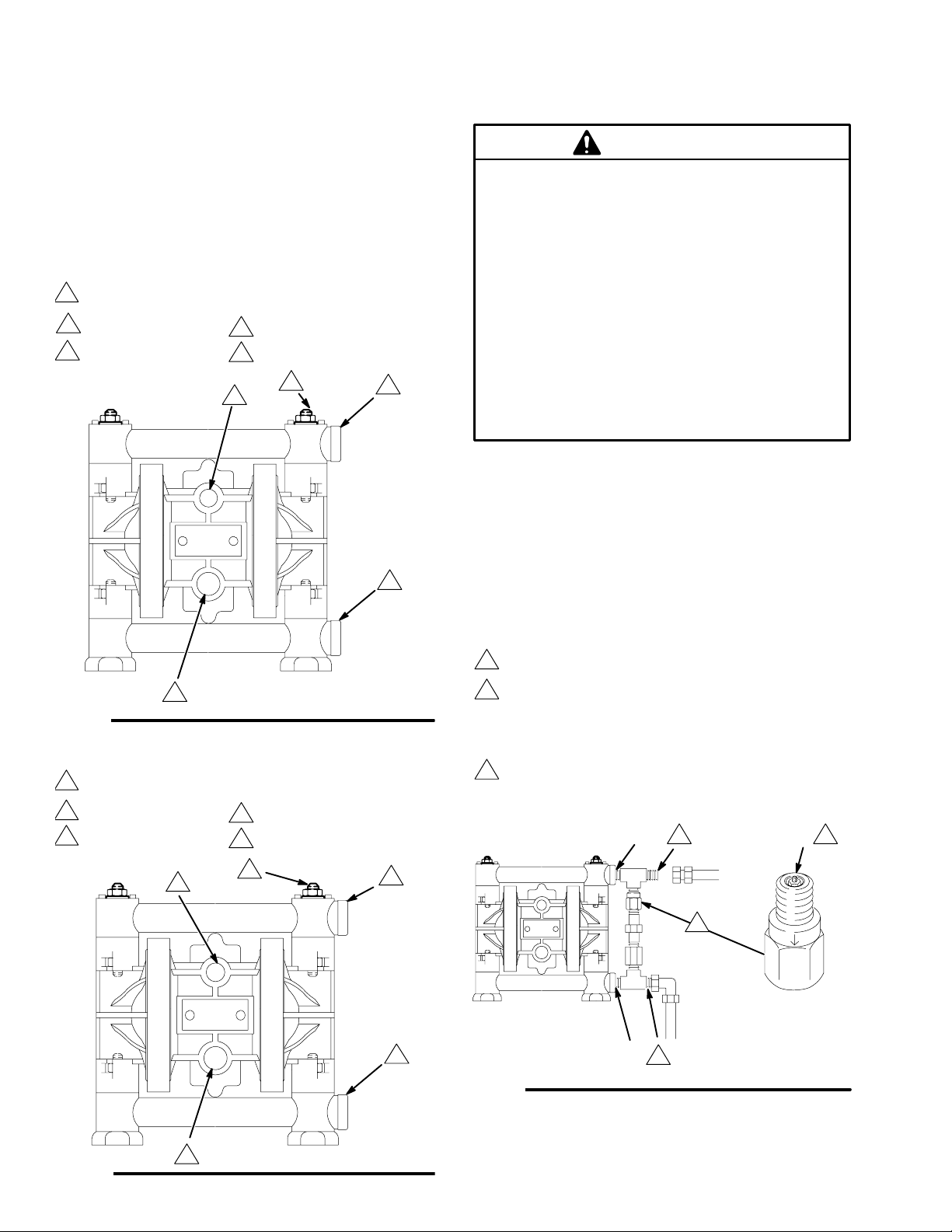

D The Typical Installations in Fig. 5 to Fig. 7 are only

guides for selecting and installing system components.

Contact your Graymills distributor for assistance in

planning a system to suit your needs.

D Always use Genuine Graymills Parts and Accessories,

available from your Graymills distributor. If you supply

your own accessories, be sure they are adequately sized

and pressure rated for your system.

D Use a compatible, liquid thread sealant or Teflonr tape

on all male threads. Tighten all connections firmly to

avoid air or fluid leaks. Do not over-

tighten plastic threads.

D Reference numbers and letters in parentheses refer to

the callouts in the Figures and lists on pages 27 to 28.

CAUTION

Safe Operating Temperature

Minimum: 40_F (4.4_C); Maximum: 150_F (66_C).

Operating outside these temperature limits will

adversely affect the strength of the pump housing.

Certain chemicals may further reduce the operating

temperature range. Consult engineering guides for

chemical compatibilities and temperature limits, or

contact your Graymills distributor.

Tightening Threaded Fasteners Before

First Use

After unpacking the pump, and before using it for the first

time, check and retorque all external fasteners. See the

Service section for torque specifications. After the first

day of operation, retorque the fasteners again. Although

the recommended frequency for retorquing fasteners varies

with pump usage, a general guideline is to retorque fasteners every two months.

Mountings

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause

serious injury or death if splashed in the

eyes or on the skin, inhaled, or swallowed.

1. Read HAZARDOUS FLUIDS on page 2.

2. Use fluids and solvents which are compatible with

the equipment wetted parts. Refer to the Technical

Data section of all equipment manuals. Read the

fluid and solvent manufacturer’s warnings.

D Be sure the mounting can support the weight of the

pump, hoses, and accessories, as well as the stress

caused during operation.

D The pump can be used in a variety of installations, some

of which are shown in Fig. 5 to Fig. 7.

D For all other mountings, be sure the pump is adequately

secured.

Dual Manifolds

Dual manifold kits are available to enable you to pump two

fluids simultaneously, or to mix two fluids in the pump.

5

Installation

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

This pump must be grounded. Before operating the pump, ground the system as

explained at right. Also read the section

FIRE AND EXPLOSION HAZARD on

page 3.

The polypropylene pump is not conductive.

When pumping conductive flammable fluids, always

ground the entire fluid system by making sure the fluid

system has an electrical path to a true earth ground (see

Fig. 5 through Fig. 7). Never use a polypropylene pump

with non-conductive flammable fluids as specified by

your local fire protection code.

US Code (NFPA 77 Static Electricity) recommends a

conductivity greater than 50 x 10

(mhos/meter) over your operating temperature range to

reduce the hazard of fire. Consult your fluid supplier to

determine the conductivity or resistivity of your fluid.

The resistivity must be less than 2 x 1012 ohm-centimeters.

–12

Siemans/meter

Ground all of this equipment:

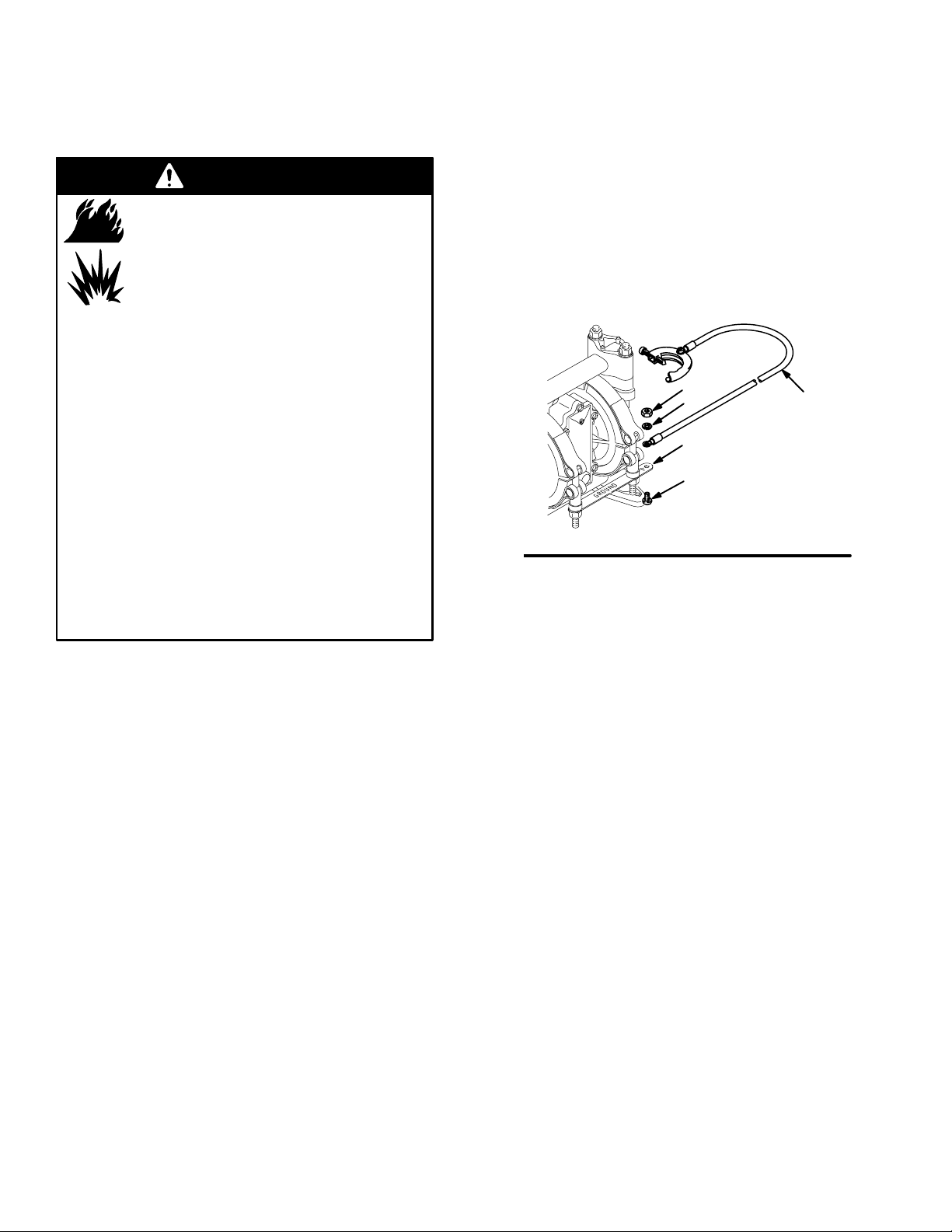

D Pump: Attach a ground wire (Y) to the grounding strip

(112) with the screw (28), lockwasher (29) and nut (27),

as shown in Fig. 1. Connect the clamp end of the

ground wire to a true earth ground.

NOTE: When pumping conductive flammable fluids with

a polypropylene pump, always ground the fluid system. See

the WARNING at left. Fig. 5 through Fig. 7 show recom-

mended methods of grounding flammable fluid containers

during filling.

27

29

112

28

Fig. 1

D Air and fluid hoses: Use only electrically conductive

hoses.

Y

01432B

To reduce the risk of static sparking, ground the pump and

all other equipment used or located in the pumping area.

Check your local electrical code for detailed grounding

instructions for your area and type of equipment.

D Air compressor: Follow the manufacturer’s recommen-

dations.

D Solvent pails used when flushing: Follow your local

code. Use only metal pails, which are conductive. Do

not place the pail on a non-conductive surface, such as

paper or cardboard, which interrupts the grounding

continuity.

D Fluid supply container: Follow your local code.

6

Installation

Air Line

WARNING

A bleed-type master air valve (B) is required in your

system to relieve air trapped between this valve and the

pump. See Fig. 5 to Fig. 7. Trapped air can cause the

pump to cycle unexpectedly, which could result in

serious injury, including splashing in the eyes or on the

skin, injury from moving parts, or contamination from

hazardous fluids.

CAUTION

The pump exhaust air may contain contaminants.

Ventilate to a remote area if the contaminants could

affect your fluid supply. See Air Exhaust Ventilation

on page 10.

1. Install the air line accessories as shown in Fig. 5 to Fig.

7. Mount these accessories on the wall or on a bracket.

Be sure the air line supplying the accessories is grounded.

a. The fluid pressure can be controlled in either of

two ways. To control it on the air side, install an

air regulator (H). To control it on the fluid side,

install a fluid regulator (M) near the pump fluid

outlet (see Fig. 5).

Fluid Suction Line

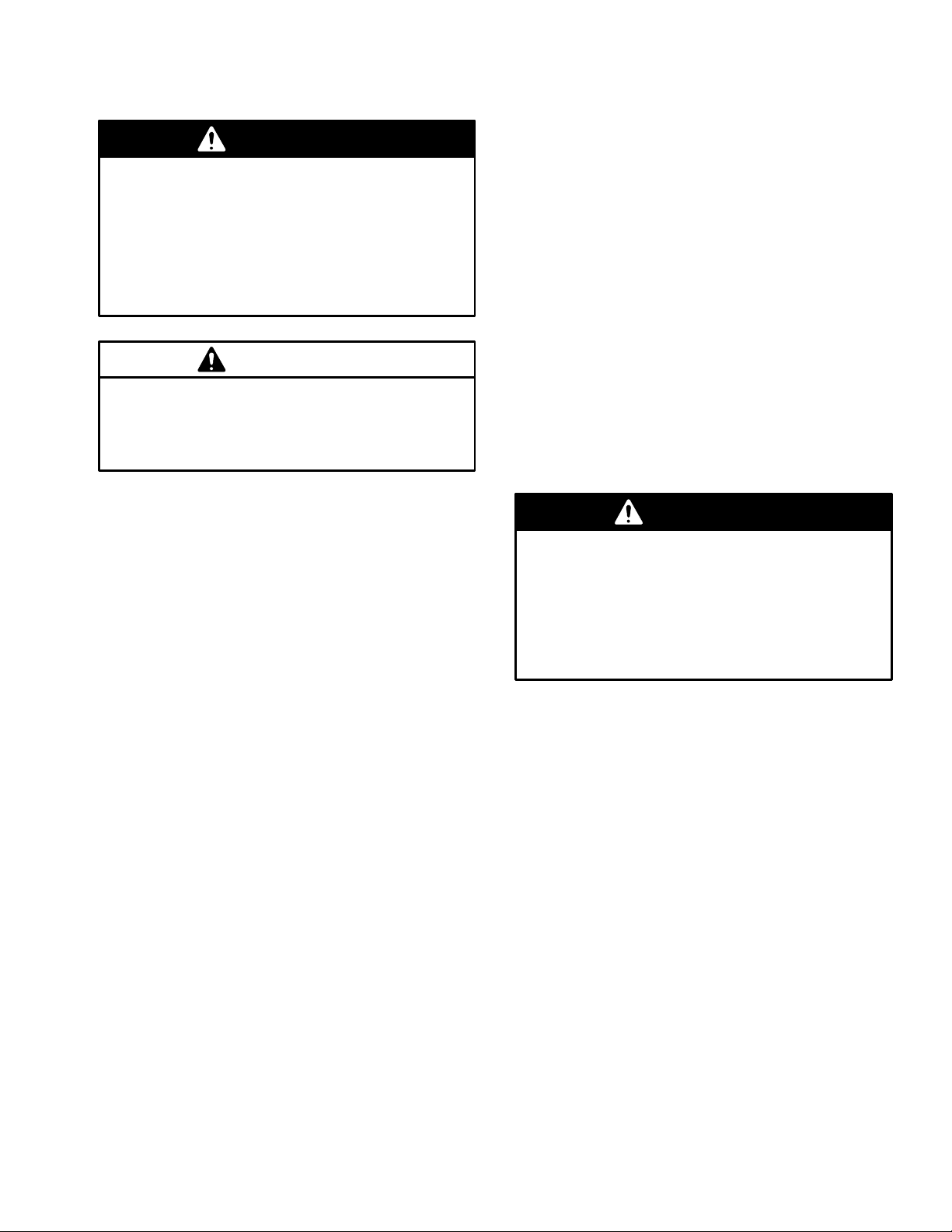

D The pump fluid inlet is 3/8 npt(f). See Fig. 2. Screw the

fluid fitting into the pump inlet snugly. Use a compatible liquid thread sealant or TeflonR tape on connections to prevent air from getting into material line.

D At inlet fluid pressures greater than 15 psi (0.1 MPa,1

bar), diaphragm life will be shortened.

D See the Technical Data on page 4 for maximum suction

lift and flow rate loss at various lift distances.

Fluid Outlet Line

WARNING

A fluid drain valve (J) is required in your system to

relieve pressure in the hose if it is plugged. See Fig. 5

to Fig. 7. The drain valve reduces the risk of serious

injury, including splashing in the eyes or on the skin, or

contamination from hazardous fluids when relieving

pressure. Install the valve close to the pump fluid

outlet.

b. Locate one bleed-type master air valve (B) close

to the pump and use it to relieve trapped air. See

the WARNING above. Locate the other master air

valve (E) upstream from all air line accessories

and use it to isolate them during cleaning and

repair.

c. The air line filter (F) removes harmful dirt and

moisture from the compressed air supply.

2. Install an electrically conductive, flexible air hose (C)

between the accessories and the 1/4 npt(f) pump air

inlet (see Fig. 2). Use a minimum 1/4” (6.3 mm) ID air

hose. Screw an air line quick disconnect coupler (D)

onto the end of the air hose (C), and screw the mating

fitting into the pump air inlet snugly. Do not connect

the coupler (D) to the fitting yet.

D Use electrically conductive fluid hoses (N). The pump

fluid outlet is 3/8 npt(f). See Fig. 2. Screw the fluid

fitting into the pump outlet snugly.

D Install a fluid regulator (M) at the pump fluid outlet to

control fluid pressure, if desired (see Fig. 6). See Air

Line, step 1a, for another method of controlling pressure.

D Install a fluid drain valve (J) near the fluid outlet. See

the WARNING above.

7

Installation

Changing the Orientation of the Fluid Inlet

and Outlet Ports

The pump is shipped with the fluid inlet and outlet ports

facing the same direction. See Fig. 2. If desired, the direction of one or both ports can be changed. Remove the

manifold(s) from the pump as explained in steps 1, 2, and 4

on page 21. Reattach with the port facing the desired

direction. Do not over-torque.

Apply thread lube, and torque to 50 to 60 in-lb (5.6

1

to 6.8 N-m). Do not over-torque.

2

1/4 npt(f) air inlet

3

3/8 npt(f) fluid inlet

4

3/8 npt(f) fluid outlet

5

3/8 npt(f) air exhaust port

2

1

4

Fluid Pressure Relief Valve

CAUTION

Some systems may require installation of a pressure

relief valve at the pump outlet to prevent overpressurization and rupture of the pump or hose. See Fig. 4.

Thermal expansion of fluid in the outlet line can cause

overpressurization. This can occur when using long

fluid lines exposed to sunlight or ambient heat, or when

pumping from a cool to a warm area (for example,

from an underground tank).

Overpressurization can also occur if the Husky pump is

being used to feed fluid to a piston pump, and the

intake valve of the piston pump does not close, causing

fluid to back up in the outlet line.

5

Fig. 2

Pump Shown

Apply thread lube, and torque to 50 to 60 in-lb (5.6

1

to 6.8 N-m). Do not over-torque.

2

1/4 npt(f) air inlet

3

3/8 npt(f) fluid inlet

2

4

3/8 npt(f) fluid outlet

5

3/8 npt(f) air exhaust port

1

01459B

KEY

3

A 3/8 npt(f) fluid inlet port

B 3/8 npt(f) fluid outlet port

C Pressure relief valve

Part No. 110134 (aluminum)

Part No. 112119 (stainless steel)

1

Install valve between fluid inlet and outlet ports.

2

Connect fluid inlet line here. Use a compatible

liquid thread sealant or TeflonR tape on connection to prevent air from getting into the

material line.

3

Connect fluid outlet line here.

B 1

3

4

1

C

Fig. 3

8

3

Fig. 4

5

01459B

A

2

01539B

Installation

BUNG-MOUNT TRANSFER INSTALLATION

KEY

A 3/8” Diaphragm Pump

B Bleed-Type Master Air

Valve

(required for pump)

C Air Supply Line

D Air Line Quick Discon-

nect

E Master Air Valve (for

accessories)

F Air Line Filter

E

F

H Pump Air Regulator

J Fluid Drain Valve (required)

L Fluid Suction Line

M Fluid Inlet Filter

N Fluid Supply Hose

Y Ground Wire (required; see

page 6

for installation instructions)

H

B

C

N

D

A

M

WALL-MOUNT TRANSFER INSTALLATION

KEY

A 3/8” Diaphragm Pump

B Bleed-Type Master Air

Valve

(required for pump)

C Air Supply Line

D Air Line Quick Discon-

nect

E Master Air Valve (for

accessories)

F Air Line Filter

E

H Pump Air Regulator

J Fluid Drain Valve

(required)

L Fluid Suction Line

N Fluid Supply Hose

S Wall Bracket

T Bung Adapter

Y Ground Wire (required;

see page 6

for installation instructions)

H

F

B

C

D

A

J

L

T

Y

N

J

L

Y

Fig. 5

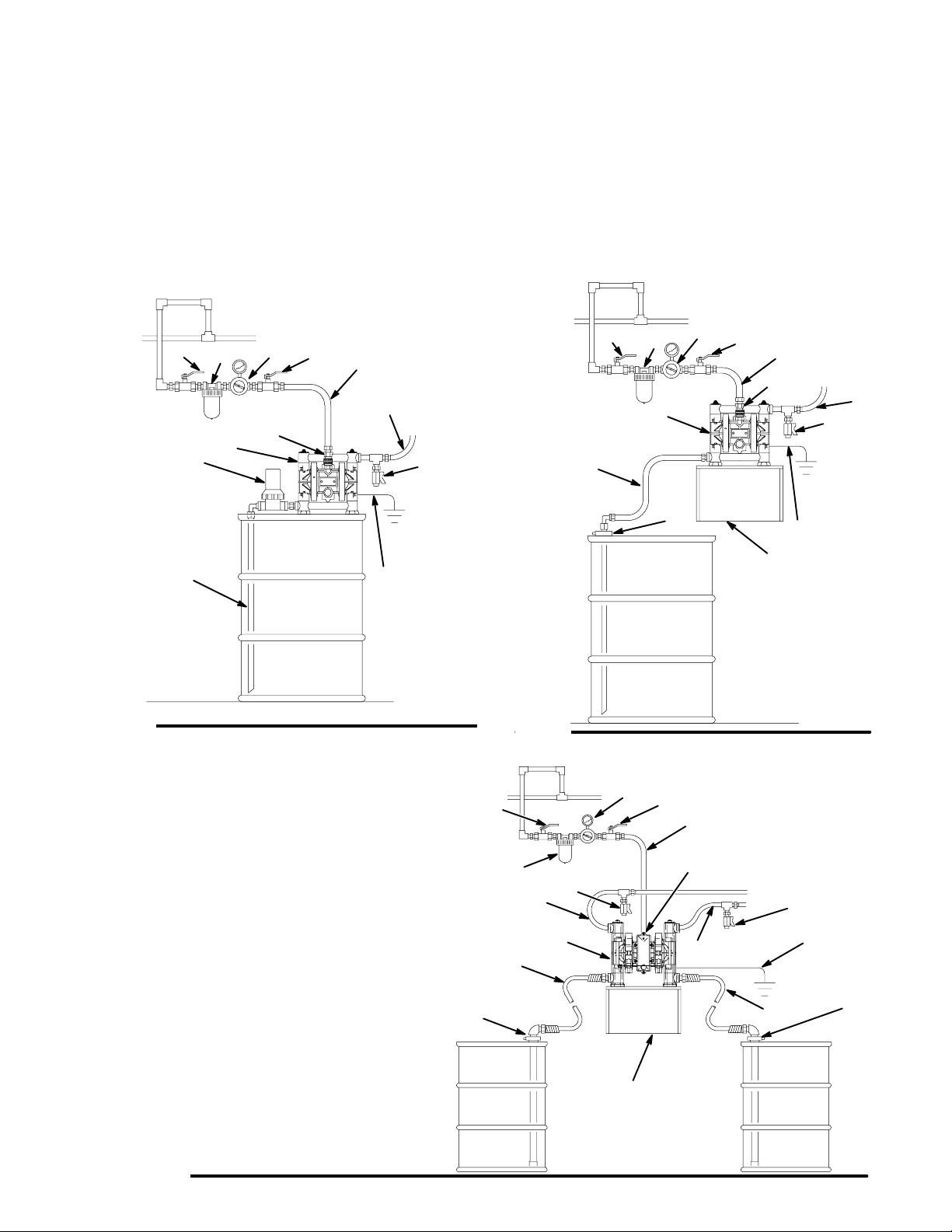

WALL-MOUNT SPLIT MANIFOLD TRANSFER

INSTALLATION

KEY

A 3/8” Diaphragm Pump

B Bleed-Type Master Air Valve

(required for pump)

C Air Supply Line

D Air Line Quick Disconnect

E Master Air Valve (for accessories)

F Air Line Filter

H Pump Air Regulator

J Fluid Drain Valve (required)

L Fluid Suction Line

N Fluid Supply Hose

S Wall Bracket

T Bung Adapter

Y Ground Wire (required; see page 6

for installation instructions)

01444B

S

Fig. 6

01457B

H

E

B

C

F

J

N

A

L

T

D

J

Y

N

T

L

Fig. 7

S

TI2196A

9

Installation

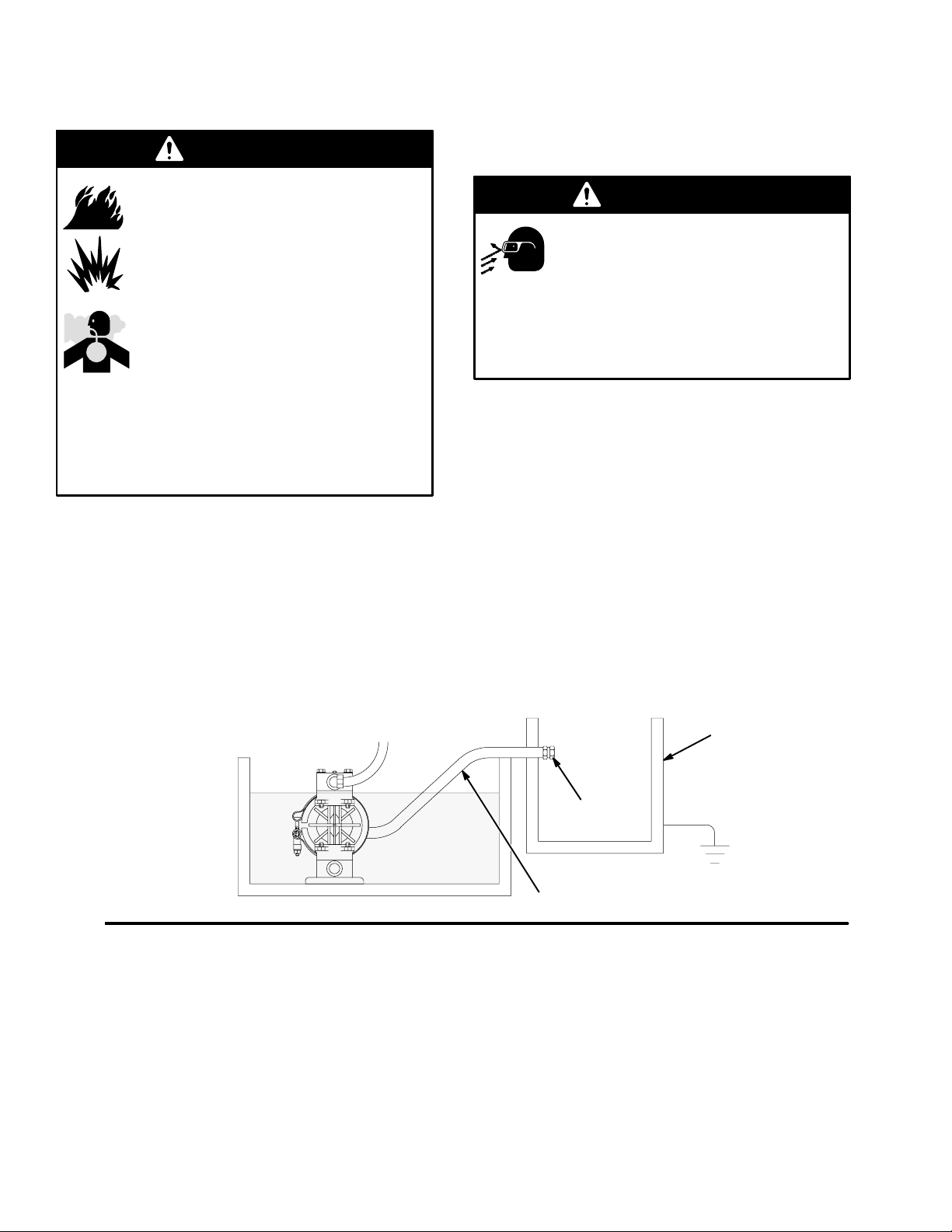

Air Exhaust Ventilation

WARNING

FIRE AND EXPLOSION HAZARD

Be sure to read FIRE OR EXPLOSION

HAZARD and TOXIC FLUID HAZARD

on page 2, before operating this pump.

Be sure the system is properly ventilated for

your type of installation. You must vent the

exhaust to a safe place, away from people,

animals, food handling areas, and all

sources of ignition when pumping flammable or hazardous fluids.

Diaphragm failure will cause the fluid being pumped to

exhaust with the air. Place an appropriate container at

the end of the air exhaust line to catch the fluid. See

Fig. 8.

The air exhaust port is 3/8 npt(f). Do not restrict the air

exhaust port. Excessive exhaust restriction can cause erratic

pump operation.

To exhaust to a remote location:

1. Remove the muffler (11) from the pump air exhaust

port.

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of serious eye injury from

ice particles, never operate the pump with

the air exhaust port open. Ice may form

during pump operation, and ice particles will be ejected

from the port along with the exhaust air. If the muffler

(11) is removed, always connect an air exhaust hose to

the exhaust port.

2. Install an electrically conductive air exhaust hose (X)

and connect the muffler to the other end of the hose.

The minimum size for the air exhaust hose is 3/8 in.

(10 mm) ID. If a hose longer than 15 ft (4.57 m) is

required, use a larger diameter hose. Avoid sharp bends

or kinks in the hose.

3. Place a container (Z) at the end of the air exhaust line

to catch fluid in case a diaphragm ruptures. If the fluid

is flammable, ground the container. See Fig. 8.

Fig. 8

VENTING EXHAUST AIR (Submerged Installation Shown)

See Fig. 4 for accessories

In a submerged installation (as shown), all wetted and non-wetted pump

parts must be compatible with the fluid being pumped.

11

X

Z

01445A

10

Loading...

Loading...