Graymills Bed Filter User Manual

Heavy Duty Coolant Tank /

Bed Filter / Magnetic Separator

Operation and

Maintenance

Instructions

WARNINGS/CAUTIONS

Do not install or operate until you have read all

warnings and instructions and understand the

operation.

• Turn off power to the unit before beginning maintenance on the Graymills Coolant Tank, Bed Filter, or

Magnetic Separator.

• Read and follow all safety instructions supplied with

chemical/coolant being used in your machine tool.

• To avoid damage to the unit, check power source for

proper voltage and phase. Unit comes standard with a

transformer capable of accepting either 230V or 460V,

3 phase power.

• As in all electrical circuits, it is highly recommended

that an electric safety device such as a fusible disconnect or circuit breaker be installed in line before unit is

connected.

• Do not use an extension cord to supply bed filter system.

795-90248

GM 4-00

BFCT40 Bed Filter with 35-gallon pump/tank

combination

MS40 Magnetic Separator for BFCT40

BFCT80 Bed Filter with 90-gallon pump/tank

combination

MS80 Magnetic Separator for BFCT80

• Make sure that pump is spinning freely. See

Maintenance instructions.

• Check the rotation of the pump before starting operation. Rotation should be in a clockwise direction looking down on the motor (match arrow on pump body).

• Ensure that all fittings and connections are properly

tightened.

• It is important that sensitive electronic equipment,

such as:

• personal electronic devices such as pacemakers

• computers

• magnetic media such as credit cards

be kept a safe distance from the Magnetic Separator

when it is in operation.

Never work with equipment you feel may be

unsafe. Contact your Supervisor immediately.

SYSTEM FEATURES

The Graymills combined Coolant Tank, Bed Filter and

(optional) Magnetic Separator are designed to keep your

cutting, grinding, drilling and milling machinery operating at peak performance. By filtering out harmful contaminants, coolant life is greatly extended, saving both

replacement and labor costs.

Coolant flows into the diffuser tray, which separates larger chips and milling by-products. The liquid then pours

onto the filter bed where it is sieved by the filter media.

As the contaminants accumulate and clog the filter

media, the solution rises in the filter bed until the float

switch is triggered. This starts the motor that moves the

chain conveyor/filter media along, until it is replaced with

clean material. The soiled filter media is moved to a

sludge box.

The benefits are:

• Keeps the coolant clean. Reduces frequency of coolant

replacement. Reduces operating costs.

• Keeps the workpiece surface cleaner.

• Grinding wheel does not need to be dressed as often.

Increases productivity and grinding wheel life.

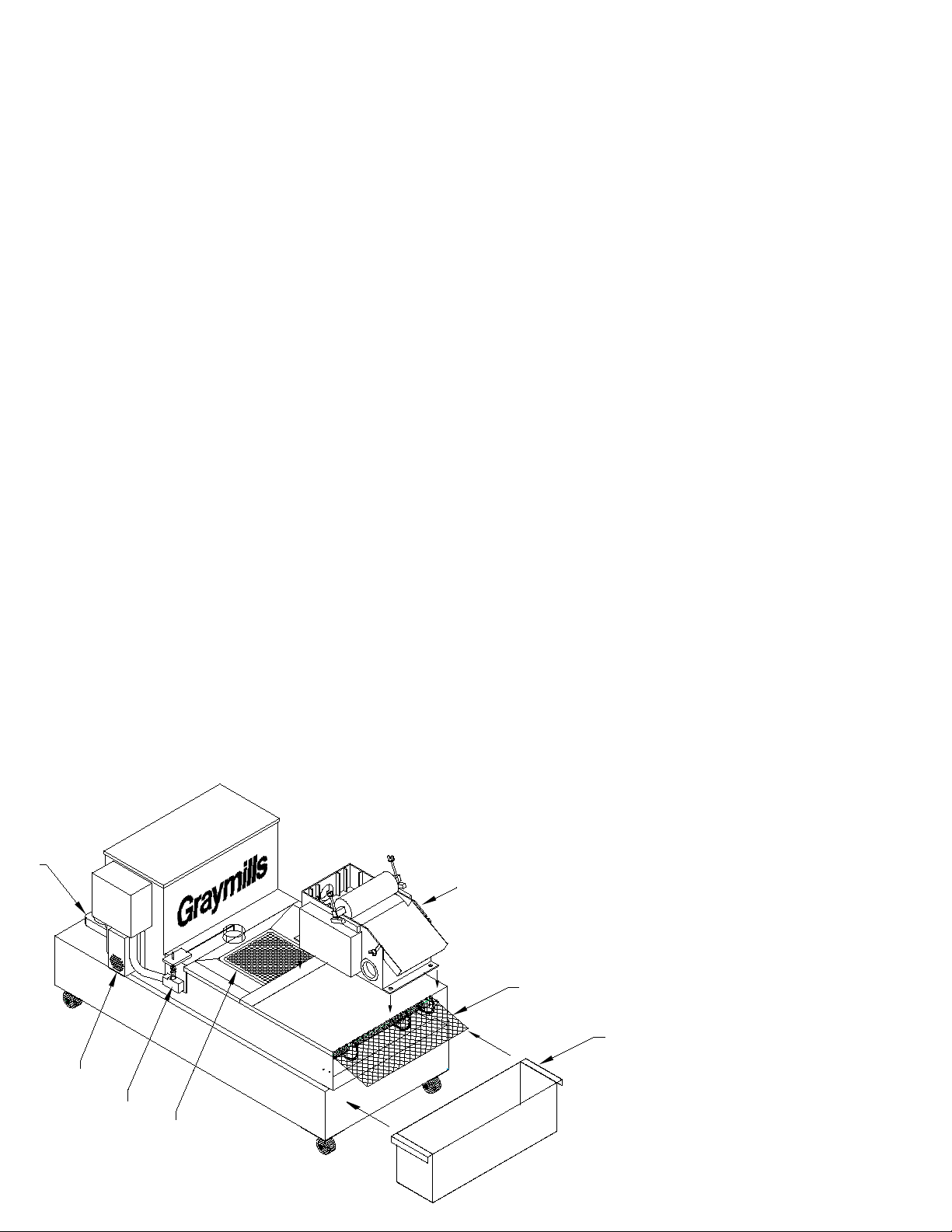

SYSTEM COMPONENTS

A Pump

Used to deliver the coolant in the tank to the machine.

B Gear reducing motor

Moves the filter media along as necessary.

C Liquid Level Control

Float switch mechanism controls the level of coolant

collected in the filter valley. Switch operates the motor

that moves the filter media along.

D Diffuser Tray

Collects larger particles before the coolant is deposited

on the filter media. Also helps spread deposits evenly,

increasing media life.

E Filter Media

Collects the particles to filter the coolant. Standard roll is

rated at 20 micron. Other micron ratings available; contact Graymills for details. 150 yard rolls.

F Sludge Box

Used to accumulate spent filter media and prevent run off

to floor.

G (Optional) Magnetic Separator

Removes ferrous material from coolant before straining

for other debris. Can be installed directly on bed filter for

dual stage separation, or run independently with pumping

system.

SET UP AND INSTALLATION

Coolant Tank and Bed Filter

1.Unpack and inspect unit carefully to verify that everything is intact and there are no obstructions in the chain

mechanism or any other electrical or mechanical components. Do not run power to system at this time.

2.Position the unit in the area in which it will be operating.

3.Remove diffuser tray and lids from paper compartment

and chain area.

4.Fill the tank cavity with coolant until level is approximately 1 to 2 inches below side wall of tank, being

careful not to overfill.

5. Proceed to feed paper through the opening at the bottom of the paper compartment and onto the chain until

the chain is completely covered. Extend filter media a

few inches past the chain. Position the sludge collection

box at the end of the tank and place end of filter paper

over box so soiled media drops into box.

6. Replace lids and reinstall diffuser tray.

7. Pump and bed filter may be wired separately in the event there is a power feed

from your machine tool to incorporate

the pump operation into the main

control. If not, you may run a

water-tight conduit (customer supplied) from the pump to the main

control box and bring your main

power feed into it for a central connection. All electrical work must be

according to applicable codes.

8. Make the necessary connections

A

B

C

D

G

E

F

Figure 1

Loading...

Loading...