Gravely 985112, 985111, 985103, 985113, 985104 User Manual

...

Professional 2-Wheel Tractor

Service Manual

Models 985103,104, 105, 107 - 115, 117

08483800 08/00

Printed in USA

TABLE OF CONTENTS

Section 1 - Introduction. . . . . . . . . . . . . . . . . . . 1-3

1.1 The Manual. . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Service And Replacement Parts. . . . . . . . . 1-3

1.3 Product Registration . . . . . . . . . . . . . . . . . . 1-3

1.4 Unauthorized Replacement Parts. . . . . . . . 1-3

1.5 Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6 Technical Service Communications . . . . . . 1-3

1.7 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Section 2 - Safety. . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1 Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 Signal Words. . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 Notations. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Practices And Laws . . . . . . . . . . . . . . . . . . 2-4

2.5 Maintenance And Storage . . . . . . . . . . . . . 2-4

2.6 Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.7 Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.8 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.9 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Section 3 - Specifications . . . . . . . . . . . . . . . . . 3-6

Section 4 - General Maintenance

& Adjustments. . . . . . . . . . . . . . . . . . . . . . 4-10

4.1 Controls And Features . . . . . . . . . . . . . . . 4-10

4.2 Filling The Fuel Tank. . . . . . . . . . . . . . . . . 4-10

4.3 General Lubrication . . . . . . . . . . . . . . . . . 4-11

4.4 Forward-Reverse Clutch Adjustment . . . . 4-11

4.5 Hi/Low Gear Clutch Adjustment . . . . . . . . 4-12

4.6 Steering Brake Adjustment

(Applicable Models) . . . . . . . . . . . . . . . . . 4-12

4.7 PTO Brake Adjustment . . . . . . . . . . . . . . . 4-13

4.8 Slip Clutch Adjustment . . . . . . . . . . . . . . . 4-14

Section 5 - Engine . . . . . . . . . . . . . . . . . . . . . . 5-15

5.1 Engine Troubleshooting . . . . . . . . . . . . . . 5-15

5.2 Checking Engine Oil . . . . . . . . . . . . . . . . . 5-16

5.3 Changing Oil. . . . . . . . . . . . . . . . . . . . . . . 5-16

5.4 Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.5 Engine Removal And Installation . . . . . . . 5-17

5.6 Engine Maintenance. . . . . . . . . . . . . . . . . 5-17

5.7 Engine Storage. . . . . . . . . . . . . . . . . . . . . 5-17

Section 6 - Steering & Controls . . . . . . . . . . . 6-18

6.1 Handlebar Assembly. . . . . . . . . . . . . . . . . 6-18

6.2 Steering Brakes (Optional) . . . . . . . . . . . . 6-19

6.3 Adjusting Brakes. . . . . . . . . . . . . . . . . . . . 6-19

6.4 Power Take Off Control. . . . . . . . . . . . . . . 6-22

6.5 Range Shift Control (Two Speed Axle) . . . 6-22

Section 7 - Drive Train . . . . . . . . . . . . . . . . . . . 7-23

7.1 Transmission Trouble Analysis . . . . . . . . . 7-23

7.2 Clutch Adjustment. . . . . . . . . . . . . . . . . . . 7-24

7.3 Transmission Removal . . . . . . . . . . . . . . . 7-24

7.4 Forward-Reverse Clutch &

Planetary System . . . . . . . . . . . . . . . . . . . 7-24

7.5 First -Second Gear, Clutch And Planetary 7-24

7.6 Differential. . . . . . . . . . . . . . . . . . . . . . . . . 7-25

7.7 Differential Removal . . . . . . . . . . . . . . . . . 7-25

7.8 Power Take Off (PTO). . . . . . . . . . . . . . . . 7-28

Section 8 - Fuel System. . . . . . . . . . . . . . . . . . 8-29

8.1 Fuel System Troubleshooting . . . . . . . . . . 8-29

8.2 Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . 8-30

8.3 Fuel System Contamination . . . . . . . . . . . 8-30

8.4 Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Section 9 - Electrical . . . . . . . . . . . . . . . . . . . . 9-31

9.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

9.2 Electrical Measurements. . . . . . . . . . . . . . 9-31

9.3 Safety Interlock System . . . . . . . . . . . . . . 9-32

9.4 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

9.5 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

9.6 Solenoid And Relays. . . . . . . . . . . . . . . . . 9-35

9.7 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

9.8 Diodes And Rectifiers . . . . . . . . . . . . . . . . 9-36

9.9 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . 9-37

9.10 Continuity Diagram . . . . . . . . . . . . . . . . . 9-38

9.11 12 HP Electric Start - Kohler . . . . . . . . . . 9-39

9.12 8 HP Manual Start - Kohler. . . . . . . . . . . 9-40

9.13 8 HP Electric Start - Kohler. . . . . . . . . . . 9-41

9.14 16 HP Electric Start - Briggs. . . . . . . . . . 9-42

9.15 Robin Engines . . . . . . . . . . . . . . . . . . . . 9-43

2

SECTION 1 - INTRODUCTION

1.1 THE MANUAL

The purpose of this manual is to provide complete

instructions for service, maintenance, disassembly,

repair, and installation of the mechanical components

for the unit.

Dealer trained service personnel should use this

manual as a supplement to and reminder of the training

sessions conducted by the company.

Read all information for servicing a part or system

before repair work is started to avoid needless

disassembly.

Operation

Before operation of the unit, carefully and completely

read manuals supplied with the unit. The contents will

provide you with an understanding of safety

instructions and controls during normal operation and

maintenance.

Safety Messages

For your safety and the safety of others always read,

understand, and follow all DANGER, WARNING, and

CAUTION messages found in manuals and on safety

decals.

Directional Reference

All reference to left, right, front, or rear are given from

the operator in the operator position and facing the

direction of forward travel.

1.2 SERVICE AND REPLACEMENT PARTS

When ordering publications, replacement parts, or

making service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product registration form in

the unit literature package. They are printed on a serial

number label, located under the hood of your unit.

1.3 PRODUCT REGISTRATION

A warranty registration card must be filled out, signed,

and returned at time of purchase. This card activates

the warranty. Claims meeting requirements during

limited warranty period will be honored.

Specific Model and Serial Numb er s are on a label

located on the frame of your Tractor and on a label

located on the product registration form. Record those

numbers below and transfer the label from the product

registration to place indicated be low. Use these

numbers whenever parts or service is required.

1.4 UNAUTHORIZED REPLACEMENT

PARTS

Use only Gravely replacement parts. The replacement

of any part on this vehicle with anything other than a

Gravely authorized replacement part may adversely

affect the performance, durability, or safety of this unit

and may void the warranty. Gravely disclaims liability

for any claims or damages, whether warranty, property

damage, personal injury, or death arising out of the use

of unauthorized replacement parts.

1.5 DISCLAIMER

Gravely reserves the right to discontinue, make

changes to, and add improvements upon its products

at any time without public notice or obligation. The

descriptions and specifications contained in this

manual were in effect at printing. Equipment described

within this manual may be optional. Some illustrations

may not be applicable to your unit.

1.6 TECHNICAL SERVICE

COMMUNICATIONS

Gravely Technical Service communicates information

to the field using Service Letters, Service Bulletins,

Product Notices, and Campaigns. Each

communication signifies a type of information and

priority. The dealer is responsible to carry out the

directive provided in the communication. The types of

communication are:

Service Letter

dealer. Technical information on how to service the

product and product improvements.

Service Bulletin

resolve certain issues or a notification of a policy

change.

Product Notices

located in a certain region. This is a limited distribution

to only those who received the product involved.

Campaigns

products must be updated and are tracked by the

factory until all units are corrected.

- General technical information for the

- Notification to update products to

- Notification of limited product

- Notification of a safety related issue. All

1 -3

1.7 PREPARATION

Before starting any removal of parts, proper

preparation is very important for efficient work. A clean

work area at the start of each job will allow you to

perform service repairs easily and quickly.

To reduce the incidence of misplaced tools or parts,

place removed components with all attaching hardware

SECTION 2 - SAFETY

in the disassembly order on a clean work surface.

Organization is a key part of proper reassembly.

T ools, instruments, and parts needed for the job should

be gathered before work is started. Interrupting a job to

locate tools or parts is a needless delay.

2.1 SAFETY ALERTS

Look for these symbols to point out

important safety precautions. They

mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

2.2 SIGNAL WORDS

The safety alert symbol is used in decals on the unit

and with proper operation procedures in this manual.

They alert you to the existence and relative degree of

hazards.

Understand the safety message. It contains important

information about personal safety on or near the unit.

DANGER:

SITUA TION! If not avoided, WILL RESULT in

death or serious injury.

WARNING:

SITUA TION! If not avoided, COULD RESULT

in death or serious injury.

CAUTION:

SITUA TION! If not avoided, MAY RESULT in

minor or moderate injury. It may also be used

to alert against unsafe practices.

IMMINENTLY HAZARDOUS

POTENTIALLY HAZARDOUS

POTENTIALLY HAZARDOUS

2.3 NOTATIONS

NOTE:

ation and maintenance practices .

IMPORTANT:

required to prevent damage to unit or attachment.

General reference information for proper oper-

Specific procedures or information

2.4 PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and others.

Understand and follow all safety messages. Be alert to

unsafe conditions and the possibility of minor,

moderate, or serious injury or death. Learn applicable

rules and laws in your area.

2.5 MAINTENANCE AND STORAGE

Keep the equipment in good condition. Maintain it as

directed in this manual. Check all hardware at regular

intervals.

Use only Gravely accessories, attachment and

replacement parts.

Do not overspeed the engine. Do not ov erride the

governor.

Before making any repairs, adjustments inspections or

cleaning unit disengage the PTO, turn off and remove

the ignition key and wait for all motion to stop.

To reduce fire hazard and overheating, keep

equipment free of grass, leaves, debris or excessive

lubricants.

Worn out mufflers can result in fire or explosion and

should be replaced immediately.

Never store equipment with gasoline in tank inside a

building where fumes may reach an open flame or

spark. Allow engine to cool before storing in any

enclosure.

2.6 SAFETY RULES

Improper use of this tractor can injure people and

damage the equipment. People using or servicing this

tractor must read and follow the instructions in this

manual.

It is important to understand that this manual and any

other Gravely instruction manuals do not cover every

possible danger. It is impossible for Gravely to know of

all possible dangers in operating and servicing the

tractor and attachments.

The purchaser must give these instructions to the

people operating and maintaining this tractor. These

people must use eye and foot protection.

2.7 TRAINING

Read this manual, the attachment manual and the

engine manual carefully before operating unit.

2 -4

Learn the location and function of all controls.

Learn how to use the controls to stop the wheels and

attachment quickly in an emergency.

Understand and follow each danger, warning, caution

and instruction decal installed on this product.

Never permit children to operate the Two-Wheel

Tractor . Do not allow adults to operate it without proper

instruction. Safe operation of this equipment requires

your complete and unimpaired attention at all times. Do

not operate unit after or during the consumption of

drugs or alcohol.

Keep all people and animals away from the operating

area.

2.8 PREPARATION

Use caution with gasoline. Gasoline is very flammable

and its vapors are explosive. Keep it in a clean, tight

and approved (Red) container. Never put gasoline in

the fuel tank while the engine is running or hot. Clean

up spilled gasoline before starting engine. Do not fill

fuel tank indoors. Never allow smoking materials,

sparks or flame (match, pilot light, etc.) near mower or

fuel container. Replace fuel tank cap and fuel container

cap securely.

Inspect area of operation and remove all material

which could be thrown by the attachment such as

stones, sticks, wires and other foreign objects.

When hauling the equipment, connect the chassis to

the transporting vehicle. Never connect from control

levers, rods, or like items that could be damaged.

Replace all parts that become damaged or lost.

Wear hand, foot, head, ear and eye protection. Do not

wear loose clothing, which might get caught in rotating

parts of the unit.

Before making adjustments, cleaning, removing

obstructions or servicing the tractor or attachment

move the PTO to "OFF", turn the ignition switch to

"OFF", remove the ignition key and wait until all moving

parts completely stop.

WARNING:

that jack stands or blocks used are stable,

strong, or secure and will hold the weight of

the unit during maintenance.

Always block wheels and know

only if at least one of the operator presence switches is

depressed.

Do not use the equipment in the dark without adequate

lighting.

Keep away from moving parts. Stay clear of the

attachment whenever the engine is running.

Do not let people other than the operator near the

operating equipment. Never direct disengage the

attachment drive when moving the tractor to and from

work areas.

Use a slow speed and engage the shift lever slowly

when operating on slopes.

Travel across slopes, not up and down. Use extreme

caution when changing direction on slopes. Do not

operate on steep slopes.

Look for and keep away from hazards, such as

dropoffs. Stay alert for holes, rocks and other hidden

hazards in the area of operation.

After hitting an object, disengage the PTO, turn off and

remove the ignition key and wait for all motion to stop.

Check for damage. Repair any damage before

restarting unit.

Look behind when operating in reverse. Look for

people and hazards.

Operate only from the operator’s position, just behind

the handlebars.

If there is a sudden change in the sound or vibration of

the equipment, disengage the PTO, turn off and

remove the ignition key, wait for all motion to stop and

check for damage. Repair any damage or failure before

restarting unit.

Never run the engine indoors except to move it outside.

Exhaust fumes are dangerous.

Go slowly on slick surfaces. Always be sure of your

footing, keep a firm grip on the handlebars and walk,

never run.

Follow traffic laws when operating on or near a road.

Before leaving the operator’s position, put the PTO

lever in the "OFF" position, turn off and remove ignition

key. Move the shift control to first gear position.

Do not touch parts which might be hot from operation.

Before attempting to maintain, adjust or service allow

such parts to cool.

2.9 OPERATION

Be certain that all shields, guards, and interlock

switches are in the correct position and operating

properly.

Before starting the engine, put the PTO lever in the

"OFF" position and the gear shift lever in the neutral

"N" position.

Check the operation of the operator presence controls

before operating the tractor. With either the PTO or the

direction control lever engaged, the engine should run

2 -5

SECTION 3 - SPECIFICATIONS

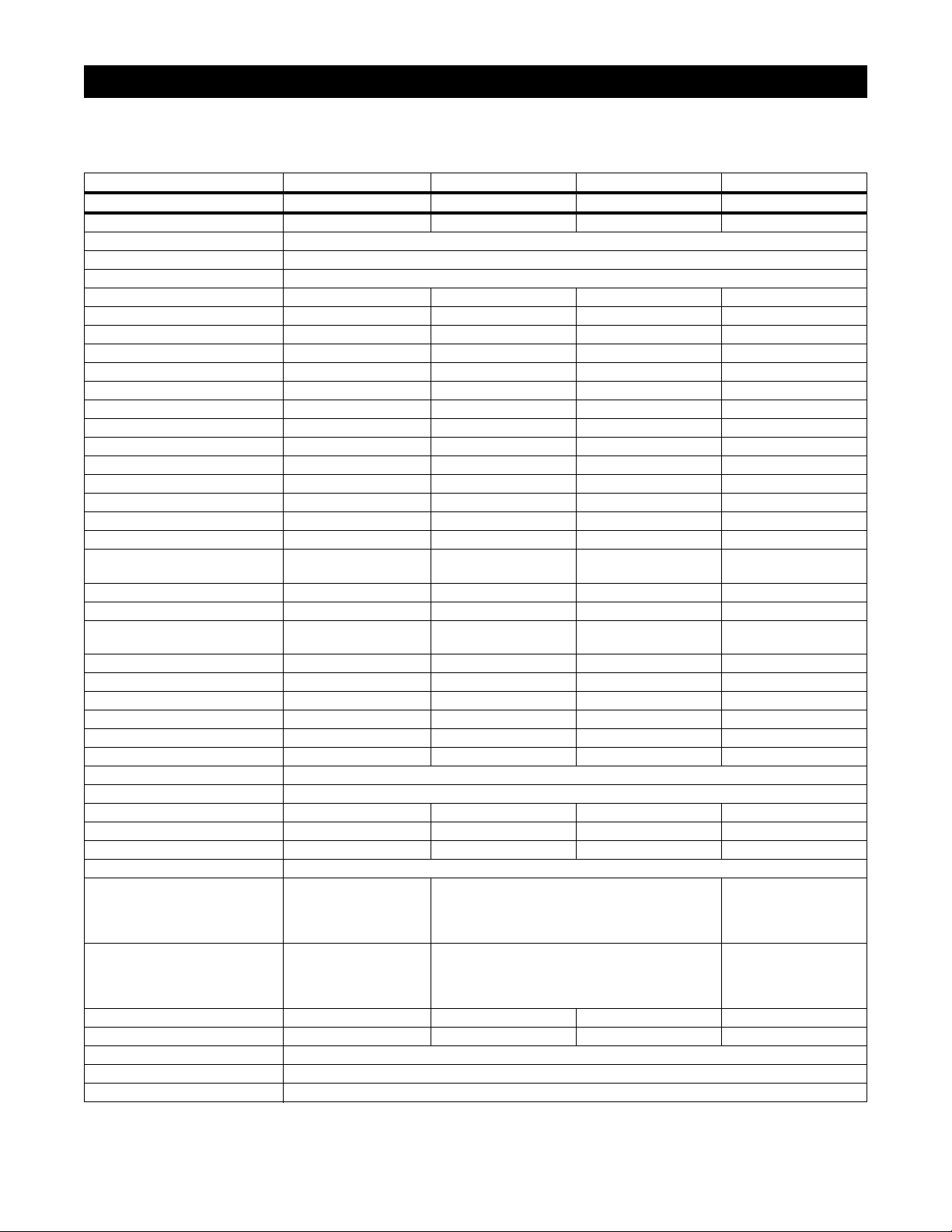

Model Number 985103 985104 985105 985107

Description 8HP Gear Drive 8HP Gear Drive 8HP Gear Drive 12 HP Gear Drive

Brakes Optional, individual, 7" (17.8 cm) x 1.75" (4.4 cm) drum type

Steering Manual, optional power steering kit available

Turning Radius Zero (with steering kit)

Minimum Uncut Circle Zero Zero Zero Zero

Optional Tire Sizes

-Stud Tread 4" x 8", 4 ply 4" x 8", 4 ply 4" x 8", 4 ply 4" x 8", 4 ply

-Trac Tread 4" x 8", 4 ply 4" x 8", 4 ply 4" x 8", 4 ply 4" x 8", 4 ply

-Turf-Chief 18" x 6.5" x 8", 4 ply 18" x 6.5" x 8", 4 ply 18" x 6.5" x 8", 4 ply 18" x 6.5" x 8", 4 ply

-Turf-Saver 18" x 8.5" x 8", 4 ply 18" x 8.5" x 8", 4 ply 18" x 8.5" x 8", 4 ply 18" x 8.5" x 8", 4 ply

-Semi-Pneumatic 16" x 5" x 3", 4 ply 16" x 5" x 3", 4 ply 16" x 5" x 3", 4 ply 16" x 5" x 3", 4 ply

Tire Pressure 18 psi 18 psi 18 psi 18 psi

Battery 12 volt, BCI group 12 volt, BCI group 12 volt, BCI group 12 volt, BCI group

Engine Kohler Kohler Kohler Kohler

-Type K181T K181T K181S M12T (PS471525)

-Horsepower 8HP at 3600 RPM 8HP at 3600 RPM 8HP at 3600 RPM 12HP at 3600 RPM

-Number of Cylinders One One One One

-Displacement 18 cu. in. (305.4 cc) 18 cu. in. (305.4 cc) 18 cu. in. (305.4 cc) 29 cu. in. (476.5 cc)

-Fuel Gasoline, 87 minimum

octane

-Fuel Capacity 1.25 gals. (4.7 L) 1.25 gals. 4.7 L) 1.25 gals. (4.7 L) 2.0 gals. (4.7 L)

-Cooling Air Air Air Air

-Air Filter Dual Element with

PreCleaner

-Lubrication Splash System Splash System Splash System Splash System

-Oil Type See Engine Manual See Engine Manual See Engine Manual See Engine Manual

-Oil Capacity 2.5 pts. (1.2 L) 2.5 pts. (1.2 L) 2.5 pts. (1.2 L) 2.5 pts. (1.2 L)

-Oil Filter N/A N/A N/A Spin on oil filter

-Charging System Recoil Recoil 12 volt, 15 amp 12 volt, 15 amp

Transmission

-Type All gear planetary transmission with fully enclosed PTO and immersion clutch

-Oil Type SAE 30W API service class SF or higher

-Oil Capacity 5 qts (4.7 L) 5 qts (4.7 L) 5 qts (4.7 L) 5 qts (4.7 L)

-Cooling Air Air Air Air

-Number of Speeds 2 forward/2 reverse 4 forward/4 reverse 4 forward/4 reverse 4 forward/4 reverse

Speeds (with 18" tires)

-Forward 1st - 2.0 mph (3.2 kph)

2nd - 2.5 mph (4.0 kph)

-Reverse 1st - 1.9 mph (3.1 kph)

2nd - 2.4 mph (3.9 kph)

PTO

-Type Internal Slip Clutch Internal Slip Clutch Internal Slip Clutch Internal Slip Clutch

-Drive All gear shaft driven off high/low planetary

-Output Speeds High - 1179 RPM, low - 888 RPM at 3300 engine RPM

Construction Cast-iron transmission case with 7-gauge framing

Gasoline, 87 minimum

octane

Dual Element with

PreCleaner

1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.4 mph (5.5 kph)

1st - 1.2 mph (2.0 kph

2nd - 1.6 mph (2.6 kph)

3rd - 2.4 mph (3.9 kph)

4th - 3.1 mph (5.0 kph)

Gasoline, 87 minimum

octane

Dual Element with

PreCleaner

Gasoline, 87 minimum

octane

Dual Element with

PreCleaner

1st - 1.4 mph (2.3 kph)

2nd - 1.8 mph (2.9 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

3 -6

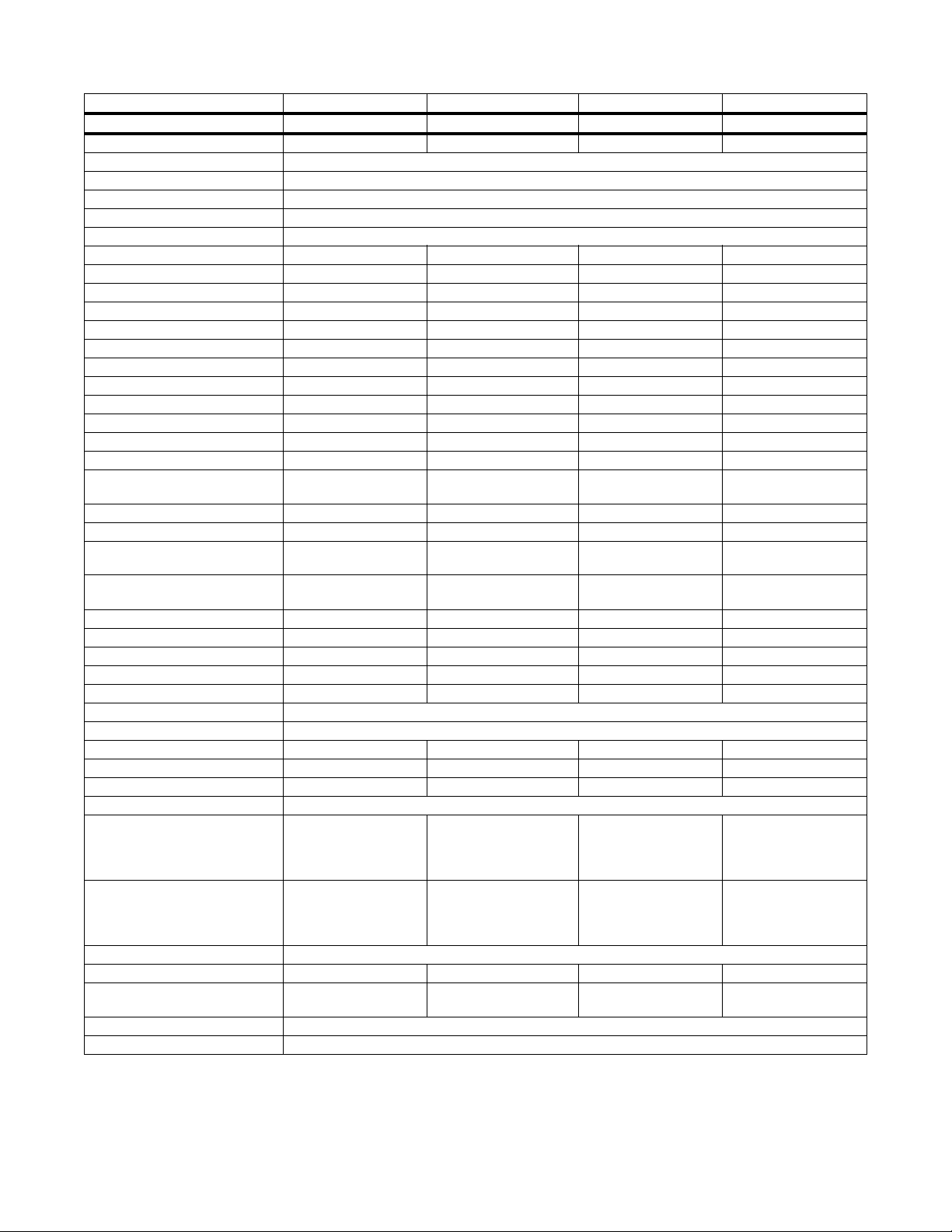

Model Number 985108 985109 985110 985111

Description 12HP Gear Drive 16HP Gear Drive 8HP Gear Drive 8HP Gear Drive

Brakes Optional, individual, 7" (17.8 cm) x 1.75 (4.4 cm) drum type

Steering Manual, optional power steering kit available

Turning Radius Zero (with steering kit)

Minimum Uncut Circle Zero

Optional Tire Sizes

-Stud Tread 4" x 8", 4 ply 4" x 8", 4 ply 4" x 8", 4 ply 4" x 8", 4 ply

-Trac Tread 4" x 8", 4 ply 4" x 8", 4 ply 4" x 8", 4 ply 4" x 8", 4 ply

-Turf-Chief 18" x 6.5" x 8", 4 ply 18" x 6.5" x 8", 4 ply 18" x 6.5" x 8", 4 ply 18" x 6.5" x 8", 4 ply

-Turf-Saver 18" x 8.5" x 8", 4 ply 18" x 8.5" x 8", 4 ply 18" x 8.5" x 8", 4 ply 18" x 8.5" x 8", 4 ply

-Semi-Pneumatic 16" x 5" x 3", 4 ply 16" x 5" x 3", 4 ply 16" x 5" x 3", 4 ply 16" x 5" x 3", 4 ply

Tire Pressure 18 psi 18 psi 18 psi 18 psi

Battery 12 volt, BCI group 12 volt, BCI group None 12 volt, BCI group

Engine Kohler Briggs & Stratton Kohler Kohler

-Type M12S (PS471529) 303447 PS-301058 PS-30159

-Horsepower 12HP at 3600 RPM 16 HP at 3600 RPM 8 HP at 3600 RPM 8 HP at 3600 RPM

-Number of Cylinders One Two One One

-Displacement 29 cu. in. (477 cc) 29.3 cu. in. (480 cc) 18 cu. in. (305.4 cc) 18 cu. in. (305.4 cc)

-Fuel Gasoline, 87 minimum

octane

-Fuel Capacity 2.0 gals. (7.5 L) 1.5 gals. (5.7 L) 1.25 gals. (4.7 L) 1.25 gals. (4.7 L)

-Cooling Air Air Air Air

-Air Filter Dual Element with

PreCleaner

-Lubrication Splash System Full pressure pump with

-Oil Type See Engine Manual See Engine Man ual See Engine Manual See Engine Manual

-Oil Capacity 2.5 pts. (1.2 L) 3.0 pts. (1.4 L) 2.5 pts. (1.2 L) 2.5 pts. (1.2 L)

-Oil Filter Spin on oil filter Spin on oil filter Spin on oil filter Spin on oil filter

-Charging System 12 volt, 15 amp 12 volt, 16 amp Recoil 12 volt, 15 amp

Transmission

-Type All gear planetary transmission with fully enclosed PTO and immersion clutch

-Oil Type SAE 30W API service class SF or higher

-Oil Capacity 5 qts (4.7 L) 5 qts (4.7 L) 5 qts (4.7 L) 5 qts (4.7 L)

-Cooling Air Air Air Air

-Number of Speeds 2 forward/2 reverse 4 forward/4 reverse 4 forward/4 reverse 4 forward/4 reverse

Speeds

-Forward 1st - 1.4 mph (2.3 kph)

2nd - 1.8 mph (2.9 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

-Reverse 1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

PTO

-Type Internal Slip Clutch Internal Slip Clutch Internal Slip Clutch Internal Slip Clutch

-Drive All gear shaft driven off

high/low planetary

Output Speeds High - 1179 RPM, low - 888 RPM at 3300 engine RPM

Construction Cast-iron transmission case with 7-gauge framing

Gasoline, 87 minimum

octane

Dual Element with

PreCleaner

oil filter

1st - 1.4 mph (2.3 kph)

2nd - 1.8 mph (2.9 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

All gear shaft driven off

high/low planetary

See Engine Manual See Engine Manual

Dual Element with

PreCleaner

Splash System Splash System

1st - 1.4 mph (2.3 kph)

2nd - 1.8 mph (2.9 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

All gear shaft driven off

high/low planetary

Dual Element with

PreCleaner

1st - 1.4 mph (2.3 kph)

2nd - 1.8 mph (2.9 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

All gear shaft driven off

high/low planetary

3 -7

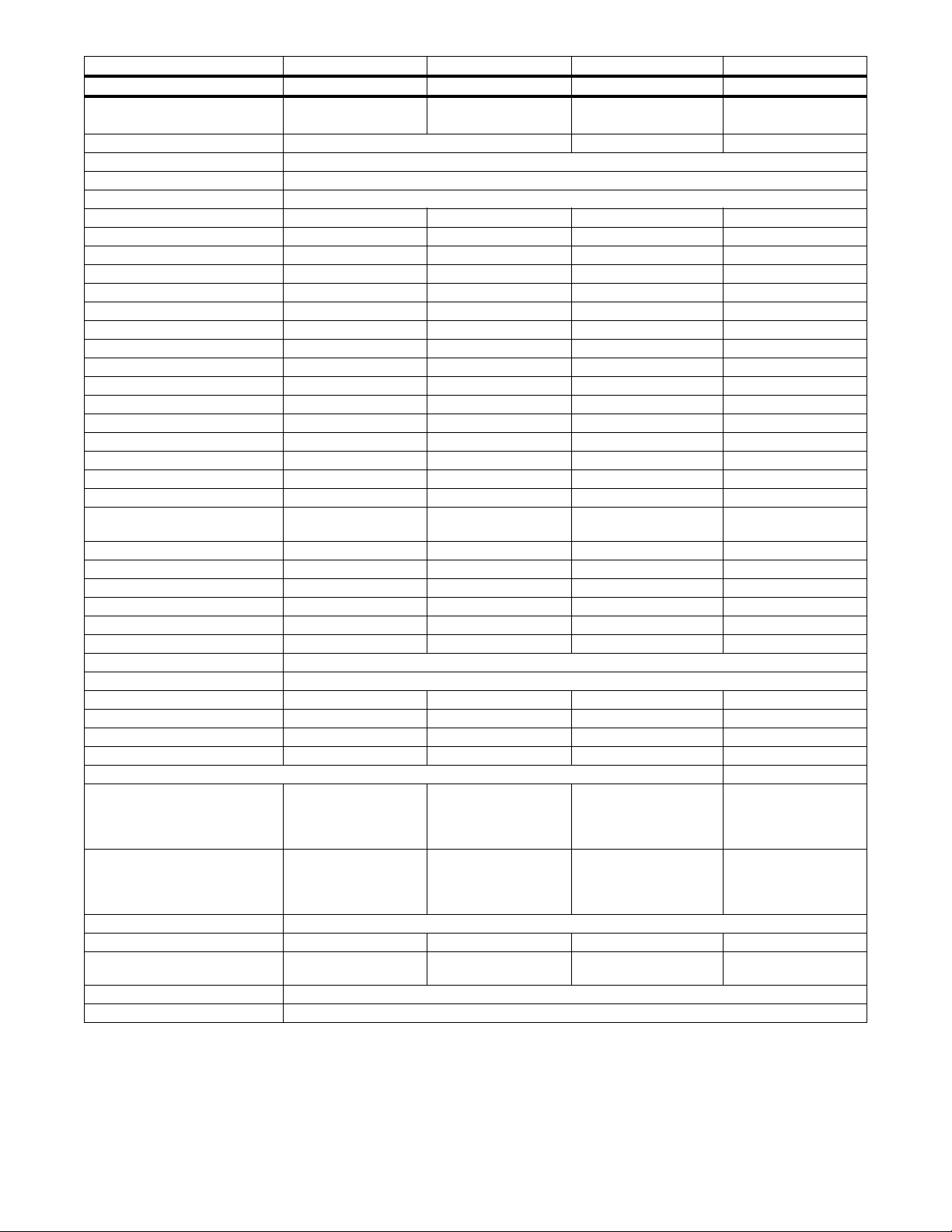

Model Number 985112 985113 985114 985115

Description 12 HP

Gear Drive

Brakes 7 x 1.75" Drum Type N/A

Steering Manual, optional power steering kit available

Turning Radius Zero (with steering kit)

Minimum Uncut Circle Zero

Optional Tire Sizes

-Stud Tread 4.00-8 4.00-8 4.00-8 4.00-8

-Trac Tread 4.00-8 4.00-8 4.00-8 4.00-8

-Turf-Chief 18" x 6.50"-8" 18" x 6.50"-8" 18" x 6.50"-8" 18" x 6.50"-8"

-Turf-Saver 18" x 8.50"-8" 18" x 8.50"-8" 18" x 8.50"-8" 18" x 8.50"-8"

-Semi-Pneumatic N/A N/A 16" x 5" x 3" 16" x 5" x 3"

Tire Pressure 18 psi (124 Kn/m2) 18 psi (124 Kn/m2) See Tire Sidewall See Tire Sidewall

Battery 12V BCI Group 12V BCI Group 12V BCI Group 12V BCI Group

Engine Kohler Kohler Briggs & Stratton Robin

-Type PS-471529 PS-471529 303447 EH252-0225T

-Horsepower 12 HP 12 HP 16 HP 8.5 HP

-Number of Cylinders One One Two One

-Displacement 29.3 cu. in. (480 cc) 15.31 cu. in. (251 cc)

-Fuel See Engine Manual See Engine Manual Auto Gasoline Auto Gasoline

-Fuel Capacity 2.0 gals. (7.5 L) 2.0 gals. (7.5 L) 1.5 gals. (5.7 L) 1.5 gals. (5.7 L)

-Cooling Air Air Air Air

-Air Filter Dual Element with

-Lubrication Splash Type Splash Type Pump w/oil filter Splash Type

-Oil Type See Engine Manual See Engine Manual See Engine Manual SAE 20#, 30# 10W-30

-Oil Capacity 2.5 pts. (1.2 L) 2.5 pts. (1.2 L) 3.0 pts. (1.4 L) 2.1 pts. (1.0 L)

-Oil Filter Spin on oil filter Spin on oil filter Spin on oil filter Spin on oil filter

-Charging System 12 volt, 15 amp 12 volt, 15 amp 12 volt, 16 amp 13 volt, 11.5 amp

Transmission

-Type All gear transmission w/fully enclosed PTO and immersion clutch

-Oil Type SAE 30W API service class SF or higher

-Oil Capacity 5 qts. (4.7 L) 5 qts. (4.7 L) 5 qts. (4.7 L) 5 qts. (4.7 L)

-Cooling Air Air Air Air

-Number of Speeds 4 forward/4 reverse 4 forward/4 reverse 4 forward/4 reverse 4 forward/4 reverse

-Direction Control

Speeds (with 18" tires) (with 14" tires)

-Forward 1st - 1.4 mph (2.3 kph)

-Reverse 1st - 1.3 mph (2.1 kph)

PTO

-Type Internal Slip Clutch Internal Slip Clutch Internal Slip Clutch Internal Slip Clutch

-Drive All gear shaft driven off

-Output Speeds High - 1179 RPM, low - 888 RPM at 3300 engine RPM

Construction Cast-iron transmission case with 7-gauge framing

PreCleaner

2nd - 1.8 mph (2.9 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

high/low planetary

2nd - 1.8 mph (2.9 kph)

2nd - 1.7 mph (2.7 kph)

12 HP

Gear Drive

Dual Element with

PreCleaner

1st - 1.4 mph (2.3 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

1st - 1.3 mph (2.1 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

All gear shaft driven off

high/low planetary

16 HP

Gear Drive

Dual Element with

PreCleaner

1st - 1.4 mph (2.3 kph)

2nd - 1.8 mph (2.9 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

All gear shaft driven off

high/low planetary

8.5 HP

Gear Drive

Dual Element with

PreCleaner

1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.4 mph (5.5 kph)

1st - 1.3 mph (2.1 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

All gear shaft driven off

high/low planetary

3 -8

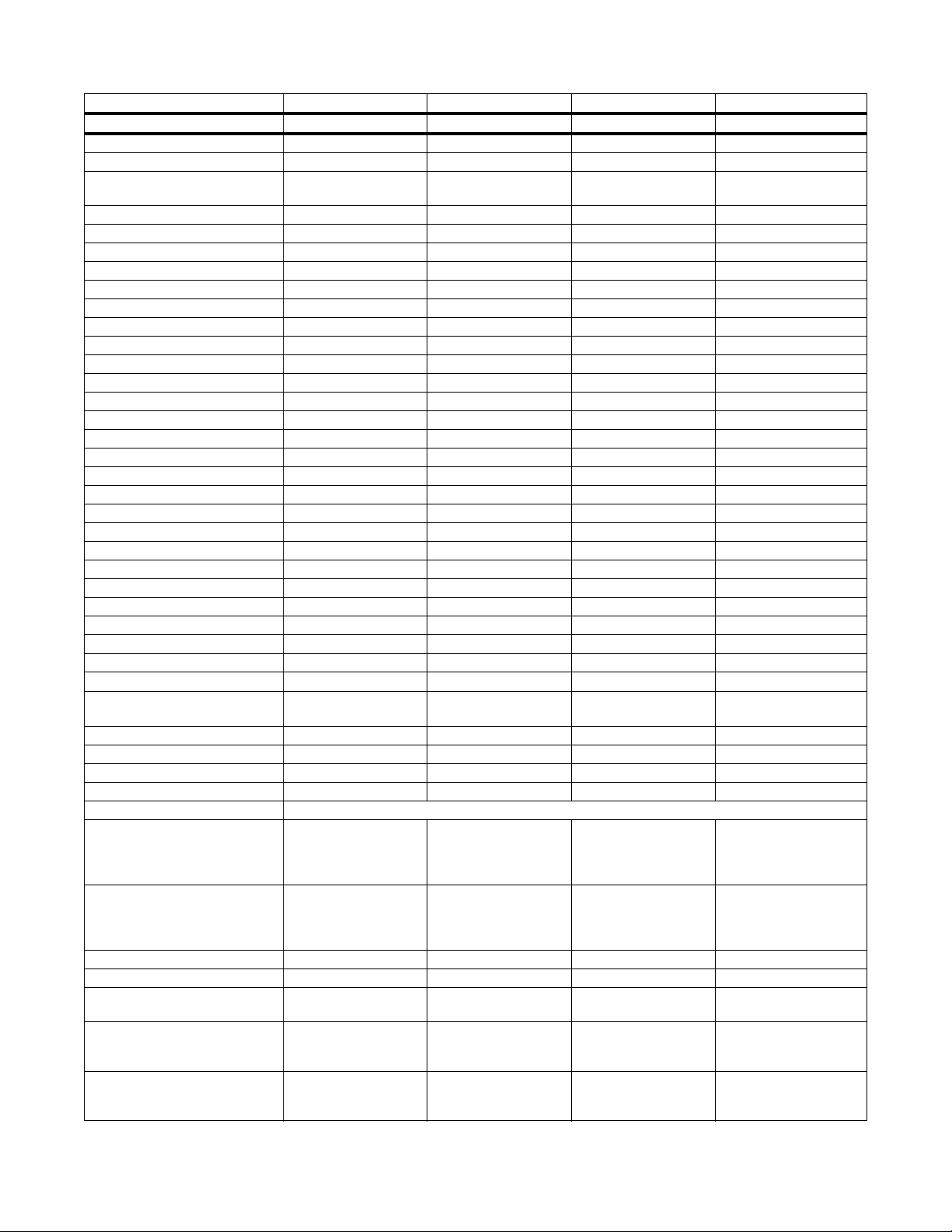

Model Number 985117

Description 13.5 HP Gear Drive

Brakes 7 x 1.75" Drum Type

Steering Manual, optional power

Turning Radius Zero (with steering kit)

Minimum Uncut Circle Zero

Optional Tire Sizes

-Stud Tread 4.00"-8"

-Trac Tread 4.00"-8"

-Turf-Chief 18" x 6.50"-8"

-Turf-Saver 18" x 8.50"-8"

-Semi-Pneumatic 16" x 5" x 3"

Tire Pressure See Tire Sidewall

Battery 12V BCI Group

Engine Robin

-Type EH410-0226T

-Horsepower 13.5 HP

-Number of Cylinders One

-Displacement 24.67 cu. in. (440 cc)

-Fuel Auto gasoline

-Fuel Capacity 1.5 gal. (5.7 L)

-Cooling Air

-Air Filter Dual element

-Lubrication Splash Type

-Oil Type See Engine Manual

-Oil Capacity 5 qts. (4.7 L)

-Oil Filter Spin on filter

-Charging System 12 volt, 12.5 amp

Transmission

-Type Gear transmission

-Oil Type SAE 30W API service

-Oil Capacity 5 qts. (4.7 L)

-Cooling Air

-Number of Speeds 4 forward/4 reverse

-Direction Control

Speeds (with 18" tires)

-Forward 1st - 1.4 mph (2.3 kph)

-Reverse 1st - 1.3 mph (2.1 kph)

PTO

-Type Internal Slip Clutch

-Drive All gear shaft driven off

-Output Speeds High - 1179 RPM,

Construction Cast-iron transmission

steering kit available

class SF or higher

2nd - 1.8 mph (2.9 kph)

3rd - 2.7 mph (4.4 kph)

4th - 3.7 mph (6.0 kph)

2nd - 1.7 mph (2.7 kph)

3rd - 2.6 mph (4.2 kph)

4th - 3.3 mph (5.3 kph)

high/low planetary

Low - 888 RPM at 3300

engine RPM

case with 7-gauge

framing

3 -9

SECTION 4 - GENERAL MAINTENANCE & ADJUSTMENTS

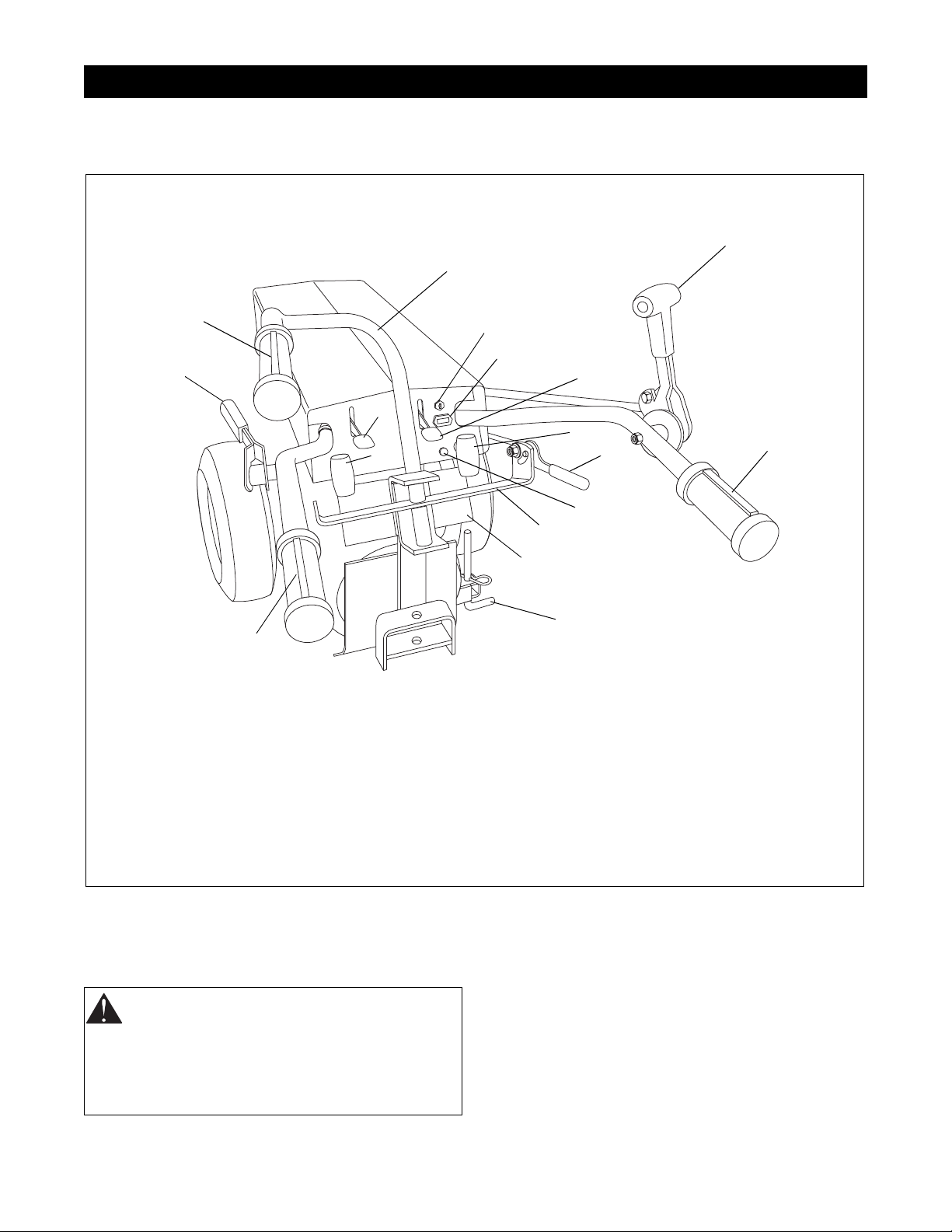

4.1 CONTROLS AND FEATURES

1

2

4

3

9

6

4

1. Direction Control Lever

2. Steering Brake Han dlebar (Opti onal)

3. Gear Shift Lever (Hi/Low Gear)

4. Operator Presence Control

5. Choke Control Knob (Models with Briggs & Stratton

Engines)

6. PTO Control

7. Ignition Switch

7

10

15

12

13

4

5

11

14

8

8. Kick Stand

9. Throttle Control

10. Hour meter

11. Brake Handle Cross Bar

12. Range Shift Handle (Two Speed Axle)

13. Parking Brake Handle (Optional on 8.5 HP)

14. Instruction Plate

15. Choke Lever (Models with Robin Engines)

16. Choke Control Knob (Models with Briggs & Stratton

OH0160

4.2 FILLING THE FUEL TANK

WARNING:

flammable. Keep fuel in a clean and tight

container. Keep fuel away from fire or heat.

Never put fuel in the fuel tank while the engine

is running or hot. Clean up any spilled fuel

before starting engin e.

Use caution with fuel. Fuel is very

Figure 1

Add fuel to the fuel tank as needed. See your engine

manual for the correct type and grade of fuel.

Put the unit in an open area. Stop the engine and lock

the brake. Clean the fuel cap and the area around the

fuel cap to prevent dirt from entering the fuel tank.

Remove the cap from the fuel tank. Fill the fuel tank.

Be careful not to spill the fuel. Install the cap on the fuel

tank and tighten. Clean up any spilled fuel before

starting the engine.

4 -10

4.3 GENERAL LUBRICATION

Control Linkage Lubrication

Every 25 hours of operation put a drop of engine oil on

the pivots of the throttle lever, the direction control

lever, the gear shift lever, the PTO control, and range

shift handle.

NOTE:

There are no grease fittings on the tractor.

Transmission

Capacity: 5 U.S. Quarts (4.7 liters)

Grade: SAE 30W API service class SF or higher

Viscosity: Summer: SAE 30W or SAE 10W-30

Winter: (32

• After every 100 hours of operation, check the level

of the lubricant in the transmission. Never operate

the tractor when the transmission oil level is below

the "LOW’ mark on the dipstick.

• Stop the engine and raise the hood. Make sure that

the tractor is level. Clean the dipstick tube and the

dipstick (Figure 2). Remove the dipstick, wipe it

with a clean cloth or towel and put it back in the

tube. Pull the dipstick out again and look at the oil.

• If the oil level is below the low mark on the dipstick,

clean the area around the filler plug and remove

the filler plug. Add new clean lubricant until the

dipstick indicates that the oil level is correct. See

specification. Install the filler plug and dipstick.

1

o

F or below) SAE 10W or

SAE 10W-30

CAUTION:

Before performing any service or

adjustments:

• Turn PT O switch "OFF".

• Park mower on a hard, flat, level surface.

• Place steering control levers in neutral

lock (fully outward) posi tion .

• Set parking brake.

• Turn ignition switch "OFF" and remove

key.

• Wait for all moving parts to stop.

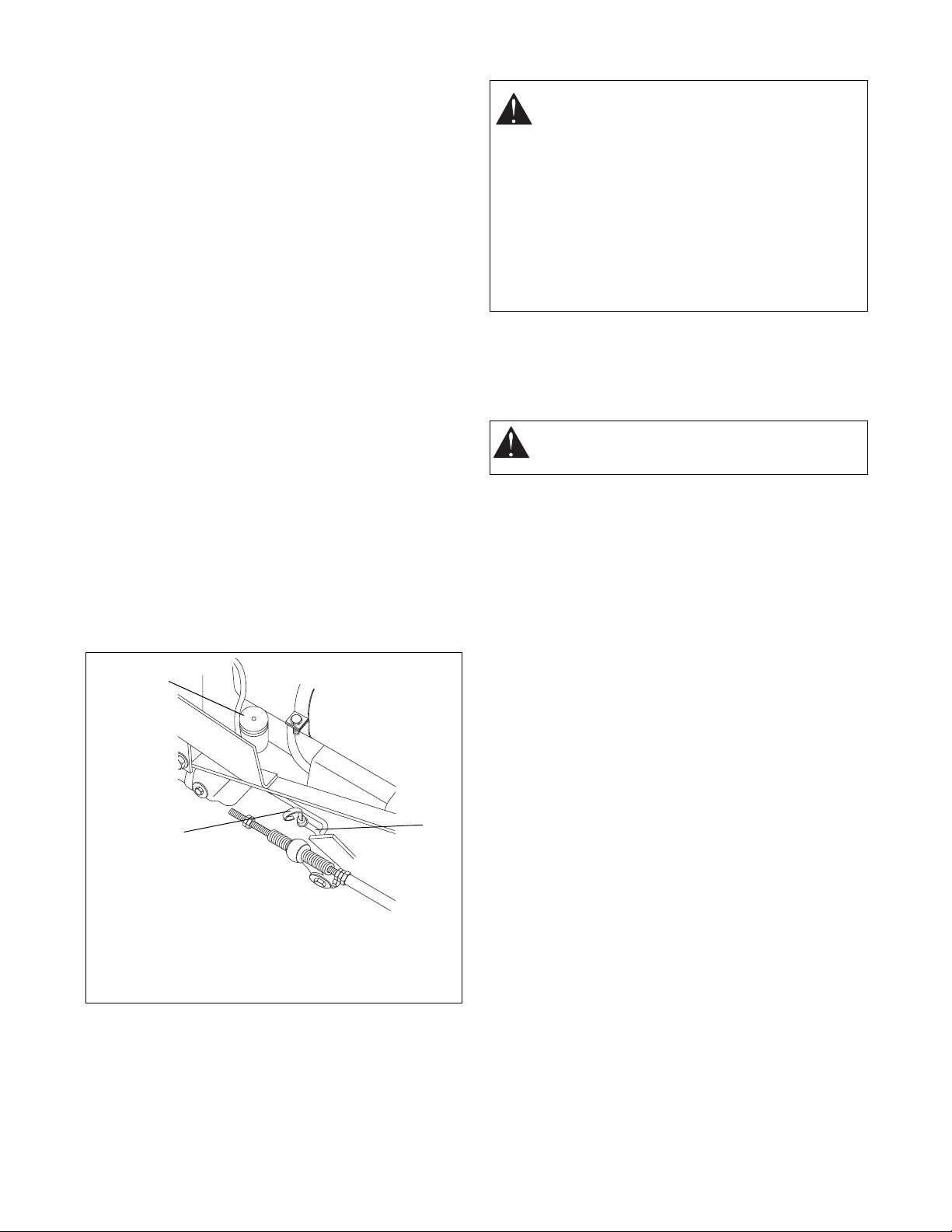

4.4 FORWARD-REVERSE CLUTCH

ADJUSTMENT

• After 25 hours of operation, check the adjustment

of the forward-reverse clutch.

WARNING:

the forward-reverse clutch.

• The reverse clutch is adjusted correctly when the

direction control lever stops 15 degrees past

vertical to the rear. The lever should return to

neutral position from reverse w hen adjus ted

correctly.

• To adjust the reverse clutch, loosen the control

extension rod jam nuts on the end of the fwd-rev

control rod. Adjust the rear nut so that the direction

control lever stops 15 degrees past vertical to the

rear. Hold the rear nut and jam with the forward nut

(Figure 3) .

• The forward clutch is adjusted correctly when the

direction control lever is in the full forward position

and the large spring has a coil clearance of .010"

(.254 mm).

Stop the engine before adjusting

2

1. Oil Filler Plug

2. Dipstick

3. Dipstick Tube

Figure 2

3

OH0230

4 -11

2

1

6

7

1

7

7

5

4

9

1

7

8

3

10

1. Jam Nuts

2. Fwd-Rev Control Rod

3. Control Extension Rod

4. Fwd-Rev Neutral

Spring

5. Large Spring

6. Brake Rod Assembly

7. Adjusting

nuts

8. Fwd-Re v Lever

Assembly

9. Adjustment Bracket

10. Cam Lever Arm

Figure 3

OH0181

• To adjust the forward clutch, put the direction

control in the forward position. Loosen the control

extension rod rear set of jam nuts on the fwd-rev

control rod. Adjust the forward nut until the large

spring coils are .010" (.254mm) apart. Hold the

forward nut and jam with the rear nut.

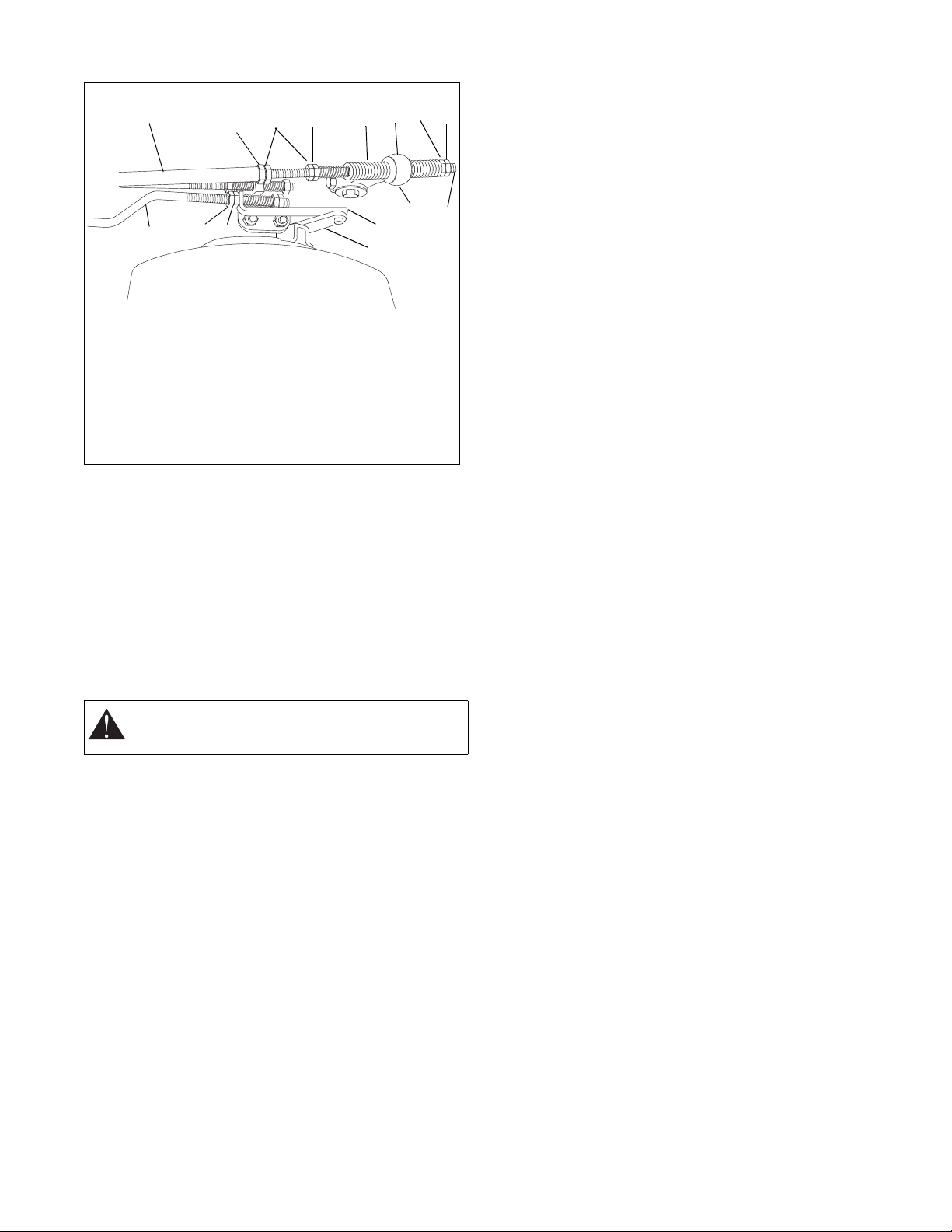

4.5 HI/LOW GEAR CLUTCH ADJUSTMENT

• After every 25 hours of operation, check the

adjustment of the gear clutch.

WARNING:

the gear clutch.

Stop the engine before adjusting

4.6 STEERING BRAKE ADJUSTMENT

(APPLICABLE MODELS)

• Park the unit in a level area. Put the parking brake

handle in the "OFF" (down) position. Loosen the

jam nuts on the right and left brake rod assemblies

(Figures 2 & 3). Turn the adjusting nuts until the

brake handle cross bar is parallel with the

instrument panel (Figure 1).

• Move the brake handlebar all the way to the right

and measure the distance from the right end edge

of the brake handle cross bar to the right side of

the instrument panel. Move the brake handlebar all

the way to the left and make the same

measurement on the left.

• Adjust the nuts until the difference between the two

measurements is 1/2" to 3/4" (13 to 19 mm). Turn

both adjusting nuts the same amount, clockwise to

increase the measurement difference or

counterclockwise to decrease the measurement

difference. Tighten the jam nuts.

• Loosen the jam nuts below the compression spring

(Figure 4) on the right side of the tractor and adjust

until one has the desired tension for the right

brake. Tighten the jam nuts.

IMPORTANT:

worn to rivet heads.

If correct braking action cannot be achieved after

performing the above procedures, do the following:

1. Loosen the 5/16-24 nut and bolt which fastens cam

lever arm to brake cam.

2. Remove cam lever arm from the brake cam. Rotate

the cam lever arm one spine to the rear and put

back on brake cam. Tighten nut and bolt.

Replace brake shoes before lining is

• The clutch is adjusted correctly when the gear shift

lever is in the "HIGH" or "LOW" position and the

spring coils are .010" (.254 mm) apart.

• To adjust the "HIGH" clutch, loosen and separate

the hi-low control rod jam nuts on the rear of the

control extension rod. Put the gear shift lever in the

"HIGH" position. Adjust the nut (front) near the

spring until the spring coils are .010" (.254 mm)

apart. Move the gear shift lever to the "NEUTRAL"

position. Hold the nut adjusted to the spring and

jam with the other (rear) nut (Figure 4).

• To adjust the "LOW" clutch, loosen and separate

the hi-lo control rod jam nuts on the end of the

control extension rod. Put the gear shift lever in the

"LOW" position. Adjust the nut (rear) near the

spring until the spring coils are 0.10" (.254 mm)

apart. Move the gear shift lever to the "NEUTRAL"

position. Hold the nut adjusted to the spring and

jam with the other (front) nut.

4 -12

1

1

9

2

3

4

2

5

2

7

1

8

1

2

6

1. Adjusting Nuts

2. Jam Nuts

3. Adjustment Bracket

4. Pivot Plate

5. Brake Rod Assembly

6. Hi-Lo Control Rod

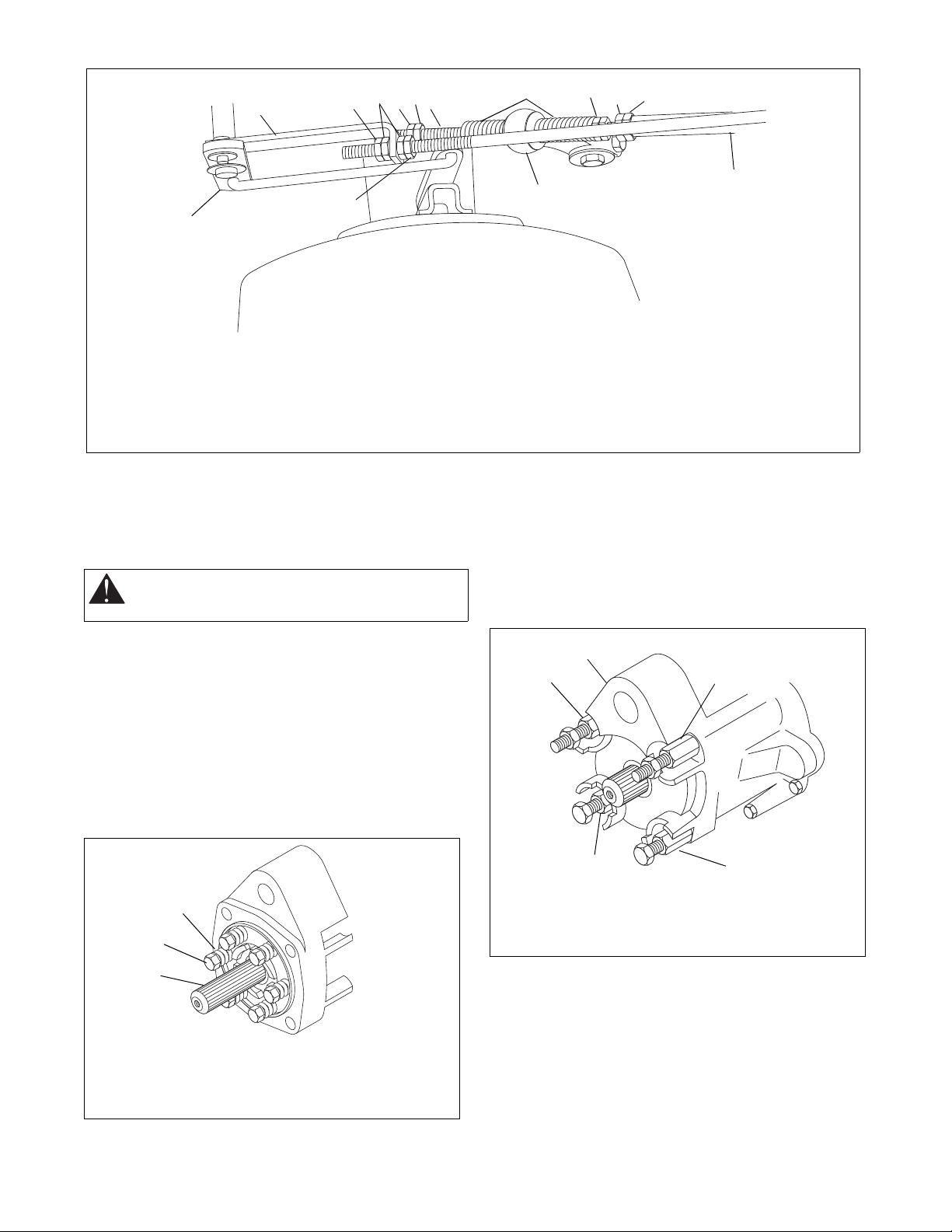

4.7 PTO BRAKE ADJUSTMENT

• Adjust the PTO brake after every 100 hours of

operation.

WARNING:

the PTO brake.

• Remove the attachment and lower the rear of the

tractor to the ground. Carefully clean the front of

the transmission. Remove the quick hitch studs

from the transmission and remove the quick hitch

casting and PTO brake assembly (Figure 5).

NOTE:

The attachment gasket must be replaced if

damaged.

• Tighten all PTO brake bolts until the springs are

solid. Back all bolts up 1/2 turn (Figure 5).

Stop the engine before adjusting

7. Large Spring

8. Hi-Lo Lever Assembly

9. Control Extension Rod

Figure 4

NOTE:

Do not tighten the bolts in a circular sequence,

by tightening the bolt next to one which was just tightened. The bolts should be tightened in a cross

sequence, by tightening one bolt, then tightening the

bolt which is across from it on the plate. Continue

tightening the bolts in this sequence until all the bolts

are tightened.

1

2

2

OH0191

2

1

3

1. PTO Brake Bolts

2. Springs

Figure 5

3. PTO Shaft

OH0210

2

1. Quick Hitch Adapter

2. Quick Hitch Stud

2

Figure 6

• Make sure the trunnion block is on the shipper

shaft and held in place by the dog. The dog should

rest on the spiral teeth of the clutch dog plate.

Install the gasket.

• Align the splines on the quick hitch shaft with those

in the dog. Slide the quick hitch casting and PTO

brake assembly back into the place on the front of

the transmission. Install the quick hitch studs and

tighten.

4 -13

OH0200

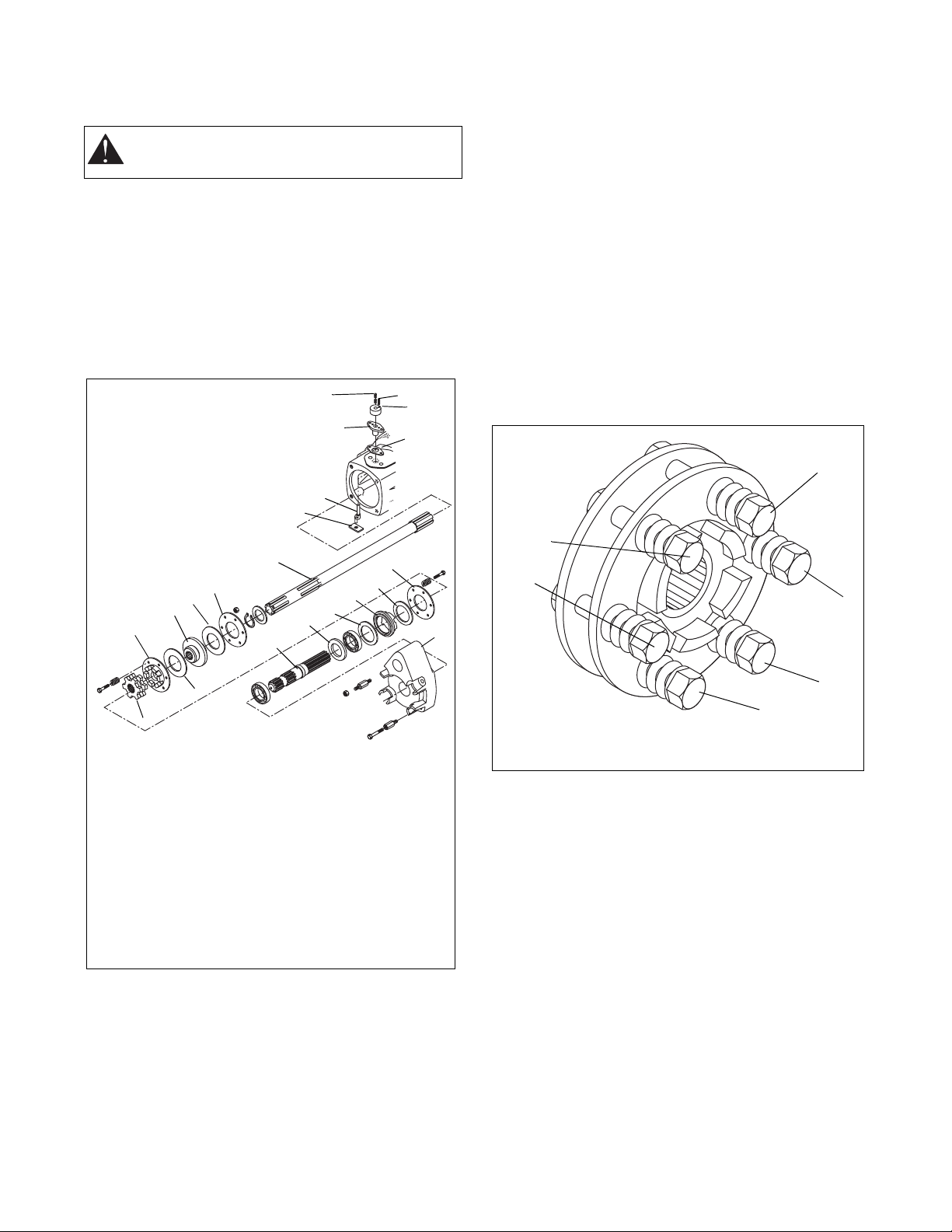

4.8 SLIP CLUTCH ADJUSTMENT

1

2

Figure 8

OH0220

3

2

4

5

6

• Adjust the slip clutch after every 100 hours of

operation.

WARNING:

the slip clutch.

• Remove the attachment and lower the rear of the

tractor to the ground. Carefully clean the front of

the transmission. Remove the quick hitch studs

from the transmission and remove the quick hitch

PTO assembly and PTO brake assembly (Figures

5 & 6).

NOTE:

The attachment gasket must be replaced if

damaged.

Stop the engine before adjusting

19

18

20

17

16

15

4

• Remove the dog and trunnion block. Disconnect

the wiring harness from the PTO brake interlock

switch and remove the shifter parts. Slide the

shipper shaft assembly through the top of the

advance casting. Slide the clutch assembly and

pinion shaft out of the transmission. Remove the

retaining ring and slide the clutch assembly off of

the pinion shaft. Turn all of the jam nuts

counterclockwise to loosen.

• Torque bolts in stages using the pattern shown in

Figure 8:

1. Tighten bolts down until the spring starts to

compress.

2. Tighten bolts to 80-85 in-lbs (9-9.6 Nm).

3. Tighten nuts to 165-170 in-lbs (18.6-19.2 Nm).

4. Finish tightening the nuts to 100-150 ft-lbs

(136-203 Nm).

10

11

12

14

13

2

5

6

1

2

3

7

9

8

1. Back Plate

2. Brake Disc

3. Dog Plate Brake

4. Trunnion Block

5. Seal

6. Quick Hitch Shaft

7. Quick Hitch Casting

8. Dog

9. Friction Washer

10.Dog Plate

Figure 7

11.Drive Plate

12.Friction Washer

13.Back Plate

14.Pinion Shaft

15.Shipper Shaft

16.Shipper Shaft Gasket

17.Shipper Shaft Body

18.Shipper Shaft

19.Set Screw

20.Roll Pin

NOTE:

Do not tighten the bolts in a circular sequence,

that is, by tightening the bolt next to one which was just

tightened. The bolts should be tightened in a cross

sequence, that is, by tightening one bolt, then

tightening the bolt which is across from it on the plate.

Continue tightening the bolts in this sequence until all

the bolts are tightened. (Figure 8)

• Slide the clutch assembly back onto the pinion

shaft, install the retaining ring and slide the pinion

shaft completely into the transmission. Install the

shipper shaft and other parts that were removed

previously. Make sure the trunnion block is on the

shipper shaft and held in place by the dog. The

dog should rest on the spiral teeth of the clutch dog

plate. Install the gasket. Align the splines on the

quick hitch shaft with those in the dog. Slide the

quick hitch casting and PTO brake assembly back

into place on the front of the transmission. Install

the quick hitch studs and tighten.

4 -14

Loading...

Loading...