Gravely 810, 812, 818T, 816S, 816T Owner's Manual

®

GRAVELY

READ THIS MANUAL BEFORE ATTEMPTING

TO

OPERATE THE EQUIPMENT.

OWNER'S MANUAL

OPERATOR'S INSTRUCTION

800

SERIES

Form No. 22454 (9-77)

Printed in USA.

BrentChalmers.com

BrentChalmers.com

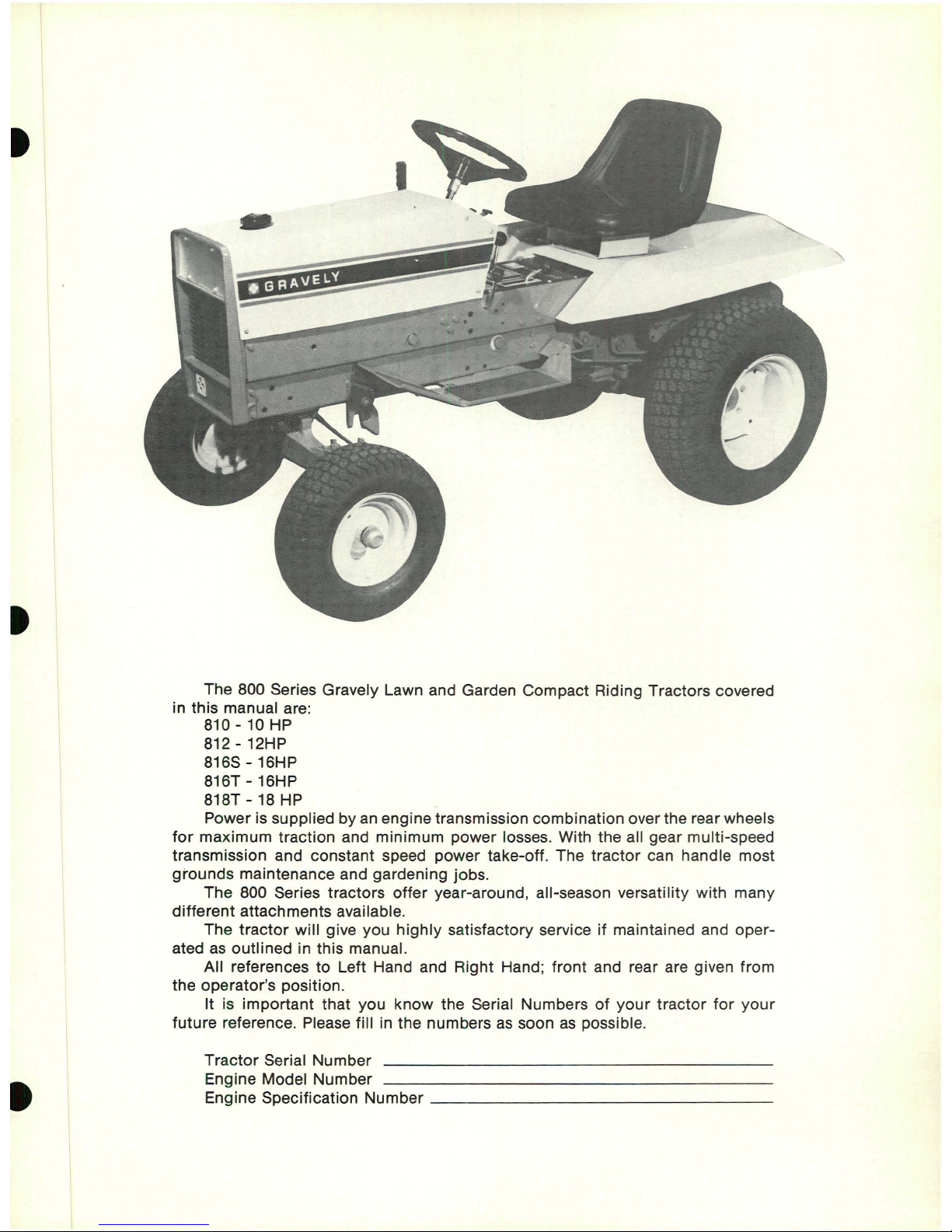

The 800 Series Gravely Lawn and Garden

Compact

Riding Tractors covered

in this manual are:

810 - 10 HP

812-12HP

816S - 16HP

816T - 16HP

818T - 18 HP

Power is supplied

by

an enginetransmission combination over the rear wheels

for

maximum

traction and

minimum

power losses. With the all gear multi-speed

transmission and constant speed

power

take-off. The

tractor

can handle most

grounds

maintenance and gardening jobs.

The 800 Series tractors

offer

year-around, all-season versatility with many

different

attachments available.

The

tractor

will

give you

highly

satisfactory service if maintained and

oper-

atedasoutlined

in this manual.

All references

to

Left Hand and Right Hand;

front

and rear are given

from

the operator's position.

It is

important

that you

know

the Serial Numbersofyour

tractor

for

your

future

reference. Please fill in the numbersassoon as possible.

Tractor

Serial

Number

Engine Model

Number

Engine Specification

Number

_

BrentChalmers.com

KNOW THE GRAVELY

Read this manual carefully and understand howtooperate and maintain

The

Tractor

before attempting

to

use it. The Tractor has been designed and

built

to

traditionally

high standards for which it is famous. With proper operation and

maintenance The

Tractor

will

perform

for

many years to come.

Before actually using The

Tractor

with

an

implement (after reading

and

un-

derstanding

this

manual)

spend some time with ittoget the feel and confidence

of

what The

Tractor

can do. Practice starting, turning, backing, changing direc-

tions, gear changes, stopping, etc. Knowing how

to

use The

Tractoristhe largest

partofgetting the

job

done.

It is very important that the SAFETY PRECAUTIONS be read, understood

and adhered to. Remeber, Safety First!

ABOUT THE WARflANTY

The Gravelyisdesigned and

built

for longevity. To maintain warranty, it is

the owners responsibilitytohave it operated and maintainedasoutlined in this

manual. A failure duetolackofmaintenanceorimproper useisnot covered

by

warranty.

Itisthe natureofmachines to "wear out". A failure duetoa defect usual-

ly

shows up early in the lifeofa machine. When The Tractor is in the warranty

period, the manufacturerormanufacturer's authorized representative will decide

whether a partisdefectiveorworn-out.

(The warranty statement appears in the back of this manual)

CONTENTS

INTRODUCTION 2

SAFETY OPERATING PRACTICES 3

CONTROLS 5

OPERATION 8

SERVICE INTERVALS 9

MAINTENANCE

&ADJUSTMENTS

10

STORAGE

17

TROUBLE SHOOTING · 17

SPECIFICATIONS

18

EQUIPMENT CHARTS

·.··

19

2

BrentChalmers.com

SAFETY OPERATING PRACTICES

I

Since the

tractor

is seldom used

without

powering

some

typeofequipment, these precautions are also

directed towards the operation

of

that

equipment.

Improper

use

of

the

tractor

and its attachments

may result in damage

to

the machinery

and/or

injury

to the operator. Practice these safety precautions

and pay attention

to

the

job

being done.

TRAINING

1.

Read this manual and the attachment manuals.

Be

thoroughly

familiar with the controls and

proper use

of

the equipment. Know

howtostop

the

unit

and disengage the controls quickly.

2.

Never

allow

childrentooperate the equipment.

Never

allow

adultstooperate equipment

without

proper

instructions.

3.

Keep area

of

operation clear of all persons,

especially small children and pets. Never direct

the attachment discharge toward bystanders

or

allow

anyone in

frontofthe unit.

PREPARATION

1.

Thoroughly

inspect the

work

area where the

equipment is

to

be used and remove all stones,

glass, metal, bones, sticks, wires and any

other

foreign objects. Stay alert

for

holes and

other

hidden hazards.

2.

Before attempting

to

start the engine, the

PTa

must be in the

OUT

position and the Direction

Control lever in Neutral

to

engage the interlock

switches.

3.

Do

not

put

handsorfeet nearorunder rotating

parts.

4.

Never operate the machine

without

good

visibil-

ity and light.

5.

Do

not

wear loose

fitting

clothingoraccessories

that

might

get

caught

in moving partsoron the

controls. Keep hands, feet, hair, clothing, etc.,

away from moving parts. Wear eye protection.

6.

Never attempt

to

make any adjustments while

engine

is

running (except where specifically rec-

ommended

by

the manufacturer).

7.

Handle fuel with care, it is

highly

flammable.

(A) Do

not

smoke while handling fuel.

(B) Use approved fuel container.

(C) Never add fuel

to

a running engine

or

hot

engine.

3

(D) Fill fuel tank

outdoors

with extreme care.

Never fill fuel tank indoors.

(E) Replace gasoline cap securely and wipe

spilled fuel from equipment.

OPERATION

1.

Operate the

tractor

only

from the operator's pos-

ition. Keep the feet on the

foot

rests.

2.

Before making any repairsoradjustments, STOP

the engine and put the

PTa

in the

OUT

position,

and set parking brake.

3.

When connected power equipment is

not

in use

or

is being transported, put the

PTa

in the

OUT

position.

4.

After striking a foreign object, STOP the engine

and put the

PTa

in the

OUT

position, and set

parking brake, before inspecting

for

damage.

Any

damage must be repaired before restarting

the equipment.

5.

Exercise caution, especially when operating in

reverse.

6.

Use care when pulling loads

or

using heavy

equipment.

(A) Use

only

the hitch connection pointsasde-

scribed in the manual.

(B) Limit loads

to

those that can

be

safely

con-

trolled.

(C) Do

not

make sharp turns especially when

backing

to

avoid jackknifing.

(D) Use auxiliary weight when suggested in the

attachment manual.

7.

Do

not

operate equipment except

from

proper

operator's position.

8.

Keep safety devices and shields in at all times.

9.

Do

not

allow

passengers

to

accompany

the

operator at any time.

10.

Disengage

PTa

before crossing a gravel drive,

walks

or

roads. Stay alert

for

hidden hazards

or

traffic.

11.

Use extreme caution when operating on slopes.

Reduce speed on all slopes and sharp turns

to

prevent

tipping

overorlossofcontrol.

12.

Before cleaning, repairing,

or

inspecting, make

certain all moving parts have stopped. Remove

the key and disconnect the spark plug wire

to

prevent accidental starting.

BrentChalmers.com

13.

If the unit should start

to

vibrate abnormally,

stop the engine, disengage the

PTa,

and check

for

the cause. Abnormal vibration is generally a

warning

of

trouble. If unabletolocate cause, call

your

service dealer.

14.

Never makeanattachment adjustment while engine is runningifthe operator must dismount to

do so.

15.

Take all possible precautions when parking

or

leaving the equipment unattended: STOP the

engine, remove the key, put the direction control

in neutral, and lower equipment.

16.

Do

not

run engine indoors, except when starting

engine and

for

transporting equipmentinor

out

of

building. Open outside

doorasexhaust fumes

are dangerous.

17. Never operate machine at high transport speeds

on slippery surfaces.

18.

Disengage the

tractor

PTa

when transporting

or

not

in use.

19.

Do

not

overload machine capacitybyattempting

to

operate equipment at

too

fast a rate.

20.

Use

only

attachments and accessories approved

by manufacturerofthe equipment. Unapproved

attachments can result in damagetothe equip-

mentorin personal injury.

21.

Be alert

for

traffic when nearorcrossing road-

ways.

22.

Do not startorstop suddenly when going up

or

down slopes. When mowing,

go

up and down

the face

of

slopes, never across. DO

NOT

mow

excessively steep slopes.

23.

When using the

tractor

with powered equipment,

never direct the discharge so astoendanger life

or

property

such

as

people, pets, structures,

cars, etc.

24.

Stay alert

for

holes in the terrain and

other

hid-

den hazards.

25.

Keep the equipment in good operating

condi-

tion, and keep safety devices in place.

26.

Do

not

change the engine governor settings

or

overspeed the engine.

4

MAINTENANCE AND STORAGE

1.

Keep all bolts, nuts, screws

tight

to

be sure

equipment is in safe working condition.

2.

Never store equipment with gasoline in the tank, t

inside a building where open flames

or

sparks

are present.

Allow

the engine

to

cool before

storing in any enclosure.

3.

Keep engine free of grass, leaves,ordebris,orexcessive grease to prevent overheating and possible fire hazard.

4.

Do not touch the mufflerorexhaust pipes until

they have had sufficient time to cool.

5.

Do not change the engine governor beyond

specified setting. (3600 RPM)

6.

Prevent accidental starting by removing the

spark plug wire from the spark plug. Remove the

key, and set parking brake when servicing the

tractor.

BrentChalmers.com

CONTROLS

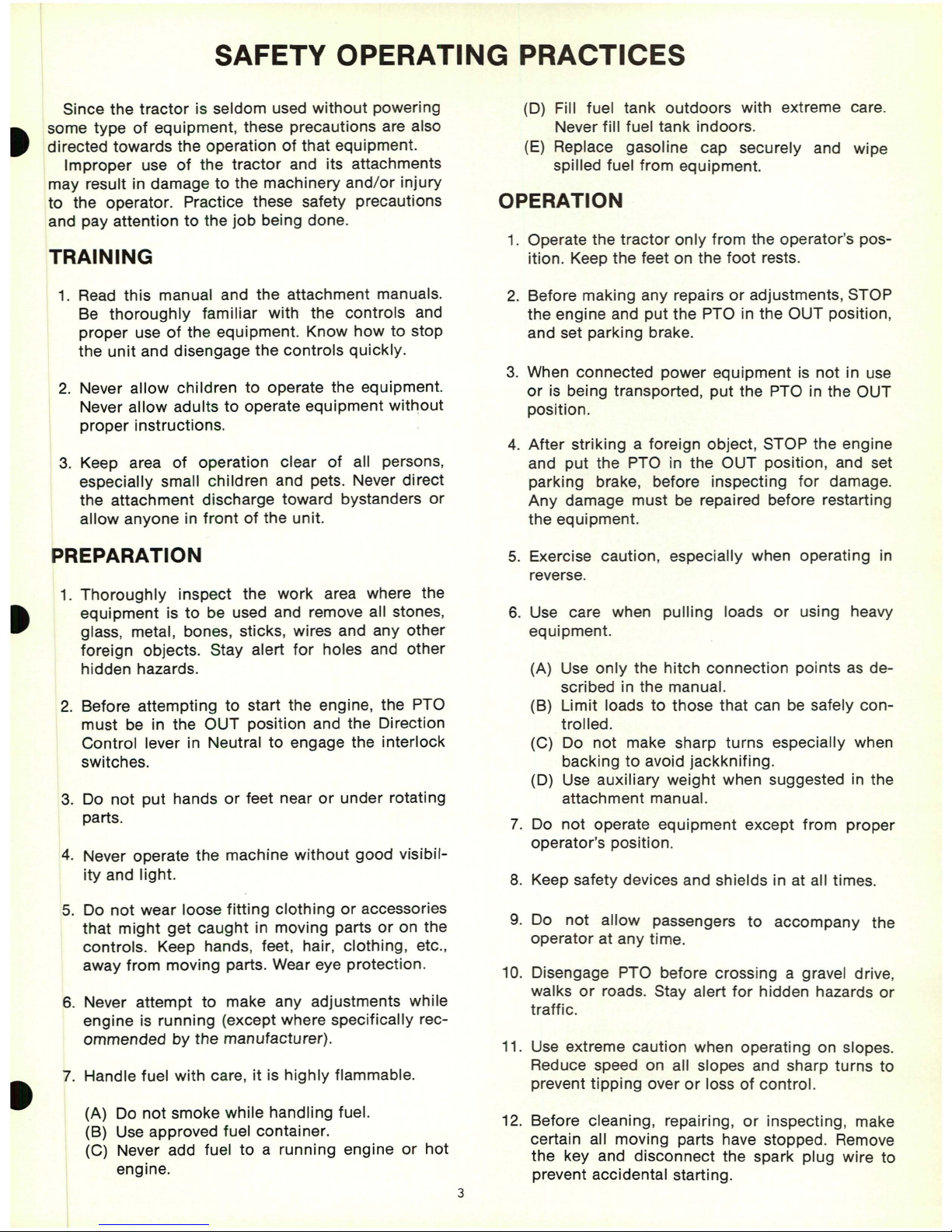

DIRECTION CONTROL LEVER

• The Direction

Control

Lever operates the unique,

• instant Forward and Reverse clutches that give, you

instant forward

to

reverse

controlofthe tractor. DO

NOT

continuously

slip the clutch. MOVE THE

CON-

TROL

LEVER TO A FULLY ENGAGED POSITION AS

SOON AS POSSIBLE AFTER GETTING UNDERWAY.

The Directional

Control

lever is located on the

right

sideofthe tractor. See fig.

1.

PROCEDURE

1.

Push the lever forward (away from operator)

to

go

forward.

2.

Pull the lever back (toward the operator)

for

re-

verse.

3.

Neutral is a straight up and down (vertical) posi-

tion.

4.

The Direction

Control

must be in the Neutral

po,

sition before engine will start due to the ignition

interlock switch.

5.

The operationofthe service brake will return the

Control

to

Neutral. (See Brake) The Control

t requires routine maintenance lubrication.

BRAKE-SERVICE AND PARKING

The Brake pedal operates master brake on the

transmission. Brake requires adjustmenttomaintain

effective braking. Brake must be adjusted to return

Direction

Control

to

Neutral before braking action

begins. (See Maintenance)

SERVICE BRAKE

Figure 1

GEAR SELECTOR

Figure 2

I

Pushing on pedal will stop the tractor. Pedal dis-

engages and returns Direction Control to Neutral.

PARKING BRAKE

Stop-rod: Depress pedal and move stop-rod lever

back (toward operator). To release, depress pedal

and move stop-rod lever forward. See fig. 1

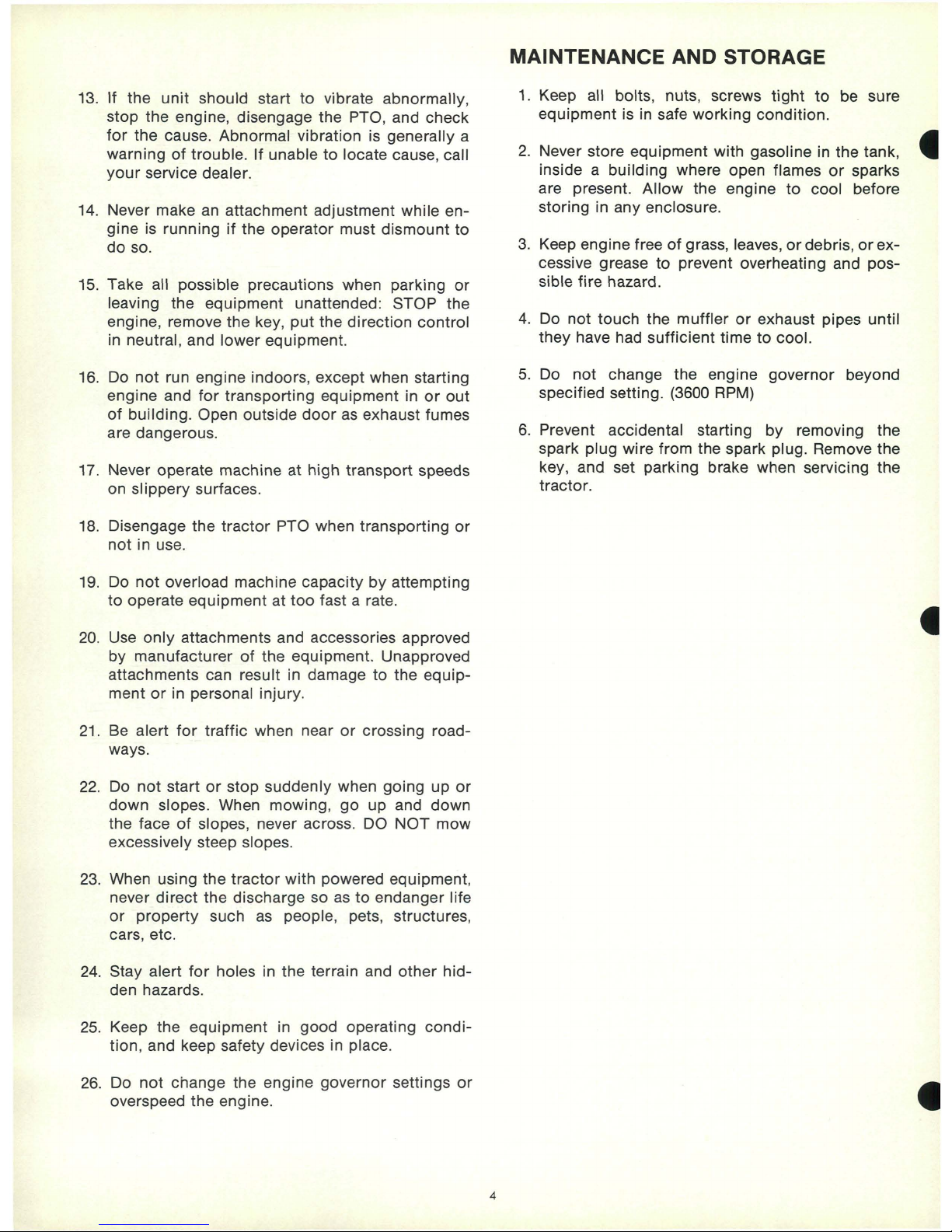

GEAR AND RANGE SELECTORS

The

controls

are used in combinationtogive you

eight

ground

speedstoselect from. Experiment

by

varying

ground

speedstofind the

optimum

speed

for

the

equipment

used. CAUTION: DO

NOT

ATTEMPT

TO SHIFT GEARS WHEN MOVING. DAMAGE WILL

RESULT. Always come

to

a complete stoptochange

range

and/or

gear. See fig

2.

5

RANGE SELECTOR

The

HI-LO

Range hasnodetented neutral position.

The

control

is either in HI

or

LO range. The Range

Selector

significantly

affects the

ground

speed

with-

out

affecting the PTO speedofthe power driven at-

tachment. See ground speed chart on page

18.

GEAR SELECTOR

The Gear Selector has

four

gearstochoose from.

The

"NEUTRAL"

position is the middleofthe

"H"

pattern.

PTO CONTROL

The PTO Control (power take-off) engages and

disengages the PTO clutch inside the transmission.

Follow all SAFETY PRECAUTIONS concerning the

PTO. See fig

2.

BrentChalmers.com

PROCEDURE

1.

PTO can be engaged at any engine speed.

(A)

Slowly

move control forwardtoengage.

"IN"

(B) Do

not

operate equipment until PTO is

fully

engaged and engine is at full throttle.

2.

Move

control

back toward

operatortodisengage

PTO.

3.

Control must be in

OUT

position before engine

will start due

to

ignition interlock.

4.

Control

requires maintenance

for

free-travel.

(See MAINTENANCE)

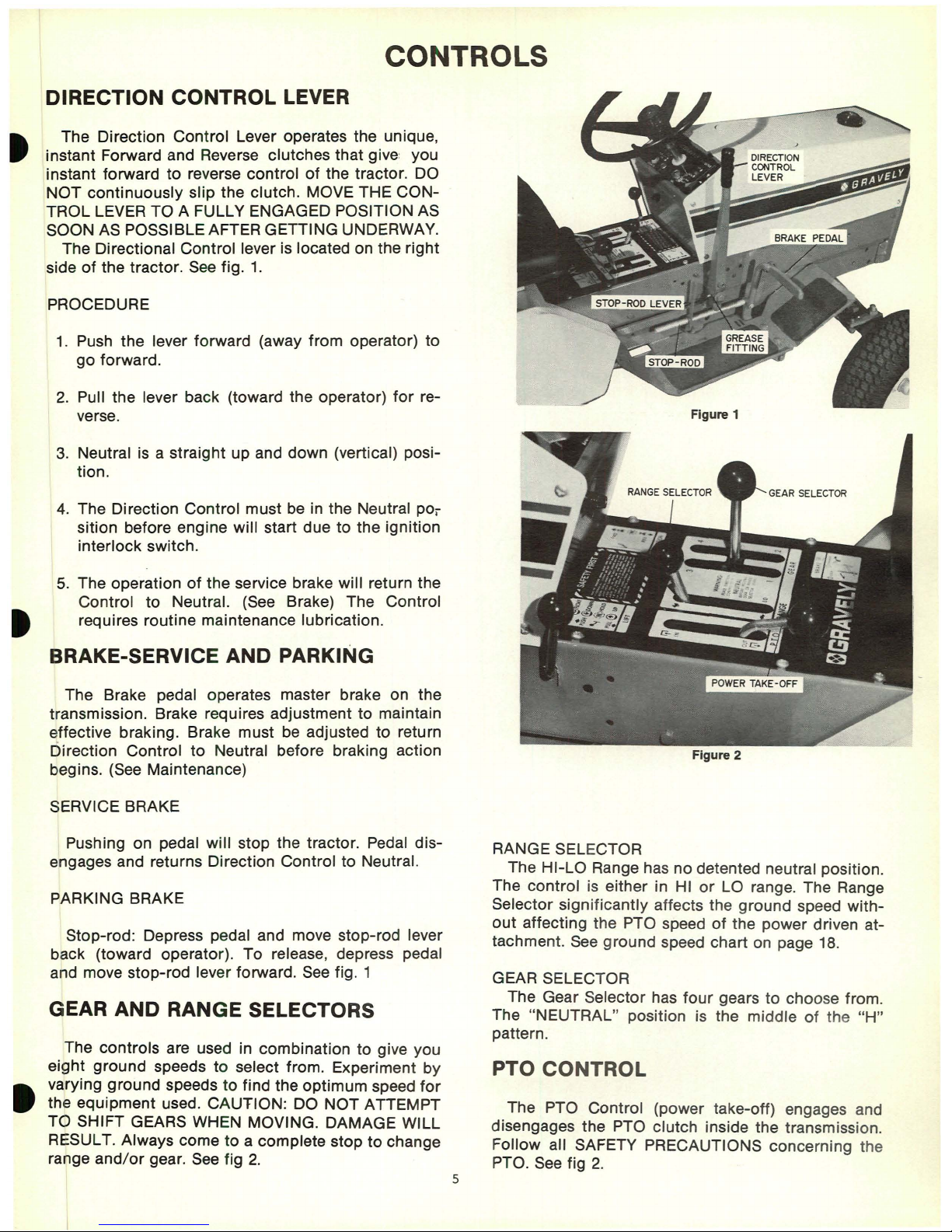

EQUIPMENT LIFT

The equipment

lift

provides a meansofraising

or

lowering front, center

or

rear mounted equipment.

Both HYDRAULIC and

MANUAL

LIFTS are located on

left side

of

tractor.

MANUAL

LIFT

1.

To

raise equipment, pull the lever towards

operator

untilitlocks. (Will

notgoback down).

2.

To lower equipment, pull back

slightly

and de-

press the button on top of lever, and push

for-

ward (away from operator). See fig

3.

MANUAL

LIFT POSITION LOCK

The Position Lock limits downward travel

of

lever

and can be adjusted

without

leaving operator's posi-

tion. See fig

3.

(A)

To

limit

downward travel, put the

Lift

Lever

in the raised position.

Liftupon the Position

Lock and at the same time,

pullout

towards

the operator.

II

Figure

3

(B)

To

put the equipment in the float position,

(follow ground contour) put the

Lift

Lever in

the raised position,

lift

up on the Position

Lock and at the same time push in.

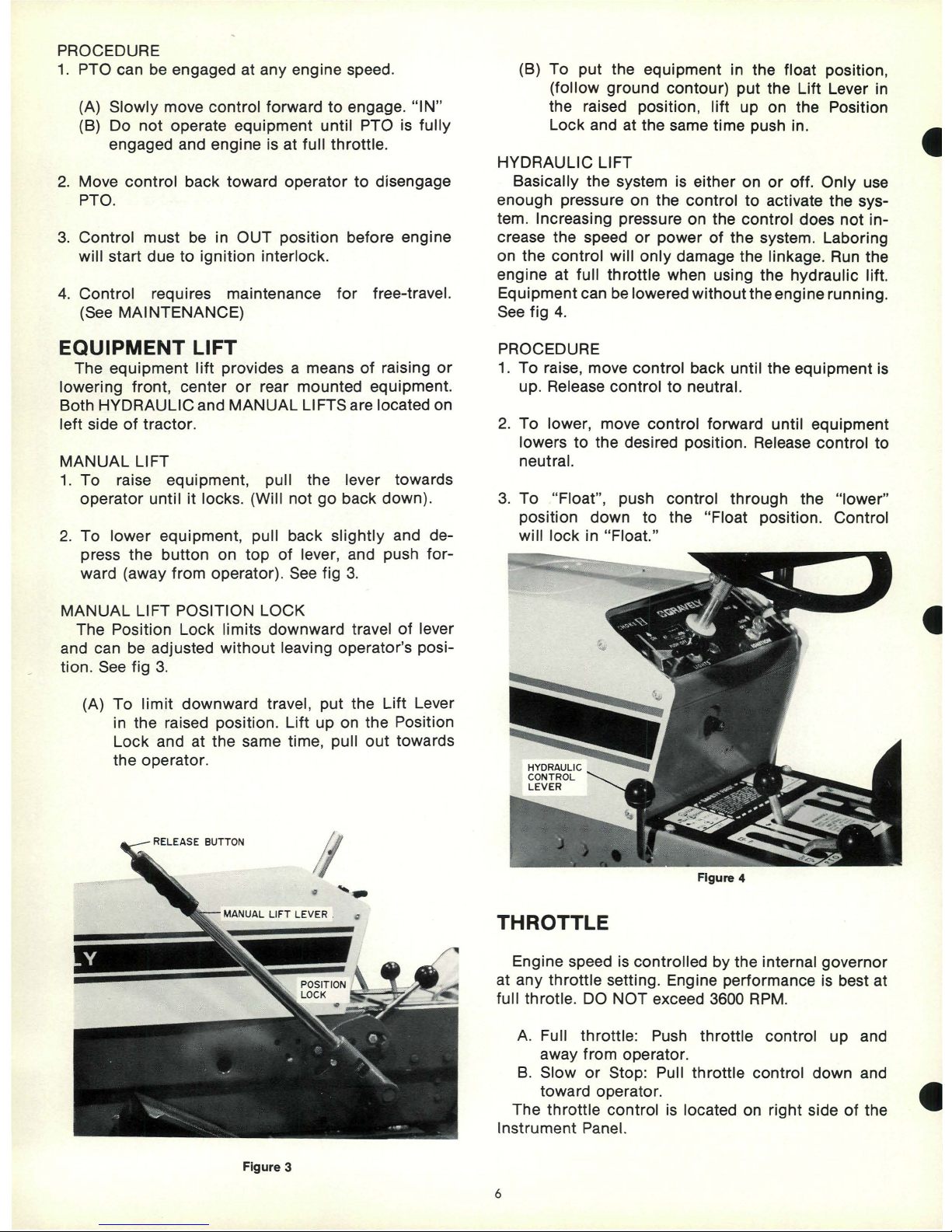

HYDRAULIC LIFT

Basically the system is either on

or

off.

Only

use

enough pressure on the control

to

activate the sys-

tem. Increasing pressure on the control does

not

increase the speedorpowerofthe system. Laboring

on the

control

will

only

damage the linkage. Run the

engine at full throttle when using the hydraulic lift.

Equipmentcan be lowered

without

theenginerunning.

See

fig

4.

PROCEDURE

1.

To

raise, move control back until the equipment is

up. Release control

to

neutral.

2.

To lower, move control forward until equipment

lowers

to

the desired position. Release control to

neutral.

3.

To

"Float", push control

through

the

"lower"

position down

to

the "Float position. Control

will lock in "Float."

Figure 4

THROTTLE

Engine speed is controlled by the internal governor

at

any

throttle setting. Engine performance is best

at

full throtle. DO

NOT

exceed 3600 RPM.

A.

Full throttle: Push throttle control

up

and

away from operator.

B.

Slow

or

Stop: Pull throttle control down and

toward operator.

I

The throttle controlislocated on right sideofthe

Instrument Panel.

6

BrentChalmers.com

Loading...

Loading...