Page 1

Appendix

Appendix .................................................................... 220

Declaration of conformity ........................................... 226

Graupner Service Centre .......................................... 227

Warranty certificate .................................................... 227

Before use

We are glad that you have chosen a Graupner mz-18

HoTT or mz-24 HoTT 2.4 GHz remote control system.

This system is extremely versatile and can be used by

both beginners and experts.

Please carefully review this manual to achieve the best

results with your remote control, and especially for safe

flying. If any difficulties arise during use, consult the

manual, contact your dealer, or contact the Graupner

Service Center.

Due to technical changes, the information within this

manual may be changed without prior notification.

Introduction

The Graupner remote-control system can be used to

control airplanes, gliders and helicopter models, and

is the perfect choice for anyone looking for a superior

remote-control system. The HoTT system transmits

a range of real-time data such as the motor speed,

voltage, temperature, warnings programmed by the

user, etc. Such data are for example transmitted directly

from a HoTT-compatible governor without requiring

additional sensors. Of course, these data can also be

transmitted from separately-connectable sensors that

are compatible with the HoTT system.

WARNING:

Read all of the instructions so that you

become familiar with how to operate the

system before you start using it. Misuse can

damage the system, cause property damage and/or

serious injury.

Warning and advisory symbols and their meaning

WARNING:

This symbol indicates subsequent information

that is essential for the user to observe. If

operation of the system and safety of the operator and

third parties cannot be ensured.

NOTE:

damage of every category, a loss of warranty, etc.

these instructions or suggestions are not followed,

damage of every category can result.

period.

these instructions are not followed, the reliable

This symbol indicates subsequent information

that the user must observe. If these

instructions are not followed, it may result in

Without a specific heading, this symbol

indicates subsequent information or

suggestions which the user must follow. If

This symbol indicates instructions and

suggestions of all kinds which the user must

follow.

This symbol indicates instructions on the care

of the device that the user must follow to

P

ensure the device remains useful over a long

Before use

3

Page 2

Safety instructions

Please follow the instructions.

To extend your enjoyment of your model, carefully read

this entire manual and pay special attention to the safety

instructions. You should also register now under https://

www.graupner.de/en/service/product_registration.aspx

to automatically receive latest product information by

e-mail.

If you are a beginner on remote-controlled model

airplanes, ships our cars, contact an experienced model

pilot for their advice.

PROPER USE

NOTE:

This remote-control system mast only be

used for the purpose specified by the

control models without passengers. Any other type

of use is not permitted and may damage the system

and cause significant property damage and/or

personal injury. No warranty or liability is therefore

offered for any improper use not covered by these

provisions.

NOTE:

TROLLED MODELS ARE NOT TOYS.

If improperly used or mishandled by third parties, even

small models can cause significant property damage

and/or personal injury.

control system. These instructions must therefore be

stored in a safe place and passed on to any subsequent

user.

4

manufacturer for operation of remote

THIS SYSTEM IS UNSUITABLE FOR UNSUPERVISED CHILDREN UNDER 14. SAFETY

IS INTENTIONAL, AND REMOTE-CON-

This operating manual is considered part of

the product. It contains important instructions

on how to operate and handle your remote

The warranty expires in case of not observing

the operating and safety instructions.

Safety instructions

Additional instructions and warnings

Technical defects of electrical or mechanical

nature may cause motors to start without

warning, or may generate flying parts which

can cause significant injury to both you and others.

Avoid short-circuits in any circumstance. Shor t-circuits

can destroy parts of the remote control system and

cause serious burns or explosions depending on the

circumstances and the battery charge.

All parts driven by the motor such as air and water

propellers as well as helicopter rotors, exposed gears,

etc. always pose an injury hazard. Never touch these

parts! A fast-rotating propeller can cut off a finger! Make

sure that no other objects come into contact with driven

parts.

Once the battery is connected or the motor is running,

always maintain a safe distance from the hazard area

posed by the propulsion system.

While programming, make sure that a connected

gas motor or electric motor cannot start accidentally.

Disconnect the fuel supply or drive battery beforehand.

Protect all equipment from dust, dirt, moisture and other

foreign parts. All equipment must be protected from

vibration as well as excessive heat or cold. The models

may only be operated remotely in normal outside

temperatures such as from -10°C to +55°C.

Avoid impacts and crushing. Check for damage to

the housing and cables. Devices that become wet or

damaged may not be used anymore even if they dry out.

Only use the components and recommended spare

parts. Always use matching, original Graupner plug-in

connectors of the same design and material.

When running the cables, make sure that they are not

excessively tight, kinked, or severed. A sharp edge may

damage insulation.

Make sure that all of the plug-in connectors are tight.

When disconnecting the plug-in connectors, do not pull

the cables.

No changes may be made to the devices. This will void

permission to use the device along with the warranty. If

appropriate, send the relevant device to the responsible

Graupner service center; see page 227.

Installing the receiver

For flying models, the receiver is installed

behind a strong rib and is protected against

dust and splash water in car and ship models.

When you install your receiver, make sure that it is not

excessively airtight to prevent it from overheating during

operation.

The receiver may not not directly touch the fuselage

or chassis since this may can directly transmit motor

vibration or impact from landing. When installing the

receiver in a model with a gas motor, all of the parts

must be protected to prevent exhaust or oil from

penetrating. This holds true in particular for the ON/OFF

switch that is installed in the shell of the model in most

cases.

Install the receiver so that the connecting cables for

the servos and power supply remain loose, and so that

the receiving antennas are at least 5 cm from all large

metal parts or wires that do not directly originate from

the receiver. This includes carbon fiber parts, servos,

electric motors, fuel pumps, all types of cables, etc. in

addition to metal parts.

It is preferable to install the receiver away from all

other installed parts at an easily accessible location

in the model. Servo cables may not be wound around

antennas or run next to them.

Make sure that the cables cannot shift to lie directly

adjacent to antennas during flight.

Installing the receiver antennas

The receiver and antennas should be as far away as

possible from drives of all kinds. If the tails are made of

carbon fiber, the ends of the antennas should extend

from the fuselage by at least 35 mm. If necessary,

exchange the approx. 145 mm standard antennas of

HoTT receivers with longer antennas.

It does not matter how the antennas are aligned.

However, a vertical installation of a single receiver

antenna in the model is advantageous. In the case of

Page 3

diversity antennas (two antennas), the active end of the

second antenna should be at a 90° angle from the end

of the first antenna, and the distance between the active

ends should ideally be more than 125 mm.

Installing the servos

Always install the servos with the provided rubber

vibration damper as shown in the "Installation

instructions" on page 34. This is the only way to

protect them somewhat from excessive vibration.

Installing the linkages

The linkage must be installed so that it is unhindered

and can move easily. It is particularly important for all a

rudder levers to execute their entire range of movement

without any mechanical restrictions.

To make it possible for running motors to be stopped

at any time, the linkage must be adjusted so that the

carburettor is completely closed when the throttle

control stick and trim are moved into idling end position.

Make sure that no metal parts rub against each other

when moving the rudder, vibrations, rotating parts, etc.

This may produce glitches and malfunction of receiver.

Aligning the transmitter antenna

The field strength emitted from the transmitter antenna

when it is pointing in a straight line is weak. It is therefore incorrect to point the transmitter antenna directly to

the model in the belief that this will increase reception.

When a number of remote control systems are being

used at the same time, the pilots should stand next to

each other in a loose group. Pilots standing away from

the group pose a danger both to their own model and

those of others.

If two or more pilots are using a 2.4 GHz remote control

system and are closer than 5 m from each other, it can

cause interference with the feedback channel, and a

range warning may be generated too early. The pilots

should move away from each other until the range

warning stops.

Checklist before starting

Before turning on the receiver, make sure that the

throttle control stick is at stop/idle.

Always switch on the transmitter before the receiver.

Always switch off the receiver before

switching off the transmitter.

WARNING:

If this sequence is not observed and the

receiver is switched on while the associa-

ted transmitter is "OFF", the receiver can

respond to other transmitters, interference, etc. This

can cause the model to move in an uncontrolled

manner and cause property damage or personal

injury.

When models have a mechanical gyro, the following

holds true:

Before turning on your receiver, make sure that the

motor cannot start unintentionally by disconnecting the

power supply.

When the gyro is running down, it frequently

generates so much voltage that the receiver thinks

that the throttle signals are okay. This can cause the

motor to start unintentionally.

Range and function test

Before every use, check the range and

functioning. Firmly secure the model, and

make sure that no one is nearby.

Perform at least one complete range and function

test on the ground, and run through an entire flight

simulation to determine if there are any problems with

the system or the programming of the model. Follow the

instructions on page 77.

WARNING:

If the range and function test as well as the

flight simulation are not performed

completely and conscientiously,

malfunctions may go unrecognized and

reception may be lost which could cause a loss of

control or even cause the model to crash. This

can result in major property damage and/or

personal injury.

Operating models: Airplane, helicopter, ship and

automobile

WARNING:

•

close to power lines. In addition, never operate

your model close to locks and open nautical

traffic. Do not operate your model on open roads,

highways, paths, public walkways, etc.

• Never switch off the transmitter while operating

the model! If this nonetheless accidentally

happens, do not panic, and wait until the

transmitter display goes dark which indicates

that the transmitter is completely off. This will

take at least 3 seconds. After this time, switch on

the transmitter again. Otherwise, the transmitter

may freeze directly after being switched on,

and you will be unable to control the model.

The transmitter may only be switched on again

after it has been switched off and the described

procedure has been correctly repeated.

Towing

WARNING:

the satellite receiver is an option. Otherwise,

malfunctions from the feedback channel are

possible.

Checking the transmitter and receiver batteries

message " Charge the battery!" appears in the display,

and an acoustic warning sounds.

Regularly check the battery charge, especially of the

receiver battery. Do not wait until the movements of

Never fly the model over the heads

of observers or other pilots. Never

endanger people or animals. Never fly

When operating towed models, maintain a

minimum distance of approximately 50 cm

between the participating receivers. Using

Stop operation and recharge the transmitter

battery at the latest when the

transmitter battery is running low, the

Safety instructions

5

Page 4

the rudder are noticeably slower. Replace damaged

batteries in a timely manner.

Always follow the manufacturers charging instructions.

Do not charge the batteries without monitoring them.

Never attempt to charge dry batteries. An acute

explosion hazard exists.

All batteries must be charged before each use. To

prevent short-circuits, first plug the banana plugs of the

charging cable into the charger (make sure the poles

are correct). Then plug in the charging cable plugs into

the sockets of the transmitter and receiver battery.

If you are not going to use your model for a while,

disconnect all power sources.

Never use rechargeable or replaceable batteries with

damaged, defective or different cell types; that is, a

mixture of old and new cells, or cells by a different

manufacturer.

Capacity and operating time

The following applies to all power sources: The capacity

decreases with each charge. At low temperatures,

the internal resistance increases while the capacity

decreases further. As a result, the battery's ability to

discharge and retain power is reduced.

Frequently charging and/or using battery care programs

can also gradually reduce the capacity. Nevertheless,

check the capacity of power sources at least every

six months, and replace them if their performance is

significantly low.

Only use original Graupner rechargeable batteries!

Suppressing interference in electric motors

All conventional electric motors generate

sparks between the collector and

operation of the remote control system depending on

the type of motor.

Interference-suppressed electric motors are therefore

required for the system to work well. Particularly when

the models have an electric drive, the interference

for each motor must be carefully suppressed. Noise

6

brushes which more or less interfere with the

Safety instructions

filters largely suppress such interference and must be

installed.

Follow the related instructions in the motor's operation

and installation instructions.

Additional details on noise filters can be found in the

main Graupner FS catalogue or on the Internet at www.

graupner.de.

Servo noise filters for extension cables

Order No. 1040

The servo noise filter is required when using longer-

than-usual servo cables. The filter is connected directly

to the receiver output. In critical cases, a second filter

can be placed on the servo.

Electronic speed controllers

The performance of the electric motor determines which

electronic speed controller is used.

To keep the speed controller from overloading or

becoming damaged, the current carrying capacity of

the speed controller should be at least 150 % that of the

maximum stall current of the motor.

Exercise caution with tuning motors, because they only

have a few windings and take several times their rated

current in a stall which can destroy the speed controller.

Electrical ignitions

Ignition systems of gas motors also generate interference that may impair the correct function of remote

controls.

The power supply for electrical ignitions should always

be from a separate source.

Only use interference-suppressed spark plugs and

spark plug connectors and shielded ignition cables.

The receiver should be at a sufficient distance from the

ignition system.

Static energy

WARNING:

Magnetic shock waves generated by

lightning can cause remote control

systems to malfunction even if the

lightning is miles away. If a thunderstorm is

approaching, land your model. Static discharge via

the antenna can also be life-threatening.

Note:

• To satisfy the high-frequency transmission

be maintained between the transmitter antenna and

people. Operation at a closer distance is therefore

not recommended.

• Make sure that no other transmitter is closer than

20 cm to prevent electrical malfunctions and impairment of emissions.

• To operate the remote control system, the country setting must be correct for the transmitter. This

is required to satisfy the various national guidelines

(FCC, ETSI, CE, etc.). Follow the respective instructions for the transmitter and receiver.

• Before each flight, perform at least one complete

range and function test, and run through an entire

flight simulation to determine if there are any problems with the system or the programming of the

model. Follow the instructions on page 77.

• Never program the transmitter or receiver while using the model.

Care

P

Components and accessories

NOTE:

accepted by Firma Graupner|SJ GmbH for suitability,

functioning and safety. If this is done, Graupner|SJ

GmbH will assume responsibility for the product.

However, Graupner|SJ GmbH assumes no liability

requirements of the FCC for mobile transmitters, a distance of 20 cm or more must

Never clean the housing, antenna, etc. with

cleansers, gas, water, etc. Only use a dry, soft

cloth.

As the manufacturer, Graupner|SJ GmbH

recommends only using components and

accessories that have been tested and

Page 5

for products or accessories by other manufacturers

that have not been approved, and is incapable

of evaluating every single third-party product to

determine if it can be used safely.

Disclaimer/damages

This manual is exclusively for information

purposes and is subject to change without

assumes no responsibility or liability for mistakes or

ambiguities that may be found in this manual.

Graupner|SJ GmbH is also incapable of ensuring that

the installation and operation instructions are observed,

and cannot monitor the maintenance of the conditions

and methods for installation, operation, use and

servicing the remote control components. Graupner|SJ

GmbH is also not liable for any loss, damage or costs

arising from, or in anywise associated with, improper

use and operation.

As permitted by law, the responsibility of Graupner|SJ

GmbH shall be restricted to damages, for whatever legal

reason, equivalent to the invoice value of the equipment

of Graupner|SJ GmbH directly involved in the event

leading to the loss. This does not apply in the event of

unlimited liability on the part of Graupner|SJ GmbH due

to intent or gross negligence according to binding law.

page 26 and "Timer" on page 80. The transmitter must also be updated to the most recent software.

Please note, for technical reasons there is no data

recording during playing mp3 files.

In order to be aware of important software updates, you

should therefore register at https://www.graupner.de/en/

service/product_registration.aspx. This will allow you to

automatically receive updates by e-mail.

prior notification. Graupner|SJ GmbH

Furthermore, only those claims can be

reimbursed which are supported by a log

file (see "Collecting/saving data" on

Safety instructions

7

Page 6

Safety instructions and handling guidelines for nickel metal hydride rechargeable

batteries

As is the case with all high-quality products, the following safety instructions and handling guidelines must be

observed to ensure long, trouble-free and safe use.

NOTE:

•

of children.

• Before each use, make sure that the batteries are in

a satisfactory condition. Defective or damaged cells

or batteries may not be used.

• Cells and batteries may only be used in accordance

with the technical specifications for the specific cell

type.

• Batteries and cells may not be heated, burned,

short-circuited or charged with excessive current

or with reversed polarity.

• Batteries from parallel-connected cells, combinations of old and new cells, cells of different

makes, sizes, capacities, manufacturers, brands

or type may not be used.

• Batteries which have been installed in a device

should always be removed when the device is not

being used. Always switch off devices after you have

finished using them to prevent battery drainage. Be

sure to charge the batteries in a timely manner.

• While they are being charged, the batteries must be

placed on a nonflammable, heat-resistant and nonconductive surface. Combustible or highly flammable

objects are to be kept away from the charging area.

• Batteries must be monitored while they are being

charged. The maximum charging current specified

for the respective cell type may not be exceeded.

• If the battery heats up above 60°C while it is being

charged, stop charging and let the battery cool down

to approximately 30°C.

• Do not charge batteries that have already been

charged, are hot, or have not discharged to the

specified level.

Batteries as well as individual cells are not

toys and must be kept from children. They

must therefore be stored out of the reach

• The batteries may not be modified. Do not directly

solder or weld the cells.

• If handled improperly, there is a danger of fire,

explosion, irritation and burns. To extinguish a fire,

use a fire extinguishing blanket, CO2 extinguisher

or sand.

• Leaked electrolyte is caustic and should not be

touched or come into contact with your eyes. In case

of emergency, rinse with a large quantity of water

and then consult a physician.

• The valve openings for the cells should never be

blocked or sealed, for example with solder. When

soldering, the maximum soldering temperature of

220°C should not exceed 20 seconds.

• To avoid deformation, avoid excessive mechanical

pressure.

• If the batteries overheat, proceed as follows:

Disconnect the battery, and place it on a nonflamm-

able surface (such as cement) until it cools down.

Never hold the battery in your hand due to the risk of

explosion.

• Make sure to observe the charging and discharging

instructions.

General instructions

The battery capacity decreases each time it is

charged and discharged. Storage can also

gradually reduce the battery's capacity.

Storage

Batteries may only be stored completely discharged

in dry rooms with an ambient temperature of +5°C to

+25°C.

NOTE:

The cell voltage should not fall below 1.2 V

when stored for a long time. Before being

stored, the battery may have to be charged.

Equalizing the individual battery cells

• To adjust the cells of a new battery to each other,

charge them normally to the maximum charge. As a

rule of thumb, charge empty batteries for 12 hours

with a current which is 1/10 of the rated capacity

(the "1/10 C" method) The cells will then all have the

same charge. The cell charge should be equalized

about every 10th charge in order to extend the life of

the battery.

• If you are able to discharge individual cells, do this

before each charging. Otherwise, the battery pack

should be discharged to 0.9 V per cell. With the fourpack used in the transmitter, this corresponds for

example to a discharge voltage of 3.6 V.

Charging

While charging, the specified current, charging time and

temperature range should be observed under constant

monitoring. If you do not have a suitable fast charger

that allows the charging current to be precisely adjusted,

charge the battery the usual way using the 1/10 C

method (see the example above).

Given the different charges of the cell, transmitter

batteries should be charged using the 1/10 C

method whenever possible. The charging current

should never exceed the maximum permissible level

indicated in the transmitter instructions.

Fast charging

If your charger has this option, set the delta peak cutoff

voltage to 5 mV per cell. Most chargers are permanently

set to 15 … 20 mV per cell and can therefore be used

for both NiCd batteries as well as NiMH batteries. In

case of doubt, consult the operating instructions or the

dealer to determine whether your device can handle

NiMH batteries. In case of doubt, charge your batteries

with one-half the indicated maximum charging current.

Discharging

All of the batteries that are sold by Graupner and GMRacing can handle a maximum continuous charging

current of 6… 13 C depending on the battery type (refer

to the manufacturer's specifications). The battery life

decreases as the continuous current load increases.

Reflex charging as well as charging/discharging pro-

Safety instructions

8

Page 7

grams unnecessarily shorten the life of batteries and are

only suitable for checking the battery quality or restoring

old cells. It is likewise not recommendable to charge and

discharge a battery before a single use unless you want

to check the battery's quality.

Instructions on the mz-18 HoTT remote control set

Order No. S1005

The respective Transmitter set is equipped

with a four-cell NiMH transmitter battery

default undervoltage limit of 4.8 V, a warning message

appears in the display of the transmitter.

(subject to change). After reaching the factory

Safety instructions

9

Page 8

Safety instructions and handling guidelines for lithium-ion and lithium polymer

rechargeable batteries

As is the case with all high-quality products, the following safety instructions and handling guidelines must be

observed to ensure long, trouble-free and safe use of

lithium-ion and polymer batteries.

Lithium-ion/lithium polymer batteries require special

treatment. This is true when charging, discharging,

storing and all other types of handling. Observe the

following specifications:

Special instructions on charging Graupner

lithium-ion/lithium polymer batteries

NOTE:

•

voided upon incorrect charging or discharging.

• Only use the approved chargers with the associated

charging cables to charge lithium-ion/lithium polymer

batteries. Any alterations to the charger or charging

cables can cause serious damage.

• The maximum charging capacity must be limited to a

factor of 1.05 of the battery capacity.

Example: 700 mAh battery = 735 mAh max. charging

capacity

• To charge and discharge lithium-ion/lithium polymer

batteries, only use the plug-in charger in the set,

or the specially designed charger/dischargers by

Graupner, see page 16 or listed at www.graupner.

de.

• Make sure that the number of cells, charging cutoff

and discharging cutoff voltage are set correctly.

Refer to the operating instructions of your charger/

discharger.

• Under these prerequisites, Graupner lithium-ion/

lithium polymer batteries can be charged with a

maximum 2 C (1 C corresponds to the cell capacity)

charging current. Starting at a maximum 4.2 V per

cell, continue charging at a constant 4.2 V per cell

until the charging current falls below 0.1… 0.2 A.

• Do not charge with more than 4.20 V per cell. This

10

Since Graupner|SJ GmbH is unable to

monitor whether the batteries are correctly

charged and discharged, all warranties are

Safety and handling instructions for lithium-ion/lithium polymer batteries

would permanently damage the cell and may cause

a fire. To keep from overcharging individual cells

within the pack, set the cutoff voltage between 4.10

… 4.15 V per cell in order to extend the battery life.

• The permissible temperature range for charging and

discharging lithium-ion/lithium polymer batteries is

0 … +50 °C.

• Batteries as well as individual cells are no toys and

must be kept from children. They must therefore be

stored out of the reach of children.

• Keep batteries away from infants and small children.

If a battery is swallowed, immediately consult a

physician or go to an emergency room.

• Never place a battery in a microwave or under

pressure. This may cause smoke, fire or an

explosion.

• Do not disassemble lithium-ion/lithium polymer

batteries. Disassembling a battery can cause internal

short-circuits. This same results in the release of gas,

fire and explosion, or other problems.

• The electrolyte and electrolyte vapours within

lithium-ion/lithium polymer batteries are hazardous

to health. Avoid direct contact with electrolytes. If the

electrolyte comes into contact with your skin, eyes or

other body parts, use a large amount of fresh water

for rinsing and then consult a doctor.

• Before each use, make sure that the batteries are in

a satisfactory condition. Defective or damaged cells

or batteries may not be used.

• Cells and batteries may only be used in accordance

with the technical specifications for the specific cell

type.

• Batteries and cells may not be heated, burned,

short-circuited or charged with excessive current

or with reversed polarity.

If handled improperly, there is a danger of fire,

explosion, irritation and burns. To extinguish

a fire, use a fire extinguishing blanket, CO2

extinguisher or sand.

• If the batteries overheat, proceed as follows:

Disconnect the battery, and place it on a

nonflammable surface (such as cement) until it cools

down. Never hold the battery in your hand due to the

risk of explosion.

• Batteries from parallel-connected cells, combinations of old and new cells, cells of different

makes, sizes, capacities, manufacturers, brands

or type may not be used.

• Batteries which have been installed in a device

should always be removed when the device is not

being used. Always switch off devices after you have

finished using them to prevent battery drainage.

Dead lithium-ion/lithium polymer batteries are

considered defective and may not be reused.

• Be sure to charge the batteries in a timely manner.

While they are being charged, the batteries must be

placed on a nonflammable, heat-resistant and nonconductive surface. Combustible or highly flammable

objects are to be kept away from the charging area.

• Batteries must be monitored while they are being

charged. The maximum charging current specified

for the respective cell type may not be exceeded.

• You may only charge a pack of series-connected lithium-ion/lithium polymer batteries all at once as long

as the voltage of the individual cells does not deviate

by more than 0.05 V, or if the differences in voltage

are monitored and equalized by a balancer connector using a balancer or equalizer during charging.

The lithium-ion battery in the set comes with a

special safety shut off. The voltage differences

between individual cells are therefore not balanced

by means of the usual balancer plug-in connector.

• If the battery heats up above 60 °C while it is being

charged, stop charging and let the battery cool down

to approximately 30 °C.

• The batteries may not be modified. Do not directly

solder or weld the cells.

• To avoid deformation, avoid excessive mechanical

pressure.

Page 9

• Make sure to observe the charging and discharging

instructions.

Storage

Lithium lithium-ion/lithium polymer cells should

be stored charged with 10-20% of their

lithium-ion/lithium polymer cells must be recharged to

10-20% of the full capacity. Otherwise, the battery will

die during storage and become useless.

Special instructions on discharging Graupner

lithium-ion/lithium polymer batteries

•

• Discharging below 2.5 V per cell will damage the

• The batteries should never be short-circuited. Short-

• The battery's temperature during discharging should

Additional instructions on handling

•

capacity. If the cell voltage falls below 3 V, the

A continuous current of approximately 1 C

does not pose a problem for Graupner

lithium-ion/lithium polymer batteries. If the

current is higher, refer to the instructions in the

catalogue. Bear in mind the maximum load for the

plug-in system (see the maximum discharge current

on battery).

cells and should therefore be avoided at all costs.

circuits generate a very high current which heats

up the cells. This causes a loss of electrolyte, gas

formation or even explosions. Graupner lithium-ion/

lithium polymer batteries should therefore be kept

away from and not touch conductive surfaces due to

the short-circuit hazard.

never exceed +70°C. Otherwise, make sure that the

battery is sufficiently cooled, or reduce the discharge

current. The temperature can be easily checked

using the infrared thermometer (order No. 1963).

However, the battery may not be discharged using

the transmitter's charging socket. This socket is not

designed for this purpose.

The battery capacity decreases each time

it is charged and discharged. Charging

when the temperature is too high or too

low can also gradually reduce the battery's capacity.

After 50 cycles, the battery capacity of models is

only 50-80% of that of a new battery due to the

occasionally high discharge current and induction

current of the motor, even when all charging and

discharging instructions have been followed.

• Batteries may only be series-connected or parallelconnected in exceptions since the cell capacity and

charge can differ. The battery packs that we supply

are therefore preferable.

• The connectors of lithium-ion/lithium polymer

batteries are not as robust as other batteries. This

holds true particularly for the plus connector. The

connectors can easily break.

Cell connector

Direct soldering on the battery cells is not

permitted.

The heat from direct soldering can damage

battery components such as the separator or isolator.

Battery connectors should only be created by spot

welding in the factory. If the cable is missing or severed,

have it repaired professionally by the manufacturer or

dealer.

Replacing individual battery cells

Individually battery cells may only be

exchanged by the manufacturer or dealer and

not by the user.

Do not use damaged cells

Damaged cells may not be used.

Indications of damaged cells include damaged

housing packaging, deformed cells, the smell

of electrolyte or leaking electrolyte. The battery may not

be used in these cases.

Damaged or useless cells are considered hazardous

waste and must be disposed of properly.

General warnings

Batteries may not be immersed in liquid such

as tap water, sea water or beverages. Avoid all

contact with liquids of any kind.

Safety and handling instructions for lithium-ion/lithium polymer batteries

Instructions on the mz-24 HoTT remote control set

Order No. S1006

The remote control set comes standard with a

lithium-ion transmitter battery with an

integrated protective circuit (subject to

modification). A warning appears in the transmitter

display after the voltage falls below the default lowvoltage limit of 3.60 V which may be modified by the

user.

11

Page 10

Disposal of used single-use and rechargeable

batteries

According to the Germany Battery Directive,

consumers are bound by law to return all used

single-use and disposable batteries.

They may not be disposed of in household garbage. Old

single-use and rechargeable batteries can be dropped

off without reimbursement at municipal collection

sites, at our sales outlets and wherever single-use or

rechargeable batteries of the relevant type are sold. Old

rechargeable and single-used batteries supplied by us

can also be reswitched postage-paid to the following

address:

Graupner|SJ GmbH

Service: Used batteries

Henriettenstrasse 96

D-73230 Kirchheim unter Teck

Thank you for protecting the environment!

CAUTION:

Damaged batteries may require special

packaging when shipped because they

may be highly toxic!

Environmental protection information

If this symbol is on the product, instructions for use or packaging, it indicates

that the product may not be disposed

with normal household waste once it

has reached the end of its service life. It

must be sent to a recycling collection

point for electrical and electronic

equipment.

Individual markings indicate which materials can be

recycled. By reusing the product, recycling the materials

or recycling used equipment in other ways, you make

an important contribution to protecting the environment.

Any batteries (including rechargeable batteries) must be

removed from the device and disposed of separately at

an appropriate collection point.

If necessary, contact your local authorities to find the

proper disposal site.

Instructions on disposal and environmental protection

12

Page 11

Computer systems for the mz-18 and mz-24 series

two remote control sets with a 2.4 GHz Graupner HoTT system (hopping telemetry transmission)

Common features

• Microcomputer remote control system using the

latest 2.4 GHz Graupner HoTT technology

• Maximum insensitivity to interference from optimized

frequency hopping over a max. 75 channels and a

wide channel spread

• Intelligent data transmission with a correction function

• Ultrafast reaction times by direct data transmission

from the main processor to the 2.4 GHz RF module

with reliable transmission. No additional delays or

rerouting through other processors.

• Bidirectional communication between the transmitter

and receiver

• Extremely fast rebinding even at maximum distances

• Range test and warning function

• Receiver low voltage warning in the transmitter

display

• Extremely wide receiver operating voltage range

from 3.6 V to 8.4 V (fully functional down to 2.5 V)

• Fail Safe

• A host of programming and evaluation functions

shown directly on the transmitter with special

telemetry displays

• All components may be updated which extends

usefulness

• Cutting-edge wireless trainer system for easy

beginner training

• Touch-sensitive coloured TFT display

• Additional side control buttons

• Etc.

mz-18 remote control set, order No. S1005

• Delivered items

mz-18 HoTT transmitter, order No. S1005.en, with

installed fl at NiMH transmitter battery 4NH-2000

RX RTU (subject to modifi cation), plug-in charger

(5.6 V/200 mA), bidirectional Graupner receiver GR-

12L HoTT (order No. S1012) and GR-24 HoTT (order No. 33512), USB adapter/interface (order No.

7168.6) including USB cable and adapter cable (order No. 7168.6S) for receiver updates, carrying strap

and instructions, warranty card and stylus for alternative use of the touch sensitive display

• Individual transmitter features

Max. 9 control channels

30 model memories

2 trimmable control stick systems (controls 1… 4)

1 two-position switch with long handle (S6*)

1 three-position switch with long handle (S3*)

4 three-position switches with short handle (S1*, S4*,

S5* and S7*)

2 one-side, self-neutralizing three-position switches

with long handle (S2* and S8*)

2 rear proportional sliders (SL1* and SL2*)

2 front proportional dials (DV1 and DV2*)

mz-24 remote control set, order No. S1006

• Delivered items

mz-24 HoTT transmitter, order No. S1006.de, with

installed lithium polymer transmitter battery LiPo

1s2p/4000mAh/3.7 V TX (subject to modifi cation),

plug-in charger (4.2 V/500 mA), bidirectional

Graupner receiver GR-12L HoTT (order No. S1012)

and GR-24 HoTT (order No. 33512), USB adapter/

interface (order No. 7168.6) including USB cable

and adapter cable (order No. 7168.6S) for receiver

updates, as well as a micro SD card with adapter

for card readers, carrying strap, carrying case and

instructions, warranty card and stylus for alternative

use of the touch sensitive display

• Individual transmitter features

Max. 12 control channels

30 model memories

Integrated MP3 player

2 trimmable control stick systems (controls 1… 4)

1 two-position switch with long handle (S6*)

1 three-position switch with long handle (S3*)

4 three-position switches with short handle (S1*, S4*,

S5* and S7*)

2 one-side, self-neutralizing three-position switches

with long handle (S2* and S8*)

2 INC/DEC buttons (DT1* and DT2*)

2 rear proportional sliders (SL1* and SL2*)

4 proportional dials (DV1* … DV4*)

* See "Transmitter control elements" on page 18

Description of the transmitter

13

Page 12

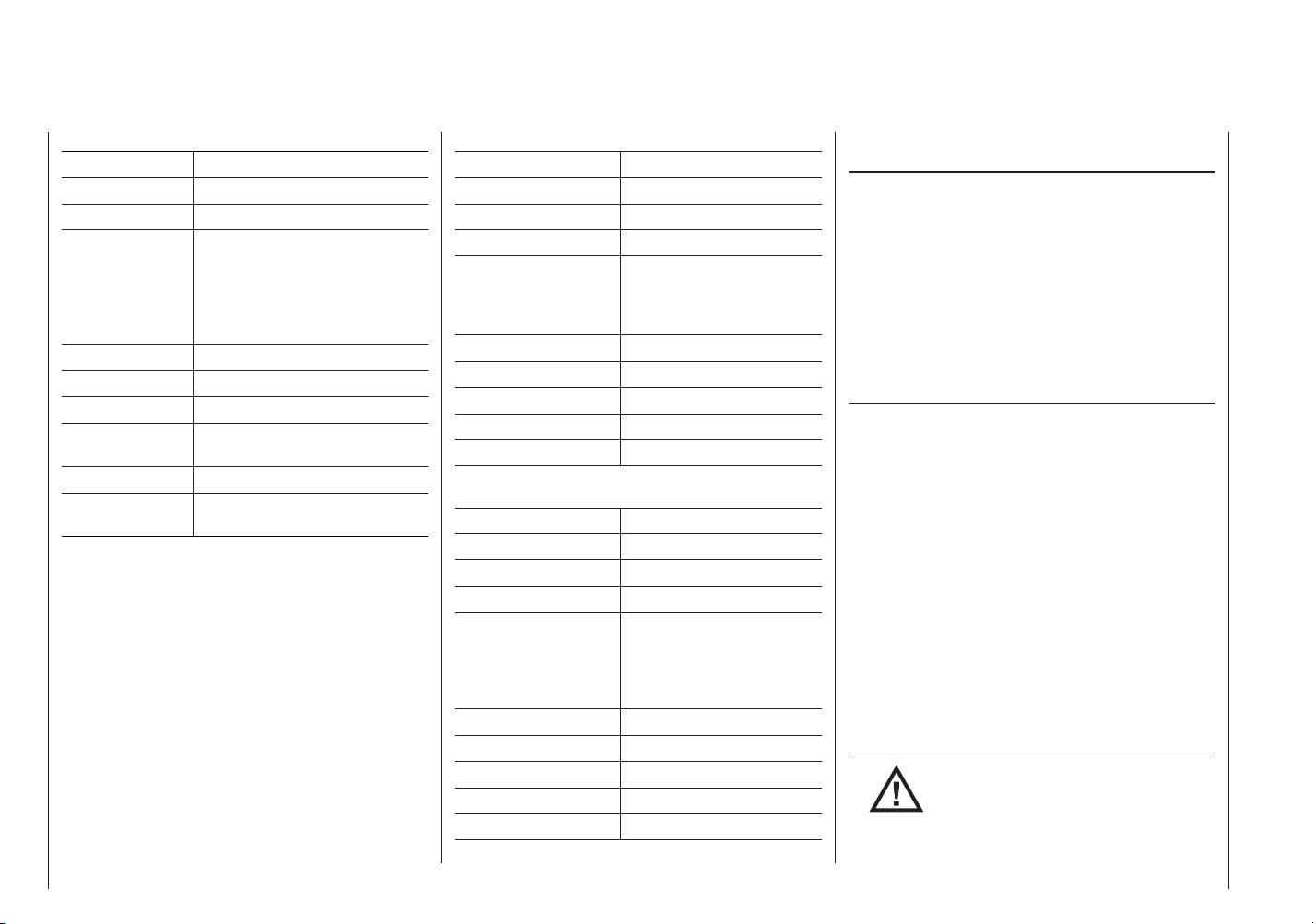

Technical data

mz-18 and mz-24 HoTT transmitters

Frequency band 2.4 … 2.4835 GHz

Modulation FHSS

Transmitting power 100 mW EIRP

Control functions mz-18 HoTT:

9 functions of which 4 can be

trimmed

mz-24 HoTT

12 functions of which 4 can be

trimmed

Temperature range -10 … +55 °C

Antenna Can be turned and folded

Operating voltage 3.4 … 6 V

Power

Approximately 540 mA

consumption

Dimension Approx. 194 x 287 x 112 mm

Weight approx. 840 g with transmitter

battery

Description of the transmitter - Technical data

14

GR-12L HoTT receiver order No. S1012

Operating voltage 3.6 … 8.4 V*

Power consumption Approximately 70 mA

Frequency band 2.4 … 2.4835 GHz

Modulation FHSS

Antenna 1 x approx. 145 mm long,

approx. 115 mm

encapsulated and approx.

30 mm active

Pluggable servos 6

Pluggable sensors 1 (instead of servo 5)

Temperature range Approx. -10 ° … +55 °C

Dimension Approx. 36 x 21 x 10 mm

Weight Approx. 7 g

GR-24 HoTT receiver order No. 33512

Operating voltage 3.6 … 8.4 V*

Power consumption Approximately 70 mA

Frequency band 2.4 … 2.4835 GHz

Modulation FHSS

Antenna Diversity antennas,

2 x approx. 145 mm long,

approx. 115 mm

encapsulated and approx.

30 mm active

Pluggable servos 12

Pluggable sensors 1

Temperature range Approx. -10 ° … +55 °C

Dimension Approx. 46 x 31 x 14 mm

Weight Approx. 16 g

Accessories

Order No. Description

1121 Shoulder strap, 20 mm wide

70 Shoulder strap, 30 mm wide

3097 Windshield for manual transmitters

For additional accessories, see the Annex or the

Internet at www.graupner.de You can also contact your

dealer. He would be glad to assist you.

Trainer cable for the HoTT transmitter,

see page 110

Replacement parts

Order No. Description

S8360 HoTT aluminum case for the mz

transmitter

2498.4FBEC 4NH-2000 RX RTU flat

S8345 Lithium-ion 1s2p/4000mAh/3.7 V

33800 HoTT transmitter antenna

* The specified permissible operating voltage

range applies exclusively to the receiver. In this

context, please note that the input voltage for the

receiver is provided unregulated to the servo

connectors; however, the permissible operating voltage

range for most of the servos, speed controllers, gyros, etc.

on the market is only 4.8 to 6 V.

Page 13

General operating instructions

mz-18 and mz-24 HoTT transmitters

Transmitter power supply

The mz-18 HoTT transmitter comes standard with a

rechargeable NiMH battery with 2000 mAh capacity, and

the mz-24 HoTT transmitter comes standard with a

1s2p lithium-ion battery with 4000 mAh capacity (subject

to modifi cation).

The standard battery installed in the

transmitter is uncharged upon delivery.

The transmitter battery voltage should be monitored in

the LCD display during operation. Once the adjustable

voltage in the "battery warning threshold" is reached in

the "Etc.Set" submenu of the system menu, page 202,

a standard 4.8 V (NiMH) for the mz-18 HoTT transmitter

and 3.6 V (lith.) for the mz-24 HoTT transmitter, a

warning beep sounds, and the following window

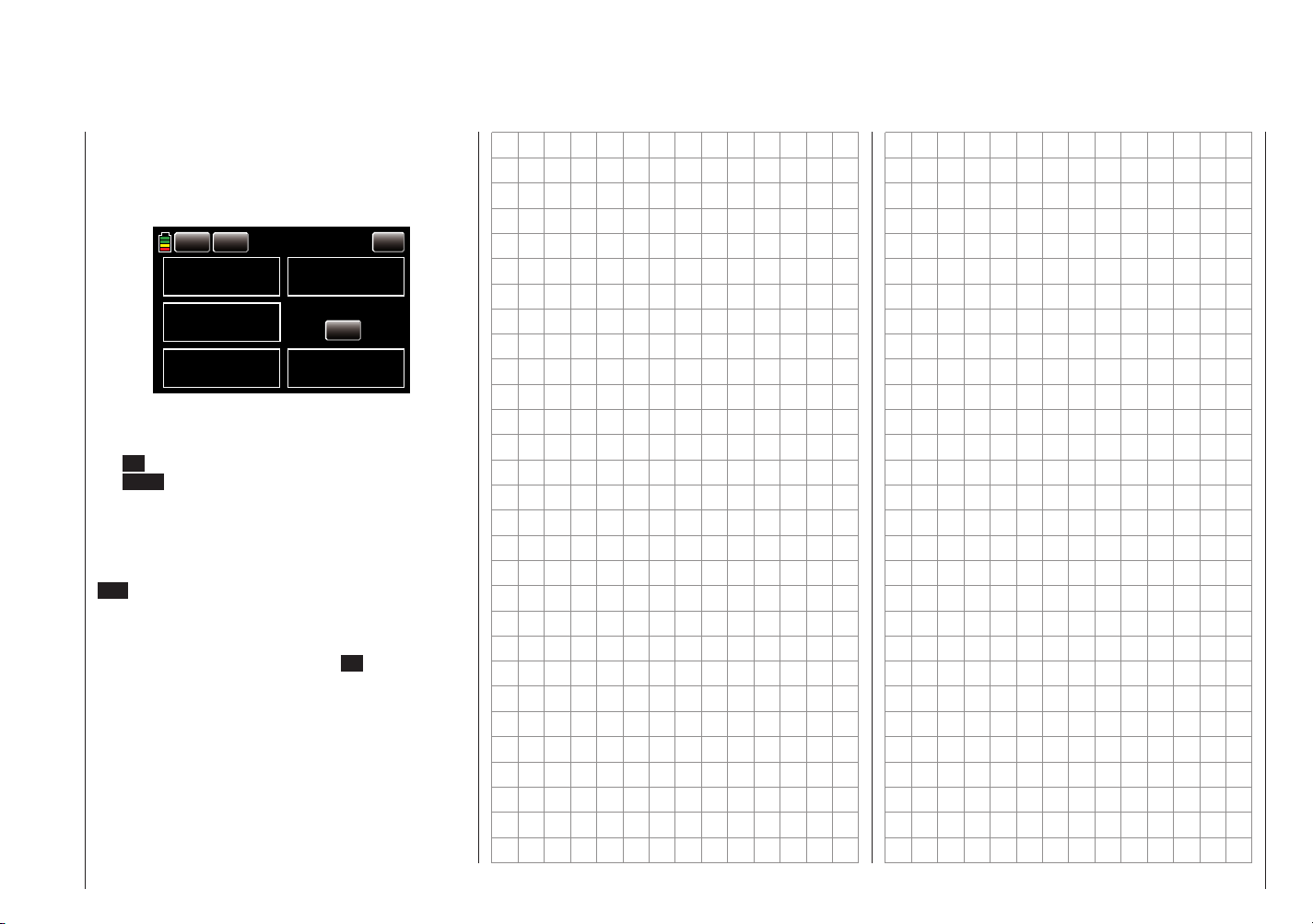

appears in the display:

BACK

CLR

TX VOLT

4.7V

STRENGTH

000%

ESC CUR.

000.0A

RX VOLT

02

STRENGTH ALARM

00

ESC VOLT

00

AUTO LOAD

ON

00

3.7V

ON

00

00.0V

or:

BACK

CLR

TX VOLT

3.5V

STRENGTH

000%

ESC CUR.

000.0A

RX VOLT

04

STRENGTH ALARM

00

ESC VOLT

00

AUTO LOAD

ON

00

3.7V

ON

00

00.0V

Now at the latest, stop operation and recharge

the transmitter battery.

Note:

•

Make sure that the correct battery type has

been set in the submenu "Etc.Set" of the

system menu, page 202!

• In a special calibration menu that can be opened by

touching the voltage display in the basic display of

the transmitter using a fi nger or the provided stylus,

the real displayed voltage can be fi ne-tuned (see

"Battery warning" on page 202).

The rechargeable NiMh battery of the mz-18 HoTT

transmitter or the 1s2p lithium-ion battery of the mz-24

HoTT transmitter may be charged as described below

using the charging socket on the rear labelled CHARGE

with the provided plug-in charger:

The charging socket comes standard with a protective

diode that protects against polarity reversal. Original

Graupner automatic chargers recognize the battery

charge. Note the setting instructions of the charger

which is used.

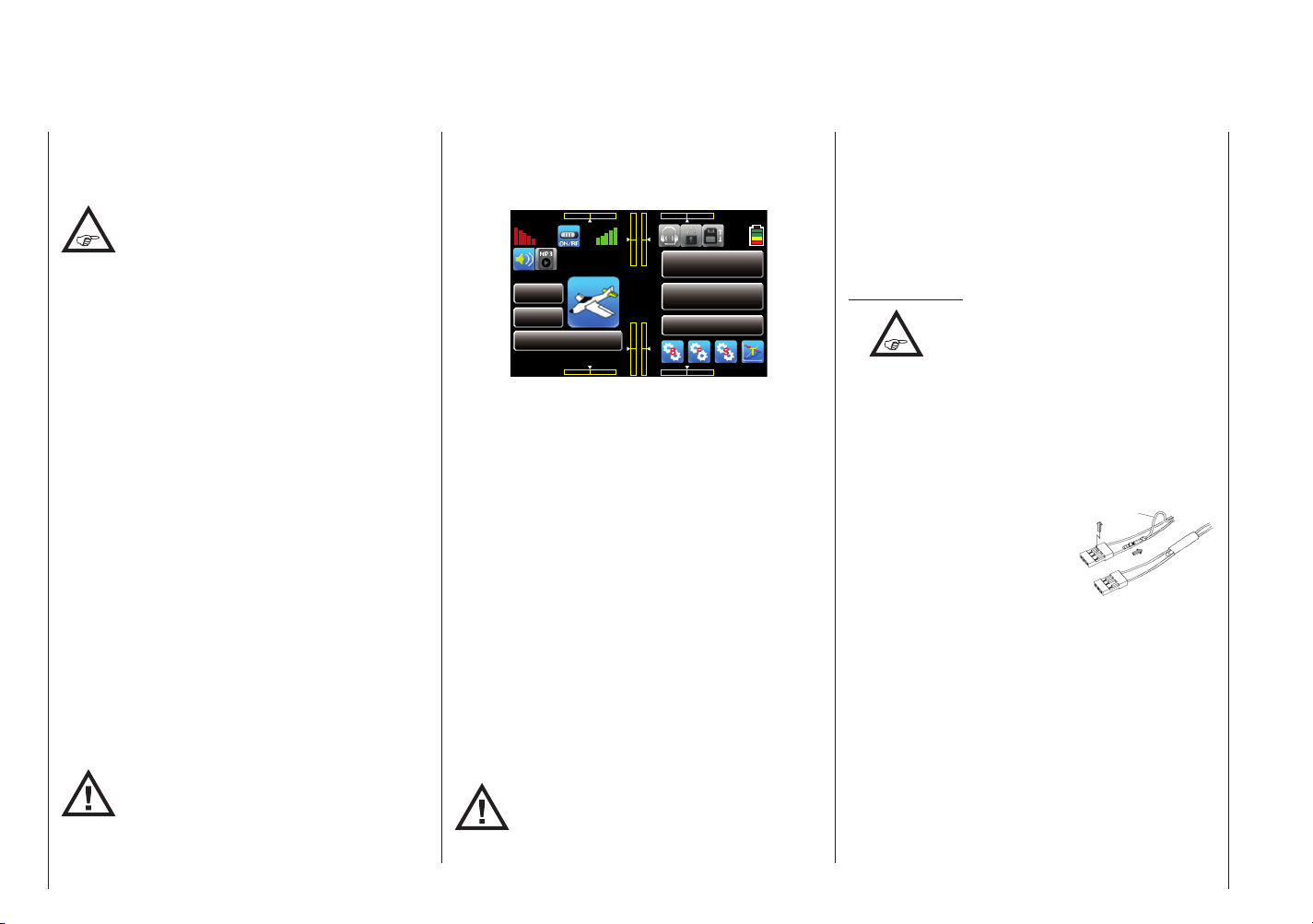

Polarity of the mz charging socket

The charging cables available on the market by other

manufacturers frequently have different polarities. For

this reason, you should only use original Graupner

charging cables with order No. 3022.

Charging the transmitter battery using the plug-in

charger

The charging time with

the plug-in charger

provided in the set may

be up to 15 hours depending on the existing

transmitter battery

charge.

Do not use

plug-in

chargers by other manufacturers or chargers

designed for different battery types. If the output voltage

is too high or the plug polarity is incorrect (see above), it

can cause signifi cant damage. We recommend labelling

the plug-in charger.

Consult the corresponding safety instructions on

pages 4 … 12.

The transmitter must be switched off while

charging. Never switch on the transmitter

when it is connected to the charger. If the

charging is interrupted even for a short time, the

charging voltage can rise enough to immediately

damage the transmitter from overvoltage. You should

therefore make sure that all plug-in connectors are

well-seated.

Description of the transmitter - General operating instructions

15

Page 14

Charging using automatic chargers

000

000

To fast charge the transmitter battery, Graupner automatic chargers can be used. The following table offers a

selection.

Recommended chargers (accessories)

Suitable for

the following

battery types

Order No.

Name

Connection 230 V AC

Connection 12 V DC

NiCd

NiMH

LiPo

integrated balancer

Lead battery

6411 Ultramat 8 x x x x x

6463 Ultramat 12 plus x x x x x x

6464 Ultramat 14 plus x x x x x x x

6466 Ultra Trio plus 14 x x x x x x x

6468 Ultramat 16S x x x x x x x

6469 Ultra Trio Plus 16 x x x x x x

6470 Ultramat 18 x x x x x x x

6475 Ultra Duo Plus 45 x x x x x x

6478 Ultra Duo Plus 60 x x x x x x x

6480 Ultra Duo Plus 80 x x x x x x

For charging the transmitter battery, the charging cable with

order No. 3022 is required, and for charging the receiver battery,

the charger cable with order No. 3021 is required.

Other chargers as well as details on the listed chargers can be

found in the main Graupner FS catalogue or on the Internet at

www.graupner.de.

First plug the banana plugs of the charging

cable into the charger, and then plug the

other end of the charging cable into

the transmitter charging socket. Never connect the

bare ends of the plugs of a charging cable that is

already connected to the transmitter!

Description of the transmitter - General operating instructions

16

To prevent damage to the transmitter, the charging

current should generally not exceed 1.5 A. Limit the

charge current if necessary.

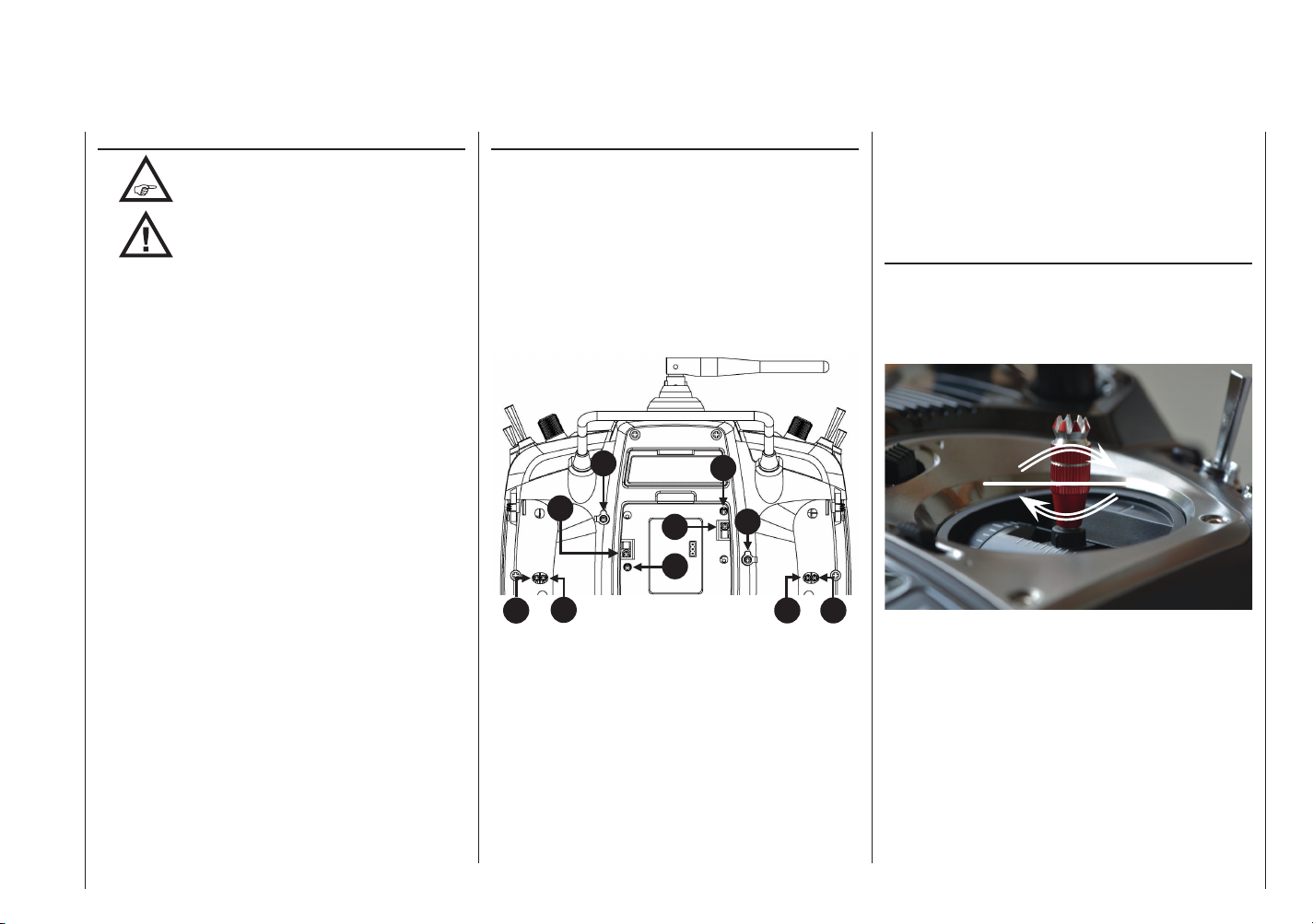

Removing the transmitter battery

To remove the transmitter battery, fi rst remove the cover

of the battery compartment on the back of the transmitter.

Battery connecting plug

Then disconnect the transmitter battery plug by carefully

pulling the supply cable. Then lift the battery and pull it

gently off of the velcro.

(The display shows the battery for the transmitter

mz-24 HoTT.)

Inserting the transmitter battery

The battery connector is protected by two bevelled

edges from polarity reversal when plugging in. The free

socket of the battery connector faces upward at the

bottom of the battery compartment as can be seen in

the following picture. The plus pole (red cable) is in the

middle, and the minus pole (brown or black cable) is on

the side facing the battery.

Never forcefully insert the plug into the socket on the

transmitter board.

Then place the battery into the compartment, and close

the battery cover.

Battery operating time in the bottom left display

The time (green) is automatically reset to 0:00 once the

transmitter battery voltage is recognizably higher than

the most recent voltage after the transmitter is started,

and the display shows the cumulative operating time of

the transmitter since last charging.

000%

0:01:23

M 1

MODEL NAME 1

BATT TIME 00: 01: 23

000 000

mz

000

000

000%

4.2V

000:00.0

000:00.0

NORMAL

Page 15

General charging instructions

•

•

transmitter, the transmitter charging current should

generally not exceed 1.5 A. Limit the charge current

if necessary.

If the transmitter battery is charged with more than

1.5 A, it must be charged outside of the transmitter.

Otherwise, the printed circuit board may be damaged

from overloading the printed connectors and/or

overheating the battery.

• Perform a few test charges to make sure that the

automatic cutoff of automatic chargers works. This is

especially true when you want to use an automatic

charger to charge the NiMH battery which comes

standard in the mz-18 HoTT transmitter, or the

lithium battery which comes standard in the mz-24

HoTT transmitter. Monitor the cutoff behaviour if the

charger that you are using has this option.

• Do not discharge the battery or run battery care

programs using the charging socket. The charging

socket is only for charging.

• Always first connect the charging cable to the charger, and then connect it to the receiver or transmitter

battery. This prevents unintentional short-circuiting

with the bare ends of the charging cable plug.

• If the battery becomes hot, check the battery and

exchange it or reduce the charging current.

• Do not charge the batteries without monitoring

them.

• Follow the safety instructions and handling

guidelines starting page 4.

Follow the charging instructions of the

charger manufacturer and battery

manufacturer.

Do not exceed the maximum permissible

charging current of the battery

manufacturer. To prevent damage to the

Adjusting the control sticks

Both the left and right control sticks can optionally be

set from neutralizing to non-neutralizing and vice versa.

The resetting force on the control sticks can be set to

the pilot's preferences. The related adjusting system

is on the back of the transmitter in the battery compartment, under the rubber covers, and under the side

grips attached with double-sided adhesive tape (see the

marks in the following picture). Make the desired adjustment by turning the relevant setscrew using a Phillips

or standard screwdriver. Hold the control stick tight as a

precaution:

4

3

1 2

• 1 and 2 / 9 and 10

Adjust the braking force with the outermost of the

two screws, and adjust the strength of the control

stick ratchet using the innermost screw.

• 4 and 5 / 7 and 8

Adjust the return force of the control direction by

turning the relevant setscrew using a Phillips or

standard screwdriver.

7

6

5

8

9 10

• 3 and 6

To change the standard setting of the left and right

control sticks, turn the screw toward the inside of the

transmitter until the relevant control stick can move

freely from stop to stop, or turn it outward until the

control stick resets itself independently.

Adjusting the length of the control sticks

Both control sticks can be gradually adjusted over

approximately 8 mm to adapt the transmitter control to

the pilot's preferences.

Hold down the bottom half of the knurled grip, and

loosen the screwed connection by turning the top part:

You can now lengthen or shorten the control stick by

screwing it up or down. Then clamp the top and bottom

part of the grip by rotating them against each other.

Description of the transmitter - General operating instructions

17

Page 16

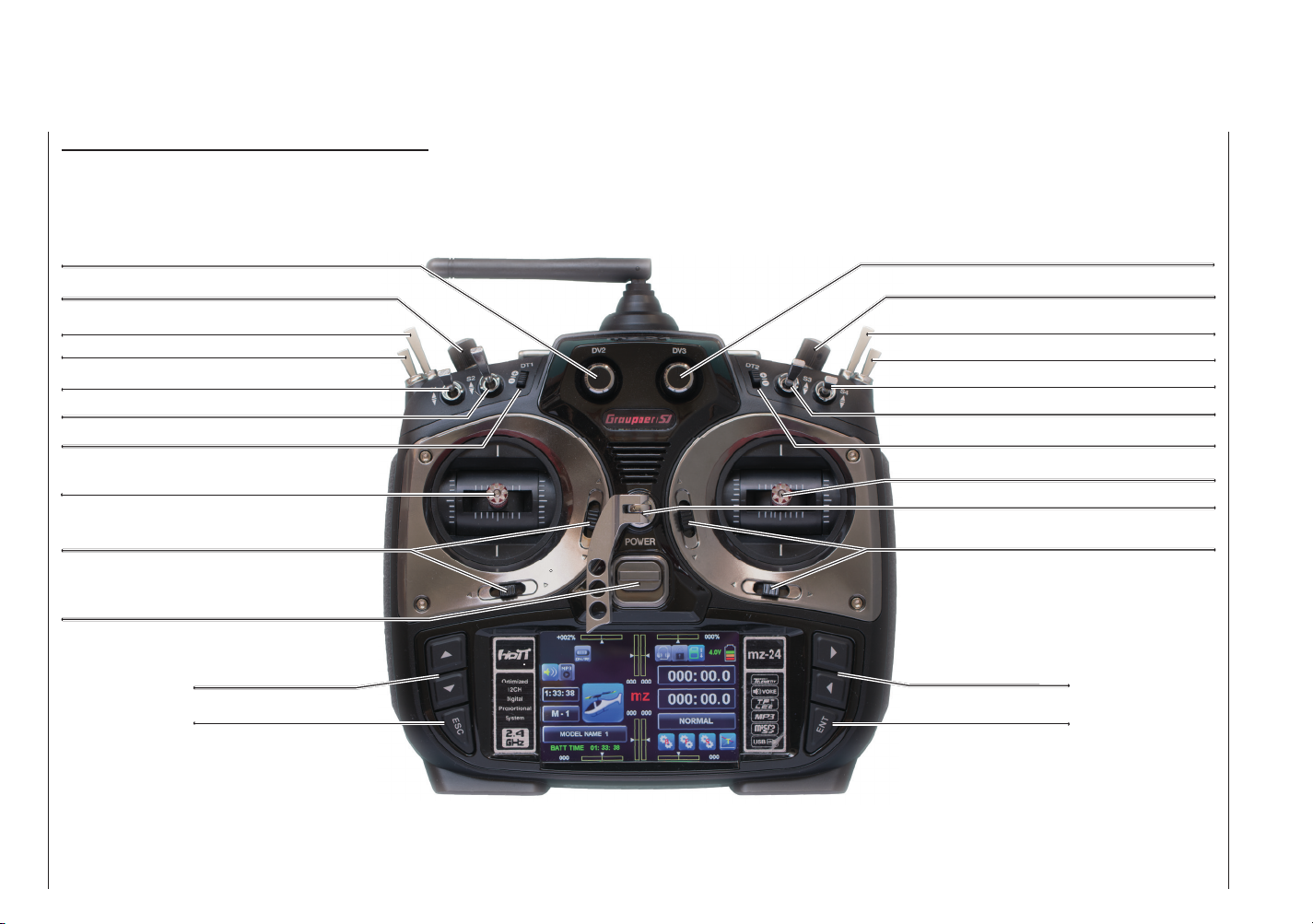

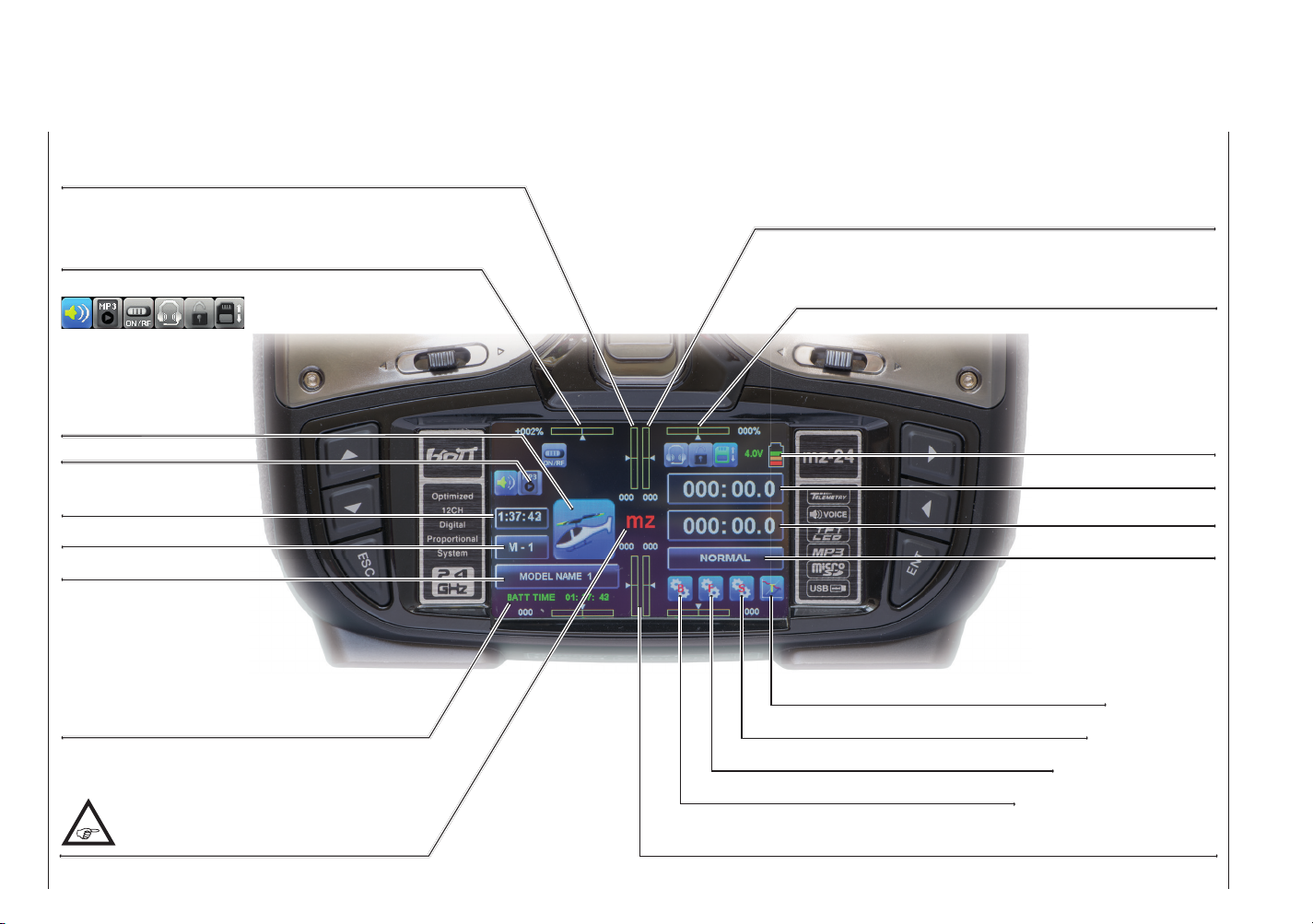

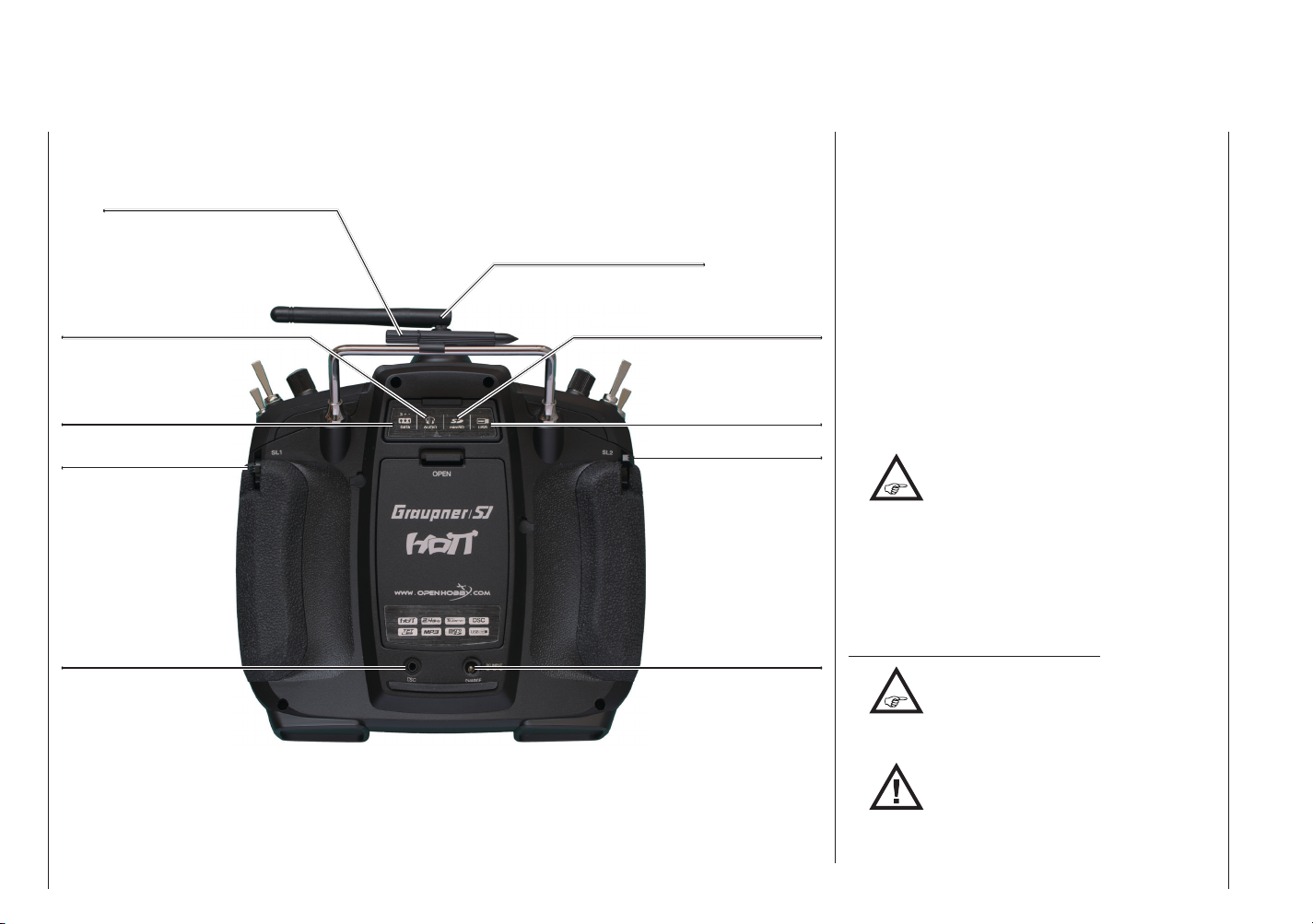

Transmitter description

Front side

Control elements on the mz-24 HoTT transmitter

proportional dial DV2

proportional dial DV1

Switch SW 6

Switch SW 5

Switch SW 1

Switch SW 2

INC/DEC buttons DT1

Left control stick

Tr i m

ON/OFF switch

Alternative selection

buttons

ESC button

Rotatable and foldable antenna

proportional dial DV3

proportional dial DV4

Switch SW 8

Switch SW 7

Switch SW 4

Switch SW 3

INC/DEC buttons DT2

Right control stick

Eyelet for carrying strap

Tr i m

Alternative adjusting

buttons

ENTER button

Description of the transmitter - Front (control elements)

18

Page 17

Button lock Digital trim

Access to adjustments can be blocked in the basic

transmitter display by simultaneously pressing the ESC

and ENT buttons for about one second. This is indicated

by a change of colour of the button icon at the top right

in the display from gray to blue/yellow:

The lock is activated immediately, but the controls

remain operational.

Press the ESC and ENT buttons again for about three

seconds to release the lock. The colour of the icon

returns to grey:

Buttons as well as ESC and

ENT

Although the two mz-18 HoTT and mz-24 HoTT

transmitters are primarily operated by touching the

touch-sensitive screen with a fi nger or the provided

stylus, the transmitters can be operated in special cases

using the two sets of three buttons on the side of the

display.

Buttons to the left of the display

• Adjusting buttons

1. Set the parameters in the setting fi elds after they

are activated by pressing the ENT button.

2. Simultaneously press the buttons to reset a

changed parameter in the active entry fi eld to the

default ( CLEAR).

3. Simultaneously pressing the buttons in the basic

display as well as in all menus with SERVO or

a Sv button switches directly to the »Servo dis-

play«.

• ESC button

Firmware version before V 1.023

Press the ESC button to confi rm the current

setting and deactivate the active settings fi eld.

Firmware version V 1.023 and higher

Pressing the ESC button brings about a stepwise return to function selection or back to the basic display.

Any setting changed in the meantime is retained.

Buttons to the right of the display

• Selection buttons

"Scrolling" through the menu lines in the setting menus or through the icons that can be called up in the

basic display.

• ENT button

Activate (confi rm) the settings fi elds by pressing the

ENT button.

With an optical and acoustic display

The two control sticks come with digital trim. Briefl y

touch the trim switch to move the neutral position of the

control stick by a specifi c value with each click. Hold

down the switch to move the trim in the corresponding

direction with increasing speed.

The adjustment is made audible by tones of varying

levels. It is therefore easy to fi nd the middle position

during fl ight without looking at the display. If you go past

the middle position, a brief pause is inserted.

The current trim values are automatically saved when

the model memory is changed. In addition, the digital

trim functions within a memory in specifi c relation to the

Quick Link (with the exception of the trim of the Throttle/

brake valves or the gas/pitch control stick called control

function "THR" (channel 1)).

When a gas motor is selected in the "Drive type" display,

page 47, the trim of the throttle control stick only functions for wing or helicopter models in the bottom half of

the control stick path, that is, only in the starting range.

The current trim positions are displayed numerically and

graphically in the transmitter's basic display (see the

picture on the left and on the next page) as well as in a

special display, see page 88.

Description of the transmitter - Buttons, button lock and digital trimming

19

Page 18

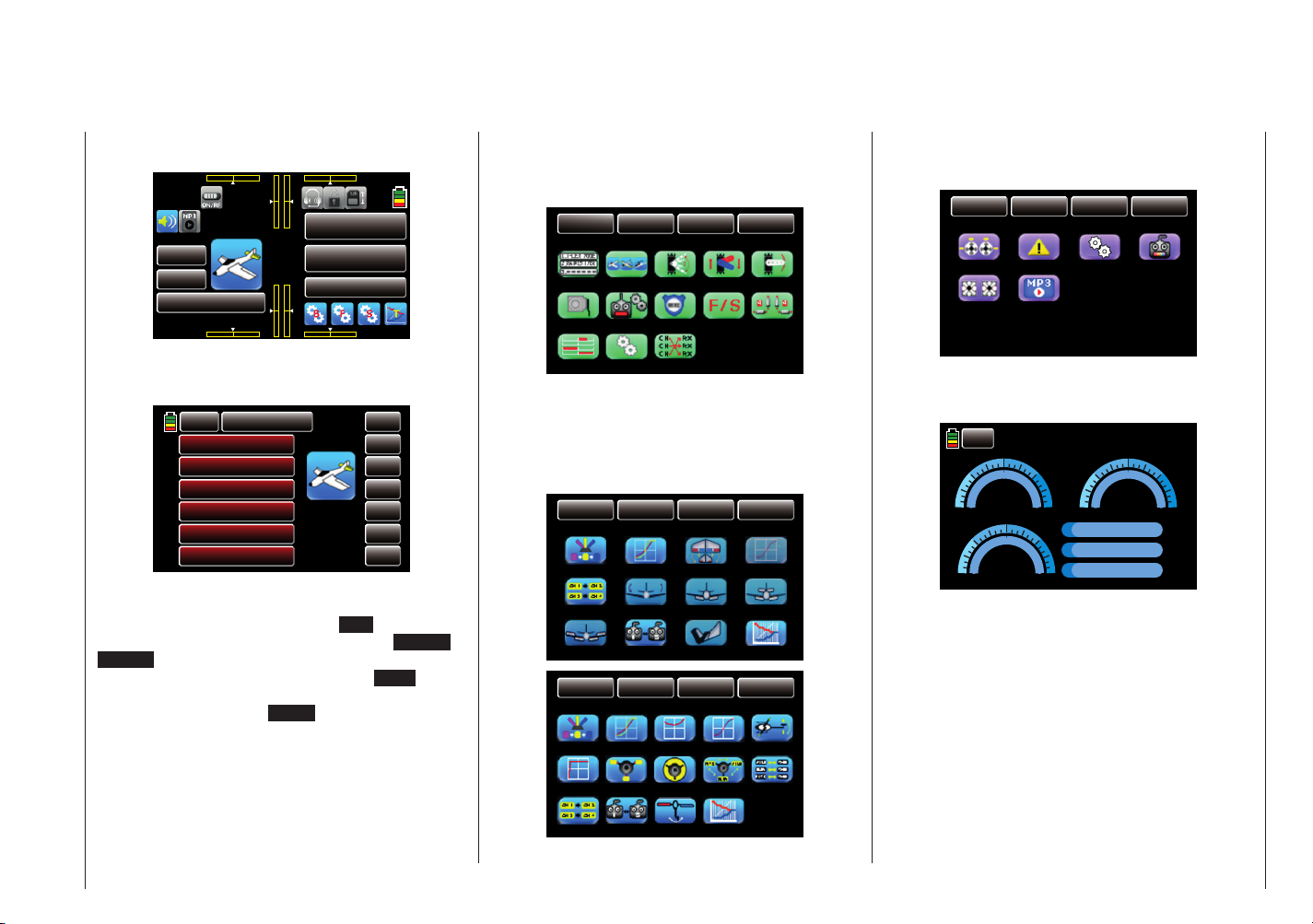

Display

Graphic display of the position of the standard, left INC/DEC

button DT 1 with a numeric position and direction display that

only comes with the mz-24 HoTT transmitter.

Graphic display of the position of the proportional dials DV 1

(mz-18 HoTT) and DV 2 (mz-24 HoTT) with a numeric

position and direction display.

Graphic display of the position of the standard, right INC/DEC

button DT 2 with a numeric position and direction display that

only comes with the mz-24 HoTT transmitter.

Graphic display of the position of the proportional dials DV 2

(mz-18 HoTT) and DV 3 (mz-24 HoTT) with a numeric

position and direction display.

These icons are for

information only:

coloured = active

Gray = inactive

Model type*

MP3 player* (as of V 1.023)

Model operating time*

Model memory …*

Model name*

Transmitter operating time: This is automatically reset

to zero after charging or changing the battery.

Touching "mz" like all of the fi elds on this page

identifi ed with an asterisk (*) at the end of the

description opens a context menu.

Three colour display of the

transmitter battery voltage.

Once a set warning threshold is reached, a warning

appears on the display and

acoustic warning signals

are emitted*.

Timer 1*

Timer 2*

Quick Link name*

Button for opening the telemetry displays

Button for opening the system settings

Button for opening the model settings

Button for opening the basic settings

Graphic display of the position of the four digital trim levers with a numeric position

and direction display.

Description of the transmitter - Display

20

Page 19

000

000

Operating the displays

The display is basically operated by touching the

desired fi eld with a fi nger or the provided stylus:

000%

0:01:23

M 1

MODEL NAME 1

BATT TIME 00: 01: 23

000 000

mz

000

000

000%

4.2V

000:00.0

000:00.0

NORMAL

By touching the model memory fi eld labelled "M 1" in

the above display with a fi nger or the provided stylus,

the "Model memory" selection menu opens.

MODEL NAME 1

BACK

01

02

03

04

05

06

MODEL NAME 1

MODEL NAME 2

MODEL NAME 3

MODEL NAME 4

MODEL NAME 5

MODEL NAME 6

NEXT

SEL

NEW

IMP.M

EXP.M

RES

CPY

In this menu, you can change the model by touching the

desired model memory.

Just as described on page 45, touch NEW to start

programming a new model, or touch the fi eld MODEL

NAME 1 at the upper edge of the display to switch

to the "Model name" entry menu, or touch BACK at

the top left to return to the previous menu item. In

contrast, touch the button NEXT [next page] (generally

using the rotation method) which is also available in

several menus to go to the next page. In the above

display of the model memory, to the display of model

memories 07 … 12, etc.

The other fi elds on the left side identifi ed with an

asterisk (*) basically function the same way.

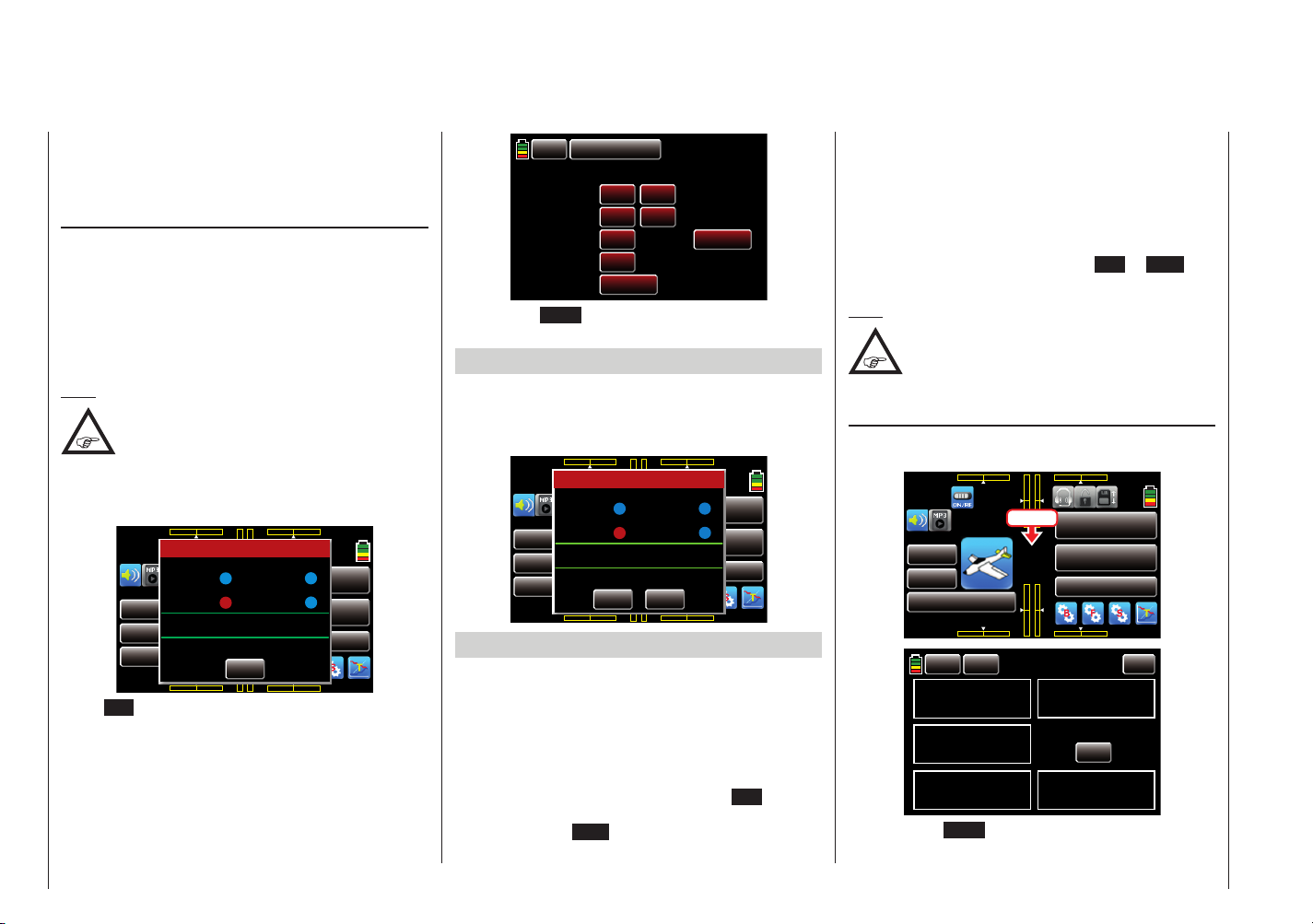

In contrast, if you touch one of the three gear icons

identifi ed with"B", "F", and "S", special selection menus

open on the bottom right from which you can switch to

other submenus. Starting with the green base menu,

see page 44the selection displays appear as follows:

BASE

E.P.A

Timer

Out.Swap

FUNCTION

Rev/Slow

Fail Safe

SYSTEM

Sub-Trim

Trim Step

BACK

Model Sel

Motor

Servo

Model Type

TX ctl

CH Set

It should be noted that they blue FUNCTION menu

which is described starting on page 100 or 171

contains model-type-specifi c submenus. The fi rst of the

two following pictures therefore shows examples of the

menu structure of a fi xed-wing model, and the second

one shows the menu structure of a helicopter model:

BASE

D/R,EXP

Aile diff

Trainer

BASE

PIT.CRV

S.Limit

PIT>>RUDD

FUNCTION

Wing MIX

Flap MIX

V-Tail

FUNCTION

THR.CRV

S.MIX

Telemetry

SYSTEM

THR.CRV

Flap sett

Telemetry

SYSTEM

Gyr/Gover

THR.MIX

BACK

Q.Link

Prog.MIX

Butterfly

BACK

Q.Link

THR.HOLD

Prog.MIX

D/R,EXP

Swash

Trainer

The pink SYSTEM menu that can be opened by

pressing "S" and is explained starting on page 208

appears as follows:

BASE

Warning

MP3

FUNCTION

Etc. Set

SYSTEM

Display

BACK

ST mode

Stick Cali

The telemetry displays which can be opened by

pressing "T" and are described in detail starting on page

213 appear as follows:

R

00dB

BACK

3.0 3.0

VO LT

0.0V

0 0

-20

6.0 6.0

40.0

TEMP

00°C

70

T

00dB

L-VOLT

0.0V

Q

S

L

000%

000%

0000ms

Description of the transmitter - Display

21

Page 20

Warnings

000

000

000

000

000%

000%

000

000

Depending on the context, different warning windows

appear in the display for the mz-18 HoTT transmitter

and the mz-24 HoTT transmitter. These can be divided

into two groups:

Warning display

These smaller windows primarily appear after the

transmitter is switched on and indicate certain operating states. In the following illustration, for instance, the

red dot after "CH1-POS" indicates that the CH1 control

stick, or as of fi rmware version V 1.023, the gas servo,

connected to output 1 on a surface model and to output

6 on a helicopter model, is not in the idle position and

there is the risk of a runaway engine.

Note:

The default "Rear idle" can be switched to

"Front idle" for fi xed-wing models in the "THR.

CRV" menu, page 144, by inverting the

control curve.

The bottom line also indicates that a receiver has not

been bound to the current model memory.

000%

RX TX

RX 00.0V

Thr.HOLD

Thr.POS

0:01:23

M 1

BIND is not setup

MODEL NAME 1

BATT TIME 00: 01: 23

Warning

000 000

mz

000

SET

000

Thr.CUT

QLink

F/S setup t.b.d

000%

3.8V

000:00.0

000:00.0

NORMAL

Touch SET with a fi nger or the provided stylus to go

directly to the "Transmitter control" display in which

you can link the receiver to the model memory as

described on page 74:

Description of the transmitter - Warning

22

BACK

MODEL NAME 1

RX2

RX1

OFF

BIND ON/OFF

TX OUT SET

RF ON/OFF

RANGE TEST

DSC OUTPUT

OFF

SET

OFF

OFF

PPM10

SET

RF TYPE

99sek

NORMAL

Or touch the BACK button at top left to terminate the

procedure.

Firmware versions up to and including V 1.022

If in contrast a receiver is already linked to the current

model memory and it is not switched on or out of the

range when the transmitter is switched on, a related

warning window appears:

000%

RX TX

RX 00.0V

Thr.HOLD

Thr.POS

0:01:23

Normal signal

M 1

Please select RF ON/OFF

MODELLNAME 1

AKKUZEIT 00: 01: 23

WARNUNG

Warning

000 000

mz

000

ON

Thr.CUT

QLink

000

OFF

000%

3.8V

000:00.0

000:00.0

NORMAL

Firmware versions as of V 1.023 and higher

As of fi rmware version V 1.023 and higher, switching on

the transmitter generally also activates the HF transmissions and the display shown above appears in the centre of the transmitter display. At the same time, audible

warning signals sound for a few seconds.

You now have the option of waiting a few seconds until

the display disappears automatically or maintaining the

HF transmissions by manually tapping the ON button

with your fi nger or the provided stylus, or switching them

off by tapping the OFF button.

In the fi eld between the two green lines, the message

"Normal signal" indicates that the transmitter is set to

normal remote control. Alternately, messages such as

"TEACH signal" or "PUPIL signal" can appear here.

Another – possible – variant is to display "F/S setup t.b.d"

as an indication that no fail-safe settings have yet been

made.

Answer the request "Turn RF ON/OFF" in the area below as desired by touching the button ON or OFF with

a fi nger or the provided stylus.

Note:

By default, only the monitoring of the "THR

position" is activated in the display of the

submenu "Warning" of the system menu,

page 201.

"acute warning" display

You can open this display by touching mz in the middle

of the transmitter's basic display:

RX TX

RX 00.0V

0:01:23

M 1

MODEL NAME 1

BATT TIME 00: 01: 23

BACK

CLR

TX VOLT

3.6V

STRENGTH

000%

ESC CUR.

000.0A

Touch

000 000

mz

000

000

RX VOLT

00

STRENGTH ALARM

00

ESC VOLT

00

000:00.0

000:00.0

AUTO LOAD

4.2V

NORMAL

ON

00

3.7V

ON

00

00.0V

And touch the BACK button at top left to close the

display.

Page 21

If acoustic warnings sound and the normal transmitter

display is covered by this display, take note of the

message in red. For example because the transmitter's

supply voltage has reached the warning threshold set in

the submenu "Etc.Set" of the system menu, page 202:

BACK

CLR

TX VOLT

3.5V

STRENGTH

000%

ESC CUR.

000.0A

RX VOLT

03

STRENGTH ALARM

00

ESC VOLT

00

AUTO LOAD

ON

00

3.7V

ON

00

00.0V

At the same time, the display contrast is reduced to 05

to save power.

This warning can be kept from reappearing by touching

the ON button at the top right then deleted by touching

the BACK button at the top left in the display. (In specific

cases, stop operating the model as soon as possible

and charge the transmitter).

The red number at the top right shows the number of

current warnings; in the above example, the warning is

the third one. This count can be deleted by touching the

CLR button at top left.

All other warnings in this display can be handled in

the same way. However, in the case of a field strength

alarm, you can also suppress other alarms triggered by

the low field strength by touching the ON button under

"STRENGTH ALARM" for the duration of the current

operation of the transmitter.

Description of the transmitter - Warning

23

Page 22

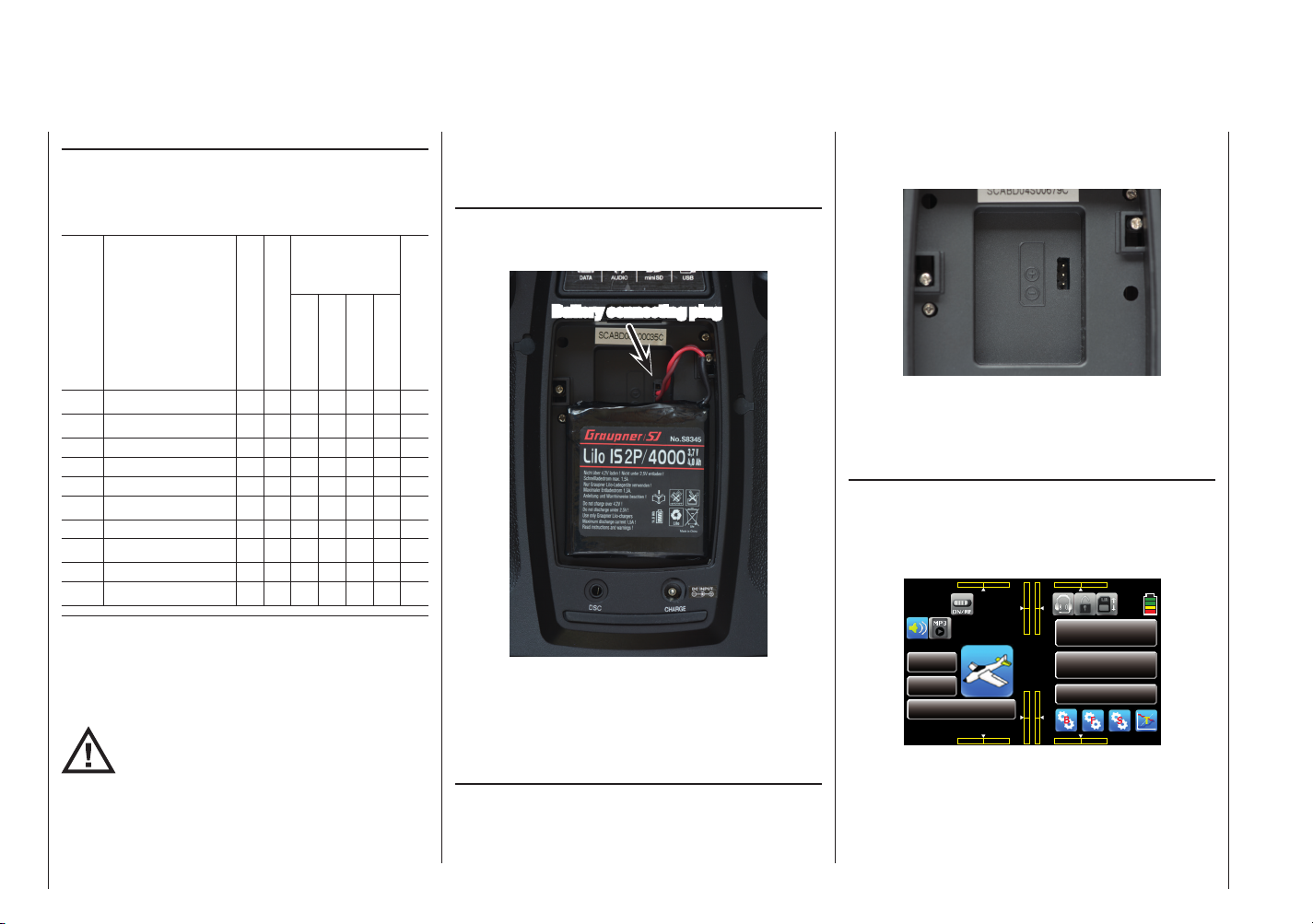

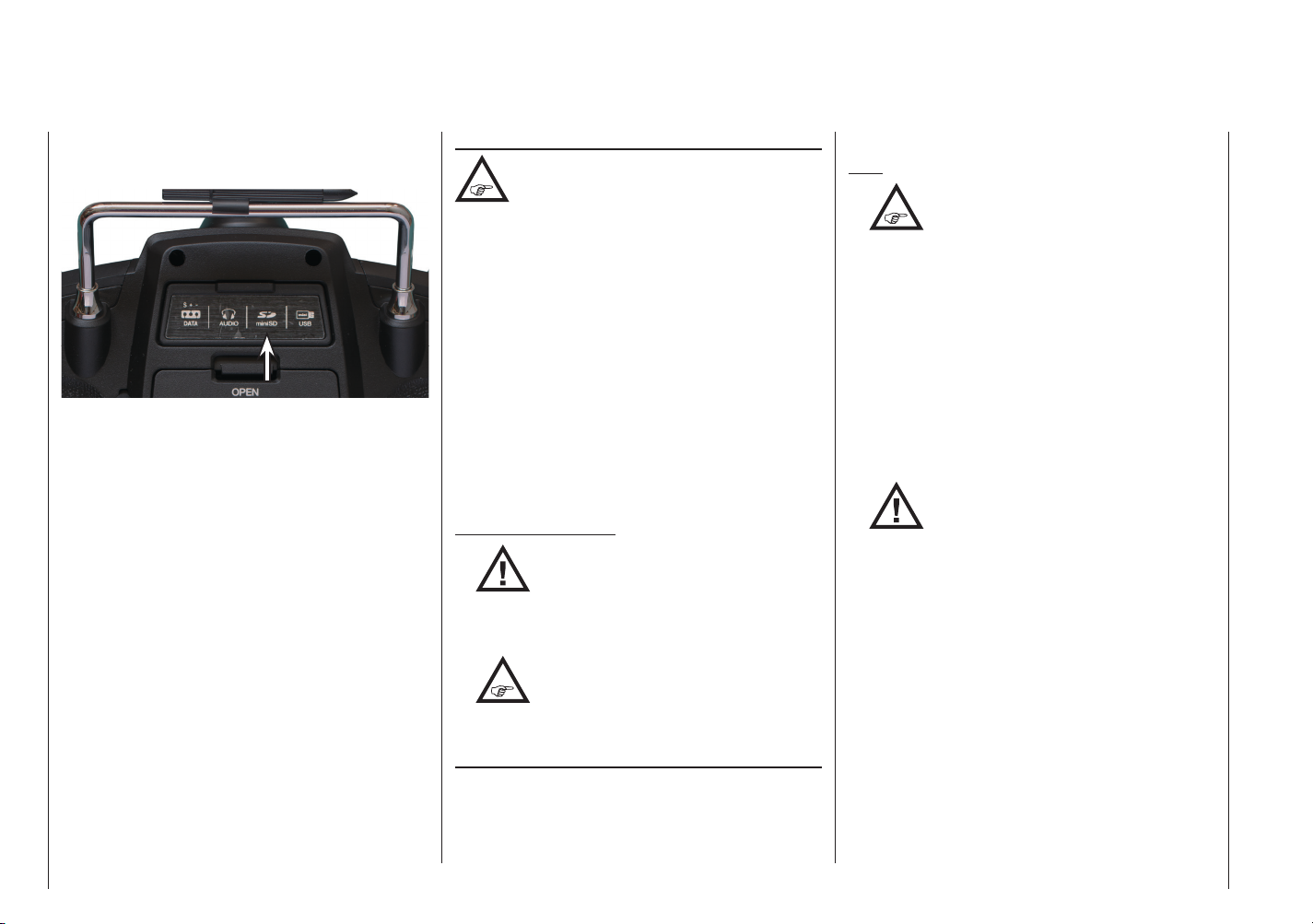

Backside of the transmitter

(The fi gure shows the mz-24 HoTT transmitter.)

Carrying handle with attached

stylus for alternatively operating

the touch-sensitive display

Rotatable and foldable antenna

Connector socket for

headphones

Data socket, for example

to connect a smart box

Proportional slider SL1

DSC socket Charging socket

Description of the transmitter - Back side and connections on the back

24

Card slot for micro SD cards

5-pin mini-USB connector

Proportional slider SL2

DSC socket

The abbreviation "DSC" is from the initial letters of the

original function, "direct servo control". With the HoTT

system, "direct servo control" using a diagnostic cable is

not possible for technical reasons.

The standard two-pin DSC socket on the back of the

mz-18 HoTT and mz-24 HoTT transmitters functions

as a trainer or pupil socket as well as an interface for

fl ight simulators or other external devices.

To ensure a correct DSC connection, observe the

following:

1. Perform any necessary adaptations in the menu.

To adapt to the transmitter to a trainer system, see

page 107.

2. Connect the other end of the connecting cable to the

desired device while observing the relevant operating

instructions.

Important:

Make sure that all the plugs are

securely inserted in the respective

plug-in connectors with a 2-pin jack plug on the

DSC side.

3. In the "Transmitter control" submenu, page 74,

you can set one of the following modes in the "DSC

output" line depending on the number of functions to

be transmitted: PPM10, PPM16, PPM18 and PPM24.

Default: PPM10.

Instructions regarding fl ight simulators:

•

to be adapted by Graupner Service.

NOTE:

•

computer interface is connected to your simulator,

the transmitter may be destroyed by electrostatic

discharge. This type of connection should therefore

sockets, and only use the provided

Given the numerous fl ight simulators on

the market, it is possible that the contacts

on the jack plug or DSC module may have

When your transmitter is directly connected

to a desktop computer or laptop by a

connecting cable (DSC cable) and/or a

Page 23

Data socket

Headphone connector

only be used if you protect yourself from electrostatic

discharge while operating the simulator by wearing a

commercially available grounding armband.

Graupner therefore strongly recommends only using

wireless simulators.

The so-called DATA socket is found under the back

cover of the mz-18 HoTT mz-24 HoTT transmitters:

This is for connecting the optional Smart Box (order

No. 33700).

Further information on the Smart Box can be found in

the main Graupner FS catalogue and on the Internet at

www.graupner.de for the respective product.

The headphone connector is found left of center under

the back cover of the mz-18 HoTT mz-24 HoTT

transmitters:

The socket is for connecting commercially available

earbuds or headphones with a 3.5 mm stereo jack (not

included in the set). When headphones are plugged in,

the transmitter's speaker is switched off, and the stylized

icon of a headphone is depicted in colour and not grey

in the basic display, see page 20.

In addition acoustic signals from the transmitter, signals

and messages associated with the "Telemetry" menu

are output via this connector. These messages are in

German language by default. Further information can

be found under "Messages" in the section "Telemetry"

starting on page 114.

Description of the transmitter - Connections on the back

25

Page 24

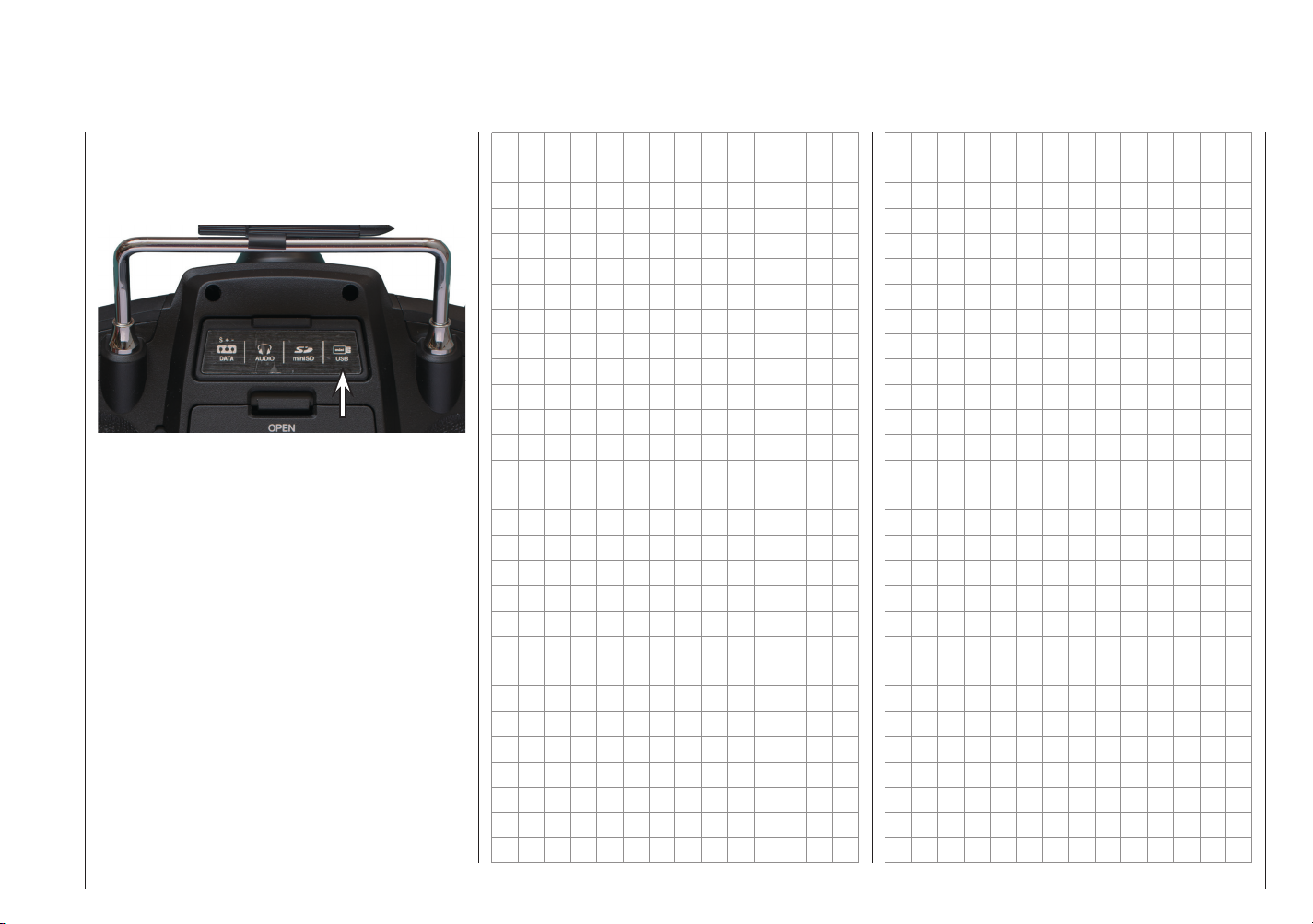

Card slot

micro-SD and micro-SDHC

The card slot for micro-SD and micro-SDHC memory

cards is found right of center under the back cover of the

mz-18 HoTT mz-24 HoTT transmitters:

In addition to the micro-SD memory cards that come

standard, all conventional micro-SD memory cards with

up to 2 GB and micro-SDHC cards with up to 32 GB

memory can be used. The manufacturer recommends