GRAUPNER LEKI EXTRA 330SC Assembly Instructions Manual

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved! No liability for printing errors! 10/2011

- 1 -

Order No. 9352

ASSEMBLY INSTRUCTIONS

LEKI EXTRA 330SC

RC aerobatic model for 2 LiPo cells

This model requires a HoTT radio control system

with at least four functions

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved! No liability for printing errors! 10/2011

- 2 -

It is essential to read and observe the safety notes in the appendix to these instructions. If you

ever pass this model on to another person, be sure to include the complete assembly

instructions.

Introduction

The LEKI EXTRA 330SC is a superbly manoeuvrable RC aerobatic model, and its

compact dimensions make it easy to transport. The small dimensions should not

mislead you into thinking that the assembly and operation of the model do not require

any model aircraft experience. The model is very highly pre-fabricated. Nevertheless

the construction stages described in these instructions must be carried out with great

care to ensure that the model can be used safely and successfully. The all-up

weight must not exceed 1000 g.

RC system accessories (not included)

You will need the items listed below in order to complete and operate the model.

COMPUTER SYSTEM MX-16 GRAUPNER HoTT 2.4 GHz Order No.33116

Transmitter charge lead Order No.3022

Brushless motor COMPACT 345Z Order No.7738

ELECTRIC PROP 10x5” Order No.1326.10x5

GRP propeller spacer Order No. 197.60

COMPACT CONTROL 45 Order No.7224

LiPo 2/1600 7.4 V/1.6 Ah Order No.7634.2

G 3.5 charge lead Order No.2970.L

ULTRAMAT 16 S battery charger Order No.6468

Servo DES 476 BB (5 required) Order No. 7915

Servo extension lead 100 mm (2 required) Order No.3935.11

Servo extension lead 180 mm (2 required) Order No.3935.18

Hose binders 102 mm Order No. 1521.52

Hose binders 188 mm Order No. 1005

Hook-and-loop cable ties Order No. 1587

Tools and adhesives required (not included)

Balsa knife Order No.980

Quick-drying glue Order No.5821

Activator for quick-drying glue Order No.953.150

UHU ALL PURPOSE ADHESIVEPower Order No.1096

You will also need the following items: Philips screwdriver, open-end spanner SW 12,

flat-nose pliers, wire cutter, drill Ø 1.6, Allen wrenches SW 1.5 and SW 2.5 mm,

soldering gun and solder, hair dryer, sandpaper, geometric protractor, overhead

marker, transparent tape, wood pulp paper, protective gloves, safety glasses.

Assembly instructions

Please read these building instructions completely before you start building, so that

you have a clear idea of the sequence required. Before each stage, identify all the

parts, tools and adhesives you will need, and have them ready. When working,

always lay the parts on a clean, smooth surface, or a layer of foam material. Unless

the instructions specifically state otherwise, use quick-drying glue with activator as

adhesive. The best method is to apply glue to one face, then spray activator on the

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved! No liability for printing errors! 10/2011

- 3 -

opposite face. Make sure that no residual adhesive gets on your hands or on the

surface of the model. Immediately wipe of excess adhesive with wood pulp paper.

Caution:

Cyano-acrylates must not come into contact with any part of your body or the

eyes. For this reason, we recommend that you wear protective goggles when

using this material. Store the adhesive out of the reach of children. For safety

reasons, use only the adhesive mentioned above. Please observe the operating

instructions and safety notices for the respective accessories

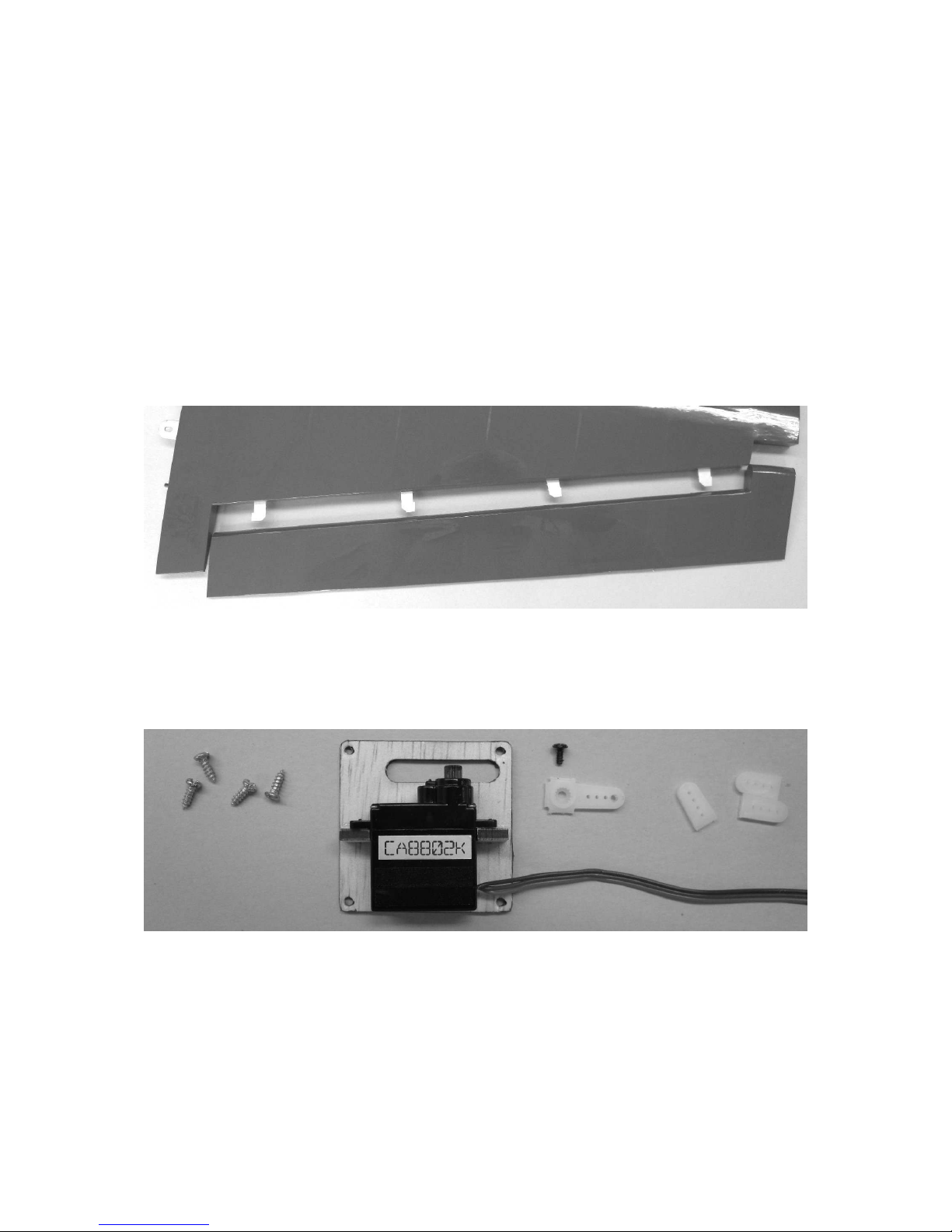

The wing

First apply adhesive (UHU ALL PURPOSE ADHESIVE Power) to the inserted aileron

hinges and push up the aileron until there is a gap of about 1 mm. After waiting for it

to dry, check whether the aileron is secure.

Unscrew the servo cover from the wing and fit in the servo. Separate the excess

levers and drill the outermost hole of the servo lever to Ø 1.6 mm. Put the servo into

the neutral position, attach the servo level vertically, and screw it tight. Use cyanoacrylate to glue the servo to the respective attachment tab.

Insert a string to pull the servo lead carefully into the wing. Screw on the servo cover

and make the aileron connection. Connect the pushrods and glue in the horn of the

aileron. Note: If you want to do extreme flight manoeuvres, you should use the longer

servo levers that are also included with the servo.

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved! No liability for printing errors! 10/2011

- 4 -

The figure shows the assembled aileron linkage. Please note that the servo level

length should be at least 12 mm to keep the clevis from colliding with the wing.

The figure shows the servo lead exiting at the wing root. Later, use the CRP tube Ø

8x280 mm to push the halves of the wing onto the fuselage.

Fuselage and tail group

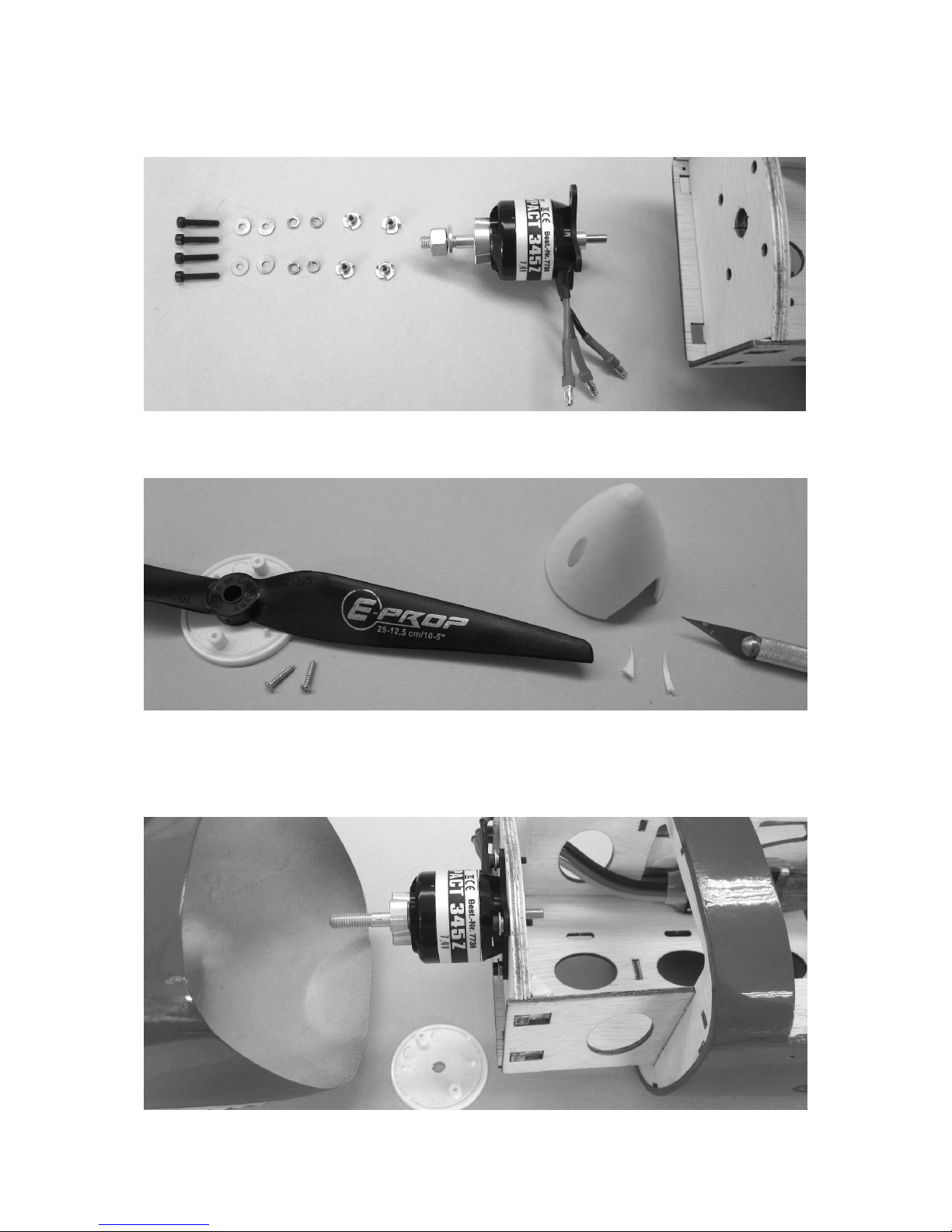

First place the motor spindle, motor mount, and locking ring onto the motor; these

parts are included as accessories in the package for Order No. 7738.

The figure shows the individual parts for the motor spindle and motor mount; tighten

all screws.

The figure shows the motor with attached motor mount and motor spindle. Separate

the motor leads and remove about 5 mm of insulation. Apply solder to the ends of all

leads and then solder on the G 3.5 connectors (included with Order No.7738).

Insulate the connector shaft with the heat-shrink sleeves (included with Order

No.7738) . Use a hair dryer to shrink the heat-shrink sleeve. Then do a test run of

GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved! No liability for printing errors! 10/2011

- 5 -

the motor. Viewed in flight direction, the motor should rotate to the right; if this is not

the case, switch any two of the leads and re-insert.

Using the 4 M 3x10 mm and the washers and locking rings shown, screw the motor

in tight.

Place the GRP propeller spacer onto the propeller, enlarge the cut-outs in the spinner

cap to fit the propeller, separate the two short pins on the spinner back plate, so that

the spinner cap fits and can be pushed on without any stress.

Loading...

Loading...