Page 1

XtenDD (HD)

DIGITAL HDTV PRODUCTION SWITCHERS

Planning and Installation

Revision 3

Document Order Number: RU 3111 / 000212311100

April 2005

the most watched worldwide

Page 2

Published by

Thomson Broadcast and Media Solutions GmbH

Brunnenweg 9

D-64331 Weiterstadt, Germany

P.O. Box 1165

Tel: +49 (0) 6150-104-0

Fax: +49 (0) 6150-104-300

Web Site

www.thomsongrassvalley.com

Trademarks

All product names mentioned in this manual are the trademarks of their respective owners.

Copyrights

Information in this document is subject to change without notice.

This document and any updates and/or supplemental information, including any copies thereof, cannot be reproduced, neither

communicated to a third party, without written authorization from THOMSON Broadcast and Media Solutions.

Please notify THOMSON Broadcast and Media Solutions of any errors in this document. Wealsowouldappreciateanycomments

you have to improve this manual.

E Thomson Broadcast and Media Solutions GmbH 2005. All rights reserved.

Page 3

Number: 510057.001

The Quality System of:

Thomson Broadcast & Media Solutions

TBMS TBMS

400 Providence Mine Road 17 rue du Petit Albi -BP 8244

Nevada City, CA 95945 95801 Cergy Pontoise

Cergy, France

TBMS

Weiterstadt, Germany TBMS

Brunnenweg 9 10 Presidential Way, 3rd Floor, Suite 300

D-64331 Weiterstadt, Germany Woburn, MA 08101

TBMS TBMS

15655 SW Greystone Ct. 2300 South Decker Lake Blvd.

Beaverton, OR 97006 Salt Lake City, UT 84119

TBMS TBMS - PCB

Nederland B.V. Rennes, France

4800 RP BREDA Rue du Clos Courtel

The Nederlands Cesson-Sevigne, Cedex

France

TBMS/Nextream TBMS/Nextream

Rennes, France Technopole Brest Iroise

Rue du Clos Courtel CS 73808

Cesson-Sevigne, Cedex 29238 Brest Cedex 3

France France

Including its implementation, meets the requirements of the standard:

ISO 9001:2000

Scope: The design, manufacture and support of video hardware and software products

and related systems.

This Certificate is valid until: June 14, 2006

Revision Date: September 9, 2003

Renewal Date: June 14, 2003

Issued for the first time: June 14, 2000

Page 4

CONTENTS

1. General

1.1 Overview HD Family 1 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 HD35 Digital HD Production Switcher 1 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Key Features 1 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Commanding Creative Power ... Innovating your Image 1 - 2. . . . . . . . . . . . . . . . .

1.2.3 Unlimited Custom Solutions 1 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Power not Complexity 1 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Networking your Resources 1 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Picture Quality and Flexibility 1 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Mission Control 1 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.8 And if That’s not Enough ... 1 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Panel Overview 1 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 RPS35-2/S Control Panel 1 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 RPS35-2 Control Panel Set 1 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 RPS35-3/24 Control Panel Set 1 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 RPS35-3/32 Control Panel Set 1 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.5 RPS35-4/32 Control Panel Set 1 - 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

1.4 Overall Block Diagams 1 - 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Video Schematics SH -1/2/3/4-BM Mainframe 1 - 12. . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Video Schematics SH -1/2S-BM Mainframe 1 - 12. . . . . . . . . . . . . . . . . . . . . . . . . .

2. Technical Data

2.1 Mainframe 2 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Inputs 2 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Outputs 2 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Video System Data 2 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 Power Supply Mainframe 2 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.5 Mechanical Data Mainframe 2 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.7 Environmental Data 2 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.8 Interface Data 2 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Control Panels 2 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Integrated Side Panel PC 2 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Power Supply Control Panels 2 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Installing Mainframe

3.1 Unpacking 3 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Mechanical Dimensions 3 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Mainframe SH- 1/2/3/4-BM 3 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Mainframe SH- 1/2S-BM 3 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Installation in a Cabinet 3 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Ventilation 3 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Mainframe SH- 1/2/3/4-BM 3 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Mainframe SH- 1/2S-BM 3 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Planning and Installation - Rev. 3 / 04.2005

I

Page 5

Contents

4. Installing Control Panels

4.1 Unpacking 4 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Mechanical Dimensions 4 - 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 RPS35-2/S Control Panel 4 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 RPS35-2 Control Panel Set 4 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 RPS35-3/24 Control Panel Set 4 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 RPS35-3/32 Control Panel Set 4 - 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 RPS35-4/32 Control Panel Set 4 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.6 Desk Cut-Out for RPS35-2/S 4 - 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.7 Desk Cut-Out for RPS35-2 4 - 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.8 Desk Cut-Outs for RPS35-3/24 4 - 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.9 Desk Cut-Outs for RPS35-3/32 4 - 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.10 Desk Cut-Outs for RPS35-4/32 4 - 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.11 Remote Panel RSAT2 4 - 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.12 Desk Cut-Out for Remote Panel RSAT2 4 - 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.13 Desk Cut-Out for Satellit Panel RSAT1 4 - 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Installing Panels 4 - 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Single Module Mounting 4 - 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Mounting with “all-in-one” Mounting Frame 4 - 21. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Ventilation 4 - 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Connection and Startup

5.1 Grounding Requirements 5 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Connecting Power and Earth Lines 5 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Control Panel Connectors 5 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Control Panel RPS35-2/S 5 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1.1 Connection of a PS2 Keyboard to the RPS35-2S Control Panel 5 - 6. . . . . . . . .

5.3.1.2 Power Supply Connectors RC 2375 5 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1.3 Controller Connectors RC 2374 5 - 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1.4 IPC Connectors RC 2360 5 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Control Panel Set RPS35-2; RPS35-3, RPS35-4/32 5 - 11. . . . . . . . . . . . . . . . . . .

5.3.2.1 Power Supply Connectors RC 2375 5 - 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2.2 Controller Connectors RC 2374 5 - 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2.3 PC Connectors RC 2371 5 - 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2.4 Wipe Panel Connectors 5 - 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2.5 Display Panel Connectors 5 - 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2.6 Aux Panel Connectors 5 - 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Panel Inter-Unit Cabling 5 - 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Panel Set RPS35-2 5 - 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Panel Set RPS35-3, RPS35-4/32 5 - 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Mainframe Connectors 5 - 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 SH- 1/2/3/4- BM Mainframe 5 - 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1.1 Overview Mainframe Connection Unit 5 - 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1.2 AC Power, Grounding 5 - 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1.3 Video Inputs 5 - 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1.4 AUX Outputs 5 - 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1.5 Video Reference 5 - 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1.6 LAN 5 - 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II

Planning and Installation - Rev. 3 / 04.2005

Page 6

5.5.1.7 Serial Ports, GPI, GPO 5 - 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1.8 Modem 5 - 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1.9 Alarm 5 - 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 SH- 1/2S- BM Mainframe 5 - 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2.1 AC Power, Grounding 5 - 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2.2 Video Inputs 5 - 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2.3 Video Outputs 5 - 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2.4 Control Connectors 5 - 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2.5 LAN Interface, Audio Interface 5 - 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2.6 DC In, DC Out 5 - 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Pin Assignments 5 - 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Alarm Specification 5 - 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 LAN Specification 5 - 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Network Configuration 5 - 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Network Earthing 5 - 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

6. Tally Signalling

6.1 Introduction 6 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Operation Modes 6 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Tally Installation Menu 6 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Pin Assignment 6 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Tally Outputs 6 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Tally Inputs 6 - 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Monitor Tally Operation 6 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Monitor Tally Main, M/E1 - 3, Clean 6 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Monitor Tally Aux 1 - 15 6 - 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Tally Ready Input 6 - 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Description MI-3040 Tally Box 6 - 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Initial Installation

7.1 Installation Check List 7 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 SH- 1/2/3/4- BM Mainframe 7 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Power Supply 7 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Mainframe Boards 7 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 SH- 1/2S- BM Mainframe 7 - 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Mainframe Boards 7 - 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Mainframe Board Settings 7 - 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1 Input Processor RY 3040 / RY 3041 7 - 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1.1 Mounting the Input Processor Board RY 3040/41 7 - 16. . . . . . . . . . . . . . . . . . . . .

Planning and Installation - Rev. 3 / 04.2005

III

Page 7

Contents

7.4.2 ME Processor RY 3010 7 - 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.3 Key Processor RY 3020 7 - 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.4 Wipe Processor RY 3025 7 - 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.5 Output Processor RY 3030 / RY 3031 7 - 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.6 Genlock RY 3080 7 - 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.7 RAM Recorder RY 3050 7 - 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.8 Fx Processor RY 3060 7 - 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.9 Mainframe Controller RY 3156 7 - 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.9.1 Front View with LED’s and Control Elements 7 - 25. . . . . . . . . . . . . . . . . . . . . . . . .

7.4.9.2 P.C. Board with LED’s and Control Elements 7 - 26. . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Control Panel Boards Settings 7 - 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Fader Connection Panel RC 1855 7 - 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Panel Controller RY 2370 7 - 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.3 Panel Controller RY 2100 7 - 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Timing / Genlock Alignment 7 - 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.1 Genlock Adjustment 7 - 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Installing External Devices

8.1 Aux Control Panels 8 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 General 8 - 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Installation 8 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2.1 Installation E-Box 8 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2.2 Installation Panel 8 - 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Configuration 8 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3.1 Config E-Box 8 - 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3.2 Config Panel 8 - 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3.3 Input Assign (internal sources) 8 - 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.4 Front Panel Operation 8 - 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Under Monitor Displays 8 - 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 General 8 - 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Installation 8 - 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Configuration 8 - 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.4 Operationg Hints 8 - 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV

Planning and Installation - Rev. 3 / 04.2005

Page 8

1. GENERAL

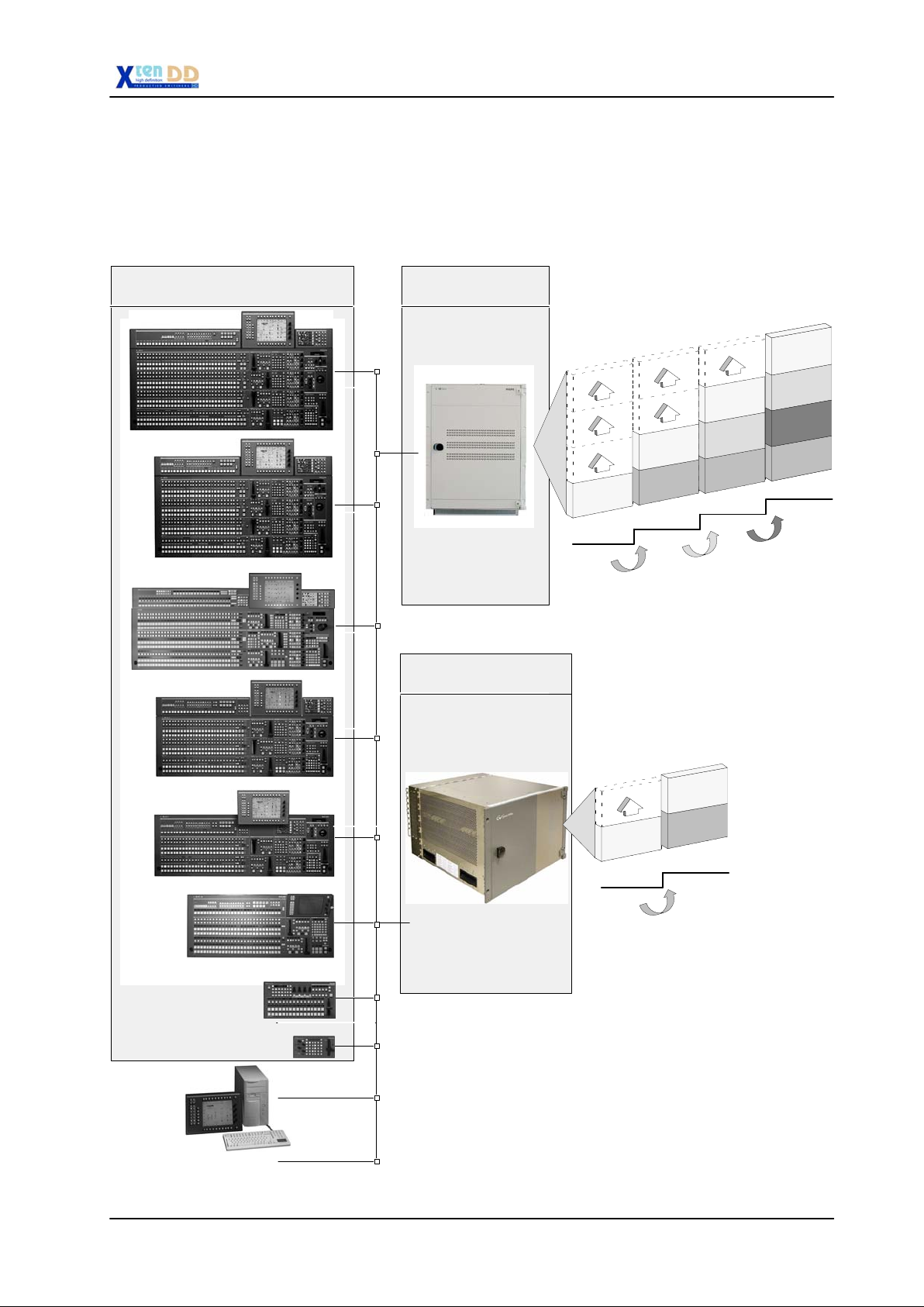

1.1 OVERVIEW HD XtenDD FAMILY

Configuration Overview

1. General

RPS35-4LX(32)

RPS35-4L

RPS35-3/32

RPS35-3

RPS35-x Basic Mainframe

++

Small Mainframe

SH-2-BM

1 M/E + P/P

Upgrade 1

=

M/E 1

P/P

HD35

Upgrade 2

Options

SH-1-BM

M/E 1

1 M/E

Mainframe Configurations

SH-3-BM

M/E 1

M/E 2

P/P

2 M/E + P/P

Upgrade 3

SH-4-BM

M/E 1

M/E 2

M/E 3

P/P

3 M/E + P/P

RPS35-2

RPS35-2/S

DD35 GUI PC *

Service PC

RSAT2 *

RSAT1 *

LAN

SH-2S-BM

SH-1S-BM

M/E 1

M/E 1

1 M/E

Small Mainframe Configurations / Upgrade

*Note:

For more details there are separate manuals available.

They can be ordered under the order numbers:

DD35 GUI PC RU 0063, 0 212 247 500

RSAT1

RSAT2

RU 0061, 0 212 174 600

RU 0065, 0 351 763 000

P/P

1 M/E + P/P

Upgrade 1

Planning and Installation - Rev. 3 / 04.2005

1 - 1

Page 9

1. General

1.2 DIGITAL HD PRODUCTION SWITCHER

1.2.1 KEY FEATURES

D 1.5 Gb/s video processing

D Selectable picture format

D 1, 2, 3 and 4 M/E versions with two mainframetypes

D 5 layers per M/E with 3 keyers and 2 background generators

D 90 inputs

D 36 outputs

D Integrated 2D DVE effects + RAM Recorder

D Machine Control interfaces to major Digital Disk Recorders (DDRs), servers,

laser disks and Video Tape Recorders (VTRs)

D Name-Follow-Video intelligent Router interface

D Full control interoperability with SDTV equipment

D Two compact mainframes types and low power consumption

1.2.2 COMMANDING CREATIVE POWER ... INNOVATING YOUR IMAGE

The HD XtenDD family is a new and exciting Production Switcher bringing creative

power to the heart of your High Definition (HD) production facility. This new product

is based on the user friendly and flexible DD35 series production switcher. The HD

XtenDD’s new electronic architecture has the capacity expand to ninety inputs and

twenty auxiliary outputs. This powerful combination ensures that even the most advanced HD production tasks can be achieved quickly with a minimum learning

curve.

Typical of the many stunning features is the Dyna Chrome TM Chroma Key. The

enhanced HD version now provides breath-taking levels of realism, delivering outstanding production value.

The HD XtenDD is not just a production switcher, it is your total production control

center. The system incorporates interfaces to major production peripherals putting

you in control of the entire production with remarkable simplicity.

Whatever your budget or production demands, the scalability of the HD XtenDD

allows you to adapt it to your precise needs. Guaranteed to be hassle free, it is

founded on the experience gained from over 1,200 THOMSON DD-series digital

production switchers in use around the globe with over 8 years of leadership in the

design of HD broadcast equipment.

1 - 2

Planning and Installation - Rev. 3 / 04.2005

Page 10

1.2.3 UNLIMITED CUSTOM SOLUTIONS

Recognizing that every user has different requirements, the modular architecture

of the THOMSON HD XtenDD allows you to configure the switcher to your precise

needs and budget without having to pay for unnecessary features.

The switcher is designed to accept additional modules which, as they become

available, will enable you to enhance your system with new features. Furthermore,

the resolution independence gives you the assurance that you can produce on any

of the current HD formats.

1.2.4 POWER NOT COMPLEXITY

With the substantial number of inputs and auxiliary outputs, the need to rely on external routing becomes minimized. This improves your operation by assuring frame

accuracy and synchronization of events.

With the capacity of 90 inputs, 20 auxiliary buses outputs, and 4 dedicated output

per M/E, there is virtually no job that is beyond the power of the THOMSON HD

XtenDD.

The Integrated Machine Control feature focuses the action to where it should be

... right at your finger - tips ... eliminating the need to move away from the production

switcher control panel. Without the need for a dedicated operator for every piece

of equipment, the technical director can be at the very center of activity, with full

control of the action.

1. General

1.2.5 NETWORKING YOUR RESOURCES

THOMSON traditional operation flexibility is the nucleus of the HD XtenDD, offering

virtually unlimited networking possibilities. Resources may be shared, combined

or remoted almost without limitation.

This flexibility maximizes the value of installed equipment by allowing unused resources to be reassigned to other users or tasks. Capabilities can range from enabling remote access (typically to allow on site rehearsal), or sharing one mixer between several users (two M/Es could be switching a show live while another M/E

is editing an off line interview).

This system flexibility will eventually lead to simultaneous HD and SD production

for simulcasts. All with a single panel, a single operator, and without additional cost.

1.2.6 PICTURE QUALITY AND FLEXIBILITY

The concept of the HD XtenDD is made possible by THOMSON powerful M/Es,

existing in several configurations; from a single M/E, to four full featured M/Es. This

switcher establishes the foundation from which your creative talent can develop the

most sophisticated productions.

The internal key processing quality and flexibility provided within each M/E and

PGM/PST is particularly noteworthy. Dyna Chrome TM , THOMSON’ acclaimed

chromakey processor, has been further enhanced for high definition. Dyna Chrome

TM, combined with the precise auto set -up, guarantees realistic keying with speed

and repeatability.

Planning and Installation - Rev. 3 / 04.2005

1 - 3

Page 11

1. General

With it’s potential of 6 downstream keyers, the HD XtenDD simplifies the creation

of cascaded inserts or multiple versioned outputs. Now the complicated task of split

feeds with different program keys is a breeze. And with three keyers per M/E, the

only limit to image composition is your imagination.

1.2.7 MISSION CONTROL

The HD XtenDD shares the same control panel family as the intuitive and widely

accepted THOMSON DD35 series switchers. Their functions and layout are the result of close discussion with many Technical Directors, truly making these panels

”Designed by TD’s, manufactured by THOMSON”.

Simplicity is further enhanced by features such as button-per-function and Name

Follow Video TM. With a knob and a button for every control function, and mnemonics that clearly identify source names you can, every input and every feature is immediately available for ultimate confidence that the ”mission” will go as planned.

Further refinements, including those provided by the exceptional MaKE- Memo TM

Macros, increase productivity and creativity and eliminate the pressure that can

lead to mistakes. With THOMSON MaKE- Memo TM the most complex of sequences can be programmed and recalled from a single keystroke.

The Graphical User Interface (GUI) provides you with additional access to the

many features of the HD XtenDD. Yet at no time is the reliability of mission- critical

tasks ever compromised. The GUI computer is in addition to the switcher main

processors. In an emergency, the switcher can be operated from the GUI in the unlikely event of a control panel failure. On the other hand, the switcher is totally functional without the GUI. These are examples of the exceptional levels of security and

redundancy designed into the HD XtenDD.

1.2.8 AND IF THAT’S NOT ENOUGH ...

Every one of the feature enhancing accessories designed for the DD35 are also

available for the HD XtenDD. This includes programmable remote control panels,

button separators and many more. These accessories increase the ease of use

and open doors to more applications.

1 - 4

Planning and Installation - Rev. 3 / 04.2005

Page 12

1.3 PANEL OVERVIEW

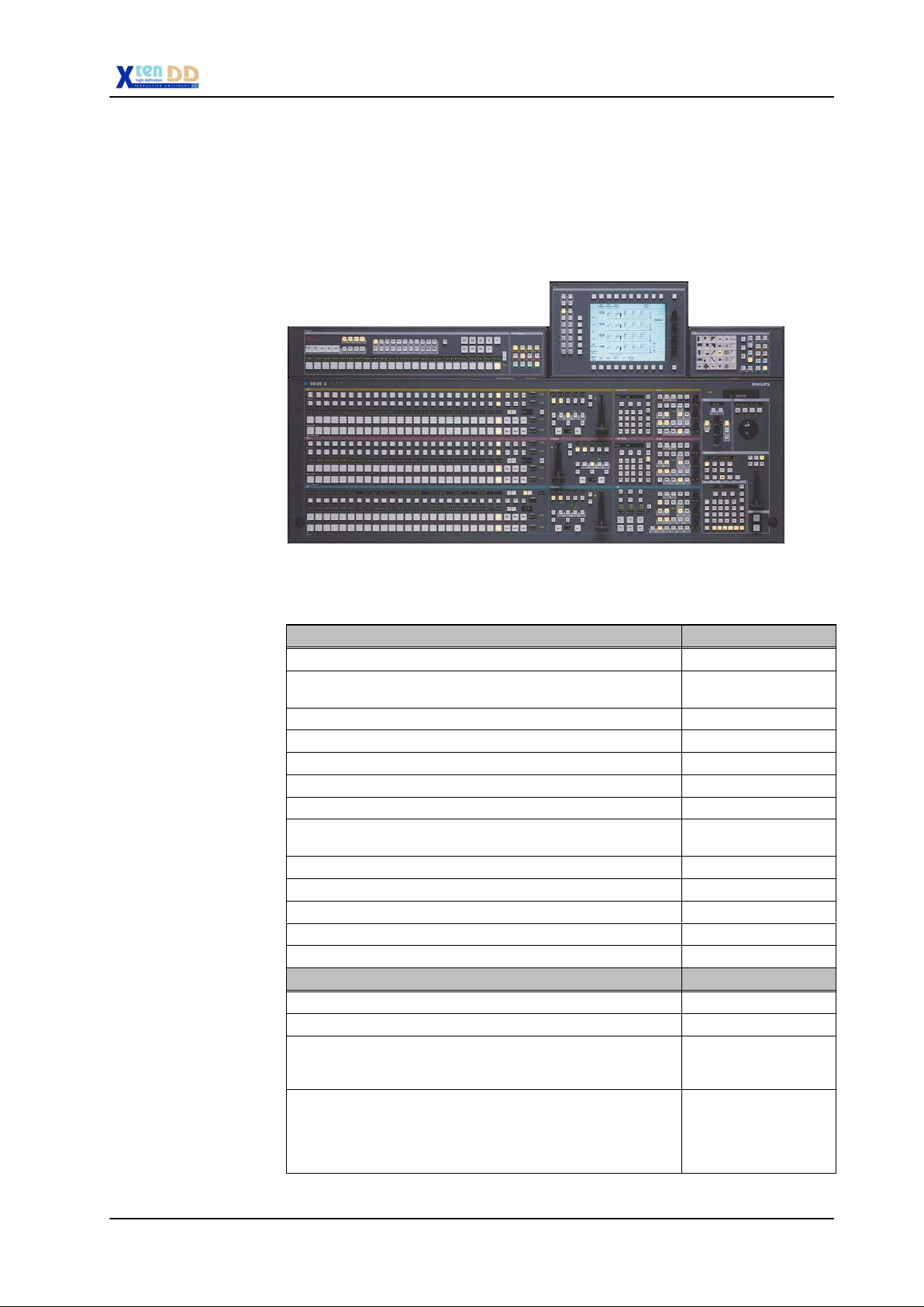

1.3.1 RPS35-2/S CONTROL PANEL

The production switcher panel RPS35-2/S with one mixing level M/E and one Program/Preset, as well as the touch screen display panel.

1. General

Fig. 101: Control Panel RPS35-2S

Panel Order number

RPS35-2S Control panel (OnAir normal lighting) 000 351 860 510

RPS35-2S-HL Control panel (OnAir high lighting) 000 351 862 510

Options Order number

RC 2453

RC 2456

RC 2351 Fanless Power Supply

RC 2376 Redundant Power Supply

RC 2380 Operating System Windows NT for PC 000 351 775 800

Input mnemonics for RPS 35-2S

P/P, MaKE, M/E 1 and AUX

Initial order only.

Input mnemonics for RPS35-2S

AUX, P/P, M/E 1 without

MaKE mnemonics

Initial order only.

Redundancy included

Initial order only.

(retrofitting possible)

000 212 265 311

000 212 265 610

000 351 772 100

000 351 774 600

Planning and Installation - Rev. 3 / 04.2005

1 - 5

Page 13

1. General

1.3.2 RPS35-2 CONTROL PANEL SET

The production switcher panel set RPS35-2 comprises the basic unit RPD35-2 with

one mixing level M/E and one Program/Preset, as well as the stand-alone display

panel RPV35-4TS.

The mnemonics for P/P and Make Memo Aux are standard.

Fig. 102: Control panel set RPS35-2

Panel Order number

RPS35-2 Control panel set

(OnAir normal lighting) including:

RPD35-2 Basic panel 000 351 861 810

RPV35-4TS Display panel 000 351 852 010

RPS35-2-HL Control panel set

(OnAir highlighting) including:

RPD35-2-HL Basic panel 000 351 863 210

RPV35-4TS Display panel 000 351 852 010

Options Order number

RC 2396 RPV mounting frame

used to mount the RPV display panel

onto the base panel

RC 2362 Input mnemonics extension

Initial order only.

RC 2351 Fanless Power Supply

Redundancy included

Initial order only.

RC 2148 Emergency Hard Disk Drive IDE, min.

2 GB. Must be order initially together

with basic panel.

Operating Software pre-configured.

RC 2376 Redundant Power Supply

(retrofitting possible)

RC 2380 Operating System Windows NT for PC 000 351 775 800

000 351 860 410

000 351 862 410

000 351 777 410

000 351 773 200

000 351 772 100

000 351 745 000

000 351 774 600

1 - 6

RC 2397 Stand tiltable for display panel 000 351 777 510

Planning and Installation - Rev. 3 / 04.2005

Page 14

1.3.3 RPS35-3/24 CONTROL PANEL SET

The production switcher panel set RPS35-3/24 comprises the RPD35-3/24 with

two mixing levels M/E and one Program/Preset, the display panel RPV35-4TS, the

wipe panel RPW35-3/-4 and the aux panel RPA35-3/24.

All mnemonics are standard.

1. General

Fig. 103: Control panel set RPS35-3

Panel Order number

RPS35-3/24 Control panel set

(OnAir normal lighting) including:

RPD35-3/24 Basic panel 000 351 861 410

RPV35-4TS Display panel 000 351 852 010

RPA35-3/24 Aux panel 000 351 861 510

RPW35-3/-4 Wipe panel 000 351 861 710

RPS35-3/24-HL Control panel set (OnAir highlighting)

including:

RPD35-3/24-HL Basic panel 000 351 863 010

RPV35-4TS Display panel 000 351 852 010

RPA35-3/24-HL Aux panel 000 351 863 110

RPW35-3/-4 Wipe panel 000 351 861 710

Options Order number

000 351 860 310

000 351 862 310

RC 2360 Mounting frame set 000 351 773 000

RC 2351 Fanless Power Supply

RC 2214 Detachment cables (2.5 m) AUX or

Planning and Installation - Rev. 3 / 04.2005

000 351 772 100

Redundancy included

Initial order only.

000 351 747 000

Wipe.

For AUX or Wipe the set must be ordered separatly

(usually 2x needed!)

1 - 7

Page 15

1. General

Options Order number

RC 2148 Emergency Hard Disk Drive IDE, min.

2 GB. Must be ordered initially together

with basic panel.

Operating Software pre-configured.

RC 2376 Redundant Power Supply

(retrofitting possible)

RC 2380 Operating System Windows NT for PC 000 351 775 800

000 351 745 000

000 351 774 600

1 - 8

Planning and Installation - Rev. 3 / 04.2005

Page 16

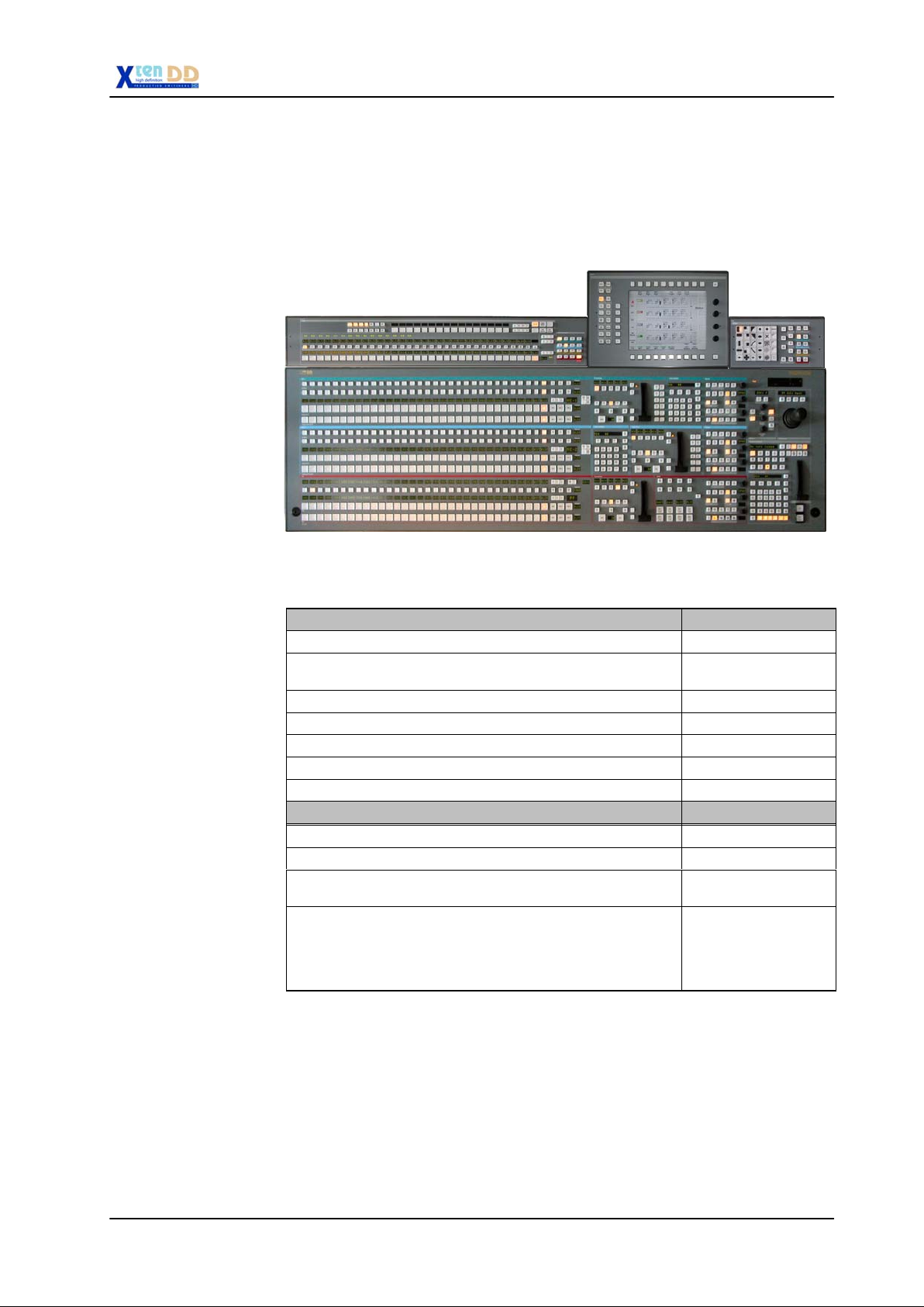

1.3.4 RPS35-3/32 CONTROL PANEL SET

The production switcher panel set RPS35-3/32 comprises the RPD35-3/32 with

two mixing levels M/E and one Program/Preset, the display panel RPV35-4TS, the

wipe panel RPW35-3/-4 and the aux panel RPA35-3/32.

The mnemonics for P/P, Make Memo and Aux are standard.

1. General

Fig. 104: Control panel set RPS35-3/32

Panel Order number

RPS35-3/32 Control panel set (OnAir highlighting)

including:

RPD35-3/32 Basic panel 000 351 845 010

RPV35-4TS Display panel 000 351 852 010

RPA35-3/32 Aux panel 000 351 862 810

RPW35-3/-4 Wipe panel 000 351 861 710

Options Order number

RC 2360 Mounting frame set 000 351 773 000

RC 2351 Fanless Power Supply

Initial order only.

RC 2214 Detachment cables (2.5 m) AUX or

Wipe.

For AUX or Wipe the set must be ordered separatly

(usually 2x needed!)

000 351 840 010

000 351 772 100

000 351 747 000

Planning and Installation - Rev. 3 / 04.2005

1 - 9

Page 17

1. General

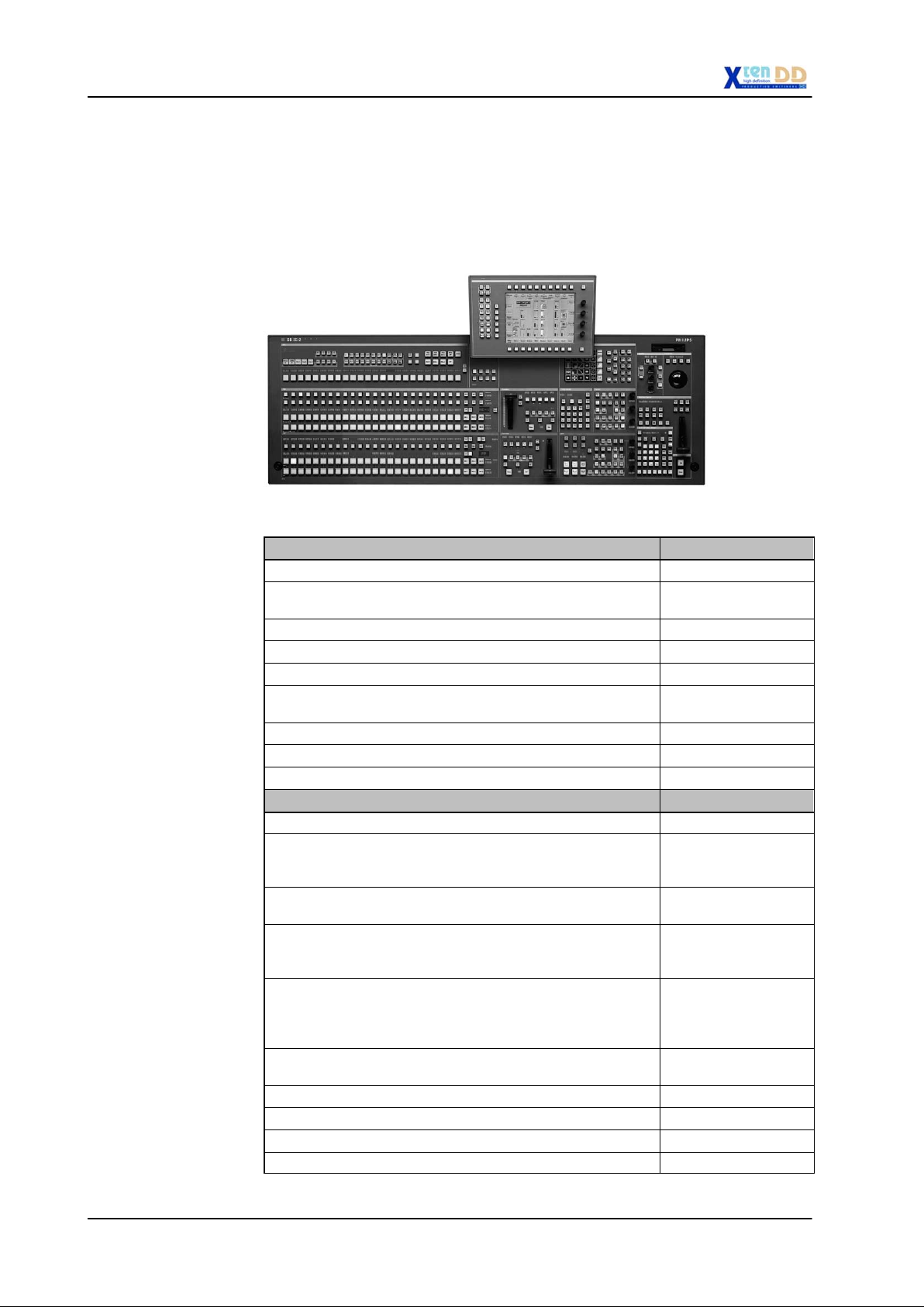

1.3.5 RPS35-4/32 CONTROL PANEL SET

The production switcher panel set RPS35-4/32 comprises the RPD35-4/32 with

three mixing levels M/E and one Program/Preset, the display panel RPV35-4TS,

the wipe panel RPW35-3/-4 and the aux panel RPA35-4/32.

The redundant power supply and input mnemonics are standard.

Fig. 105: Control panel set RPS35-4/32

There are two versions available:

1. Control Panel Set RPS35-4/32

OnAir normal lighting as all other DD35 family panels

2. Control Panel Set RPS35-4/32 HL

OnAir highlighting, where crosspoint buttons are high tallied when the bus is

OnAir and low tallied when not OnAir

Panel Order number

RPS35-4/32 Control panel set

(On Air normal lighting) including:

RPD35-4/32 Basic panel 000 351 855 000

RPV35-4TS Display panel 000 351 852 010

RPA35-4/32 Aux panel 000 351 853 000

RPW35-3/-4 Wipe panel 000 351 861 710

000 351 850 010

1 - 10

RPS35-4/32 HL Control panel set (OnAir highlighting)

including:

RPD35-4/32 HL Basic panel 000 351 862 610

RPV35-4TS Display panel 000 351 852 010

RPA35-4/32 HL Aux panel 000 351 862 810

RPW35-3/-4 Wipe panel 000 351 861 710

000 351 863 310

Planning and Installation - Rev. 3 / 04.2005

Page 18

1. General

Options Order number

RC 2840 Mounting frame set 000 351 854 000

RC 2148 Emergency Hard Disk Drive IDE, min.

2 GB. Must be ordered initially togehter

with basic panel.

Operating Software pre-configured.

RC 2351 Fanless Power Supply

Redundancy included

Initial order only.

RC 2376 Redundant Power Supply

(retrofitting possible)

RC 2380 Operating System Windows NT for PC 000 351 775 800

000 351 745 000

000 351 772 100

000 351 774 600

Planning and Installation - Rev. 3 / 04.2005

1 - 11

Page 19

1. General

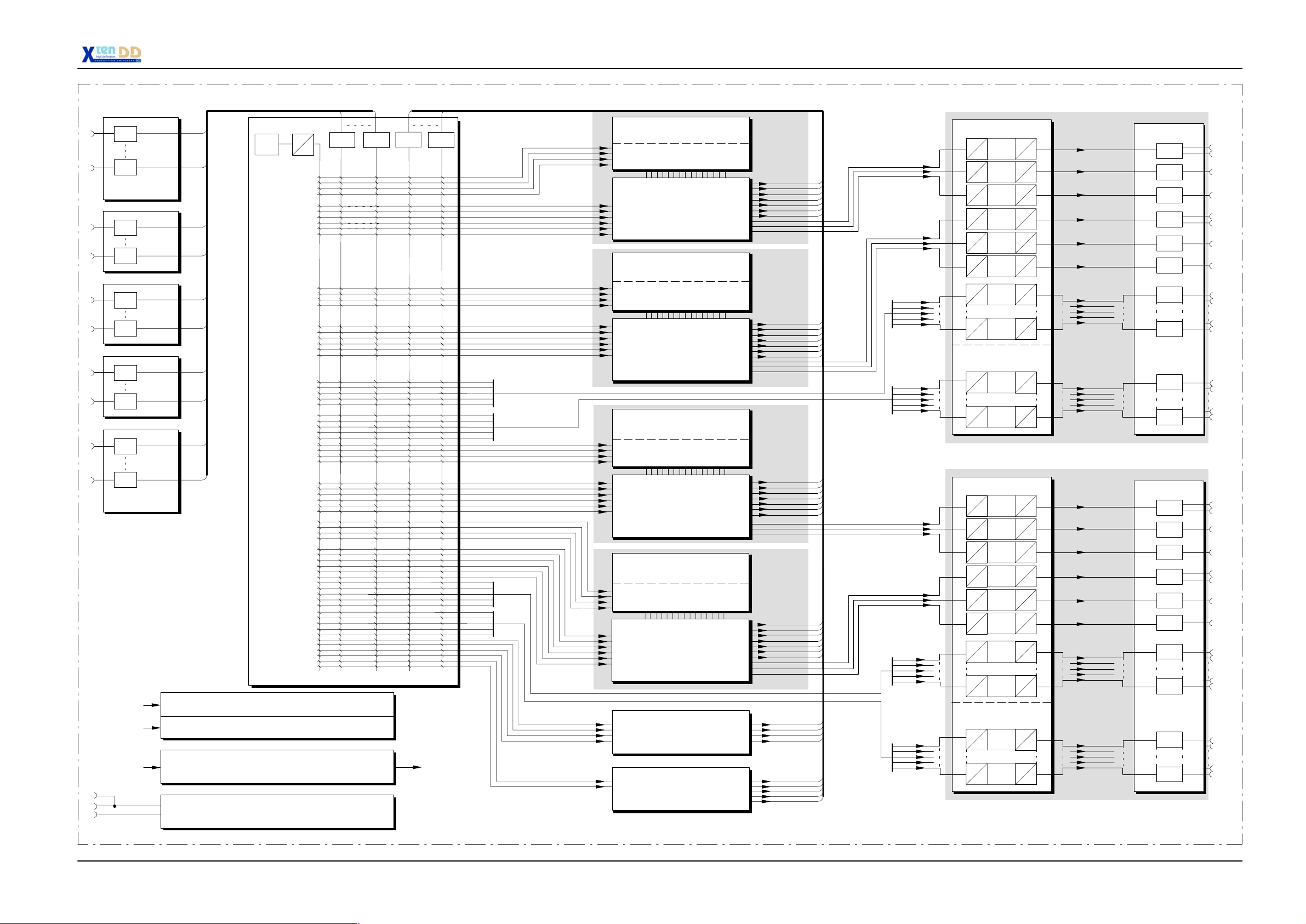

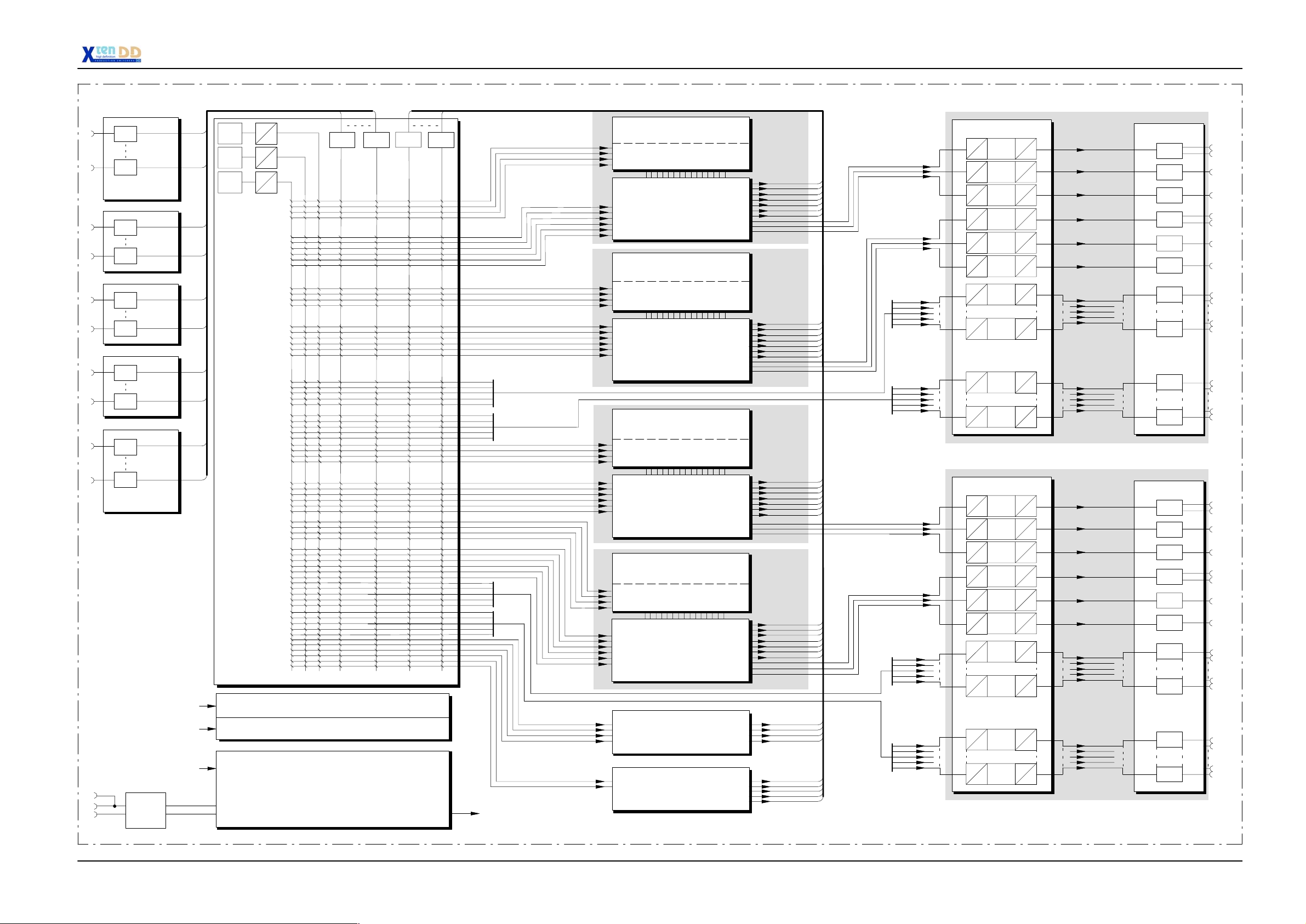

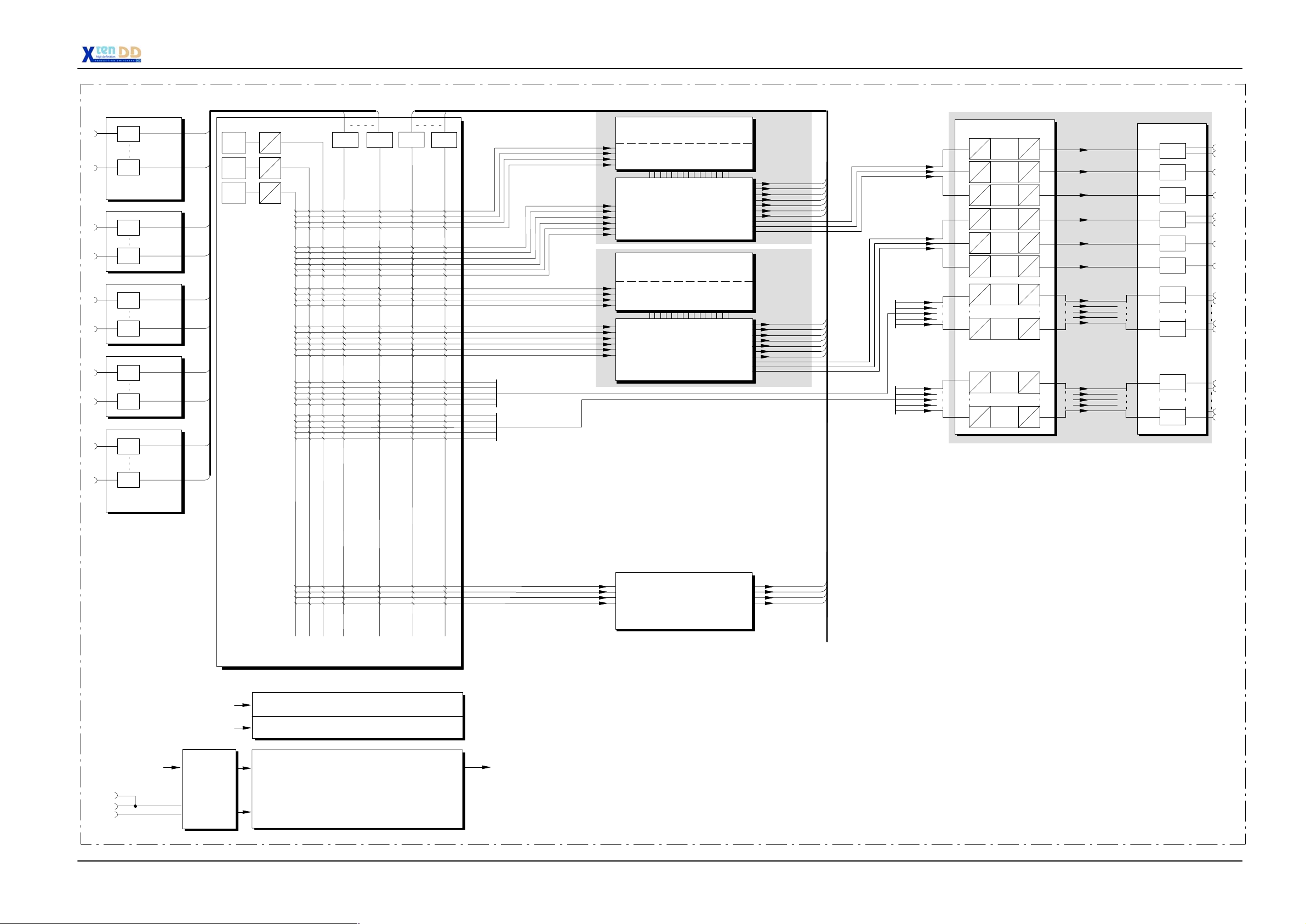

1.4 OVERALL BLOCK DIAGAMS

1.4.1 VIDEO SCHEMATICS SH 1/2/3/4 BM MAINFRAME

See block diagram on page 1- 13

1.4.2 VIDEO SCHEMATICS SH 1/2S BM SMALL MAINFRAME

See block diagram on page 1- 15

1 - 12

Planning and Installation - Rev. 3 / 04.2005

Page 20

1. General

Planning and Installation - Rev. 3 / 04.2005

1 - 13

Page 21

1. General

1

18

19

36

37

54

55

72

73

EQUAL

EQUAL

INPUT MODULE

RY 3004

EQUAL

EQUAL

EQUAL

EQUAL

EQUAL

EQUAL

EQUAL

90 EXTERNAL90 EXTERNAL SIGNALS

WHITE

PAR

BUFFER BUFFER BUFFER

SER

BUFFER

37 INTERNAL SIGNALS

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

KEY 1

KEY 2

KEY 3

KEY 4

WIPE PROCESSOR

RY 3025 / RY 3026

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

WIPE PROCESSOR

RY 3025 / RY 3026

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

WIPE PROCESSOR

RY 3025 / RY 3026

KEY PROCESSOR

RY 3020

ME 1

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

ME PP

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

ME 2

PGM

PVW

CLEAN

PGM

PVW

CLEAN

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

AUX8

AUX9

AUX10

OUTPUT PROCESSOR

RY 3030

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

SER

PAR

SER

PAR

OUTPUT PROCESSOR

EXTENSION RY 3035

SER

PAR

SER

PAR

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

OUTPUTS A

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

AUX8

AUX9

AUX10

OUTPUT MODULE

RY 3005

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

PGM/23

PGM/24

PVW/21

CLEAN/22

PGM//27

PGM/28

PVW/25

CLEAN/26

1

5

6

10

90

EQUAL

INPUT MODULE

RY 3004

AC IN

AC IN

REMOTE

GPI IN

SERIAL IN

BLACK BURST

SER VID

INPUT PROCESSOR RY 3040

2x POWER SUPPLY RY 3009

2x POWER SUPPLY RY 3009 REDUNDANT

OPTION

CONTROLLER RY 3156

GENLOCK RY 3080

SERIALOUT

REMOTE

GPI OUT

TALLY

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

_

SRC 1

SPR

_

SRC 2

SPR

_

SRC 3

SPR

_

SPR

SRC 4

STORE 1

STORE 2

ME PROCESSOR

RY 3010

WIPE PROCESSOR

RY 3025 / RY 3026

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

SPARE

RY 3060

STORE

RY 3050

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

ME 3

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

_

SPR

RET 1

_

RET 2

SPR

_

RET 3

SPR

SPR_RET 4

STO_KEY 1

STO_VID 1

STO_KEY 2

_

STO

VID 2

_

MAT

BGD

PGM

PVW

CLEAN

PGM

PVW

CLEAN

AUX11

AUX12

AUX13

AUX14

AUX15

AUX16

AUX17

AUX18

AUX19

AUX20

OUTPUT PROCESSOR

RY 3030

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

SER

PAR

SER

PAR

OUTPUT PROCESSOR

EXTENSION RY 3035

SER

PAR

SER

PAR

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

OUTPUTS B

AUX11

AUX12

AUX13

AUX14

AUX15

AUX16

AUX17

AUX18

AUX19

AUX20

OUTPUT MODULE

RY 3005

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

PGM/31

PGM/32

PVW/29

CLEAN/30

PGM/35

PGM/36

PVW/33

CLEAN/34

11

15

16

20

Planning and Installation - Rev. 3 / 04.2005

1 - 15

Page 22

1. General

1 - 16

Planning and Installation - Rev. 3 / 04.2005

Page 23

1. General

1

18

19

36

37

54

55

72

73

EQUAL

EQUAL

INPUT MODULE

RY 3140

Option

EQUAL

EQUAL

RC 3141

Option

EQUAL

EQUAL

RC 3142

Option

EQUAL

EQUAL

RC 3143

Option

EQUAL

90 EXTERNAL90 EXTERNAL SIGNALS

WHITE

COL 1

COL 2

PAR

SER

PAR

SER

PAR

SER

BUFFER BUFFER BUFFER

BUFFER

37 INTERNAL SIGNALS

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

KEY 1

KEY 2

KEY 3

KEY 4

WIPE PROCESSOR

RY 3025

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

WIPE PROCESSOR

RY 3025

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

WIPE PROCESSOR

RY 3025

KEY PROCESSOR

RY 3020

ME 1

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

ME PP

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

ME 2

PGM

PVW

CLEAN

PGM

PVW

CLEAN

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

AUX8

AUX9

AUX10

OUTPUT PROCESSOR

RY 3031

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

OUTPUTS A

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

AUX8

AUX9

AUX10

OUTPUT MODULE

RY 3160

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

PGM/23

PGM/24

PVW/21

CLEAN/22

PGM//27

PGM/28

PVW/25

CLEAN/26

1

5

6

10

90

EQUAL

INPUT MODULE

RY 3144

VidRev

Module

RY 3008

AC IN

AC IN

REMOTE

GPI IN

SERIAL IN

BLACK BURST

SER VID

INPUT PROCESSOR RY 3442

2x POWER SUPPLY RY 3009

2x POWER SUPPLY RY 3009 REDUNDANT

OPTION

GENLOCK + CONTROLLER

RY 3490

SERIALOUT

REMOTE

GPI OUT

TALLY

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

_

SRC 1

SPR

_

SRC 2

SPR

_

SRC 3

SPR

_

SRC 4

SPR

STORE 1

STORE 2

ME PROCESSOR

RY 3010

WIPE PROCESSOR

RY 3025

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

RAMREC RY 3050

Option

SPARE RY 3060

HD DVE PROCESSOR RY 3060

Option

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

ME 3

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

SPR_RET 1

_

RET 2

SPR

_

RET 3

SPR

_

RET 4

SPR

STO_KEY 1

STO_VID 1

STO_KEY 2

_

STO

VID 2

_

MAT

BGD

PGM

PVW

CLEAN

PGM

PVW

CLEAN

AUX11

AUX12

AUX13

AUX14

AUX15

AUX16

AUX17

AUX18

AUX19

AUX20

OUTPUT PROCESSOR

RY 3031

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

OUTPUTS B

AUX11

AUX12

AUX13

AUX14

AUX15

AUX16

AUX17

AUX18

AUX19

AUX20

OUTPUT MODULE

RY 3061

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

PGM/31

PGM/32

PVW/29

CLEAN/30

PGM/35

PGM/36

PVW/33

CLEAN/34

11

15

16

20

Planning and Installation - Rev. 3 / 04.2005

1 - 17

Page 24

1. General

1 - 18

Planning and Installation - Rev. 3 / 04.2005

Page 25

1. General

1

18

19

36

37

54

55

72

EQUAL

EQUAL

INPUT MODULE

RY 3603

EQUAL

EQUAL

EQUAL

EQUAL

EQUAL

EQUAL

90 EXTERNAL90 EXTERNAL SIGNALS

WHITE

PAR

BUFFER BUFFER BUFFER

SER

BUFFER

37 INTERNAL SIGNALS

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

WIPE PROCESSOR

RY 3025 / RY 3026

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

WIPE PROCESSOR

RY 3025 / RY 3026

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

ME 1

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

ME PP

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

PGM

PVW

CLEAN

PGM

PVW

CLEAN

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

AUX8

AUX9

AUX10

OUTPUT PROCESSOR

RY 3031

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

SER

PAR

SER

PAR

OUTPUT PROCESSOR

EXTENSION RY 3035

SER

PAR

SER

PAR

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

OUTPUTS A

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

AUX8

AUX9

AUX10

OUTPUT MODULE

RY 3604

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

PGM/23

PGM/24

PVW/21

CLEAN/22

PGM//27

PGM/28

PVW/25

CLEAN/26

1

5

6

10

73

90

EQUAL

EQUAL

INPUT MODULE

RY 3603

REMOTE

GPI IN

SERIAL IN

BLACK BURST

SER VID

AC IN

AC IN

CONTROL

MODULE

RY 3605

INPUT PROCESSOR RY 3641

POWER SUPPLY UNIT RC 3406

REDUNDANT

POWER SUPPLY UNIT RC 3406

CONTROLLER RY 3156

GENLOCK RY 3080

SERIALOUT

REMOTE

GPI OUT

TALLY

SPR

SPR

SPR

SPR

_

SRC 1

_

SRC 2

_

SRC 3

_

SRC 4

RAM RECORDER

RY 3050

OPTION

SPR_RET 1

_

RET 2

SPR

_

RET 3

SPR

_

RET 4

SPR

Planning and Installation - Rev. 3 / 04.2005

1 - 19

Page 26

1. General

1 - 20

Planning and Installation - Rev. 3 / 04.2005

Page 27

1. General

1

18

19

36

37

54

55

72

73

EQUAL

EQUAL

INPUT MODULE

RC 3610

Option

EQUAL

EQUAL

RC 3611

Option

EQUAL

EQUAL

RC 3612

Option

EQUAL

EQUAL

RC 3613

Option

EQUAL

90 EXTERNAL90 EXTERNAL SIGNALS

WHITE

COL 1

COL 2

PAR

PAR

PAR

SER

SER

SER

BUFFER BUFFER BUFFER

BUFFER

37 INTERNAL SIGNALS

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

KEY 1

KEY 2

KEY 3

KEY 4

KEY FILL 1

KEY FILL 2

KEY FILL 3

DVE

PST

BGD

WIPE PROCESSOR

RY 3025

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

WIPE PROCESSOR

RY 3025

KEY PROCESSOR

RY 3020

ME PROCESSOR

RY 3010

ME 1

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

ME PP

PGM

PVW

CLEAN

UTIL A

UTIL B

UTIL C

KEY

PGM

PVW

CLEAN

PGM

PVW

CLEAN

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

AUX8

AUX9

AUX10

OUTPUT PROCESSOR

RY 3031

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

LVDS

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

5 Channel

AUTO

PHASE

AUTO

PHASE

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

PAR

SER

OUTPUTS A

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

AUX8

AUX9

AUX10

OUTPUT MODULE

RY 3620

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

BUFFER

PGM/23

PGM/24

PVW/21

CLEAN/22

PGM//27

PGM/28

PVW/25

CLEAN/26

1

5

6

10

90

EQUAL

INPUT MODULE

RY 3614

REMOTE

GPI IN

SERIAL IN

BLACK BURST

SER VID

AC IN

AC IN

CONTROL

MODULE

RC 3630

Option

INPUT PROCESSOR RY 3442

POWER SUPPLY UNIT RC 3470

REDUNDANT

POWER SUPPLY UNIT RC 3470

GENLOCK + CONTROLLER

RY 3490

SERIALOUT

REMOTE

GPI OUT

TALLY

SPR

SPR

SPR

SPR

_

SRC 1

_

SRC 2

_

SRC 3

_

SRC 4

RAMREC RY 3050

Option

OR

FX RY 3060

Option

SPR_RET 1

_

SPR

RET 2

_

SPR

RET 3

_

RET 4

SPR

Planning and Installation - Rev. 3 / 04.2005

1 - 21

Page 28

1. General

1 - 22

Planning and Installation - Rev. 3 / 04.2005

Page 29

2. TECHNICAL DATA

2.1 MAINFRAME

2.1.1 INPUTS

Number & format Up to 90 inputs

2. Technical Data

10 bit, Serial component

according to SMPTE 292M (DSC), 1.5Gbit/s

Autophasing range: >

Asynchronous signals: switchable

Reference: tri- level Sync or DSC in (SMPTE 292M)

Return loss reference up to 1.5GHz >

Cable lengh max 80 m (high quality coax cable Belton 1694A)

2.1.2 OUTPUTS

Number & format 10 bit, Serial component

2.1.3 VIDEO SYSTEM DATA

HD standards 1080x50i

0.5 line dependent on standard

-10dB

according to SMPTE 292M (DSC), 1.5Gbit/s

up to 20 Aux Busses

Per M/E:

2x Program Video,

1x Preview, and

1x Clean Feed

1080x59.94i

1080x60i

1080x23fs

1080x24fs

1080x25fs

1080x29fs

1080x30fs

1080x23p

1080x24p

1080x25p

1080x29p

1080x30p

720x50p in preparation

720x59.94p

720x60p,

Planning and Installation - Rev. 3 / 04.2005

2 - 1

Page 30

2. Technical Data

Aspect ratio: 16:9

Overall Input/

PGM output delay: < 0.5 line dependent on standard

Blanking: switchable:

2.1.4 POWER SUPPLY MAINFRAME

Line voltage: 200 V to 240 V AC $10 % (SH- 1/2/3/4- BM)

Line current: 13 A max

Line frequency: 50 Hz / 60 Hz $5 %

Power Consumption: max. 1200W (SH -1/2/3/4 -BM)

Touch (leakage) currents: < 2.5 mA (for each power supply)

transparent for background signal or blanked

100 V to 240 V AC $10 % (SH-1/2S- BM)

max. 700 W (SH- 1/2S- BM)

2.1.5 MECHANICAL DATA SH- 1/2/3/4 - BM STANDARD MAINFRAME

)

Dimensions: 19” rackframe, 12 + 1

*

RU high

Hight 533 mm (20.98”)

Width 483 mm (19”)

Depht 554 mm (21.8”)

)

*

1 RU under the electronics box has to be

left free for ventilation, security tube

and slide-in rails

Weight: < 154 lbs / 70 kg.

2.1.6 MECHANICAL DATA SH- 1/2S- BM SMALL MAINFRAME

Dimensions: 19” rackframe, 7 RU high

Hight 310 mm (12.2”)

Width 483 mm (19”)

Depht 508 mm (20”)

Weight: < 77 lbs / 35 kg (incl. all options)

2.1.7 ENVIRONMENTAL DATA

Storage temperature: -4°F to +158°F

Operating Temperature: +41

Relative humidity: <= 80% non- condensing

2 - 2

(-20°C to +70°C)

°

F to +95°F

°

C to +35°C)

(+5

Planning and Installation - Rev. 3 / 04.2005

Page 31

2.1.8 INTERFACE DATA

• 8+6 intern GPI, 8+6 intern GPO

• 9 Serial ports (Mainframe) D-Sub sockets 9-pin, female, RS 485/422,

• 1 RS485/RS422-Serial Extension, D-Sub socket 9-pin, female

• 5 Serial ports (Mainframe)

2. Technical Data

GPI: Opto coupler, dry contact or active in, (8 Mainframe, 6 Panel) max. 40mA.

GPO: Silicon switches, potential free, 40V/0.3A.

D-Sub socket 50-pin, female (panel 25-pin, female) 40 V, 0.5 A

38.4 kbd max.

Tributary-Bus Controller mode switchable, for DVE, Edit Systems, ext DSK,

port for serial Tally & more optional Tallies: CH1 (r), CH2 (g), Preset (y),

GP I/Os- support of up to 68 ext. Tally Outputs

- support of up to 21 ext. Tally inputs

- further 40 GPI/GPO channels

2x D-Sub sockets 9-pin, female, RS 232C, 38.4 kbd max,

1x D-Sub socket 15-pin, female (Multi Port) with 3x RS 232C

• 3 Service ports, D-Sub sockets 9-pin, female, RS 232C

(2x Mainframe, 1x Panel)

• 2 Modem ports, D-Sub sockets 25-pin, female, RS 232C

(1x Mainframe, 1x Panel)

• LAN (mainframe), 1 BNC (remote), cheapernet,

50 ohms, 150 m, with repeater max. 2.5 km,

can be looped through with a T-type connector

• LAN (control panel), 1 BNC, cheapernet,

50 ohms, 150 m, with repeater max. 2.5 km,

can be looped through with a T-type connector

• LAN (panel PC), 1 BNC , cheapernet,

50 ohms, 150 m, with repeater max. 2.5 km,

can be looped through with a T-type connector

• 4 Serial ports (Control Panel), D-sub sockets 9-pin, female, RS485/422C

for UMDs or Aux extensions

• 2 Serial ports (Control Panel), 2x D-sub sockets 9-pin, female,

RS232C, 38.4 kbd

• PC Communication Ports (several) VGA Port, LCD, PS/2, RS 232C

Planning and Installation - Rev. 3 / 04.2005

2 - 3

Page 32

2. Technical Data

2.2 CONTROL PANELS

2.2.1 INTEGRATED SIDE PANEL PC

• Industry PC board

• RPV-Panel connectors:

RPS35-4 connected via RS232 Port and TFT connector

RPS35-2 / RPS35-3 connected via Panel Link port

• Serial Ports RS232:

RPS35-4 with 2x RS232 serial communication ports for RPV

and peripheral devices

RPS35-2 and RPS35-3 with 1x RS232 serial communication ports

for peripheral devices

• 1 PC-Keyboard Connector PS/2- type

• 1 Parallel Port (for Printer)

• 10.4” Color active matrix TFT LCD Display

• PC-Board communication via LAN- Adapter

• Built-in floppy drive & hard disk

• Suited for adaption of peripheral devices

(Tablet, Mouse, Pen, TouchScreen)

• VGA port D-Sub socket 15-pin, male

2.2.2 POWER SUPPLY CONTROL PANELS

• 1 power modules LPQ 250 standard

• 1 redundant power module LPQ 250 optional

• Line voltage 100 V to 240 V AC $10 %, autosense

• Line current 2.5 A max

• Line frequency 50 Hz to 60 Hz

• Active power factor connection PFC

• Output voltages +5 V, + 12 V, - 12 V

• Power connection connector type IEC 320, VDE 0625 Part 1

• Safety UL 1950 /CSA 22.2 No. 950

• Power consumption control panels < 250 W

2 - 4

Planning and Installation - Rev. 3 / 04.2005

Page 33

3. INSTALLING MAINFRAME

3.1 UNPACKING

Your equipment may be shipped in several different boxes, depending upon order

size and configuration.

Check the contents of each box against the packing list to ensure your order is complete. If equipment is missing or damaged, contact the shipping company immediately.

3. Installing Mainframes

Box 1 - Mainframe

Box 1 contents the following parts:

D Mainframe (equipped with ordered option boards)

D Power cord (standard)

D Power cord (redundant power supply, if ordered)

D Accessory pack 002 212 240 011:

BNC T-type connector, 50 ohms

BNC terminator, 50 ohms

BNC terminator, 50 ohms, with ground connector

BNC terminator, 75 ohms

10 Fuses M 10/250E

10 Fuses UL T 0.8/250B

Mounting set

Earth wire

Planning and Installation - Rev. 3 / 04.2005

3 - 1

Page 34

3. Installing Mainframes

3.2 MECHANICAL DIMENSIONS

3.2.1 MAINFRAME SH - 1/2/3/4 - BM

The mainframe of the switcher is located in a closed 19-inch frame which houses

the individual plug-in cards of the video and control electronics as well as the power

supply units.

17.3” = 440 mm

12 RU

533 mm

19” = 483 mm

1RU

43 mm

18.6” = 474 mm

21.8” = 554 mm

3 - 2

Planning and Installation - Rev. 3 / 04.2005

Page 35

3.2.2 SMALL MAINFRAME SH -1/2S -BM

The mainframe of the switcher is located in a closed 19-inch frame which houses

the individual plug-in cards of the video and control electronics as well as the power

supply units.

3. Installing Mainframes

17.6” = 447 mm

7RU

12.2”

310.3 mm

19” = 483 mm

20” = 508 mm

21,3” = 540 mm

(incl. connectors)

Planning and Installation - Rev. 3 / 04.2005

3 - 3

Page 36

3. Installing Mainframes

3.3 INSTALLATION IN A CABINET

General rack mounting instructions

D The maximum ambient temperature for this unit is 40°C.

D Installing the unit in a closed or multi-unit rack assembly, together with other

units could increase the maximum ambient for this unit.

D If the unit is installed in a rack, no ventilation openings should be blocked or

otherwise covered. Ensure a sufficient amount of airflow.

D Mounting of the unit in the rack should be such that a hazardous condition is

not achieved due to uneven mechanical loading.

D When connecting the unit to the supply circuit be sure that the supply circuit of

the rack is not overloaded. For ratings see chapter Technical Data.

D The unit must be grounded to a good earth ground using a wire as specified

by the local electrical code. This wire is attached to the protective earth connector on the rear. For details refer to chapter General Grounding Requirements.

D When connecting the unit in a closed or multi-unit rack assembly together with

other units be sure that the summation of the touch (leakage) currents for each

power supply circuit is not higher than 3.5 mA . In this case the rack must be

permanently connected with an earth terminal. Earth connection is essential

before connecting supply voltage! For details see chapter Technical Data.

For installation, Thomson optionally provides a 19-inch cabinet with recommended

mounting accessories. When using cabinets of other manufacturers, observe the

respective mounting instructions.

Note: For installation into a DIN cabinet, adapter pieces of the respec-

tive cabinet manufacturer have to be mounted on both sides of

the lateral fastening flanges.

For relieving the front mounting brackets, the mainframe has also to be supported

in the rear part of the frame. The corresponding mounting parts can be obtained

as accessories from the manufacturer of the cabinet-type rack.

CAUTION

Do not use the rack ears as primary mounting means.

WARNING

3 - 4

With the standard modules installed, the SH - 1/2/3/4 -BM mainframe weights

70 kg (154 lbs). During installation and until secured in the rack, use an appropriate lifting device to lift and support the mainframe. Failure to follow

this precaution can result in injury to personnel and damage to equipment.

Planning and Installation - Rev. 3 / 04.2005

Page 37

3.4 VENTILATION

3.4.1 MAINFRAME SH -1/2/3/4 -BM

The ambient temperature during operation must not fall below + 5 °C or exceed

+ 35 °C (41 °F to 95°F). Optimum operation is ensured at an ambient temperature

of 20 °C.

For ventilation of the mainframe, 3 fans are provided in the upper part. These blowers serve to support air circulation in the unit and to lead the heated air into the

room. The air supply is made from the front and from the bottom. Fans blow the

heated air into the rear part of the cabinet.

In order to ensure continuous air circulation, make sure that the air slots in

the bottom part of the unit are not covered when mounting the mainframe.

3. Installing Mainframes

Exhaust air exits from the rear at top

Note: The door is an integral part of the cooling airflow design.

For proper cooling keep the door closed during normal

operation.

Cleaning the

Air filter

Planning and Installation - Rev. 3 / 04.2005

Ensure that the air filter fitted to the SH- 1/2/3/4- BM mainframe front door is cleaned periodically with a vacuum cleaner to ensure the adequate cooling. The color

of the filter (normally white) can be used as a guide to their condition.

Air intake (both sides and front)

3 - 5

Page 38

3. Installing Mainframes

3.4.2 SMALL MAINFRAME SH-1/2S BM

The ambient temperature during operation must not fall below + 5 °C or exceed

+ 40 °C (41 °F to 104°F). Optimum operation is ensured at an ambient temperature

of 20 °C.

The mainframe is ventilated by the fan unit (8 fans) being mounted at the left side

in the mainframe. The air is sucked in at the left side of the mainframe and is exhausted at the right side through the louvers. These fans serve to support air circulation in the unit and to lead the heated air into the room. The power supplies in

the lower part of the carrier are cooled by two internal fans. The air is sucked in at

the front and is let out through the louvers at the rear.

In order to ensure continuous air circulation, make sure that the air slots on

the left and right side and on the rear side of the unit are not covered when

mounting the mainframe.

Air intake

from the left side

Note: The door is an integral part of the cooling airflow design.

Exhaust air exits from

the right of the unit

For proper cooling keep the door closed during normal

operation.

3 - 6

Planning and Installation - Rev. 3 / 04.2005

Page 39

4. INSTALLING THE CONTROL PANELS

4.1 UNPACKING

Your equipment may be shipped in several different boxes, depending upon order

size and configuration.

Check the contents of each box against the packing list to ensure your order is

complete. If equipment is missing or damaged, contact the shipping company immediately.

4. Installing Control Panels

Box 2 - Control panel

Box 2 contents the following parts:

D Basic control panel

D Aux control panel module

D Display panel module

D Wipe control panel

D Power cord (standard)

D Power cord (redundant power supply, if ordered)

D 7 control cable 1.2 m or 2.5 m (if ordered)

D Cheapernet cable 20 m

D Cheapernet cable 1 m

D Customer’s manual

D Final test report with Quality certification

Planning and Installation - Rev. 3 / 04.2005

4 - 1

Page 40

4. Installing Control Panels

D Software package:

Mouse

CD-ROM HD35 software

CD-ROM Intel PII Bus Master Device Drivers

CD-ROMs Microsoft Windows 95 package

3.5” Diskette Microsoft Setup Boot Disk

3.5” Diskette Philips Ethernet Link Driver

3.5” Diskettes Philips WGE10 Utilities (2 disks)

Motherboard documentation

D Accessory pack 002 351 740 051:

Locking tool for sub-panels

Panel keys

BNC T-type connector, 50 ohms

BNC terminator, 50 ohms

Pushbutton inlay sets

2 Fuses ATC-7 1/2

2 Fuses ATC-5

12 caps for sub-panels locking holes

Box 3 - All-in-one mounting frame (optional)

Box 3 contents the following parts:

D All-in-one mounting frame

D Fastening screws

4.2 MECHANICAL DIMENSIONS

The figures on the next pages shows all mechanical dimensions of the control panels which are relevant for installation in a master control desk.

The size of the desk cutout is also indicated.

4 - 2

Planning and Installation - Rev. 3 / 04.2005

Page 41

4.2.1 RPS35-2/S CONTROL PANEL

FRONT

4. Installing Control Panels

1084

13

314.5

1

1058

43.3

1

13

LEFT

o

25

89

51.5

Keep free for cabling!

5

13

20

Please keep free for service working!

10

o

o

90

1 1

434

460

75

o

7

51.5

160

13

TOP

1080

1084

2112

ISO

460

456

11

Note!

All measurements are [mm].

Tolerance +/- 0,2

Planning and Installation - Rev. 3 / 04.2005

4 - 3

Page 42

4. Installing Control Panels

TOUCHSCREEN DISPLAY OF THE RPS35-2S PANEL

65 60

21.6328.08

M4

298.5

278.5

288

294

311.5

314.5

1.5

10.6139.35

152.87

81

0.8

9.8

160.58

44.5

1.3

4 - 4

Attention!

When separating the display from the control panel,

D the EMV protection is not ensured any longer (radiation is also possible via the cables)

D the ESD protection is not ensured any longer (damage to electronic components is possible)

D the UL and other permissions are not applicable any longer

D warrenty is not ensured any longer

Note!

All measurements are [mm].

Planning and Installation - Rev. 3 / 04.2005

Page 43

4.2.2 RPS35-2 CONTROL PANEL

Mechanical dimensions see next page.

4. Installing Control Panels

LEFTFRONT

51.5

o

105

160

TOP

1364

460

Keep free for cabling!

o

15

11

434

Note:

There are two possibilities of mounting Display Module RPV35-2.

3. Mounting the display module with the mounting frame outside the switcher

into the control desk or wall. See section 4.3.1 Single Module Mounting.

4. Stand-alone display with rigid stand.

The stand has to be mounted on the control panel in the place provided for this

purpose, between Aux and Wipe panel.

For mounting the stand, see the mounting drawing on the next page.

The associated mounting material will be delivered with the stand-alone display.

ISO

Planning and Installation - Rev. 3 / 04.2005

1386

1390

2

11

2

11

Note

All measurements are [mm].

Tolerance +/- 0,2

4 - 5

Page 44

4. Installing Control Panels

49

RPV35-2 Stand-Alone Display Panel

261

mounting plate

89.04

20.4

4 max

15.23

6.5

30

265

20

o

4 - 6

9

0

15

25

385

164.25

30

3

2

389

100

70

50

M5

75

85

100

Planning and Installation - Rev. 3 / 04.2005

Page 45

4.2.3 RPS35-3/24 CONTROL PANEL

4. Installing Control Panels

o

FRONT

TOP

1390

1364

3.5

238.2

141

o

100

LEFT

390724

3.5

270

258.4

max. 273

Keep free for cabling!

202.1

184.6

184

163.3

124

106

434

11

51.5

o

105

160

o

15

1386

1390

187.4

ISO

649

460

2

11

2

11

Note

All measurements are [mm].

Tolerance +/- 0,2

Planning and Installation - Rev. 3 / 04.2005

4 - 7

Page 46

4. Installing Control Panels

4.2.4 RPS35-3/32 CONTROL PANEL

192.5

FRONT

TOP

1602

1576

3.5

LEFT

649,5

390935

3.5

270

259

141

160

Option - Fanless Power Supply

189,55

Option - Mounting Frame

159,5 7,3

13

558

13

434

1598

1602

187.4

649

460

2

11

2

11

ISO

Note

All measurements are [mm].

Tolerance +/- 0.2

4 - 8

Planning and Installation - Rev. 3 / 04.2005

Page 47

4.2.5 RPS35-4/32 CONTROL PANEL

4. Installing Control Panels

o

192.5

FRONT

TOP

1602

1576

3.5

238.2

o

192.5

100

LEFT

390935

3.5

270

141

258.4

max. 273

Keep free for cabling!

202.1

184.6

184

163.3

124

106

570

11

51.5

o

105

196

o

15

1598

1602

187.4

ISO

785

596

2

11

2

11

Note

All measurements are [mm].

Tolerance +/- 0.2

Planning and Installation - Rev. 3 / 04.2005

4 - 9

Page 48

4. Installing Control Panels

4.2.6 DESK CUT OUT FOR RPS35-2/S

12

12

legend

Cut-out

module edge

1060

0

-1

Cut- out measurements

Note

All measurements are [mm].

12

12

0

-1

436

4 - 10

Planning and Installation - Rev. 3 / 04.2005

Page 49

4.2.7 DESK CUT OUT FOR RPS35-2

4. Installing Control Panels

12

legend

Cut-out

module edge

0

1366

-1

1390

Cut- out measurements

Note

All measurements are [mm].

12

0

-1

436

460

Planning and Installation - Rev. 3 / 04.2005

4 - 11

Page 50

4. Installing Control Panels

4.2.8 DESK CUT-OUTS FOR RPS35-3/24

143460

0

119

-1

436

701

725

-1

390

0

0

-1

23

22

17

270

246346

-1

0

0

-1

12

226

266

0

-1

649

625

4 - 12

12

12

legend

Cut-out

module edge

0

1366

-1

1390

Cut- out measurements for single module mounting

12

Cut- out measurements for panels with

”All-in-One” Mounting Frame RC 2360

Note

All measurements are [mm].

Planning and Installation - Rev. 3 / 04.2005

Page 51

4.2.9 DESK CUT-OUTS FOR RPS35-3/32

4. Installing Control Panels

195

460

0

0

171

436

-1

-1

911

935

-1

246

270

-1

0

0

-1

0

-1

119

226

143

266

0

-1

625

649

390

0

346

23

17

0

-1

22

12

12

legend

Planning and Installation - Rev. 3 / 04.2005

Cut-out

module edge

0

1578

-1

1602

Cut- out measurements for single module mounting

12

Cut- out measurements for panels with

”All-in-One” Mounting Frame RC 2840

Note

All measurements are [mm].

4 - 13

Page 52

4. Installing Control Panels

4.2.10 DESK CUT-OUTS FOR RPS35-4/32

195

596

0

0