Page 1

Communication

Transmission

Camera Power

Cable

Power

On Air

XCU WorldCam Triax

3922 496 32111 February 2018 v1.6

XCU

User’s Guide

eXchangeable Control Unit

Page 2

Declaration of Conformity

We, Grass Valley Nederland B.V., Bergschot 69, 4817 PA Breda, The Netherlands,

declare under our sole responsibility that these products are in compliance with the

following standards:

– EN60065 Safety

– EN55103-1:2009 EMC (Emission) for the following environments:

(E1) Residential;

(E2) Commercial and light industrial;

(E3) Urban outdoors;

(E4) Controlled EMC environment, and the rural outdoors environment.

– The average half-cycle r.m.s. inrush currents for this product are:

- 16 A (on intial switch-on);

- 11 A (after a supply interruption of 5 s).

– EN55103-2 EMC (Immunity)

following the provisions of:

– the EMC Directive 2004/108/EC

the Low Voltage Directive 2006/95/EC

FCC CLASS A Statement

This product generates, uses, and can radiate radio frequency energy and if not installed and

used in accordance with the instructions, may cause interference to radio communications.

It has been tested and found to comply with the limits for a CLASS A digital device pursuant to

part 15 of the FCC rules, which are designed to provide reasonable protection against such

interference when operated in a commercial environment.

Operation of this product in a residential area is likely to cause interference in which case the

user at his own expense will be required to take whatever measures may be required to

correct the interference.

Copyright

Copyright Grass Valley Canada 2014-2018. Copying of this document and giving it to others,

and the use or communication of the contents thereof, are forbidden without express

authority. Offenders are liable to the payment of damages. All rights are reserved in the event

of the grant of a patent or the registration of a utility model or design. Liable to technical

alterations in the course of further development.

Website

Visit the Grass Valley public website to download the latest user’s guide updates and additional

information about your broadcast product:

www.grassvalley.com

Page 3

XCU eXchangeable Control Unit User’s Guide (v1.6) 3

Table of contents

Chapter 1 – Introduction

1.1 Welcome. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.1.1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1.2 Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.2 Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1.2.1 Unique Cradle concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

1.2.2 3G Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

1.2.3 XCU models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.4 Camera control and monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3 Main features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2 – Installation

2.1 Rack installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.1 Installing rack mounting rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.1.2 Installing the cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.3 Transporting rack mounted XCUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.4 Connecting studio cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Mounting the XCU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3 Setting up the control network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Setting up intercom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4.1 Two-wire systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4.2 Four-wire systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.5 Setting up studio signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5.1 Dry contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.5.2 Dry contact with multiple XCUs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5.3 Common ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.5.4 Voltage level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5.5 Open circuit/Voltage level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2.6 Setting up external audio level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.7 Using private data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 3 – Setup

3.1 Front navigation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.2 Setting the camera number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.3 Accessing the menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.3.1 Using the XCU front navigation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.2 Using the OCP 400 operation control panel . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.4 Navigating the menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.1 Entering the menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.4.2 Finding your way . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4.3 Leaving the menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.4.4 Making changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4.5 User levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Page 4

4 XCU eXchangeable Control Unit User’s Guide (v1.6)

3.5 Intercom setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.5.1 Studio interface setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.6 Color bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.7 Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Chapter 4 – Operation

4.1 Front panel indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2 Transmission diagnostics on the OCP 400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.3 Replacement of fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Chapter 5 – XCU menu reference

5.1 Video menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5.2 Monitoring menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3 Audio/Intercom menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4 Install menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.5 Security menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.6 Licenses menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5.7 Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

5.8 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Chapter 6 – Connectors and signals

6.1 XCU back panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.1.1 Mains power connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.1.2 Triax connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.1.3 Hybrid fiber connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.2 Cradle back panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.2.1 Main video connector panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.2.2 External video input connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.2.3 Main (HD Video) output connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.2.4 SDI Out video connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.2.5 Monitoring connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2.6 Teleprompter connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2.7 Reference connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.2.8 Signalling connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.9 Intercom connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.10 Auxiliary (AUX) connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

6.2.11 C2IP connector (top) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

6.2.12 Ethernet connector (bottom) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2.13 Digital Audio OUT 1+2 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2.14 Digital Audio OUT 3+4 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2.15 Analog Audio OUT 1 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

6.2.16 Analog Audio OUT 2 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Chapter 7 – Specifications

7.1 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.2 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Page 5

XCU eXchangeable Control Unit User’s Guide (v1.6) 5

Recycling

Visit www.grassvalley.com for recycling information.

Packing for return

If a unit is being returned to Grass Valley for servicing, try to use the containers and materials

of the original packaging. Attach a tag indicating the type of service required, return address,

model number, full serial number and the return number which will be supplied by your Grass

Valley service centre.

If the original packing is not available or can no longer be used contact your regional Grass

Valley service representative to have a return package provided.

Page 6

6 XCU eXchangeable Control Unit User’s Guide (v1.6)

Important information

Read these instructions carefully and retain them for future reference.

During installation and operation of this equipment, local building safety and fire protection

standards must be observed.

Whenever it is likely that safe operation is impaired, the apparatus must be made inoperative

and secured against any unintended operation. The appropriate servicing authority must then

be informed. For example, safety is likely to be impaired if the apparatus fails to perform the

intended function or shows visible damage.

Any changes or modifications not expressly approved in this manual could void your authority

to operate this equipment.

Cautions and Warnings

Read and comply with the warning and caution notices that appear in the manual.

– Warnings indicate danger that requires correct procedures or practices to prevent

death or injury to personnel.

– Cautions indicate procedures or practices that should be followed to prevent damage

or destruction to equipment or property.

Warnings

To prevent fire or shock hazard, do not expose the unit to rain or moisture.

To avoid electrical shock, do not remove covers or panels. Refer servicing to qualified

personnel only.

In case of an emergency ensure that power is disconnected.

Use only fuses of the type and rating specified.

Connect the unit only to a power source with the specified voltage rating.

To prevent risk of overheating, ventilate the unit correctly.

For safety reasons the unit must be mounted in a 19-inch rack which has safety covers

according to IEC65.

Page 7

XCU eXchangeable Control Unit User’s Guide (v1.6) 7

Fiber-optic transmission units

Laser safety statement (Europe)

Fiber-optic transmission units are classified as a “CLASS 1 Laser Product” according to

EN

60825-1, Safety of Laser products. Class 1 laser products are considered safe and do not

result in biological hazard if used according to the instructions.

Laser safety statement (US)

Fiber-optic transmission units are classified as a “CLASS 1 Laser Product” according to

21CFR

1040.10 of the US Food and Drug Administration (FDA) Center for Devices and

Radiological Health.

Use of controls, adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

To ensure proper use of this product, please read this instruction manual carefully and retain

for future reference. Should the unit ever require maintenance, contact an authorized service

location.

Fiber-optic cable precautions

Fiber-optic cables and connectors are easily damaged; take the following percautions into

account:

– Do not bend the cable beyond the minimum permissible bend range specified for the

cable.

– Avoid kinks in the cable.

– Avoid subjecting the cable to a high tension force (even momentarily).

– Do not twist the cable when connecting it to equipment.

– Insert connectors straight and fully into their corresponding sockets.

– In fiber-optic cable systems always put the dust caps on cable and panel connectors

immediately after disconnecting a cable. Keep the dust caps clean.

Page 8

8 XCU eXchangeable Control Unit User’s Guide (v1.6)

Cleaning fiber-optic connectors

WARNING

Never clean an optical connector attached to a fiber that is carrying light.

Particles of foreign matter on the tip of a ferrule can have a disabling effect on fiber-optic

transmission. Fiber-optic connectors need to be cleaned every time they are mated and

unmated; it is essential that fiber-optic users develop the necessary discipline to always clean

the connectors before they are mated.

Use a commerially available cleaning kit specifically designed for fiber-optic connectors and

follow the manufacturer's instructions carefully.

• The connector sections to be cleaned include the tips and sides of ferrules, the interior

walls of alignment sleeves, and the interior and exterior of connector shells.

• For plugs, the interior surfaces of alignment sleeves and the tips of ferrules are to be

cleaned with a cleaning stick treated with the appropriate fluid. (Cleaning sticks with a

slender design are available that allow alignment sleeves to be cleaned without having to

detach them.)

• For jacks, it is important to clean both the tips and sides of the completely protruding

ferrules.

• Both the male and female connector shells tend to attract dust and metal particles, so it is

important to clean both the insides and outsides.

• The fiber end face and ferrule must be absolutely clean before it is inserted into a

transmitter or receiver.

• Mate the connector immediately! Do not let the connector lie around and collect dust

before mating.

• Air can be used to remove lint or loose dust from the port of a transmitter or receiver to be

mated with the connector. Never insert any liquid into the ports.

Page 9

XCU eXchangeable Control Unit User’s Guide (v1.6) 9

Mains lead wiring for UK users

The wires in the mains lead are colored in accordance with the following code:

GREEN and YELLOW- EARTH

BLUE- NEUTRAL

BROWN- LIVE

As the colors of the wires in the mains lead of this apparatus may not correspond with the

colored markings identifying the terminals in your plug proceed as follows:

• The wire colored GREEN AND YELLOW must be connected to the terminal on the plug

marked with the letter E or by the safety earth symbol

or colored GREEN or GREEN

AND YELLOW.

• The wire colored BROWN must be connected to the terminal marked with the letter L or

colored RED.

• The wire colored BLUE must be connected to the terminal marked with the letter N or

colored BLACK.

Ensure that your equipment is connected correctly - if you are in any doubt consult a qualified

electrician.

Page 10

10 XCU eXchangeable Control Unit User’s Guide (v1.6)

Page 11

XCU eXchangeable Control Unit User’s Guide (v1.6) 11

Chapter 1 - Introduction

Chapter 1

Introduction

1.1 Welcome

Grass Valley’s XCU (eXchangeable Control Unit) is a heavy duty, multi-standard transmission

and power system designed for Grass Valley studio cameras.

1.1.1 About this manual

The purpose of this manual is to present a detailed description of how to install and operate

the XCU . It provides the information necessary to install, set up and operate the unit in

different configurations.

1.1.2 Related documents

Before proceeding, check the Grass valley website at www.grassvalley.com for the latest

version of this user’s guide and additional information:

• Online versions of documentation; updated versions of user’s guides, data sheets,

brochures, application notes in pdf-format are available for download.

• Software downloads; camera software updates, release notes and installation instructions

are available for download.

Page 12

12 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 1 - Introduction

1.2 Technology

1.2.1 Unique Cradle concept

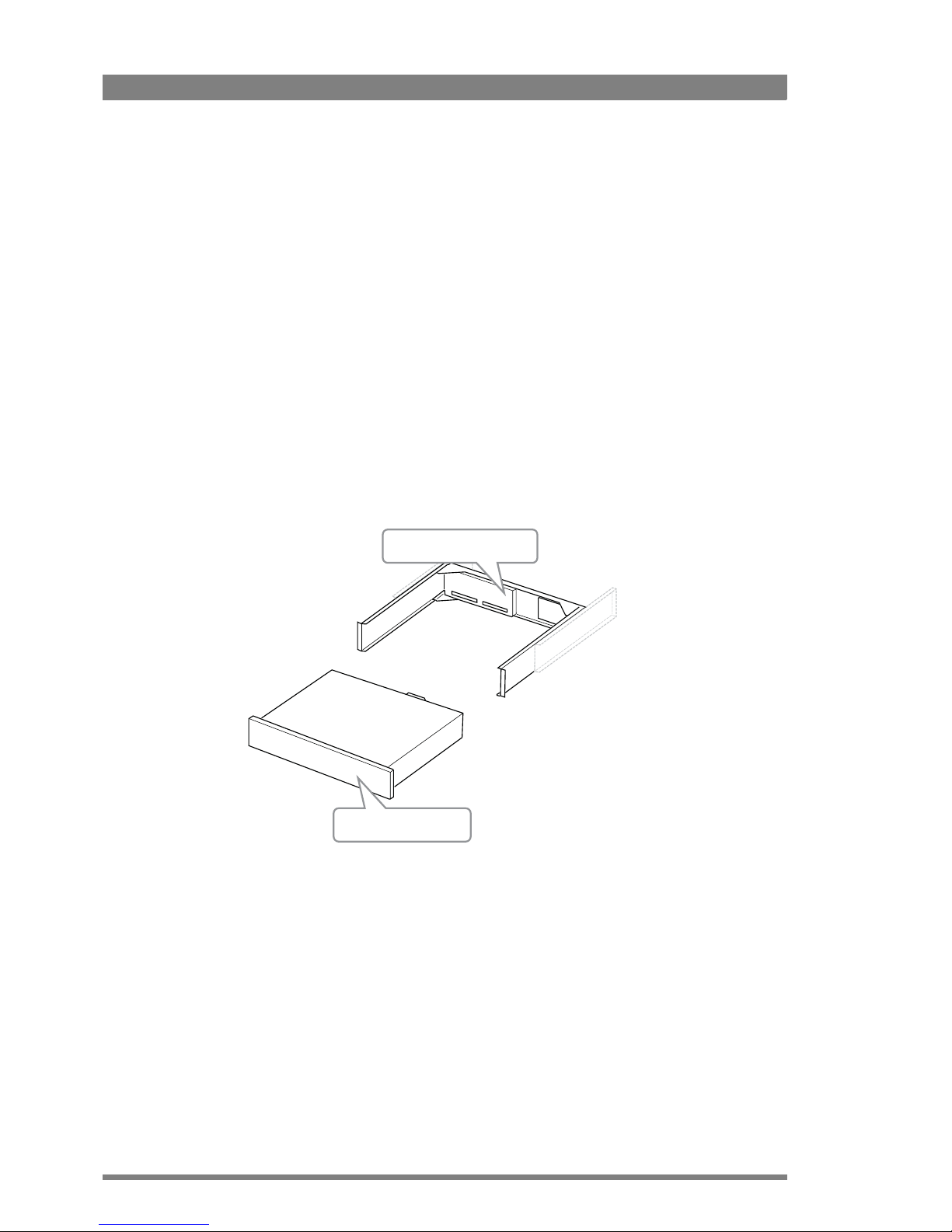

The eXchangeable Control Unit system is like no other in the world. Its unique cradle can be

pre-mounted and pre-wired in a 19-inch rack, making a secure mechanical and electrical

connection, permitting the XCU box to easily slide in and out whenever needed. Each XCU

comes with one cradle, but additional cradles may be acquired to extend usability across

different environments, allowing you to quickly and easily transfer XCUs between OB vans,

studios, or anyplace.

The cradle concept allows for moving boxes easily and quickly between locations such as

trucks and studios. Pre-mounted and pre-wired to eliminate cabling errors, the unique cradle

provides on-demand resources for fast paced productions, resulting in less set up time and

more on-air time. Compatibility with the LDX Series and many LDK Series cameras extends

the cradle's usefulness across all types of productions.

Triax and/or Fiber connectors can easily be exchanged during production and in the field. All

other connectors are mounted on a separate connector panel in the cradle. After disconnecting

mains power and the Triax/Fiber transmission the box can be removed.

Page 13

XCU eXchangeable Control Unit User’s Guide (v1.6) 13

Chapter 1 - Introduction

1.2.2 3G Transmission

Grass Valley’s latest XCU is based on full digital transmission and a proven and robust power

system. The 3G transmission system consists of a dockable camera adapter that fits on Grass

Valley HD camera heads and an XCU that takes care of power, signal transport and conversion

and connection to the studio or OB van.

A wide range of 3G transmission versions is available, so there is always an option that suits

your operational situation best.

XCU 3G Triax

The XCU 3G Triax makes camera transmission fully compatible with industry standard Triax

cables. This allows the use of existing, reliable and valuable cable inventories and at the same

time increases already long cable runs with up to 25% greater distances.

3G Triax offers video transmission and remote control of cameras up to a distance of 1,500 m

(5,000 ft) and beyond, using standard 14 mm (0.55 in.) Triax cables.

XCU 3G Fiber

The XCU 3G Fiber is equipped with a hybrid fiber connector.

3G Fiber offers video transmission and remote control of cameras up to a distance of 3,000 m

(10,000 ft) and beyond, using hybrid fiber cables.

XCU 3G Dual

The XCU 3G Dual combines a Triax connector with a hybrid fiber connector.

XCU 3G Twin

The XCU 3G Twin combines a Triax connector with two dark fiber connectors.

1.2.3 XCU models

There are two XCU models available:

Elite

This model supports 720p/1080i/1080PsF video modes and offers 8x 1.5 Gbit/s HD-SDI video

outputs.

Connect the following cameras:

• LDX Series (720p, 1080i and 1080psf video modes only) and LDX 86 HS/XS (single speed

only)

• LDK 8000, LDK 8000 Elite and LDK 8300 (single speed only)

WorldCam

This model supports 720p/1080i/1080p/1080PsF video modes and offers 6x 3 Gbit/s, 2x

1.5 Gbit/s or 8x 1.5 Gbit/s HD-SDI video outputs.

Connect the following cameras:

• LDX Series (all video modes) and LDX 86 HS/XS (single speed only)

• LDK 8000, LDK 8000 Elite and LDK 8300 (single speed only)

Page 14

14 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 1 - Introduction

1.2.4 Camera control and monitoring

You can access the XCU menu, which contains all operational settings, from an Operational

Control Panel. In addition to the operational menu, the installation and service menus can be

accessed directly from the XCU. The XCU is compatible with all existing control system

components.

An OCP 400 operational control panel can be connected directly to the XCU using a cross-over

Ethernet cable. Full camera control is provided via a C2IP Ethernet-based control network.

The communication facilities provide for two-wire or four-wire high quality intercom signals.

Transmission quality can be continuously monitored before and during operation from the

OCP

400 operational control panel and/or the Connect Gateway.

Page 15

XCU eXchangeable Control Unit User’s Guide (v1.6) 15

Chapter 1 - Introduction

1.3 Main features

• Flexible and multiple audio and video connectivity.

• Unique cradle mounting concept ensures maximum flexibility at a minimum set-up time.

• Many different video transmission systems are available.

• Reliable video transmission of many video formats:

– 1080p50 and 1080p59.94 (XCU WorldCam versions only)

– 1080i50 and 1080i/59.94

– 720p50 and 720p59.94

– and many psf HD video formats.

• Transports the following digital signals from camera to XCU: main video signal, four audio

channels (including embedded digital audio), two intercom channels, control and private

data.

• Transports the following digital signals from XCU to camera: power, three external HD

video inputs, teleprompter signal, three intercom channels, control and private data.

• Full camera control via Grass Valley’s C2IP Ethernet-based control network.

• Three channel (two-wire or four-wire) intercom system compatible with international

standards.

• Built in a compact 2U high, 19-inch rack housing.

• Teleprompter, color bar, HD-SDI outputs standard on board.

• The digital transmission backbone and power module meet the most demanding

broadcasting needs.

• Heavy-duty design with a new reliable power unit with low power consumption, ideal for

outside broadcast vans.

• HD and simultaneous high-quality SD outputs available.

Page 16

16 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 1 - Introduction

Page 17

XCU eXchangeable Control Unit User’s Guide (v1.6) 17

Chapter 2 - Installation

Chapter 2

Installation

2.1 Rack installation

2.1.1 Installing rack mounting rails

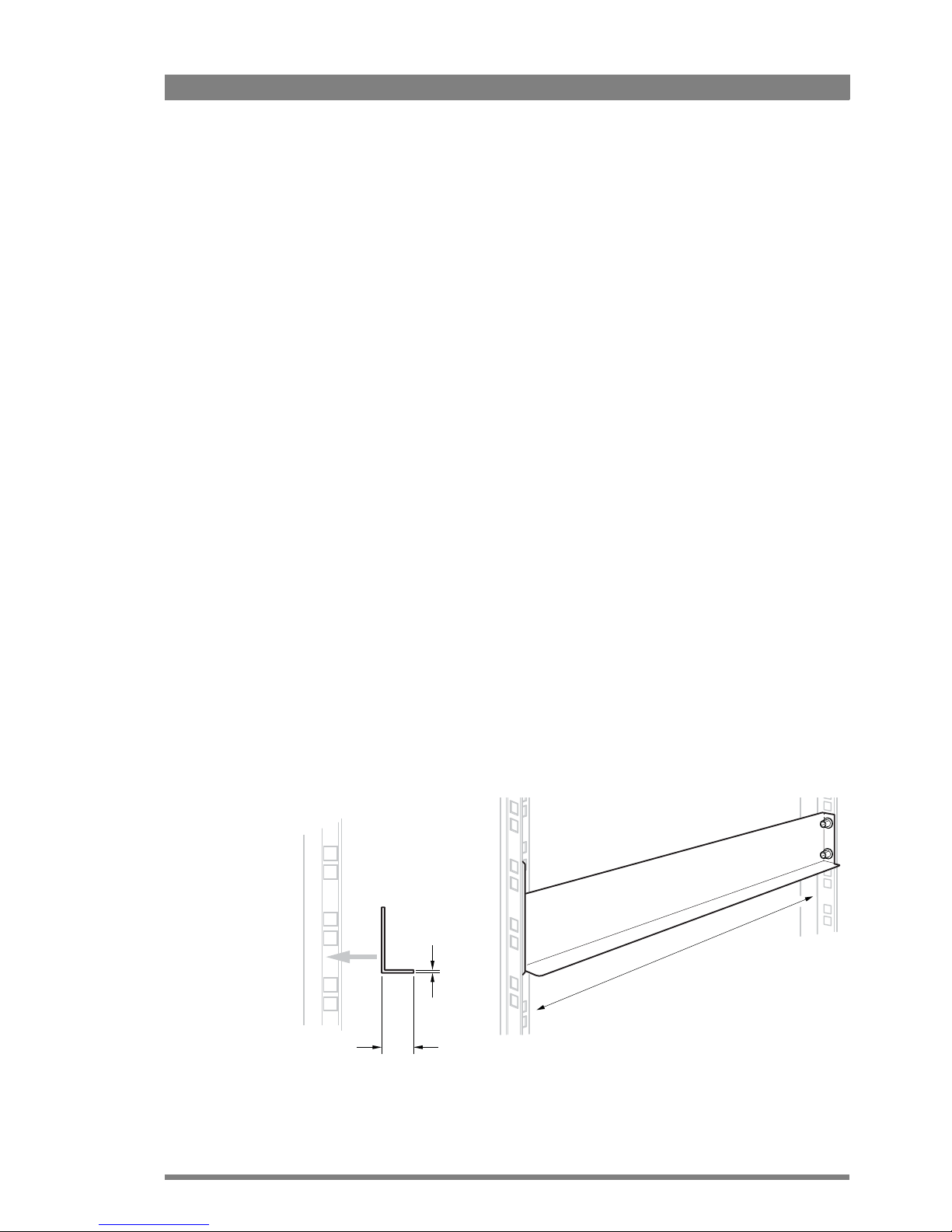

The XCU Cradle can be mounted in most standard 19-inch video or IT rack types. The unit

needs two rack units (2 RU) of vertical space in the rack.

Install two L-shaped rack mounting rails (not supplied) that match your rack type. Refer to the

documentation of your mounting rails or rack for installation instructions.

• Make sure that both front and back end of the rails are attached to the rack. Allow a

minimum distance of 30 cm (11.8 in.) between the secured points.

• There should be a blind/untapped area in the front of the vertical rack beam where the

locking mechanism of the XCU engages the rack.

• The thickness of the horizontal leg of the L-shaped mounting rails must not exceed 2 mm

(0.08

in.) in order to leave enough space for more cradles to be mounted below the unit.

Below is an example of a rack mounting rail installed in a 19-inch rack. Note that your specific

situation may be different.

min. 30 cm (11.8 in.)

min. 12 mm (0.5 in.)

max. 2 mm (0.08 in.)

Page 18

18 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 2 - Installation

2.1.2 Installing the cradle

After mounting the rack mounting rails, install the cradle:

1. Slide the cradle into the rack so it is supported by the L-shaped mounting rails.

2. Fix the cradle to the front rack posts using four M6-screws (not supplied with the unit).

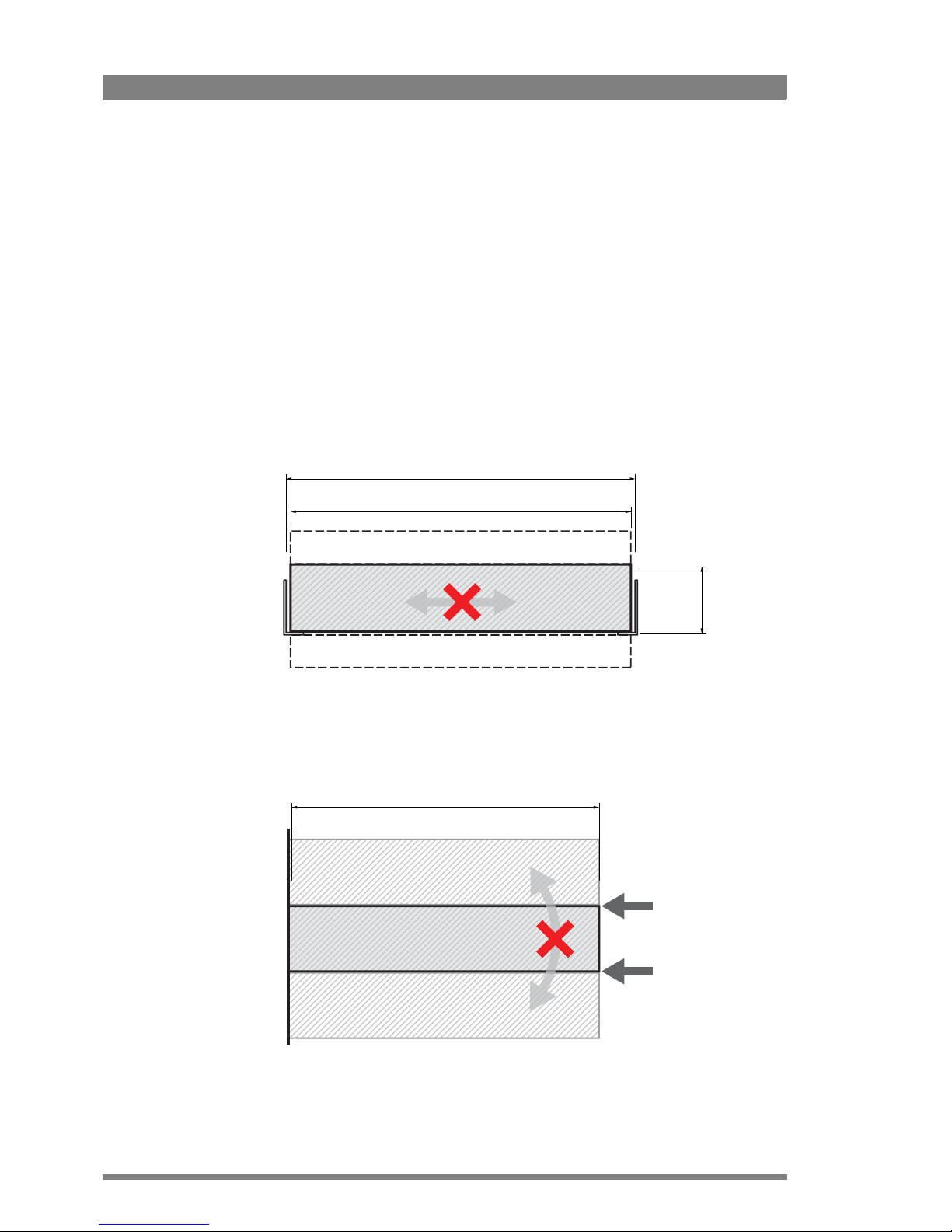

2.1.3 Transporting rack mounted XCUs

When transporting rack mounted XCUs in a flightcase make sure to take the following

precautions:

• Use proper shock absorbers for the rack to prevent damage during transport.

• To prevent any horizontal movement of the cradle and XCU during transport, make sure

there is as little horizontal clearance as possible between the cradle and the mounting

rails:

• To prevent any vertical movement of the cradle during transport, lock up the cradle

between other units and the vertical rail stands as indicated in the illustration below. Make

sure there is enough support at the back of the unit, at a minimum distance of 400 mm

from the rack front/

438 mm

450 mm — 455 mm

88 mm (2 RU)

XCU

(free space)

(free space)

400 mm

FRONT XCU

XCU or other rack device

XCU or other rack device

Page 19

XCU eXchangeable Control Unit User’s Guide (v1.6) 19

Chapter 2 - Installation

2.1.4 Connecting studio cabling

The studio cabling (main video outputs, control and intercom connections, studio signalling)

can now be connected according to your application and studio configuration. Refer to “Cradle

back panel” on page 50 for connectors and signals available on the cradle.

More information about studio signalling, control network, intercom cabling and other studio

infrastructure can be found further down this chapter.

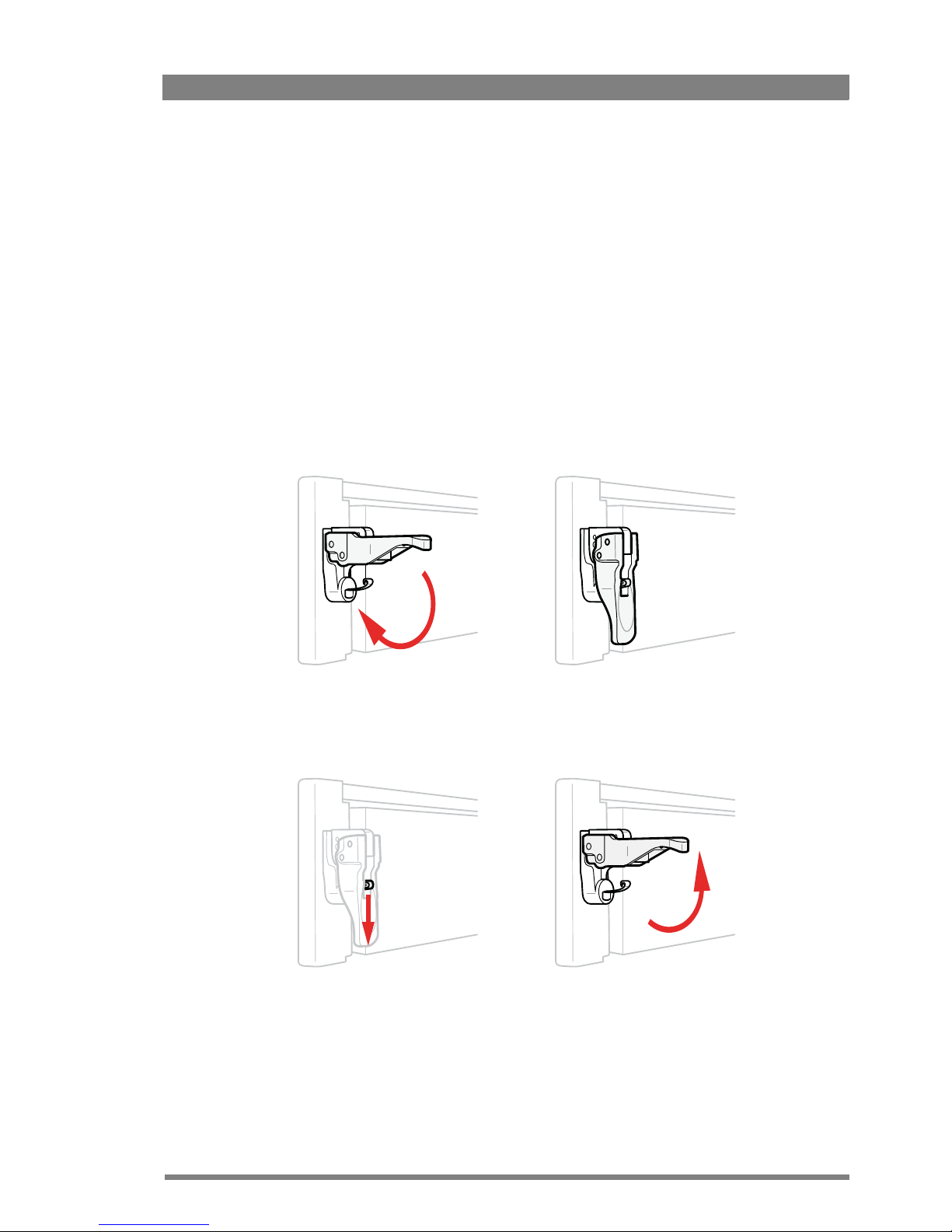

2.2 Mounting the XCU

To mount the XCU into the cradle, proceed as follows:

• Place the XCU onto the sliding rails of the cradle, slide the unit into the cradle and push

firmly.

• Push down the right and left locking handles until they snap down.

To remove the XCU from the cradle, proceed as follows:

• Hold down the springs inside the locking handles and at the same time swing them open.

• Pull out the XCU from the cradle by pulling the XCU at its sides.

• Now the transmission and mains cables can be connected. Refer to “XCU back panel” on

page 49 for connectors and signals available on the XCU.

Page 20

20 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 2 - Installation

2.3 Setting up the control network

The XCU is connected to the control network hub or router via an Ethernet cable (straightthrough, not cross-over) via the C2IP (RJ45) connector. An OCP 400 (Operational Control Panel)

and, if required an MCP 450 (Master Control PC), are also connected to the Ethernet network

via a hub or router. An OCP 400 can also be connected directly to the XCU using a (cross-over

or a straight-through) Ethernet cable.

The IP address and other options for the Ethernet connection can be set up in the XCU menu.

☞

Note

☞

Note

By default, the Ethernet connection is set up for Auto IP configuration.

2.4 Setting up intercom

Connect the studio intercom system to the rear of the XCU. Both a two and four-wire cabling

can be used. In the

AUDIO/INTERCOM > INTERCOM > ENG > WIRE MODE menu select the

cabling system: 2wire or 4wire.

The wiring of the panel connector is shown below for two-wire and four-wire systems.

2.4.1 Two-wire systems

2.4.2 Four-wire systems

Signal Value

Signal level 0 dBu (RMS)

Load impedance 200

Voltage level max. 40 VDC

8

1

15

9

Housing

Prod

Housing

Eng in/out

Prod in/out

Signal Value

Output signal level +6 or 0 dBu (RMS) selectable

Output impedance max. 50 symmetrical

Input signal level +6 or 0 dBu (RMS) selectable

Impedance min. 9 k symmetrical

8

1

15

9

Housing

Eng in/out

Prod in/out

Housing

Prog in ret

Prog in

Prod in ret

Prod in

Eng in ret

Eng in

Page 21

XCU eXchangeable Control Unit User’s Guide (v1.6) 21

Chapter 2 - Installation

2.5 Setting up studio signalling

Connect the studio signalling system to the rear of the XCU. The wiring of the signalling

connector is shown below:

There are several connection methods for the ISO (On Air Yellow), On Air and Call signalling

functions: dry contact, common ground, voltage level and open circuit/voltage level.

A selection in the INSTALL > SIGNALLING INPUT menu allows you to make the activity state

of the function (Active or Inactive) correspond to a particular input signal. There are two leads

for each connection - Send and Return.

2.5.1 Dry contact

☞

Note

☞

Note

A common return (not ground!) can be used for all three functions (ISO, On Air and Call)

If a contact is closed, the corresponding function is Active or Inactive, depending on the

selection in the INSTALL > SIGNALLING INPUT menu:

1

8

9

15

Call out send

Prev.out send

Prev.out ret.

ISO in send

ISO in return

Call in send

Call in return

5 V

Housing

Call out return

On Air send

On Air return

Audio 1 level

Audio 2 level

GND

Signal Send pin Return pin

ISO 3 11

On Air 4 12

Call 2 10

ISO 1a

ISO 1b

On-Air (Tally) 1a

On-Air (Tally) 1b

Call 1a

Call 1b

ISO in ext. send (pin 3)

ISO in ext. return (pin 11)

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

Call in ext. (pin 5)

Call in ext. return (pin 13)

External ISO signalling

(dry contact)

External On-Air signalling

(dry contact)

External Call signalling

(dry contact)

Page 22

22 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 2 - Installation

2.5.2 Dry contact with multiple XCUs

This is an example of an On Air signalling with multiple XCUs using a common contact.

☞

Note

☞

Note

Use either Send or Return only, but do not mix.

If a contact is closed, the corresponding function is Active or Inactive, depending on the

selection in the INSTALL > SIGNALLING INPUT menu:

Menu setting Input is shorted: Input is open:

LH (low-high) Function is Active Function is Inactive

HL (high-low) Function is Inactive Function is Active

On-Air (Tally) 1

On-Air (Tally) 2

On-Air (Tally) n

Common

External On-Air signalling

(common contact)

On-Air in ext. send (pin 4) Signalling connector

On-Air in ext. return (pin 12) Base Station 1

Signalling connector

Base Station 2

Signalling connector

Base Station n

On-Air in ext. send (pin 4)

On-Air in ext. return (pin 12)

On-Air in ext. send (pin 4)

On-Air in ext. return (pin 12)

Menu setting Input is shorted: Input is open:

LH (low-high) Function is Active Function is Inactive

HL (high-low) Function is Inactive Function is Active

Page 23

XCU eXchangeable Control Unit User’s Guide (v1.6) 23

Chapter 2 - Installation

2.5.3 Common ground

☞

Note

☞

Note

Ensure that a reliable ground coupling exists between the control device ground and the XCU

ground.

If a contact is closed, the corresponding function is Active or Inactive, depending on the

selection in the INSTALL > SIGNALLING INPUT menu:

On-Air (Tally) 1

On-Air (Tally) 2

On-Air (Tally) n

External On-Air signalling

(common ground contact)

On-Air in ext. (pin 4) Signalling connector

On-Air in ext. return (pin 12) Base Station 1

Signalling connector

Base Station 2

Signalling connector

Base Station n

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

On-Air (Tally) 1

On-Air (Tally) 2

On-Air (Tally) n

External On-Air signalling

(common ground contact)

On-Air in ext. (pin 4) Signalling connector

On-Air in ext. return (pin 12) Base Station 1

Signalling connector

Base Station 2

Signalling connector

Base Station n

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

Menu setting Input is shorted: Input is open:

LH (low-high) Function is Active Function is Inactive

HL (high-low) Function is Inactive Function is Active

Page 24

24 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 2 - Installation

2.5.4 Voltage level

Apply a DC voltage to the inputs (respect polarity). If the voltage is low (0 to 2.5 V), the function

is Active (or Inactive). If the voltage is high (4 to 24 V) the function is Inactive (or Active). The

function state depends on the selection in the INSTALL > SIGNALLING INPUT menu:

2.5.5 Open circuit/Voltage level

Leave the circuit open or apply a DC voltage to the inputs (respect polarity). If the circuit is

open, the function is Active (or Inactive). If the voltage is high (4 to 24 V) the function is Inactive

Menu setting Input is 0 to 2.5V: Input is 4 to 24V:

LH (low-high) Function is Active Function is Inactive

HL (high-low) Function is Inactive Function is Active

ISO 1a

0 .. 2.5 V

DC

4 .. 24 V

DC

0 .. 2.5 V

DC

4 .. 24 V

DC

0 .. 2.5 V

DC

4 .. 24 V

DC

ISO 1b

On-Air (Tally) 1a

On-Air (Tally) 1b

Call 1a

Call 1b

ISO in ext. send (pin 3)

ISO in ext. return (pin 11)

On-Air in ext. send (pin 4)

On-Air in ext. return (pin 12)

Call in ext. send (pin 5)

Call in ext. return (pin 13)

+

-

+

-

+

-

ISO 1a

Open/

4..24 V

DC

Open/

4..24 V

DC

Open/

4..24 V

DC

ISO 1b

On-Air (Tally) 1a

On-Air (Tally) 1b

Call 1a

Call 1b

ISO in ext. send (pin 3)

ISO in ext. return (pin 11)

On-Air in ext. send (pin 4)

On-Air in ext. return (pin 12)

Call in ext. send (pin 5)

Call in ext. return (pin 13)

Page 25

XCU eXchangeable Control Unit User’s Guide (v1.6) 25

Chapter 2 - Installation

(or Active).

The function state depends on the selection in the INSTALL > SIGNALLING INPUT menu:

2.6 Setting up external audio level

The camera audio levels for channel 1 and 2 can be externally controlled by the XCU. In the

camera system menu, go to the INSTALL

> AUDIO > AUDIO GAIN MODE item and select Ext.

On the OCP 400, push the SETUP button and choose the Cam submenu. Use the NEXT

button to scroll to the REM AUDIO menu and select Rem. Apply a DC voltage to pins 6 and 14

of the signalling connector to control the levels of audio channels 1 and 2 respectively, as

shown in the figure below:

The actual audio level depends on the setting of the switches at the back panel of the camera

adapter. When Mic is selected, the max. gain level is -64 dBu, while max. line level is -32 dBu.

Menu setting Input is open: Input is 4 to 24V:

OH (open-high) Function is Active Function is Inactive

HO (high-open) Function is Inactive Function is Active

Audio 1 level (pin 6)

Audio 2 level (pin 14)

Mic/Line

Mic/5 V (pin 7)

GND (pin 15)

1k

1k

1k

1k

1k

1k

1k

1k

+4.3V

+3.7V

+3.1V

+2.5V

+1.9V

+1.3V

+0.7V

0V

-22/+12dBu

-28/+4dBu

-34/-2dBu

-40/-8dBu

-46/-14dBu

-52/-20dBu

-58/-26dBu

-64/-32dBu

Page 26

26 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 2 - Installation

2.7 Using private data

Private data channels can be used for sending serial data via the transmission cable. For

example, electronic scriptboard or character data for a video display unit or pan and tilt data can

be transmitted to the camera.

☞

Note

☞

Note

Propagation-delay times vary with cable length, especially if a return signal is involved. At

max.lengths the total delay is at least 25 μs and can be more than 30 μs depending on the type

of cable. The duty cycle difference between input and output is max. 5%.

5

4

3

2

1

9

8

7

6

Private

data in

Private

data out

Function Value

Bitrate max. 100 kbit/s

Output level (high) > 4 V

Output level (low) < 4 V

Output impedance 250

Input level (high) > 2 V (max. 12 V)

Input level (low) < 2 V

Input impedance > 4.7 k

Page 27

XCU eXchangeable Control Unit User’s Guide (v1.6) 27

Chapter 3 - Setup

Chapter 3

Setup

3.1 Front navigation panel

The front navigation panel is used to set the camera number and to access and navigate the

internal XCU menu.

3.2 Setting the camera number

Hold the Select button [5] until the camera number on the display [1] starts flashing. Now use

the Up [3] and Down [4] buttons to select the camera number. Push Select again to confirm the

settings or push Back [2] to undo the selection.

3.3 Accessing the menu

3.3.1 Using the XCU front navigation panel

To access the internal XCU menu, push the Select [5] button. The display [1] shows “nn”.

Communication

Transmission

Camera Power

Cable

PowerOn Air

1 32

4 5

Display Back Up

SelectDown

Page 28

28 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 3 - Setup

3.3.2 Using the OCP 400 operation control panel

The OCP 400 can be used to access the XCU menu remotely:

1. Push the SETUP button on the OCP 400 to open the setup menu.

2. Push the Selection button to choose the BS menu.

3. Push the Selection button enter the menu,.

4. The menu appears on the Monitoring outputs of the XCU. Use the appropriate selection

buttons to navigate the menu. You can also use the rotary contol on the OCP

400 to move

up or down through the menu.

3.4 Navigating the menu

The XCU menu is used for configuring the unit. As there are a large number of functions and

set-up options available, it may require some time to become familiar with them all. The menu

is available on the Monitoring outputs.

3.4.1 Entering the menu

Use the navigation panel on the XCU or the OCP 400 to access the menu. The functions of the

XCU are grouped into menus and sub-menus. When accessed, the main menu appears on the

monitor outputs:

The main menu screen shows five items and the name of the menu (at the bottom). One or

more item can be hidden but become visible when you scroll down. A cursor shows your

position in the menu. Use the Up and Down buttons to move the cursor up and down.

TOGGLE

PREV NEXT

EXIT

BS

Diag

Cam

OCP

TOGGLE

PREV NEXT

EXIT

Menu

TOGGLE

PREV NEXT

EXIT

DOWNUPSELECT

Video

Monitoring

Audio/Intercom

Install

Security

Diagnostics

MENU OFF

Root

>>

>>

>>

>>

>>

>>

Page 29

XCU eXchangeable Control Unit User’s Guide (v1.6) 29

Chapter 3 - Setup

3.4.2 Finding your way

Use the navigation buttons to move the cursor through the menu items. If a double arrow (>>)

is visible, then pressing the Select button brings you one level lower in the menu system. Only

five items are visible in each menu. Scroll up or down to see more items.

When you first enter a menu (other than the main menu) the cursor is positioned next to the

first item. The TOP and PREVIOUS entries are not immediately visible but are located above

the first item. Use the control to scroll up to them.

• Select TOP to bring you back to the Main menu.

• Select PREVIOUS to go back to the menu that you were in before the current one.

The System menu above shows the items displayed when you first enter the menu and the

other items that are available by scrolling up or down.

3.4.3 Leaving the menu

If you are deep within the menu structure, follow these steps to leave:

• If necessary move the cursor to the left column.

• Scroll upwards until the cursor points to TOP (this is the main menu).

• Press the Select button; the cursor now points to the Menu Off item of the Main menu.

• Press the Select button to leave the menu.

This is the recommended way of leaving the system menu. The menu system disappears after

a few seconds when you stop navigating. This delay can be set in the MONITORING > MENU.

However, when you enter the menu again you enter at the last position of the cursor and not at

the top of main menu. To prevent confusion the next time you enter the system menu, it is

advisable to leave the system menu by returning to the main menu (TOP) and selecting MENU

OFF.

3.4.4 Making changes

To find out where to change a function, consult “XCU menu reference” on page 37 to find out

under which menu group or subgroup the function is located. If the cursor points to an item

(and there are no double arrows to indicate a sub-menu) then the item pointed to has a value.

The value can be:

Camera Number

IP Address

Ethernet

Serial

Camera Power

NoSignal

Video Mode

Teleprompter

TOP

PREVIOUS

System

1

>>

>>

>>

On

Col.Bar

720p59

Off

Page 30

30 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 3 - Setup

• a toggle value (only two values, for example Yes or No)

• a list value (more than two values)

• an analog value (variable from 00 to 99)

• or unavailable (---).

If the value is unavailable it cannot be changed. This is indicated by three dashes (---). This can

occur, for example, when a function is switched off. The analog values associated with that

function are then unavailable. If there are only two values associated with the function, then

pressing the Select button toggles between these two values. If a value is displayed next to a

function that is one of several possible values, then pressing the Select button places the

cursor in a list menu indicating the value currently selected. Use the Up and Down buttons to

point to a new value. Press the Select button to return the cursor to the function list. If an

analog value is displayed next to a function name, pressing the Select button places the cursor

in front of the value and the navigation control is used to change the analog value. Press the

Select button to return the cursor to the function list.

Using Recall File to undo changes

If you make changes to the settings in the menu and you decide not to keep them, use the

Recall File function to recall a standard or stored set of values for the parameters. These files

are available in the Files menu.

3.4.5 User levels

There are four user levels: user 0, user 1, user 2 and user 3. The purpose of the user levels is to

restrict the set of functions which can be changed by whoever is operating the unit. User level

0 is a special protection level which locks most of the operational controls of the camera. Use

this level to ensure that a camera that has been set-up is not tampered with. User level 0 is not

normally used for operational purposes as it is too restrictive for normal circumstances. The

recommended minimum user level is 1. For full control set the level to 3. When you switch off

the power, the access rights that were obtained by the use of the PIN code are disabled and

the camera starts at the assigned user level when switched on again.

Page 31

XCU eXchangeable Control Unit User’s Guide (v1.6) 31

Chapter 3 - Setup

3.5 Intercom setup

The studio camera systems offer extensive intercom facilities between cameraman, tracker

(floor man), XCU and studio. To help you set up and operate the intercom system, the following

controls are available:

• XCU menu system

• Camera head menu system

• Camera adapter rear panel

• Camera head switches

Tip

✎

When setting up a system it is usually more convenient to use an OCP 400 to set your

preferences in both the XCU and camera head menus.

3.5.1 Studio interface setup

A four-wire or a two-wire studio system can be connected to the XCU. In the AUDIO/

INTERCOM > INTERCOM menu, select the Wire Mode for the engineering (ENG), production

(PROD) and program (PROG) channels. By default these values are set to four-wire.

Isolate

The isolate function completely disconnects the XCU intercom from the studio system.

Levels

In the four-wire mode the menu gives you a choice of either a 0 dBu or a +6 dBu signal level. In

the two-wire mode this level is set to 0 dBu.

• Set the input and output intercom levels for the PROD and ENG channels. The range is 0

to 99; default is 50.

• Set the input level for the PROG channel.

• Set the levels for the sidetone in a two-wire system in this menu.

Page 32

32 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 3 - Setup

3.6 Color bars

For set up and test purposes, the XCU can generate a color bar signal at the HD-SDI output

connectors. This signal will be only present when no camera is connected and no valid video

signal is received.

• To turn on the XCU color bar, go to the VIDEO > COLOR BAR > COLOR BAR item and select

On.

• The color bar type can be selected with the VIDEO > COLOR BAR > COLOR BAR TYPE

item. Two color bar types are available: Split (default) and Full.

3.7 Timing

All main HD Video, SD and monitoring output signals coming from the XCU are in phase. Still,

due to different cable lengths or other delays, the signals from different XCUs can be out of

phase when they are connected to a video switcher or router.

This variation in phase can be compensated for in the XCU by using horizontal phase (H-phase)

adjustment. Go the INSTALL > TIMING menu and adjust the H-PHASE item.

☞

Note

☞

Note

The phase shift can be further adjusted in the INSTALL > TIMING > SHIFT menu. Use the

PIXELS and LINES items to shift the signals over one or more pixels and one or more lines,

respecively. The maximum shift is exactly one frame.

Page 33

XCU eXchangeable Control Unit User’s Guide (v1.6) 33

Chapter 4 - Operation

Chapter 4

Operation

4.1 Front panel indicators

During setup and operation, transmission can be monitored on the XCU front panel. A display

and several LED indicators provide information about important operational functions.

Camera number display

In normal operation the segment display shows the camera number of the camera connected

to the XCU. When the internal menu is accessed, the display shows “nn”.

Communication indicator

This green indicator lights when communication between the camera and XCU is established

and working correctly. A red indicator indicates a communication error.

Transmission indicator

This indicator lights when a working signal transmission is established between the camera

and XCU. In case of a Triax connection, this indicator lights green. A correct Fiber connection is

indicated by a blue light. A red light indicates a connection error.

Communication

Transmission

Camera Power

Cable

PowerOn Air

293 4 5

7 86

1

1

2

3

Page 34

34 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 4 - Operation

Camera Power indicator

A green light means that the connected camera is powered by the XCU and switched on. A

blinking green light indicates that a camera is connected but not switched on. A red light

indicates a power supply error (e.g. a power overload).

Cable indicator

This green indicator lights when a transmission cable is correctly connected between the

camera and XCU. A blinking red light indicates a missing or interrupted transmission cable. A

red light indicates that a cable is connected but there is an error (e.g. a short circuit).

On Air indicator

The On Air indicator lights (red) when the connected camera is switched On Air.

On Air Yellow indicator (or ISO)

The On Air Yellow indicator lights when the connected camera is switched to On Air Yellow or

when the camera is in ISO mode.

On Air Green indicator (or Call)

The On Air Green indicator lights when the connected camera is switched to On Air Green or

when a Call signal is sent or received.

Power indicator

This green indicator lights when the XCU is switched on. A blinking green indicator means that

the unit is shutting down.

4.2 Transmission diagnostics on the OCP 400

With an Operational Control Panel (OCP 400) is connected to the system, transmission can be

monitored in the diagnostics page of the panel:

4

5

6

7

8

9

Indication Description

Cable or signal quality is OK.

Cable or signal quality is below optimum, transmission is still in operation. The

quality level can vary between 6 (high) and 0 (low) units.

TOGGLE

PREV NEXT

EXIT

Signal NoSignal

FibB Cable ERROR

Signal

FibA Cable

|

OK

Signal quality from XCU to

camera

Sgnal quality from camera to

XCU.

Cable quality from camera to

XCU.

Cable quality from XCU to

camera

OK

|

Page 35

XCU eXchangeable Control Unit User’s Guide (v1.6) 35

Chapter 4 - Operation

4.3 Replacement of fuses

Caution

Switch off the XCU and disconnect power cables before proceeding.

Use only fuses of the type and rating specified. Always replace both fuses at the same time.

The XCU is equipped with 2x T8AH type 250 V fuses . They are located in the mains entry at

the back of the unit. Follow these steps to replace the fuses located in the mains entry:

1. Insert a very small screwdriver into the hole at the left side and then at the right side of

the fuseholder to unclip both side of the fuseholder.

2. Extract the fuseholder from the mains entry by pulling of the small clip at the bottom of

the fuseholder.

3. Replace both fuses.

4. Insert the fuseholder until it clicks into place.

5. Connect the power supply for the XCU to the IEC connector at the rear.

Cable or signal quality is poor. Check cable and connectors for interruptions, broken

or dirty optical connections.

Cable error. Check cable and connectors for interruptions, broken or dirty optical

connections.

No signal is received. Check cable and connectors for interruptions, broken or dirty

optical connections.

Indication Description

|

ERROR

NoSignal

Insert small flat

screwdriver here

to open clip

Insert small flat

screwdriver here

to open clip

Page 36

36 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 4 - Operation

Page 37

XCU eXchangeable Control Unit User’s Guide (v1.6) 37

Chapter 5 - XCU menu reference

Chapter 5

XCU menu reference

5.1 Video menu

Menu item Settings Default Level Stored Description

Colour Bar

Colour Bar Off, On Off User 1 — Turns color bar on or off (when camera signal is

not present)

Bar Type Split, Full Split User 1 Cradle Selects color bar type.

SD Detail

Detail Off, On Off User 1 XCU Turns SD Detail on or off

Source R, G, Y, R+G Y User 1 XCU Selects the source for SD Detail signal

generation.

Level 0..99 25 User 1 XCU Sets overall SD Detail level: amount of detail

added to the SD video signal.

Vertical Lvl 0..99 50 User 1 XCU Sets the level of the vertical component in

the SD Detail signal.

Noise Slicer 0..99 10 User 1 XCU Sets the level of the Noise Slicer.

Coarse/Fine 0..99 90 User 1 XCU Sets SD Detail balance between coarse and fine

structures (0 = coarse, 99 = fine).

Level Dependence 0..99 30 User 1 XCU Sets the SD Detail reduction level for shadow

areas.

Soft Detail Off, On Off User 1 XCU Switches SD Soft Detail on or off. This function

reduces the amount of detail added fo large

transitions.

Soft Detail Lvl 0..99 50 User 1 XCU Sets the maximum limit level of detail for

Soft Detail.

Page 38

38 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 5 - XCU menu reference

5.2 Monitoring menu

5.3 Audio/Intercom menu

Menu item Settings Default Level Stored Description

Display On, Time Time User 2 XCU Selects the camera menu to be permanently On

or to disappear after a set Time.

Menu time 3..30 10 User 3 XCU Sets the length of time the menu is dis-played

when the Display mode is set to Time.

Statusbar

Camera Number Off, On Off User 1 — Switch on to show the camera number in the

status bar.

Name Off, Alias, Dev ID,

Head ID

Off User 1 — Switch on and select Alias, device ID (of the

XCU) or Head ID (of the connected camera) to

be shown in the status bar.

Cable Info Off, On Off User 1 — Switch on to show transmission cable

information in the status bar.

Menu item Settings Default Level Stored Description

Audio

Audio 1 Level 0dB, 6dB 6dB User 1 — Selects studio audio attenuation level for Audio

input 1.

Audio 2 Level 0dB, 6dB 6dB User 1 — Selects studio audio attenuation level for Audio

input 2

Intercom

Isolate

Isolate Isolate, System System User 1 Cradle Isolate = Isolate Program and Production

intercom from camera head;

System = isolate is off

Eng

Wire Mode 4wire, 2wire 4wire User 1 Cradle Selects wiring mode for the Engineering

intercom channel.

Volt/Cur drive 4wire, 2wire 4wire Service — Selects voltage of current drive mode.

2/4 wire 4wire, 2wire 4wire Service — Selects 2 or 4 wire intercom mode.

Level 0dB, 6dB 6dB User 1 XCU Selects intercom channel attenuation.

Side Tone 0..99 50 User 1 Cradle Sets side tone (feedback) volume level.

Prod

Wire Mode 4wire, 2wire 4wire User 1 Cradle Selects wiring mode for the Production

intercom channel.

Volt/Cur drive 4wire, 2wire 4wire Service — Selects voltage of current drive mode.

2/4 wire 4wire, 2wire 4wire Service — Selects 2 or 4 wire intercom mode.

Level 0dB, 6dB 6dB User 1 XCU Selects intercom channel attenuation.

Side Tone 0..99 50 User 1 Cradle Sets side tone (feedback) volume level.

Prog

Page 39

XCU eXchangeable Control Unit User’s Guide (v1.6) 39

Chapter 5 - XCU menu reference

5.4 Install menu

Wire Mode 4wire, 2wire 4wire User 1 Cradle Selects wiring mode for Program intercom

channel.

Level 0dB, 6dB 6dB User 1 XCU Selects intercom channel attenuation.

Menu item Settings Default Level Stored Description

Menu item Settings Default Level Stored Description

Camera Number 1..99 1 User 2 Cradle Sets logical camera number (preferred method

to set this is via the front panel).

Alias <text> — User 2 XCU Sets Alias for the camera system.

Device ID <text> — User 2 Cradle Sets Device ID for the XCU.

Timing

H Phase 0..99 50 User 0 Cradle Sets the horizontal (H) synchronization phase.

Shift

Pixels 0..1920 0 Service Cradle Selects output time shift for all video outputs in

pixels.

Lines 0..1080 0 Service Cradle Selects output time shift for all video outputs in

video lines.

Time/Date

Time <Time> User 2 — Shows current time.

Date <Date> User 2 — Shows current date.

Change Time

Hours (24h) 0..23 0 User 2 — Sets the value for hours.

Minutes 0..59 0 User 2 — Sets the value for minutes.

Set time Exec, .. User 2 — Apply new time settings.

Change Date

Day 1..31 1 User 2 — Sets the value for day.

Month 1..12 1 User 2 — Sets the value for month.

Year 2000...2199 2012 User 2 — Sets the value for year.

Set date Exec, .. User 2 — Apply new date settings.

Status NotSet, DataLoss,

Error, Ok

Ok User 2 — Shows the time/date setting status.

Batt. Status Ok, Low, Error Ok User 2 — Show Battery Status. When low, have the

internal battery replaced.

Signalling input

Onair Source GPIO, Ethernet GPIO User 0 Cradle GPIO (General Purpose Input/Output): On Air is

controlled by the signalling connector on the

XCU;

Ethernet: On Air is controlled via the C2IP

(Ethernet) network, e.g. by the OCP 400.

Onair R Inp. Low/High, High/

Low, Open/High,

High/Open

Low/

High

User 0 Cradle Selects switch mode for the Red On Air

signalling input.

Page 40

40 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 5 - XCU menu reference

Onair Y Inp. Low/High, High/

Low, Open/High,

High/Open

Low/

High

User 0 Cradle Selects switch mode for the Yellow On Air (ISO)

signalling input.

Call Input Low/High, High/

Low, Open/High,

High/Open

Low/

High

User 0 Cradle Selects switch mode for the Call signalling input.

Signalling Outp.

Crash2Air On, Off Off Service XCU (special purpose)

Network

IP mode Auto, Manual Auto User 0 — Selects manual or automatic IP configuration

mode.

Subnet Mask 0..31 0 User 0 — Sets the subnet mask value (when manual IP

mode is selected).

BS IP digit 1 1..250 0 User 0 Cradle

Sets XCU IP address (when IP mode is manual).

BS IP digit 2 0..255 0 User 0 Cradle

BS IP digit 3 0..255 0 User 0 Cradle

BS IP digit 4 1..254 0 User 0 Cradle

CAM IP digit 1 1..250 0 User 0 Cradle

Sets camera head IP address (when IP mode is

manual).

CAM IP digit 2 0..255 0 User 0 Cradle

CAM IP digit 3 0..255 0 User 0 Cradle

CAM IP digit4 1..254 0 User 0 Cradle

Apply IP settings Exec, .... Exec User 0 — Select Exec to apply the new IP settings.

AFD

Insert On. Off Off Service XCU Turns AFD (Active Format Description)

embedding in video signal on or off.

Setting 16:9 (Full), 4:3

(Center)

16:9

(Full)

User 3 — Selects type of AFD (Active Format

Description) code to be embedded in the

video signal.

Extern Video

Aspect Ratio 16:9, 4:3 16:9 User 3 Cradle Selects aspect ratio for external video inputs.

No Signal Col.Bar, Black Col.Bar User 3 — Selects a color bar or a black frame signal is

output when no camera is connected

Video Mode 1080i50 ... — User 3 XCU Selects a video mode for the XCU test signal

when no camera is connected.

3G Output Level A, Level B Level A User 3 XCU Selects SMPTE 425M Level-A or Level-B

mapping to be used for the 3G video outputs.

HD-SDI Out D HD, SD HD User 3 XCU Selects video output signal (HD or SD) on video

connector D.

Out D Scaling 1080i, 720p 1080i User 3 XCU Selects scaler to use for output signal on video

connector D (when HD-SDI Out D = HD)

SD AspectRatio 16:9, 4:3 16:9 User 3 — Selects aspect ratio for SD outputs.

SD LetterBox Off, 16:9 Off User 3 — Selects letter box mode ratio for SD outputs.

HDSDI LensData Off, On Off Service Cradle Enable to embed lens data into HD-SDI signal.

Menu item Settings Default Level Stored Description

Page 41

XCU eXchangeable Control Unit User’s Guide (v1.6) 41

Chapter 5 - XCU menu reference

5.5 Security menu

5.6 Licenses menu

Menu item Settings Default Level File Description

Installed level User0 .. User3 User 0 Service — Selects XCU user level.

Note: switch the unit off and on to take the

changes into effect.

Cur. User Level No Oper, User0 ..

Serv1

User 0 Service — Selects current XCU user level.

PIN Code <code> — Service — Enter a PIN code to access Service level

Key

Type Unknown Unknown Service — (advanced settings)

Number 0 .. 1000 0 Service — (advanced settings)

Factory Defaults Exec, ... Exec Service — Resets all XCU settings to their factory

defaults.

Menu item Values Default Level File Description

Active Licenses

WorldCam Unknown, Not

Applicable, Not

Present,

Temporary,

Perpetual, Trial,

Clock Error

Unknown User 2 — Shows status of the WorldCam License,

when installed.

Time Left 0..65535 sec — User 2 — Shows time left in seconds for WorldCam

License.

New Licenses

Find Licenses

Search Next Exec, ... Exec User 2 — Execute to search the next license (if

existing) on the USB Flash Drive or internal

memory.

Add License Exec, ... Exec User 2 — Execute to add the found license.

Type None, WorldCam None User 2 — Shows the type of the found license

Status Unknown, Not

Applicable, Not

Present,

Temporary,

Perpetual, Trial,

Clock Error

Unknown

User 2 — Shows the status of the found license.

Trial License

Select Type None, WorldCam None User 2 — Selects License type to use for trial

licensing.

Activate Exec, ... Exec User 2 — Execute to make the selected trial license

active (trial licenses are active for 3

minutes).

Page 42

42 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 5 - XCU menu reference

5.7 Diagnostics menu

Time Left 0..179 sec — User 2 — Shows time left after activating a trial

license.

Menu item Values Default Level File Description

Menu item Values Default Level Stored Description

Cable Power

Camera Power On, Off On User 2 — (advanced settings)

Connector None, Fiber, Triax,

Error

None User 2 (advanced settings)

Status Unknown, Open,

Power Off,

Overload, Short,

Cam Off, Cam On,

Error

UnknownUser 2 — (advanced settings)

Int.Error Unknown, VMtest,

STtest, CStest,

FBtest, Start,

Shutdown,

nonFlex, Family

UnknownUser 2 — (advanced settings)

Communication

Cam Connected Yes, No No User 2 — (advanced settings)

C2IP Panels 0..99 0 User 2 — (advanced settings)

LDK Connect Gw Yes, No No User 2 — (advanced settings)

Ethernet

MAC-Address <####> — User 2 Cradle (advanced settings)

Link state Connected,

Disconn

Disconn User 2 — (advanced settings)

Link type Unknown, 10Mb/

Half, 10Mb/Full,

100Mb/Half,

100Mb/Full,

Negotiate

UnknownUser 2 — (advanced settings)

Loopback test

Loopback test Off, On Off Service — (advanced settings)

Data count <####> Service — (advanced settings)

Data errors 0..65535 0 Service — (advanced settings)

Data loss 0..65535 0 Service — (advanced settings)

Transmission

Transm. path T2F Conv, F2T

Conv, 3GTriax,

3GFiber, Unknown,

None

None User 0 — (advanced settings)

Transm. select

Priority Auto, Triax, Fiber Auto User 0 — (advanced settings)

Page 43

XCU eXchangeable Control Unit User’s Guide (v1.6) 43

Chapter 5 - XCU menu reference

Transmission Triax, Fiber Triax User 0 — (advanced settings)

Transm. profile

Selection Mode Auto, Manual Auto Service XCU (advanced settings)

Profile 3G Optimal, HD

Optimal, 3G Robot,

HD Robot

3G

Optimal

Service XCU (advanced settings)

Triax

Cable Length <####> — User 0 — (advanced settings)

Cable Status OK, Critic, Error,

NoSig, Unknown

NoSig User 0 — (advanced settings)

Rx Sig.Status OK, Critic, Error,

NoSig, Unknown

NoSig User 0 — (advanced settings)

Tx Sig.Status OK, Critic, Error,

NoSig, Unknown

NoSig User 0 — (advanced settings)

Fiber

Fib A (CAM->XCU)

Cable Status OK, Critic, Error,

NoSig, Unknown

NoSig User 0 — (advanced settings)

Signal Status OK, Critic, Error,

NoSig, Unknown

NoSig User 0 — (advanced settings)

RX Margin — — User 0 — (advanced settings)

CRC Error Count 0..65535 50 Service — (advanced settings)

Fib B (XCU->CAM)

Cable Status OK, Critic, Error,

NoSig, Unknown

NoSig User 0 — (advanced settings)

Signal Status OK, Critic, Error,

NoSig, Unknown

NoSig User 0 — (advanced settings)

RX Margin — — User 0 — (advanced settings)

CRC Error Count 0..65535 50 Service — (advanced settings)

T2F Converter (Triax to Fiber Converter)

Temperature Ok, Unknown,

Critic, Error

UnknownUser 0 — (advanced settings)

FPGA Temp <temp> — Service — (advanced settings)

Fan — — User 0 — (advanced settings)

Cable Power Unknown, Open,

Power Off,

Overload, Short,

Cam Off, Cam On,

Error

Error User 0 — (advanced settings)

Int.Error Unknown, VMtest,

STtest, CStest,

FBtest, Start,

Shutdown,

nonFlex, Family

UnknownUser 0 — (advanced settings)

Package Ok. Not Ok Not Ok User 0 (advanced settings)

Package 12NC 0..65535 0 User 0 (advanced settings)

Package Version 0..65535 0 User 0 (advanced settings)

Menu item Values Default Level Stored Description

Page 44

44 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 5 - XCU menu reference

F2T Converter (Fiber to Triax Converter)

Temperature Ok, Unknown,

Critic, Error

UnknownUser 0 — (advanced settings)

FPGA Temp <temp> — Service — (advanced settings)

Package Ok. Not Ok Not Ok User 0 (advanced settings)

Package 12NC 0..65535 0 User 0 (advanced settings)

Package Version 0..65535 0 User 0 (advanced settings)

Transm. Details

Triax

Triax Locked Yes, No No Service — (advanced settings)

->XCU

Cable Length 0..65535 135 Service — (advanced settings)

Total Quality 0..65535 255 Service — (advanced settings)

Cable Quality Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Signal Quality Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Avg MER Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Max MER Good, Average,

Bad, Undef

Undef Service — (advanced settings)

EQ Taps Good, Average,

Bad, Undef

Undef Service — (advanced settings)

RS Error Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Filter MER Good, Average,

Bad, Undef

Undef Service — (advanced settings)

<-XCU

Cable Length 0..65535 0 Service — (advanced settings)

Total Quality 0..65535 255 Service — (advanced settings)

Cable Quality Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Signal Quality Good, Average,

Bad, Undef

Undef Service — (advanced settings)

->Conv

Cable Length 0..65535 135 Service — (advanced settings)

Total Quality 0..65535 255 Service — (advanced settings)

Cable Quality Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Signal Quality Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Avg MER Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Max MER Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Menu item Values Default Level Stored Description

Page 45

XCU eXchangeable Control Unit User’s Guide (v1.6) 45

Chapter 5 - XCU menu reference

EQ Taps Good, Average,

Bad, Undef

Undef Service — (advanced settings)

RS Error Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Filter MER Good, Average,

Bad, Undef

Undef Service — (advanced settings)

<-Conv

Cable Length 0..65535 0 Service — (advanced settings)

Total Quality 0..65535 255 Service — (advanced settings)

Cable Quality Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Signal Quality Good, Average,

Bad, Undef

Undef Service — (advanced settings)

Fiber

Fiber Locked Yes, No No Service — (advanced settings)

Fiber Locked Yes, No No Service — (advanced settings)

-> XCU

RX Margin — — Service — (advanced settings)

CRC Error

Count

0..65535 50 Service — (advanced settings)

<- XCU

RX Margin — — Service — (advanced settings)

CRC Error

Count

0..65535 50 Service — (advanced settings)

-> CAM

RX Margin — — Service — (advanced settings)

CRC Error

Count

0..65535 50 Service — (advanced settings)

<- CAM

RX Margin — — Service — (advanced settings)

CRC Error

Count

0..65535 50 Service — (advanced settings)

SFP Module

Opt. Module Unknown,

FTLF1424P2

UnknownService — (advanced settings)

RX Power — — Service — (advanced settings)

RX Power — — Service — (advanced settings)

TX Power — — Service — (advanced settings)

TX Power — — Service — (advanced settings)

Audio mute Off, On On Service — (advanced settings)

Video mute Off, On On Service — (advanced settings)

Data Error Stats

UART Errors 0..65335 0 Service — (advanced settings)

Decompr Errors 0..65335 0 Service — (advanced settings)

Menu item Values Default Level Stored Description

Page 46

46 XCU eXchangeable Control Unit User’s Guide (v1.6)

Chapter 5 - XCU menu reference

IP Errors 0..65335 0 Service — (advanced settings)

TCP Errors 0..65335 0 Service — (advanced settings)

TCP Retries 0..65335 0 Service — (advanced settings)

Reset Statistics Off, On Off Service — (advanced settings)

Temperature

Fan

Actual — — User 0 — (advanced settings)

Required — — User 0 — (advanced settings)

Temp (C)

Power — — User 0 — (advanced settings)

Generic FPGA0 — — User 0 — (advanced settings)

Generic FPGA1 — — User 0 — (advanced settings)

Transm FPGA — — User 0 — (advanced settings)

SFP Module — — User 0 — (advanced settings)

Temp (F)

Power — — User 0 — (advanced settings)

Generic FPGA0 — — User 0 — (advanced settings)

Generic FPGA1 — — User 0 — (advanced settings)

Transm FPGA — — User 0 — (advanced settings)

SFP Module — — User 0 — (advanced settings)

Video inputs

Extern 1

Carrier Yes, No No User 1 — (advanced settings)

Locked Yes, No No User 1 — (advanced settings)

VideoMode Unknown, SD,

1080i59, 1080i50,

720p59, 720p50,

1080p59, 1080p50,

1080i47

UnknownUser 1 — (advanced settings)

Extern 2

Carrier Yes, No No User 1 — (advanced settings)

Locked Yes, No No User 1 — (advanced settings)

VideoMode Unknown, SD,

1080i59, 1080i50,

720p59, 720p50,

1080p59, 1080p50,

1080i47

UnknownUser 1 — (advanced settings)

Extern 3

Carrier Yes, No No User 1 — (advanced settings)

Locked Yes, No No User 1 — (advanced settings)

VideoMode Unknown, SD,

1080i59, 1080i50,

720p59, 720p50,

1080p59, 1080p50,

1080i47

UnknownUser 1 — (advanced settings)

Menu item Values Default Level Stored Description

Page 47

XCU eXchangeable Control Unit User’s Guide (v1.6) 47

Chapter 5 - XCU menu reference

Teleprompter Unknown, None,

PAL, NTSC

UnknownUser 0 — (advanced settings)

Reference In Unknown, 1080i59,

1080i50, 720p59,

720p50, 1080p59,

1080p50, 1080i48,

PAL, NTSC

UnknownUser 0 — (advanced settings)

Gen Lock Yes, No No User 0 — (advanced settings)

XCU Type Unknown, <range

of XCU Types>

UnknownUser 2 — (advanced settings)

XCU Status Unknown, Ok,

Illegal

UnknownUser 2 — (advanced settings)

XCU PID <####> — User 2 — (advanced settings)

Package Info

Package Ok, Not Ok Ok User 2 — (advanced settings)

Package 12NC 0..65535 0 User 2 — (advanced settings)

Package Version 0..65535 0 User 2 — (advanced settings)

Component Appl SW, GEB FW,

GEB Nios, TRB FW,

PFB SW, Config

SW, Bootloader

Appl SWUser 2 — (advanced settings)

Valid Ok, Not Ok, N/A Not Ok User 2 — (advanced settings)

12NC 0..65535 0 User 2 — (advanced settings)

Version 0..65535 0 User 2 — (advanced settings)

PCB Info

Board GEB, UIB, COB,

IDB, TRB, PDB,

PFB

GEB User 2 — (advanced settings)

PID — — User 2 — (advanced settings)

12NC 0..65535 0 User 2 — (advanced settings)

Status 0..255 0 User 2 — (advanced settings)

Metrics

Metrics ??, NoAccess,

Recovered, Init,

Valid

?? User 2 — (advanced settings)

Run Hours 0..65535 0 User 2 — (advanced settings)

Total Run Hours 0..65535 0 User 2 — (advanced settings)

Power Cycles 0..65535 0 User 2 — (advanced settings)

Minimum Temp — — User 2 — (advanced settings)