Page 1

TRX-PS-BU Series

Trinix Backup Power Supplies

Installation Manual

071 8443 00

September 22, 2005

Page 2

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support:

(530) 478-4148

Sales:

(530) 478-3347

Support:

(530) 478-3181

Grass Valley

400 Providence Mine Rd.

P.O. Box 599000

Nevada City, CA

95959-7900

USA

www.thomsongrassvalley.com

Pacific Operations +852-2585-6688

Support: 852-2585-

6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Grass Valley Inc. All rights reserved.

+852-2802-2996

Grass Valley Web Site

The www.thomsongrassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Software updates, drivers, and patches can be down-

loaded.

2 TRX-PS-BU Series Installation Manual

Page 3

Contents

Preface

Safety Summary

Regulatory Notices

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Terms in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Certifications and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

FCC Emission Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Canadian EMC Notice of Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

EN55022 Class A Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Canadian Certified Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Canadian Certified AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Laser Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FCC Emission Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section 1 — Introduction

DV-33128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DV-33256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DV-33512. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Materials Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Equipment Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Software Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 2 — Installation

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TRX-PS-BU Series Installation Manual 3

Page 4

Contents

Appendix A — Specifications

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Air Intake/Exhaust Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 TRX-PS-BU Series Installation Manual

Page 5

Preface

About This Manual

Additional Documentation

This manual provides installation instructions for the Trinix backup power

supplies.

Trinix Installation and Operating Manual, part no. 071 8276 xx. Includes

planning and installation instructions.

A printed copy of the documentation set is normally provided with the

system. Individual manuals may be ordered by contacting Technical Support. For contact information, see page 2. Electronic copies of all routing

products documentation are available on the following documentation

CDs:

CD 071 8274 xx. Includes Jupiter VM-3000 and Jupiter CM-4000 manuals.

CD 071 8130 xx. Includes Encore Control System manuals.

These documents are also available on our web site. See page 2.

TRX-PS-BU Series Installation Manual 5

Page 6

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury to persons.

Additional specific warnings not listed here may be found throughout the

manual.

WARNING Any instructions in this manual that require opening the equipment cover

or enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

sonal injury or loss of life.

CAUTION Caution statements identify conditions or practices that may result in damage

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

Terms on the Product

The following terms may appear on the product:

DANGER — A personal injury hazard is immediately accessible as you read

the marking.

WARNING — A personal injury hazard exists but is not immediately acces-

sible as you read the marking.

CAUTION — A hazard to property, product, and other equipment is present.

TRX-PS-BU Series Installation Manual 6

Page 7

Safety Summary

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer

to product manual(s) for important operating, maintenance,

or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth ground prior to making any other equipment

connections.

Warnings

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present — Disconnect power and remove

battery (if applicable) before removing protective panels, soldering, or

replacing components.

Do not service alone — Do not internally service this product unless another

person capable of rendering first aid and resuscitation is present.

Remove jewelry — Prior to servicing, remove jewelry such as rings, watches,

and other metallic objects.

Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

7 TRX-PS-BU Series Installation Manual

Page 8

— Safety Summary

Use proper power cord — Use only the power cord supplied or specified for

this product.

Ground product — Connect the grounding conductor of the power cord to

earth ground.

Operate only with covers and enclosure panels in place — Do not operate this

product when covers or enclosure panels are removed.

Use correct fuse — Use only the fuse type and rating specified for this

product.

Use only in dry environment — Do not operate in wet or damp conditions.

Use only in non-explosive environment — Do not operate this product in an

explosive atmosphere.

High leakage current may be present — Earth connection of product is essential

before connecting power.

Dual power supplies may be present — Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Cautions

Double pole neutral fusing — Disconnect mains power prior to servicing.

Use proper lift points — Do not use door latches to lift or move equipment.

Avoid mechanical hazards — Allow all rotating devices to come to a stop before

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source — Do not operate this product from a power source

that applies more than the voltage specified for the product.

Use correct voltage setting — If this product lacks auto-ranging power sup-

plies, before applying power ensure that the each power supply is set to

match the power source.

Provide proper ventilation — To prevent product overheating, provide equip-

ment ventilation in accordance with installation instructions.

Use anti-static procedures — Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

8 TRX-PS-BU Series Installation Manual

Page 9

Safety Summary

Do not operate with suspected equipment failure — If you suspect product

damage or equipment failure, have the equipment inspected by qualified

service personnel.

Ensure mains disconnect — If mains switch is not provided, the power cord(s)

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly — Route power cords and other cables so that they ar not

likely to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply cords — Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery — This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

Troubleshoot only to board level — Circuit boards in this product are densely

populated with surface mount technology (SMT) components and application specific integrated circuits (ASICS). As a result, circuit board repair at

the component level is very difficult in the field, if not impossible. For warranty compliance, do not troubleshoot systems beyond the board level.

9 TRX-PS-BU Series Installation Manual

Page 10

Regulatory Notices

Certifications and Compliances

FCC Emission Control

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Grass Valley Group

can affect emission compliance and could void the user’s authority to

operate this equipment.

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numeriques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

EN55022 Class A Warning

For products that comply with Class A. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

TRX-PS-BU Series Installation Manual 10

Page 11

Regulatory Notices

Canadian Certified Power Cords

Canadian Certified AC Adapter

Laser Compliance

Laser Safety Requirements

Canadian approval includes the products and power cords appropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

The device used in this product is a Class 1 certified laser product. Operating this product outside specifications or altering from its original design

may result in hazardous radiation exposure, and may be considered an act

of modifying or new manufacturing of a laser product under U.S. regulations contained in 21CFR Chapter1, subchapter J or CENELEC regulations

in HD 482 S1. People performing such an act are required by law to recertify

and reidentify this product in accordance with provisions of 21CFR subchapter J for distribution within the U.S.A., and in accordance with

CENELEC HD 482 S1 for distribution within countries using the IEC 825

standard.

Laser Safety

Laser safety in the United States is regulated by the Center for Devices and

Radiological Health (CDRH). The laser safety regulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The international Electrotechnical Commission (IEC) Standard 825, “Radiation of Laser Products, Equipment Classification, Requirements and

User’s Guide,” governs laser products outside the United States. Europe

and member nations of the European Free trade Association fall under the

jurisdiction of the Comite European de Normalization Electrotechnique

(CENELEC).

For the CDRH: The radiant power is detected trough a 7 mm aperture at a

distance of 200 mm from the source focused through a lens with a focal

length of 100 mm.

For IEC compliance: The radiant power is detected trough a 7 mm aperture

at a distance of 100 mm from the source focused through a lens with a focal

length of 100 mm.

11 TRX-PS-BU Series Installation Manual

Page 12

FCC Emission Limits

Certification

Regulatory Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may no cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesirable operation. This device

has been tested and found to comply with FCC Part 15 Class B limits for a

digital device when tested with a representative laser-based fiber optical

system that complies with ANSI X3T11 Fiber Channel Standard.

Category Standard Designed/tested for compliance with:

Safety UL1950 Safety of Information Technology Equipment, including Electrical

Business Equipment (Second edition, 1993).

IEC 950 Safety of Information Technology Equipment, including Electrical

Business Equipment (Second edition, 1991).

CAN/CSA C22.2, No. 950-93 Safety of Information Technology Equipment, including Electrical

Business Equipment.

EN60950 Safety of Information Technology Equipment, including Electrical

Business Equipment.

TRX-PS-BU Series Installation Manual 12

Page 13

Certifications and Compliances

TRX-PS-BU Series Installation Manual 13

Page 14

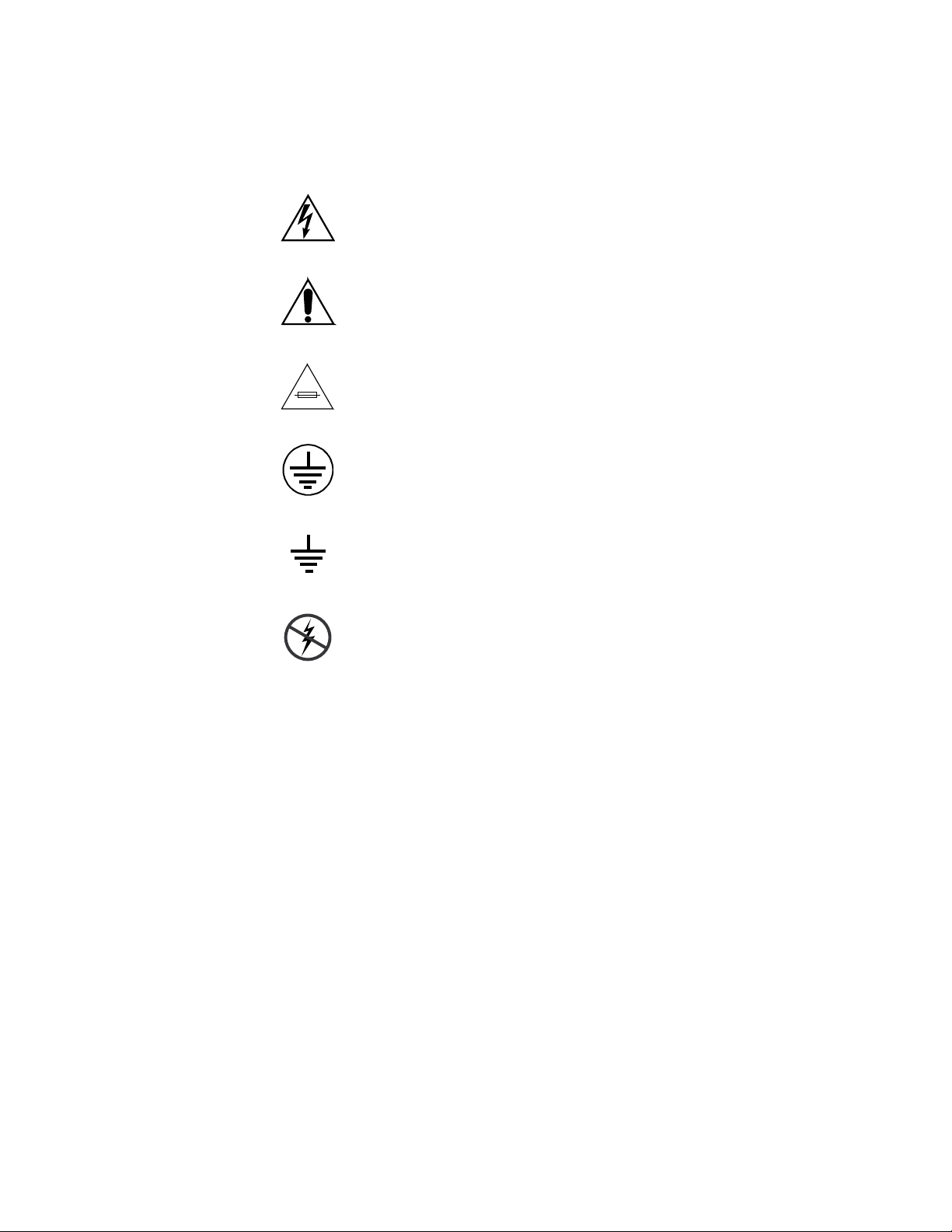

Figure 1. TRX-PS-BU Trinix Backup Power Supplies

TRX-PS-BU1200

OR

TRX-PS-BU2400

TRX-PS-BU2400

TRX-PS-BU3600

DV-33128

DV-33256

OR

TRX-PS-BU2400

TRX-PS-BU2400

TRX-PS-BU3600

TRX-PS-BU3600

DV-33512

OR

14 TRX-PS-BU Series Installation Manual

Page 15

Introduction

The TRX-PS-BU series of products are designed to supplement the Trinix

DV-33128, DV-33256 and DV-33512 internal power supplies to provide

increased backup protection.. Three packages are available:

• TRX-PS-BU1200 - 1 ea. 1200 watt module mounted in a 1 RU frame

• TRX-PS-BU2400 - 2 ea. 1200 watt modules mounted in a 1 RU frame

• TRX-PS-BU3600 - 3 ea. 1200 watt modules mounted in a 1 RU frame

Each module consists of a Unipower TPCP 7000 1200 watt power supply.

The rack frame is a Unipower TPCP R1U3-B 1.75-inch chassis.

As shown on the facing page, these packages can be used in various combinations with Trinix DV-33128, DV-33256, and DV-33512 routers.

Section 1

DV-33128

The power supplies are essentially bussed together so that the power load

is shared at all times. If one supply fails, the remaining supplies on that bus

will continue to provide power. The failed supply should be replaced as

soon as possible.

For DV-33128 routers, installation of one TRX-PS-BU1200 will provide a

total of three on-line power supplies: two internally-mounted supplies and

one supply mounted in the external chassis. Any one of these three supplies can fully power the DV-33128 router.

Installation of one TRX-PS-BU2400 will provide a total of four on-line

power supplies: two internally-mounted supplies and two supplies

mounted in the external chassis. Any one of these four supplies can fully

power the DV-33128 router.

TRX-PS-BU Series Installation Manual 15

Page 16

Section 1 — Introduction

DV-33256

DV-33512

For DV-33256 routers, installation of one TRX-PS-BU2400 will provide a

total of four on-line power supplies: two internally-mounted supplies and

two supplies mounted in the external chassis. Any one of these four supplies can fully power the DV-33256 router.

Installation of one TRX-PS-BU3600 will provide a total of five on-line

power supplies: two internally-mounted supplies and three supplies

mounted in the external chassis. Any one of these five supplies can fully

power the DV-33256 router.

For DV-33512 routers, installation of two TRX-PS-BU2400s will provide a

total of eight on-line power supplies divided into two groups:

• One group consists of internal supplies A and B and the two supplies

in one of the external chassis (total of four supplies). The four supplies

in this group power half the boards in the router. Any one of the four

supplies can provide all needed power to these boards.

• The opposite group consists of internal supplies C and D and the two

supplies in the other external chassis (total of four supplies). The four

supplies in this group power half the boards in the router. Any one of

the five supplies can provide all needed power to these boards

Installation of two TRX-PS-BU3600s will provide a total of ten on-line

power supplies divided into two groups:

• One group consists of internal supplies A and B and the three supplies

in one of the external chassis (total of five supplies). The five supplies

in this group power half the boards in the router. Any one of the five

supplies can provide all needed power to these boards.

• The opposite group consists of internal supplies C and D and the three

supplies in the other external chassis (total of five supplies). The five

supplies in this group power half the boards in the router. Any one of

the five supplies can provide all needed power to these boards.

16 TRX-PS-BU Series Installation Manual

Page 17

Materials Supplied

Each of the three packages includes the following:

Specifications

Qty

1 Power cable assembly, power supply rack to Trinix, 9 ft.

1, 2, or 3 AC mains power cord kit (type varies per destination country)

1, 2, or 3 Power supply, Unipower TPCP 7000, 1200 W 48 VDC

1 Power supply rack, Unipower TPCP R1U3-B

1 or 2 Blank panels for power supply rack

2Small pattern 6 nut

2 Split lock no. 6 washer

2 4-40 x 1/4 SEMS screw

4 6-32 x 1/4 SEMS screw

2 1/4-20 UNC nut

2 Internal lock washer

2No. 6 flat washer

Equipment Required

TRX-PS-BU1200 installations:

1.75 in. (1 RU) rack space in Trinix or adjacent rack, and

1 AC power outlet, 1200 watts.

TRX-PS-BU2400 installations:

Description

Software Required

Specifications

1.75 in. (1 RU) rack space in Trinix or adjacent rack, and

2 AC power outlets, 1200 W each (total 2400 W)

TRX-PS-BU3600 installations:

1.75 in. (1 RU) rack space in Trinix or adjacent rack, and

3 AC power outlets, 1200 W each (total 3600 W)

No software changes are needed.

For mechanical, environmental, and electrical specifications, see Appendix

A - Specifications.

TRX-PS-BU Series Installation Manual 17

Page 18

Section 1 — Introduction

Ordering Information

Tab l e 1.

TRX-PS-BU1200 POWER SUPPLY 1200 W 1 RU STAND ALONE DC OUTPUT

TRX-PS-BU2400 POWER SUPPLY 2400 W 1 RU STAND ALONE DC OUTPUT

TRX-PS-BU3600 POWER SUPPLY 3600 W 1 RU STAND ALONE DC OUTPUT

18 TRX-PS-BU Series Installation Manual

Page 19

Ordering Information

TRX-PS-BU Series Installation Manual 19

Page 20

Figure 2. TRX-PS-BU Trinix Backup Power Supplies

Y

g

Red

ellow/

reen

Plain

black

DC INPUT 2 NOT FUSED

42 - 54 VDC

30 - 24 AMPS

DC IN +

DC IN -

DC INPUT 1 NOT FUSED

42 - 54 VDC

30 - 24 AMPS

DC IN + DC IN -

INPUTSINPUTS

INPUTS

161 - 192

193 - 224

129 - 160

DC OUTPUT 2

42 - 54 VDC

30 - 24 AMPS

DC OUT -DC OUT +

DC INPUT 2

42 - 54 VDC

30 - 24 AMPS

DC IN -DC IN +

AC INPUT: 100-240 V ~, 10.0-5.0A, 50-60Hz

100-120V: 12.5A, 250V, SLO BLO

200-240V: T6.3A, 250V

PS D

L

E

N

Blue

DC INPUT

42 - 54 VDC

30-24 AMPS

DC IN -DC IN +

PS D PS C

A

1

B

A

2

B

OP

MON

A

3

B

A

4

B

1

2

REF

IN

3

4

OUTPUTSINPUTS

OUTPUTS

OUTPUTS

INPUTS

OUTPUTS

OUTPUTS

OUTPUTS

449 - 480

417 - 448

225 - 256

385 - 416

481 - 512

257 - 288

DC OUTPUT 1

42 - 54 VDC

30 - 24 AMPS

DC OUT +DC OUT -

DC INPUT 1

42 - 54 VDC

30 - 24 AMPS

DC IN -DC IN +

AC INPUT: 100-240 V ~, 10.0-5.0A, 50-60Hz

100-120V: 12.5A, 250V, SLO BLO

WARNING: FOR CONTINUED PROTECTION

AGAINST RISK OF FIRE, REPLACE ONLY

WITH SAME TYPE AND RATING OF FUSE

PS B

200-240V: T6.3A, 250V

L

E

N

PS C PS A

N

E

L

Red

Yellow/

green

OUTPUTS

289 - 320

N

E

L

Plain

black

PS IFC FAN IFC

XPT BUS

COM BUSCOM BUS

LEVEL

SUPER

0

0

2

32

14

96

112

15

16

1

80

13

48

3

64

4

64

12

80

5

48

11

16

112

79

32

96

610

8

0

ULTRA

FRAME

MONITOR

1024

0

512

1536

2

14

15

1

13

3

2048

4

12

5

11

7

9

6

10

8

INPUTS

INPUTS

OUTPUTS

OUTPUTS

INPUTS

289 - 320

353 - 384

321 - 352

257 - 288

1

2

REF IN

COM BUS

CONSOLE A

4

3

REF IN

COM BUS

CONSOLE B

GPIO/TC

XPT BUS

CONTROL

DV-33512

ALARM

INPUT EXPAND

OUTPUT EXPAND

SYNC REDUNDANT

INT XPT CNTL

60Hz ENABLE

A

B

C

INPUTS

INPUTS

353 - 384

321 - 352

PRIMARY

NIC A

SECONDARY

NIC B

FRAME IFC

Blue

DC INPUT

42 - 54 VDC

30-24 AMPS

PS B PS A

DV-33128

PRIMARY

SECONDARY

NIC B

NIC A

DV-33256

PS B

PS A

IN EXPAND

96

112

OP EXPAND

80

VIT REDUNDANT

64

INT XPT CNTL

48

60Hz ENABLE

16

32

A

ULTRA

B

C

DC INPUT

42 - 54 VDC

30-24 AMPS

DC IN -DC IN +

WARNING: FOR CONTINUED PROTECTION

PS B

L

E

N

INPUTS INPUTS

33-641-32

17

1

1

18

2

2

19

3

3

20

4

4

21

5

5

22

6

6

23

7

7

24

8

8

25

9

9

DC IN -DC IN +

26

10

10

27

11

11

28

12

12

29

13

13

30

14

14

31

15

15

32

16

16

AGAINST RISK OF FIRE, REPLACE ONLY

PS A

WITH SAME TYPE AND RATING OF FUSE

115: 12.5A 250V SLOW BLOW

230: T6.3A 240V

N

E

AUTO SELECT

L

100-130V/200-240V

10.0A/5.0A

47-63HZ

INPUTS

OUTPUTS

INPUTSINPUTS

OUTPUTS OUTPUTS

17

17

17

17

1

1

1

1

18

18

18

18

2

2

2

2

19

19

19

19

3

3

3

3

20

20

20

20

4

4

4

4

21

21

21

21

5

5

5

5

22

22

22

22

6

6

6

6

23

23

23

23

7

7

7

7

24

24

24

24

8

8

8

8

25

25

25

25

9

9

9

9

26

26

26

26

10

10

10

10

27

27

27

27

11

11

11

11

28

28

28

28

12

12

12

12

29

29

29

29

13

13

13

13

30

30

30

30

14

14

14

14

31

31

31

31

15

15

15

15

32

32

32

32

16

16

16

16

MONITOR

OUTPUTS

OUTPUTS

OUTPUTS OUTPUTSOUTPUTS

OUTPUTS

17

17

17

17

1

1

1

1

18

18

18

18

2

2

2

2

19

19

19

19

3

3

3

3

20

20

20

20

4

4

4

4

21

21

21

21

5

5

5

5

22

22

22

22

6

6

6

6

23

23

23

23

7

7

7

7

24

24

24

24

8

8

8

8

25

25

25

25

9

9

9

9

26

26

26

26

10

10

10

10

27

27

27

27

11

11

11

11

28

28

28

28

12

12

12

12

29

29

29

29

13

13

13

13

30

30

30

30

14

14

14

14

31

31

31

31

15

15

15

15

32

32

32

32

16

16

16

16

31

OP

OP

MON

MON

42

COM BUS

COM BUS

1

CONSOLE

CONSOLE

B

A

REF

REF

IN

IN

432

LEVEL

0

SUPER

0

14

32

2

15

16

1

13

48

3

12

64

4

11

5

80

79

112

6

10

96

8

0

FRAME

128

0

14

384

2

256

15

1

13

512

3

12

4

5

11

79

6

10

8

17

1

18

2

19

3

20

4

21

5

22

6

23

7

24

8

25

9

26

10

27

11

28

12

29

13

30

14

31

15

32

16

CROSSPOINT BUS

GPIO/TC

CONTROL

ALARM

INPUTS

INPUTS

INPUTS INPUTS

INPUTS

193-224161-192 225-256

129-160

225-256193-224129-160 161-19265-9633-64 97-1281-3297-12865-96

17

17

17

17

17

1

18

18

2

19

19

3

20

20

4

21

21

5

22

22

6

23

23

7

24

24

8

25

25

9

26

26

10

27

27

11

28

28

12

29

29

13

30

30

14

31

31

15

32

32

16

17

1

1

1

1

18

18

18

18

2

2

2

2

19

19

19

19

3

3

3

3

20

20

20

20

4

4

4

4

21

21

21

21

5

5

5

5

22

22

22

22

6

6

6

6

23

23

23

23

7

7

7

7

24

24

24

24

8

8

8

8

25

25

25

25

9

9

9

9

26

26

26

26

10

10

10

10

27

27

27

27

11

11

11

11

28

28

28

28

12

12

12

12

29

29

29

29

13

13

13

13

30

30

30

30

14

14

14

14

31

31

31

31

15

15

15

15

32

32

32

32

16

16

16

16

White

Yellow

White

Yellow

Table 2. DC power cord pinouts.

Trinix DC Input connector Cable description

(Ground) Yellow/green

Plain black

DC IN + (left) 1 (red)

DC IN + (right) 2 (blue)

DC IN - (left) 3 (white)

DC IN - (right) 4 (yellow)

TRX-PS-BU Series Installation Manual 20

Page 21

Installation

Procedure

The following procedure will not disrupt normal operation of the router.

1. Install the supplied TPCP R1U3-B power supply frame(s).

The frames are shipped with the DC cables already connected.

The power supply frames should preferably be mounted in the same

equipment rack as the Trinix, but they may be mounted in an adjacent

rack if necessary. The cables provided for connection to the Trinix are

approximately nine feet (2.7 m) long.

No special ventilation spacing is needed for these frames since the

airflow is from front to back.

2. Connect the DC power cable(s) to the Trinix rear panel DC Input

connector(s).

Section 2

See Table 2 fo r pinout information.

3. Connect the supplied AC power cords.

All LEDs on the front of the power supply array(s) should now be

green.The left LED of each supply monitors AC; the right LED monitors

DC.

4. Check the DC voltage now being provided at the Trinix “DC In”

connector(s). Voltage should be between 47.0 and 48.5 VDC.

5. At an appropriate time, check the fail-over function of the new

supplies.This procedure should not cause any interruption to router

operation; however, Grass Valley recommends that you perform this

check when the consequences of possible signal interruption are at a

minimum.

• For DV-33128 and DV-33256 units, pull both internal power supplies out a few inches. The r outer should r emain powere d up. Push

the internal supplies back into position.

• For DV -33512 units, f irst make su re that both power supply frames

are installed and powered on per the above procedure. Open the

main chassis door. Open the power supply chassis and pull the A

and B supplies out a few inches. The r outer should remain power ed

up. Replace the A and B supplies. Pull the C and D supplies; the

router should remain powered. Replace the C and D supplies.

TRX-PS-BU Series Installation Manual 21

Page 22

Section 2 — Installation

6. This completes the installation.

22 TRX-PS-BU Series Installation Manual

Page 23

Specifications

Mechanical

Table 3. Mechanical Specifications

TRX-PS-BU1200 11.56 in. / 294 mm 19.0 in. / 483 mm 1.75 in. / 44 mm 7.2 lb. / 3.2 kg 1

TRX-PS-BU2400 11.56 in. / 294 mm 19.0 in. / 483 mm 1.75 in. / 44 mm 10.3 lb. / 4.6 kg 1

TRX-PS-BU3600 11.56 in. / 294 mm 19.0 in. / 483 mm 1.75 in. / 44 mm 13.5 lb. / 6.1 kg 1

a

Allow a minimum of 6 in. (152 mm) of clear space at the rear of the MCP for proper cable clearance and air flow.

b

All weights approximate.

Depth

Appendix A

, a

Width Height Weight

b

Rack Units

Environmental

T able 4.

Air Intake/Exhaust Locations

All modules draw cooling air through fans in the front. Warm air is

exhausted through openings in the back. It is not necessary to leave open

space above or below the chassis.

Environmental Characteristics (operation with required forced air cooling)

Operating temperature 32 to 158 degrees F (0 to 70 degrees C) ambient

Full specifications met 32 to 122 degrees F (0 to 50 degrees C)

Storage temperature -40 to 185 F (-40 to +85 degrees C)

TRX-PS-BU Series Installation Manual 23

Page 24

Appendix A — Specifications

Electrical

Table 5.

Total Output Power,

Continuous, Max

Input voltage range 85 - 264 VAC

Input frequency 47 - 63 Hz

Hot-swap operation Yes

800 - 1200 watts per module

24 TRX-PS-BU Series Installation Manual

Loading...

Loading...