Page 1

Instruction Manual

Grass Valley Series 6000

Compact Signal Management System

TP3529-02 A1

First Printing: November 1996

Page 2

Telephone Numbers

North America

(800) 547-8949

Fax: (530) 478-3181

Elsewhere

Distributor or sales office from

which equipment was purchased.

Web Addresses

Grass Valley Email Support

GVGSERVICE@tek.com

Grass Valley W eb Page

http://www.tek.com/Grass_V alle y

Tektr onix Web Site

http://www.tek.com

Customer Support

Tektronix Grass Valley Products is committed to providing the most

responsive and professional product support available. We have a fully

staffed, highly trained support team ready to respond to anything from a

simple question to an emergency repair . Support is available via telephone

or email. For new and updated customer support documents, as well as

new product information, check the Tektronix web site and Grass Valley’s

web page.

Postal Addresses

Mail

Tektronix Grass Valley Products

P.O. Box 1114

Grass Valley, CA 95945

Shipping

Tektronix Grass Valley Products

400 Providence Mine Rd.,

Nevada City, CA 95959

Copyright © Tektronix, Inc. All rights reserved. Printed in U.S.A.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material. Specifications

and price change privileges reserved. TEKTRONIX, TEK, Grass Valley Group, Borderline,

E-MEM, TEN-X, Wavelink, and are registered trademarks, and Air Link, Auto Match,

Doubletake, E-Disk, Eagle V, Emphasys, EZ-Link, 409, Grass Valley, Horizon, Jogger, Kadenza, Kaleidoscope, K-Mask, Key-Layer, Key-Link, Krystal, MASTER System, Master 21,

MAX, Omni-Key, Performer, Programmed Motion, Silhouette, Softset, SqueezeBack,

Streamline, Super Edit, TEN-20, 20-TEN, Trace, TrailBlazer, VideoDesktop, Flex-Time, and

XEDL are trademarks of Tektronix, Inc. P.O. Box 1000 Wilsonville, OR 97070-1000 U.S.A.

The information in this manual is furnished for informational use only, is subject to change

without notice, and should not be construed as a commitment by Tektronix, Inc. Tektronix

assumes no responsibility or liability for any errors or inaccuracies that may appear in this

publication.

Tektronix, Inc., Video and Networking Division, P.O. Box 1114 Grass Valley, California

95945 U.S.A.

Page 3

Page 4

Page 5

Page 6

Contents

Important Safeguards and Regulatory Notices

Symbols and Their Meanings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Power Cord Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

North American Power Supply Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

International Power Supply Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Section 1 — Introduction

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

The System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

The Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Analog Video Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Signal Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Crosspoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Serial Digital Video Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Signal Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Crosspoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Analog Audio Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Crosspoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

AES/EBU Digital Audio Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Crosspoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Data Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Crosspoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

vii

Page 7

Contents

Section 1—Introduction (continued)

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Configuration Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Control Bus Quick-Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Computer Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Serial Interface SMS–CSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Installation in Matrix Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

RS422 or RS232 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Baud Rate and Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

External Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

The RS232 Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Local Control Panel SMS–CMXY-LP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Power System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Cooling Fan - 1RU frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Cooling Fan - 3RU frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Ground and Power Fail Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Remote Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

General Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Section 2 — Installation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Physical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Remote Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Equipment Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Video Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Video Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Audio Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Data Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Control — Quick-Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

RS232/422 Computer Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Joystick Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Setting the Power Line Voltage in the Frames . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Setting the Power Line Voltage in the Panels . . . . . . . . . . . . . . . . . . . . . . . . 2-11

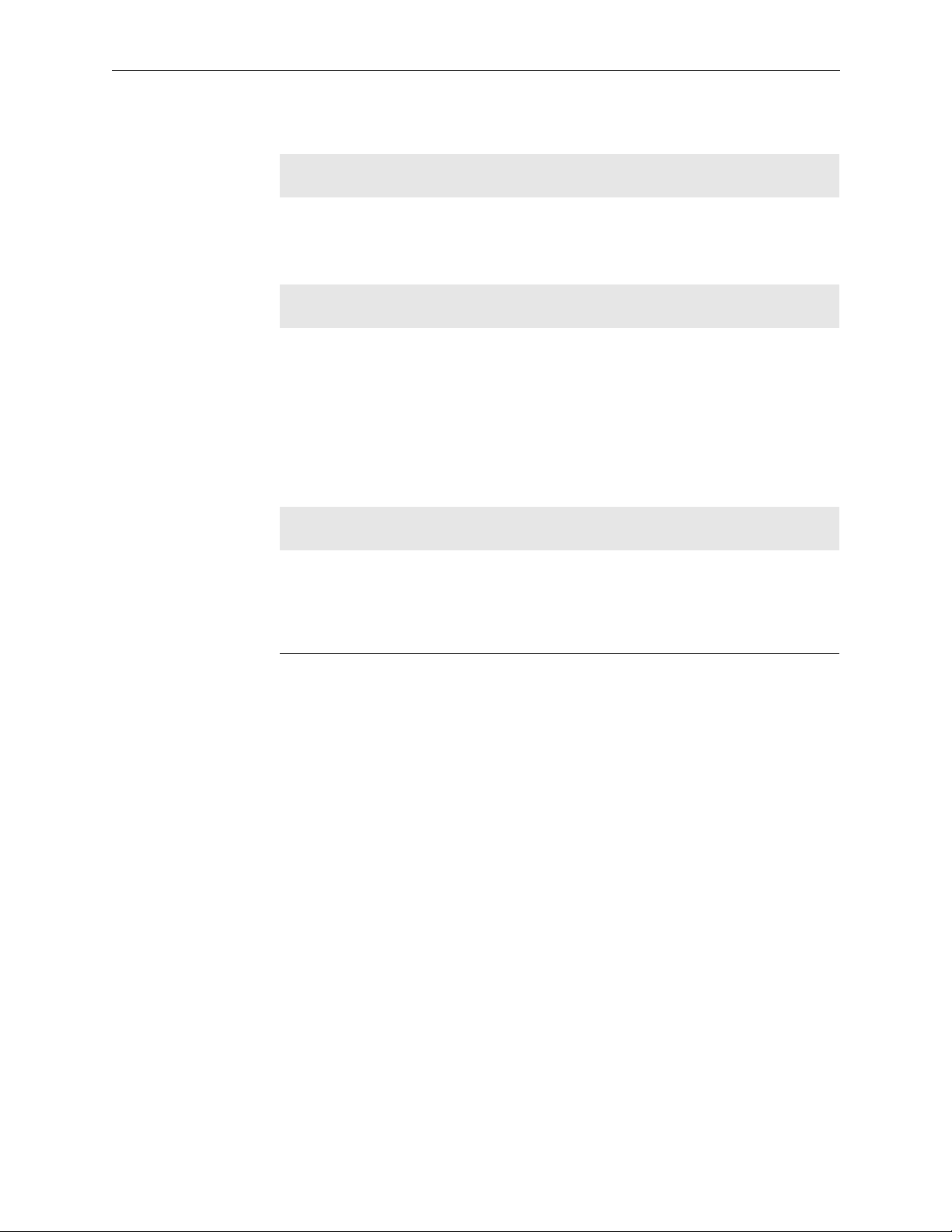

Frame and Parallel I/F Rear Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

viii

Page 8

Configuring the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Analog Video Matrix Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Input Coupling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Serial Digital Video Matrix Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Input Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

TV Line Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Frame Priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Address Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Configuring Remote Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Panel Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

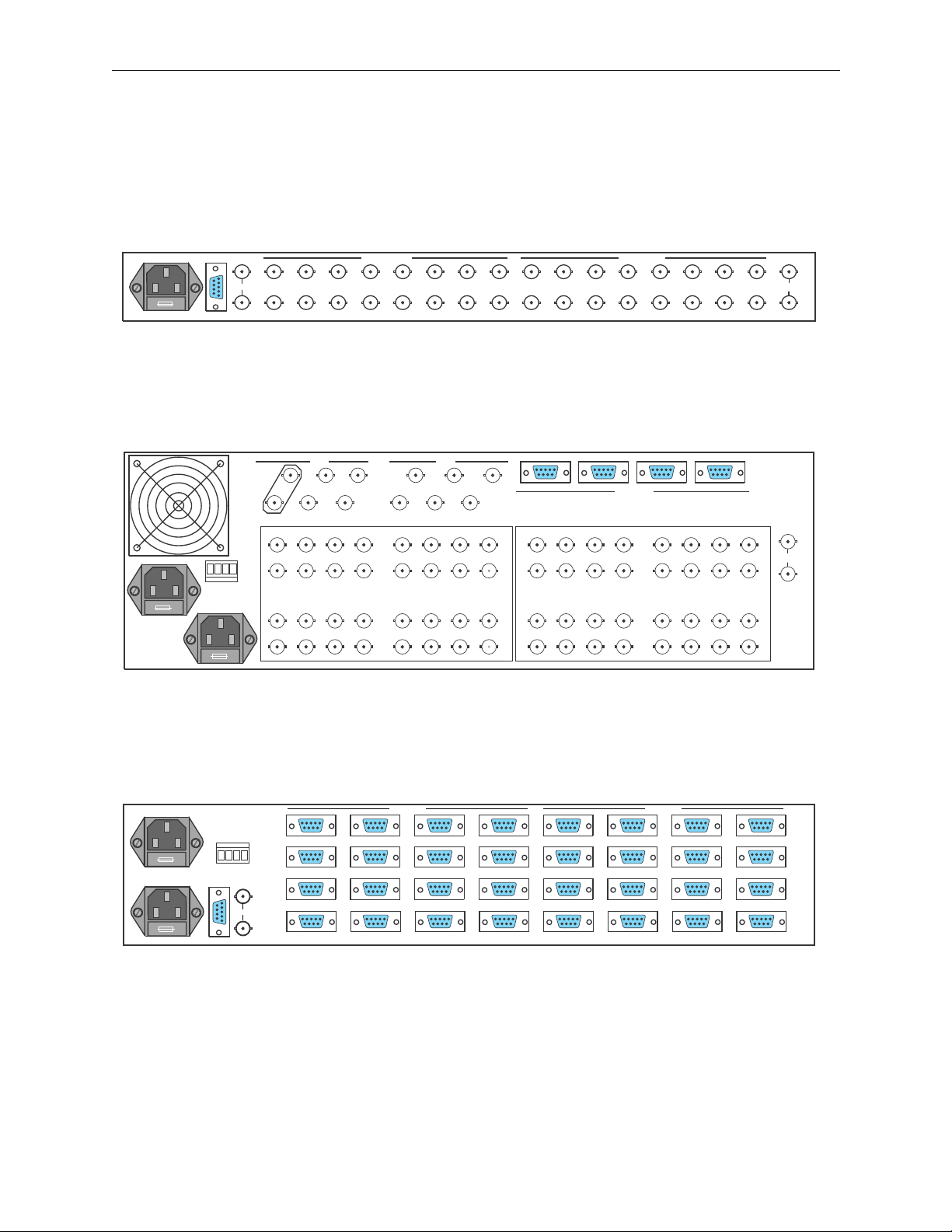

Control Panel Front Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Section 3 — SMS-6000 Configuration Editor

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Configuring the SMS-6000 Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Create a New Configuration, or Open and/or Copy an Existing One . . . . 3-3

Create (or Change, if Desired) the Configuration Items . . . . . . . . . . . . . . . . 3-4

Pre-Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Simple Frames, Virtual Matrices, Levels, Sources, and Destinations . . 3-5

Partial Frame and Custom Multi-Xpt: Frames, Virtual Matrices, and Lev-

els . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Sources and Destinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Save the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Download the Configuration to Your SMS-6000 Router . . . . . . . . . . . . . . . 3-24

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Actions Windows Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Delete Confirmation Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Comm Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Button Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Help Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Contents

ix

Page 9

Contents

Section 4 — Control Panels

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

SMS–CMXY Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Designation Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Computer Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Destinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Breakaways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Chop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Joystick or Microswitch Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

SMS–C16BPS Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Designation Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Chop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Joystick or Microswitch Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

SMS-CXY Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Destinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Take Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Breakaways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Chop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Sleep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Joystick or Microswitch Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

SMS-C32BPS Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Destinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Breakaways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Joystick or Microswitch Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

x

Page 10

Section 5 — Maintenance

Module Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Finding Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Initial Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Reset Microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Edge Connector Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Common Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Remote Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Further Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Analog Video Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Insertion Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Frequency Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Audio Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Insertion Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Serial Digital Video Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Input Standard Phase-Locked Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Cooling Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

3RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Cleaning the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Replacing the Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

1RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Replacing the Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Replacing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Contents

Appendix — Remote Control Protocol

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Set crosspoint Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Free (Unlock) System, Level, Or Destination . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Interrogate Crosspoint Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Crosspoint Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Special Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Acknowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

xi

Page 11

Contents

List of Illustrations

Figure 1-1. Series 6000 Compact Signal Management System . . . . . . . . . . . . . . . . . . 1-1

Figure 1-2. Serial Interface Jumper Setiings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

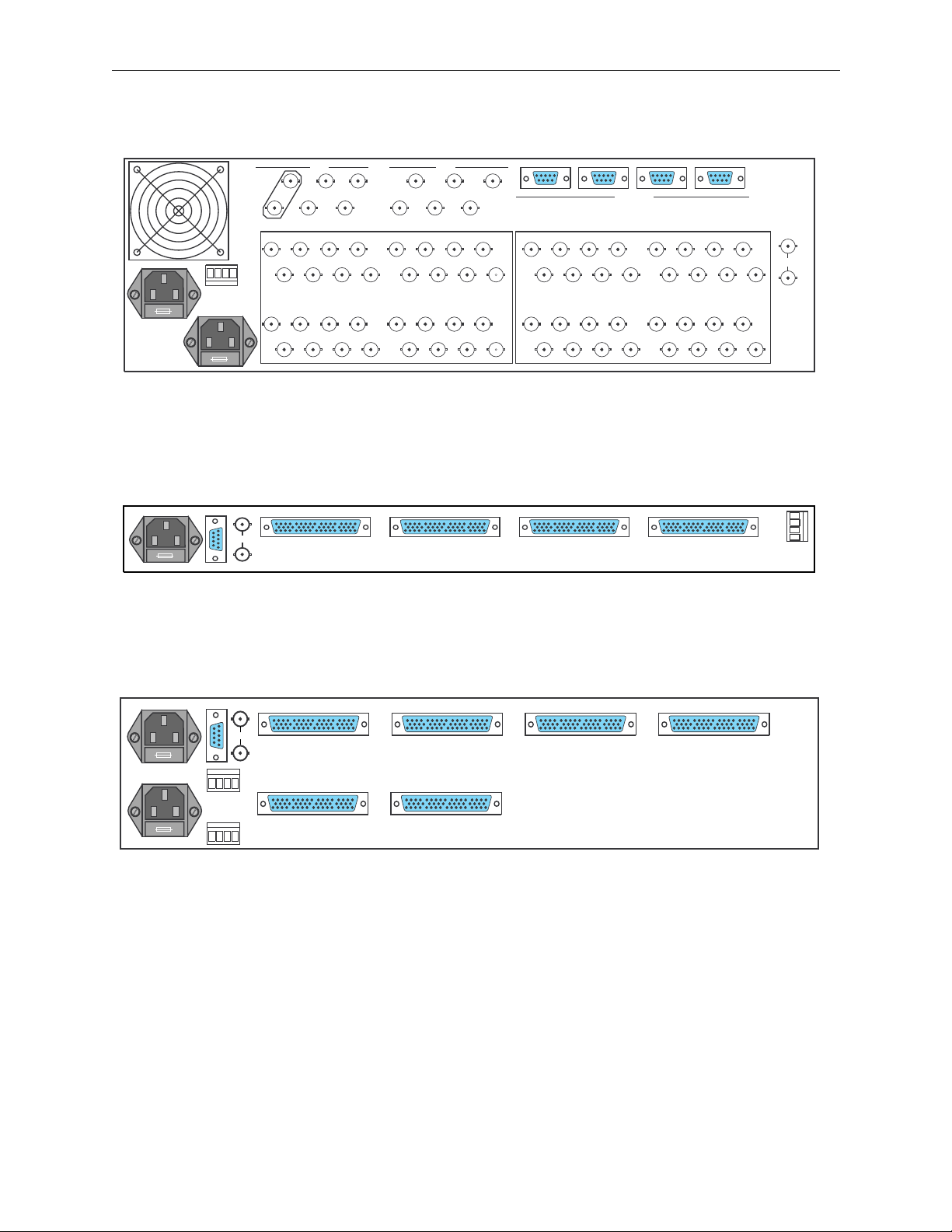

Figure 2-1. 16x4 and 16x16 Video Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-2. 32x32 Analog Video Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-3. Data Matrix Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

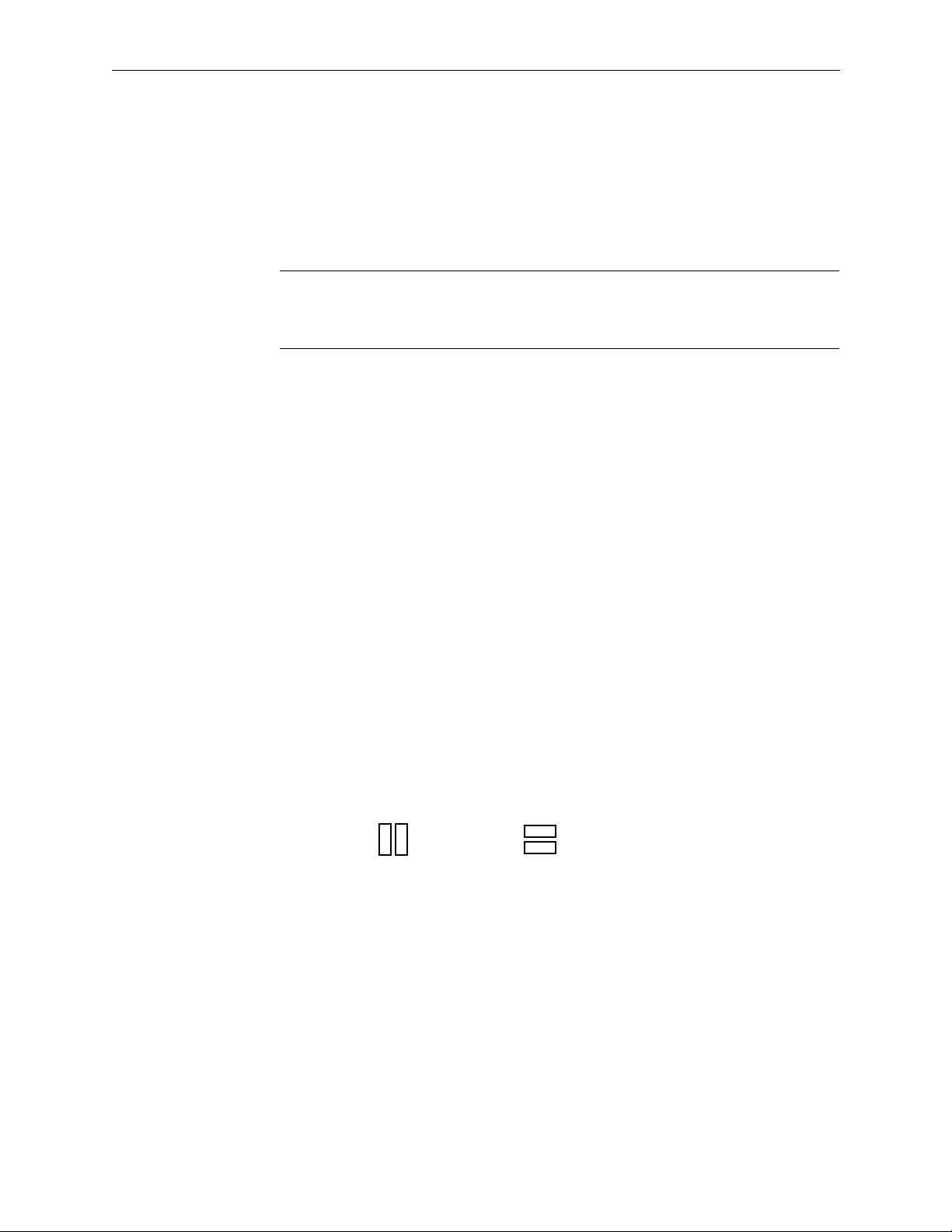

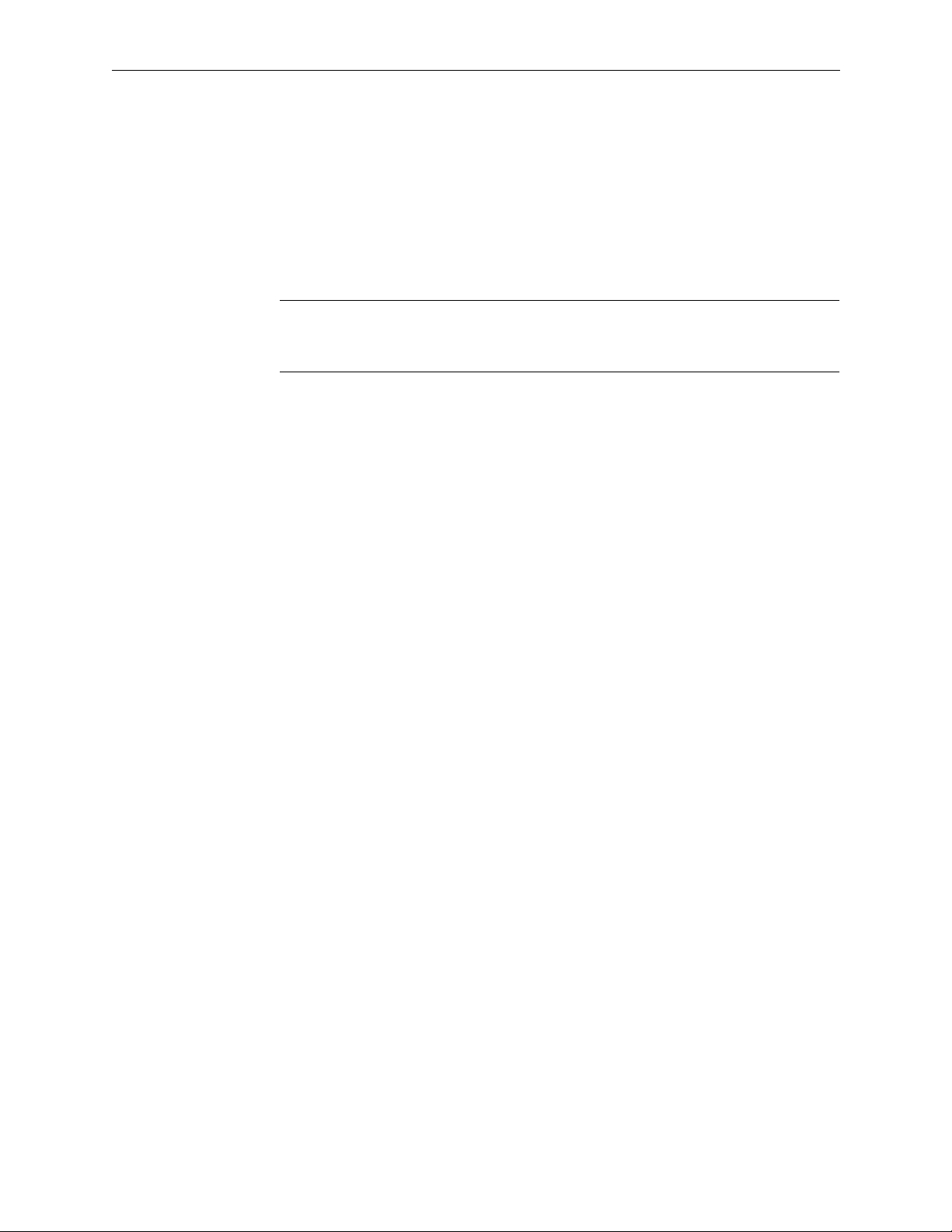

Figure 2-4. 32x32 Serial Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-5. 16x4 and 16x16 Audio Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-6. 32x32 Audio Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

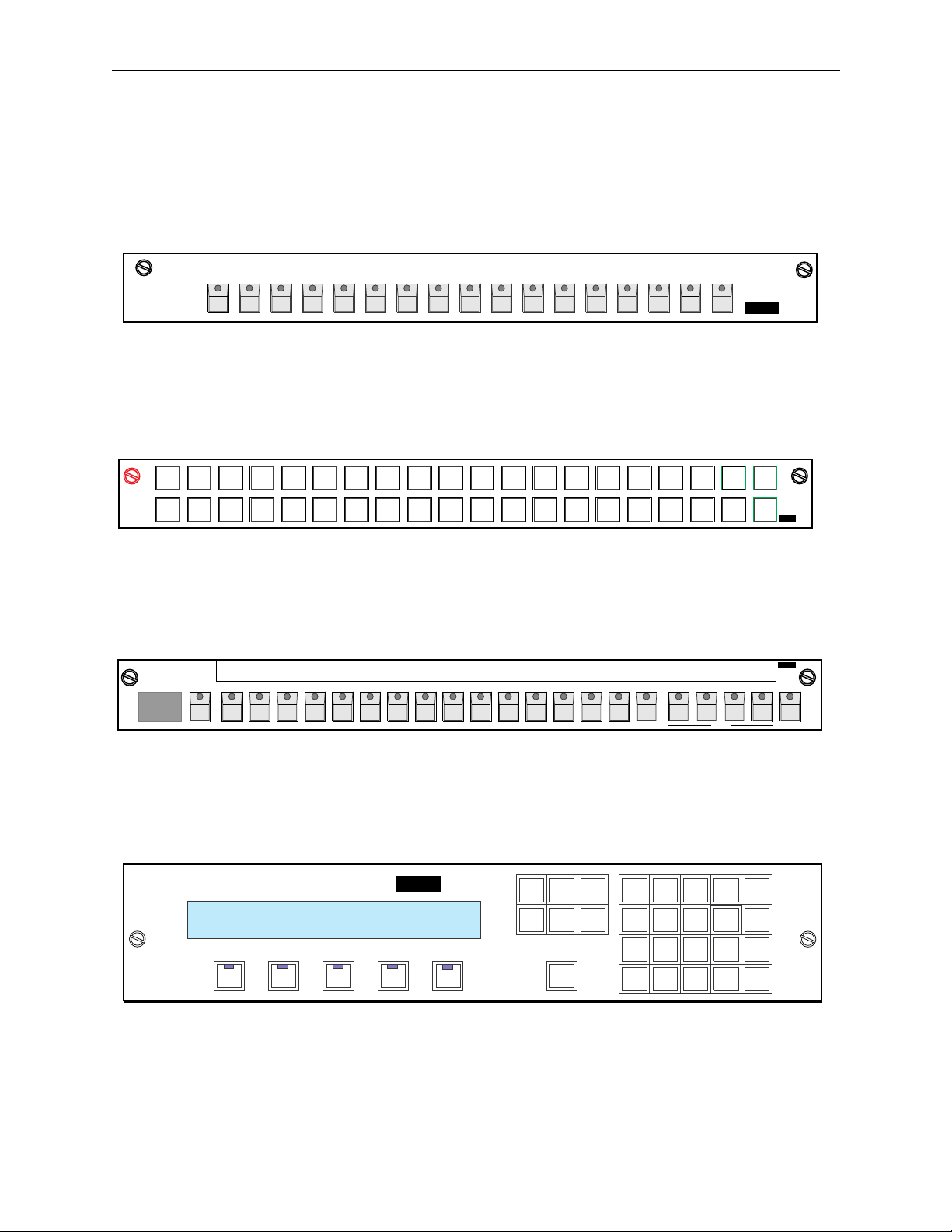

Figure 2-7. C16 Button Per–Source Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-8. C32 Button Per-Source Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-9. CMXY Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-10. CXY Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 3-1. Acrobat Reader Tool Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Figure 3-2. File, Open, and Save As Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

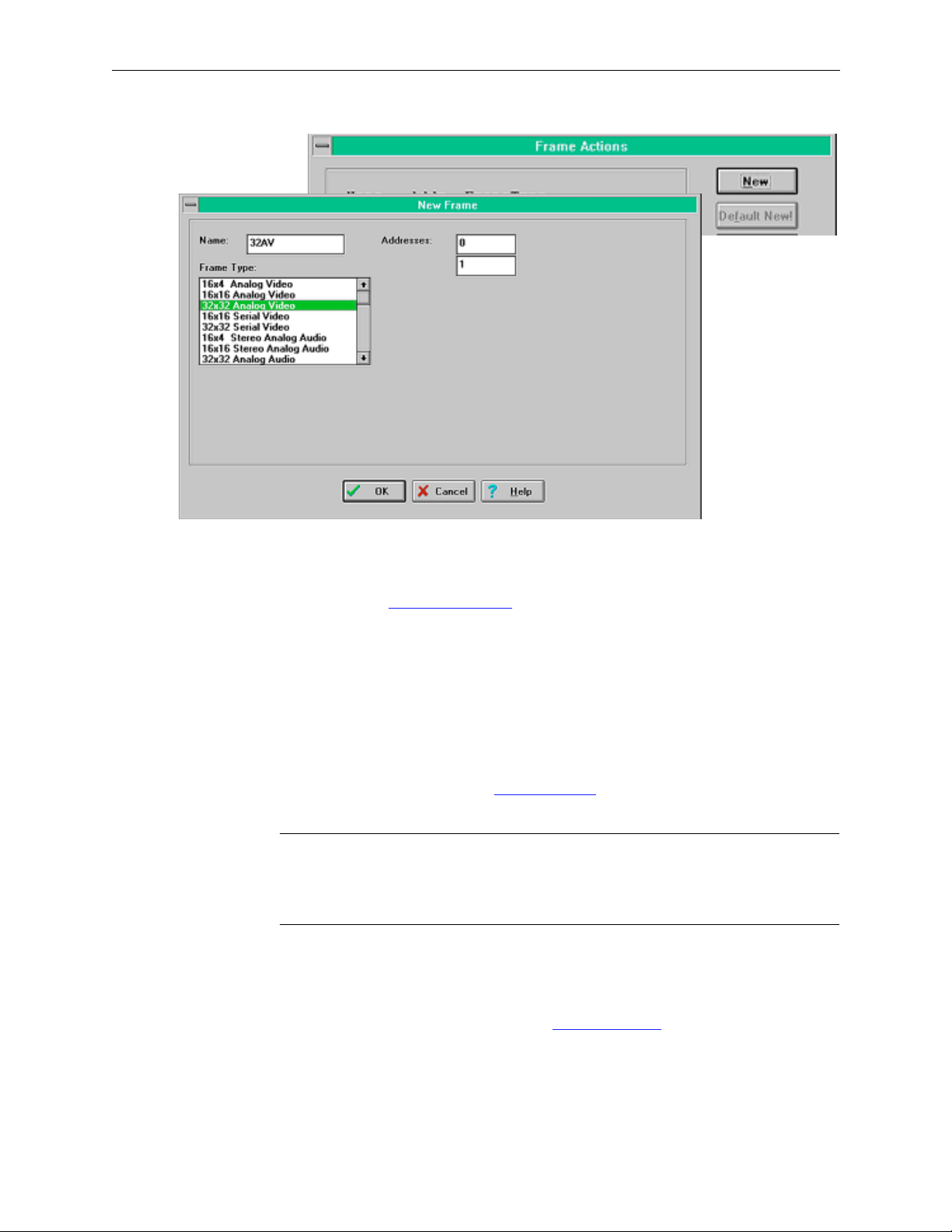

Figure 3-3. Creating a New Serial Video or Data Matrix Frame . . . . . . . . . . . . . . . . 3-6

Figure 3-4. Virtual Matrix Actions Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-5. Level Actions Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

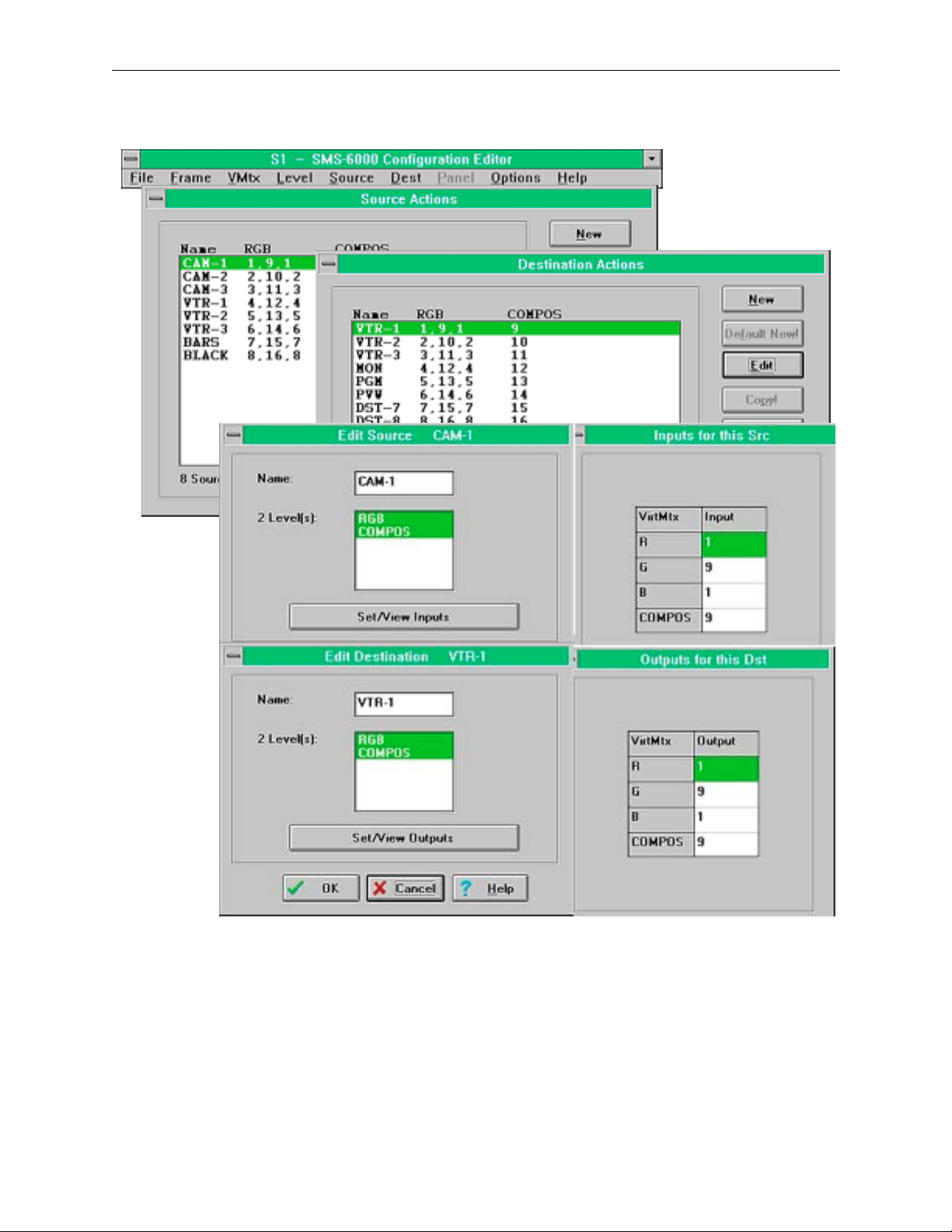

Figure 3-6. Source and Destination Actions Windows . . . . . . . . . . . . . . . . . . . . . . . . 3-8

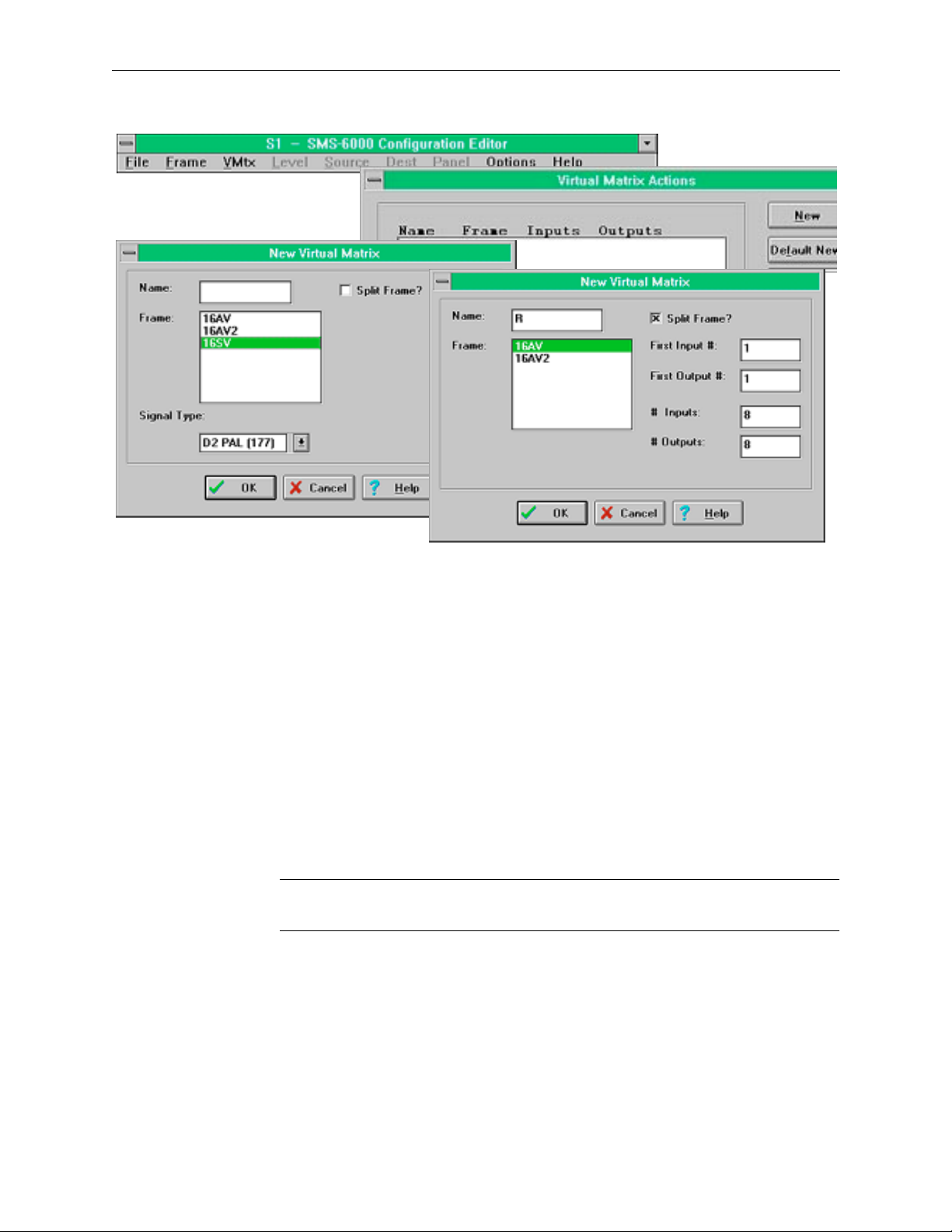

Figure 3-7. Partial Frames and Custom Multi-Xpts Frames Windows . . . . . . . . . . 3-10

Figure 3-8. Partial Frame and Multi-Xpt Frames Virtual Matrices Windows . . . . 3-11

Figure 3-9. Partial Frame and Custom Multi-Xpt Levels Windows . . . . . . . . . . . . 3-12

Figure 3-10. Partial Frame and Custom Multi-Xpt Sources and

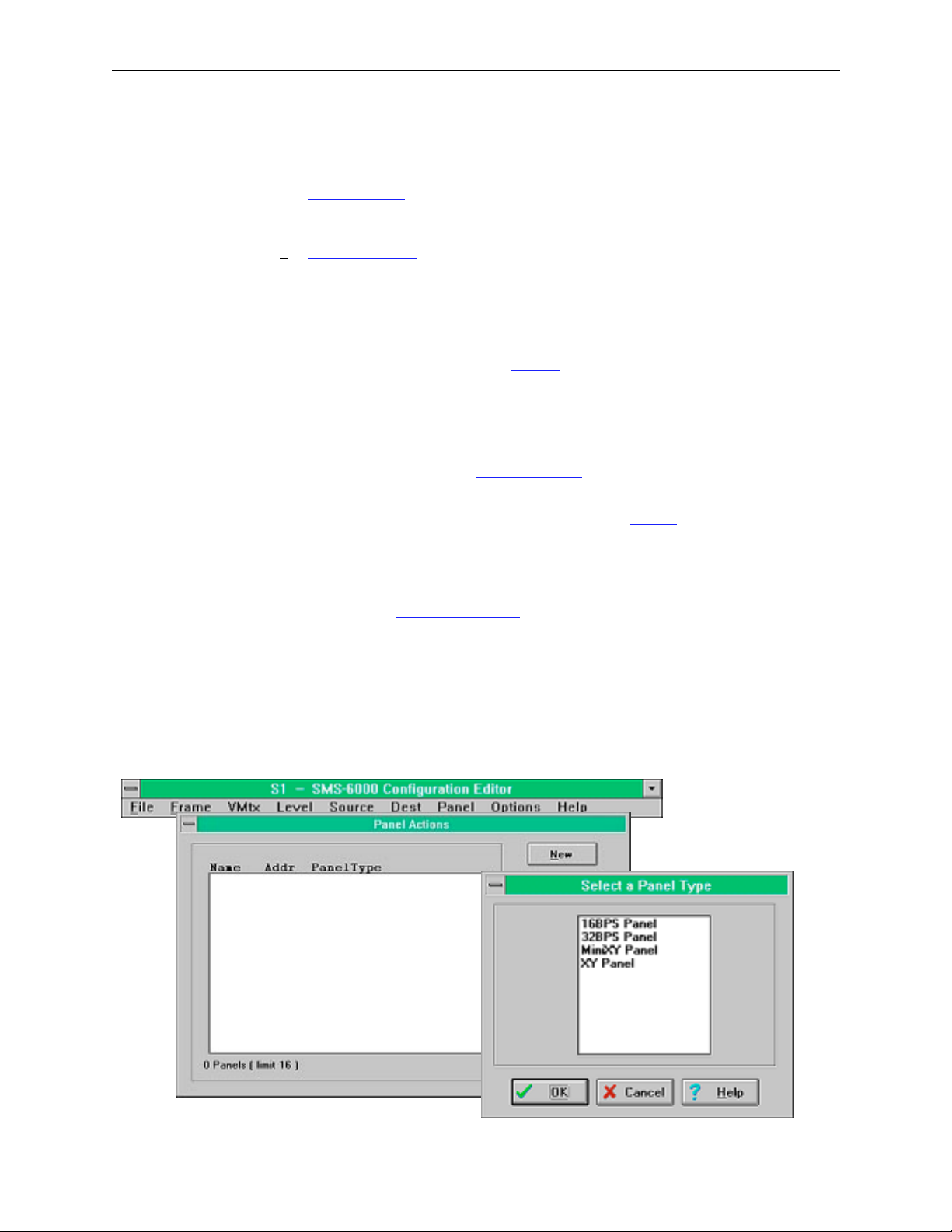

Figure 3-11. Panel Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

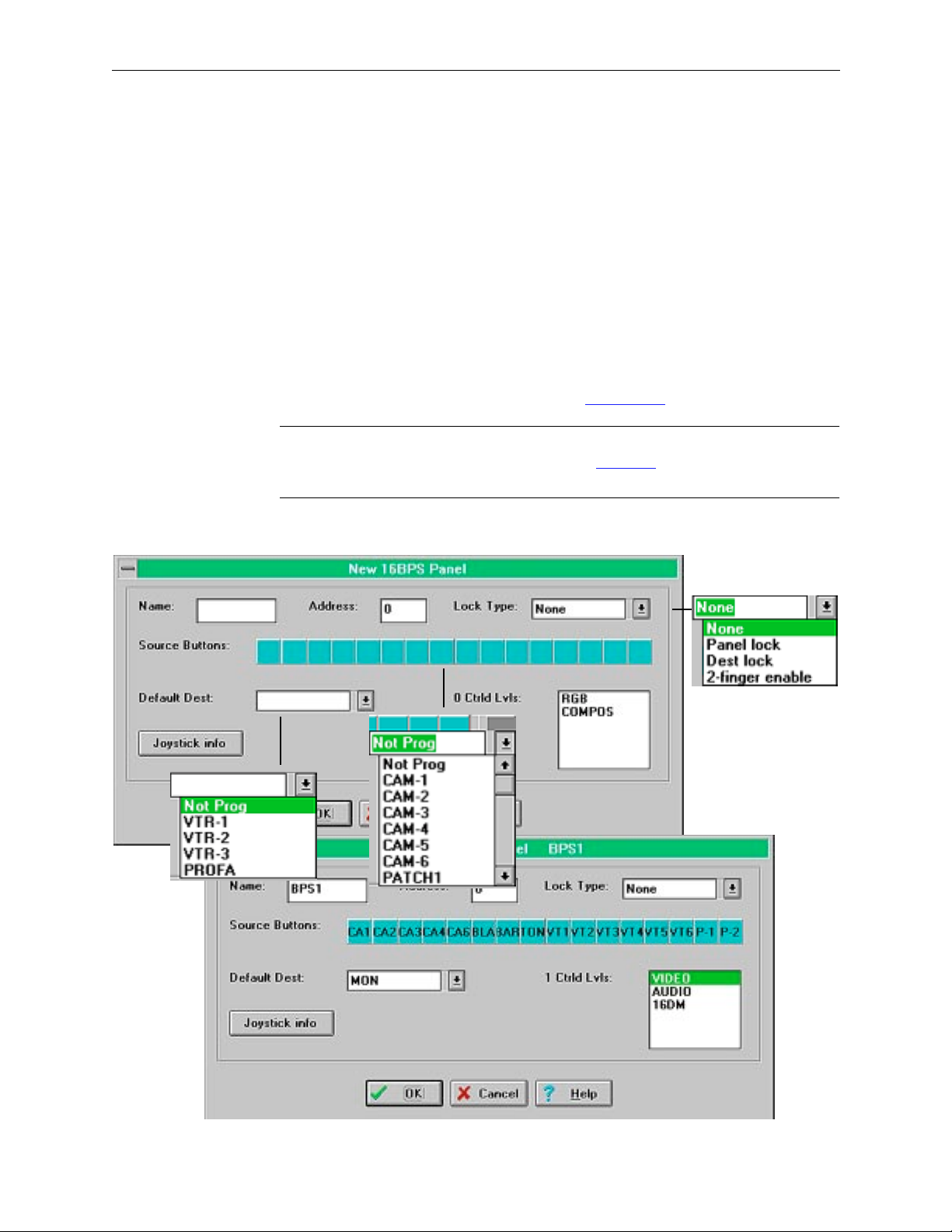

Figure 3-12. 16BPSPanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Figure 3-13. 32BPS Panel Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

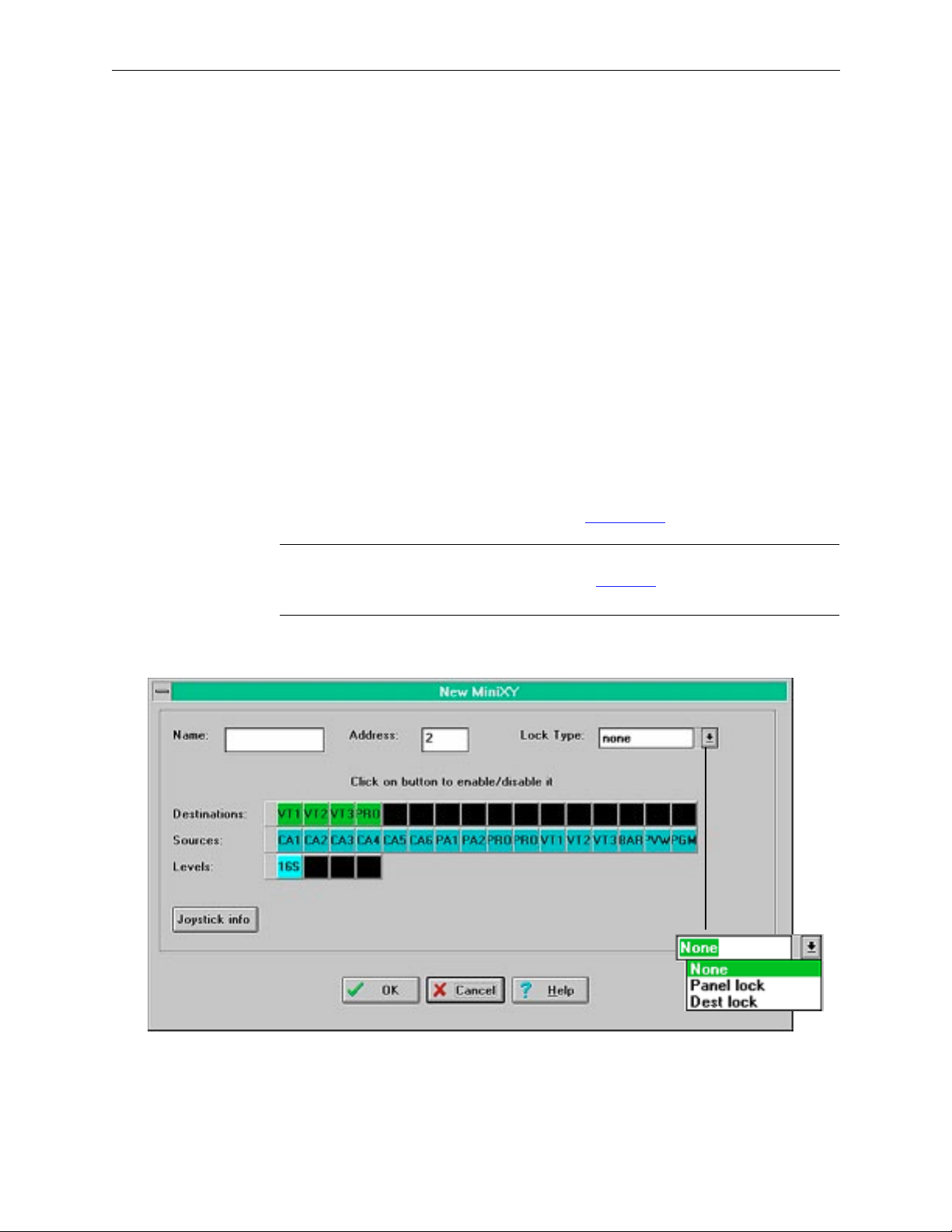

Figure 3-14. Mini XY Panel Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Figure 3-15. XY Keypad Panel Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Figure 3-16. Joy Stick Override Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Figure 3-17. Save Configuration Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Figure 3-18. Rotary, Dip, and Reset Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Figure 3-19. Download Status and Error Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Figure 3-20. Welcome Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Figure 3-21. File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Figure 3-22. Action Windows Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

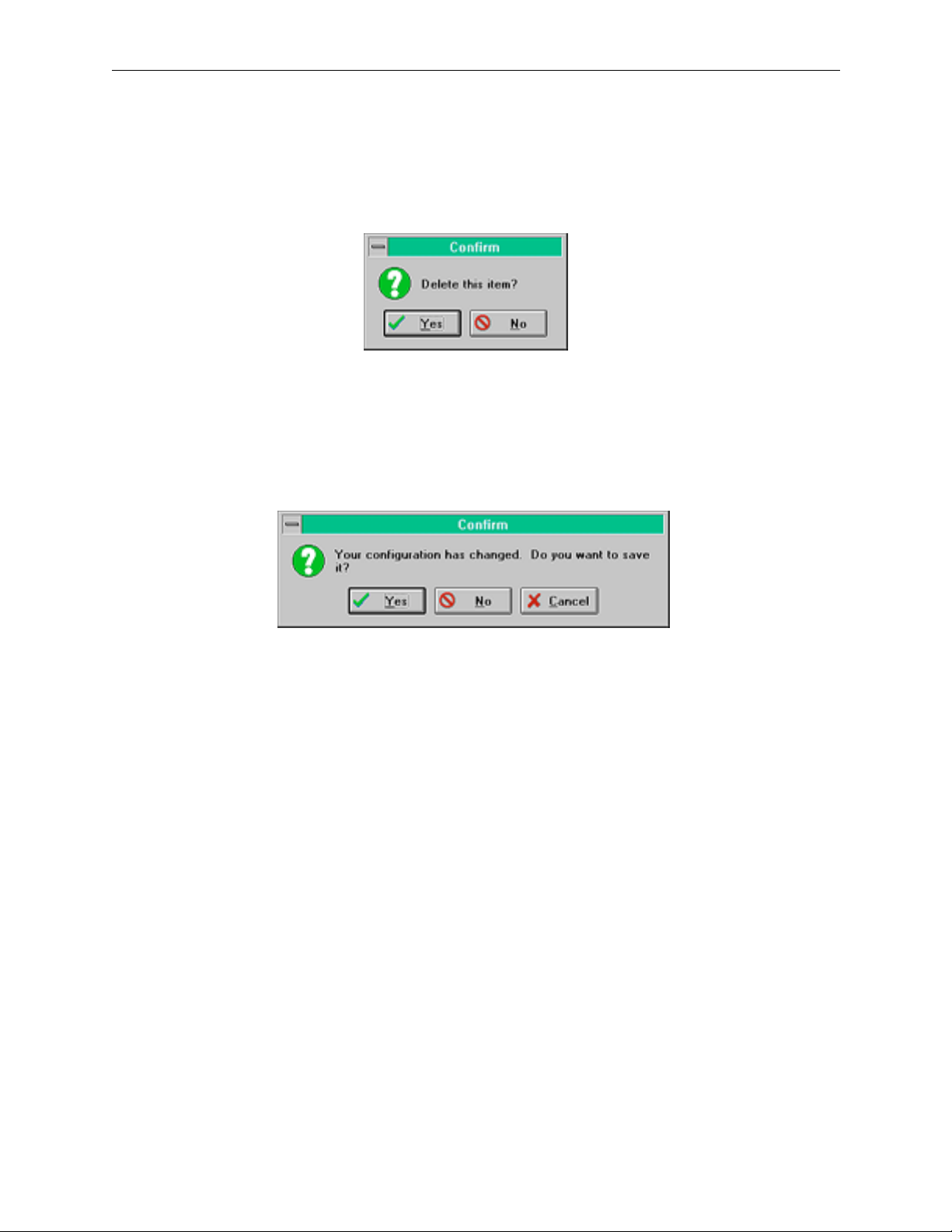

Figure 3-23. Delete Confirmation Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Figure 3-24. Exit Confirmation Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Figure 3-25. Comm Parameters and Button Colors Windows . . . . . . . . . . . . . . . . . . 3-28

Figure 3-26. Help Information Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Figure 3-27. About Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Figure 3-28. Open Window for On-Line Documentation . . . . . . . . . . . . . . . . . . . . . . 3-29

Destinations Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

xii

Figure 4-1. SMS–CMXY Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2. SMS–C16BPS Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-3. SMS-CXY Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-4. SMS-C32BPS Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Page 12

Contents

List of Tables

Table 1-1. Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table 1-2. RS232 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Table 1-3. RS232 and RS422 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Table 1-4. Personal Computer Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Table 1-5. Analog Video Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Table 1-6. Analog Audio Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Table 1-7. Serial Digital Video Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Table 1-8. AES/EBU Digital Audio Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Table 1-9. RS422 Control Level Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Table 2-1. Audio Input Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table 2-2. Audio Outputs Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Table 2-3. Data Matrix Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2-4. Joystick Override Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table 2-5. Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Table A-1. Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table A-2. RS232 and RS422 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Table A-3. Personal Computer Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Table A-4. Sample Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Table A-5. Sample Replies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table A-6. Multi-level Command Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table A-7. Sample Reply — Multi-level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Table A-8. Unlock Commands & Replies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Table A-9. Special Command Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Table A-10. Examples of Various Commands/Replies . . . . . . . . . . . . . . . . . . . . . . . A-10

xiii

Page 13

Contents

xiv

Page 14

Important Safeguards and

Regulatory Notices

Information on the following pages provides important safety guidelines

for both Operator and Service Personnel. Specific warnings and cautions

will be found throughout the manual where they apply, but may not

appear here. Please read and follow the important safety information,

noting especially those instructions related to risk of fire, electric shock or

injury to persons.

WARNING

Any instructions in this manual that require opening the equipment cover or

enclosure are for use by qualified service personnel only . To reduce the risk

of electric shock, do not perform any servicing other than that contained in

the operating instructions unless you are qualified to do so.

Symbols and Their Meanings

The lightning flash with arrowhead symbol, within an equilateral triangle,

alerts the user to the presence of “dangerous voltage” within the

equipment’s enclosure that may be of sufficient magnitude to constitute a

risk of electric shock to persons.

The exclamation point within an equilateral triangle alerts the user to the

presence of important operating and maintenance (servicing) instructions

in the literature accompanying the equipment.

The fuse symbol indicates that the fuse referenced in the text must be

replaced with one having the ratings indicated.

This symbol represents an internal protective grounding terminal. Such a

terminal must be connected to earth ground prior to making any other

connections to the equipment.

xv

Page 15

Safeguards and Notices

Danger

This symbol represents an external protective grounding terminal. Such a

terminal may be connected to earth ground as a supplement to an internal

grounding terminal.

CAUTION

This equipment contains static sensitive components. Use anti-static grounding

equipment whenever handling or servicing modules and components. When circuit

modules are removed from the frame, place them on a flat static-controlled

surface. Failure to follow this precaution can result in component damage due to

electrostatic discharge.

Warnings

Electrical potential is still applied to some internal components even

■

when the power switch/breaker is in the off position. To prevent

electrical shock when working on this equipment, disconnect the AC

line cord from the AC source before working on any internal

components.

A residual voltage may be present immediately after unplugging the

■

system due to slow discharge of large power supply capacitors. Wait 30

seconds to allow capacitors to discharge before working on the system

■

<Specify any other dangerous conditions that apply to this equipment

here.>

■

Heed all warnings on the unit and in the operating instructions.

Do not use this equipment in or near water.

■

Disconnect ac power before installing any options.

■

■

The attachment plug receptacles in the vicinity of the equipment are all

to be of a grounding type, and the equipment grounding conductors

serving these are to be connected to earth ground at the service

equipment.

xvi

This equipment is grounded through the grounding conductor of the

■

power cord. To avoid electrical shock, connect the power cord to the

equipment and plug it into a properly wired receptacle before

connecting the equipment inputs and outputs.

■

Route power cords and other cables so that they are not likely to be

damaged.

Disconnect power before cleaning. Do not use liquid or aerosol

■

cleaners; use only a damp cloth.

Page 16

Safeguards and Notices

■

Dangerous voltages exist at several points in this equipment. To avoid

personal injury, refer all servicing to qualified personnel.

■

Do not wear hand jewelry or watches when troubleshooting high

current circuits, such as the power supplies.

■

During installation, do not use the door handles or front panels to lift

the equipment as they may open abruptly and injure you.

To avoid fire hazard, use only components of the the specified type,

■

voltage and current rating as referenced in the appropriate parts list.

Always refer fuse replacement to qualified service personnel.

To avoid explosion, do not operate this equipment in an explosive

■

atmosphere unless it has been specifically certified for such operation.

■

Have qualified personnel perform safety checks after any completed

service.

■

To reduce the risk of electric shock, ensure that the two power supply

cords are each plugged into a separate branch circuit.

Cautions

■

If equipped with redundant power, this unit has two power cords. To

reduce the risk of electric shock disconnect both power supply cords

before servicing.

To prevent damage to equipment when replacing fuses, locate and

■

correct the trouble that caused the fuse to blow before applying power.

Verify that all power supply lights are off before removing the power

■

supply or servicing equipment.

Use only specified replacement parts.

■

Follow static precautions at all times when handling this equipment.

■

Leave the back of the frame clear for air exhaust cooling and to allow

■

room for cabling. Slots and openings in the cabinet are provided for

ventilation. Do not block them.

■

The front door is part of the fire enclosure and should be kept closed

during normal operation.

■

To prevent damage to this equipment read the instructions in this

document for proper input voltage range selection.

■

Circuit boards in this equipment are populated with surface mount and

ASIC components. Special tools and techniques are required to safely

and effectively troubleshoot and repair modules that use SMT or ASIC

components. For this reason, service and repair of Grass Valley

products incorporating surface mount technology are supported only

on a module exchange basis. Customers should not attempt to

troubleshoot or repair modules that contain SMT components.

Teltrpmox assumes no liability for damage caused by unauthorized

repairs. This applies to both in- and out-of-warranty products.

xvii

Page 17

Safeguards and Notices

Power Cord Notices

North American Power Supply Cords

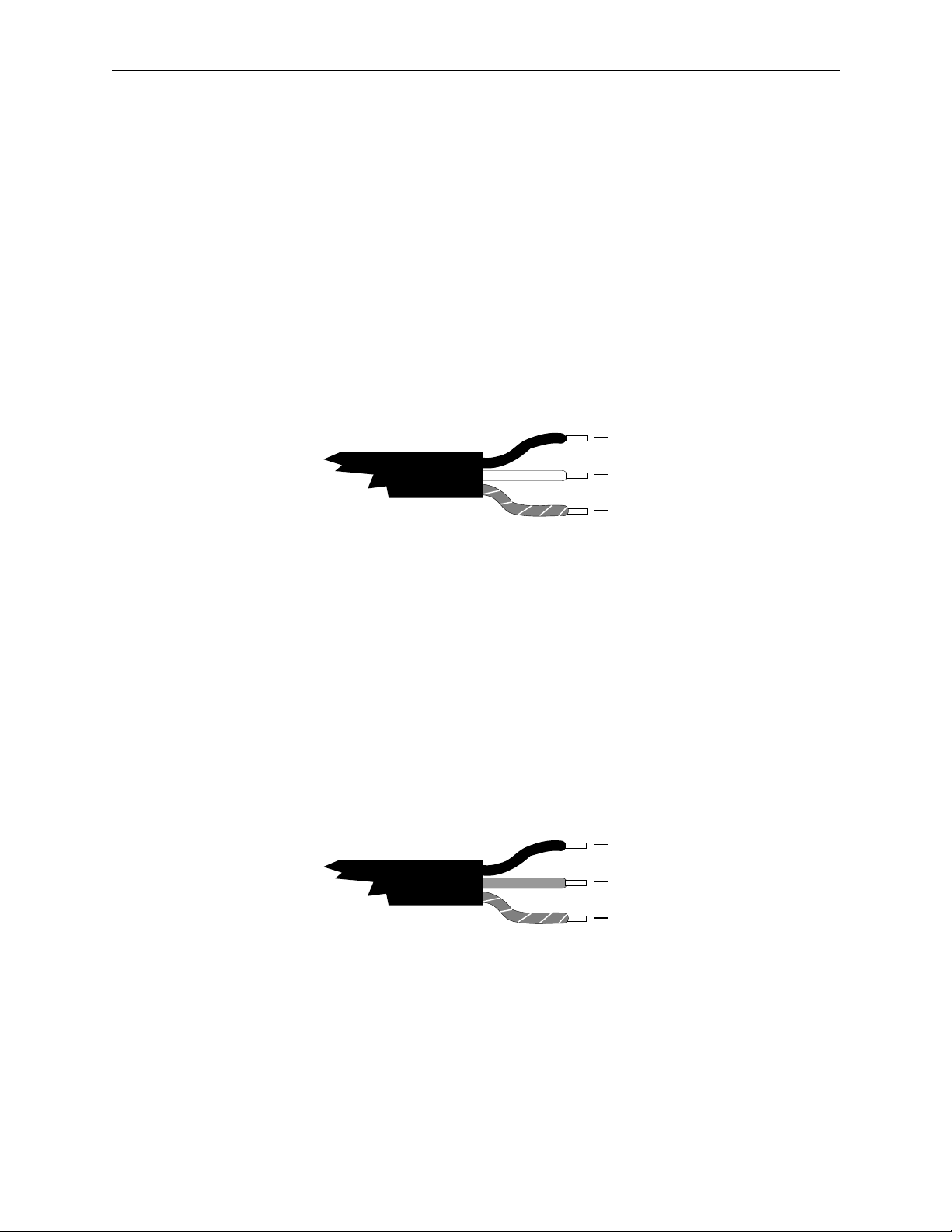

This equipment is supplied with a molded grounding plug (

at one end and a molded grounding receptacle (IEC 320-C13) at the other

end. Conductors are color coded white (neutral), black (line) and green or

green/yellow (ground).

Operation of this equipment at voltages exceeding 130 Vac will require

power supply cords which comply with NEMA configurations.

International Power Supply Cord

This equipment is supplied with a molded grounding receptacle (IEC 320-

C13) at one end and stripped conductors (50/5 mm) at the other end.

Conductors are CEE color coded—light blue (neutral), brown (line) and

green/yellow (ground). Other IEC 320 C-13 type power supply cords can

be used if they comply with the safety regulations of the country in which

they are installed.

Black

White

Green or Green

with Yellow stripe

Line

Neutral

Ground

(Earth)

NEMA 5-15P

NOTE: The

illustrated U.S. cord

is for 110/125 Vac

only.

For 220 Vac, the line

cord has two hot

lines and no neutral.

)

xviii

Brown

Blue

Green with

Yellow stripe

Line

Neutral

Ground

(Earth)

NOTE: This

international cord is

for both 110 and 220

Vac.

Europe uses singleor 3-phase 230 Vac,

with one hot line and

one neutral.

Page 18

1

Description

Introduction

The Series 6000 Compact Signal Management System has been designed

with the smaller routing switcher applications in mind. In sizes of 1RU,

2RU, or 3RU, it accommodates matrices from 16 x 4 to 32 x 32.

With the Series 6000, you can mix serial composite and component digital

video in the same frame. And you can combine routing matrices of

different formats to build a multiformat system that meets your exact

needs.

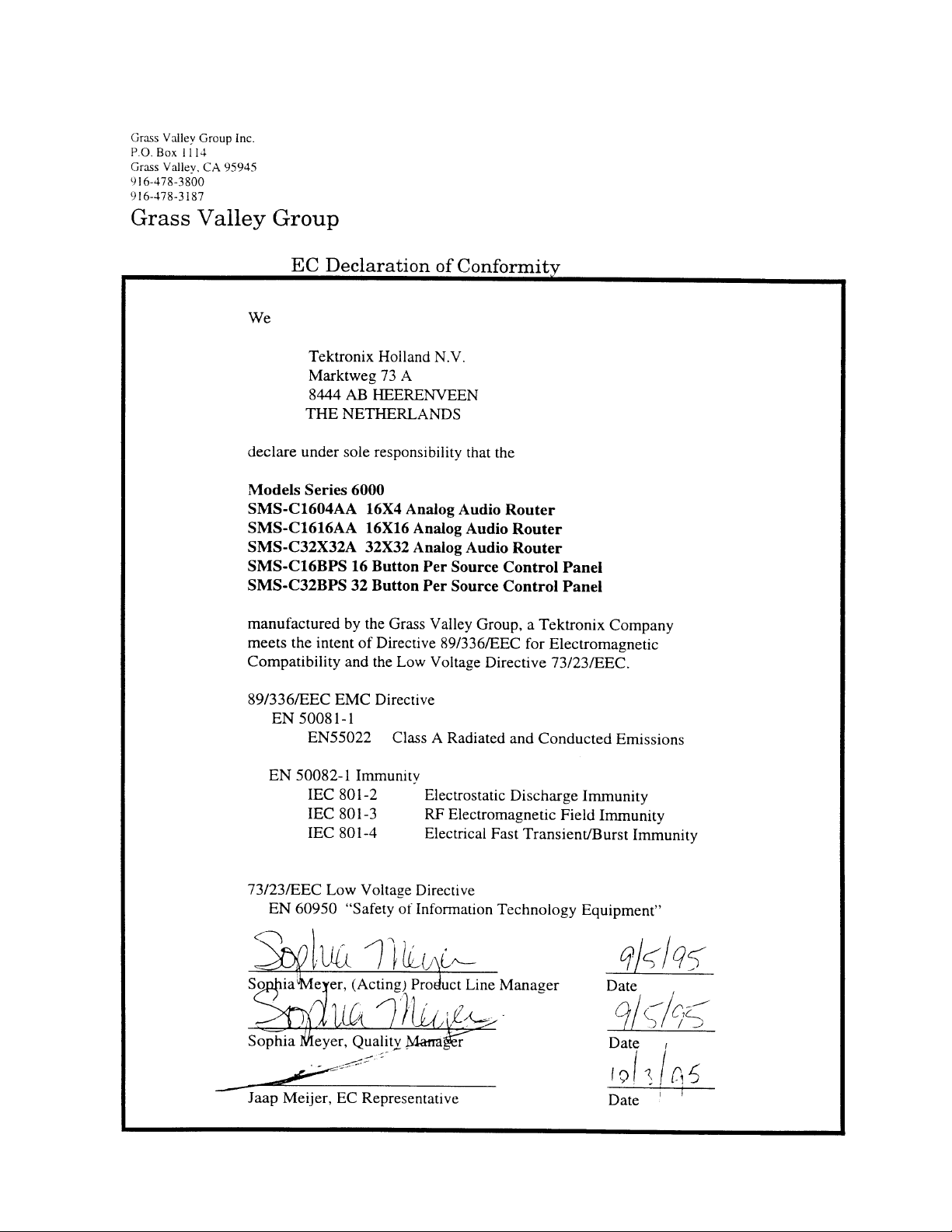

This section describes the features of the Series 6000 and how to apply them

in your own particular application. A Series 6000 system is illustrated in

Figure 1-1.

3529-00

Figure 1-1. Series 6000 Compact Signal Management System

1-1

Page 19

Section 1 — Introduction

The System

The Series 6000 system comprises video, audio and control level (RS422)

routers, all based on the standard block size of 16 inputs to 16 outputs.

Video and audio matrices are housed in separate rack-mount frames

complete with power supply and microprocessor control.

Units are stacked together to provide multiple levels. For example, a

system could be provided with serial digital, composite video, three levels

of component video, four levels of audio, time code and RS422.

Remote control panels are usually supplied as part of a system and these

are connected back to the frames by a single coax

each of the frames and remote control panels in the system.

Quick-Link Bus through

The Frame

The frames are of solid construction and house plug-in modules. The main

router modules — video, audio or control level — are located on the left-

hand side and the power supply module(s) on the right.

The plug-in modules are positively locked in place to prevent them from

coming loose when installed in a mobile vehicle. Yet they can be easily

removed from the front of the frame by removing the front panel/local

control panel and releasing the modules held in place by special quick

release handles. The modules may be removed while the unit is under

power.

Analog Video Routing

The Series 6000 analog video matrix is suitable for wideband applications.

There are two 1RU frames, 16x4 and 16x16. The 3RU 32x32 matrix is built

from four 16x16 modules. These are organized in pairs so that each pair

provides 32x16 (32 inputs to 16 outputs). The pair of modules is bolted

together with connectors between them, and slides into the frame as a pair.

The upper module of the pair is fully loaded but the lower module contains

only the input and crosspoint stages. The upper module of the pair routes

inputs 1–16 and the lower module inputs 17–32.

1-2

Two of these 32x16 pairs of modules are used to build up a 32x32 matrix.

The upper pair of modules routes outputs 1–16 and the lower pair outputs

17–32.

In a single frame, there is no redundant power supply available. Dual

power supplies can be installed in the 3RU frame.

Page 20

Signal Path

Inputs

The Frame

The signal path has been designed to be as short as possible which reduces

the variations in path length between channels and maintains the overall

transparency through the router so important in broadcast applications

where multiple passes through equipment are required.

The video inputs are terminated in 75 Ω .

The main video module contains input buffers which have a high input

impedance to aid the return loss performance and an output capable of

driving the bank of crosspoint switches. The buffers can operate in two

modes: DC restored for use with composite signals or component signals

with sync present.

Crosspoints

Outputs

Alternatively the buffers can be set to operate in a DC coupled mode for

use with RGB or color difference signals which have no sync component.

The mode is selected by the user for each input by jumper links on the main

plug-in video module. This means that a single video matrix can handle a

mixture of composite and component inputs.

The DC restorer is a feedback sync tip restorer which prevents any

crushing of the sync signal.

The video crosspoint matrix consists of an array of 16x1 surface mount

assemblies. Sixteen of these assemblies are required to provide a matrix of

16x16 on each matrix module.

The video modules have output amplifiers built on thick film hybrid

circuits. They incorporate adjustment controls for gain and high frequency

response which are factory set.

1-3

Page 21

Section 1 — Introduction

Serial Digital Video Routing

The serial digital video matrix is capable of handling signals in the

following formats:

■

143Mb/s D2 NTSC composite

177Mb/s D2 PAL composite

■

270Mb/s D1 component

■

■

360Mb/s D1 component

Signal Path

The signal path is differential throughout to optimize waveform symmetry

and reduce crosstalk, which is important for transmission down long

cables.

Inputs

Crosspoints

The video inputs are terminated in 75 Ω .

The serial video signal passes through an input receiver circuit built onto a

plug-in SIMM socket so that extra channels can be added in the field. These

circuits provide equalization for losses, mainly at high frequencies, to serial

video signals which have travelled down long cables. This equalization is

varied automatically to suit the length and type of video cable used.

The circuit then locks an oscillator to re-clock the signal so that the correct

pulse widths and timings are regenerated. The circuit can be set to any of

the standards mentioned above, each input being programmed into the

setup of the system, either at the factory or from a PC using the SMS-6000

Configuration Editor. The phase-locked loop is designed to minimize the

jitter on the signal.

A single crosspoint chip selects the 16 inputs to the 16 outputs. It is rated to

operate to over 1Gb/s ensuring minimum degradation of edge speeds and

symmetry.

Outputs

1-4

The output amplifiers are designed to drive 75 Ω video cables.

Page 22

Analog Audio Routing

In the 1RU frame, the main analog audio matrix module provides a dual

channel 16x16 matrix. The 16x4 stereo audio is also a 1RU frame. This

matrix fits in a 1RU frame, which supports only a single power supply.

In the 2RU frame, two 16x16 matrix modules are used to make a 32x16

matrix. The main (lower) audio router module routes inputs 1–16 and the

submodule inputs 17–32. The output stages and their gain adjustments are

installed on the (upper) submodule for accessibility. Two 32x16 pairs of

modules are used to build up a 32x32 mono audio matrix. Dual power

supplies can be installed in this frame. Two frames are used for stereo.

Inputs

The inputs are electronically balanced. This provides a high common mode

rejection ratio over a wide frequency range. Also, the balance is maintained

even if the source is floating. Some designs of electronically balanced

inputs cause the input lines to become unbalanced which can cause an

increase in crosstalk if the input cables are unscreened and run together

over long distances.

Analog Audio Routing

Crosspoints

Outputs

The input and output connectors are 50-pin D connectors.

The signals are filtered to reduce out-of-band high frequency signals and

re-balanced for internal use. The use of balanced circuitry throughout is of

immense value to the overall quality of performance. It improves virtually

every measured parameter by at least a factor of 2 compared to a similar

unbalanced design.

The matrix uses balanced 4x4 crosspoint chips. These exhibit excellent

signal path performance together with minimal crosstalk and switching

noise.

The only adjustment in the audio path is the output gain control. It offers a

±2dB gain control and is mainly provided to allow the gain to be adjusted

up slightly if the outputs are terminated in 600Ω. As this is now an unusual

practice, the insertion gain is factory set for unity into a load of 10kΩ.

1-5

Page 23

Section 1 — Introduction

AES/EBU Digital Audio Routing

The AES/EBU digital audio matrix is capable of handling signals in the

following formats:

■ 32KHz broadcast standard; NICAM

■ 44.1KHz compact disk

■ 48KHz AES/EBU standard

It can be supplied equipped for 16x16 or 32x32.

Inputs

The audio inputs are transformer-coupled and normally terminated in

110Ω.

The audio signal passes through an input receiver circuit which locks an

oscillator to re-clock the signal so that the correct pulse widths and timings

are regenerated. The circuit automatically sets to any of the standards

mentioned above. The phase-locked loop is designed to minimize the jitter

on the signal.

Crosspoints

Outputs

Inputs 1–16 are installed on the main matrix module and Inputs 17–32 on

a submodule.

A single crosspoint chip has the capacity to switch 32 inputs to the 32

outputs.

The output drivers are normally arranged to drive 110Ω lines.

The module has the capability of 32 outputs, but for systems with 16

outputs it is installed with only 16 output stages.

1-6

Page 24

Data Routing

Inputs

Crosspoints

Data Routing

A solid state router is used mainly for machine control, such as to assign

VTRs to an edit controller. RS422 uses four wires with one pair used for the

transmit signal and the other pair for the receive, so the router handles both

a forward and a reverse signal path through the matrix. It can be supplied

equipped for 8x8 or 16x16.

The RS422 inputs are terminated in 110Ω. Inputs 1–8 are installed on the

main matrix module and Inputs 9–16 on a submodule.

Outputs

A single crosspoint chip has the capacity to switch 16 inputs to the 16

outputs.

The output drivers are designed to drive 110Ω lines.

The module has the capability of 16 outputs, but for systems with 8 outputs

it is installed with only 8 output stages.

1-7

Page 25

Section 1 — Introduction

Control System

The microprocessor-based control system activities are:

■ Read buttons and update displays on both local and remote control

■ Respond to data received through the computer port

■ Update the router crosspoint switches

■ Handle the communications between different switching levels such as

The system is shipped with a “basic” configuration. A customer may

change this configuration to fit their specific requirements using the

configuration software. This configuration is normally stored in an

NVRAM inside the Master unit (see below).

The control system maintains its status in a battery-backed memory so that

when the unit is powered down the router remembers its current settings

and on powering up again it switches the unit to those settings. The non-

volatile RAM which stores this information is located inside the Master

unit of the system (see below).

panels

audio and video frames

Configuration Switches

There are a number of switches provided which are used to configure the

system to suit your own requirements. They are briefly described below,

but for more details and a procedure for how to set them up, refer to

Section 2: Installation.

Address Switch

A rotary “hex” switch in each frame and panel determines its unique

address in the system. This ensures that each frame and each panel has a

different code allowing the communications down the coaxial Quick-Link

to distinguish different units. A frame and a panel can share the same code.

The firmware can tell from permanent links on the boards which ones are

panels and which ones are frames.

1-8

Page 26

Control System

DIP Switches

There are four positions available on the DIP switch at the front of the

crosspoint modules. They operate in the same way for video and audio

crosspoint modules. Refer toTable 1-1 for the correct settings of the DIP

switch for either a master frame or a slave frame.

Table 1-1. Dip Switch Settings

DIP Switch Position Master Frame Slave Frame

1 UP UP

2DOWNUP

3DOWN UP

4UPUP

Control Bus Quick-Link

The Quick-Link used to interconnect the panels and frames uses a single

coaxial cable.

The Quick-Link is daisy-chained from one panel to the next and between

the frames. Messages are sent by injecting signal currents onto the link, to

be received by all the other panels or frames on the line. The link is

terminated with 75Ω at both ends.

A hex switch in each frame and panel sets the identity of each so that they

are correctly addressed by the control system. Up to 16 panels and 16

frames can be supported. Local control panels can be optionally mounted

on any 1RU frame (except 32 x 32 AES/EBU 1RU frame) to increase total

panel count to 32.

Two BNC sockets are provided on the frames fed from a single driver/

receiver. Thus short lengths of coax cable can be used to interconnect the

frames in a multi-frame system by looping through the frames. The panels

use one BNC connector and a T-piece to tap off the Quick-Link into the

panels. In this way a panel can be removed from service without the Quick-

Link being interrupted, even momentarily.

A total run of 500 meters (1641 ft.) of video cable can be used between

panels and the frames.

As part of the fault diagnosis system, detectors are provided in the frame

and panels to identify faults. If either one or both terminations has been

omitted or if the cable is too loose and risks communication errors then

these are highlighted by the control system with LEDs on the front of the

router module. These features are very useful at installation as it enables

the cable and its terminations to be verified.

1-9

Page 27

Section 1 — Introduction

Computer Ports

The computer port is used to connect to dumb terminals or to computers.

An IBM 80486, or higher, is recommended. At a minimum the users should

have the following:

■ IBM PC, PS/2 or 100% compatible

■ MS–Dos 3.3 or higher

■ 4MB RAM

■ 1 MB hard disk required

■ RS232 Serial Port

■ MS or compatible mouse

NOTE:

Run setup from DOS or there may not be sufficient memory to use the text

editor.

Serial Interface SMS–CSI

The Serial Interface can be used to enable a computer to be used with the

SMS-6000 Configuration Editor, or for remote control applications. It is an

option which is installed in the master frame.

Normally this option is installed at the factory prior to shipment. The

instructions below are for use if the option is supplied after shipment of the

main unit.

Installation

Remove the serial interface submodule from its packing. Check that its

pins are straight and undamaged. Set the jumpers on the Serial Interface

module. Follow the steps listed below.

Installation in Matrix Frames

1-10

1. Unplug the power.

2. Unscrew the front panel retaining screws. The blank panel can then be

removed. If a local control panel is mounted on the frame, disconnect

the ribbon cables from the front of the matrix module. Release the

retaining latches to withdraw the ribbon cable plugs and remove the

panel.

3. Use the release catches at the sides of the matrix module to release the

locks which hold the module in place. Then pull the catches outwards

to eject the module from its edge connectors.

Page 28

Serial Interface SMS–CSI

4. Remove the module and carefully place it on an anti-static surface.

5. Position the serial interface submodule over the matrix module using

the hole as a guide.

CAUTION

If the module is positioned incorrectly, damage may result to both assemblies.

6. Line the pins over the sockets and push the submodule down gently

and evenly so that all pins enter the sockets at the same time. Push

firmly to completely seat the submodule.

7. Reinstall the matrix module in the frame. Press the module in firmly to

seat it in its connector.

8. Reconnect the power.

Setup

RS422 or RS232 Mode

This is the hardware standard supported by the Computer Port. Set it to

suit the computer or terminal to be used by moving jumper links on the

Serial Interface module. Position the module so that the large chip is top

left.

Depending on which Serial Interface module you have the jumper settings

are as follows:

Set jumpers LK1-5 toward the front of the frame for RS422

toward the rear of the frame for RS232

or

Set the single jumper to the left for RS232 or to the right for RS422 as

indicated on the module

162106-00

• • •

232 422

• • • • •

• • • • •

• • • • •

162180-00

RS422

Figure 1-2. Serial Interface Jumper Setiings

RS232

1-11

Page 29

Section 1 — Introduction

Baud Rate and Data Format

The emulation mode used by the computer interface is set to VT100 or

compatible at the factory. The baud rate is set to 9600 with 8 data bits, 1 stop

bit, and no parity.

External Connections

The wiring of the connectors is different for RS232 and RS422.

The frame has been built to minimize RF emissions. It is important you use

tin and dimple D type connectors with metallized shells connected to the

shield of external cables in order to achieve low RF emissions from this

equipment. The shells are fixed with screwlocks with 4–40 UNC threads.

The RS232 Interface Cable

The interface connector on the router is a 9-pin D socket. The cable between

the PC and the router only needs to use TX, RX, and GND as shown in

Table 1-2.

Table 1-2. RS232 Cable Connections

Computer

9-Pin D

Socket

2 (RXD) 7 (TXD) 3 (RXD) 7 (TXD)

3 (TXD) 3 (RXD) 2 (TXD) TX–3 (RXD)

5 (GND) 6 (GND) 7 (GND) 6 (GND)

NOTES:

The SMS-6000 Configuration Editor requires an RS232 Connection.

Router

9-Pin D Plug

Computer

25-Pin D

Socket

Router

9-Pin D Plug

Remote control can be performed with either the RS232 or the RS422 format.

1-12

Page 30

Serial Interface SMS–CSI

The interface connector on the router is a D9 socket using Table 1-3 pinouts.

Table 1-3. RS232 and RS422 Cable Connections

RS232 RS422

Pin # Signal Pin # Signal

1 GND 1 GND

2 RTS 2 TX–

3 TXD 3 RX+

4 0V 4 RX 0V

5 24V High 5 24V High

6 0V 6 TX 0V

7 TXD 7 TX+

8 CTS 8 RX–

9 not used 9 not used

Table 1-4 pinout is normally used on personal computers, but check your

own computer's documentation.

Table 1-4. Personal Computer Cable Connections

9-Pin D Connector 25-Pin D Connector

Pin # Signal Pin # Signal

1 DCD 2 TXD

2 RXD 3 RXD

3 TXD 4 RTS

4 DTR 5 CTS

5 GND 6 DSR

6 DSR 7 GND

7 RTS 8 DCD

8 CTS 20 DTR

9RI 22RI

1-13

Page 31

Section 1 — Introduction

Local Control Panel SMS–CMXY-LP

This panel is available only on 1RU frames, (except the 32 x 32 AES/EBU

1RU frame). The design of the panel is similar to that of the SMS–CMXY

remote panel.

The SMS–CMXY-LP panel can be installed to the front of the frame. This

saves an extra rack unit when a panel is required adjacent to the rack,

perhaps for engineering use and, because it shares the electronics

hardware in the main unit, it is of lower cost than the SMS–CMXY remote

panel.

This panel has the capability to control all 16 inputs, 16 outputs and four

signal levels, and has a lock feature to protect established routes. Refer to

Section 4: Control Panels and Operation for details of how it is used.

1-14

Page 32

Power System

Power System

1RU frame, can have only a single power supply, whereas 2 or 3RU frames

have the option of dual supplies to protect against the failure of one of the

supplies or, the loss of incoming AC power on one power bus. There are

two AC power connectors so that a backup supply can be fed from a

completely separate power lead, thereby offering maximum protection

against loss of power. The AC connectors are located on the rear panel and

incorporate a fuse and adjacent voltage selector for convenience during

installation.

A traditional transformer system in the rear of the matrix frame is used to

step down the mains voltage to around 20 volts AC. On the plug-in power

module the AC voltages are rectified and smoothed to produce raw DC

rails of 20–30 volts. Low voltage switching techniques are then used to

convert the raw DC into the smooth DC voltages used on the router

modules. This method has the benefit of low heat generation without the

high stress of mains voltages on the components found in traditional

switch-mode designs. These features both contribute to high reliability.

CAUTION

Different modules need different power rails and these rails are selected by jumper

links on the power module. If the incorrect module is plugged into a frame, then

permanent damage may be caused to the main module. Some modules are

installed with a linearly regulated third (+12V) rail to drive a cooling fan.

A standby switch at the front of each Power Supply (PS) module enables

the DC power to be switched off but does not disconnect the mains power.

Cooling Fan - 1RU frame

On some frames a cooling fan installed on the right-hand side of the frame

draws cool air from the side and expels it through the vents along the lefthand side of the frame. The Power Supply module provides the 12V DC

supply for this purpose, which is not switched by the standby switch on the

PS module so the fan will always run when the power cord is plugged in.

Cooling Fan - 3RU frame

The cooling fan installed in the rear of the frame draws cool air from the

rear and expels it through the vents along the left-hand side of the frame.

It is powered from both power modules, so that if either fails then it

continues to run. The Power module provides the 12V DC supply for this

purpose, which is not switched by the standby switch on the PS module so

the fan will always run when the power cord is plugged in.

1-15

Page 33

Section 1 — Introduction

Ground and Power Fail Alarms

A terminal strip is provided on some units to select how the system is

grounded.

Separate connections are provided on the rear of audio frames for:

■ TECH 0V Internal technical 0V

■ GND To ground pin of power connector and to the

■ O/P SCREENS The 16 shield pins on the two Output connectors are

■ I/P SCREENS Connection to the shield pins of the two Input

CAUTION

The TECH 0V must be connected to an earth ground in order to operate the

equipment safely.

external metalwork

connected together and to this pin

connectors

The equipment is shipped from the factory with the TECH 0V and GND

linked together to ensure that the electronics hardware is properly

grounded.

The input and output shields terminals are provided to avoid the problems

of ground loops caused by differences in the ground potentials on the

shields (screens) of the input cables and the output cables. It is common to

connect the O/P SCREENS to GND at the driving end, but some installers

prefer to connect I/P SCREENS to GND instead. However it is inadvisable

to connect both sets of shields to GND.

On the 3RU video frame the terminal strip has the following connections:

■ TECH 0V Internal technical 0V

■ GND To ground pin of power connector and to the

external metalwork

■ POWER FAIL Pair of contacts held closed, so long as both power

supplies are installed, switched on and working

CAUTION

The TECH 0V must be connected to an earth in order to operate the equipment

safely.

1-16

The equipment is shipped from the factory with the TECH 0V and GND

linked together to ensure that the electronics hardware is properly

grounded.

Page 34

Remote Control Panels

Refer to Section 4: Control Panels for details of the control panels and their

operation. The following points apply to most panels.

General Points

Remote panels are used to indicate current crosspoint connections and to

make new selections at various locations to suit the user. Most panels are

connected to the frame via the Quick-Link coaxial link. The identity of each

panel is determined by the unique setting of a rotary hex switch in each

panel.

Each panel is set up to operate in a particular way by the system

configuration located in the master frame of the system. This determines, for

instance, which destinations can be controlled from each panel. The rotary

hex switch mentioned above serves to route the correct setup to each panel.

Remote Control Panels

Panels are powered from a local 115V/230V mains supply.

1-17

Page 35

Section 1 — Introduction

Specifications

Specifications are subject to change without prior notice.

Video Inputs

Nominal Signal Level

Maximum Signal Level

Impedance 75Ω terminating

Table 1-5. Analog Video Specifications

Video signal

Sync pulses

Subcarrier

DC restored inputs video signal

DC restored inputs sync pulses

DC coupled inputs video or Subcarrier

1V p-p

2V p-p

1V p-p

+6dB

2.5V p-p

±–0.7V

Return loss to 5.5 MHz 40dB

DC on input (DC restored) ±3V

Video Outputs

Impedance 75Ω

Return loss to 5.5 MHz 35dB

DC on output

†

±50mV

Insertion Gain

Insertion gain ±0.1dB

Gain spread between inputs ±0.05dB

Adjustment range ±0.5dB

Linear Distortion

HF response 15KHz to 5.5MHz

5.5 to 10MHz

10MHz to 30MHz

above 30MHz

±0.1dB

±0.2dB

+0.5, –1.0dB

smooth roll off

1-18

HF adjustment at subcarrier ±0.5dB

LF response, tilt at 50/60 Hz ±0.5%

2T pulse 0.25%K

2T pulse/bar ratio 0.25%K

Page 36

Table 1-5. Analog Video Specifications - (continued)

Linear Distortion (continued)

2T bar slope 0.25%K

Y-C gain inequality ±0.5%

Y-C delay inequality ±5ns

Non-Linear Distortion

Differential gain (10–90% APL) 0.15%

Specifications

Differential phase (10–90%APL) 0.15

Luminance non-linearity 0.2%

C-Y intermodulation 0.5%

Dynamic gain (Y, C, syncs) 0.5%

Transient gain (Y, C, syncs) 1%

o

Propagation Delay

Path length 13ns typical

Timing spread at 4.43MHz

one output

all outputs

±1°

±2°

Crosstalk/Noise

Crosstalk, to 5.5MHz worst case 60dB, 30MHz version

Noise to 5.5MHz –70dB rms

Video spikes at switching ±20mV

Switching Reference

Signal level 1V p-p ±3dB

1–4V pulses

Impedance 75Ω looping

DC on input ±1V

Switching occurs on lines 7/320 to 11/324, field or frame rate,

jumper selectable

1-19

Page 37

Section 1 — Introduction

Power

Table 1-5. Analog Video Specifications - (continued)

Rear panel voltage selector 90–132V 50/60Hz

Power consumption (1RI) 25 watts

Power consumption (3RU) 90 watts

Connector (1RU) IEC with retaining latch

Connector (3RU) IEC with retaining latch, backup optional

Power fail alarm output

Both Power Supplies good

One Power Supply failed or absent

Technical & chassis ground (3RU only) screw terminals

180–264V 50/60Hz

screw terminals

closing relay contact, rated at 250mA, 50V

open relay contact

Control

Quick-Link to remote panels 75Ω video cable

Computer port RS232/RS422 D9 socket

500M (1641 ft) max length

Mechanical

Height 1RU, 1.75 in (44mm)

Width 19 in rack mount

Depth 19.75 in (500mm)

Weight 1RU, 13.5 lb (6Kg)

3RU, 3.5 in (133mm)

2RU, 26.5 lb (12Kg)

Environmental

Ambient T emper ature

Operating and storage

Specification maintained

Humidity 10–90% non-condensing

† In the DC coupled mode the DC on the output is specified with the input terminated in 75Ω. In

the DC restored mode the specification refers to the black level when the sync amplitude is

300mV.

0–40°C

20–30°C

1-20

Page 38

Specifications

Table 1-6. Analog Audio Specifications

Audio Inputs

Signal level 0dBu nominal, +24dBu maximum

Impedance 20KΩ

Common Mode Rejection

20Hz to 3KHz

3KHz to 20KHz

Common Mode Level +30dBu maximum with no signal

Audio Outputs

Impedance 40Ω balanced

DC on output ±50mV

–80dB, –100dB typical

–60dB, –70dB typical

Signal Path

Impedance ±0.1dB

Frequency Response 20Hz to 20KHz

to 150KHz

Relative delay between two routes 1 µs

Total harmonic distortion

–10dBu to +20dBu, 20Hz to 20KHz 0.02%, 0.01% typical

Crosstalk 20Hz to 20KHz –90dB worst case, –105dB typical

Noise 20Hz to 20KHz –85dBu rms unweighted, –90dBu typical

±0.25dB

3dB

Power

Rear panel voltage selector 90–132V 50/60H

Power consumption 1RU, 25 watts

Connector 1RU, IEC with retaining latch

180–264V 50/60Hz

2RU, 50 watts

2RU, IEC with retaining latch, backup

optional

Power fail alarm output

Both Power Supplies good

Power Supply failed or absent

Technical and chassis ground,

cable shields

screw terminals

closing relay contact, rated at 250mA, 50V

open relay contact

screw terminals

1-21

Page 39

Section 1 — Introduction

Control

Table 1-6. Analog Audio Specifications - (continued)

Quick-Link to remote panels 75Ω video cable

Computer port RS232/RS422 D9 socket

500M (1641 ft) max length

Mechanical

Height 1RU, 1.75 in (44mm)

Width 19 in rack mount

Depth 19.75 in (500mm)

Audio Connectors 50-pin D connector

Weight 1RU, 13.5 lb (6Kg)

2RU, 3.5 in (88mm)

2RU, 22.25 lb (10Kg)

Environmental

Ambient T emper ature

Operating and storage

Specification maintained

0–40°C

20–30°C

Humidity 10–90% non-condensing

1-22

Page 40

Table 1-7. Serial Digital Video Specifications

Video Input

Signal level 800mV p-p, nominal

Impedance 75Ω terminating

Return loss, 5 to 270 MHz 15dB, 16dB typical

DC on input ±3V

Specifications

Cable equalization at 270Mb/s 250M (820.25 ft), 300M (984.5 ft) typical

Belden 8281, PSF 1/2

150M (492.25 ft), 200M (656.25) typical

PSF 1/3

Video Outputs

Signal level 800mV ±–10%

Impedance 75Ω

Return loss, 5 to 270MHz 15dB

DC offset ±0.5V

Rise/fall time into 75Ω resistive load,

20 to 80%

Jitter 500ps p-p max

0.6 to 0.9ns

Switching Reference

Signal level 1V p-p ±–3dB or 1–4V pulses

Impedance 75Ω looping

DC on input ±1V

Switching occurs on lines 7/320 to 11/324, field or frame rate, link

selectable

1-23

Page 41

Section 1 — Introduction

Power

Table 1-7. Serial Digital Video Specifications - (continued)

Rear panel voltage selector 90–132V 50/60H

Power consumption 1RU, 30 watts

Connector 1RU, IEC with retaining latch

Power fail alarm output

Both power supplies good

One power supply failed or absent

Technical and chassis ground screw terminals

180–264V 50/60Hz

3RU, 60 watts

2RU, IEC with retaining latch, backup

optional

screw terminals

closing relay contact, rated at 250mA, 50V

open relay contact

Control

Quick-Link to remote panels 75Ω video cable

Computer port RS232/RS422 D9 socket

500M (1641 ft) max length

Mechanical

Height 1RU, 1.75 in (44mm)

3RU, 3.5 in (133mm)

Width 19 in rack mount

Depth 19.75 in (500mm)

Weight 1RU, 13.5 lb (6Kg)

3RU, 22.25 lb (10Kg)

Environmental

Ambient T emper ature

Operating and storage

Specification maintained

Fan-cooled by drawing cool air from right-hand side (1RU) or rear (3RU) of frame and

exhausting the warm air from the left-hand side.

Humidity 10–90% non-condensing

0–40°C

10–30°C

1-24

Page 42

Specifications

Table 1-8. AES/EBU Digital Audio Specifications

VAES/EBU Input

Sample rates 32, 44.1, 48KHz

Impedance 10Ω ±20% transformer coupled

Signal level 0.2–7V p-p

DC on input ±50V

AES/EBU Outputs

Rise/fall times into 110Ω resistive load 5–30ns

Jitter <20ns

Signal Level 2–7V p-p

Impedance 110Ω transformer coupled

DC isolation ±50V

Power

Rear panel voltage selector 90–132V 50/60Hz

Power consumption 15 watts

Connector (1RU frame) IEC with retaining latch

Connector (2RU frame only) IEC with retaining latch, backup optional

Power fail alarm output (2RU frame only)

Both power supplies good

One power supply failed or absent

Technical and chassis ground, cable

shields(screens)

180–264V 50/60Hz

screw terminals

closing relay contact, rated at 250mA, 50V

open relay contact

screw terminals

1-25

Page 43

Section 1 — Introduction

Control

Table 1-8. AES/EBU Digital Audio Specifications - (continued)

Quick-Link to remote panels 75Ω video cable

Computer port RS232/RS422 D9 socket

500M (1641 ft) max length

Mechanical

Height 1RU, 1.75 in (44mm)

Width 19 in rack mount

Depth 19.75 in (500mm)

Weight 13.5 lb (6Kg)

Audio Connectors 50-pin D connector

Environmental