Page 1

Stand-Alone Controller

RSE 1

Customer‘s Manual

Page 2

Pub

lished by

BTS Media Solutions GmbH

Brunnenweg 9

D-64331 Weiterstadt, Germany

P.O. Box 1165

Tel: +49 (0) 6155-870-0

Fax: +49 (0) 6155-870-300

Copyrights

Für diese Unterlage behalten wir uns alle

Rechte vor (Gemäß DIN 34).

Technische Änderungen im Zuge der

Weiterentwicklung vorbehalten.

BTS Media Solutions GmbH 2001

Copying of this document and giving it to

others, and the use or communication of

the contents thereof, are forbidden without

expressed authority. O ffenders are liable to

the payment of damages. All rights are reserved in the event of the grant of a patent

or the registration of a utility model or design.

Liable to technical alterations in the course

of further development.

Toute communication ou reproduction de

ce document, toute exploitation ou communication de son contenu sont interdites,

sauf autorisation expressé. Tout manquement à cette règle est illicite et expose son

auteur au versement de dommages et

intérêts. Tous nos droits sont réservés

pour le cas de la délivrance d’un brevet ou

de l’enregistrement d’un modèle d’utilité.

Sous réserve de modification au cours de

l’évolution technique.

Page 3

Revision Report

Stand-Alone Controlle RSE 1

Documentation Order Number

Customer’s Manual

Before reading the entire

manual, please check for any

supplements at the end

of the manual.

Item Rev Date SerNoPages affected Contents Remarks

1 0 10.01 100 all Customer’s Manual 1st Edition

Page 4

CONTENTS

Revision Report

Declaration of Conformity

1. Applications 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Technical Data 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Installation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ContentsStand-Alone Controller RSE 1

Page

2.1 Mechanical Dimensions 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Safety Instructions 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Mounting into a Cabinet 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 General Grounding Requirements 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Connection Unit 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Pin Assignments 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Network Configuration 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Advanced DD35 SD / Seraph HD Configuration 17. . . . . . . . . . . . . .

5.1.1 DD35 with GUI-PC 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 DD35 SD / Seraph HD with two Control Panels 20. . . . . . . . . . . . . . . . .

5.1.3 DD35 SD / Seraph HD with RSAT 2 and RSE 1 22. . . . . . . . . . . . . . . . .

5.1.4 DD35 SD / Seraph HD Simulcasting 24. . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.5 Two Complete Systems 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Connecting a RSAT Panel to the RSE1 29. . . . . . . . . . . . . . . . . . .

6.1 Creating an Application File for the RSE1 29. . . . . . . . . . . . . . . . . . .

6.2 Loading default Macros from the Sidepanel 31. . . . . . . . . . . . . . . . .

6.3 List of default Macros 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Servicing 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rev. 1 / 02.2002

6.4 Saving Environmental Data 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Exchanging the Lithium Battery 34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Page 5

Contents Stand-Alone Controller RSE 1

II

Rev. 1 / 02.2002

Page 6

1. APPLICATIONS

1. Control Panel Emulation

Install the standard DD35 series control panel software on the RSE1 hardware

platform like on a standard control panel. This RSE 1 will then behave as a

panel where you can connect e.g. a RSAT 1 or RSAT 2 panel and UMD’s or

Aux-CP’s. The panel software supports the first 4 serial ports J1 ... J4, RS485,

bus controller mode. For protocol selections etc. you have to attach a Sidepanel (Sidepanel application on a standard PC or Sidepanel of a real DD35

panel) to the RSE1.

Stand-Alone ControllerRSE 1

Rev. 1 / 02.2002

1

Page 7

RSE 1Stand-Alone Controller

2

Rev. 1 / 02.2002

Page 8

RSE 1 Stand-Alone Controller

2. TECHNICAL DATA

Mechanics 19” Rackframe

Width: 482 mm (19”)

Depth: 251 mm (9.9”)

Height: 43mm (1.7”)

Weight: approx. 7 kg

Voltage supply AC IN voltage 100 – 240 V / max. 500 mA

Line frequency 50 Hz to 60 Hz

Power consumption: approx. 20 W

Touch current ≤ 1 mA

Environmental Operating temperature: +0° C ... 40° C

requirements Storage/transport temp: –40° C ... 85° C

Humidity: ≤ 95%, DIN IEC 68-2-14

non-condensing

Electromagnetic EN 55103-1/-2, EN 55 022, Class B

compability FCC 47 Part 15

Safety VDE 0805, EN 60 950

UL 1419

CSA C.22.60950

Interfaces

• up to 7 intern GPI or 7 intern GPO GPI: Opto coupler , dry contact or active

(free selectable) in, max. 20 V

• 1 Service port (Diagnostic) D-Sub socket 9-pin, female, RS 232C

• LAN port (AUI) D-Sub socket 15-pin, female, by use of

• Genlock 2 BNCs, 50 ohms

• 14 Serial ports D-sub sockets 9-pin, female,

• 1 Serial port D-sub socket 9-pin, female, RS232C

GPO: Silicon switches, potential free,

40V/0.3A.

D-Sub socket 15-pin, female

Thin Coax Transceiver

(IEEE 802.3 /10Base-2), cheapernet,

50 ohms, 150m,

with repeater max. 2.5 km,

connect with

Loop – through

RS485/422

for UMDs, RSAT 2, RSAT 1 or

Auxiliary panels

38.4 kbd max.

Rev. 1 / 02.2002

3

Page 9

Stand-Alone Controller RSE 1

4

Rev. 1 / 02.2002

Page 10

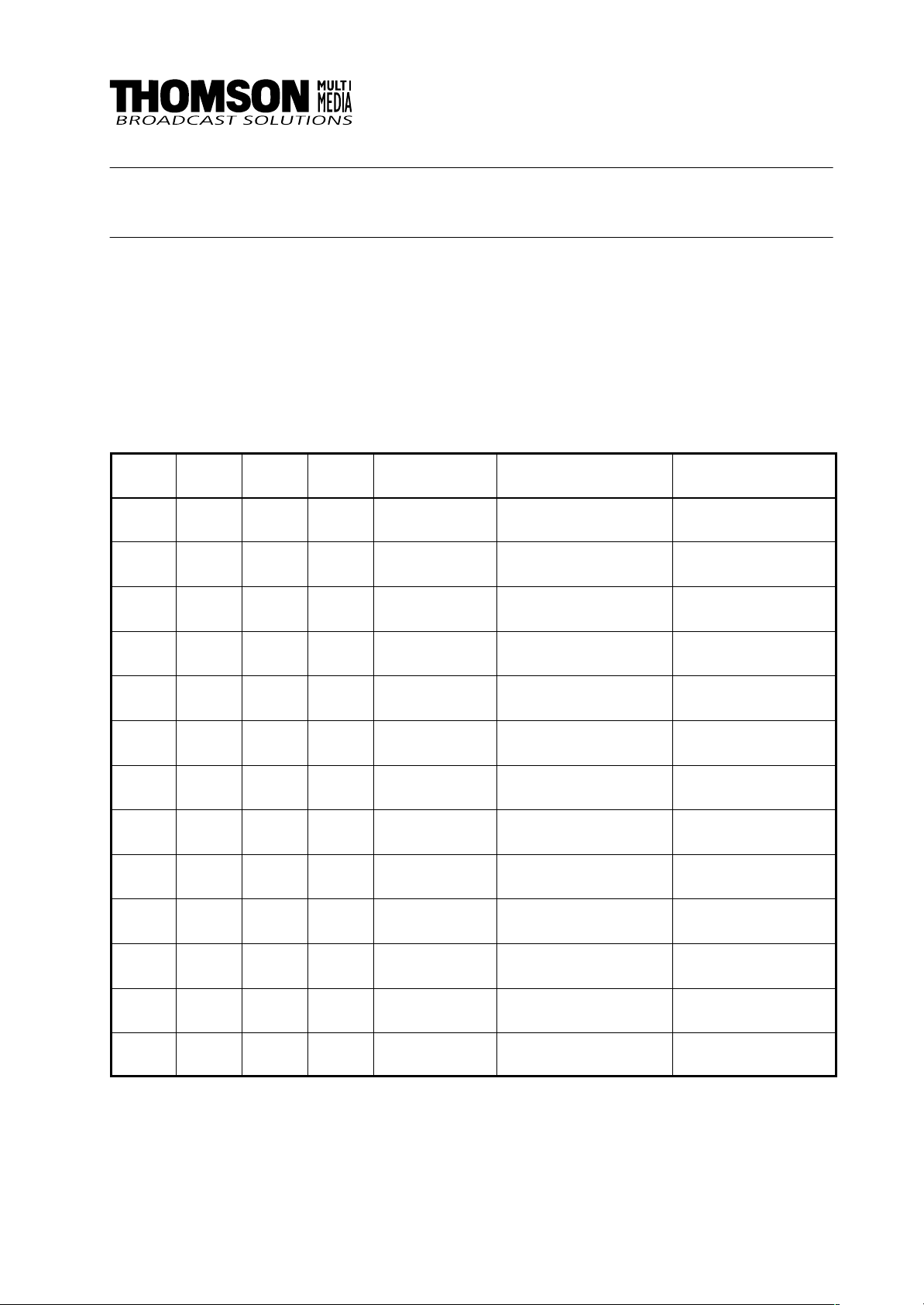

2.1 MECHANICAL DIMENSIONS

28

Stand-Alone ControllerRSE 1

96

7

176

22

438

251

251

43

43

5.62

Fig. 1: Mechanical dimensions

Rev. 1 / 02.2002

2

8.5

20.5

482

All dimensions are [ mm ]

5

Page 11

RSE 1Stand-Alone Controller

6

Rev. 1 / 02.2002

Page 12

RSE 1 Stand-Alone Controller

3. INSTALLATION

3.1 SAFETY INSTRUCTIONS

Caution!

These instructions are for use by qualified personnel only. T o reduce the risk

of electric shock, do not perform any installation other than that contained

in the Operating Instructions unless you are qualified to do so. Refer all servicing to qualified service personnel.

Attention!

Electrostatic sensitive devices on the p. c. boards. Observe the following

precaution for handling:

Handling or mounting the RSE1 unit call for special attention to personal safety.

Personnel should be connected to ground potential via a wristlet (e.g. 3M Wristlet Serial 2200).

Do not touch the p. c. boards during mounting.

Repair the p. c. boards only at static-safe work stations.

Use antistatical protective bags when carrying the p.c. boards.

Attention!

Danger of explosion when the battery is not correctly inserted. Replace the

battery only by a battery from the same manufacturer or by an equivalent

type recommended by the manufacturer.

Protect the environment!

Dead batteries do not belong in the garbage. Hand the used batteries over

to a local disposal place or observe the respective instructions of the

manufacturer!

Rev. 1 / 02.2002

7

Page 13

3.2 MOUNTING INTO A CABINET

General rack mounting instructions

The maximum ambient for this unit is 40°C.

Installing the unit in a closed or multi–unit rack assembly, together with other

units could increase the maximum ambient for this unit.

If the unit is installed in a rack, no ventilation openings should be blocked or

otherwise covered. Ensure a sufficient amount of airflow.

Mounting of the unit in the rack should be such that a hazardous condition is

not achieved due to uneven mechanical loading.

When connecting the unit to the supply circuit be sure that the supply circuit of

the rack is not overloaded. For ratings see chapter Technical Data.

The unit must be grounded to a good earth ground using a wire as specified

by the local electrical code. This wire is attached to the protective earth connector on the rear. For details refer to chapter General Grounding Requirements.

RSE1Stand-Alone Controller

When connecting the unit in a closed or multi–unit rack assembly together with

other units be sure that the summation of the touch (leakage) currents is not

higher than 3.5 mA. In this case the rack must be permanently connected with

an earth terminal. Earth connection is essential before connecting supply voltage! For details see chapter Technical Data.

For installation, Thomson optionally provides a 19-inch cabinet with recommended

mounting accessories. When using cabinets of other manufacturers, observe the

respective mounting instructions.

Note: For installation into a DIN cabinet, adapter pieces of the respec-

tive cabinet manufacturer have to be mounted on both sides of

the lateral fastening flanges.

For relieving the front mounting brackets, the Stand–Alone Controller RSE1 has

also to be supported in the rear part of the frame. The corresponding mounting

parts can be obtained as accessories from the manufacturer of the cabinet-type

rack.

8

Rev. 1 / 02.2002

Page 14

RSE 1 Stand-Alone Controller

3.3 GENERAL GROUNDING REQUIREMENTS

For grounding of the devices, the following three methods are

possible:

PE TE

Protective grounding

1. Grounding with the protective earth of the mains cable which

contains the earthed protective conductors (normally).

2. Additional protective grounding as a potential compensation or earth

conductor with large cross section with PE terminal. The jumper

TE –– PE must not be broken!

The earth connection has to be made before connecting the mains cable!

3. Additional noiseless functional protective earth low on extraneous voltage

with TE terminal. The jumper TE –– PE must be disconnected!

The earth connection has to be made prior to mains cable connections!

Detailed information see in the sections below.

Grounding of the device serves the product safety and meets the requirements in

conformity with safety class I.

The device is connected with the protective earth of the power supply circuit (e.g.

the studio) by means of the mains cable which also contains the earthed protective

conductor PE.

Precondition is an earthed and checked mains socket!

In the device, the power socket is provided with a leading protective contact. This

protective contact is internally connected with the parts to be earthed, e.g. the case.

The effect of the protective earth connection must not be neutralized through the

use of an extension cord without protective earth conductor, through an excessively long cable, nor must its function be disabled in any other way!

Additional earth conductor

At the rear, the device provides separate screw terminals for protective earth and

video earth grounding. On delivery to the customer , PE and TE terminals are joined

by a short-circuit jumper.

The PE terminal, marked by the symbol

ternally connected with the AC IN power socket and the metal case parts.

The TE terminal, marked by the symbol

earth, technical earth), is connected with the reference potentials (ground, GND)

of the internal supply DC voltages and the video earth.

When connecting an additional earth conductor, this connection has always to be

made before connecting the mains cables.

417-IEC-5017 (protective earth), is in-

417-IEC-5018 (video earth, system

Rev. 1 / 02.2002

9

Page 15

RSE1Stand-Alone Controller

Internal wiring

Internal protective earth

PE TE

AC IN

Case

Video earth

(insulated mounting)

For additional grounding of the devices, the following methods are possible:

1. As a potential compensation or as an additional earth conductor with large

cross section:

The jumper between the PE and TE terminal screws must be in place. The central protective conductors of the studio have to be screwed to the PE terminal

screw. The protective conductor should have a cross section greater than that

of the neutral conductor N of the mains cable, however, 2.5 mm

protected installation) (4mm

2

with unprotected installation). Fusing up to 25A.

2

at least (with

Standards: VDE 0800, part 2, table 1/ VDE 0100 T.540 / IEC 364-5-54, 543.1.

Color code of the insulation: green/yellow.

TN-C power systems

2. Additional noiseless functional protective earth FPE (functional earth with protective qualities) low on extraneous voltage:

If required, e.g. in studios with separate protective and technical earth systems,

the jumper between the PE and TE terminals can be broken. In this case, the

central functional earth has to be additionally connected to the TE terminal

screw.

The cross section has to be dimensioned as described above. A low-impedance interconnection of both earth conductors must be provided at the central

studio grounding point or at the earth bus.

Device

Example 1

Protective earth

Device

Example 2

Video earth

Jumper not broken!!

Jumper broken!!

Central

earthing point

10

In case of TN-C power systems (combination of neutral conductor and protective

conductor), it is necessary to observe the regulations in conformity with IEC

364-5-54 (VDE 0100 T-540) and IEC 364-4-41, IEC 364-4-47 (VDE 0100 T.410)

or the applicable national regulations.

Rev. 1 / 02.2002

Page 16

RSE 1 Stand-Alone Controller

Any break of the protective earth conductor inside or outside the device or

disconnection of the protective conductor connector may entail that, in the

event of a failure, the operational safety of the device will no longer be ensured! All mains sockets of the devices being interconnected with signal

cables have to be checked. The protective earth conductors must not be live!

Abbreviations:

FPE = functional protective earth

L = live, outer conductor (phase, R, S, T)

N = neutral conductor

PE = protective earth conductor

TE = technical earth = functional noiseless earth

IEC = International Electrotechnical Commission

VDE = Association of German electrotechnicians and electrical engineers

DIN = German industrial standards

(In conformity with DIN 42 400 or IEC Publication 445)

(earlier designation: PROTECT GND)

color code of the PE wire: green/yellow

(video earth, audio earth with protective earth qualities

color code of the TE wire: black

Rev. 1 / 02.2002

11

Page 17

RSE1Stand-Alone Controller

12

Rev. 1 / 02.2002

Page 18

RSE 1 Stand-Alone Controller

3.4 CONNECTION UNIT

Example:

Stand-Alone Controller RSE 1

rear view

Protective Earth

RS-485 / RS-422 Ports

RS 232

J 8

GPDiagn

AUI

J 17

J 18

N4067

U

T

AC IN

J19

AC POWER IN

100 – 240 V / max. 500mA – 50/60 Hz

Caution:

J 22

J 21

J 20

For continued protection against risk of fire,

repplace only with same type and rating of fuse.

Genlock

LAN TP

RS 485 / RS 422

PE

J 1

J 9

J 2 J 3 J 4 J 5 J 6

J 10 J 11 J 12 J 13 J 14

J 7

J 15 J 16

Fuses

RS-485 / RS-422 Cable

(Option)

Protective Earth

Remote Control Panel RSAT 2

rear view

AC INFuses

RS-485 / RS-422 Cable

(Option)

Marker for port configuration

Factory setting: RS-422/RS-485

Satellite Panel RSAT 1

rear view

Fixture for DC cable

DC IN

any polarity

Befor mounting the Satellite

Panel, switch to ON

Notes:

- It is only possible to connect one RSAT panel to the RSE1, either a RSAT1 panel or a RSAT2 panel.

- The panel software supports only the first four serial ports J1 ... J4, RS485, bus controller mode.

Fig. 2: Example RSAT assignment

Rev. 1 / 02.2002

13

Page 19

Stand-Alone ControllerRSE 1

14

Rev. 1 / 02.2002

Page 20

RSE 1 Stand-Alone Controller

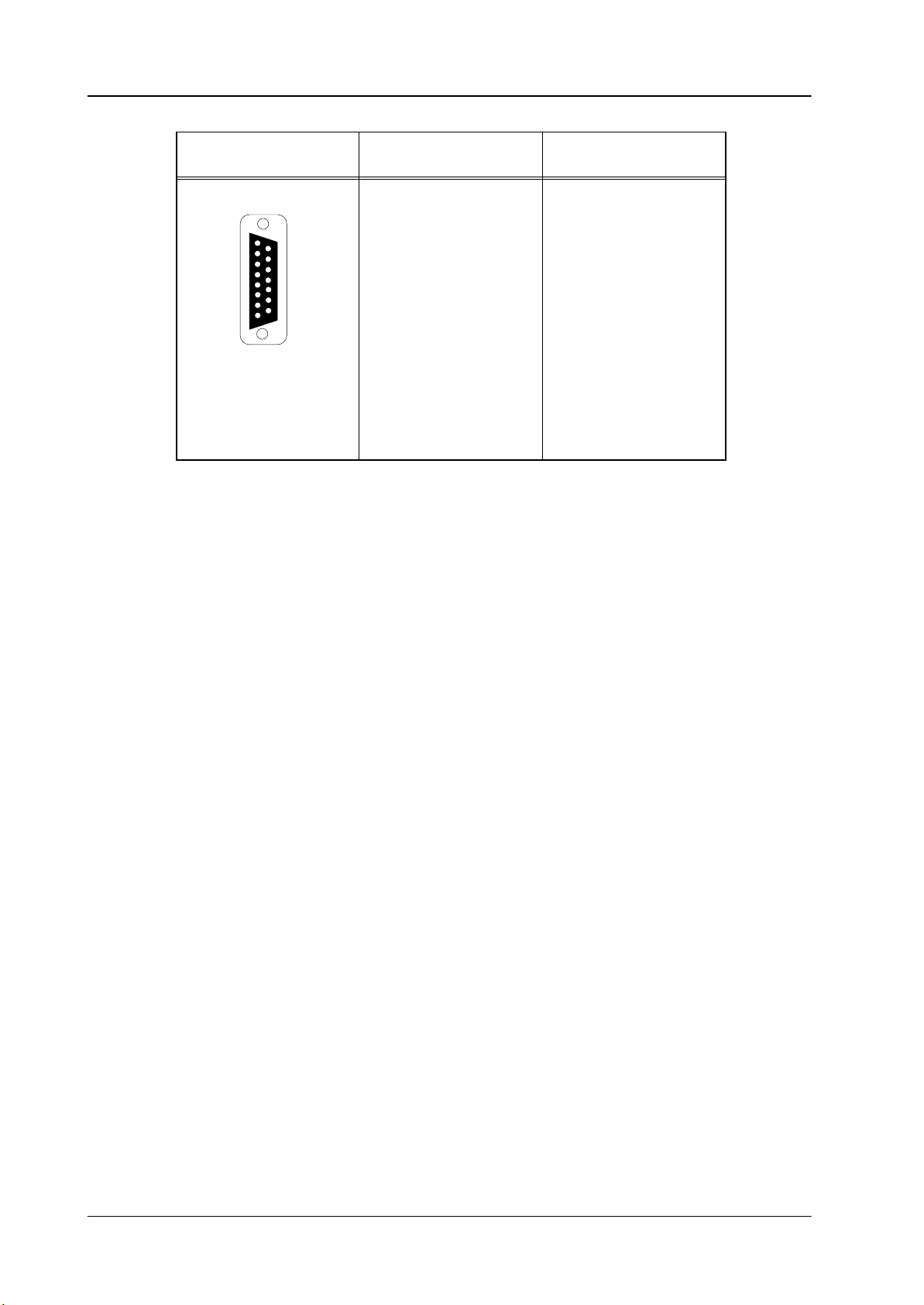

4. PIN ASSIGNMENTS

PORT RS-422/485 Pin Signal

Bus Contr Tributary

1

5

9-pin D-type

female

6

2

3

1

9

4

5

6

7

8

9

Signal Ground

RxA (–) TxA (–)

TxB (+) RxB (+)

Signal Ground

not used

Signal Ground

RxB (+) TxB (+)

TxA (–) RxA (–)

Signal Ground

PORT RS-232 Pin Signal

1

5

9-pin D-type

female

6

2

3

1

9

4

5

6

7

8

9

not used

Transmit Data

Receive Data

not used

Signal Ground

not used

not used

not used

not used

GPI/GPO

Panel

1

8

15-pin D-type

female

15

Pin Signal

1

2

9

3

4

5

6

7

8

9

10

11

12

13

14

15

GPI/O 0–

GPI/O 1–

GPI/O 2–

GPI/O 3–

GPI/O 4–

GPI/O 5–

GPI/O 6–

Signal Ground

GPI/O 0+

GPI/O 1+

GPI/O 2+

GPI/O 3+

GPI/O 4+

GPI/O 5+

GPI/O 6+

Rev. 1 / 02.2002

15

Page 21

Stand-Alone Controller

RSE 1

AUI

Panel

1

8

15-pin D-type

female

15

Pin Signal

1

2

9

3

4

5

6

7

8

9

10

11

12

13

14

15

AUI Ground

AUI CD+

AUI TX+

AUI Ground

AUI RX+

AUI Ground

AUI not used

AUI not used

AUI CD–

AUI TX–

AUI Ground

AUI RX–

AUI +12V

AUI Signal Ground

AUI not used

16

Rev. 1 / 02.2002

Page 22

RSE 1

5. NETWORK CONFIGURATION

Mainframe, panel and panel PC are network devices using TCP/IP protocol. The

devices are shipped with default IP addresses; however, as more resources are

attached to the network, addresses must be changed.

Default address ranges for the DD35 devices:

IP address (class C network) 192.168.0.1

up to

192.168.0.254

The factory configures the following addresses:

mainframe: 192.168.0.70 (incl. two automatically calcula

control panel: 192.168.0.73

sidepanel (panel PC): 192.168.0.74

RSE1 192.168.0.78

Stand-Alone Controller

ted for internal communication ... 71, ... 72)

rotary switch: 0x46

rotary switch: 0x49

rotary switch:0x4C

GUI-PC 192.168.0.77

Please note that the mainframe occupies three consecutive addresses!

Attention:

The IP addresses of the individual devices working on the network must be

different. For mainframe and control panel, the setting can be undertaken directly on the controller board. The lowest address byte can be set in the

range from 0 to 255 with a Hex rotary switch.

The IP address of the panel PC can be set with the Windows 95 or ’98 tool

“Settings/Control Panel/Network” directly.

Note on Windowst registry settings:

The graphical user interface (a.k.a. sidepanel program) writes its registry settings on program close. Changing any setting by regedit therefore is in vain

if the sidepanel program is active. It must be closed before.

5.1 ADVANCED DD35 / SERAPH HD CONFIGURATIONS

This section will explain how to install and configure DD35/Seraph HD systems that

include more devices on the LAN than mainframe and control panel (with built-in

sidepanel).

Rev. 1 / 02.2002

In particular the following configurations will be explained:

DD35/Seraph HD system plus GUI–PC

DD35/Seraph HD system with two control panels

DD35/Seraph HD system with RSAT2 and RSE1 (or RSAT1 and RSE1)

DD35/Seraph HD system with HD/DD simulcasting

Two complete systems

17

Page 23

Stand-Alone Controller

5.1.1 DD35 WITH GUI-PC

This also applies to users of ”DS 0103 Software License for additional Side-Con-

trol”.

5.1.1.1 Schematic

RSE 1

BNC T-type

50 W

Terminator

Mainframe

5.1.1.2 IP Addresses

BNC T-type BNC T-type

Panel

BNC T-type

50 W

Terminator

GUI-PC

The following assumes that the GUI-PC is physically connected to the LAN.

As stated under ”Network Configuration” all devices on the LAN must have an unique IP address.

To successfully integrate the GUI-PC in the network take the steps as follows:

1. Look up the IP addresses of all devices.

2. Check for conflict (i.e. two identical IP addresses).

The factory default setting avoids conflict, but better check twice.

3. If there is a conflict, change the IP address of the GUI-PC to a free address and

reboot the GUI-PC.

Now the GUI-PC is installed and is able to connect to the mainframe.

18

Rev. 1 / 02.2002

Page 24

RSE 1

5.1.1.3 Restrict Access

Stand-Alone Controller

Under certain circumstances it may be necessary to restrict the access of the GUIPC to a certain M/E. E.g. when the GUI-PC is used in an Edit bay for key and wipe

adjustments.

There is a registry setting that allows this.

The setting is the key ”ME_ENABLED” in

HKEY_CURRENT_USER\Software\BTS\SP\RESOURCE.

It is a DWORD (4 bytes) value. The table shows which values have to be used.

Access Value

P/P only 0x01000000

M/E1 only 0x00010000

M/E2 only 0x00000100

M/E3 only 0x00000001

default all M/Es 0x01010101

For any other combination just add the values.

Rev. 1 / 02.2002

19

Page 25

Stand-Alone Controller

5.1.2 DD35 / SERAPH HD WITH TWO CONTROL PANELS

5.1.2.1 Schematic

RSE 1

BNC T-type

50 W

Terminator

DD35 mainframe SD

5.1.2.2 IP addresses

BNC T-type BNC T-type

RPS35-2S control panel

BNC T-type BNC T-type

50 W

Terminator

RPS35-2S control panel

The following assumes that the Control Panel (both LAN connectors) is connected

to the LAN.

As stated under ”Network Configuration” all devices on the LAN must have an unique IP address.

To successfully integrate the second control panel (with its built-in sidepanel) in the

network take the steps as follows:

1. look up the IP addresses of all devices

2. check for conflict (i.e. two identical IP addresses).

If the second control panel has factory default setting then there is an address

conflict.

3. If there is a conflict, change the IP address of the second control panel and the

built-in sidepanel to free addresses.

The control panel address could be changed to 192.168.0.75 (rotary switch =

0x4B) and the sidepanel to 192.168.0.76. (by Windows network settings).

In case the second control panel is ordered with initial order the factory sets up

those addresses.

4. Reboot the panel.

Both control panels operate fully in parallel.

20

Rev. 1 / 02.2002

Page 26

RSE 1

5.1.2.3 Restrict Access

Stand-Alone Controller

There may be situations when both control panels must not interfere with each

other.

For example one control panel operates ME1 and PP , and the second control panel

operates ME2.

The way to ensure this has two aspects

restrict access of the sidepanel (see above)

mechanically block the ME Delegation buttons which must not be pressed on

both panels respectively.

Stored Applications

See chapter 5.1.5.3 Stored Applications.

Rev. 1 / 02.2002

21

Page 27

Stand-Alone Controller

5.1.3 DD35 / SERAPH HD WITH RSAT2 AND RSE 1

5.1.3.1 Schematic

RSE 1

BNC T-type

50 W

Terminator

DD35 mainframe SD

BNC T-type BNC T-type BNC T-type

RPS35-2S control panel

5.1.3.2 Connecting the RSE1 to the Network

The RSE must be connected with the delivered Micro transciever to the switcher’s

network.

1. Connect the delivered Micro Transciever AT-MX 10S to the AUI / J18 port.

2. Connect a BNC cable to the switchers network (see above) and to the Micro

Transciever of the RSE1.

RSAT2

50 W

Terminator

RSE1

5.1.3.3 IP Addresses

The factory setting for the IP address (192.168.0.78) should avoid any conflict.

Nevertheless it is recommended to proceed in the normal way.

1. Look up the IP addresses of all devices

2. Check for conflict (i.e. two identical IP addresses).

The factory default setting avoids conflict, but better check twice.

3. If there is a conflict, select a free IP address and change the rotary hex switches

of the RSE1 accordingly.

Example: IP 192.168.0.16 (rotary switch setting 0x10).

Reset (or power cycle) the RSE 1.

5.1.3.4 Setting Up the RSE 1

To set up the RSE1 the sidepanel of the existing control panel is used.

The RSE1 must temporarily attached to the sidepanel.

1. Select menu Startup.

2. Open the Panel selection box with the Panel softkey.

3. Select the entry with the IP address of the RSE 1.

22

Rev. 1 / 02.2002

Page 28

RSE 1

Stand-Alone Controller

4. Press Attach.

Note:

It is possible that the sidepanel loses the connection to the mainframe. This

happens if the RSE 1 is not already connected to the same mainframe.

If this happens

- open the E-Box connection box with the E-Box softkey.

- select the mainframe’s address

- press Connect.

5. Now you can select the menu Install-Panel.

6. Select the filecard SatPanel in order to define the type of RSAT (RSAT1 or

RSAT2) which is connected and to which port.

7. Select Type, press Modify and select the protocol driver.

satpanel_vnnn for RSAT1.

sat2panel_vnnn for RSAT2.

(nnn is the version number of the driver. Normally there is only one version of

each available.)

8. Select Port, press Modify and select the port e.g. 1.

(note: current software allows to use ports 1 to 4)

9. Now the RSE 1 talks to the RSA T and the ”Disconnected” indicator (yellow flash

on the panel) of the RSAT panel goes off.

In addition to the RSAT you can connect UMDs and Auxiliary control panels (AUXCP) to the RSE 1. To do that refer to the sections Installation Menu and Configu-

ration Menu of the Operation Manual.

After these settings have been made it is necessary for normal operation to attach

the sidepanel again to the original control panel (in menu Startup). Both, the sidepanel and the RSAT panel are now connected.

5.1.3.5 Configuration for the RSAT2

Refer also to the RSAT2 Customer Manual.

Rev. 1 / 02.2002

23

Page 29

Stand-Alone Controller

5.1.4 DD35 AND SERAPH HD SIMULCASTING

5.1.4.1 Schematic

RSE 1

DD35 SD mainframe

BNC T-type

50 W

Terminator

RPS35-2 control panel

5.1.4.2 IP Addresses

Seraph HD mainframe

BNC T-type

RPS35-3 control panel

BNC T-type

50 W

Terminator

The following assumes that both mainframes and the control panels are connected

to the LAN.

24

As stated under ”Network Configuration” all devices on the LAN must have an unique IP address.

To successfully integrate the second mainframe (with its 3 IP addresses) in the network take the steps as follows:

1. Look up the IP addresses of all devices.

2. Check for conflict (i.e. two identical IP addresses).

If the second mainframe has factory default setting then there is an address

conflict.

3. If there is a conflict, change the IP address of the second mainframe to free addresses.

The mainframe IP address could be changed to 192.168.0.80 (rotary switch

= 0x50). The second mainframe now occupies the addresses 192.168.0.80,

... .81, and ... .82.

4. Reboot the mainframe.

Rev. 1 / 02.2002

Page 30

RSE 1

5.1.4.3 Simulcast Operation

In simulcast operation the control panel talks to two mainframes at the same time.

Setup

One of the mainframes is selected in the StartUp menu with the Connect softkey.

This mainframe is considered the main or ’Master’ mainframe.

The second mainframe (or ’Slave’) is identified in the menu Install-Panel-Global

by the setting ’SimulcastAddress’.

A value of 1 .. 254 indicates that there is a simulcast ’slave’ mainframe and the last

byte of its IP address.

If the address of the second mainframe is 192.168.0.80 (as suggested above) enter

80 here.

A value of ’0’ indicates that there is no simulcast ’slave’ mainframe.

Note:

The Simulcast Address can also be entered in the local panel setup under

”Install Panel –> SimulcastAdr”

Stand-Alone Controller

Operation and breakaway

If there is a valid ’Simulcast Address’ entered, the control panel can send all commands to both mainframes. Which effectively tells both mainframes to do the same.

There might be situations where it is necessary to send commands only to one

mainframe.

This is accomplished by the setting Simulcast in the panel setup (Install Panel).

It can be set to:

– MASTER = Master control only

– SLAVE = Slave control only

– BOTH = Simultaneous control

– DEF = Default ( = Master only)

There is a new function Simulcast Master in the selection list for the User Pro-

grammable Keys (UPK). (GUI Version 3.1.2)

This allows to program actual buttons on the control panel with that function.

When programmed to a button that button operates in the following way:

– when button is held down the commands are sent to the Master only.

– when released the commands are sent to BOTH.

S-M (= Master only) and S-S (= Slave only) are in the selection list for the User

Programmable Keys (UPK) in the Local Panel Setup.

This allows to program actual buttons on the control panel with that function.

Rev. 1 / 02.2002

When the Master only button is held down commands are sent to the Master only .

And the same with Slave only. When Master only (or Slave only) button is released,

all commands are again sent to both mainframes.

Note:

After a reset (or power cycle) the control panel resets the Simulcast Mode to

’Master only’.

25

Page 31

Stand-Alone Controller

RSE 1

Source substitution

Sometimes it is not 100% possible to cable the SD sources and the respective HD

sources to the same inputs of the mainframes.

A new setting in Install-EBox-Input allows to substitute the input number of the

incoming command by another input number. This feature uses one of the Substitu-

tion tables that are already used for AUX and M/E-couple.

The setting is ”Subst. Table” and is normally unchangeable (greyed out).

For those users who need this substitution it can be enabled by a registry setting:

The setting is the key ” INPUT_SUBSTAB_SELECTABLE” in

HKEY_CURRENT_USER\Software\BTS\SP\USERINTERFACE.

It is a DWORD value. ”0” disables the selection of the substitution table; ”1” enables

it.

Please note!

If there is a Subsitution table selected, it is in effect even if the ”Subst. T able” selec-

tion is greyed out.

5.1.5 TWO COMPLETE SYSTEMS

5.1.5.1 Schematic

DD35 SD mainframe

BNC T-type

50 W

Terminator

DD35 SD mainframe

BNC T-type

BNC T-type

50 W

Terminator

26

RPS35-2 control panel

RPS35-3 control panel

The following assumes that both mainframes and all the Control Panels are connected to the LAN.

Rev. 1 / 02.2002

Page 32

RSE 1

5.1.5.2 IP Addresses

Stand-Alone Controller

As stated under ”Network Configuration” all devices on the LAN must have an unique IP address.

To successfully integrate the second system in the network take the steps as follows:

1. Look up the IP addresses of all devices

2. Check for conflict (i.e. two identical IP addresses).

If the second mainframe and control panel has factory default setting then there

is an address conflict.

3. If there is a conflict.

Change the IP address of the second mainframe and the second panel to free

addresses.

The mainframe IP address could be changed to 192.168.0.80 (rotary switch

= 0x50). The second mainframe now occupies the addresses 192.168.0.80,

... .81, and ... .82.

The control panel IP address could be changed to 192.168.0.83 (rotary switch

= 0x53).

The sidepanel IP address could be changed to 192.168.0.84.

4. Now switch on.

5. Verify how the sidepanels are attached to control panels and how both are con-

nected to the mainframes.

Very likely there will be the following situation:

50 W

Terminator

DD35 Standard mainframe 1 (70)

DD35 Small mainframe 2 (80)

DD35–SBM

BNC T-type

50 W

Terminator

Sidepanel 2 (84)

RPS35-4LX control panel 1 (73)

Rev. 1 / 02.2002

RPS35-2 control panel 2 (83)

27

Page 33

Stand-Alone Controller

RSE 1

The control panel and sidepanel remember the IP address where they are connected and attached. There is one attachment that is now wrong:

Sidepanel 2 <–> Control Panel 1.

This MUST be corrected in the startup-menu of Sidepanel 2. (Detach from 73 and

Attach to 83).

Also re-inforce the attachment between Sidepanel 1 and Control Panel 1. (Detach

from 73 and Attach to 73 again).

In such a system it may be useful to avoid a mis–attachment totally. And enforce

that the control panel and sidepanel that are mounted in one tub are attached to

each other.

There are two ways to do so:

a) On software installation (of DS0203 or DS0103)

– select ”SinglePanel” installation

– on the next page enter the (complete) IP address of the control panel.

as result there will be no ”Panel” softkey in the StartUp menu.

b) In the registry

the key ”AttachToCp” in

HKEY_CURRENT_USER\Software\BTS\SP\LAN is a string value.

Legal strings are

”NONE” (= do not attach to any control panel)

”EVERY” (= the ”Panel” softkey is present and allows detach and attach)

”192.168.0.xxx” (= the IP address of the control panel to permanently attach to).

6. Now connect to the appropriate mainframe.

5.1.5.3 Stored Applications

Applications that are stored in sidepanel 1 (the one with the original IP address) can

be loaded into switcher 1 and will load fine.

Applications that are stored in sidepanel 2 (the one with the changed IP address)

can be loaded.

BUT without precaution they will load into the connected mainframe and control panel 1 and NOT control panel 2!

It is strongly recommended to use the Change device function the menu Config-

Copy-Simple to correct that.

The connections shown in the drawing can be useful – for two operator shows

or if mainframe 2 is there for emergency backup.

28

Rev. 1 / 02.2002

Page 34

RSE 1 Stand-Alone Controller

6. CONNECTING A RSAT PANEL TO THE RSE1

To load a macro for RSAT1 or RSAT2 panel per default you have to know the exact

name of this macro. The macro names are shown in the setup menu in the Master

TiM/E Memo section of the panel (Panel / RSatMac:), see also Operating part in

the Customer Manual chapter 4.4 Local Panel Setup, or at the list at the end of this

chapter.

The preferred macro has to be entered into the application file of the RSE1 (appli_cp.ini).

6.1 CREATING AN APPLICATION FILE FOR THE RSE1

With the RSE1 between a RSAT panel and the sidepanel it is not possible to load

default macros direct from the sidepanel to the RSA T panel. To copy the prepared

macros from the sidepanel to the RSAT panel you have to create first an appli_cp.ini file in each application you want to have the default macros present.

To have an appli_cp.ini file present at one application of the RSE1 you must do the

following steps.

1. T o find or create the appli_cp.ini file of an application you have to open with the

Windows explorer the devices.ini of the sidepanel PC (c:\pro-

gramme\DD35\appli\“application-name”\devices.ini).

Example of a devices.ini file:

Rev. 1 / 02.2002

2. It is very important that the IP Address of the RSE1 is contained in the devices.ini file. If not, attach the RSE1 temporarily to the mainframe in the Side-

panel program (Startup menu) and save the application (Config menu).

3. Now you have to check with the Windows explorer if a folder with the name of

the RSE1 is created in the devices.ini (see above, e.g. C:\pro-

gramme\dd35\appli\“application-name“\cp9).

29

Page 35

RSE 1Stand-Alone Controller

If there is no folder created, you must copy the folder of the control panel (e.g.

CP1). Paste the folder in the same application and rename it to the name of the

RSE1 (e.g. CP9) as it is listed in the devices.ini.

Example:

30

Rev. 1 / 02.2002

Page 36

RSE 1 Stand-Alone Controller

6.2 LOADING DEFAULT MACROS FROM THE SIDEPANEL

After creating an appli_cp.ini file in the application you must load a default macro

(see chapter 6.3 List of default Macros) into the appli_cp.ini file. This is necessary

to have the default macro available after every restart of the RSAT panel.

1. Open the appli_cp.ini file of the RSE1 folder (e.g. CP9) and go to the end of

the file to [SATPANEL1].

2. Enter the name of your preferred macro into the filename, as it is shown in the

picture below. Do not forget to add the extension .sat and note that the macro

names are case sensitive (use only small letters).

Example of the appli_cp.ini file:

3. After that save the appli_cp.ini file and reload the running application of the

sidepanel. The entered macro will be loaded to the connected RSAT panel.

Notes:

With a RSAT panel connected to a RSE1 you cannot learn single buttons

like with a RSAT panel connected directly to the sidepanel.

Whenever you change the default macro you have to reload the applica-

tion.

Rev. 1 / 02.2002

31

Page 37

6.3 LIST OF DEFAULT MACROS

The following list contains all available macros. You are also able to save your ow n

macros and load them as default. For further details refer to the RSAT Manuals.

Note:

All macros are specified for one RSAT panel type, e.g. RSAT1 or RSA T2 panel.

The names of the macros for the RSAT1 panel begin with 1xxxxxxx.sat and

for the RSAT2 panel with 2xxxxxxx.sat, see table below.

Macros for RSAT1 panel Macros for RSAT2 panel

1_me1ky1.sat 2_pp_24.sat

1_me1ky2.sat 2_me1_24.sat

1_me1ky3.sat 2_me2_24.sat

1_me1mem.sat 2_me3_24.sat

1_me1trn.sat 2_pp_32.sat

1_me2ky1.sat 2_me1_32.sat

1_me2ky2.sat 2_me2_32.sat

1_me2ky3.sat 2_me3_32.sat

1_me2mem.sat 2pp_24ml.sat

1_me2trn.sat 2m1_24ml.sat

1_me3ky1.sat 2m2_24ml.sat

1_me3ky2.sat 2m3_24ml.sat

1_me3ky3.sat 2pp_32ml.sat

1_me3mem.sat 2m1_32ml.sat

1_me3trn.sat 2m2_32ml.sat

1_medel.sat 2m3_32ml.sat

1_mntpr1.sat

1_mntpr2.sat

1_mstmem.sat

1_ppdsk1.sat

1_ppdsk2.sat

1_ppdsk3.sat

1_ppdsk4.sat

1_ppdsk5.sat

1_ppdsk6.sat

1_ppmemo.sat

1_pptrns.sat

1_tape1.sat

1_tape2.sat

1_tape3.sat

1_tape4.sat

1_vstore.sat

RSE 1Stand-Alone Controller

32

Note:

All macro names are case sensitive! Only use small letters.

Rev. 1 / 02.2002

Page 38

RSE 1 Stand-Alone Controller

6.4 SAVING ENVIRONMENTAL DATA

Attention:

If you use the copy function in the Config menu while you are attached to a

RSE1 you will overwrite the environment file (envir_cp.ini) of the control

panel and your configurations for the control panel will get lost.

Saving the configurations of the RSE1:

At first it is recommended to save the configurations of the panel. Be sure that

the control panel is attached and not the RSE1 (see Startup menu)! Save with

the Copy function in the Config menu the configurations of the control panel.

Rename the envir_cp.ini file of the control panel with the Windows Explorer

(c:\programme\dd35\Envir\envir_cp.ini) to e.g. envir_cpanel.ini.

Attach the RSE1 in the Startup menu.

Save your RSE1 configurations with the Copy function in the Config menu. Now

the RSE1 configurations are saved in the envir_cp.ini file of the Envir folder.

Rename the envir_cp.ini file of the RSE1 (c:\programme\dd35\Envir\en-

vir_cp.ini) to e.g. envir_rse1.ini.

Attach the control panel in the Startup menu.

In this case the configurations for the RSE1 and the control panel will be save without overwriting any environment file. To load the wished configuration you must first

rename the envir_XXX.ini file to envir_cp.ini.

Rev. 1 / 02.2002

33

Page 39

7. SERVICING

7.1 EXCHANGING THE LITHIUM BATTERY

The Stand-Alone Controller RY2600 contains a lithium battery. The battery supplies the buffered SRAM with voltage, thus storing the last data set when the voltage supply of the unit is switched off or interrupted. When switching on again, the

controller resumes its last-selected operating mode with all parameters.

According to the specifications by the manufacturer, the lithium battery of the controller boards has a life time of up to 10 years. To ensure that no data loss will occur

in the off-state, Thomson recommends as a precaution to exchange the lithium battery after 5 years of operation. A label with an adequate note is provided on the unit.

A spare battery can be ordered from Thomson under the order number

3 119100195 or on the market under the type designation VARTA CR1/2 AA.

Attention!

RSE 1Stand-Alone Controller

Danger of explosion when the battery is not correctly inserted. Replace the

battery only by a battery from the same manufacturer or by an equivalent

type recommended by the manufacturer.

Protect the environment!

Dead batteries do not belong in the garbage. Hand the used batteries over

to a local disposal place or observe the respective instructions of the

manufacturer!

Change has to be carried out in the following steps:

1. Reset the controller by pressing the Reset button on the controller board. Doing

so, after restart the current environment data is written into the “flash” disk.

2. Store the current application data of the Stand-Alone Controller in the Config

Main menu by Save or Save As onto the hard disk of the PC in the connected

control panel.

3. Exchange the battery as follows:

4. Switch off the controller.

5. Demount the case cover.

34

6. Using an appropriate ESD tool and a grounded soldering iron, separate the soldered connections of the battery from the solder tags and remove the battery.

7. Solder in the new battery observing the polarity.

8. When starting the controller again, the Ramdisk and the Appdisk have to be

reformatted.

For this purpose, prior to switching on, activate DIL switch 2 (verbose mode)

on the corresponding Controller Board.

Rev. 1 / 02.2002

Page 40

RSE 1 Stand-Alone Controller

DIL-Schalter 2 (verbose mode) Board

T26 Panel controller RY 2600

Start the Hyper terminal on service PC and connect it to the service connectors

of the controller boards.

Press the Reset button, wait until the Boot program reaches the point where

the inquiry “Format the ramdisk?” is displayed. Acknowledge with “y” (yes).

The inquiry “Format the ramdisk?” is displayed once more, this time for formatting the Appdisk. Acknowledge with “y” (yes).

Attention:

The “flash disk” must not be formatted! That means ignore the corre-

sponding stop of the boot sequence and let it continue automatically.

9. If required, set the system clock in the controller:

Enter:

sysDate <return>

inquire the current time setting. Doing so, watch capitalization.

If the current time is not exact, it has to be entered according to the input inquiry

sysDate “dd-mm-yyyy hh:mm:ss”

Example:

“06-02-2001 13:00:00”

Subsequently reset DIL switch 2 again.

Rev. 1 / 02.2002

35

Loading...

Loading...