Page 1

Instruction Manual

Profile

®

RAID Storage

PRS 250

Printed in USA or United Kingdom

Tektronix, Inc.

PO Box 1000

Wilsonville, OR 97070-1000 USA

1-800-547-8949 (USA and Canada)

1-503-682-7300

http://www.tek.com

N 60

Page 2

Copyright 1998 Tektronix, Inc. Wilsonville, Oregon.

Printed in the United States of America or the United Kingdom. All rights reserved. This document may not be copied in whole or in part, or

otherwise reproduced except as specificallypermittedunder U.S. copyright law, without the prior written consent of Tektronix, Inc., P.O. Box

1000, Wilsonville, Oregon 97070-1000 USA.

TEKTRONIX, TEK, and Profile are registered trademarks of Tektronix, Inc. Other trade names used in this document are trademarks or

registered trademarks of the manufacturers or vendors of the associated products.

Manual Revision Status

PRODUCT: PRS250 RAID Storage

REV DATE DESCRIPTION

May 1998 Original Issue. Manual part number 071-0226-00.

Page 3

Tektronix Product Support

You can get technical assistance, check on the status of problems, or report new problems by

contacting our Product Support Group.

United States and Canada

Monday–Friday 5:30AM–5:00PM Pacific Time (800) 547-8949

Europe

Monday–Friday 9:00AM–5:30PM

Austria 222-799-3535 Netherlands 010-495-4255

Belgium 02-714-3401 Norway 22-83-85-69

Denmark 3543-5259 Spain 91-564-4692

Finland 161-691-98559 Sweden 08-679-8419

Germany 069-935-25001 Switzerland 041-210-6009

Italy 44-1908-681-706 United Kingdom 01908-681-703

Luxembourg 400-848 Other 44-1908-681-703

Email: EuroProfile@tek.com

Asia and South America

Australia 61-2-888-7066 Korea 82-2-528-5299

Brazil 55-11-543-1911 Mexico 52-5-666-6333

Hong Kong 852-2585-6688 Singapore 65-356-3900

Japan 81-3-3448-3111 Taiwan 886-2-765-6362

World Wide

24-hour Emergency Hotline (503) 685-2345 (Contract and warranty customers)

World Wide Web http://www.tek.com/VND/support

FTP Site ftp.tek.com

Email ProfileSupport@tek.com

i

Page 4

ii

Page 5

Table of Contents

General Safety Summary

Injury Precautions .................................................................................................................. v

Product Damage Precautions................................................................................................ vi

Safety Terms and Symbols.................................................................................................... vi

Regulatory Information

Certifications and Compliances.............................................................................................. vii

Chapter 1 Introduction

Organization of the Manual.................................................................................................... 1-1

About the RAID Storage Chassis........................................................................................... 1-2

RAID Storage Components.................................................................................................... 1-3

Storage-control Processor (SP) ........................................................................................ 1-4

Disk Drive Modules ........................................................................................................... 1-5

Voltage Semi-regulated Converters (VSCs)...................................................................... 1-6

Fan Module ....................................................................................................................... 1-7

Chapter 2 Installation

Installing RAID in a Cabinet................................................................................................... 2-1

Attaching the Slot Matrix Label.......................................................................................... 2-1

Mounting RAID in a Cabinet.............................................................................................. 2-1

Configuring the Profile Disk Drives ........................................................................................ 2-8

Removal of Profile Internal Disk Drives............................................................................. 2-8

Connection to the Profile System........................................................................................... 2-10

Connecting Serial (console) Cables.................................................................................. 2-10

Setting SP SCSI IDs.......................................................................................................... 2-11

Configurations and Cabling............................................................................................... 2-13

Two-Channel Profile/Single-SP RAID .......................................................................... 2-14

Two-Channel Profile/X Single-SP RAIDs..................................................................... 2-15

Two-Channel PDR200/One Dual-SP RAID ................................................................. 2-16

Four Channel Profile/2 RAIDs...................................................................................... 2-17

Four-Channel Profile/Multiple RAIDs............................................................................ 2-18

Four-Channel PDR200/One Dual-SP RAID................................................................. 2-20

Connecting the Power Cord.............................................................................................. 2-21

Powering Up the Storage Chassis .................................................................................... 2-22

Configuring and Managing the RAID ..................................................................................... 2-23

Running DASSMGR.......................................................................................................... 2-23

Before You Begin ......................................................................................................... 2-23

Starting DASSMGR...................................................................................................... 2-23

Setting Password Protection............................................................................................. 2-24

Changing the Password.................................................................................................... 2-25

Setting Storage System Date and Time............................................................................ 2-26

Chapter 3 Servicing the System

Checking Status with the Presentation Utility......................................................................... 3-1

Moving the Grid Cursor ................................................................................................ 3-4

Reconfiguring a Storage System ........................................................................................... 3-5

Changing Physical Disk Configurations ............................................................................ 3-5

Adding Disk Modules and Creating New Logical Units ................................................ 3-5

Binding Disk Modules as a Logical Unit ....................................................................... 3-6

Binding with Two SPs................................................................................................... 3-8

Unbinding a Physical Disk Unit..................................................................................... 3-9

RAID Instructions iii

Page 6

Table of Contents

Changing Physical Disk Unit Parameters ......................................................................... 3-10

Changing the Rebuild Time.......................................................................................... 3-10

Updating Licensed Internal Code...................................................................................... 3-11

Installing a New Revision of Licensed Internal Code................................................... 3-12

Upgrade and Repair of a Storage System............................................................................. 3-14

Handling CRUs ................................................................................................................. 3-15

Avoiding Electrostatic Discharge (ESD) Damage ........................................................ 3-15

Emergency Procedures (without an ESD kit)............................................................... 3-16

Precautions When Removing, Installing, or Storing CRUs .......................................... 3-16

Opening and Closing the Fan Module............................................................................... 3-17

Replacing or Adding a Disk Module.................................................................................. 3-18

Removing a Disk Module ............................................................................................. 3-18

Installing a Disk Module ............................................................................................... 3-20

Removing or Installing a Disk Filler Module...................................................................... 3-22

Installing or Removing SP Memory Modules.................................................................... 3-23

Installing SP Memory Modules..................................................................................... 3-23

Removing SP Memory Modules................................................................................... 3-24

Replacing an SP ............................................................................................................... 3-25

Removing an SP .......................................................................................................... 3-25

Installing an SP ............................................................................................................ 3-27

Removing or Installing an SP Filler Board ........................................................................ 3-28

Replacing or Adding a VSC .............................................................................................. 3-30

Replacing a Fan Module................................................................................................... 3-32

Appendix A Technical Specifications

AC power requirements................................................................................................ A-1

Power cables................................................................................................................ A-1

Operating limits ............................................................................................................ A-1

Non-operating limits (shipping and storing).................................................................. A-1

Physical........................................................................................................................ A-2

Service clearance......................................................................................................... A-2

Cabling......................................................................................................................... A-2

Miscellaneous............................................................................................................... A-2

Appendix B Ordering Information

Customer Replaceable Units................................................................................................. B-1

Field Replaceable Units......................................................................................................... B-2

iv RAID Instructions

Page 7

General Safety Summary

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the

system. Read the General Safety summary in other system manuals for

warnings and cautions related to operating the system.

Injury Precautions

Use Proper Power

Cord

Ground the Product This product is grounded through the grounding conductor of the power

Do Not Operate

Without Covers

Use Proper Fuse To avoid fire hazard, use only the fuse type and rating specified for this

Do Not operate in

Wet/Damp

Conditions

Do Not Operate in an

Explosive

Atmosphere

Avoid Exposed

Circuitry

To avoid fire hazard, use only the power cord specified for this product.

cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or

output terminals of the product, ensure that the product is properly

grounded.

To avoid electric shock or fire hazard, do not operate this product with

covers or panels removed.

product.

To avoid electric shock, do not operate this product in wet or damp

conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other

metallic objects. Do not touch exposed connections and components

when power is present.

RAID Instructions v

Page 8

General Safety Summary

Product Damage Precautions

Use Proper Power

Source

Use Proper Voltage

Setting

Provide Proper

Ventilation

Do Not Operate With

Suspected Failures

Do not operate this product from a power source that applies more than

the voltage specified.

Before applying power, ensure that the line selector is in the proper

position for the power source being used.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by

qualified service personnel.

Safety Terms and Symbols

Terms in This

Manual

!

!

!

!

These terms may appear in this manual:

WARNING:Warning statementsidentify conditionsor practices that can

result in personal injury or loss of life.

CAUTION: Caution statements identify conditions or practices that can

result in damage to the equipment or other property.

Terms on the

Product

Symbols on the

Product

!

!

These terms may appear on the product:

DANGER indicates a personal injury hazard immediately accessible as

one reads the marking.

WARNING indicates a personal injury hazard not immediately

accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

DANGER high voltage

Protective ground (earth) terminal

ATTENTION – refer to manual

vi RAID Instructions

Page 9

Regulatory Information

Regulatory Information

Certifications and Compliances

Canadian Certified

Power Cords

Canadian Certified

AC Adapter

FCC Emission

Control

Canadian EMC

Notice of

Compliance

Canadianapproval includes the products and power cordsappropriate for

use in the North America power network. All other power cords supplied

are approved for the country of use.

Canadian approval includes the AC adapters appropriate for use in the

North America power network. All other AC adapters supplied are

approved for the country of use.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with this

installation manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his or her own expense. Changes or

modifications not expressly approved by Tektronix can affect emission

complianceand could void the user’s authority tooperate this equipment.

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

EN55022 Class A

Warning

Le présent appareil numérique n’émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

For products that comply with Class A. In a domestic environment, this

product may cause radio interference, in which case the user may be

required to take adequate measures.

RAID Instructions vii

Page 10

Regulatory Information

viii RAID Instructions

Page 11

Chapter

1

Introduction

This manual explains how to install the rack-mounted RAID Storage chassis, how to

configure and manage the system, and how to replace and/or add customer

replaceable units (CRUs). The manual is for technical personnel who want to install

and maintain the RAID Storage chassis. It assumes familiarity with Profile

Professional Disk Recorders. For information on RAID usage, see the Profile User

Guide.

NOTE: Using the PRS250 RAID Storage chassis requires Profile System Software

V2.2 or higher. For optimum performance from your PRS250, you should use

Profile System Software V2.4.

Organization of the Manual

The manual is organized into chapters which are identified and briefly described

below.

Chapter 1 - Introduction: Introduces the RAID Storage chassis and its components.

Chapter 2 - Installation: Describes how to install and configure the RAID Storage

chassis.

Chapter 3 - Servicing the System: Describes how to monitor and service the RAID

Storage chassis.

Appendix A: Lists the technical specifications of the RAID Storage chassis.

Appendix B: Provides ordering information for CRUs and Field Replaceable Units

for the RAID Storage chassis.

RAID Instructions 1-1

Page 12

Chapter 1 Introduction

About the RAID Storage Chassis

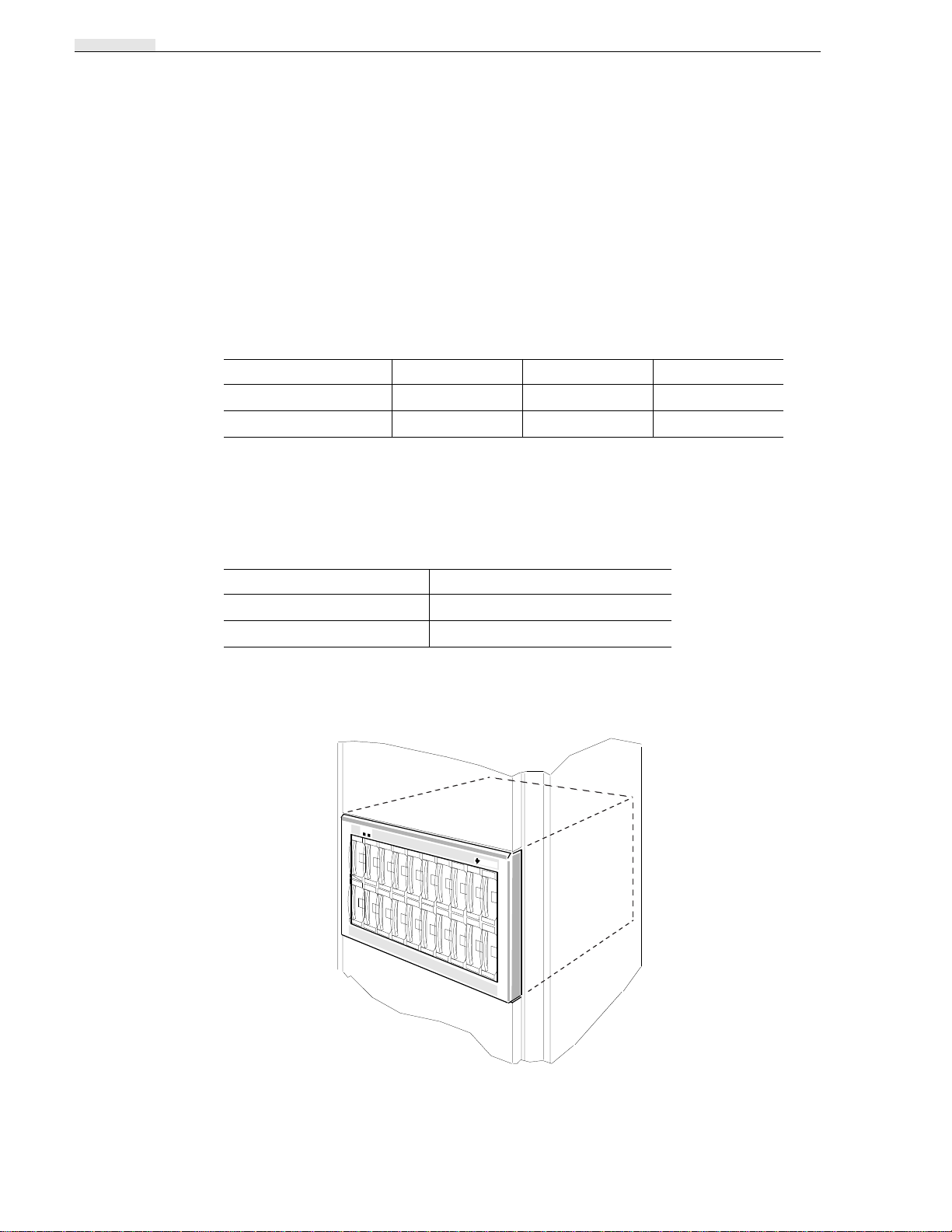

This RAID Storage provides a compact, high-capacity, high-availability source of

disk storage for the Profile Professional Disk Recorder. A single RAID Storage

chassis offers a large capacity of high-availability disk storage in as many as 20 disk

modules that can individually be replaced while the system is powered up.

Two models are available, the PRS250 and the PRS250M. The PRS250M offers two

storage processors, which increase the bandwidth of the RAID chassis.

Approximate storage times

Video Compression Type 10 Disk Drives 15 Disk Drive 20 Disk Drives

M-JPEG 6 hours 9 hours 12 hours

MPEG 12 hours 18 hours 24 hours

a.

At 24 Mb/sec for MJPEG, 8 Mb/sec for MPEG, 4 audio tracks per video

a

The following table lists the maximum number of RAIDs that can be connected to a

Profile Professional Disk Recorder.

Maximum number of RAIDs per Profile system

Number Of Profile Channels Maximum Number of RAID Chassis

26

412

a.

Requires Profile System Software V2.4. To reach maximum

capacity, connect no more than 3 RAID chassis per SCSI bus,

with no other external SCSI devices connected.

a

1-2 RAID Instructions

Page 13

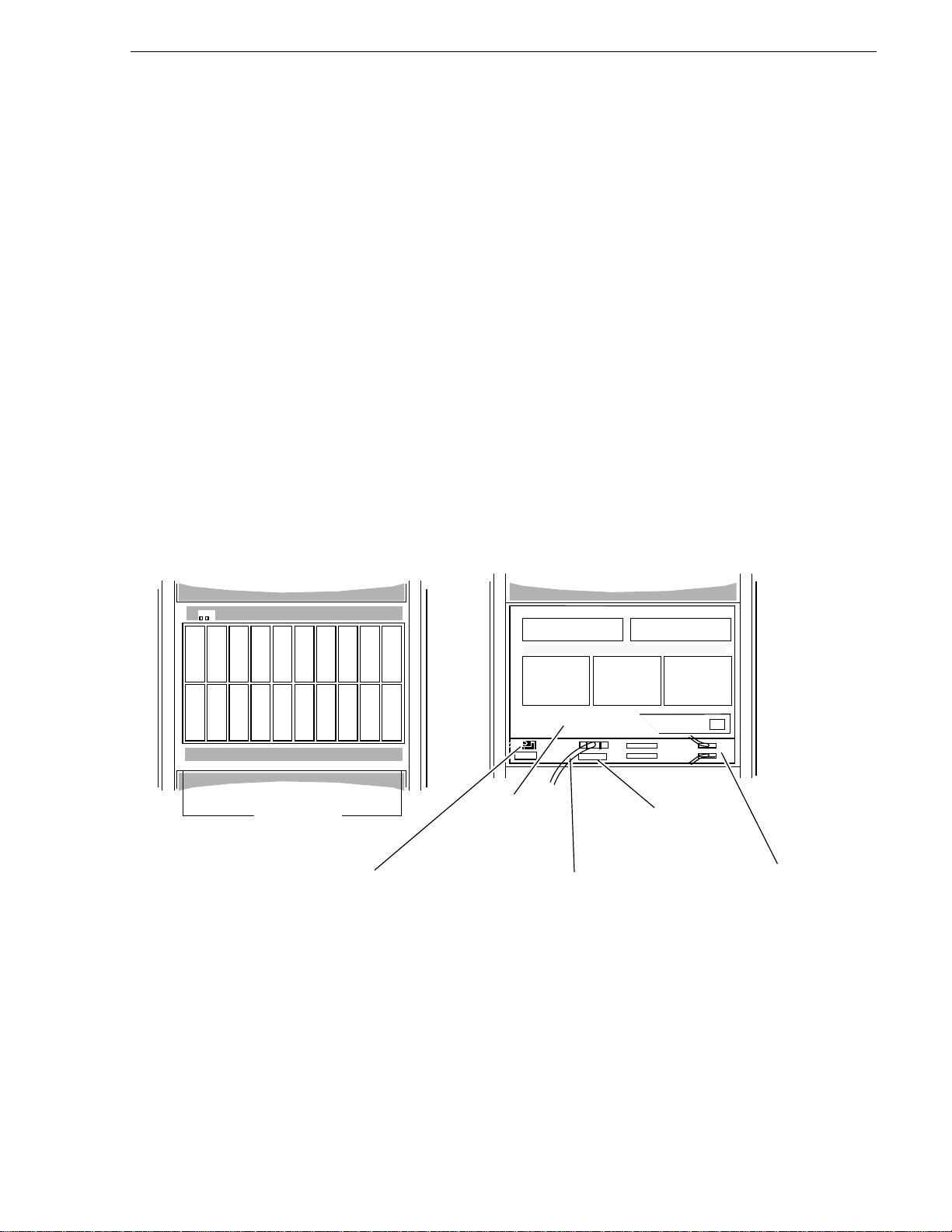

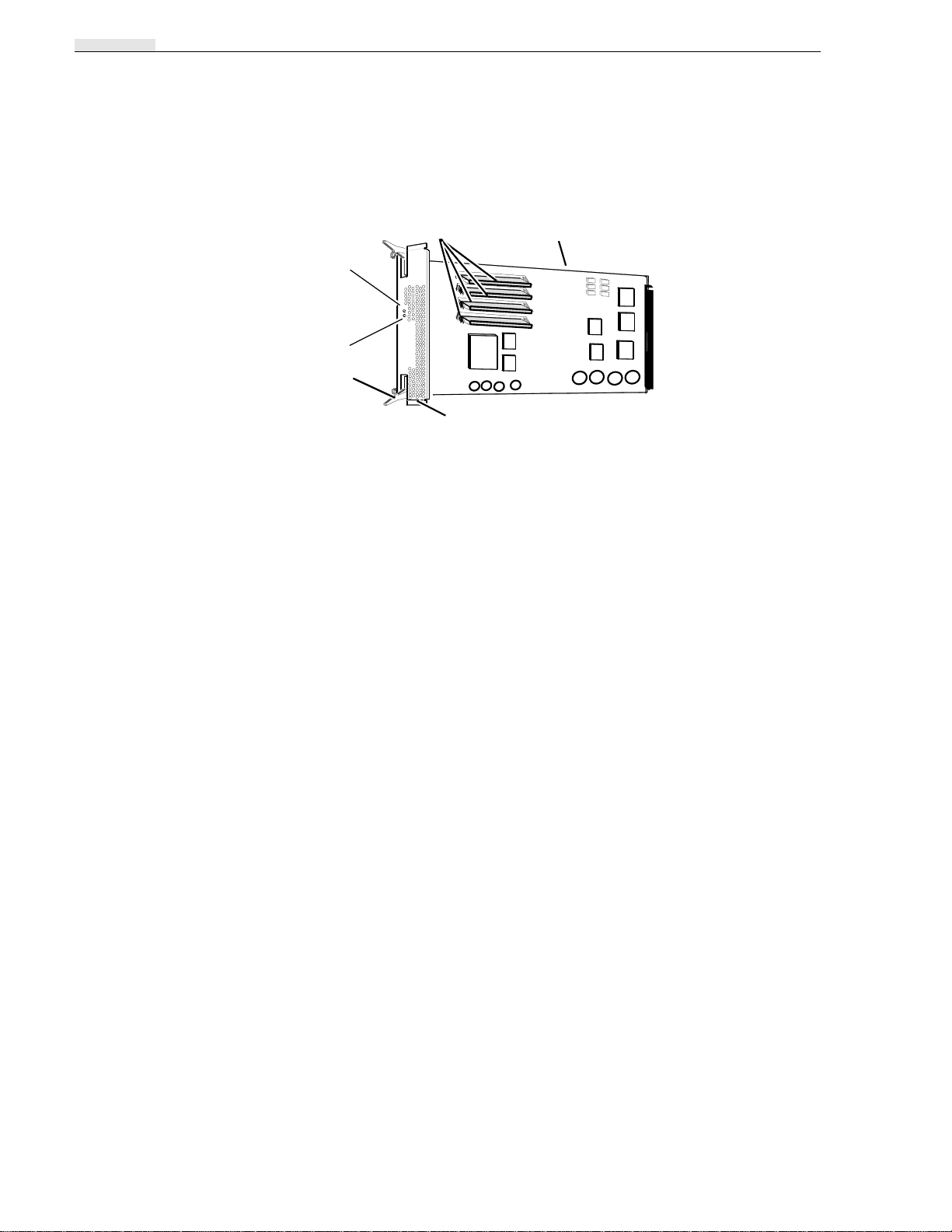

RAID Storage Components

The RAID Storage chassis contains the components listed below.

• One (PRS250) or two (PRS250M) storage-control processors (SP).

• 10, 15, or 20 disk drive modules.

• One fan module.

• Three voltage semi-regulated converters (VSCs) power supplies

The SPs, disk modules, fan module, and VSCs in the RAID Storage chassis are

customer-replaceable units (CRUs), which you can install or replace yourself.

The following illustration shows the location of the RAID’s CRUs, which also

include the SCSI bus cable, SCSI terminator plug, power cord, and the optional

asynchronous cables. In addition to the CRUs, the RAID Storage chassis contains

field-replaceable units (FRUs). Only qualified service personnel should replace an

FRU.

Location of the customer-replaceable units in the storage chassis

RAID Storage Components

Front of RAID Storage chassis

A0

A1

B0

B1

C0

C1

D0

D1

E0

E1

A2

A3

B2

B3

C2

C3

D2

D3

10,15, or 20

Disk drive

modules

Power cord

E2

E3

Back of RAID Storage chassis

Fan module

(not shown)

SCSI bus cable

SP A SP B

VSC

VSC

SCSI terminator

plug

VSC

Serial cables

(optional)

RAID Instructions 1-3

Page 14

Chapter 1 Introduction

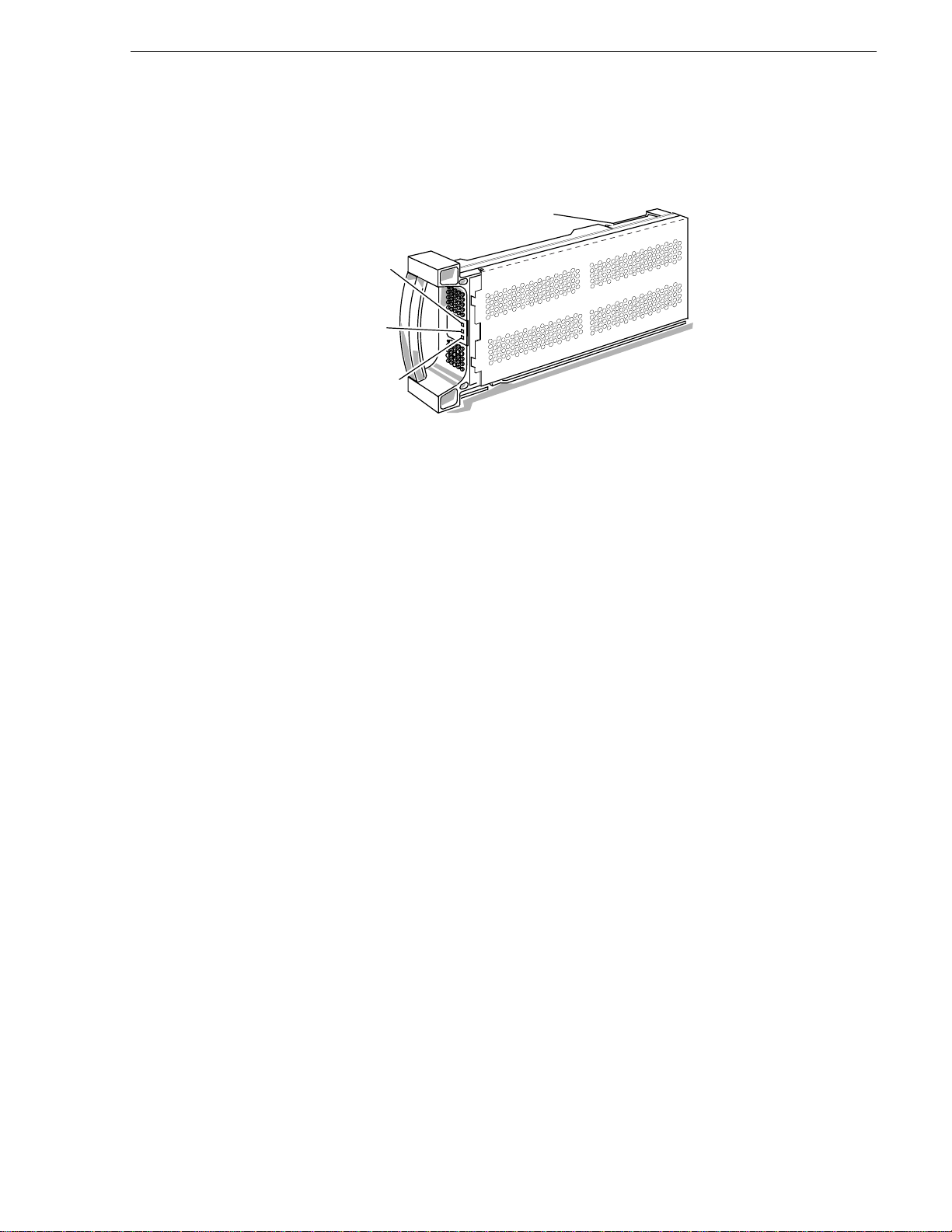

Storage-control Processor (SP)

Memory modules

Service light

(amber)

Ready light

(green)

Latch

Bezel

Printed-circuit

board

TheSP consists ofa printed circuitboard with two or four memory modules (DIMMs)

and a bezel with status lights, and latches to secure the SP in place. The memory

modules provide 32 Mbytes of SP memory. The SP uses 4Mbytes of this memory for

system buffers. The remaining memory is available for system use.

Two status lights on the SP indicate the following:

Ready light (green) — Lights while the SP is powered on and operating normally.

Service light (amber) — Lights when the SP is not working properly.

The SPs are visible when you swing the fan module down from the back of the RAID

Storage chassis.

The SPprocesses data written to or read from the disk drive modules, and controls the

disk modules in the storage chassis through a synchronous SCSI bus. It has five

internal SCSI buses, each supporting four disk drive modules for a total of 20 disk

drive modules. The Disk Array Storage System Manager (dassmgr) uses an RS-232

connection to the RAID Storage chassis to communicate with an SP. Using the

dassmgr, you can set up RAID Storage memory, bind disk modules into logical units

(LUNs), update the RAID Storage Licensed Internal Code, and check RAID Storage

status.

A second SP increases the RAID chassis bandwidth for improved performance,

provided the two SPs are connected to separate SCSI busses. Do not connect both SPs

to the same SCSI bus.

IMPORTANT You should never attempt to replace any of the SP’s

components, except the memory modules.

1-4 RAID Instructions

Page 15

Disk Drive Modules

Ready light

(green)

Busy light

(green)

Fault light

(amber)

A disk drive module, also called a disk module, consists of a disk drive, a power

regulator board, internal cabling, and a plastic carrier. The carrier has a handle and

guides for inserting and holding the module in the RAID Storage chassis. A label

attached to the carrier’s side shows the drive module’s model number and capacity.

Disk Drive Modules

Disk drive module’s model

number label

Three status lights on the module indicate the following:

Ready light (green) — Lights while the disk drive module is powered up and ready

for use.

Busy light (green) — Lights while the drive is in use; for example, during formatting

or user I/O operations.

Fault light (amber) — Lights when the module is shut down by the SP because the

module failed. Also lights after you replace the drive, while the replacement drive

spins up to speed.

You can remove or install any one module at a time within a group of five drives

either while the storage chassis is running or in the idle mode (not running). You

should never open a disk drive module or attempt to replace any of its internal

components.

RAID Instructions 1-5

Page 16

Chapter 1 Introduction

Voltage Semi-regulated Converters (VSCs)

The VSCs are power supplies that convert the installation site’s ac line voltage to the

48, 24, and 18Vdc required to power the modules in the RAID Storage chassis. The

chassis contains three VSCs for high-availability operation.

Replace light

(amber)

Ready light

(green)

Two status lights on each VSC indicate the following:

Ready light (green) — Lights while VSC is operating normally.

Replace light (amber) — Lights when the SP determines that the VSC has failed.

The VSCs are visible when you swing the fan module down on the back of the RAID

Storage chassis.

You can remove or install a VSC while the storage chassis is running.

If a VSC fails, replace it as quickly as possible. With three VSCs, if one of them fails,

the RAID Storage continues to operate but you still should replace the failed VSC as

soon as possible to restore high-availability operation. Failure to replace the VSC

could cause the RAID Storagechassis to shut downif either the fan module or another

VSC fails. You should never open a VSC or attempt to replace any of its internal

components.

1-6 RAID Instructions

Page 17

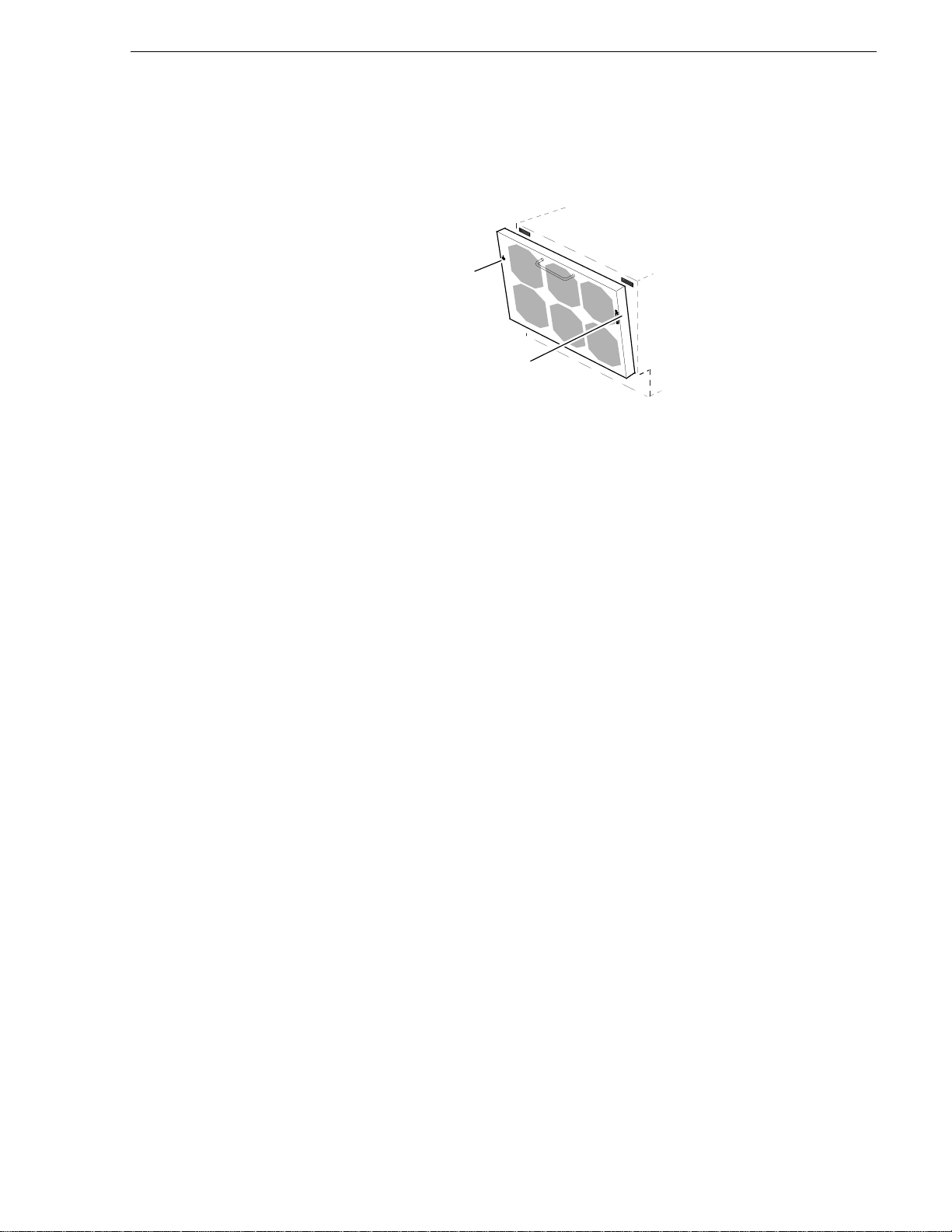

Fan Module

The RAID Storage chassis uses a single fan module, also called a fan pack, that

attaches to the back of the chassis. The fan module contains six high-capacity,

multiple speed fans, and a control/monitor board.

Fan Module

Replacelight

(amber)

Lock

One status light on the fan module indicates the following:

Replace light (amber) — Lights when a fan in the module is not working.

For high-availability operation, if a fan stops working, the remaining five fans speed

up to maintain air flow. The Replace light turns on to indicate that you must replace

the fan module as soon as possible.

The fan module is mounted on hinges so you can swing it down away from the

chassis. A mechanical lock and magnetic catches hold the fan module closed.

NOTE:If the fan moduleremains open formore than approximately 2minutes, the

storage chassis automatically shuts down to prevent overheating.

You can remove a fan module while the storage chassis is running. You should never

open the module or attempt to replace any of its internal components. If one of the

fans in the module fails, replace the fan module as quickly as possible to maintain

high-availability operation. Failure to replace the module could cause the RAID

Storage to shut down if either a VSC module or another fan fails.

RAID Instructions 1-7

Page 18

Chapter 1 Introduction

1-8 RAID Instructions

Page 19

Chapter

2

Installation

The procedures in this chapter assume the installation site meets the ac power

requirements and operating limits listed in Appendix A.

Installing RAID in a Cabinet

Attaching the Slot Matrix Label

Three sticky-backed labels are shipped with the storage chassis: a rack slot matrix

diagram showing the disk drive module locations, and two sheets of stickers for

identifying disk modules. Attach the rack slot matrix to your storage chassis so it is

visible. Save the two sheets of stickers for the person configuring the disk modules

into physical disks.

Mounting RAID in a Cabinet

You can mount RAID in a standard 19-inch cabinet using the hardware mounting kit,

which is supplied with the storage chassis.

WARNING: Since the RAID chassis weighs a minimum of about 46 kg (101 lbs),

installing it in the cabinet requires at least two people.

WARNING: Before opening the cabinet to install RAID, follow the cabinet

manufacturer’s recommendations for powering down the cabinet.

RAID Instructions 2-1

Page 20

Chapter 2 Installation

To install RAID in a cabinet

1. If you want to lessen the weight of the chassis, remove disk modules from the chassis

CAUTION: If you remove disk modules from the RAID chassis, be sure to label

each module and return all the modules to their original locations. Failure to

correctly locate the disk modules will result in one or more inaccessible LUNs, and

may even make the entire storage chassis inaccessible.

(see Removing a Disk Module in Chapter 3), making sure that as you remove each

module, you write on the module’s label the ID number of the slot (A0, for example)

from which you removed the module. Black out the lower ten slot postions on the slot

matrix label, since these positions are not available on the PRS250.

For the slot ID numbers, refer to the slot matrix label, which you should have just

attached to the RAID chassis, or to the following illustration.

Disk module slot ID numbers

A0

A1

B0

B1

C0

C1

D0

D1

E0

E1

A2

A3

B2

B3

2. Remove the chassis front panel as shown below.

Removing the front panel

E2

C2

D2

E3

C3

D3

Pull panel from one

side then the other.

3. Remove any trim and/or open the doors of the cabinet in which you are installing

2-2 RAID Instructions

the chassis. For information on opening the cabinet, refer to the documentation for

the cabinet.

Page 21

Mounting RAID in a Cabinet

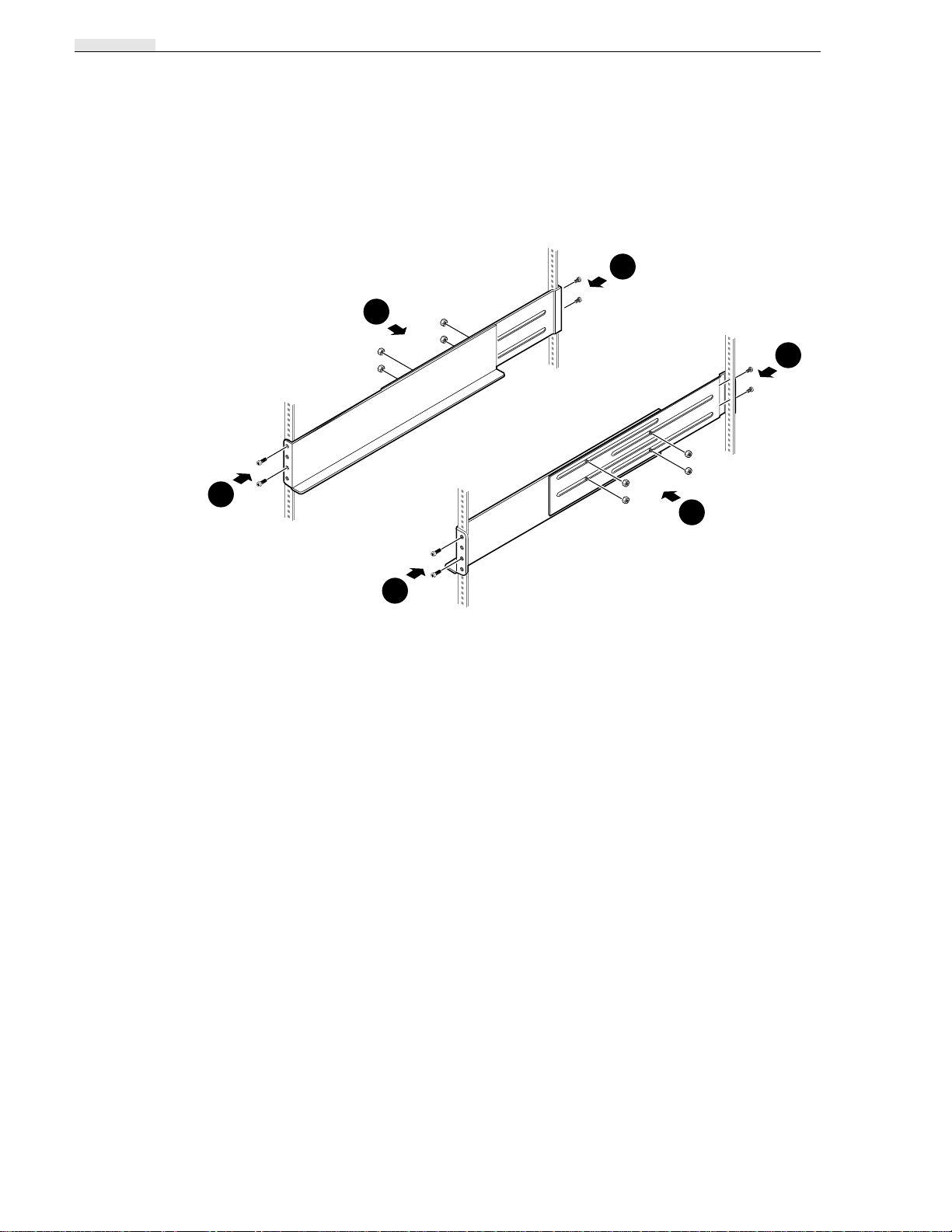

4. Attach the mounting rails to the cabinet according to the following instructions,

using the rails and parts in the hardware mounting kit.

a. Make sure that you have 14-inch clearance in the cabinet in which you will

install the storage chassis.

b. Mark and label a baseline in a 1/2-inch space (measured between the center of

adjacent holes) on the front and middle cabinet channels, as shown in the

following illustration. (Do not position the baseline between two 5/8-inch

spaced holes.)

Chassis location in the cabinet

1/2

inch

space

Front cabinet channels

Middle cabinet channels

toptop

Top of chassis

24 holes

or

14 inches

Base line

(bottom of chassis)

IMPORTANT You must mark a baseline in a 1/2-inch space or the chassis

won’t fit in the space where you plan to install it. The spaces on a channel,

measured between the center of adjacent holes, are either 1/2 inch or 5/8 inch

wide.

c. From the baseline, count up 24 holes. Mark the top-of-chassis line above the top

hole on the front and middle cabinet channels, as shown in the illustration.

RAID Instructions 2-3

Page 22

Chapter 2 Installation

2

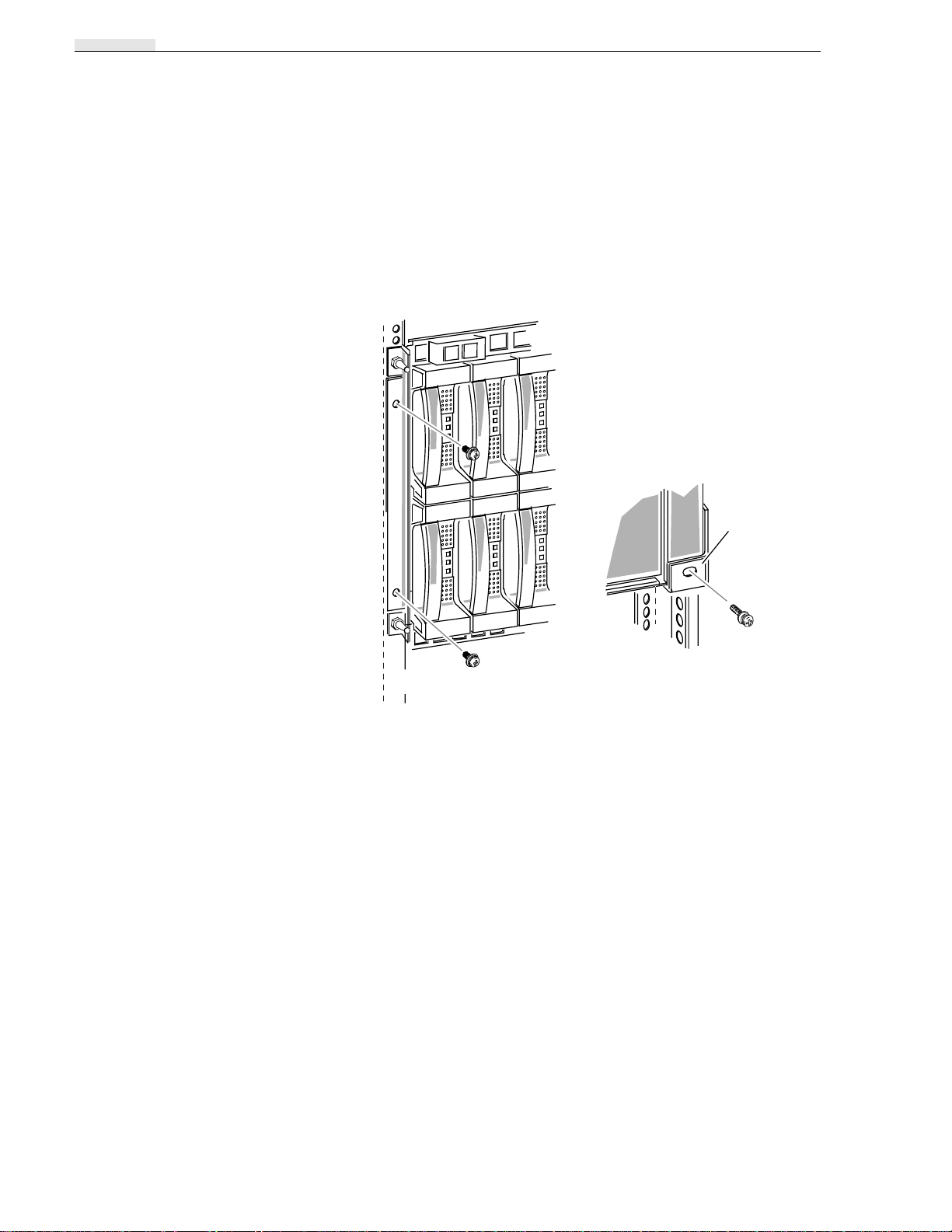

d. .Loosen thesecuring nuts➊on the two mounting railsas shown in the following

illustration.

Attaching the rails

2

1

2

0226-7

1

Slide rails to correct

length and tighten nuts

2

e. .If the front channel does not have threaded screw holes, attach clip nuts to the

front channel.

f. Align the bottom of the rail is aligned with the baseline mark on the cabinet’s

channel. Attach the mounting rails to the rack mount cabinet as shown (➋).

2-4 RAID Instructions

Page 23

Mounting RAID in a Cabinet

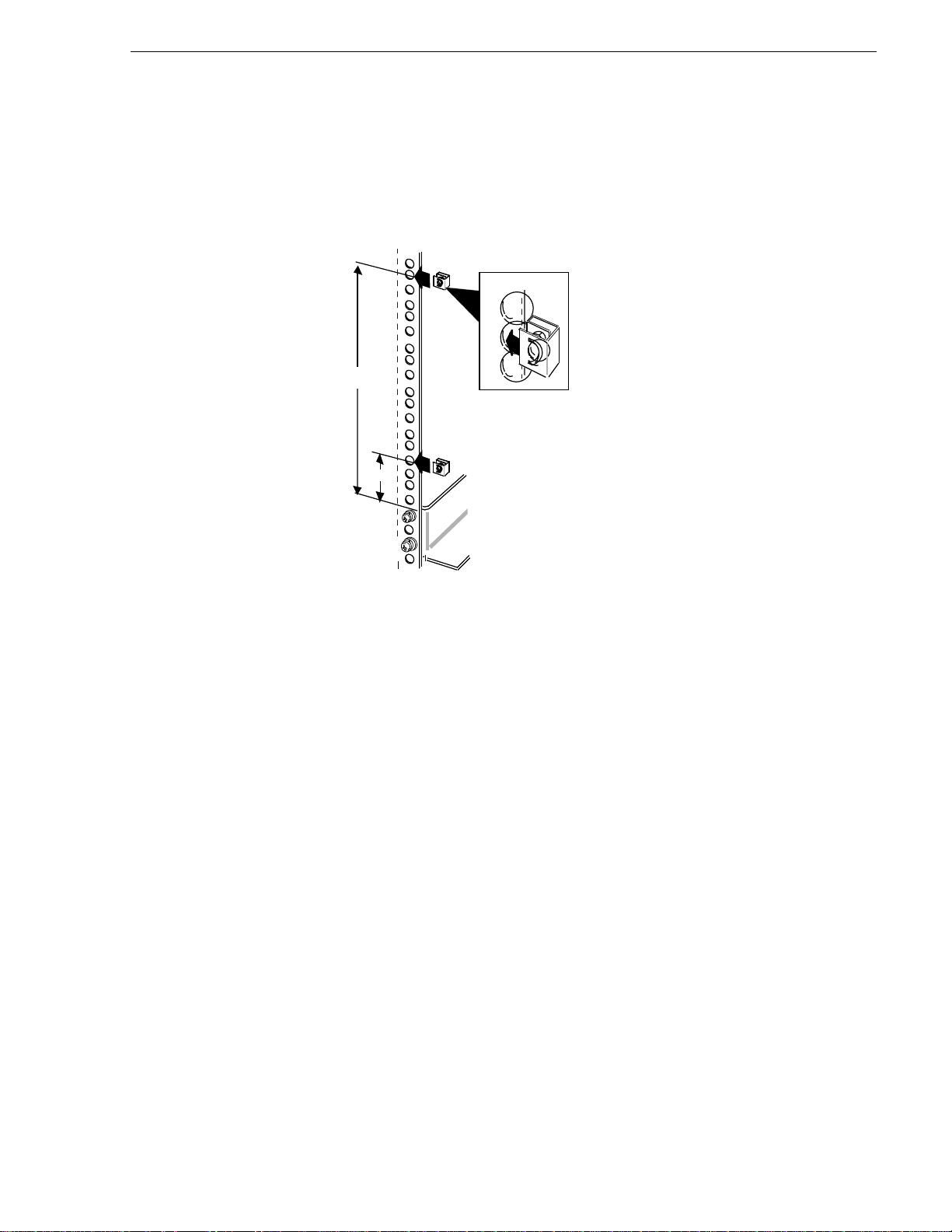

g. Slide the two clip nuts onto each front channel as shown below.

Attaching the clip nuts

Counting from the top of the rail, slide

clip nuts onto the 4th and 17th holes

of each front channel.

Rail

You are now ready to install the chassis in the cabinet

RAID Instructions 2-5

Page 24

Chapter 2 Installation

CAUTION: Do not lift the RAID chassis by the handle on the fan module at the

back of the storage chassis or by the disk drive module handles.

5. Mount the storage chassis in the cabinet with the remaining parts in the hardware

A. Slide chassis onto rails and

into the cabinet.

B. Fasten front of chassis to

cabinet with four screws

(2perside).

mounting kit as shown in the following illustration.

Attaching the storage chassis to the cabinet

Rail

C. Fasten back of chassis to left

and right rails with two screws

(1 per rail).

6. Reinstall any disk modules that you removed, being sure to put each module back

into its original slot.

2-6 RAID Instructions

Page 25

Mounting RAID in a Cabinet

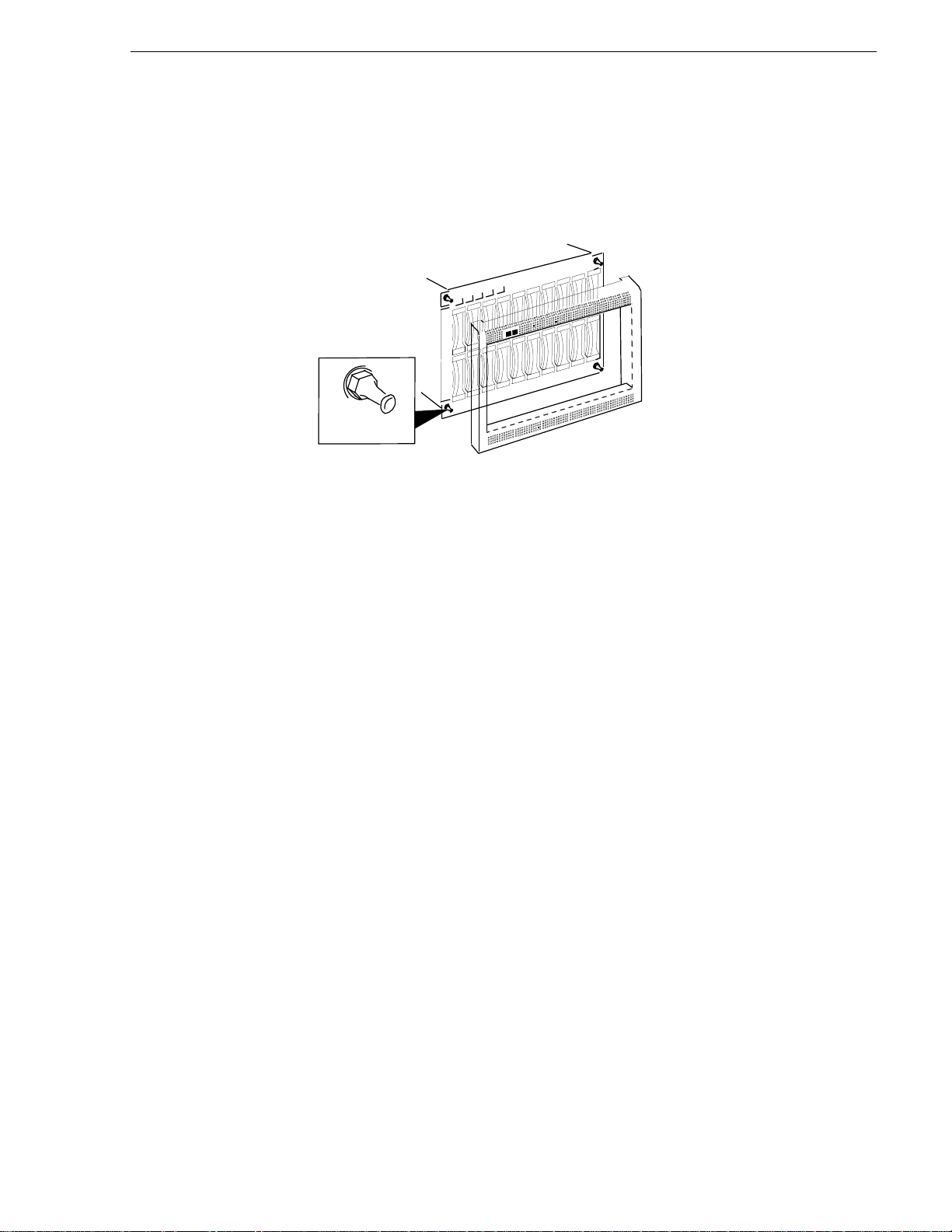

7. Reinstall the storage chassis’s front panel as shown in the following illustration.

Installing the front panel

Ballstud

Press panel onto four ballstuds.

(one at each corner)

8. Reinstall any trim you removed from the cabinet, and close any cabinet doors you

opened.

RAID Instructions 2-7

Page 26

Chapter 2 Installation

Configuring the Profile Disk Drives

The Profile disk recorder internal drives can not be used when a RAID unit is

connected. To disable the Profile system’s internal disk drives and enable the RAID

Storage, refer to your Profile User Manual.

Removal of Profile Internal Disk Drives

NOTE: Only qualified service personnel should perform the following procedure.

If you want to use a Profile disk recorder with attached RAID Storage, and are sure

you will not be using thatProfile without RAID Storage, you can remove the Profile

system’s internal disk drives for use elsewhere. Two procedures follow, one for the

PDR100 and one for the PDR200.

Removing PDR100 Internal Drives

To remove the internal disk drives from the PDR100, perform the following

procedure:

1. Turn all power to the Profile Off.

NOTE: You should NOT discard any hardware or cables.

2. Refer to your Profile Service Manual to remove the top cover from the Profile

chassis.

3. Refer to your Profile Service Manual to remove the SCSI cable(s). (If you have a

2-channelsystem there willbe a SCSI A cable only. If you have a 4-channel system

there will be both a SCSI A and a SCSI B cable.)

4. Refer to your Profile Service Manual to remove the Hard Disk Carrier Tray from

the Profile chassis.

5. Refer to your Profile Service Manual to remove the hard disk drives from the tray.

(There will be 4 hard disk drives if you have a 2-channel system and 8 hard disk

drives if you have a 4-channel system.)

6. Refer to your Profile Service Manual to reinstall the empty Hard Disk Carrier Tray

into the Profile chassis.

7. Use cable ties to anchor the loose hard disk drive cable(s) to the inner top edge of

the Hard Disk Carrier Tray.

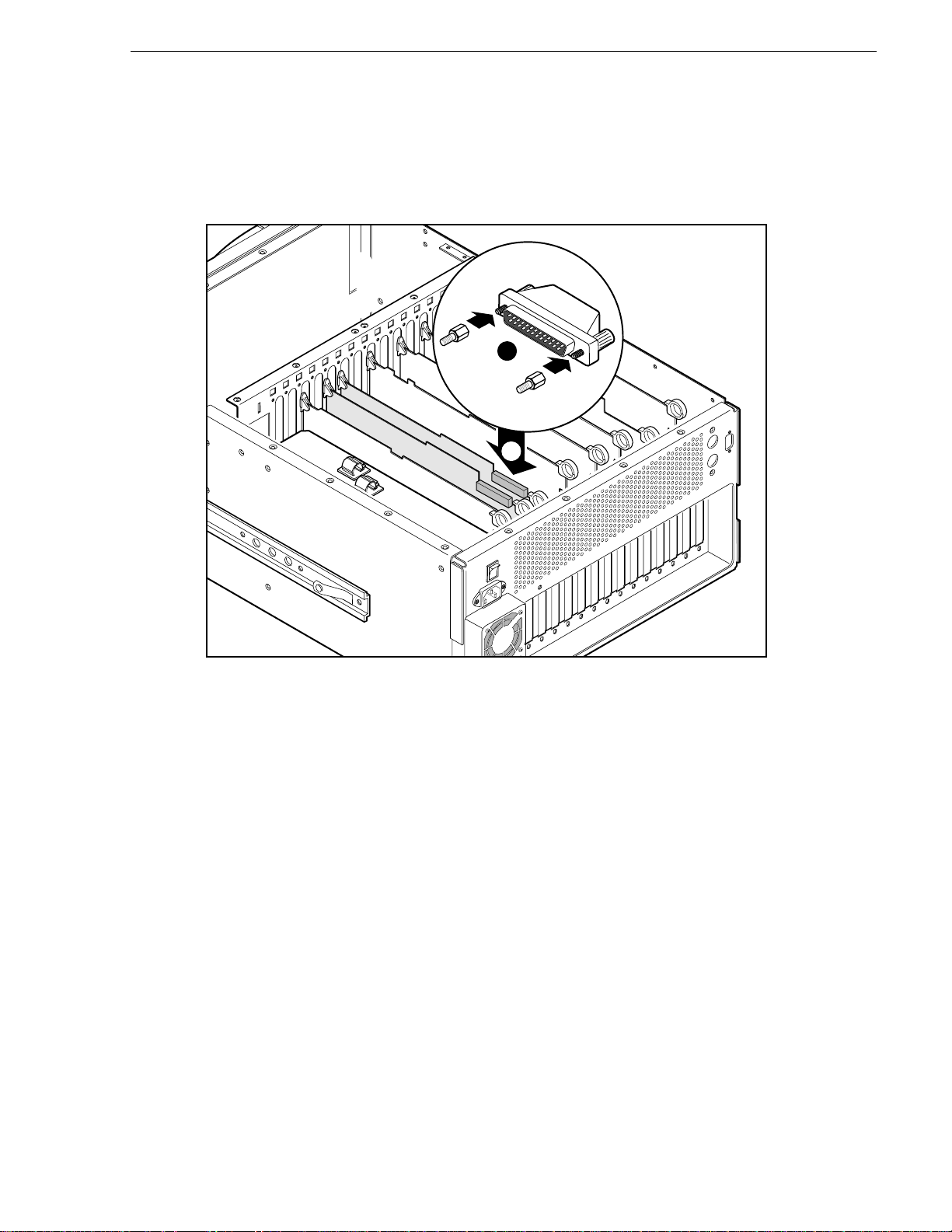

8. Attach jack screws (2 each, P/N 214-4689-00) to the bus terminator (P/N

011-0170-00), both of which came with your RAID Storage chassis. Refer to ➊ in

the following illustration.

9. Attach the bus terminator(s) to the Disk Recorder board(s). (There will be one

board if you have a 2-channel system and two if you have a 4-channel system.)

Refer to ➋ in the following illustration

2-8 RAID Instructions

Page 27

Removal of Profile Internal Disk Drives

Installing the internal disk recorder terminator

1

2

.

10.Reinstall the Profile covers.

Removing PDR200 Internal Disk Drives

To remove the internal disk drives from the PDR200 perform the following

procedure:

1. Turn all power to the Profile system off.

NOTE: You should NOT discard any hardware or cables.

2. Refer to your Profile Service Manual to remove the top covers from the Profile

chassis.

3. Refer to your Profile Service Manual to remove the hard disks from the system. At

the same time, remove the SCSI cable(s) connected between the disk recorder

board(s) and the SCSI Distribution board.

4. Reinstall the Profile chassis covers.

9674-20

RAID Instructions 2-9

Page 28

Chapter 2 Installation

Connection to the Profile System

The RAID Storage chassis connects to the Profile disk recorder through a wide

SCSI-2 differential bus. This SCSI bus connection allows the Profile system to

communicate with the disks in the RAID Storage chassis. Also, you can administer,

configure, and monitor the RAID Storage chassis using dassmgr through an

asynchronous communications connection between its asynchronous (console) port

and the Profile system’s RS-232 port.

The procedures in this chapter assume the following:

• You have all the cables and cable adapters that you need.

• If necessary, someone has installed and/or updated the Profile System Software.

• The Profile operating system is shutdown, and the Profile disk recorder is turned

• If the Profile system has a PDX Disk Expansion unit, it must be removed from the

Connecting Serial (console) Cables

off.

system. You can not connect both a RAID and a PDX Disk Expansion unit to the

same Profile disk recorder.

To use dassmgr to bind disk modules into logical units, set up storage chassis

caching, and monitor storage chassis operation, you must connect the console SP port

for each SP in a storage chassis to an serial port of the Profile system.

1. Attach a 25-pin female-to-9-pin female null modem cable to the Profile system’s

RS-232 connector in the upper right corner on the Profile system’s rear panel.

Attaching the 25-pin female-to-9-pin female null modem cable

Profile system’s

RS-232 connector

2. Attach the male end of the serial (console) cable to the 25-pin connector on the

2-10 RAID Instructions

adapter cable.

Page 29

Setting SP SCSI IDs

3. Attach the other end of the serial cable to the RAID CONSOLE SP-A connector. See

the following illustration.

Attaching the cable to the SP’s console A connector

Rear of storage chassis

Setting SP SCSI IDs

Each SP connected to the same SCSI bus requires a unique SCSI ID number (that is,

a number that is not used by any other device on the bus). The back of the storage

chassis, see the following illustration, has two SCSI ID switch packs. Each switch

pack has four switches (ID0-ID3). One switch pack sets the SCSI ID for SP A, and

the other sets the SCSI ID for SPB. Set the SCSI ID switches for both SP A and SPB

to 8, if this ID is unused. If it is used, set their SCSI IDs to the next highest unused ID

number.

NOTE: If you wish to configure your RAID Storage units as two external file

systems, the RAID Storage units in the second file system must be set to SCSI ID s

12 and higher. Refer to the Disk Utility section of the Profile User manual for

information on how to create file systems.

B

A

Flat blade

screwdriver

RAID Instructions 2-11

Page 30

Chapter 2 Installation

Back of storage chassis

SP B

SCSI ID

ID 0

ID 1

ID 2

ID 3

ID 0

ID 1

ID 2

ID 3

Setting an SP’s SCSI ID

ON

SCSI ID Switch number

number ID 0 ID 1 ID 2 ID 3

0 OnOnOnOn

1 Off On On On

2 On Off On On

3 Off Off On On

4 On On Off On

5 Off On Off On

6 On Off Off On

7 Off Off Off On

8 OnOnOnOff

9 Off On On Off

10 On Off On Off

11 Off Off On Off

12 On On Off Off

13 Off On Off Off

14 On Off Off Off

15 Off Off Off Off

SP A

SCSI ID

TheProfile will support two separate external filesystems. The RAIDStorage chassis

is an external attachment which can be assigned SCSI IDs 8 through 15.

If the RAID units are configured as two external file systems, the first unit or pair of

units of the second file system must be set to SCSI ID 12. If only a single RAID is to

be used, it should be assigned the lowest SCSI ID available. See the following two

examples.

EXAMPLE 1: Two RAIDs daisy-chained to a Profile with a single external SCSI

bus would have SCSI IDs 8 & 9.

EXAMPLE 2: Six RAIDs attached to a Profile with two external SCSI buses

(three daisy-chained RAIDs to each bus) would have SCSI IDs 8, 9, & 10 on each

bus.

NOTE: RAID units should be attached symmetrically to the two buses (that is, the

same number of RAIDs on each bus with the same number of disk modules in each

chain).

2-12 RAID Instructions

Page 31

Configurations and Cabling

You can connect your PRS250/M in a variety of ways, depending on your Profile

Disk Recorder model and the whether your RAID chassis has one (PRS250) or two

(PRS250M) SPs. Choose the procedure on the following pages that most closely

matches your needs. As stated earlier in this chapter, if the Profile has a PDX disk

expansion unit it must be removed. For installations involving multiple RAID units

keep in mind the maximum number of RAIDs that can be used with your Profile disk

recorder. Refer to About the RAID Storage Chassis on page 1-2 for more information.

The following illustration shows SCSI connectors on the rear panel of a RAID unit.

RAID SCSI connectors

Back view

Configurations and Cabling

SCSI-B INSCSI-A IN

SCSI-A

OUT

SCSI-B

OUT

NOTE: SCSI-B connectors are used on a PRS250 only (two SPs).

RAID Instructions 2-13

Page 32

Chapter 2 Installation

Two-Channel Profile/Single-SP RAID

This configuration, see the following illustration, consists of a two-channel Profile

disk recorder (one Master Disk Recorder - MDR) connected to a single RAID chassis

with one SP.

1. Connect a SCSI-2 cable from the Profile MDR rear panel connector to the RAID

2. Connect a SCSI terminator plug to the RAID chassis SCSI A OUT connector.

chassis SCSI A IN connector.

2-Channel Profile Disk Recorder

SCSI-2 Cable

RAID Chassis

J10

SCSI-2 Terminator

0226-1

2-14 RAID Instructions

Page 33

Two-Channel Profile/X Single-SP RAIDs

This configuration, see the following illustration, consists of a two-channel Profile

disk recorder (one MDR) connected to multiple RAID chassis, daisy-chained

together.

1. Connect a SCSI-2 cable from the Profile MDR rear panel connector to the first

RAID chassis SCSI A IN connector.

2. Connect a second SCSI-2 cable from the first RAID chassis SCSI A OUT

connector to the second RAID chassis SCSI A IN connector.

3. Connect a third SCSI-2 cable from the second RAID chassis SCSI A OUT

connector to the third SCSI A IN connector.

4. Repeat Steps 2 and 3 for the remaining number of RAIDs. See page 2-13 to

determine the maximum number of RAIDs that can be connected to your Profile

disk recorder.

5. Connect a SCSI terminator to the SCSI A OUT connector of the last RAID chassis

in the chain.

Configurations and Cabling

2-Channel Profile Disk Recorder

J10

RAID Chassis

SCSI-2 Cable

SCSI-2 Terminator

0226-2

RAID Instructions 2-15

Page 34

Chapter 2 Installation

Two-Channel PDR200/One Dual-SP RAID

This configuration, see the following illustration, consists of a two-channel PDR200

(one Master Disk Recorder - MDR) connected to a single RAID chassis with two SPs.

1. Connect a SCSI-2 cable from the Profile MDR rear panel connector (SCSI-A) to

2. Connect a SCSI-2 cable from the PDR200 SCSI-B rear panel connector to the

3. Connect a SCSI terminator plug to the RAID chassis SCSI A OUT connector.

4. Connect a SCSI terminator plug to the RAID chassis SCSI B OUT connector.

the RAID chassis SCSI A IN connector.

RAID chassis SCSI B IN connector.

2-Channel Profile Disk Recorder

SCSI B

SCSI-2 Cable

RAID Chassis

J10

SCSI-2 Terminator

0226-3

2-16 RAID Instructions

Page 35

Four Channel Profile/2 RAIDs

This configuration, see the following illustration, consists of a 4-channel Profile (one

MDR and one Slave Disk Recorder - SDR) and two symmetrical RAID Storage

chassis (each RAID chain with the same number of disk modules).

1. Connect a SCSI-2 cable from the Profile MDR rear panel connector to the RAID

chassis SCSI A IN connector

2. Connect a second SCSI-2 cable from the SDR rear panel connector to a second

RAID SCSI A IN connector.

3. Connect a SCSI terminator plug to each RAID chassis SCSI A OUT connector.

4-Channel Profile Disk Recorder

Configurations and Cabling

SCSI-2 Cable

RAID Chassis

J11

J10

SCSI-2 Terminator

Note:

Each RAID chassis must have

the same number of drives.

0226-6

RAID Instructions 2-17

Page 36

Chapter 2 Installation

Four-Channel Profile/Multiple RAIDs

This configuration, see the following illustration, has a four-channel Profile (one

MDR and one SDR) and two symmetrical RAID Storage chassis chains (the RAID

chainattached to the MDR matches, innumber of disk modules, thechain attached

to the SDR).

1. Connect a SCSI-2 cable from the Profile MDR rear panel connector to the first

2. Connect a SCSI-2 cable from the first RAID chassis SCSI A OUT connector to the

3. Connect a SCSI-2 cable from the second RAID chassis SCSI A OUT connector to

4. Repeat Steps 2 and 3 for the remaining RAIDs in the MDR chain. See page 2-13

5. Connect a SCSI-2 cable from the Profile SDR rear panel connector to the first

6. Connect a SCSI-2 cable from the first RAID chassis SCSI A OUT connector to the

RAID chassis SCSI A IN connector in the MDR chain.

next RAID chassis SCSI A IN connector in the MDR chain.

the next RAID chassis SCSI IN connector in the MDR chain.

to determine the maximum number of RAIDs that can be connected to your Profile.

RAID chassis SCSI A IN connector in the SDR chain.

second RAID chassis SCSIA IN connector in the SDR chain.

7. Connect a SCSI-2 cable from the second RAID chassis SCSI A OUT connector to

the next RAID chassis SCSI IN connector in the SDR chain.

8. Repeat Steps 6 and 7 for the remaining RAIDs in the SDR chain. Remember to not

exceed the maximum number of RAIDs that can be attached to your Profile.

9. Connect a SCSI terminator plug to the SCSI A OUT connector of the last RAID

chassis in each chain.

2-18 RAID Instructions

Page 37

4-Channel Profile Disk Recorder

Configurations and Cabling

SCSI-2 Cable

J10

J11

RAID Chassis Chain

RAID Chassis Chain

SCSI-2 Terminator

Note:

Each RAID chassis chain must

have the same number of drives.

0226-5

RAID Instructions 2-19

Page 38

Chapter 2 Installation

Four-Channel PDR200/One Dual-SP RAID

This configuration, see the following illustration, consists of a four-channel PDR200

(one Master Enhanced Disk Recorder - MEDR, one Slave Enhanced Disk Recorder SEDR) connected to a single RAID chassis with two SPs.

1. Connect a SCSI-2 cable from the PDR200 MEDR rear panel connector (SCSI-A)

2. Connect aSCSI-2 cable from the PDR200 SEDR rear panelconnector to theRAID

3. Connect a SCSI terminator plug to the RAID chassis SCSI A OUT connector.

4. Connect a SCSI terminator plug to the RAID chassis SCSI B OUT connector.

to the RAID chassis SCSI A IN connector.

chassis SCSI B IN connector.

4-Channel Profile Disk Recorder

SCSI-2 Cable

RAID Chassis

J11

J10

SCSI-2 Terminator

0226-4

2-20 RAID Instructions

Page 39

Connecting the Power Cord

1. Make sure that the storage chassis power switch is off, then connect the power cord

to the storage chassis.

NOTE: Several types of power cord are supplied with the product. Use the power

cord that is appropriate to your installation.

2. Plug the other end of the power cord into an ac power outlet.

Plugging in the ac power cord

Back of storage

Connecting the Power Cord

A. Push power switch

to off (0) position.

B. Plug power cord into

power connector.

You are ready to power up the storage chassis as described in the following section,

Powering Up the Storage Chassis.

RAID Instructions 2-21

Page 40

Chapter 2 Installation

Powering Up the Storage Chassis

NOTE: When powering up a Profile with RAID system, the RAID unit must be

turned on at least two minutes before power is applied to the Profile.

1. Turn on the storage chassis’s power and wait two minutes.

The green power light on the front of the storage chassis turns on and the fans

rotate.

Turning on storage chassis power

Back of storage

2. Power up the Profile. (See Profile’s Installation manual for information on how to

power up the Profile.)

Front of storage chassis

2-22 RAID Instructions

Page 41

Configuring and Managing the RAID

Configuring and Managing the RAID

To set up the RAID Storagechassis, you need to setthe storage chassis date, time, and

optional password protection.

You perform these tasks using the Disk Array Storage System Manager

(DASSMGR).

Running DASSMGR

You can run DASSMGR from a bootable diskette, or install it on the Profile system

hard disk and run it from that disk.

Before You Begin

Before you can run DASSMGR, someone must have performed these tasks:

• Connected the storage chassis to the Profile.

• Connected the RS-232 port on the storage chassis to a spare COM port on the

Profile. See “Connecting Serial (console) Cables” on page 2-10.

Starting DASSMGR

To start DASSMGR:

1. Power up the storage chassis.

IMPORTANT Make sure you specify the correct communications port when you

issue the DASSMGR command in the next step. Specifying the wrong port may

cause problems with the device connected to that port.

2. Run DASSMGR using the command DASSMGR x, where x represents the

communication port. For example, to run DASSMGR with communication port 2,

at the MS-DOS command prompt enter

DASSMGR 2 ↵

The Disk Array Storage System Manager Main Menu appears. Use the up, down,

and Enter keys on your keyboard to move around in the menus.

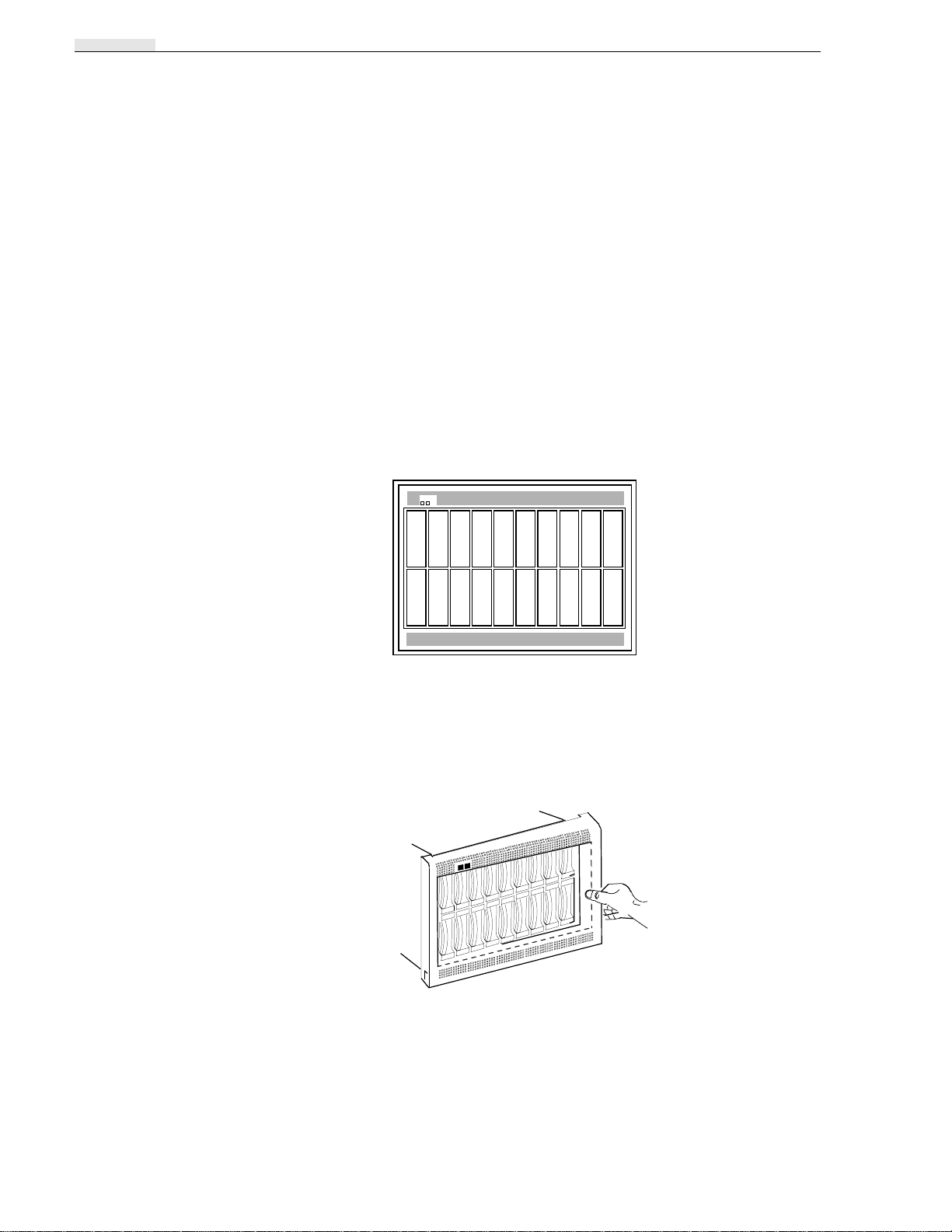

Disk Array Storage System Manager Main Menu

Grid Management (monitor, bind & unbind arrays)

Update Licensed Internal Code

Update Drive Code

Change COM port (present port set to COM1)

Exit

RAID Instructions 2-23

Page 42

Chapter 2 Installation

Setting Password Protection

Password protection lets you restrict access to functions that can destroy all data on

logical units. To enable password protection, you enable password mode and specify

a password. This password is then required to access the GridMgr Main Menu.

To specify a password:

1. From the DASSMGR Main Menu, select the Grid Management option.

2. From the GridMgr Main Menu, follow this menu path:

SP A

SP SCSI ID 1 Change Storage System Parameters Menu

1. View System Memory Configuration

2. Change Main Menu Password

3. Change System Date and Time

Change Parameters → Change Storage System Parameters

The Change Storage System Parameters Menu appears, similar to the following.

At any prompt enter ˆ to GO BACK TO PREVIOUS MENU, ? for HELP

Enter Choice:

3. From the Change Storage System Parameters Menu, choose the Change Main

Menu Password option.

The Password Utility screen appears, similar to the following.

Password Utility

Enter ? for HELP, ^ to GO BACK TO PREVIOUS MENU

Set password:(Y/N/?/^)?[N]

Enable password mode:(Y/N) ?[N]

Enter new password:(CR/NL for none)

Verify new password:

9613-1

2-24 RAID Instructions

Page 43

4. At the Set password prompt, enter Y.

5. At the Enable password mode prompt, enter Y.

6. At the Enter new password prompt, enter the password.

The password can be up to 15 characters, and can consist of any characters except

the null character and defined control characters. The password is case sensitive,

so you must specify your password exactly as you have defined it.

7. At the Verify new password prompt, enter the same password again.

Once you have set and enabled a password, you are prompted for the password at the

Presentation Utility screen. See “Checking Status with the Presentation Utility” in

Chapter 3. After you enter the correct password, you can access the GridMgr Main

Menu. If password mode is disabled, you are not prompted for the password.

Changing the Password

If you have specified apassword, DASSMGR asks forthat password when youselect

the Change Main Menu Password option from the Change Storage System

Parameters Menu. The Password Utility screen appears.

Changing the Password

Password Utility

Enter ? for HELP, ^ to GO BACK TO PREVIOUS MENU

Enter old password:(password/?/^)?

To change the password

1. At the Enter old password prompt, enter the password that you had

originally specified.

2. At the Change password prompt, enter Y.

3. At the Enable password mode prompt, enter Y.

4. At the Enter new password prompt, enter the new password.

5. At the Verify new password prompt, enter the new password again.

RAID Instructions 2-25

Page 44

Chapter 2 Installation

Setting Storage System Date and Time

The storage chassis clock controls the date and time displayed on the Presentation

Utility screen and with events recorded in an SP’s unsolicited event log. This clock is

local to the storage chassis, and has no relation to the Profile’s system or boot clock.

To set the storage chassis date and time:

1. From the GridMgr Main Menu, follow this menu path:

SP A

SP SCSI ID 1 Change Storage System Parameters Menu

1. View System Memory Configuration

2. Change Main Menu Password

3. Change System Date and Time

Change Parameters → Change Storage System Parameters

The Change Storage System Parameters Menu appears, similar to the following.

At any prompt enter ˆ to GO BACK TO PREVIOUS MENU, ? for HELP

Enter Choice:

9613-1

2-26 RAID Instructions

Page 45

Setting Storage System Date and Time

2. From the Change Storage System Parameters Menu, choose the Change System

Date and Time option.

The Change System Date and Time screen appears, similar to the following.

SP A Change System Date and Time

SP SCSI ID 1

Current system time is: 10/12/1995 (Monday) 22:44:06

Enter the new system time in the format: MM/DD/YYYY HH:MM:SS. HH

is the number of hours that have elapsed since midnight (0-23).

Enter a ^ if you do not want to change the system time.

New time:

At the New time prompt, enter the new date and time, or type ^ if you want to

leave the time unchanged.

The format for the date and time is

MM/DD/YYYY HH:MM:SS

For example, 06/01/1996 01:23:55.

RAID Instructions 2-27

Page 46

Chapter 2 Installation

2-28 RAID Instructions

Page 47

Chapter

3

Servicing the System

This chapter describes how to service the RAID Storage chassis.

Checking Status with the Presentation Utility

You can check storage-system status using the Presentation Utility. Perform the

following steps to display the DASSMGR Presentation Utility screen:

1. Start DASSMGR.

2. From the Disk Array Storage System Manager Main Menu, select the appropriate

COM port.

3. From the Disk Array Storage System Manager Main Menu, select Grid

Management.

4. From the Gri d Main Menu, select the Presentation Utility option.

NOTE: If the Presentation Utility screen does not appear, enter carets (^) until the

GridMgr Main Menu appears, and then choose the Presentation Utility option.

A Presentation Utility screen appears similar to the following:

RAID Instructions 3-1

Page 48

Chapter 3 Servicing the System

Sample Presentation Utility screen

Module

Status

SPidentifier

SPSCSIID

Disk status

LUN number

Heartbeat

(blinking asterisk)

Fault field (on a fault,

displays blinking

FAULT message)

SPA

SPSCSIID0

PROM Revision

1.01

FAN A OK Microcode Revision

FAN B OK 2.00.00

VSC A OK StatisticsLogging

VSC B OK DISABLED

VSC C OK

BBU -- REMOVED

The grid above shows a 20 slot storage system configured as follows:

* Two five-disk RAID-3 groups (LUN 0 and LUN 1). LUN 0 includes modules A0, B0, C0, D0, and E0. LUN 1 includes

modules A1, B1, C1, D1, and E1. The status of each disk module in LUN 0 is ENA, and in LUN 1 is BIN (binding).

* Ten empty slots are also shown. The empty module slots include modules A2, B2, C2, D2, E2, A3, B3, C3, D3, and E3.

0 ENA ENA ENA ENA ENA

00000

A B C D E

1 BIN BIN BIN BIN BIN

11111

Grid cursor

SCSI bus

PresentationUtility(*)

06/01/1996 14:33

2

A B C D E

Peer SP

3

Requests Completed

6K

Cache States

Write:DISABLED

Read:DISABLED

Heartbeat — Following the screen title (Presentation Utility) is an asterisk in

parentheses (*). This asterisk indicates the heartbeat status of the SP. It should blink

every several seconds to indicate that the SP is functioning. If it does not appear to

blink, the SP may not be working. Try pressing Ctrl-Q. If the asterisk still does not

blink, the SP requires service.

Storage System date and time — The date and time of the storage chassis, which is

controlled by the storage chassis’s clock, appears under the screen title (Presentation

Utility). This date and time is also displayed with the storage chassis log events. You

can set the date and time as described in Setting the Storage-system Date and Time

later in this chapter.

SP identifier — Specifies the SP (SP A or SP B) connected to the asynchronous

RS-232 port you are using.

3-2 RAID Instructions

Page 49

Checking Status with the Presentation Utility

Module status — The first column shows the status of the fan modules and VSC

(voltage semi-regulated controller) modules.

FAN x - Fan module status codes are as follows:

Code Fan module status

OK Operating normally.

- - Failed.

VSC x - VSC module status codes are as follows:

Code Fan module status

OK Operating normally.

- - Failedor not present. If youdo not know whether aVSC has failed, examine the fault

light on the VSC.

BBU - Holds up the RAID-3 buffer while the SP attempt to write the contents of the

buffer to disk in the event of a power failure.

BBU status codes are as follows:

Code Fan module status

OK Operating normally.

NRR Not ready, charging. After a power outage, a BBU takes 15 minutes or less to

recharge. From total depletion, recharging takes an hour less.

TE Weekly BBU test is in progress.

- - Failed or not present.

Disk status — In the grid itself, the blocks of boxes identify slots for disk modules in

the chassis. Associated with each slot is an identifier (ID) based on the slot’s position

in the chassis. You identify a disk module by its disk ID, which is the ID of the slot

containing it. A disk ID is made up of a letter indicating the SCSI bus for the slot and

a number indicating the slot’s position on the SCSI bus. The disk IDs for the storage

chassis are

SCSI bus Positions Disk IDs

A0, B0, C0, D0, E0

A1, B1, C1, D1, E1

A2, B2, C2, D2, E2

A3, B3, C3, D3, E3

For each slot that contains a disk module, the box shows a three letter status code. The

table on the next page lists the status codes. If a disk module is not bound, the

displayed code is UNB with two asterisks (**). For a bound module, the box shows

the code and logical unit number (of the RAID group, individual unit, or hot spare) to

which the module is bound. A box without text indicates an empty slot, that is, one

not containing a disk module.

RAID Instructions 3-3

Page 50

Chapter 3 Servicing the System

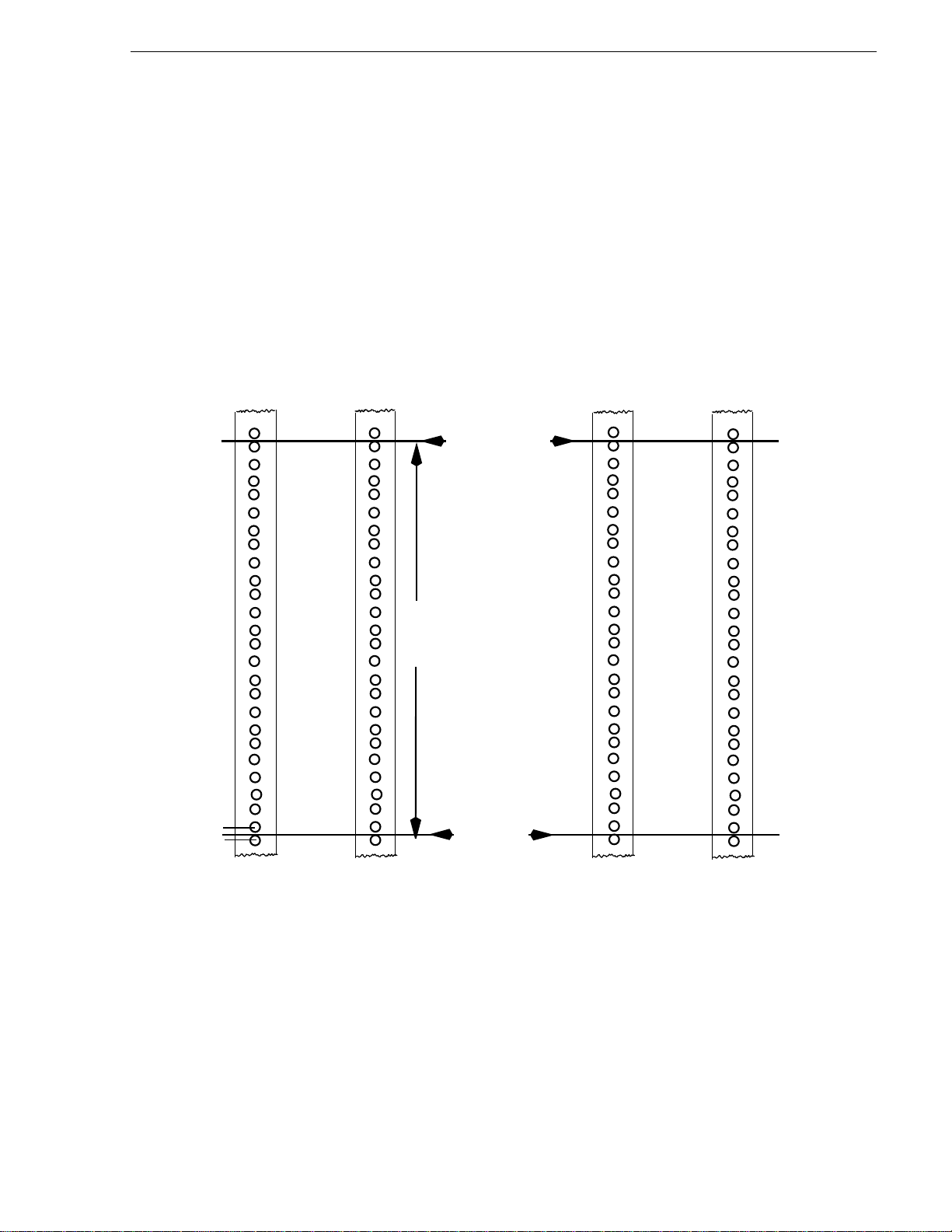

Moving the Grid Cursor

You can move the grid cursor from box to box using the keys listed in the following

table.

Dassmgr control keys

H or ←

J or ↓

K or ↑ Moves cursor up one box.

L or →

Space bar Moves the cursor downa box, or in some menus, fromthe bottom box to thetop of the next column.

1

If the arrow keys do not work, use the corresponding letter keys.

Moves cursor left one box.

Moves cursor down one box.

Moves cursor right one box.

From the last box, returns the cursor to the top left. Also moves cursor from one unbound unit to

the next unbound unit when you are binding or from one bound unit to the next bound unit when

you are unbinding.

Disk module status codes

BIN Presentation Utility screen Binding; module is being bound into a LUN.

ENA Enabled; module is part of a bound logical unit that is assigned to (owned by) the SP whose display

you are viewing. If the storage chassis has another SP, this module’s status is RDY on that SP’s

display.

FMT Formatting; module is being hardware formatted. Generally, modules do not need hardware

formatting.

OFF Module has been powered off by SP, which can happen if you insert the wrong size module; a

message also appears in the unsolicited event log.

POW Powering up; power is being applied to the disk module.

RDY Ready;module is part of a broken logical unit or a unit that is bound and unassigned, which can mean

that the disk module is part of a unit that is

disk module is part of a unit assigned to the other SP, the module’s status is ENA on the other SP’s

display.

REB Rebuilding;module is either a hot spare or replacement disk that replaced a failed module in a logical

unit.

UNB Unbound; module is ready to be bound into a logical unit.

blank

UNS Disk module not supported.

No disk module is in the slot.

3-4 RAID Instructions

not

owned by the SP whose display you are viewing. If the

Page 51

Reconfiguring a Storage System

The following explains how to reconfigure a storage chassis in these ways:

• Changing physical disk configurations

• Changing physical disk unit parameters

• Updating Licensed Internal Code

The procedures below assume you are using DASSMGR to reconfigure the storage

chassis.

Changing Physical Disk Configurations

As your organization’s needs change, you may want to add disk modules to any

unused compartments (slots).

Adding Disk Modules and Creating New Logical Units

If the storage chassis has unused disk module slots, you can increase the available

storage capacity by installing additional disk modules, as described in “Replacing or

Adding a Disk Module” on page 18. Normal processing can continue while you

install disk modules.

IMPORTANT All disk modules in any one storage chassis and in any

storage chassis in chains must be of the same capacity.

Reconfiguring a Storage System

We recommend that you add disk modules in groups of five to the slots in the

following order:

A0, B0, C0, D0, E0,

A1, B1, C1, D1, E1,

A2, B2, C2, D2, E2,

A3, B3, C3, D3, E3

To add a physical disk unit:

1. Update the worksheets that define your configuration.

2. Remove the disk filler modules and install the additional disk modules. Refer to

“Upgrade and Repair of a Storage System” on page 14 for instructions.

3. Bind the newly installed disk modules into the desired logical unit. See “Binding

Disk Modules as a Logical Unit” on page 6.

4. Refer to your Profile User Manual to make the newly created physical disks

available to the Profile operating system.

RAID Instructions 3-5

Page 52

Chapter 3 Servicing the System

Binding Disk Modules as a Logical Unit

You must bind exactly five disk modules. You can bind one less module per group

than you will eventually use by selecting a box representing an empty slot. However,

the group operates in a degraded mode until a module is installed in the empty slot,

and the storage chassis integrates it into the group. You can select the modules in any

order.

To bind disk modules into a logical unit:

1. From the GridMgr Main Menu, choose the Bind Logical Units option.

The program displays the grid for the RAID-3 option. The grid depicts the drive

modules in the storage chassis, and highlights the first group of disk modules

available to be bound (UNB). The figure below shows a sample grid.

SP A

SP SCSI ID 0

Bind RAID-3 Group (Parallel Access Array)

ENA

ENA

0

0

AB CD E

UNB**UNB**UNB**UNB**UNB

1

ENA0ENA0ENA

0

0

**

2. Use the direction arrows keys (

ENA

2

3

ENA1ENA1ENA1ENA

1

AB C D E

UNB**UNB**UNB**UNB

UNB

**

↓

↑, ←,

, →) to move the cursor to the group of disk

1

**

9613-6

modules you want to bind (the module becomes highlighted) and press the Enter

key to select that group. The modules in the selected group appear in dimmed

reverse video.

If you want to deselect a group, highlight the group and press the Del key.

3. When the screen shows the groups you want to bind, press B (for bind). The Bind

Options screen appears with the first of two options. The currently selected or

default value appears in brackets.

3-6 RAID Instructions

Page 53

Changing Physical Disk Configurations

Sample Bind Options screen

Bind Options

Logical unit number (0-1F hex)? [default]

Logical unit number —The default logical unit number for the first disk unit you

bind is 0, the second disk unit is 1, the third disk unit is 2; and the fourth is 3.

4. Enter 0, 1, 2, or 3 (hex) depending on which you are binding (see the sample grid

above). (Note that for Profile systems, only LUNs 0 - 3 are valid).

5. Press Enter. The following option appears immediately below the first option.

Maximum rebuild time <hours> [default]

Maximumrebuild time — The maximum rebuild timeis the approximateamount

of time that the storage chassis allots to reconstruct the data on a new disk module

that replaces a failed disk module in a logical unit. The actual rebuild time may be

longer or shorter. You can change the rebuild time with DASSMGR later without

damaging the information stored on the disk.

6. Press 24 hours and then press Enter.

Bind Options

Logical unit number (0-1F hex)? [1]

Maximum rebuild time <hours>? [24]

Confirm bind options <Y/N>? [N]

7. To accept, type Y, and press Enter. To reject, just press Enter.

If you confirm, you are asked whether or not to bind the modules. If you reject, the

cursor returns to the Logical unit number prompt, so you can change any values

you want.

8. In response to the question, type Y and press Enter if you want to bind the group

as specified; otherwise, type N and press Enter.

If you type N, the original grid appears so you can return to Step 4 and start

selecting modules again.

If you typed Y, the program changes the UNB to BIN for a RAID group or

individual unit, and starts creating the logical unit you specified. The time the SP

takes to complete the binding operation depends on the size and number of disk

RAID Instructions 3-7

Page 54

Chapter 3 Servicing the System

modules being bound. Generally, binding takes about 30 minutes to initialize data

on 4-Gbyte modules.

As soon as the binding operation starts, it changes the unbound module symbol

(**) to logical unit number you specified for each module being bound.

While a unit is binding, you can proceed to bind another unit by repeating the

procedure. After you have selected the last LUN and started it binding you will get

an error message stating there are no more modules available to bind. This is

normal. Press ^ to get back to Grid Manager and view the binding progress. When

the binding is finished, the disk status changes from BIN to ENA.

IMPORTANT To determinethe progress of the binding procedure, highlight

one of the group’s disk modules and press Enter. The Performance statistics

screen displays a percentage complete figure. For more information, see

Performance statistics screen later in this chapter.

9. Reboot the RAID Storage chassis.

Binding with Two SPs

If your RAID storage chassis is configured with two SPs, you should bind

approximately half of your disk modules with each SP. This will ensure maximum

transfer speeds to and from the RAID storage chassis.

For example, if you have ten disk modules, you should bind A0 through E0 into LUN

0 with SP A, and A1 though E1 into LUN 1 with SP B. If you have twenty disk

modules, you should bind LUN 0 and LUN 2 with SP A,and LUN 1 and LUN 3 with

SP B. If you have fifteen disk modules, bind ten with one SP, and five with the other.

There are two ways to bind disk modules with two SPs. The easiest is to use two

Profile system COM ports to communicate with the two SPs individually.

1. Connect one Profile system COM port (COM1, for example) to the first SP with a

serial cable.

2. Connect the second Profile system COM port (COM2, for example) to the second

SP.

3. Start two instances of DASSMGR, specifying a different COM port for each

instance.

4. Bind the appropirate disk modules in each instance of DASSMGR.

You can also use the same Profile system COM port to communicate with both SPs,

one after the other.

1. Make the serial connection from one of the Profile system’s RS 232 ports (COM2

for example) to the first SP.

2. Start DASSMGR on the appropirate COM port and perform the bindings for the

first SP.

3. Exit DASSMGR.

4. Change the serial connection to the other SP.

5. Start DASSMGR on the same COM port and perform the remaining bindings with

3-8 RAID Instructions

the second SP.

Page 55

Unbinding a Physical Disk Unit

You use DASSMGR to unbind a physical disk unit. Unlike binding, unbinding takes

only a few moments.

CAUTION:Unbinding a physical disk uniteffectively erases all information onthe

physical disk unit. You cannot use any unbound module until you bind it into a

logical unit again, make the unit available to the operating system, and create a

volume on theunit. Additionally, all information in the Profile partition is lost. The

only time one would unbind is in the case of a double faulted LUN.

To unbind a physical disk unit:

1. From the GridMgr Main Menu, choose the Unbind Logical Units option.

2. After reading the advisory screen that appears, press Enter.

The grid appears with all disk modules of the first-bound logical unit (unit 0)

highlighted. The figure that follows shows a sample grid.

Sample grid for unbinding a logical unit

Changing Physical Disk Configurations

SP A

SP SCSI ID 0

0 ENA ENA ENA ENA ENA

0 0 0 0 0

A B C D E

1 ENA ENA ENA ENA ENA

1 1 1 1 1

3. Use the direction arrows to highlight the physical disk unit you want to unbind.

4. Press the Enter key to select the highlighted physical disk unit for unbinding.

5. If you want to unbind the physical disk unit, type Y and press Enter; otherwise,

Unbind Logical Units

2 UNB UNB UNB UNB UNB

** ** ** ** **

A B C D E

3 UNB UNB UNB UNB UNB

** ** ** ** **

GRIDMGR highlights all modules in the logical unit when you select one of the

modules.

A screen appears warning you that unbinding destroys all data on the physical disk

unit, and then asks if you want to unbind this physical disk unit.

cancel the unbind operation by typing N.

The SP unbinds the physical disk. For each module, the status changes from ENA

or RDY to UNB and the unit number changes to the unbound module symbol (**).

If you want to unbind another physical disk, repeat the procedure.

RAID Instructions 3-9

Page 56

Chapter 3 Servicing the System

Changing Physical Disk Unit Parameters

You can change the Rebuild time for a physical disk unit after it is bound:

Changing the Rebuild Time

The rebuild time is the amount of time that the storage chassis allots to reconstruct the

data on a new disk module that replaces a failed disk module in a logical unit. It

applies to all RAID physical disk units. The time you specify determines the amount

of resource the SP devotes to rebuilding instead of to normal I/O activity.

The default time of 24 hours is adequate for most situations. A rebuild time of less

than 24 hours rebuilds the disk more quickly, but degrades response time. A rebuild

time of 0 hours rebuilds the disk module as quickly as possible, butdegrades response

time significantly. If your site requires fast response time and you want to minimize

degradation to normal I/O activity, you can extend the rebuilding process over a

longer period of time.

NOTE: The actual rebuild time can differ significantly from the time you specify,

especially between a 2-channel and a 4-channel Profile system.

To change the rebuild time for a physical disk unit:

IMPORTANT You cannot change the rebuild time for a physical disk unit

while the unit is rebuilding.

1. From the GridMgr Main Menu, follow this menu path:

Change Parameters → Change Physical Unit Parameters →

Change Unit Rebuild Time

The Change Unit Rebuild Time screen appears.

SP A Change Unit Rebuild Time

SP SCSI ID 0

At any prompt, enter ^ to GO BACK TO PREVIOUS MENU or ? for HELP

Physical unit to change (hex)?

2. Enter the number of the physical disk unit whose rebuild time you want to change.

The program displays the current rebuild time and prompts you for a new time as

follows:

Current rebuild time is 4 hours.

Enter new rebuild time <hours>:

3-10 RAID Instructions

Page 57

3. Enter a new rebuild time. The new rebuild time is effective for the next rebuild

operation.

The Change Logical Unit Parameters screen appears.

NOTE: Tektronix recommends a minimum rebuild time of 8 hours when using

multiple video channels.

Updating Licensed Internal Code

The Licensed Internal Code (LIC) diskette may also include an update to the SP

programmable read-only memory (PROM) code. When you install Licensed Internal

Code, the SP tries to copy it to reserved areas outside operating system control on four

disk modules, which are called the database disks. The database disk modules are A0,

B0, C0, and A3. (See the figure below.)

For the LIC installation to succeed, at least two of the database disk modules must be

on-line, and ideally, all of them should be on-line. A disk module is on-line if it is

fully powered up and not faulted; that is, if it has a status code on the Presentation

Utility screen and this code is not POW or OFF. Having multiple copies of code offers

higher availability if a disk module fails.

Updating Licensed Internal Code

Disk modules the SP uses to store Licensed Internal Code

A0 B0 C0 D0 E0

A1 B1 C1 D1 E1

= Database disk module

A2 B2 C2 D2 E2

A3 B3 C3 D3 E3

RAID Instructions 3-11

Page 58

Chapter 3 Servicing the System

Installing a New Revision of Licensed Internal Code

The following procedure assumes that you have loaded the files from the Licensed

Internal Code (LIC) from the media onto the Profile. These files are the binaries for

the different types of LIC, the release notices for the binaries, and a README file,