Page 1

Profile XP

PVS SERIES MEDIA PLATFORMS

Service Manual

071-8291-01

JULY 2004

the most watched worldwide

Page 2

Copyright Copyright © 2004 T homson Broa dcas t and Medi a Solu tio ns, Inc. All righ ts res er ved. Prin ted in

the United Sta tes of America.

This document may not be copied in whole or in part, or otherwise reproduced except as

specifically permitted under U.S. copyright law, without the prior written consent of Thomson

Broadcast and Medi a Solutions, Inc., P.O. Box 59900 , Nevada City, California 95959-7 900

Trademarks Grass Valley, Profile, and Profile XP are either registered trademarks or trademarks of

Thomson Broadcast and Media Solutions, Inc. in the United States and/or other countries.

Other trademarks used in this document are either registered trademarks or trademarks of the

manufacturers or vendors of the associated products. Thomson Broadcast and Media

Solutions, Inc. products are covered by U.S. and foreign patents, issued and pending.

Additional information regarding Thomson Broadcast and Media Solutions, Inc. trademarks

and other proprietary rights may be fo und at www.thomsongrassvalley.com.

Disclaimer Product options and specifications subject to change without notice. The information in this

manual is furn i shed for informat i onal use only, is subject to ch ange without notice, and shoul d

not be construed as a commitment by Thomson Broa dcast and Media Solu tions, I nc. Thomso n

Broadcast and Media Solutions, Inc. assumes no responsibility or liability for any errors or

inaccuracie s that may appear in this publ ication.

U.S. Government

Restricted Rights

Legend

Use, duplicat ion, o r disclos ure by t he Unite d States Governme nt is su bject to restric tions as s et

forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause

at DFARS 252.277-7013 or in subparagraph c(1) and (2) of the Commercial Computer

Software Re st ri cted Rights clause at FAR 52.227-19, as applicable. Manufacturer is Thomson

Broadcast and Media Solutions, Inc., P.O. Box 59900, Nevada City, California 95959-7900

U.S.A.

Revision Status

Rev Date Description

November 8, 1999 Initial release of ProfileXP Service Manual with NetCentral,

December 3, 1999 Formal release of Profile XP Service Manual with Net Ce ntral,

September 8, 2000 Updated to include High Definiti on PVS2000 parts in formation.

November 17, 2000 Added procedures for rebuilding system disk drives; added

February 27, 2001 Updated to include new system processor board. 071-8049-02

071-0625-00.

071-0625-01.

071-8049-00.

information about WinTail and Log Capture tools. 071-8049-01

July 20, 2001 Updated to i nclude 2- and 4-channel PVS1000 pla yout models, add

NetCentral i nformation, and inc l ude PVS1100 Series. 071-8114-00

June 17, 2002 Updated to incl ude additional RAID systems. 071-8114-01.

September 20, 2002 Updated mother board replacement, N etCentral infor mation.

July 21, 2003 Updated to support Profile sof tware version 5.2

February 23, 20 04 Updated to support Profile software version 5.4, PVS3000 and

23 July 2004 Removed NetCentral monitoring of DupliDisk, added DupliDisk III.

071-8193-00.

071-8247-00.

PVS3500. 071-8291-00.

2 Profile XP Service Manual 23 July 2004

Page 3

Grass Valley Product Support

To get technical assistance, check on the status of problems, or report new problems,

contact Grass Valle y Product Support via e-mail, the Web, or by phone or f ax.

Web Technical Support

To access support information on the Web, visit t he product support Web p age on the

Grass Valley Web site. You can download software or find solutions to problems by

searching our Frequently Asked Questions (FAQ) database.

World Wide Web: http://www.thomsongrassvalley.com/support/

Technical Support E-mail Address: gvgtechsupport@thomson.net.

Phone Support

Use the following information to contact product support by pho ne during business

hours. Afterhours phone support is available for warranty and contract customers.

United States (800) 547-8949 (Toll Free) France +33 (1) 34 20 77 77

Latin America (800) 547-8949 (Toll Free) Germany +49 6155 870 606

Eastern Europe +49 6155 870 606 Greece +33 (1) 34 20 77 77

Southern Europe +33 (1) 34 20 77 77 Hong Kong +852 2531 3058

Middle East +33 (1) 34 20 77 77 Italy +39 06 8720351

Australia +61 3 9721 3737 Netherlands +31 35 6238421

Belgium +32 2 3349031 Poland +49 6155 870 606

Brazil +55 11 5509 3440 Russia +49 6155 870 606

Canada (800) 547-8949 (Toll Free) Singapore +656379 1390

China +86 106615 9450 Spain + 34 91 512 03 50

Denmark +45 45968800 Sweden +46 87680705

Dubai + 971 4 299 64 40 Switzerland +41 (1) 487 80 02

Finland +35 9 68284600 UK +44 870 903 2022

Authorized Support Representative

A local authorized support representative may be available in your country. To locate

the support representative for your country, visit the product support Web page on the

Grass Valley Web site.

Profile Users Group

You can connect with other Profile XP Media Platform users to ask questions or share

advice, tip s, and hint s. Send e-ma il to profile-users@thomson.net to join the community

and benefit from the experience of others.

23 July 2004 Profile XP Service Manual 3

Page 4

Product Support

4 Profile XP Service Manual 23 July 2004

Page 5

Safety Summaries

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage

to this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system.

Read the General Safety summary in other system manuals f or warnings an d

cautions related to operating the system.

Injury P r e cautions

Use Proper Power

Cord

Ground the Product This product is grounded through the grounding conductor of the power

Do Not Operate

Without Covers

Do Not operate in

Wet/Damp

Conditions

Do Not Operate in an

Explosive

Atmosphere

Avoid Exposed

Circuitry

To avoid fire hazard, use only the power cord specified for this product.

cord. To avoid electric shock, the grounding conductor must be connected

to earth ground. Before making connections to the input or output terminals

of the product, ensure that the product is pr operly grounded.

To avoid electric shock or fire hazard, do not operate this product with

covers or pa nels rem oved.

To avoid electric shock, do not operate this product in wet or damp

conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

To avoid injury, remove jewelry such as rings, watches, and other metallic

objects. D o not to uc h exp os e d con ne cti o ns and c ompon e nts wh en po we r is

present.

Product Dam age P recautions

Use Proper Power

Source

Provide Proper

Ventilation

Do Not Operate With

Suspected Failures

23 July 2004 Profile XP Service Manual 5

Do not operate this product from a power source that applies more than the

voltage specified.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Page 6

Safety Su m maries

Battery

Replacement

To avoid damage, replace only with the same or equivalent type

recommended by the circuit board manufacturer. Dispose of used battery

according to the circuit board manufacturer’s instructions.

Safety Terms and Symbols

Terms in This

Manual

!

!

Terms on the

Product

These terms may appear in this manual:

WARNING: Warning statements identify conditions or practices that can

result in personal injury or loss of life.

CAUTION: Caution statements identify conditions or practices that can

result in damage to the equipment or other property.

These terms may appear on the product:

DANGER indicates a personal injury hazard immediately accessible as one

reads the marking.

WARNING indicates a personal injury hazard not immediately accessible

as you read the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the

Product

!

The following symbols may appear on the product:

DANGER high voltage

Protective ground (earth) terminal

ATTENTION – refer to manual

Service Safety Summary

Do Not Service

Alone

Disconnect Power To avoid electric shock, disconnect the main power by means of the power

Use Care When

Servicing With

Power On

Do not perform internal service or adjustment of this product unless another

person capable of rendering first aid and resuscitation is present.

cord or, if provided, the power switch.

Dangerous voltages or currents may exist in this product. Disconnect power

and remove battery (if applicable) before removing protective panels,

soldering, or replacing components.

To avoid electric shock, do not touch exposed connections

6 Profile XP Service Manual 23 July 2004

Page 7

Certifications and Compliances

Canadian Certified

Power Cords

FCC Emission

Control

Canadian EMC

Notice of

Compliance

Canadian approval includes the products and power cords appropriate for

use in the North Amer ica power ne twork. All other powe r cords supp lied are

approved for the country of use.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense. Changes

or modifications not expressly approved by Tektronix can affect emiss ion

compliance and could void the user’s authority to operate this equipment.

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Le présent apparei l numérique n’émet pas de bruit s radioélectriques

dépassant les limites applicables aux appareils numériques de la classe A

préscrites dans le Règlement sur le brouillage radioélectrique édicté par le

ministère des Communications du Canada.

Canadian Certified

AC Adapter

EN55022 Class A

Warning

Laser Compliance

Laser Safety

Requirements

Canadian approval includes the AC adapters appropriate for use in the North

America power network. All other AC adapters supplied are approved for

the countr y of use.

For products that comply with Class A. In a domestic environment this

product may cause radio interference in which case the user may be required

to take adequate measures.

The device used in this product is a Class 1 certified las er product. Operating

this product outside specifications or altering its original design may resu lt

in hazardous radiation exposure, and may be considered an act of modifying

or new manu factu ring of a laser pr oduct under U. S. reg ulations contain ed in

21CFR Chapter 1, subchapter J or CENELEC regulations in HD 482 S1.

People performing such an act are required by law to recertify and reidentify

this product in accordance with provisions of 21CFR subchapter J for

distribution within the U.S.A., and in accordance with CENELEC HD 482

S1 for distribution within countries using the IEC 825 standard.

23 July 2004 Profile XP Service Manual 7

Page 8

Safety Su m maries

Laser Safety Laser safety in the United States is regulated by the Center for Devices and

Radiological Health (CDRH). The laser safety regulations are published in

the “Laser Product Performance Standard,” Code of Federal Regulation

(CFR), Title 21, Subchapter J.

The International Electrotechnical Commission (IEC) Standard 825,

“Radiation of Laser Products, Equipment Classification, Requirements and

User’s Gui de,” gove rns laser pr oducts out side the Uni ted States . Europe a nd

member nations of the European Free Trade Association fall under the

jurisdiction of the Comité Européen de Normalization Electrotechnique

(CENELEC).

FCC Emission

Limits

Certification

Category Standard

Safety Designed/tested for compliance with:

This device complies with Part 15 of the FCC Rules. Operation is s ubject to

the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesirable operation.

UL1950 - Safety of Information Technology Equipment, including Electrical Business

Equipment (Third Edition, 1995)

IEC 950 - Safety of Information Technology Equipment, including Electrical Business

Equipment (Second edition, 1991)

CAN/CSA C22.2, No. 950-95 - Safety of Information Technology Equipment,

including Electrical Business Equipment

EN60950 - Safety of Information Technology Equipment, including Electrical Business

Equipment

8 Profile XP Service Manual 23 July 2004

Page 9

Contents

Grass Valley Product Support .....................................................................................................3

Safety Summaries ......................................................................................................................... 5

Preface ......................................................................................................................................... 13

About this manual............................................ ........ .................................. ........ ......... .......13

Organization of the manual...........................................................................................13

Related documentation.................................................................................................14

Product description............................................................................................................15

Standard accessories....................................................................................................16

Profile XP Media Platform features...............................................................................17

Features common to all media platforms.................................................................17

PVS1000 features.......................................... ........ ......... ........ ......... ........ ......... .......18

PVS1100 features.......................................... ........ ......... ........ ......... ........ ......... .......19

PVS2000 features.......................................... ........ ......... ........ ......... ........ ......... .......20

PVS3000 features.......................................... ........ ......... ........ ......... ........ ......... .......21

PVS3500 features.......................................... ........ ......... ........ ......... ........ ......... .......22

Front panel controls and indicators...............................................................................23

Profile XP system overview ...............................................................................................26

Platform resources...................................................................................................26

Applications subsystem............................................................................................26

Real Time subsystem...............................................................................................27

Media storage subsystem........................................................................................27

Chapter 1 Characterizing the problem

Localizing the problem.......................................................................................................29

What was the media platform doing when the problem occurred?...............................29

What has changed?......................................................................................................30

What error indications were reported by the NetCentral system?.................................30

What attempts have you made to remedy the problem?...............................................30

Readily diagnosed problems.................................... ........ ......... ........ ......... ........ ......... .......30

Diagnostic tools..................................................................................................................31

Chapter 2 Troubleshooting Windows NT boot problems

Pre-boot problems ................................................... ........ ......... ........ ......... ........ ......... .......33

Booting Windows NT .........................................................................................................34

Invoking LastKnownGood.............................................................................................34

Windows NT boot problems..........................................................................................35

Using the emergency repair process.................................................................................36

Rebuilding the system drive...............................................................................................37

Re-installing and configuring drivers..................................................................................38

Chapter 3 Troubleshooting video problems

Checking NetCentral messages ........................................................................................39

SDI problems ................................................................................................................39

SDTI problems................................... ......... ........ ........ .................................. ......... .......40

Video playback (decode) problems...............................................................................41

Video record (encoder) problems..................................................................................42

Correcting common setup problems..................................................................................43

Correcting common video problems..................................................................................44

Chapter 4 Troubleshooting audio problems

Checking NetCentral messages ........................................................................................45

23 July 2004 Profile XP Service Manual 9

Page 10

Contents

Audio problems related to SDI board............................................................................45

Audio problems related to Audio board.........................................................................46

Correcting common audio problems..................................................................................48

Chapter 5 Troubleshooting timecode problems

Checking NetCentral messages.........................................................................................52

Correcting common timecode problems ............................................................................52

Chapter 6 Troubleshooting storage system problems

Checking NetCentral messages – PFC500.......................................................................56

Locating a drive or a chassis.........................................................................................61

Monitoring PFR 500/600 Series storage with NetCentral ..................................................62

How to set up PFR 500/600 Series NetCentral monitoring...........................................62

Using the PFR 500/600 Series device provider interface..............................................62

Monitoring PFR 700 Series storage with NetCentral .........................................................64

Correcting common storage system problems...................................................................65

Chapter 7 Troubleshooting video network problems

Checking NetCentral messages.........................................................................................67

Correcting common Fibre Channel video network problems.............................................68

Testing the Fibre Channel Video network.....................................................................69

Testing the Ethernet name resolution and connectivity............................................69

Testing Fibre Channel name resolution and connectivity.........................................70

Correcting common Ethernet video network problems ...................................................... 72

Testing the Ethernet Video network..............................................................................73

Testing the Windows NT Ethernet name resolution and connectivity ......................73

Testing video Ethernet name resolution and connectivity........................................74

Chapter 8 Troubleshooting miscellaneous system problems

Applications subsystem problems......................................................................................77

Correcting common Applications Subsystem I/O problems..........................................77

Correcting common Ethernet network problems...........................................................78

Correcting common problems using Configuration Manager........................................79

Checking Real Time Processor board NetCentral messages............................................80

Checking power supply, fan, and thermal NetCentral messages....................................... 80

Chapter 9 Troubleshooting channel control problems

Correcting common channel control problems...................................................................81

Chapter 10 Routine maintenance

Cleaning or replacing air filters...........................................................................................83

Cleaning the filters.........................................................................................................83

Additional air filters........................................................................................................83

Removing and replacing the Profile XP filters...............................................................83

Removing and replacing the PAC216 filter ...................................................................85

Cleaning and inspecting the chassis..................................................................................86

Cleaning........................................................................................................................86

Exterior.....................................................................................................................86

Interior ......................................................................................................................86

Visual Inspection...........................................................................................................86

Updating the emergency repair data..................................................................................87

Chapter 11 Parts removal and replacement

Procedures.........................................................................................................................89

External Parts Removal................................................................................................. 89

Removing the front panel.........................................................................................89

Removing the fan unit...............................................................................................90

10 Profile XP Service Manual 23 July 2004

Page 11

Contents

Removing the system disk, floppy disk, or CD-ROM drive.......................................91

Installing a new system disk or restoring a corrupt system disk...............................91

Removing the power supplies...................................................................................94

Internal parts removal....................................................................................................95

Removing the top cover............................................................................................95

Removing and installing plug-in circuit boards .........................................................96

Removing the processor board.................................................................................97

Removing the air chamber........................................................................................97

Removing the standby/on switch and fault LED.......................................................98

Removing the power distribution board....................................................................99

Removing the bulkhead..........................................................................................100

Replacing the motherboard.........................................................................................101

Removing the motherboard ....................................................................................101

Installing the motherboard......................................................................................102

Replacing parts in a system with the redundancy option............................................104

Interpreting the DupliDisk III control panel LEDs....................................................105

Operation of the DupliDisk III control panel buzzer ................................................105

Replacing a redundant system disk drive: DupliDisk III Controller.........................106

Creating a bootable DupliDisk Utilities diskette......................................................108

Interpreting the DupliDisk II control panel LEDs.....................................................109

Operation of the DupliDisk II control panel buzzer .................................................109

Replacing a redundant system disk drive: DupliDisk II Controller..........................110

Replacing a redundant system disk drive: DupliDisk Controller.............................113

Restoring a corrupt system drive............................................................................115

Replacing the Superdrive.......................................................................................118

Field-replaceable parts.....................................................................................................119

Appendix A Diagnostic Tools

Using NetCentral Lite.......................................................................................................122

Interpreting status indicators .......................................................................................122

Viewing the system tray icon..................................................................................123

Starting and stopping NetCentral Lite.....................................................................123

Viewing the NetCentral Lite main window...................................................................124

Responding to messages............................... ........ ......... ........ ......... ........ ......... .....125

To clear alarms.......................................................................................................125

To clear informational messages............................................................................126

Getting help with NetCentral Lite.................................................................................126

Launching the Profile XP Configuration Manager.......................................................126

Viewing subsystem properties.....................................................................................127

To view general properties, address, and location.................................................127

To view Thermal properties....................................................................................128

To view Storage properties.....................................................................................128

To set storage time remaining estimate perimeters:...............................................130

To view Timing properties.......................................................................................131

To view Video and Audio properties.......................................................................132

To view Board Status..............................................................................................133

To view network properties.....................................................................................134

Viewing logs............................................................................................................134

Configuring messages.................................................................................................135

Setting heartbeat polling.......................................................... ......... ........ ......... .....135

Ignoring messages ................................................. ......... ........ ......... ........ ......... .....137

Configuring actions and notifications...........................................................................138

Adding and modifying actions.................................................................................138

Controlling the front panel LED...............................................................................140

Sending e-mail and pager notifications...................................................................142

Playing a beep........................................................................................................143

Running a program.................................................................................................144

23 July 2004 Profile XP Service Manual 11

Page 12

Contents

Triggering Profile XP GPI outputs..........................................................................145

Making settings for a Profile XP system.................................................................146

Profile log tools.................................................................................................................147

Viewing Profile logs with WinTail.................................................................................147

Log Capture Tool.........................................................................................................147

Profile XP diagnostics......................................................................................................151

Starting Profile XP diagnostics....................................................................................151

Launching the tests.....................................................................................................151

Windows NT diagnostic tools...........................................................................................153

Windows NT diagnostics.............................................................................................153

Event viewer................................................................................................................153

The event logs........................................................................................................153

Event types.............................................................................................................154

Registry editor.............................................................................................................154

Role of the registry during boot ..............................................................................155

Appendix B Theory of operation

Architecture overview.................................................... ........ ......... ........ ......... ........ .........157

Applications subsystem (Windows NT system)................................................................161

Applications processor................................................................................................161

Windows NT I/O devices.............................................................................................161

Ethernet Interface..................................................... ........ ......... ........ ......... ........ .........161

Applications system disk storage ................................................................................161

RS-422 interface .........................................................................................................161

Real time subsystem........................................................................................................162

Real Time System board.............................................................................................162

Real Time Processor (RTP)...................................................................................162

LTC & GPI I/Os.......................................................................................................162

Genlock ..................................................................................................................162

MPEG-2 Encoder and Decoder boards (PVS1000 Series).........................................163

HD MPEG-2 Encoder and Decoder Boards (PVS2000, 3000, and 3500 Series).......163

Video Processor board (PVS1100, 3000, and 3500 Series).......................................163

Serial Digital Interface (SDI) boards............................................................................164

High Definition Serial Digital Interface Board..............................................................164

Serial Data Transfer Interface (SDTI) Board (optional)...............................................164

Video network adapter (optional) ................................................................................164

Audio interface ............................................................................................................165

Audio...........................................................................................................................165

Time code I/O..............................................................................................................165

Media storage subsystem................................................................................................ 165

Fibre Channel disk interface........................................................................................165

Platform resources...........................................................................................................166

Index............................................................................................................................................167

12 Profile XP Service Manual 23 July 2004

Page 13

Preface

About this manual

This service manual provides procedures for servicing the Profile XP Media Platform

to the field-replaceable unit level. Use this manual to isolate problems to a board or

module, such as the Power Supply, and to make repairs through module exchange.

Organizat io n of t he ma n ual

The Service Manual is divided into the following chapters and appendixes:

Chapter 1 - Characterizing the problem

A troubleshooting-guide starting point. Asks basic questions that:

1. enable you to determine the nature of the problem

2. guide you to the chapter that deals with that problem for further tests, analysis, an d

corrective action

This chapter also briefly discusses the various diagnostic aids available, and describes

the obvious hardware faults that require no further analysis.

Chapter 2 - Troubleshooting Windows NT boot problems

Guides you through the Windows NT boot sequence and problems associated with

booting.

Chapter 3 - Troubleshooting video problems

Lists the NetCentral messages for the video subsystem, and provides corrective action

for video problems that occur whether the media platform is controlled locally or

remotely with automation tools.

Chapter 4 - Troubleshooting audio problems

Lists the NetCentral messages for the audio subsystem, and provides corrective action

for audio problems that might occur as a result of incorrect settings, connections, etc.

Chapter 5 - Troubleshooting timecode problems

Lists the NetCentral messages for timecode problems, and provides corrective action

for timecode problems that might occur as a result of incorrect settings, connections,

etc.

Chapter 6 - Troubleshooting storage system problems

Lists the NetCentral messages for the storage system, and suggests preventive or

corrective action for common media storage problems.

Chapter 7 - Troubleshooting video network problems

Lists NetCentral messages and provides corrective action for both Fibre Channel and

Ethernet video networking problems. Includes procedures for testing either video

network.

23 July 2004 Profile XP Service Manual 13

Page 14

Preface

Chapter 8 - Troubleshooting miscellaneous system problems

Lists NetCentral messages and provides corrective action for a variety of subsystems

in the Profile XP media platform including the Applications subsystem, the Real

Time Processor board, the power supplies, the fans, and the thermal monitoring.

Chapter 9 - Troubleshooting channel control problems

Provides corrective action for some common control problems.

Chapter 10 - Routine maintenance

Provides procedures for filter cleaning and other routine maintenance tasks.

Chapter 11 - Parts removal and replacement

Provides illustrated procedures for disassembly and a list of field-replaceable parts.

Appendix A - Diagnostic Tools

Serves as a reference for use of the various diagnostic tools available on Profile XP

media platform, including instructions for using the NetCentral system, Profile XP

diagnostics, Windows NT diagnostics, and POST (power-on self-test).

Appendix B - Theory of operation

High level system overview, and high level discussions of each of the boards in the

system.

Related docum entation

Profile XP User Guide

PVS1000 Installation Guide

PVS1100 Installation Guide

PVS2000 Installation Guide

PVS3000 & PV3500 Installation Guide

Profile XP System Guide

PFC500/E Instruction Manual

PFR500/E Instruction Manual

PFR600/E Instruction Manual

PFR700/E Instruction Manual

Profile System Software Release Notes

Open SAN Instruction Manual

Open SAN Rel e ase Notes

14 Profile XP Service Manual 23 July 2004

Page 15

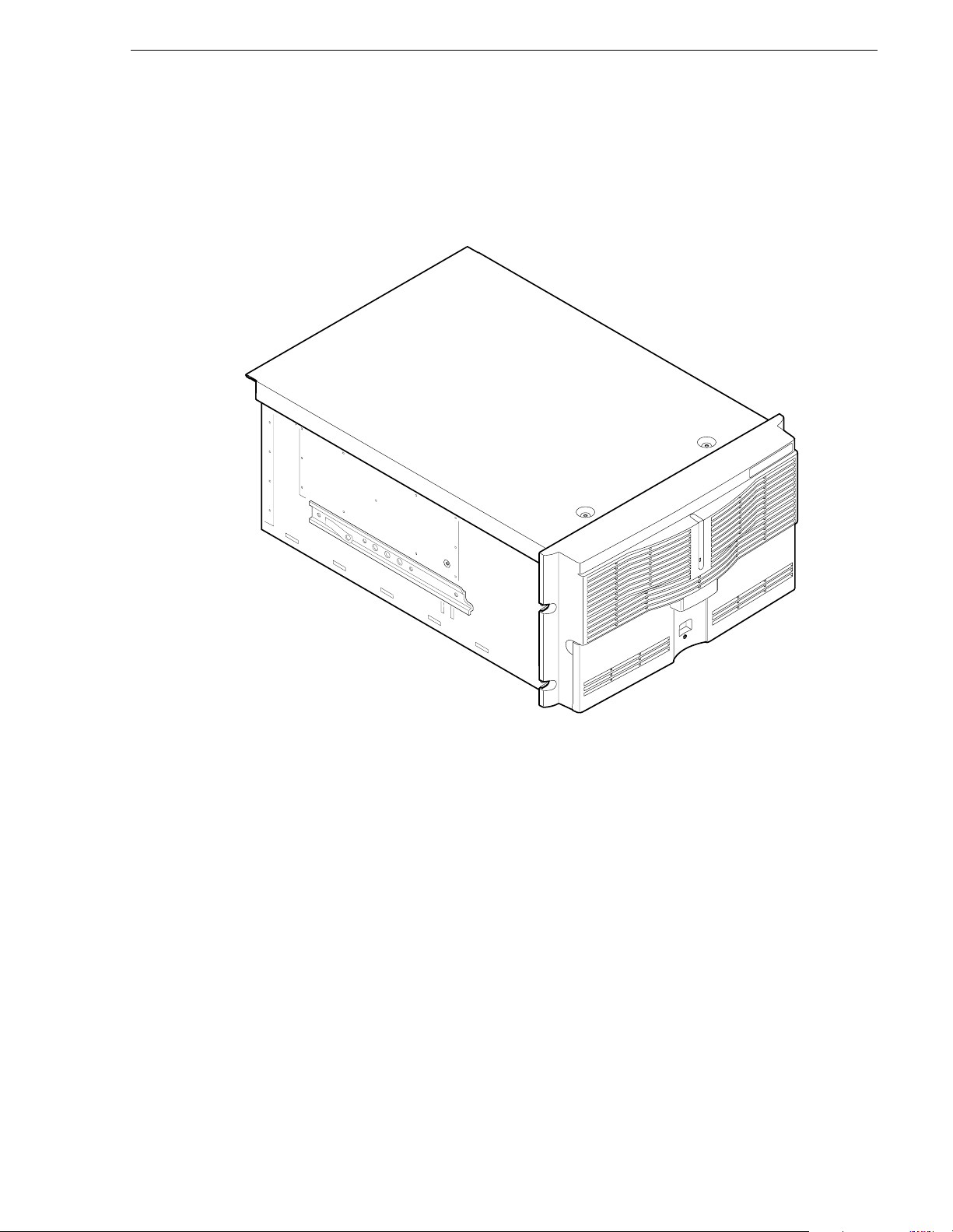

Product description

The Grass Vall ey P rofi le XP Medi a Plat form prov ides a high ban dwid th p latfo rm f or

the storage and manipulation of video and audio in professional applications

including spot insertion, program delay, store and forward, and multi-channel replay.

Product description

0625-2

The Profile XP Media Platfo rm

23 July 2004 Profile XP Service Manual 15

Page 16

Preface

Standard accessor ie s

The Profile XP Media Platform is shipped with the following standard accessories:

• Manuals Include:

- Installation Guide

- Profile XP System Guide

- Profile XP User Guide

- Profile XP Service Manual

- Profile XP Release Notes

• Software package which includes the Profile XP Software CD-ROM.

• Windows NT software package

• Keyboard and mouse

• I/O Panel and cables (provides LTC, RS-422 & GPI interfaces)

• Power cable

• Rack mounting slides

• Ethernet cable

• System rebuild CD-ROM

16 Profile XP Service Manual 23 July 2004

Page 17

Profile XP Media Platform features

Features common to all media platforms

• 16 (8 AES Pairs)/ 32 (16 AES pairs) channel audio - AES/EBU, embedded or

analog uncompressed audio, Dolby E and AC-3 compressed audio

• 600Mb / s System Bandwi dth

• Redundant power supply, NT disk, cooling fans for reliability

• External Fibre Channel RAID st orage (dua l controllers optional)

• Storage capability supported includes distributed storage for hundreds of channels

as well as centralized storage for up to 32 channels

• NetCentral™ provides remote error reporting and monitoring via SNMP

• High speed Fibre Channel networking up to 250Mb/s

• 100BaseT Ethernet networking up to 30Mb/s

• Remote control including:

- Remote Applications over Ethernet

Profile XP Media Pla tf orm fe at ures

- RS-42 2 con t ro l prot o c ol inc luding VDCP, O det i cs , BVW , or Pr of i l e prot o c o ls.

- GPI Trigger (8 I/O)

23 July 2004 Profile XP Service Manual 17

Page 18

Preface

PVS1000 features

• Up to 8 standard definition (SD) channels of broadcast-quality video

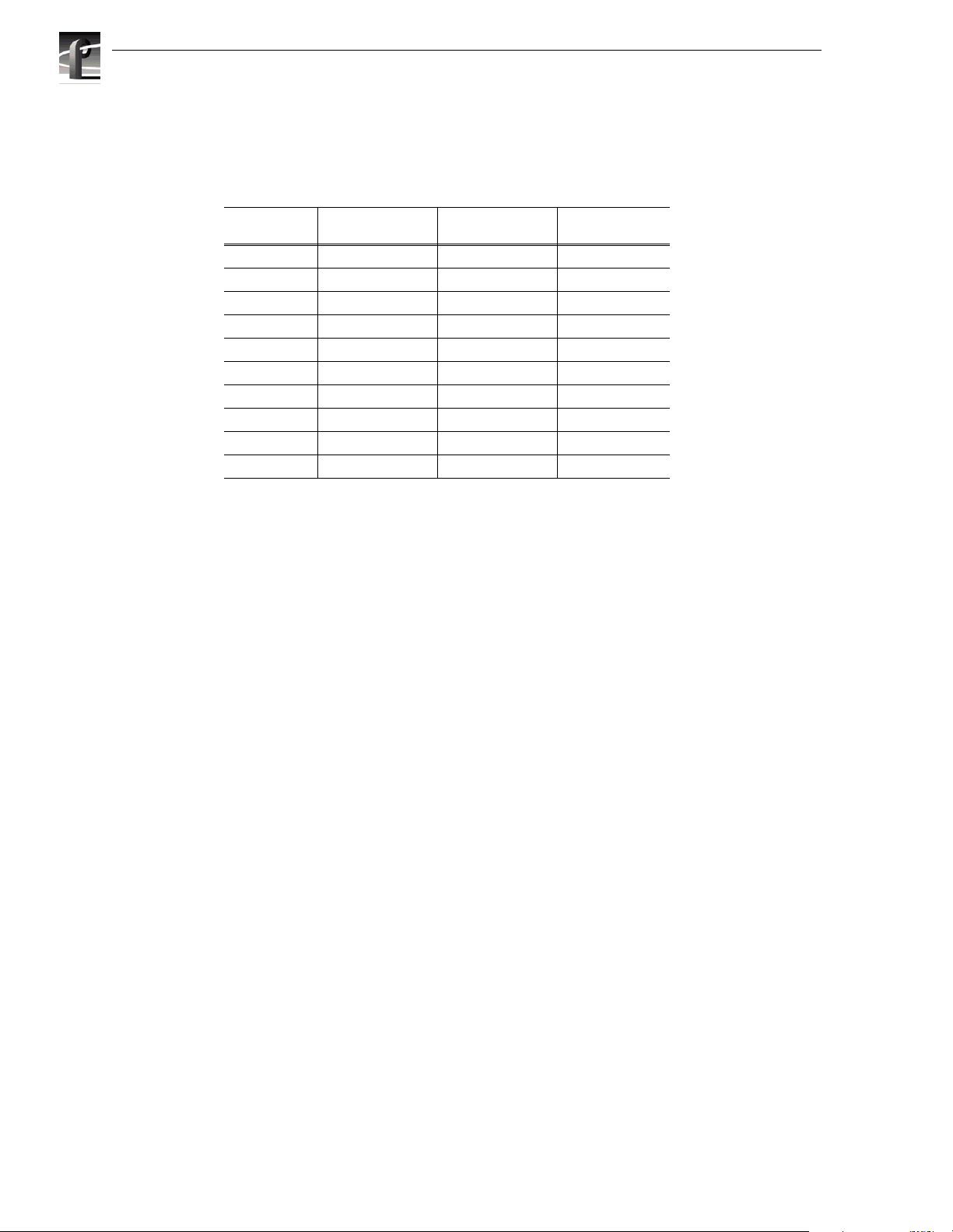

PVS1000 Series channel configurations by model

Model

Number

PVS1022 1 1 2 in/2 out

PVS1024 1 2 2 in/ 4 out

PVS1026 1 3 2 in/6 out

PVS 1042 2 1 4 in/2 out

PVS1044 2 2 4 in/4 out

PVS1062 3 1 6 in/2 out

PVS 1002 0 1 0 in/2 out

PVS 1004 0 2 0 in/4 out

PVS 1006 0 3 0 in/6 out

PVS1008 0 4 0 in/8 out

a.

MPEG Encoder and Decoder boards in PVS1000 series are Standard

Definition.

Numbe r of MP EG

Encoder Boards

Number of MPEG

a

Decoder Boards

Channel

Configuration

• MPEG-2 4: 2:2 @ Main Level from 4-50Mbs, long GOP

• SMPTE 259M, 270MHz Serial Digital I/O (Optional analog monitor with

timecode burn-in and text overlay)

• 525/60 or 625/50 operation: accepts NTSC, PAL

18 Profile XP Service Manual 23 July 2004

Page 19

PVS1100 features

• Up to 8 standard definition (SD) channels of broadcast-quality video

PVS1100 Series channel configurations by model

Profile XP Media Pla tf orm fe at ures

Model

Number

PVS1102 2 2 play/record

PVS1104 4 4 play/record

PVS1106 6 6 play/record

PVS1148 8 4 play/record

PVS1108 8 8 play/record

Number of video

codecs

Channel

Configuration

plus 4 play

• DVCPRO 25 video compression

• DVCPRO 50 video compression (req uires 50Mb/s option)

• MPEG-2 4:2:2 @ Main Level from 4 to 25Mb/s or 50Mb/s (requires 50Mb/s

option)

• MPEG-D10: I-frame to 50Mb/s CBG (requires 50Mb/s option)

• SDTI (optional): two channels, each can be configured as input or output.

DVCPRO 2 5 input at 1x, 2x, 4x; ou tput at 1x , 4x. DVCPRO 50 input at 1x, 2x;

output at 1x.

• SMPTE 259M, 270MHz Serial Digita l I/O (Opti onal analog monit o r with

timecode burn-in a nd text overlay)

• 525/60 or 625/50 operation: accepts NTSC, PAL

23 July 2004 Profile XP Service Manual 19

Page 20

Preface

PVS2000 features

• Up to 4 high definition (HD) channels of broadcast-quality video

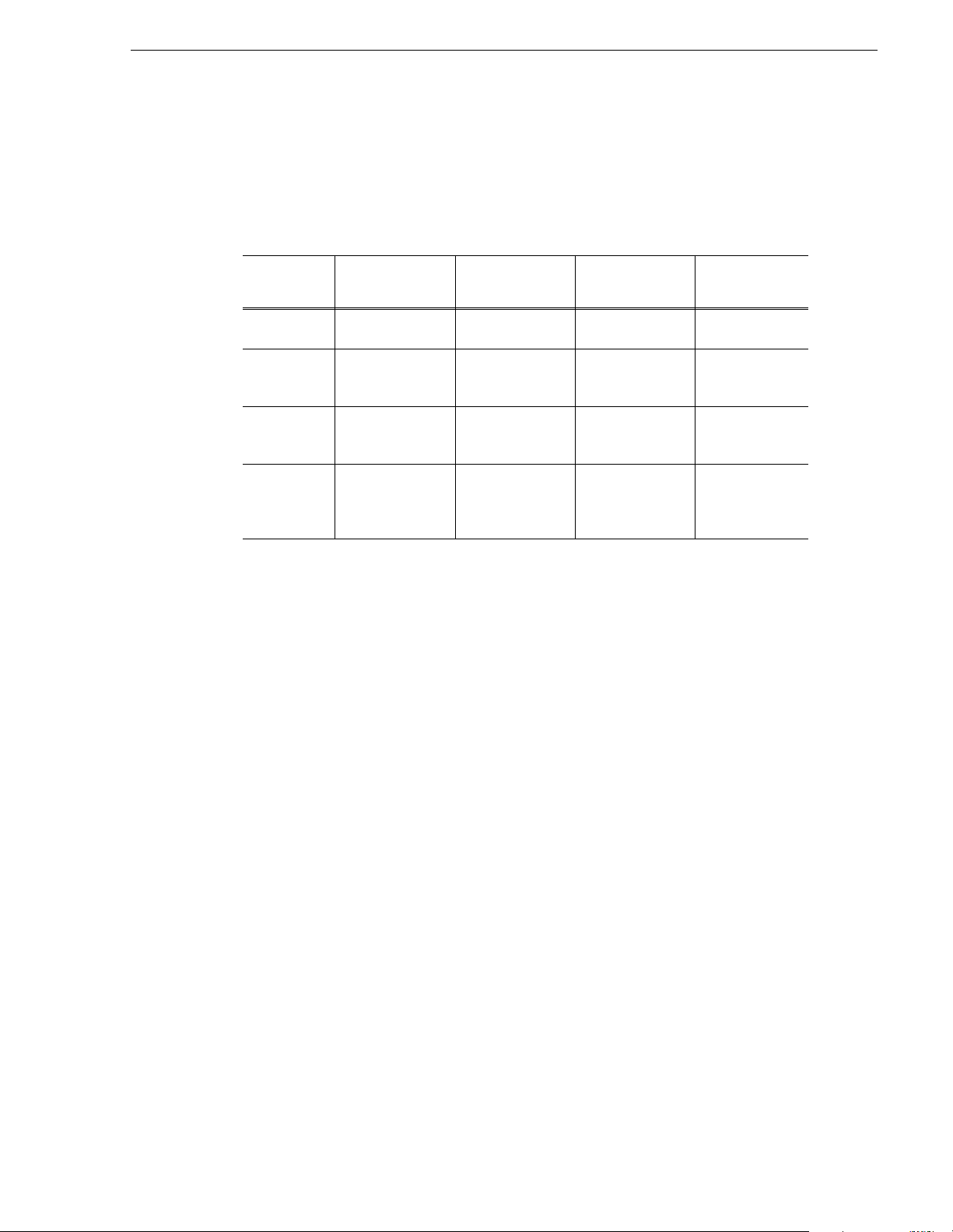

PVS2000 Series channel configurations by model

Model

Number

PVS2012 1 1 1 in/2 out

PVS2013 1 2 1 in/ 3 out

PVS2004 0 2 0 in/4 out

PVS2022 2 2 2 in/2 out

PVS2212 1 HD, 1 SD 1 HD, 1 SD 2 in/2 out (SD)

a.

MPEG Encoder and Decoder boards in PVS2000 series are High Definition.

Number of MPEG

Encoder Boards

Number of MPEG

a

Decoder Boards

Channel

Configuration

1 in/2 out (HD)

• MPEG-2 4: 2:0 @ Main Level from 24-80Mbs, long GOP (for HD )

• SMPTE 292M, 1.485 Gbs Serial Digital I/O (includes downconverted SD SDI and

composite analog monitor with text overlay and timecode burn-in)

• 1080i and 720p line rates for HD, 50 and 59.94, accepts house black and tri-level

sync reference

20 Profile XP Service Manual 23 July 2004

Page 21

PVS3000 features

• Up to 7 channels of broadcast-quality video

• Standard and high definition channels can record and play concurrently

PVS3000 Series channel configurations by model

Profile XP Media Pla tf orm fe at ures

Model

Number

PVS 3004 0 1 1 2 SD out

PVS 3014 1 1 1 2 SD out

PVS3024 0 1 1 (4 Ch.) 2 SD in

PVS3034 1 1 1 (4 Ch.) 2 SD in

Number of HD

MPEG Encoder

Boards

Number of HD

MPEG Decoder

Boards

Number of SD

Video Processor

Boards

Channel

Configuration

2 HD out

1 HD in

2 HD out

2 SD out

2 HD out

2 SD out

1 HD in

2 HD out

• MPEG-2 4:2:0 @ Main Leve l from 24-80Mbs, lo ng GOP (for HD)

• MPEG-2 4:2:2 @ Main Level from 4 to 25Mb/s or 50Mb/s (requires 50Mb/s

option)

• SMPTE 292M, 1. 485 Gbs Seri al Digi tal I/O (i ncludes downconv erted SD SDI and

composite analog monitor with text overlay and timecode burn-in)

• SMPTE 259M, 270MHz Serial Digita l I/O (Opti onal analog monit o r with

timecode burn-in a nd text overlay)

• 1080i and 720p line rates for HD, 50 and 59.94, accepts house black and tri-level

sync reference

• DVCPRO 25 video compression

• DVCPRO 50 video compression (req uires 50Mb/s option)

• MPEG- D10: I-fra me at 30, 40, or 50Mb/s CBG (requires 50Mb/s option)

• 525/60 or 625/50 operation: accepts NTSC, PAL

•

23 July 2004 Profile XP Service Manual 21

Page 22

Preface

PVS3500 features

• Up to 7 channels of broadcast-quality video.

• HD decoders can play MPEG-2 4:2:0 SD and HD clips through either an SD or an

HD SDI output, down- or up-converted as required.

PVS3500 Series channel configurations by model

Model

Number

PVS3502 0 1 0 2 HD/SD out

PVS3504 0 2 0 4 HD/SD out

PVS3512 1 1 0 1 HD in

PVS3514 1 2 0 1 HD in

PVS3522 0 1 1 2 SD in

PVS3524 0 2 1 2 SD in

PVS3532 1 1 1 2 SD in

PVS3534 1 2 1 2 SD in

Number of HD

MPEG Encoder

Boards

Number of HD

MPEG Decoder

Boards

Number of SD

Video Processor

Boards

Channel

Configuration

2 HD/SD out

4HD/SD out

2 HD/SD out

4 HD/SD out

1 HD in

2 HD/SD out

1 HD in

4 HD/SD out

• MPEG-2 4: 2:0 @ Main Level from 24-80Mbs, long GOP (for HD )

• MPEG-2 4:2:2 @ Mai n Level from 4 to 25Mb/s or 50Mb/ s (requires 50Mb/s

option)

• SMPTE 292M, 1.485 Gbs Serial Digital I/O (includes downconverted SD SDI and

composite analog monitor with text overlay and timecode burn-in)

• SMPTE 259M, 270MHz Serial Digital I/O (Optional analog monitor with

timecode burn-in and text overlay)

• 1080i and 720p line rates for HD, 50 and 59.94, accepts house black and tri-level

sync reference

• DVCPRO 25 video compression

• DVCPRO 50 video compression (requires 50Mb/s option)

• MPEG-D10: I-frame a t 30, 40, or 50Mb/s CBG (requires 50Mb/s option)

• 525/60 or 625/50 operation: accepts NTSC, PAL

22 Profile XP Service Manual 23 July 2004

Page 23

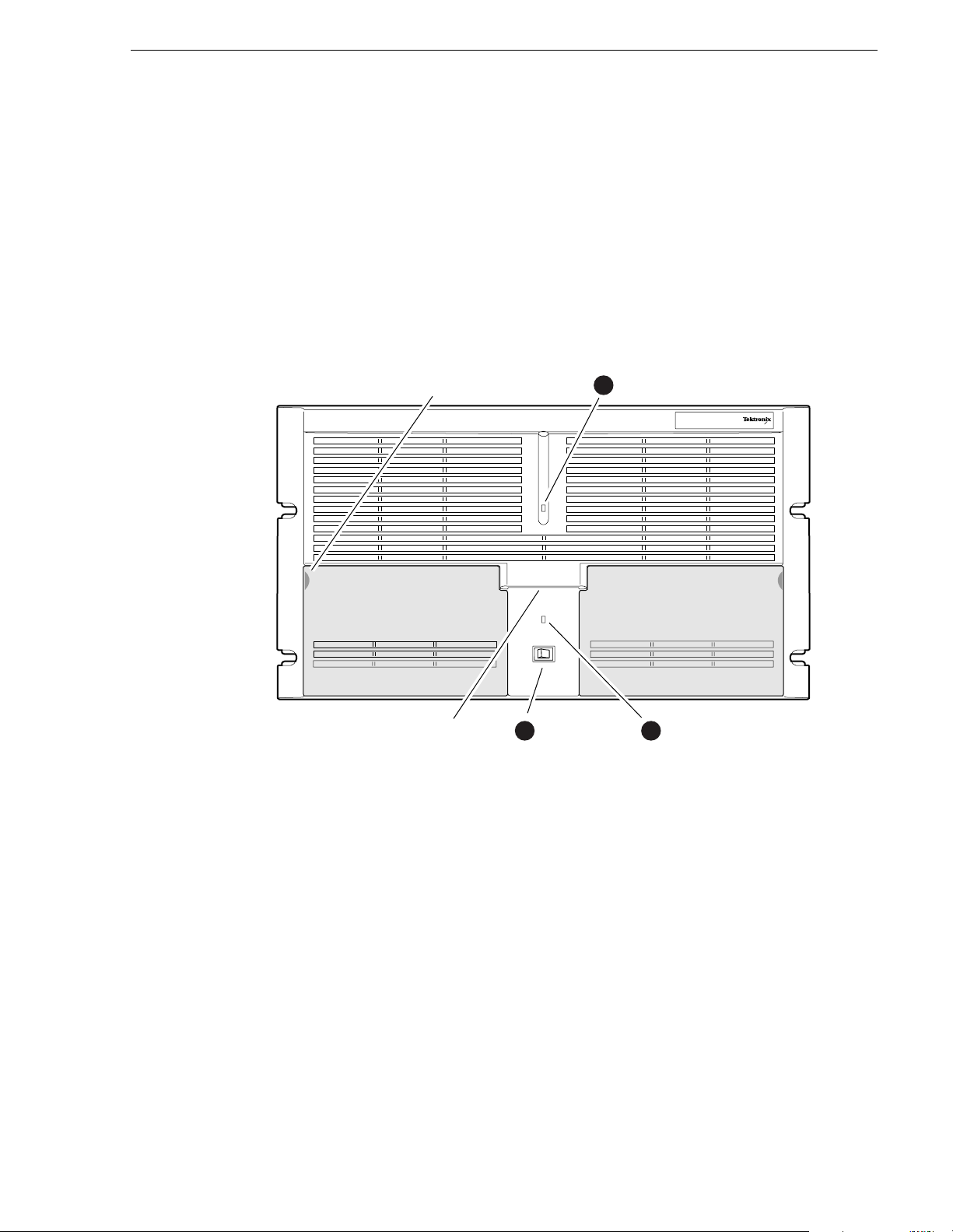

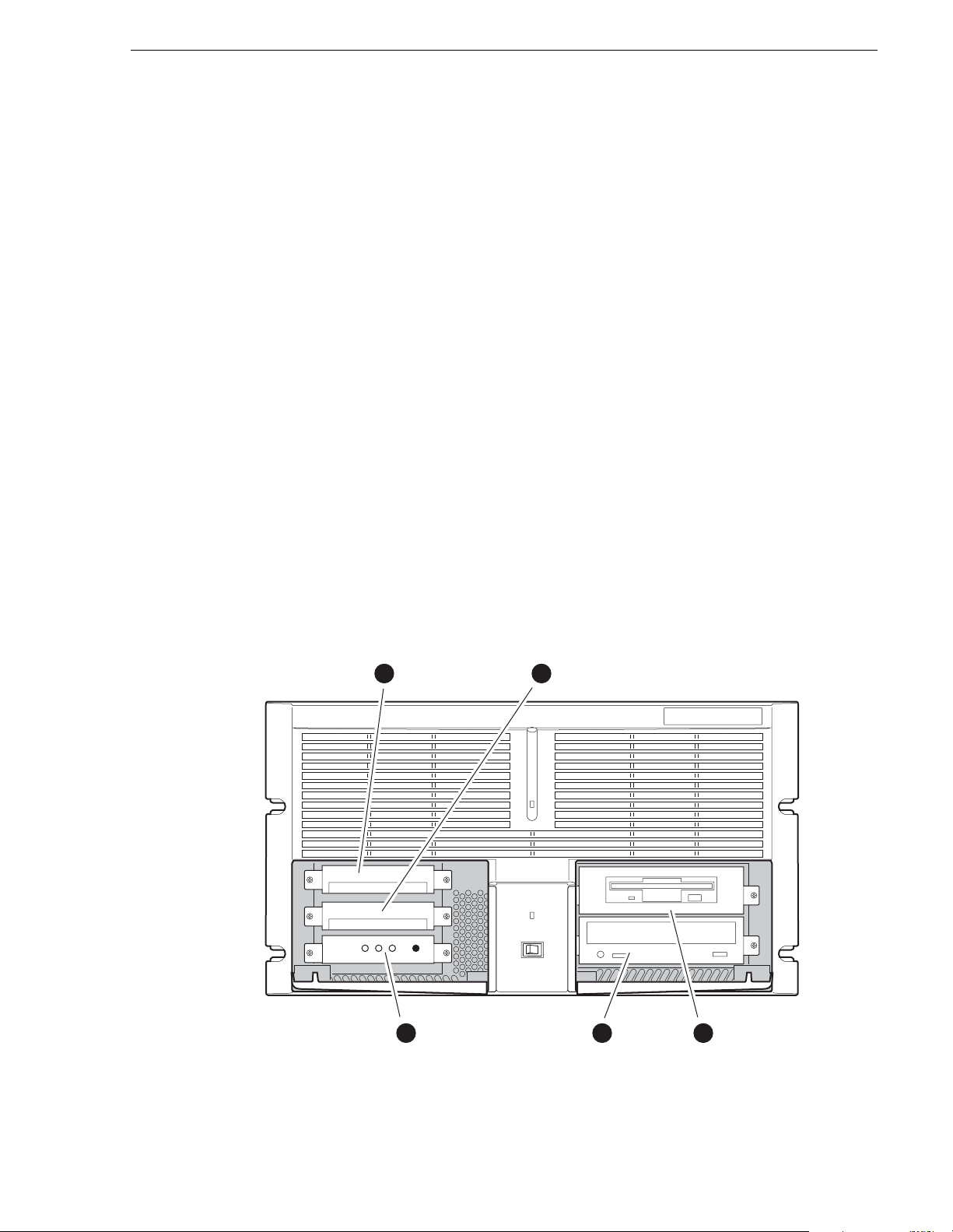

Front panel con t ro ls and indicato rs

The Profile XP Media Platform front panel shown here includes the following

controls a nd i ndicators:

➊ Standby/On LED - indicates the standby switch is in the on position and that

secondary voltages are present in the chassis.

➋ Standby/On Switch - provides system On/Off control.

➌ System Fault LED - indicates a system fault somewhere in the Profile XP system.

This LED is under control of the NetCentral system and goes off when NetCentral

receives notice from the system that the cause of the fault is cleared.

Front panel controls and indicators

Pull here to

open (each side)

Accessory

Door

Standby/On

2

Switch

Profile XP Media Platform front panel

1

Standby/On LED

Accessory

Door

System

3Chassis Pull

Fault LED

0624-5

The Profile XP front panel features two accessory doors that provide access to several

application subsystem storage devices. A system with standard equipment is shown

on page 24, while a system equipped with the redundant storage option is shown on

page 25.

23 July 2004 Profile XP Service Manual 23

Page 24

Preface

The storage devices in the standard system include:

➊ System Drive - contains Windows N T operating system and Profile XP software

and applications.

➌ 1.44MB Floppy Disk Drive - for installing operating system and Profile XP system

software upgrades.

➍ CD-ROM Drive - for installing operating system and Profile XP system software

upgrades.

NOTE: The snap-in hinges in the front panel accessory doors allow you to easily

pop the door back into place should it be accidentally knocked from its hinges.

0624-4

System

1

Disk Drive

Profile XP Media Platform with accessory doors open

Floppy

2

Disk Drive

CD-ROM

3

Drive

24 Profile XP Service Manual 23 July 2004

Page 25

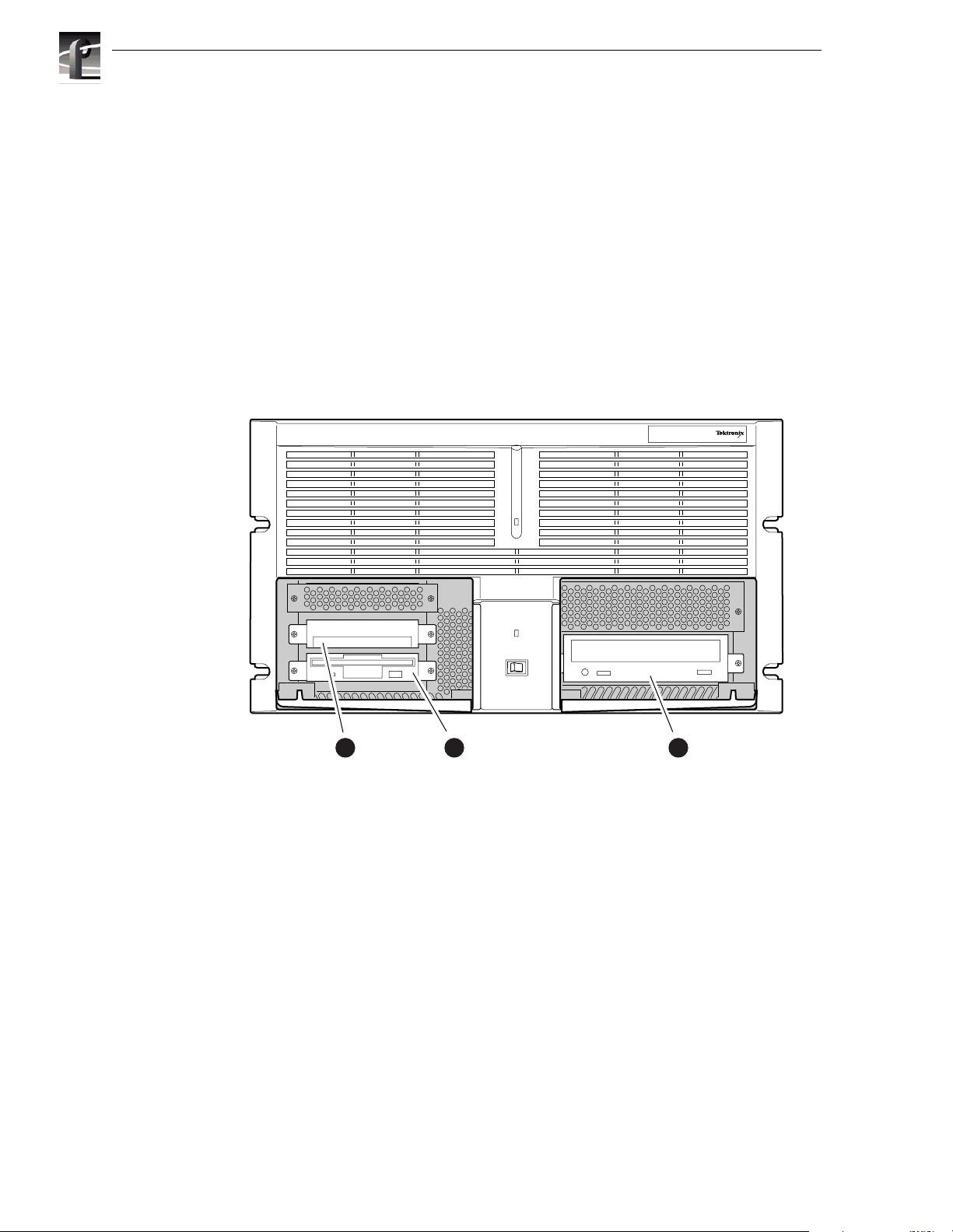

Front panel controls and indicators

The storage devices in the system with the redundant system disk option include:

➊ Primary System Drive - contains Win dows NT operating system and Profile XP

software and applications.

➋ Mirror System Di sk - mirrors primary system disk and provides automatic fail-over

in the event primary system disk fails.

➌ Drive Mirroring Controller and Indicator Panel - The Primary and Mirror LEDs

monitor the status of the channels as follows:

- Green - Drive installed on the current channel

- Red - Drive not installed or channel marked as bad

- Orange - Drive activity

The Status LED indicates the operating mode of the mirroring system:

- Green - Drives are in Mirror mode

- Red - Drives in Single mode

The Buzzer Off switch can be used to silence the buzzer, which sounds under the

following conditions:

- Short beep during power on indicates successful boot-up

- Second beep indicates the mirroring system is running in single mode

- Continuous or intermittent beep indicates a drive failure

➍ CD-ROM Drive - for installing operating system and Profile XP system software

upgrades.

➎ 120MB Superdrive or 1.44MB Floppy Drive - the Super-Drive accepts 1.44MB

floppy dis ks and 120MB disks.

DupliDisk

Primary System

1

Disk Drive

Primary

Mirror Status Buzzer

3

DupliDisk

Indicator Panel

Mirrored System

2

Disk Drive

4

CD-ROM

Drive

Superdrive or

5

Floppy Drive

0625-18

Profile XP with redundant system disk option

23 July 2004 Profile XP Service Manual 25

Page 26

Preface

Profile XP system ove rview

The Profile XP Media Platform system is an extension to a standard PCI bus based

Windows NT Computer. This standard computer base is enhanced to add

functionality and performance necessary to deliver an industrial grade, broadcast

quality, disk-based media platform. This section discusses the major architectural

blocks, what they do, and how they interconnect. A more detailed overview of the

system is available in Appendix B, Theory of operat i on.

The Profile XP Media Platform consists of two major subsystems, the Application

Subsystem and the Real Time Subsystem, and the platform resources needed for them

to functi on. Thes e are sh own in the dark er tinte d area of the hig h-level block di agram .

A third major subsystem, the Media Storage Subsystem, is external to the media

platform.

Configuration

Control

User I/F

Application

Subsystem

Platform resources

The platform resources provide the infrastructure necessary to operate, interconnect,

and integrate all the components of the Application and Real Time Subsystems. The

platform resources include the multi-slot PCI bus, the video & audio crosspoint fabric,

the power supply, and system cooling.

Applications subsystem

Video I/O

IPM

Channel

Subsystem

Platform Resources

High-level Block Diagram

Media Networking

Audio I/O

Real Time

Media Storage

Subsystem

Fibre

Channel

0625-4

The Applications Subsystem is a Windows NT computer subsystem in a standard

NLX single board computer form factor. The Applications Subsystem provides a

platform for runni ng Wi ndows b ased appli catio ns tha t co nfigu re an d contr ol t he Real

Time Subsystem both locally and remotely.

26 Profile XP Service Manual 23 July 2004

Page 27

Real Time subsystem

The Real Time Subsystem contains a real time processor and peripheral devices and

runs the VXWorks operating system.The Real Time Subsystem manages all the

hardware involved in controlling the flow of video, audio, and timecode in and out of

the system. This includes video I/O boards, audio I/O boards, video compression

boards, an d networking and storage. The Real Time Subsy s tem is controlled by

applications running on the Applications S ubsystem using Inter-Processor Messaging

channels (IPM). It is responsible for the execution of events on the play time line.

Media storage subsystem

NOTE: If your P r ofile XP Medi a Platform is part of an Open SAN, refer to th e

Open SAN Installation Guide for information about media storage.

The Storage Subsystem is where the video, audio, timecode and other media related

data is stored. This storage system is made up of one or more external RAID level 3

storage chassis containing Fibre Channel disks. The Profile XP Real Time Subsystem

controls re ad /w rit e dis k op e rati ons by se n din g SCSI pr oto col com man ds o ver one or

more Fibre Channel links.

Profile XP system overview

23 July 2004 Profile XP Service Manual 27

Page 28

Preface

28 Profile XP Service Manual 23 July 2004

Page 29

Chapter

1

Characterizing the problem

This is your first step in diagnosing the problem you are having with your Profile XP

Media Platform. The information presented here and the questions asked will enable

you to:

• Determine the nature of the problem

• Direct you to the area of the manual that deals more specifically with the problem

you are experiencing

You will also find brief discussions of the diagnostic aids available on the media

platform. In cases where the error message carries with it the remedy to the cause, you

will not need to go beyond this chapter.

Localizing the problem

In determining the nature of the problem, there are four questions that will in most

cases help you localize the problem to one of the three major subsystems.

What was the media platform doing when the problem occurred?

Another wa y to ask this would be, “What were you doing w ith the media platform

when the problem occurred?” or “How were you using the media platform when the

problem occurred?” This can include “When did the problem occur?”

• Does the problem occur at start-up?

Any failure before the desktop ap pears is mos t likely a Windows NT b oot proble m. If

you are experiencing boot problems, refer to Chapter 2, Troubleshooting Windows NT

boot proble ms, which covers the potential problems you can encounter during the

WindowsN T boot sequence.

• Can you record and play video, audio, and timecode?

Record and play problems can have a number of causes. The most frequent problems

result from a change in configuration, or cables being accidentally disconnected or

misconnected. R efer to Chapt er 3, Troubleshooting video problems, Chapter 4,

Troubleshooting audio problems, or Chapter 5, Troubles hooting tim ecode probl ems

for help determining those problems.

If an automatic controller is used to operate the media platform, refer to Chapter 9,

Troubleshooting channel control problems for dealing with possible problems cau sed

by controller interface problems.

• Is there a problem with the video network?

If you are having network problems such as an inability to access other Profile

systems on the network see Chapter 7, Troubleshooting video network problems,

which deals with possible problems in the fibre channel or ethernet video network

systems.

23 July 2004 Profile XP Service Manual 29

Page 30

Chapter 1 Characterizing the problem

What has changed?

If the media platform has been working, but has suddenly developed a problem, think

of what has changed in the system.

• Have you changed resources for any of the channels?

• Have you installed any software?

• Have you installed or removed a board?

If reversing the changes restores the system, perhaps there is a problem with the

software or hardware that was installed or removed.

What error indications wer e repo rted by the NetCentral system?

The NetCentral system monitors the operational status of the media platform, keeping

track of a number of operating parameters and the health of the circuit boards. Many

of the messages displayed by the NetCentral system contain the remedy for a problem

along with the notification. NetCentral also generates log files that you can use to help

determine where and when faults have occurred. Refer to “Viewing logs” on

page 134.

What attempts have you made to remedy the problem?

Keep track of efforts you make to remedy your problem. In the event that you need to

contact Grass Valley Support, this information can greatly assist the person working

with you to isolate and correct the problem.

Readily diagnosed problems

Many problems are easily diagnosed because they are primarily hardware faults that

are indicated by messages at boot time or because they generate a NetCentral Alarm

or an Attention message.

• Power-supply fa ilure

• Fan failure

• Temperature (fans/filter/overload)

• Applic a ti on s pr oc es s or boot failur e

Any of the plug-in circuit boards in the media platform will generate a NetCentral

Alarm message if the board fails. This message states the name of the board and its

slot location in the Profile XP media platform, and recommends that you replace the

board.

30 Profile XP Service Manual 23 July 2004

Page 31

Diagnostic tools

Several diagnostic tools are available to you for determining the nature and source of

a problem. They are listed here with brief explanations of their uses, and they are

discussed in more detail in Appendix A, Diagnostic Tools.

NetCentral — Monitors the state of the Profile XP media platform, and alerts you to

component failures and maintenance needs. This system uses SNMP managers and

agents to monitor one Profile XP media platform locally or, if you are using optional

full-featured NetCentral, many Profile XP systems from a remote location. The

system constantly monitors the status of the Profile XP media platform and generates

Attention (warning) messages when hardware failures are imminent or when

operating conditions are degrading, and generates Alarm (critical) messages when

hardware failures occur or when the operating environment exceeds safe parameters.

Profile XP Diagnostics — A diagnostic suite that checks the functionality of the

boards in the Profile XP Media Platform.

Windows NT diagnostic tools — Provid ed by Mic ros of t for us e in tr oub l esho ot in g

problems with Windows NT.

POST — Power-On Self-Test. Basic tests to assess the initial health of the system as

it boots.

Diagnostic tools

23 July 2004 Profile XP Service Manual 31

Page 32

Chapter 1 Characterizing the problem

32 Profile XP Service Manual 23 July 2004

Page 33

Chapter

2

Troubleshooting Windows NT boot problems

This chapter deals with problems that occur between setting the switch to “on” and

the appearance of the desktop on the monitor screen. During this period, the power-on

self-test runs and Windows NT boots.

Pre-boot problems

The pre-boot sequence of events occurs when you first turn on the computer before

Windows NT loads and begins to run. The problems that occur during pre-boot are

primarily hardware problems. These problems are typically in the Applications

Processor board or in one of the peripherals attached to it: the display, the keyboard,

the mouse, the system drive, or the diskette drive. When these events are complete,

the computer is ready t o begin loa ding Windows NT.

The following table lists some possible p roblem symptoms that you might see as error

messages that appear during the Power-On Self-Test (POST).

Symptom Possible Cause Solution

Error message indicating failure

in a hard disk drive.

Error message indicating failure

in diskette drive

Error message indicating

keyboard problem.

Error message indicating

inability to find boot device or

operating system.

Error message in dicating CMOS

battery low or dead.

Error message indicating

memory problem.

Error message indicating timer

or clock problems.

No display Component failure in

Hard disk drive failure Try replacing the hard disk

drive.

Connecting cable failure Check the connecting cable,

replace if necessary.

Diskette drive failure Try replacing the diskette drive.

Connecting cable failure Check the connecting cable,

replace if necessary.

Keyboard unplugged Plug in keyboard

Keyboard or connecting cable

defective

Hard disk drive failure Try replacing the hard disk

Connecting cable failure Check the connecting cable,

Battery low or dead Replace Applications Processor

Defective memory. Replace Applications Processor

Component failure in

Applications Processor board

Applications Processor board

Monitor or cable failure

Replace keyboard

drive.

replace if necessary.

board.

board.

Replace Applications Processor

board.

Replace Applications Processor

board.

23 July 2004 Profile XP Service Manual 33

Page 34

Chapter 2 Troubleshoo ting Windows NT boot probl em s

These are messages you might see reported by NetCentral at a remote monitoring

station that relate to system startup for a Profile XP system. No entry in the Possible

Cause column means that the cause is implicit in the problem statement, that knowing

the cause is unimportant to the solution, or in the case of status messages, there is no

cause.

Problem Possible Cause Corrective Action

Flash ROM image download and

execution error detected on the

boardtype board in slot Jn. The Pro file

XP system might operate incorrectly.

Power-On-Self -Test failure dete cted for

the boardtype board in slot Jn. The

Profile XP system might operate

incorrectly.

Mismatching software version detected

on the boardtype board in slot Jn. The

Profile XP system might operate

incorrectly.

Hardware failure on the

board.

Incorrect or incomplete

installation of Profile

XP System Software.

• Restart the Profile XP

system.

• Reload the system

software.

• Contact Support.

Do one or more of the following:

• Restart the Profile XP

system.

• Reload the system

software.

• Replace th e board.

• Contact Support.

Reload the system software if the

Profile XP system operates

incorrectly.

Booting Windows NT

This is the sequence that the computer follows when loading Windows NT.

1. Load NTLDR into memory and run it.

2. NTLDR reads co n te n t s o f Boot.ini. On the screen it displays the boot loader menu,

a menu that allows the user to select which operating system to load.

3. NTLDR loads Windows NT, or Windows NT VGA-mode if selected by the user.

4. NTLDR executes NTDETECT.COM.

On the screen, NTDETECT displays “NTDETEC T V1. 0 Checki n g Hard ware…”

5. Ready to load and initialize Windows NT.

Display:OS Loader V4.0

Press spacebar now to invoke Hardware Profile/Last Known Good menu.

6. Initialize Windows NT.

The screen turns blue with white lettering.

7. Begin loading Windows NT. The boot process is complete when the desktop

appears following a user log on or autologon.

Invoking

LastKnownGood

As its name implies, LastKnownGood is a copy of the configuration from the last

successful syste m boot-up. Invoking LastKnownGood allows you to overcome

configuration related boot problems. It is used to undo any configuration changes that

did not have the intended effect, such as those caused by adding a new driver to the

system, or those caused by user-modified registry values. However, LastKnownGood

does not repair corrupted or missing drivers or files.

34 Profile XP Service Manual 23 July 2004

Page 35

Windows NT boot problems

LastKnownGood is loaded in when the user presses the space bar at the prompt before

Windows NT begins to load.

It is important to remember that when you invoke LastKnownGood, any system

configuration changes made since the last successful start up are discarded. And once

you successfully log on, the configuration used becomes LastKnownGood

Windows NT bo ot problems

Possible problems that occur during the Windows NT boot sequence are listed in the

following table. These problems can be repaired using the emergency repair process

described later in this chapter.

Problem Probable cause

Windows boots without displaying Boot Loader Menu

or

Problem in Windows NT Path

New boot loader operating system menu item appears If the path for the default operating system in the boot

This will occur if Boot.ini is missing. If Boot.ini is

missing NTLDR will boot from the \winnt directory by

default. If this is the correct directory, Windows NT

boots automatically. If not, the following message

appears:

Windows NT could not start because the following

file is missing or corrupt:

\winnt root\system32\ntoskrnl.exe

Please reinstall a copy of the above file.

loader section of the boot.ini file does not match any

paths in the operating system portion of the file a new

entry, “NT (default)” will be added to the operating

system portion of the file. This new entry will be

highlighted and used to boot NT if user does not make

a selection.

The following message is displayed:

OS Loader V4.0

Windows NT could not start because of a computer disk

hardware configuration. Could not read from the selected

boot disk. Check boot path and disk hardware. Please check

the Windows NT (TM) documentation about hardware disk

configuration and your hardware reference manuals for

additional information.

The following error message is displayed:

Boot: Couldn’t find NTLDR

Please insert another disk

The following error message is displayed:

NTDETECT V1.0 Checking Hardware…

NTDETECT failed

The following error message is displayed:

Windows NT could not start because the following file is

missing or corrupt:

\winnt root\system32\ntoskrnl.exe

Please re-install a copy of the above file.

The following error message is displayed:

I/O Error accessing boot sector file

multi (0) disk (0) rdisk (0) partition (1):\bootsect.dos

Invalid device (Name, for instance) in Windows NT

path in boot.ini.

NTLDR file is corrupt or missing

Ntdetect.com file is corrupt or missing

Ntoskrnl.exe file is corrupt or missing

Bootsect.dos file is corrupt or missing

23 July 2004 Profile XP Service Manual 35

Page 36

Chapter 2 Troubleshoo ting Windows NT boot probl em s

Using the emergency repair process

The emergency repair data located in c:\winnt\repair and on the Emergency Repair

Disk (ERD) is used to restore a Windows NT workstation back to the state of the last

repair update. It is used to search for missin g or corrupt Windows NT files and to

restore the registry files, including SAM database, security information, disk

configuration, software registry entries, and other information.

Use of the Emergency Repair Disk (ERD) is called for when Windows NT Fails to

function correctly and invoking the LastKnownGood configuration does not solve the

problem. Some points to remember when using the ERD:

• The ERD is computer specific. An ERD created on one computer will not work on

another unless the computers are identical and the software is installed in the same

locations.

• If you replace the SAM database, you must remember the Administrator password

used when the ERD was updat ed.

• Using the ERD returns the system to the state it was in at the time of the last update

to the Emerge ncy Repair di rectory o r disk.

Follow this procedure to use the ERD:

1. Locate the Windows NT installation CD-ROM. You need the installation

CD-ROM in case any system files are bad or missing. Also locate the installation

media for any Service Packs or Y2K fix installed on the computer.

NOTE: If you repair System files, the emergency repair process DELETES all

Service Packs and the Y2K fix; you must re-install them at the end of the process.

2. Insert the Windows NT Setup disk 1 and restart the computer. The repair process

is a part of Windows NT Setup.

3. Insert Disk 2 when prompted , and type “

R” to select repair from the Setup Menu

that appears (do not select new or update). The following menu appears:

[X] Inspect registry files

[X] Inspect start-up environment

[X] Verify Windows NT system files.

[X] Inspect boot sector.

Continue (perform selected tasks)

4. Leave all choices selected, choose Continue, and press

5. When prompted, inse rt Windows NT Workstati on Setup Di sk #3 and press

6. When prompted to scan for mass storage devices press “

7. In the next screen press “

8. Select “Other” and press

S” again, this time to specify the CD ROM Drive.

Enter.

Enter.

Enter.

S” to skip.

9. Insert the CDROM Driver floppy disk when prompted, then press

10.Select “FIT” and press

Enter to continue.

Enter.

11.When prompted, a ga in insert Windows NT Workstation Se t up Disk #3 an d press

Enter to continue.

36 Profile XP Service Manual 23 July 2004

Page 37

Rebuilding the syst em dri ve

12.Ins ert the ERD when pr ompted. If you do not have an ER D, the repair pro cess uses

the repair data it finds under c:\winnt\system32\repair.

13.Conf irm that you want your hard disk(s) examined for co rruption by pressing

Enter.

14.The r egistry repa i r choices appear if you l eft “inspect regist ry files” selected.

[X] SYSTEM (System Configuration)

[X] SOFTWARE (Software Information)

[ ] DEFAULT (Default User Profile)

[ ] NTUSER.DAT (New User Profile)

[ ] SECURITY (Security Policy and SAM (User Accounts Database)

Continue (perform selected tasks)

Select the keys you want to restore by entering X between brackets, then highlight

Continue and press

choices because in most cases they will correct problems that require emergency

repair.

Enter. SYSTEM and SOFTWARE are the recommended

15.Press

16.Re-install the Windows NT service pack(s) and Y2K fix that were in use before

Enter to restart the computer.

you performed the emergency repair process.

Rebuilding the system drive

On occasion, the system drive might become corrupted in such a way that installation

with the ERD is impossible, or the system drive might fail and the replacement drive

has nothing on it. In such a case, you can rebuild the system drive using the process

described in “Installing a new system disk or restoring a corrupt system disk” on

page 91.

23 July 2004 Profile XP Service Manual 37

Page 38

Chapter 2 Troubleshoo ting Windows NT boot probl em s

Re-installing and configuring drivers

In the event that the display, Ethernet, or RS -422 drivers are co rrupted or the s ettings

lost, here is the information you need for re-installing the drivers and making settings

that return the Profile XP media platform to its factory default conditions. Drivers for

the Ethernet adapter, the VGA adapter, and the RS-422 board are located in

c:\profile\Drivers. When a dialog box requests a location for a file normally found on

the CD-ROM, start the path name with c:\profile\Drivers\…

In the table below, note that there are two sets of display drivers and ethernet adapters,

each set associated with a system processor board rear panel. Select the drivers

associated with the rear panel that matches the system processor in your media

platform. Note also that the one RS-422 driver is used with either system processor

board.

Hardware Driver Location Factory settings

VGA adapter for

use with this

system process or.

Ethernet adapter

for use with this

system process or.

RS-422 board for

use with all

system

processors.

VGA adapter for

use with this

system process or.

Ethernet adapter

for use with this

system process or.

ATI Rage PRO c:\profile\Drivers\ATI_RAGE Desktop Area: 1024 X 768

Intel EtherExpress

PRO Adapter 82558

Comtrol RocketPort c:\profile\Drivers\rocket Com Port Range:

Intel 810 Graphics

Controller Hub

Intel (R) GD82559ER

Fast Ethernet Adapter

c:\profile\Drivers\Intel_PRO Memory Address:

c:\profile\Drivers\Intel_810 Desktop Area: 1024 X 768

c:\profile\Drivers\Intel_GD82559ER Speed and Duplex set to

Refresh Rate: 70 Hz

Color Palate: 24 bit,

16,777,216 Colors

0xFC000000

I/O Address: 0x1000

Interrupt: 9

Starting COM Port: COM3

Scan Rate (ms): 1

Refresh Rate: 70 Hz

Color Palate: 24 bit,

16,777,216 Colors

Auto Select.

38 Profile XP Service Manual 23 July 2004

Page 39

Chapter

3

Troubleshooting video problems

If your video problem is a resul t of equipment failure, your first indication might be

a message in the NetCentral system. The tables of NetCentral messages list the

Warning and Alarm messages you might see, with some possible causes and

solutions.

When you are troubleshooting video problems and you have determined that the

problem is hardware related, remember that you are trying isolate the fault to a

field-replaceable unit. There are several field-replaceable units that could cause video

problems:

• An SDI or HD SDI board, a Video Monitor board, or the SDTI board

• the Motherboard

• the MP EG-2 Encoder or Decoder board (P VS1000 or 2000), or the V ideo