Page 1

User Manual

974-99M00-103

30 March 2014

Page 2

Copyright & Trademark Notice

Copyright © 2014, Miranda Technologies Partnership. All rights reserved.

Belden, Belden Sending All The Right Signals, and the Belden logo are trademarks or registered

trademarks of Belden Inc. or its affiliated companies in the United States and other jurisdictions.

Miranda and LUMO are trademarks or registered trademarks of Miranda Technologies

Partnership. Belden Inc., Miranda Technologies Partnership, and other parties may also have

trademark rights in other terms used herein.

Terms and Conditions

Please read the following terms and conditions carefully. By using Miranda product

documentation, you agree to the following terms and conditions:

Miranda Technologies Partnership (“Miranda”) hereby grants permission and license to

owners of Miranda products to use their product manuals for their own internal business

use. Manuals for Miranda products may not be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying and recording, for any

purpose unless specifically authorized in writing by Miranda.

A Miranda manual may have been revised to reflect changes made to the product during its

manufacturing life. Thus, different versions of a manual may exist for any given product.

Care should be taken to ensure that one obtains the proper manual version for a specific

product serial number.

Information in this document is subject to change without notice and does not represent a

commitment on the part of Miranda.

Warranty information is available in the Support section of the Miranda Web site

(www.miranda.com).

Document Revision History

Revision Published Description of Changes

974-99M00-100 10 Sep 2012 Initial release of LUMO-BNC frame.

974-99M00-101 29 Nov 2012 Release of LUMO-CPU-ETH controller card, and iControl support.

974-99M00-102 16 Apr 2013 Updatiing of safety compliance information

974-99M00-103 30 Mar 2014 Release of LUMO-DIN frame and FIO-911 series cards.

Discontinuance of FIO-901-series cards.

ii

Page 3

Safety Compliance

LUMO

User Manual

This equipment complies with:

• CSA/UL/IEC/EN 60950-1, 2nd Ed. + AM1, Information Technology Equip-

ment - Safety requirements

The power cord supplied with this equipment meets the appropriate national

standar

ds for the country of destination.

WAR NIN G:

CAUTION:

An appropriately listed/certified mains pow

for the connection of the equipment to the mains voltage at either 120V~

or 240V~.

This equipment is meant to be installed in a restricted access location.

These servicing instructions are for

To reduce the risk of electric shock, do not perform any servicing other than that

c

ontained in the operating instructions unless you are qualified to do so. Refer

all servicing to qualified service personnel. Servicing should be done in a staticfree environment.

CAUTION: THIS UNIT HAS MORE THAN ONE POWER SUPPLY CORD. DISCONNECT

TWO (2) POWER SUPPLY CORDS BEFORE SERVICING TO AVOID ELECTRIC SHOCK.

This equipment incorporates modules c

These modules are certified by the manufacturer to comply with:

use by qualified personnel only.

er supply cord must be used

ontaining Class 1 lasers

• EN 60950-1:2006+A11

• EN 60825-1:2007

• EN 60825-2:2004+A1

iii

Page 4

Electromagnetic Compatibility

This equipment has been tested for verification of compliance with FCC Part 15,

Subpart B requirements for Class A digital devices.

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

This equipment has been tested and found to comply with the requirements of the

EMC directive 2004/108/CE:

• EN 55022 Conducted emissions, Class A

• EN 55022 Radiated emissions, Class A

• EN 61000-3-2 Harmonic current emission limits

• EN 61000-3-3 Voltage fluctuation and flicker limitations

• EN 61000-4-2 Electrostatic discharge immunity

• EN 61000-4-3 Radiated electromagnetic field immunity - RF

• EN 61000-4-4 EFT immunity

• EN 61000-4-5 Surge immunity

• EN 61000-4-6 Conducted immunity

• EN 61000-4-8 Power frequency magnetic field immunity

• EN 61000-4-11 Voltage dips, short-interruption and voltage variation immunity

Environmental Protection

Based on technical specifications provided our suppliers and sub-contractors and to the best of

our knowledge

1. Cadmium (Cd) Content is 100 ppm or less

2.

3. Lead (Pd) Content is 1000 ppm or less

4. Mercury (Hg) Content is 1000 ppm or less

iv

1

, this product is in conformity with the requirements of the following directive:

2011/65/EU Of the European Parliament and of the Council of 8 June 2011 on

Hexavalent Chromium (CrVI) Content is 1000 ppm or less

the restriction of the use of certain hazardous substances in electrical and electronic equipment [*]

Page 5

LUMO

User Manual

5. Polybrominated biphenyls Content is 1000 ppm or less

6. Polybrominated diphenyl ether Content is 1000 ppm or less

Applicable exemptions:

6(a) Lead as an alloying element in steel for machining purposes and in galvanized steel

containing up to 0.35 % lead by weight

6(b) Lead as an alloying element in aluminum containing up to 0.4 % lead by weight

6(c) Copper alloy containing up to 4 % Lead by weight

7(a) Lead in high melting temperature type solders (lead-based alloys containing 85 % by

weight or more lead)

7(c)-I Electrical and electronic components containing lead in a glass or ceramic other than

dielectric ceramic in capacitors (piezoelectronic devices) or in a glass or ceramic matrix

compound

Note 1: The statement made herein is based on Miranda’s knowledge of the materials in the

manufacture of its products as of the date of such statement. All statements are contingent

upon the accuracy of such information. Miranda continues to take steps to provide accurate

information but does not conduct destructive testing or chemical analysis on incoming mate

-

rials and chemicals to verify suppliers’ representations.

[*] OJ L 174, 1.7.2011, p. 88.

v

Page 6

vi

Page 7

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction to LUMO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 LUMO Housing Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Field-Serviceable Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Status Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 LUMO-CPU-ETH Controller Card . . . . . . . . . . . . . . . . . . . . . . . . 17

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Control Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 FIO-911 O/E and E/O Converters . . . . . . . . . . . . . . . . . . . . . . . . 35

FIO-911 3G/HD/SD Optical to/from Electrical Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

FIO-911-4R-LC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

FIO-911-4T-S13-LC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

FIO-911-4TH-CwwCxxCyyCzz-LC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

iControl Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6 SFP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Installing an SFP module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Connecting the fiber optic cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Removing the fiber optic cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Removing an SFP module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Contact Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

vii

Page 8

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

viii

Page 9

Chapter 1 is an introduction to the LUMO series of products.

Topics

Introduction to LUMO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Introduction to LUMO

The LUMO is a high-density 1RU frame with 36 SFP-based fiber converters, ideal for large distribution of high bandwidth 3Gbps signals. LUMO’s 1RU size minimizes rack space, and oftencomplex cabling concerns have been greatly reduced by including fiber connectivity on one

side of the unit and coax electrical on the other.

Reliability and serviceability is further secured through the use of hot-swappable cards and a

redundant PSU, as well as remote system health monitoring and alarming for all key compo

nents, including optical signal strength.

Introduction

-

Key Features and Benefits

• High-density 1RU frame with 36 SFP-based fiber converters

• Supports 2 x 18 CWDM wavelengths

• Modular, hot-swappable SFPs and cards for efficient serviceability

• Mechanical design with fiber connectivity on one side and coax on the other for ease of

cabling

• Redundant, hot swappable built-in power supplies

• Remote system health monitoring and alarming for all key components

• Fiber support for convenient and secure optical fiber installation

Available Options

• LUMO-CPU-ETH controller for ethernet access and control

• Second power supply for redundant power security

1

Page 10

Introduction

Introduction to LUMO

Cards (maximum 9 per frame)

The following cards are available to be used with the LUMO frame:

These cards can be used in any combination to occupy the nine available slots in the LUMO

frame.

• FIO-911-4T-S13-LC Quad 3Gbps/HD/SD optical transmitter 1310 nm LC/PC connectors

• FIO-911-4R-LC Quad 3Gbps/HD/SD optical receiver LC/PC connectors

• FIO-911-4TH-CwwCxxCyyCzz-LC High power Quad 3Gbps/HD/SD optical CWDM Tx, LC/PC

connector.

CwwCxx and CyyCzz show the wavelengths of the CWDM transmitters used in this card.

2

Page 11

Overview

LUMO Housing Frame

Chapter 2 describes the LUMO housing frame and details of its installation.

Topics

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Physical Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Assembling the LUMO Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Installing Cards in the LUMO Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Installing the Power Cord Retaining Clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Field-Serviceable Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Changing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Replacing or Upgrading the Controller Card or Status Card . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Replacing the Frame Ventilation Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

The 1-RU LUMO housing frame and its associated LUMO-series cards are designed to provide

maximum configuration flexibility in a high density and low cost 1-RU chassis. The basic configuration includes one power supply unit and a chassis status

Up to 9 FIO-911-series cards can be installed within a single frame. The LUMO frame offers full

flexibility and integration of a variety of functions and signal types on BNC/DIN or fiber SFP. All

components are hot-swappable and can be quickly configured. The frame is air-cooled, the

PSUs and fan are monitored and status reporting is available. Each card has some multicolored

LEDs for status reporting as well. Remote control and status monitoring via Ethernet is available

as an option. The frame is available in two versions, identified by the rear connector type:

• LUMO-BNC

• LUMO-DIN

card for basic system monitoring.

3

Page 12

LUMO Housing Frame

Overview

Features

• 1 RU with 19” rack mount

• Up to 9 cards (72 Watts)

• Ease of serviceability

• Hot-swappable PSU with optional 2

• Hot-swappable cards, SFPs, controller and fan

• Status and alarm over IP with optional LUMO Ethernet Controller

• Cards can operate without controller

• Small granularity

• Fiber on the front, coax on the rear

• Multiple video and audio formats can be fitted in a single chassis

Physical Layout

Front Panel Appearance

nd

redundant PSU

Each card (numbered 1 to 9 from left to right as seen from the front of the unit) has its own face

plate which allows the status LEDs on the installed cards to be seen and also allows the card to

be secured in the chassis by a screw. The opening near the center of the panel is for the status or

controller card status LED.

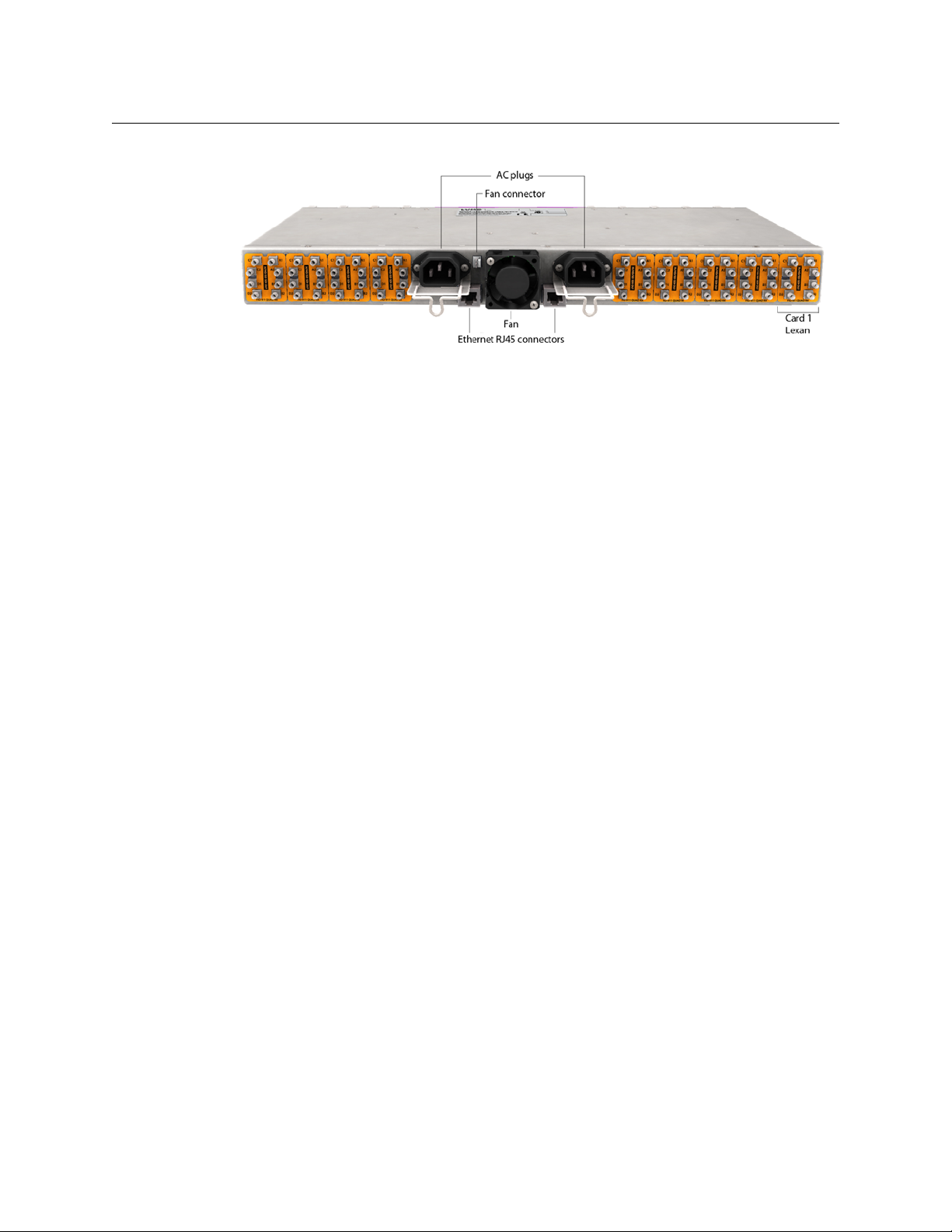

Rear Panel Appearance

The rear panel incorporates the electrical signal connectors, and so has a different appearance

for the LUMO-BNC and the LUMO-DIN. The central portion of the panel is the same for both

models.

LUMO-BNC Rear Panel

4

Page 13

LUMO-DIN Rear Panel

The functionality of Ethernet connectors is described in the Controller card chapter.

LUMO

User Manual

The details of the rear panel card lexans vary depe

Chapter 5.

Installation

Unpacking

Make sure the following items have been shipped with your LUMO frame:

nding on the card type, and are described in

• LUMO-BNC or LUMO-DIN frame, including 1 Power Supply unit (AC in) and 1 Status card

• If the optional LUMO CPU-ETH controller has been ordered, the Status card is not

included

• Rack-mounting brackets (1 pair, with 8 mounting screws)

• An AC power cord

• Power cord retaining clips (2)

• LUMO-series cards (per order) with associated lexans

• Fiber Support with 8 mounting screws

• LUMO controller card (optional)

• A second power supply and AC cord (optional)

5

Page 14

LUMO Housing Frame

Installation

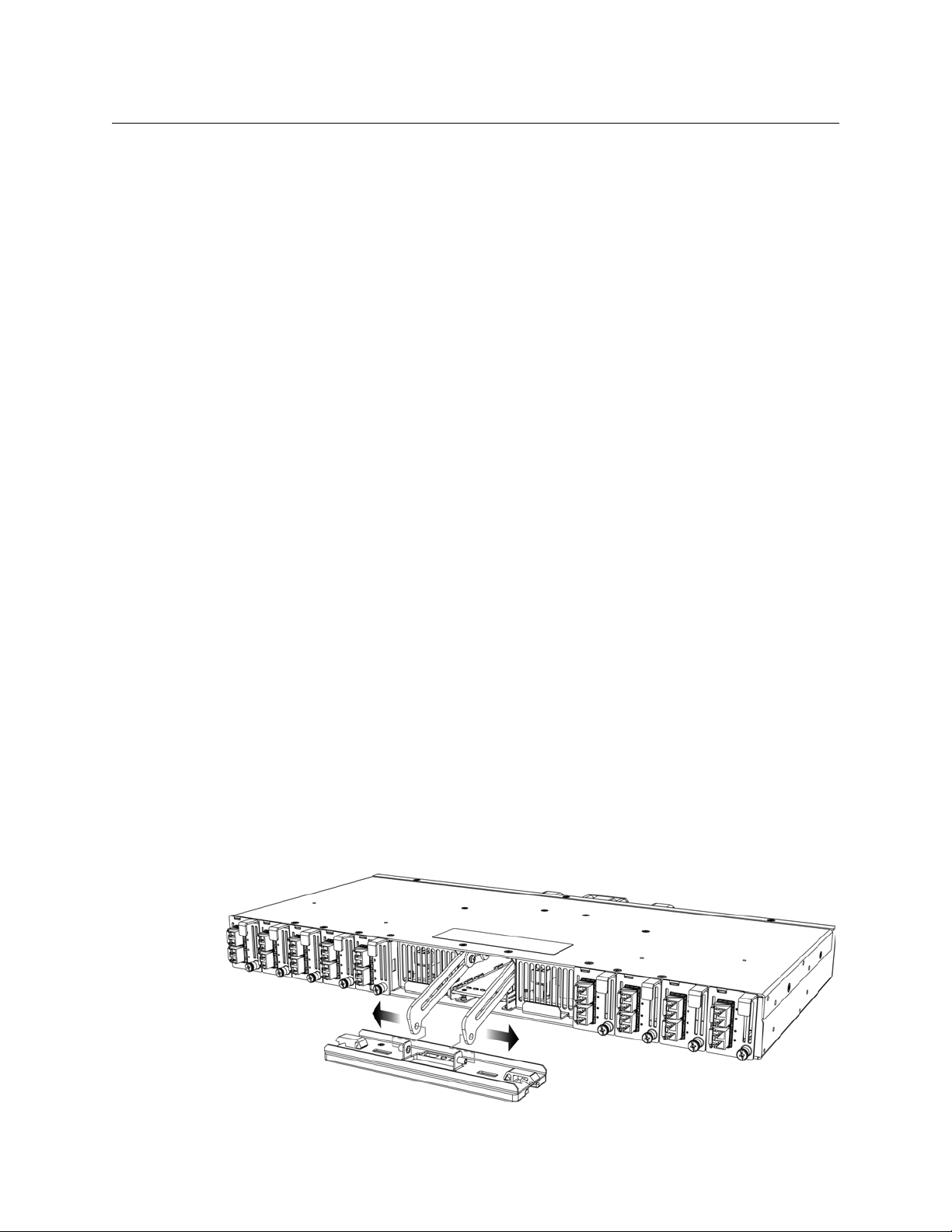

Assembling the LUMO Frame

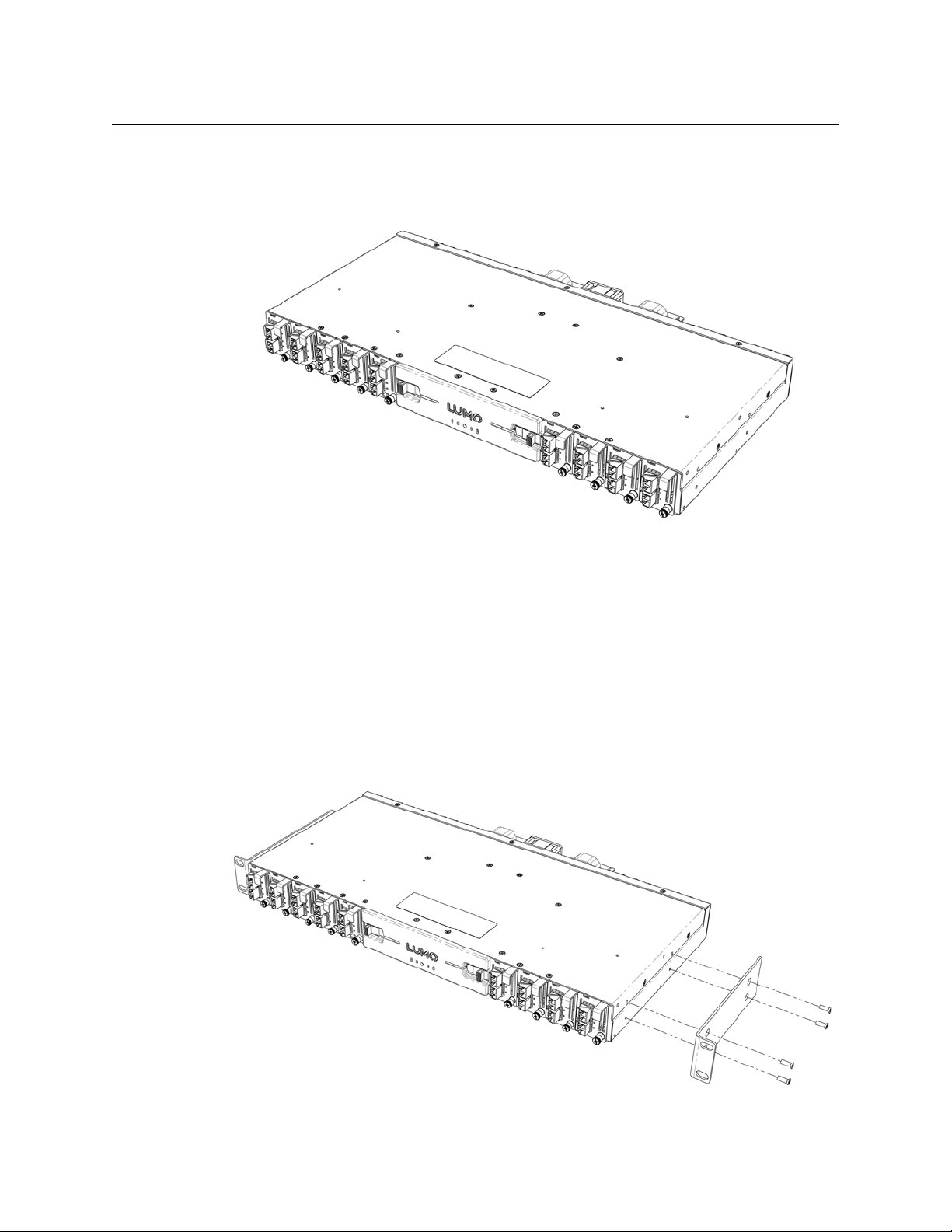

The LUMO frame is shipped with neither the frame mounting brackets nor the fiber support

installed

.

These instructions describe the insta

onto the LUMO frame.

The rack mounting brackets may be installed alone (See

fiber support.

If the rack mounting brackets are installed with the fiber support, the fiber support must be

installed first. See section B.

llation of the rack mounting brackets and the fiber support

section A), or in combination with the

A Installing the rack mounting brackets alone

Position a bracket at each side of the LUMO frame, and install them using the four provided

screws, as shown in the Figur

e.

6

Page 15

LUMO

User Manual

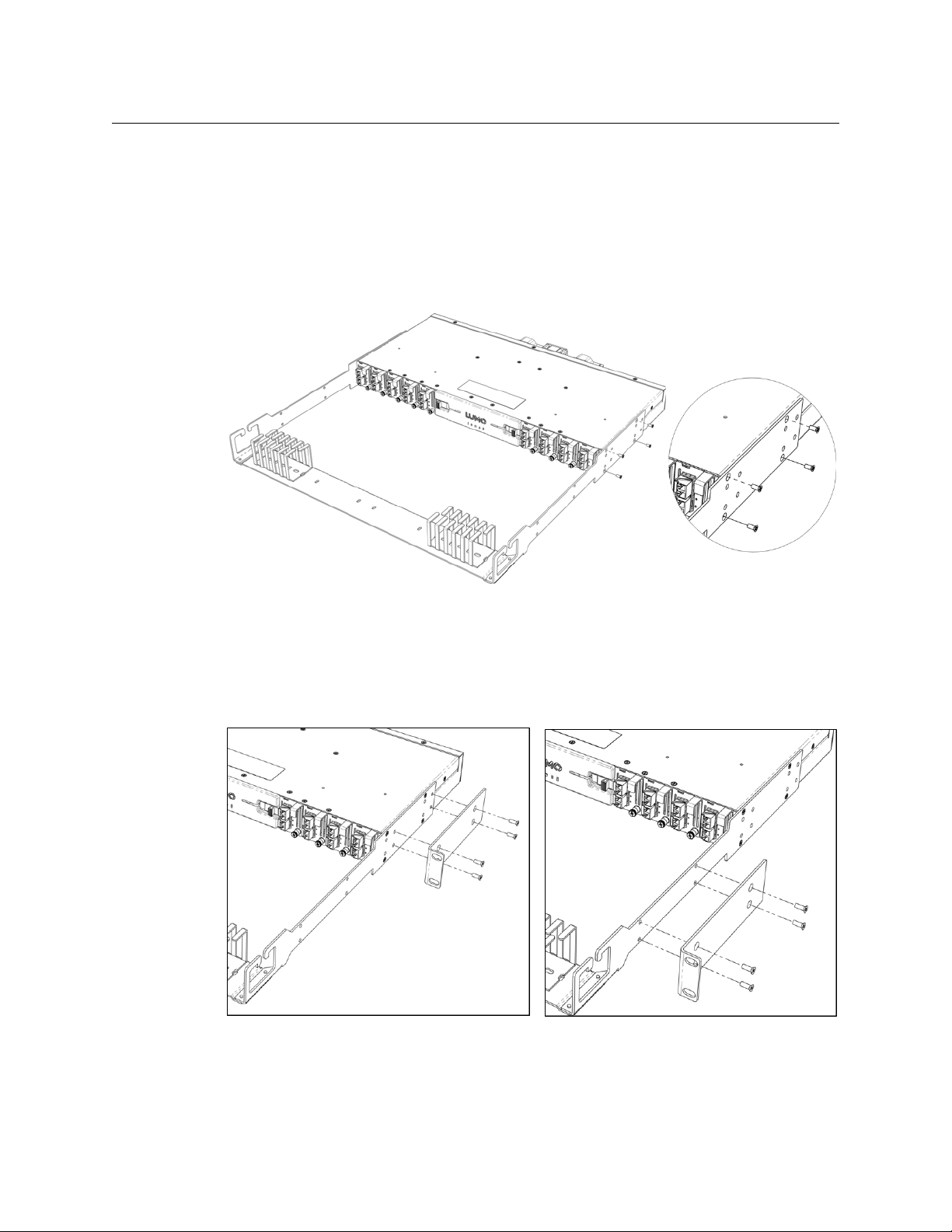

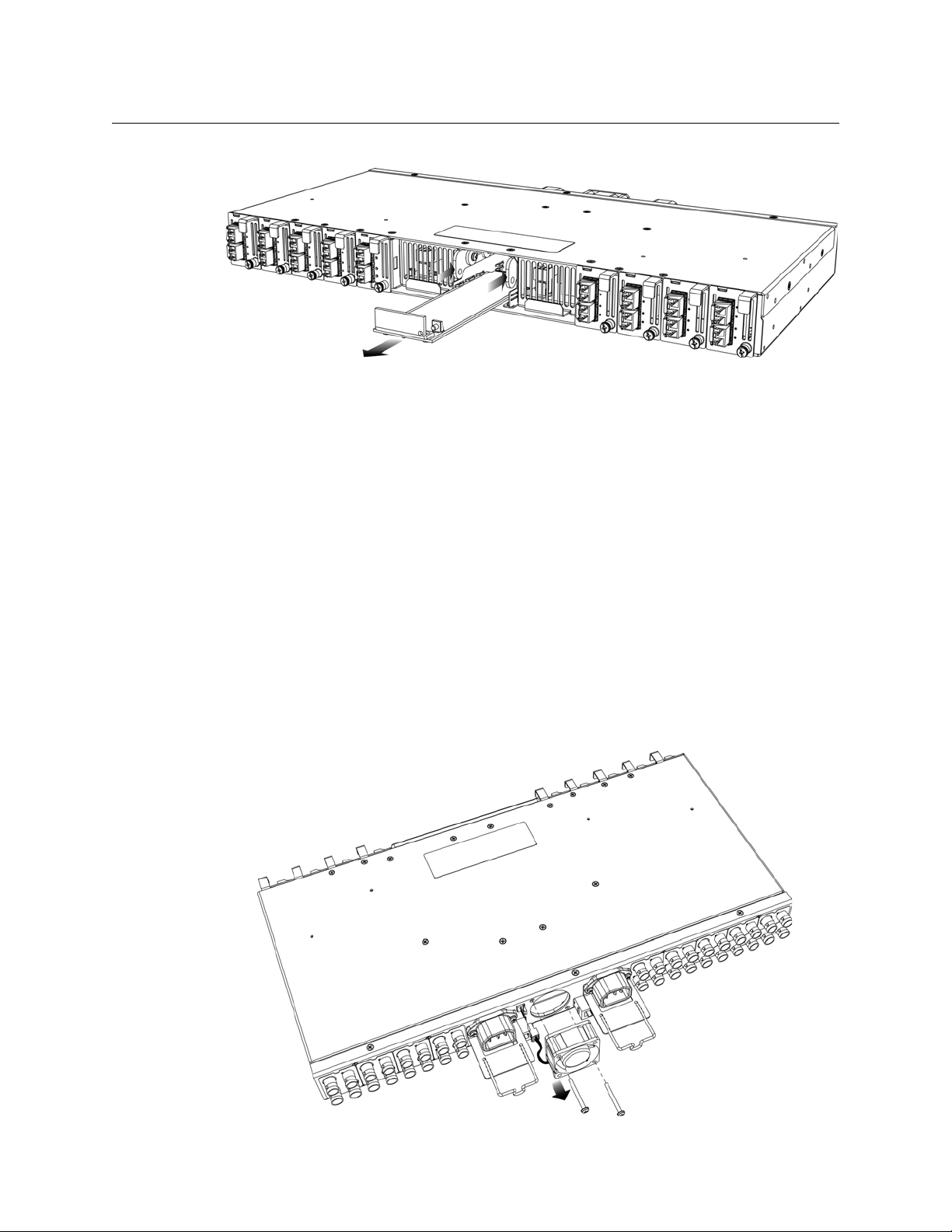

B Installing the Fiber Support

If you are installing this support onto a LUMO frame which has rack mounting brackets installed,

you must remove those brackets first, and then re-install them after the fiber support has been

installed, as described in Section C.

Position the fiber support against the LUMO frame as shown in the figure , and attach it to the

frame with the eight provided screws.

C Installing the Rack Mounting Brackets with the Fiber Support

After the fiber support is installed, you may install the rack mounting brackets in either of two

positions, using four provided screws for each bracket. The figure illustrates the two possible

mounting positions.

Once installation of the rack mount brackets is complete, the LUMO frame should be installed

directly into a standard 19” rack using 4 standard rack-mounting screws through the four holes

in the corners of the rack mount brackets.

7

Page 16

LUMO Housing Frame

Installation

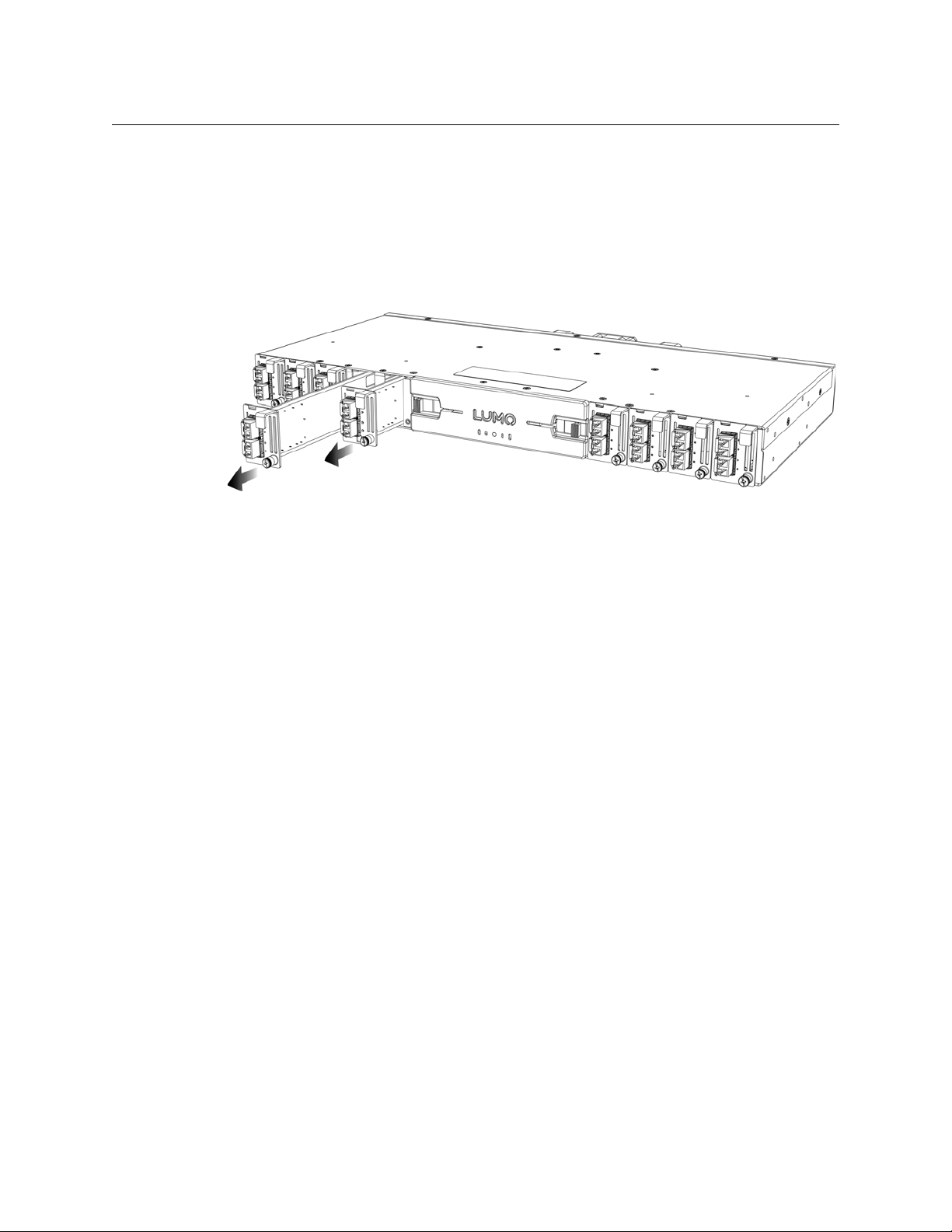

Installing Cards in the LUMO Frame

Each card includes an integrated front panel incorporating the fiber optic connectors.

All cards can be installed with the frame power on. The card has a connector which plugs into a

ba

ckplane for distribution of power, connection to the controller card, and connections to the

input and output connectors.

To install the card :

1 To remove an existing card from the slot, unscrew the existing card front panel and gently

pul

in an empty position, first remove the blank card front by unscrewing it and pulling the handle straight out of the slot.

2 Slide the new card into the slot and push gently on the handle to seat the connectors.

Secure the card in place with the provided front panel captive screw.

l the handle on the front of the card to pull the card straight out of the slot. To add a card

Slip the lexan that was shipped with the card over

rear panel that are associated with the slot into which the card was installed. The lexan identifies

the function of the connectors for that card.

Note: D

each card type.

etailed information about the rear panel connections is included in the chapters describing

the connectors ( four BNC or eight DIN) on the

Installing the Power Cord Retaining Clips

Each power supply is provided with a power cord retaining clip that holds the power cord in

place to prevent inadvertent disconnections.

With the power cord removed, install the clip into the

cord socket on the rear of the frame, by slipping the two ends of the clip into a pair of holes in

the plate, and rotating the clip down into a horizontal position. Several pairs of holes are

provided to accommodate different sizes of plugs. Use the holes that position the clip closest to

the body of the plug.

Once the clip is in place, inser

ping loop of the clip.

t the power cord into the socket, and press the cord into the grip-

plate that extends out beneath the power

8

Page 17

LUMO

User Manual

Ventilation

Ventilation for the frame is provided by a fan mounted in the center of the rear panel. The fan

draws air through the frame and exhausts it to the rear. Ventilation slots are provided in the

chassis and cards front panels to allow air to flow into the frame.

Important Note:

times when cards are installed and operating. As well, blank card front panels must be installed if no

card is present in a slot.

to ensure proper cooling, the front panel of the LUMO frame must be closed at all

Ensure that the front panel ventilation slots of the chassis and the car

Field-Serviceable Items

Field-serviceable items on the LUMO frame itself include the power supplies, the status or

controller card, and the ventilation fan.

The power supplies and status or controller card are located behind the door on the front panel.

T

he door must be opened to change the power supplies, and it must be removed to change the

status or controller card.

Opening and removing the front panel

The front panel of the LUMO frame is attached by swivel brackets. Two spring-loaded sliders

secure the panel in the closed position. To open the panel, pull the sliders toward the center of

the panel, and then pull the panel out until the support brackets allow it to move down below

the level of the power supplies. The supplies can then be removed.

To remove the status card, the door must be detached

push the flexible brackets apart until the door posts slip out of the holes in the brackets.

There are no electrical connec

Reinstall the panel by slipping the door posts int

door into position and snap it in place. The spring-loaded sliders will hold it in position.

ds are not obstructed.

from the frame. Once the door is open,

tions to the panel.

o the holes in the brackets, and then move the

Note that the door must be kept closed while the

frame is in use, to ensure proper ventilation.

9

Page 18

LUMO Housing Frame

Field-Serviceable Items

Changing the Power Supply

The LUMO frame supports dual redundant hot-swappable power supplies. The basic configuration includes a single supply, plus an empty sl

Installing a second power supply module and applying power to it automatically engages the

redundant supply mode. Each power supply has its own power socket on the rear panel, and

should be connected to the AC supply using the supplied power cord or other approved cord.

• A single supply can be installed in either of the two slots

To install or change a power supply module:

1 Open the front panel of the frame

2 Remove the power supply module by pulling on the handle on its front panel and sliding it

out of the frame

3 Slide the new power supply module into the slot, and push it gently into position to seat the

connectors. There is no guiding slot - the supply base sits on the floor of the frame.

4 Close the front panel of the LUMO frame. The panel secures the power supplies in place.

ot for the optional redundant power supply.

10

Replacing or Upgrading the Controller Card or Status Card

The Controller or Status card is located between the power supply slots at the center of the

frame. To replace the card, proceed as follows:

1 Open the center front door, remove the door

into the frame

2 Hook your finger over the plastic diffuser mounted at the front of the card, and pull out gen-

tly until the card is released from the rear connector; then slide the card out of the frame.

3 Slide the new card into the controller slot, and push gently on the card edge to engage the

rear connectors.

and push the door mounting brackets back

Page 19

LUMO

User Manual

4 Pull the door mounting brackets back out of the frame, and re-install the door onto the

brackets.

5 Be sure to close the door before operating the LUMO system, to ensure proper ventilation.

Replacing the Frame Ventilation Fan

In case of failure of the main cooling fan on the rear of the frame, replace it according to the

following steps.

1 Procure a replacement fan. It is available from Miranda as part #1974-1500-100

2 Remove the defective fan from the frame:

• Disconnect the fan power by grasping the connector and pulling straight out.

• Remove the two screws that secure the fan unit to the frame and pull the fan unit away

from the frame.

• Retain the screws, as they will be used with the replacement fan.

11

Page 20

LUMO Housing Frame

Specifications

3 Install the replacement fan:.

Specifications

MECHANICAL

Dimensions 1RU x 17.60” W (447 mm) x 10” D (254 mm) without fiber support

Weight: 8.9 lbs (4.45 kg) with 1 PSU and controller card installed

• Use the two screws that were retained when the old fan was removed to install the new

fan onto the rear panel. See the note above.

• Grasp the power connector attached to the fan assembly, and push it onto the power

outlet located to the left of the fan on the rear panel

1RU x 17.60” W (447 mm) x 20.25” D (515 mm) with fiber support

with connectors

POWER

Rating: 100-240V~

0.83 - 0.42 A

50/60 Hz

150 W max

Ambient Temperature: 40° C max

COOLING

Fans: 1 on frame, removable

COMMUNICATION

Connectors: RJ45 (2)

Compliant to: 10BaseT/100BaseTx

12

Page 21

Overview

Status Card

Chapter 3 describes the installation and functionality of the LUMO chassis status card.

Topics

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Card-Front Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

The Status card for the LUMO series is a simple status report card that monitors the presence

and voltage of the power supplies, the temperature of the air flow leaving the chassis, and the

speed status of the fan and reports it on a single bi-color front panel LED. It also carries white

LEDs to illuminate the LUMO chassis front panel.

Features

• Simple LUMO chassis health monitoring card

• Monitors the presence and voltage levels of the power supplies.

• Monitors the chassis fan speed

• Monitors the temperature of the air flow leaving the chassis

• Convenient front loading design

• The LUMO Status card can be easily replaced for maintenance

• The LUMO Status card can be replaced by the LUMO Controller card with remote control/sta-

tus monitoring through iControl and iControl Web Software

13

Page 22

Status Card

Installation

Block Diagram

The following block diagram shows the functionality of the LUMO status card.

Installation

The Miranda LUMO-series Status card is installed in the center of the LUMO chassis, between the

two power supply slots.

To remove or install a LUMO status card, follow these steps:

1 Open the center front door, remove the door and push the door mounting brackets back

into the frame

2 Hook your finger over the plastic diffuser mounted at the front of the card, and pull out gen-

tly until the card is released from the rear connector; then slide the card out of the frame.

3 Slide the new card into the controller slot, and push gently on the card edge to engage the

rear connectors.

14

4 Pull the door mounting brackets back out of the

brackets.

5 Be sure to close the door before operating the LUMO system, to ensure proper ventilation.

frame, and re-install the door onto the

Page 23

Operation

LUMO

User Manual

Card-Front Status LED

The Status card monitor LED is located on the front card-edge of the LUMO Status card, and is

visible through the LUMO frame front panel. This multi-color LED indicates the health status of

the LUMO frame by color, and by flashing/steady illumination.

The table shows how the various error conditions are flagged on the LUMO status card LED.

Alarm/Status Priority Class LED

Chassis temperature over limit 1 Critical Flashing RED

Frame fan stopped 2 Critical Flashing YELLOW

12VA or 12VB missing with

PSUA or PSUB present

Frame fan low speed 4 Maintenance problem YELLOW

All good All good Green

The front LED can display only one alarm/status, so it

example if the fan is at low speed, it should display Yellow. But if at the same time the chassis

temperature is too high, then the LED will display Flashing RED instead.

Be aware that a high priority alarm can

3 Redundancy problem RED

displays only the highest priority. For

mask a lower priority one.

15

Page 24

Status Card

Specifications

Specifications

PROCESSING PERFORMANCE

Microcontroller ARM Cortex-M3

Latency: <1 second

Power: <1W

16

Page 25

Overview

LUMO-CPU-ETH Controller Card

Chapter 4 describes the installation and functionality of the LUMO-CPU-ETH Controller card in

the LUMO housing frame.

Topics

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Control Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Using the LUMO-CPU-ETH web page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Resetting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Using the iControl interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Card-Front Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Configuring the LUMO-CPU-ETH Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

The LUMO-CPU-ETH Controller installed in the LUMO frame supports all on-frame communication between cards, and incorporates a web page for local control and adjustment of the frame.

The LUMO-CPU-ETH Controller serves as the communications port for control and alarm infor

mation entering and leaving the frame. The LUMO-CPU-ETH controller features two Ethernet

ports for system-wide monitoring and control of the frame, using Miranda’s control solutions or

a third party monitoring system. This controller card is compatible with the TCP/IP protocol and

can support polling or report on error modes (unsolicited messaging).

-

Features

• Dual Ethernet RJ-45 ports (10/100Base-T) with static IP address configuration - same address

for both ports, which are configured for active backup redundancy.

• Provides ultra-robust Ethernet connectivity for LAN/WAN

• Controls up to 9 LUMO cards of any type

• Linux-based operating system for robust, mission-critical operations

• Features web page for local configuration of the controller and frame

• Can be remotely configured via iControl

• Provides card and frame health monitoring and status reporting

• Provides extensive frame monitoring:

17

Page 26

LUMO-CPU-ETH Controller Card

Control Interfaces

- Ethernet port monitoring, with communication settings and overall bit rate

- detailed bitrate and communication thoughput from individual cards

- self-monitoring with CPU load, memory usage

- Power Supply and fan status reporting

• Individual Card parameter storage for easy card swapping

• Communication speeds of up to 100 Mbps via Ethernet ports

Control Interfaces

The LUMO-CPU-ETH controller is the control point for the LUMO frame and the LUMO-series

cards installed in the frame. There are no separate operating controls on the frame or cards.

The LUMO-CPU-ETH has two available control interfaces:

• The LUMO-CPU-ETH serves its own web page with access to some operating controls

• Control panels for the LUMO-CPU-ETH can be accessed through Miranda’s iControl system.

Using the LUMO-CPU-ETH web page

The web page served by the LUMO-CPU-ETH controller provides the only means of configuring

the IP address for the controller card.

IP Configuration

Use of this page is essential for the initial configuration of the device, or re-configuration after a

reset, in order to set it up so it can be accessed via iControl on the local area network.

LUMO-CPU-ETH controllers are shipped from the factory with the following IP configuration:

• IP address:

• Subnet mask:

In addition, the LUMO-CPU-ETH IP address will be reset to this value if the front-panel RESET

button is pushed. See the detailed instructions for the reset process on

It is necessary to change these settings to integrate the LUMO frame into the local network

setup before it can be accessed using iControl. Proceed as follows:

1 Configure a stand-alone computer with the following IP address:

• IP address:

• Subnet mask:

2 Connect the stand-alone computer to the ETH1 port on the LUMO frame (with the LUMO-

CPU-ETH controller installed, and powered up), using a crossover ethernet cable.

192.168.3.31

255.255.0.0

page 21.

192.168.x.x

255.255.0.0

18

Page 27

LUMO

User Manual

3 Start a browser on the stand-alone computer, and browse to the LUMO’s factory IP address

as given above. The LUMO’s web page will open in the browser.

19

Page 28

LUMO-CPU-ETH Controller Card

Control Interfaces

4 Select Setup > Ethernet in the menu on the left to open the ethernet setup page.

5 On the SETUP | Ethernet page, enter the required information. Consult your IT department if

necessary.

Hostname: The hostname is the unique name by which this LUMO is known on the network. The hostname should be 15 characters or less. The hostname may contain only the

ASCII letters 'a' through 'z' (case-insensitive), the digits '0' through '9', and the hyphen

DHCP: (Disabled for this controller)

IP address: Enter an address appropriate for the local network

Network Mask: Enter a mask value appropriate for the local network

Gateway: Enter a gateway address appropriate for the local network

6 Click the Apply button to save your changes

7 Disconnect the stand-alone computer from the LUMO.

The LUMO frame is now ready to be installed in its operating location and connected to the local

network.

Once it is installed, the LUMO web page can be accessed via the network at any time using a

browser and the IP address set in the controller using the above procedure.

20

Page 29

LUMO

RESET button

Status LED

User Manual

Resetting the Controller

IMPORTANT: If for any reason you cannot connect to the LUMO frame through the network

using the address you have entered:

1 Press the RESET button on the

front panel (access it through the

cutout on the panel - it is recessed

to protect against accidental activation)

2 You must keep pressing the button

for approximately 10 seconds in

order to reset the controller. During

that time, the front panel status

LED will flash yellow. You can abort

the reset at any time while the LED

is flashing by releasing the button.

3 Once the LED has stopped flashing, the LUMO-CPU-ETH will reboot, and the IP address

(along with other on-board parameters) will be reset to its factory values.

4 Follow the steps in IP Configuration on page 18 to set the IP address to the required value.

If you can connect to the LUMO-CPU-ETH controller through the network, you can reset the IP

address by browsing to the controller’s IP address, and following steps 4-6 in the

tion on page 18.

Once you have applied the changes, your browser will lose contact with the controller, but you

may re-establish contact at the new IP address.

IP Configura-

21

Page 30

LUMO-CPU-ETH Controller Card

Control Interfaces

Using the iControl interface

The LUMO-CPU-ETH controller supports remote operation through its two rear-panel 10/100

Base-T ethernet ports, using Miranda’s iControl or a third-party solution. This manual describes

the control panels associated with the LUMO-CPU-ETH and their use.

Note -

you must configure the LUMO-CPU-ETH controller with an appropriate IP address before

it can be accessed on your network by iControl. See IP Configuration on

Please consult the iControl User’s Guide for information about setting up and operating

iC

ontrol.

In iControl Navigator or iControl Websites,

double

-click on the icon of the controller to

open its control panel.

• LUMO-CPU-ETH controllers are identified

as LUMO Controller in the Type column of

the iControl Navigator window.

• For convenience, enter a descriptive Label

in the Info panel of the card, to make it

easy to locate this specific frame controller

amongst those in the list. See Identifica-

tion on page 24 for instructions.

page 18 for details.

.

The iControl panel for the LUMO-CPU-ETH

controller displays a series of buttons down

th

e left-hand side. Clicking a button changes

the contents of the main window to display

status reports and controls related to the topic

named on the button.

A full description of the use of the iControl

i

nterface to configure the LUMO-CPU-ETH

card is given below, beginning on page 23.

22

Page 31

LUMO

User Manual

Card-Front Status LED

The status LED is located on the lower-front card-edge of the controller module, and is visible

through the front access door of the LUMO frame. This multi-color LED indicates the status of

the controller card by color, and by flashing/steady illumination.

The table shows how the various error conditions are flagged on the LUMO-CPU-ETH status LED.

Alarm/Status Priority LED

Power supply failure 1 FLASHING RED

Fan failure 1 FLASHING RED

Internal error 2 RED

Normal (no errors) GREEN

The status LED can display only one alarm/status, so

example if there is an internal error, it should display RED. But if at the same time the chassis fan

has failed, then the LED will display FLASHING RED.

Be aware that a high priority alarm can

mask a lower priority one.

it displays only the highest priority. For

Configuring the LUMO-CPU-ETH Controller

This section introduces the operating features of the LUMO-CPU-ETH controller, and describes

how to access and control them using the iControl interface.

See Using the iControl interface

The following topics are covered:

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 24

Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Network Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

Data Restoration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

Factory Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 30

Time Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

on page 22 for instructions on accessing the iControl interface.

23

Page 32

LUMO-CPU-ETH Controller Card

Control Interfaces

Identification

Click the Info button

The LUMO-CPU-ETHcontroller is accessible on

a network, and must be identifiable in order to

fun

ction in the iControl environment. The

identification data is entered in the iControl

INFO control panel. This panel also shows

other data that is not user-adjustable.

You can enter the following information by

click

ing and typing in the data box:

Label: al

identifies this device when it appears in iControl applications

Short Label: a

short-form label for iControl (8 characters)

Source ID: t

LUMO-CPU-ETH controller

Comments: t

The remaining data boxes show manufac

Three buttons in the panel give access to other information:

Details:

Advanced: Show

LUMO-CPU-ETH controller in the iControl network.

Remote System Administration:.

data box, which lists remote

LUMO-CPU-ETH is registered.

lows the user to define the label that

llows the user to define the

ype a descriptive name for this

ype any desired text

turing information about this card.

Reports the Firmware version, service version, and panel version for this card

s the Miranda LongID for this card. The Miranda LongID is the address of this

Opens the Joining Locators

lookup services to which this

Add: F

orce the iControl service for this LUMO-CPU-ETH to

register itself on a user-specified Jini lookup service, using

the following syntax in the data box:

24

jini://<ip_address>

where <ip_address> is the ip address of the server running the lookup service, e.g.:

Page 33

LUMO

User Manual

Remove: select one of the services listed in the window by clicking on it, and click

Remove to open a query box allowing you to delete it from the window.

Status Monitoring

The LUMO-CPU-ETH controller continuously monitors the operating condition and status of the

housing frame’s power supplies and ventilating fans. It also monitors the status and usage of its

two ethernet ports, and the status of its on-board memory, as well as the data throughput of all

cards installed in the frame.

In addition to the information displayed on the Card-Front Status LED (se

mation acquired by the controller can be viewed in the iC

controller display through the menu.

The iControl interface always displays two

ic

ons in the upper left of the window.

These report the status of the frame’s two

power supplies.

The graphic shows the possible icon

displays and the associated messages that

appear below them. Error messages are

always displayed; other status messages

appear only upon mouse-over of the icon.

ontrol interface, and on the local

e page 23), status infor-

Click the Status button

The Status panel shows status information in four categories, each accessed by clicking the

appropriate tab.

25

Page 34

LUMO-CPU-ETH Controller Card

Control Interfaces

Status - Frame

Select the Frame tab to see a report on

the status of the frame’s CPU, fans and

power supplies.

Status - Network

Select the Network tab to see a report

on the status of the two Ethernet ports

on the LUMO-CPU-ETH card.

26

Page 35

Status - Cards

Select the Cards tab to see a chart of the

current send (Tx) and receive (Rx) data

rates, and speed, for all cards installed in

the LUMO frame.

• Note that in the LUMO frame, only

slots 1 to 9 are available

For a more detailed report on the status

of a specif

control panel in iControl.

ic card, open that card’s

LUMO

User Manual

Status - LUMO-CPU-ETH Resource

Usage

Select the Advanced tab to view a report

on the usage of the controller card’s

resources:

27

Page 36

LUMO-CPU-ETH Controller Card

Control Interfaces

Network Status

Click the Network button and select the ETH tab

The status of the LUMO-CPU-ETH

controller’s two Ethernet ports is

displayed in this panel.

NOTE: The IP address for the LUMO-CPUETH controller must be set using the onboard web page. See Using the LUMO-

CPU-ETH web page on

detailed instructions.

page 18 for

The Ethernet Link R

reported in this panel.

In LUMO, this feature is always set to

Ac

tive Backup.

edundancy status is

• The two ethernet interfaces are

bonded together and configured

with the same IP address.

• In the event that the primary inter-

face fails, network traffic is automatically switched over to the backup

interface

The MAC (Media Access Control) address is reported in the data box

• The MAC address is not user-configurable.

Data Restoration

Many of the LUMO-series cards that can be installed in the LUMO frame are complex and have a

lot of data stored on-board related to their configuration and parameter values. The LUMO-CPUETH controller provides a backup of this data, which can be restored to the card when needed.

This is valuable if the card is inadvertently reconfigured, or is replaced after failure with a new

card of the same type. The saving of the current data into the controller’s memory, and restoring

the data onto the LUMO-series card, can be done manually or automatically.

28

For manual operation:

Click the Restore Point button and view the Cards tab.

The tab show a list of the slots available in the frame, with a check box, name, and status box for

each.

• The LUMO frame uses slots 1 to 9.

Click the check box to activate the Data Rest

ore feature for the card in that slot,

Page 37

-or-

LUMO

User Manual

Click the Select All box at the top to activat

Click S

ave to controller at the bottom to

copy all restorable data from the cards in

the selected

board the LUMO-CPU-ETH controller.

Click Lo

selected slots with data from the

controller’s memory. Note that a data

restore will only work if the card in the slot

is the same type as the card that was there

when the data was saved.

slots into the memory on

ad to cards to load the cards in the

e the feature for all slots in the frame.

For automatic restore and save:

Click the Restore Point button and view the Config tab.

Restore: The LUMO-CPU-ETH card can

be set up to automatically update a card

when it is

occupied by a card of the same type

wh

can be configured automatically to

replace the card that was removed,

saving a lot of time when cards are

swapped.

Click the D

the auto restore function for all the cards

in the frame.

Save: Th

configured to automatically back up the

data on the cards in its slots according to

a set schedule.

Click the Au

automatic save function.

inserted in a slot previously

ose data was saved. Thus, a new card

efault Action box to enable

e LUMO-CPU-ETH card can be

to Save box to enable the

29

Page 38

LUMO-CPU-ETH Controller Card

Control Interfaces

Set up the schedule for data backup using the controls provided.

• Schedule: Daily, Weekly, Monthly

• Start Time (UTC): Time in hours (24-hour clock) and minutes

The label and function of the pulldown at the bottom changes to follow the Schedule selection:

Schedule Label Pulldown Options

Daily Freq Every day, Weekdays

Weekly Day Sunday, Monday, Tuesday, Wednesday, Thursday, Friday, Saturday

Monthly Week Week1, Week2, Week3, Week4, Last Week

Day Sunday, Monday, Tuesday, Wednesday, Thursday, Friday, Saturday

Factory Alignment

There may be times when the LUMO-CPU-ETH settings have been adjusted and it is useful to

restore them to a normalized condition. The LUMO-CPU-ETH controller maintains a “Factory

Default” alignment in its memory, to which it can be restored at any time.

Note: Ethernet settings are not included in the F

Factory Default alignment is installed.

Click the Factory Control button

Click the Load Factory button to restore

the card to the Factory default

alignment.

actory data set, and are not changed when the

30

Page 39

LUMO

User Manual

Time Management.

The LUMO-CPU-ETH controller is time-aware, and its internal clock can be updated manually or

via NTP.

Click the Time button

Time (UTC)

The data boxes in this section display

the time and date currently held in the

card.

Enter new values in these boxes to

ch

ange the current setting. If an automatic update via NTP is not enabled,

th

e clock will continue to run using an

on-board reference, but precision is not

guaranteed.

Note - there is no backup battery for the

time

circuit, so the time must be reset

any time the card is powered down.

NTP IP address

Click the Enable NTP

addresses of NTP servers. TheLUMO-CPU-ETH card will use the first source of valid time it finds in

this list.

box to use an NTP (Network Time Protocol) source. Enter up to three IP

Alarms

The LUMO-CPU-ETH controller generates alarms for the frame in which it is installed when error

conditions are detected. These alarms are used to set the card-front Status LED and the status

icon in the top left of the iControl window.

The alarms are reported to the iControl network.

Click the Alarm Config button

31

Page 40

LUMO-CPU-ETH Controller Card

Control Interfaces

The iControl Alarm Configuration panel opens in a new window when the Alarm Config button

is clicked, and can be resized if needed. It allows the alarm reporting of the LUMO-CPU-ETH to

be configured. The panel is organized in columns.

Status/Name

This contains an expandable tree listing all the alarms reported by this LUMO-CPU-ETH

controller.

Each alarm name includes an icon that shows its current status.

The Overall alarm and GSM contribution columns contain pulldown lists that allow the level

of contribution of each individual alarm to the alarm named in the column heading to be set.

Click on the alarm status in either of these columns to show the status options that are available,

then click on one to select it. If no options appear, the alarm is not user-configurable

Overall Alarm

This column allows configuration of the contribution of each individual alarm to the Overall

Alarm associated with this card. The Overall Alarm is shown in the upper left corner of the iCon

trol panel, and also appears at the bottom of the Status/Name column.

-

GSM Contribution

This column allows configuration of the contribution of each individual alarm to the GSM Alarm

Status associated with this card. GSM is a dynamic register of all iControl system alarms, and is

also an alarm provider for external applications. The possible values for this contribution are

related to the Overall alarm contribution:

• If the Overall alarm contribution is selected as Disabled, the GSM alarm contribution can be

set to any available value

• If the Overall alarm contribution is selected as any level other than disabled, the GSM contri-

bution is forced to follow the Overall Alarm.

Levels associated with these alarms:

The alarm status list may contain some or all of the following options:

Alarm status Significance

The alarm makes no contribution (black icon)

The alarm is of minor importance (yellow icon)

The alarm is of major importance (orange icon)

The alarm is of critical importance (red icon)

The alarm exists but has no effect (used for text and composite alarms)

32

Shortcut: if you click on “Set All” at the top of one of these columns, you will open a pulldown

list that lets you assign a level to all alarms in that column simultaneously.

Once the alarms are configured, you may accept the changes or discard them:

Page 41

LUMO

User Manual

Log Events

iControl maintains a log of alarm events associated with the card. The log is useful for troubleshooting and identifying event sequences. Click in the checkbox to enable logging of alarm

ev

ents for each individual alarm.

At the bottom of the window are several other controls:

Copy to other cards

Click this button to open a panel that

allows the alarm configuration set for

this ca

rd to be copied into other

LUMO-CPU-ETH controllers in other

frames.

Select one or more destination

c

ontrollers from the list in the window

by clicking in the checkboxes, or all of

them by clicking in the All checkbox

Get alarm keys

Click this button to open a save dialog

where you can save a file containing a

list of

all alarms on this controller and

their current values, along with an

Alarm Key for each. The alarm keys are

useful for system integration and

troubleshooting.

The file is saved in .csv format

OK, Apply, Cancel

• OK accepts the settings and closes the window once the controller confirms that there are

no errors.

• Apply accepts the settings, but leaves the window open

• Cancel closes the window without applying any changes, and leaves the previous settings

intact.

33

Page 42

LUMO-CPU-ETH Controller Card

Control Interfaces

Specifications

System Interfaces

Status LED Power ON and System Status

Ethernet Ports (2) IEEE802.3 10/100 Base-T on RJ45

Power: <3W

34

Page 43

FIO-911 O/E and E/O Converters

Chapter 5 describes the FIO-911-series optical/ electrical and electrical/opticalconverters that

are available for the LUMO housing frame.

Topics

FIO-911 3G/HD/SD Optical to/from Electrical Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 35

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

Installing cards and SFP modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

FIO-911-4R-LC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 36

FIO-911-4T-S13-LC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 38

FIO-911-4TH-CwwCxxCyyCzz-LC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 39

iControl Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 41

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 48

FIO-911 3G/HD/SD Optical to/from Electrical Converters

The FIO-911 series are flexible serial digital video To/From Fiber Optic converters for the LUMO

housing frame (both -BNC and -DIN versions). The FIO-911 series are designed for SD, HD and 3G

serial video as well as compressed bit-streams (DVB-ASI). The series supports any data rate

within the range of 19.4 Mbps to 2.97 Gbps and provides a reclocked serial digital video from

270Mbps to 2.97 Gbps.

The FIO-911 series offers three different configurations:

• Quad fiber Tx, with two dual optical transmitters

• Quad fiber Tx CWDM, with two dual high-power optical transmitters

• Quad fiber Rx, with two dual optical receivers

The series is based on SFP modules that provide easy product maintenance and flexibility when

multiple wavelengths are needed (as for CWDM). The SFP Modules are also hot-swappable.

Features

• Supports any serial data rate from 19.4 Mbps (ATSC) to 2.97 Gbps (3G SDI)

• Reclocked serial digital video for 270 Mbps, 1.49 Gbps, and 2.97 Gbps

• Provides unidirectional interface between fiber optic and serial digital

• Supports Multiple wavelength from the standard 1310 nm to multiple CWDM wavelengths

• Ideal for long video run with “Hum” immunity

35

Page 44

FIO-911 O/E and E/O Converters

FIO-911-4R-LC

• Presence/loss of signal alarm – iControl, on-board LED for presence

• SFP Optical power monitoring and report

• Internal SFP temperature alarms on the iControl interface

• SFP Module type detection and card configuration

• Remote monitoring and control

• Convenient front-loading design, SFP on the front of the card

• The cards and the SFP modules are fully hot swappable

Description

The FIO-911 card incorporates two SFP module slots on its front panel. Each slot has two dedicated status LEDs. The front panel also incorporates ventilation slots, a handle used to remove

the card from its slot in the LUMO frame, and a captive screw to secure it in position.

Within the frame, the card connects to intra-frame data and power busses, and to the connectors (four BNC or eight DIN) dedicated to its slot on the frame’s rear.

The front panel of the card is labeled to identify the FIO variant, and each status LED is labeled.

The function of the rear-panel connectors depends on the FIO-911 variant that is installed, and

is identified by a lexan that slips over the connectors on the rear panel. Lexans are supplied for

both -BNC and -DIN versions of the frame.

Installing cards and SFP modules

See Installing Cards in the LUMO Frame on page 8 for detailed instructions for installing the FIO-

911 cards in the LUMO frame.

See SFP Modules on page 51 for instructions on removing and installing SFP modules into the

FIO-911 front panel slots.

FIO-911-4R-LC

Quad 3 Gbps/HD/SD Optical Receiver with LC/PC Connector

This variant utilizes two dual optical receivers at its inputs to receive four channels, each of

which is O-to-E converted, reclocked and sent to the outputs (one BNC or two DIN) on the rear

panel of the housing frame.

36

The FIO-911-4R-LC Quad Receiver includes two SFP-RR-LC modules.All receiver channels are

wideband, responding to wavelengths ranging from1260 to 1620 nm, compatible with 1310 nm

and CWDM wavelengths.

The front panel and rear lexans (DIN and BNC) for this model are shown here:

Page 45

Lexan for DIN frame

Lexan for BNC frame

The functional block diagram of

the FIO-911 Quad Rx model is

shown here.

LUMO

User Manual

Note that the second outputs (A2,

B2, C2, D2) are only available on

the LUMO-DIN frame.

Card-Front Status LEDs

These LEDs monitor the status of the optical inputs to the FIO-911 Quad Rx:

• Green = Optical signal OK

• Yellow = No lock

• Flashing Yellow = Input level too high or too low

• Red = No signal

• Flashing Red = SFP not present, or SFP not detected, or hardware failure

37

Page 46

FIO-911 O/E and E/O Converters

Lexan for DIN frame

Lexan for BNC frame

FIO-911-4T-S13-LC

FIO-911-4T-S13-LC

Quad 3 Gbps/HD/SD Optical Transmitter 1310 nm with LC/PC

connector

This variant utilizes two dual optical transmitters at its outputs to send four channels, each of

which enters on a rear-panel connector, is equalized, reclocked, E-to-O converted, and sent to

the SFP transmitter. For the DIN frame only, each electrical input is also reclocked and sent to the

matching electrical output on the rear panel.

The FI0-911-4T-S13-LC Quad Transmitter includes two SFP-TT-S13S13-LC modules.

The front panel and rear lexans (DIN and BNC) for this model are shown here:

38

The functional block diagram

of the FIO-911 Quad Tx model

is sho

wn here.

Note that the electrical loop

outputs a

the LUMO-DIN frame.

re only available on

Page 47

Card-Front Status LEDs

These LEDs monitor the status of the electrical inputs to the FIO-911 Quad Tx:

• Green = SDI signal OK

• Yellow = No lock

• Red = No signal

• Flashing Red = SFP not present, or SFP not detected, or hardware failure

FIO-911-4TH-CwwCxxCyyCzz-LC

High Power Quad 3 Gbps/HD/SD Optical CWDM Transmitter

with LC/PC connector

This variant utilizes two dual high-power CWDM optical transmitters at its outputs to send four

channels, each of which enters on a rear-panel DIN, is equalized, reclocked, E-to-O converted,

and sent to the SFP transmitter. For the DIN frame only, each electrical input is also reclocked

and sent to the matching electrical output on the rear panel.

LUMO

User Manual

The two signals entering each CWDM transmitter module are modulated at different

wav

elengths.

The model number for this device identifies the tw

mitter modules by specifying the

CwwCxx and CyyCzz Wavelength (nm) Color Code

C27C29 1271/1291 Light Purple

C31C33 1311/1331 Yellow Green

C35C37

C39C41 1391/1411 White

C43C45

C47C49

C51C53

C55C57 1551/1571 Yellow

C59C61 1591/1611 Red

wavelengths of their output:

1351/1371 Pink

1431/1451 Black

1471/1491 Gray

1511/1531 Blue

o included SFP high-power CWDM trans-

Note that both SFP modules can operate at the same wavelengths.

39

Page 48

FIO-911 O/E and E/O Converters

Lexan for DIN frame Lexan for BNC frame

FIO-911-4TH-CwwCxxCyyCzz-LC

The front panel and rear lexans (DIN and BNC) for this model are shown below. Note that they

are identical to those for the FIO-911-4T-LC model. The clasp handles on the SFP modules are

color-coded to identify their wavelengths, and this will serve to distinguish the two FIO-series

products.

• Color coding for CWDM modules is shown in the above table.

The functional block diagram

of the FIO Quad High Power

WDM module is shown

C

here.

Note that the electrical loop

o

utputs are only available on

the LUMO-DIN frame

Card-Front Status LEDs

These LEDs monitor the status of the electrical inputs to the FIO-911 Quad High Power CWDM

Tx:

• Green = SDI signal OK

• Yellow = No lock

• Red = No signal

• Flashing Red = SFP not present, or SFP not detected, or hardware failure

40

Page 49

iControl Interface

When installed in a LUMO frame equipped with a LUMO-CPU-ETH controller card and

connected to a network (see

controlled using Miranda’s iControl system.

To use iControl with the FIO-911 cards, proceed as follows:

1 Install and configure your LUMO-CPU-ETH controller for network access to enable the iCon-

trol interface. See IP Configuration on page 18 for details.

2 In iControl Navigator (shown below) or iControl Websites, double-click on the icon of an

FIO-911 card to open its control panel.

LUMO

User Manual

Chapter 4), the FIO-911 cards may be remotely monitored and

• For convenience, enter a descriptive Label in the Info panel of the card, to make it easy to

locate this specific card amongst those in the list. See Identification and Information on

page 46 for instructions.

The iControl panel for the FIO-911 card displays a series of buttons down the left-hand side.

Clicking a button changes the contents of the main window to display.

The FIO-911 series of cards share the same basic control panel layout, but the detailed information within the main display window changes with the card’s functionality.

41

Page 50

FIO-911 O/E and E/O Converters

iControl Interface

Status

The Status window shows the status of

the four inputs to the card. One tab

show

s the status of inputs A and B, and

the status of their associated SFP module,

while a second tab provides the same

information for inputs C and D.

The Inputs are identified as Electrical or

Optical

, and status icons show the data

rate, Lock status, and Signal status.

The SFP module is identified by type, part

number

This is manufacturer-supplied information, read from the module.

Data about the two optical channels is

m

the SFP Info table: Temperature (C),

Voltage (V), Optical Power (dBm), and

Wavelength (nm)

, serial number and date code.

onitored on the card, and reported in

Reclocker and Optical

The Reclocker and Optical window allows

the user to choose whether the signal

reclockers at

BYPASSED.

• Reclocker control is provided for both

electrical and optical inputs

• A separate control is provided for

each of the four inputs A, B, C and D.

• The default setting is ON.

For FIO-911 cards with optical outputs,

c

ontrols are provided to turn the optical

transmitters in the SFP modules ON or

OFF for outputs A, B, C and D individually.

• The default setting is ON.

the inputs are ON or

42

Page 51

Factory Reset

The FIO-911 card can be reset to factoryspecified settings of all on-board parameters by clicking the Lo

ad Factory button.

LUMO

User Manual

Alarm Configuration

The FIO-911 card detects and signals alarm conditions.

A status LED is positioned beside each fiber connection to the SFP module on the front panel of

the car

d. These four LEDs report the status of their associated channel. The significance of the

LED’s appearance for each card type is given above, in the section devoted to that card.

The iControl Alarm Configuration panel opens in a new window when the Alarm C

is clicked, and can be resized if needed. It allows the alarm reporting of the LUMO-CPU-ETH to

be configured. The panel is organized in columns.

Status/Name

This contains an expandable tree listing all the alarms reported by this FIO-911 card.

Each alarm name includes an icon

Green: OK

Red: Alarm set

Black: Alarm not applicable (in this case, e.g. the

associated with them appear black.

The Ca

rd LED, Overall alarm and GSM contribution columns contain pulldown lists that allow

the level of contribution of each individual alarm to the alarm named in the column heading to

be set. Click on the alarm status in either of these columns to show the status options that are

available, then click on one to select it. If no options appear, the alarm is not user-configurable

that shows its current status:

re is no SFP for inputs A and B, so all alarms

onfig button

43

Page 52

FIO-911 O/E and E/O Converters

iControl Interface

Overall Alarm

This column allows configuration of the contribution

Alarm associated with this card. The Overall Alarm is shown in the upper left corner of the iControl panel, and also appears at the bottom of the Status/Name column.

GSM Contribution

This column allows configuration of the contribution of each individual alarm to the GSM Alarm

St

atus associated with this card. GSM is a dynamic register of all iControl system alarms, and is

also an alarm provider for external applications. The possible values for this contribution are

related to the Overall alarm contribution:

of each individual alarm to the Overall

• If the Overall alarm contribution is selected as Disabled, the GSM alarm contribution can be

set to any available value

• If the Overall alarm contribution is selected as any level other than disabled, the GSM contri-

bution is forced to follow the Overall Alarm.

44

Page 53

Levels associated with these alarms:

The alarm status list may contain some or all of the following options:

Alarm status Significance

The alarm makes no contribution (black icon)

The alarm is of minor importance (yellow icon)

The alarm is of major importance (orange icon)

The alarm is of critical importance (red icon)

The alarm exists but has no effect (used for text and composite alarms)

LUMO

User Manual

Shortcut: if y

ou click on “Set All” at the top of one of these columns, you will open a pulldown

list that lets you assign a level to all alarms in that column simultaneously.

Once the alarms are configured, you may accept the changes or discard them:

Log Events

iControl maintains a log of alarm events associated with the card. The log is useful for troubleshooting and identifying event sequences. Click in the checkbox to enable logging of alarm

ev

ents for each individual alarm.

At the bottom of the window are several other controls:

Copy to other cards

Click this button to open a panel that

allows the alarm configuration set for

this ca

rd to be copied into other FIO-

911 cards in this or other frames.

Select one or more destination cards

f

rom the list in the window by clicking

in the checkboxes, or all of them by

clicking in the All checkbox

Get alarm keys

45

Page 54

FIO-911 O/E and E/O Converters

iControl Interface

Click this button to open a save dialog

where you can save a file containing a

list of

all alarms on this card and their

current values, along with an Alarm

Key for each. The alarm keys are useful

for system integration and troubleshooting.

The file is saved in .csv format

OK, Apply, Cancel

• OK accepts the settings and closes the window once the controller confirms that there are

no errors.

• Apply accepts the settings, but leaves the window open

• Cancel closes the window without applying any changes, and leaves the previous settings

intact.

Identification and Information

Click the Info button

The FIO-911 card is accessible on a network,

and must be identifiable in order to function in

the

iControl environment. The identification

data is entered in the iControl INFO control

panel. This panel also shows other data that is

not user-adjustable.

You can enter the following information by

click

ing and typing in the data box:

Label: al

identifies this device when it appears in iControl applications

Short Label: a

short-form label for iControl (8 characters).

Source ID: t

911 card.

lows the user to define the label that

llows the user to define the

ype a descriptive name for this FIO-

46

Comments: t

The remaining data boxes show manufac

ype any desired text

turing information about this card.

Page 55

Three buttons in the panel give access to other information:

LUMO

User Manual

Details:

Advanced: Show

FIO-911 card in the iControl network.

Remote System Administration:.

data box, which lists remote

911 is registered.

Reports the Firmware version, service version, and panel version for this card

s the Miranda LongID for this card. The Miranda LongID is the address of this

Opens the Joining Locators

lookup services to which this FIO-

Add: F

orce the iControl service for this FIO-901 to register

itself on a user-specified Jini lookup service, using the following syntax in the data box:

jini://<ip_address>

where <ip_address> is the ip address of the server running the lookup service, e.g.:

Remove: select one of the services listed in the window by clicking on it, and click

Remove to open a query box allowing you to delete it from the window.

47

Page 56

FIO-911 O/E and E/O Converters

Specifications

Specifications

ELECTRICAL INPUT

Signal: 3G/HD/SD SDI SMPTE 424M, 292M, and 259M-