Page 1

LDK 7500 + LDK5490

Digital Cinematographic Camera

Technical Manual

Contents

About This Manual ................................................ ii

Viper

Safety Instructions ........................................... 1-1

Safety Summary ................................................ 1-2

Cautions and Warnings ...................................... 1-2

Installation ......................................................... 2-1

Packing/Unpacking ............................................ 2-2

Hardware Customization .................................... 2-2

Attaching an Adapter ......................................... 2-3

Detaching an Adapter ......................................... 2-3

Connectors ........................................................ 2-4

Cables and breakout box.................................... 2-8

Specifications .................................................. 2-10

Camera head dimensions ................................. 2-11

Adapter dimensions ......................................... 2-12

Replacements ................................................... 3-1

Introduction ........................................................ 3-2

Handgrip ............................................................ 3-2

Printed circuit boards ......................................... 3-3

Front unit ........................................................... 3-4

03.18.5 Technical Manual LDK 7500 + LDK 5490 Adapter i

Adjustments ..................................................... 4-1

Introduction ........................................................ 4-2

Test Equipment ................................................. 4-3

Set-up Instructions ............................................. 4-3

Video ADC Automatic Calibration ....................... 4-4

Pre-processor Calibration ................................... 4-4

3200K Adjustment ............................................. 4-4

Sawtooth Calibration .......................................... 4-4

Flare Adjustment ................................................ 4-5

Software Download ............................................ 4-5

Video Monitoring Adjustment ............................. 4-7

Exploded Views ............................................... 5-1

HD Camera head ................................................ 5-2

Camera head basic ............................................ 5-3

Left cover assembly........................................... 5-4

Right cover assembly ........................................ 5-5

Shoulder pad assembly ...................................... 5-6

Handgrip assembly ............................................ 5-7

Page 2

About This Manual

Service policy

The LDK 7500 + LDK 5490 is a sophisticated camera

containing state-of-the-art electronic components which

are designed to provide long-life operation without the

need for maintenance. With this in mind, the service

policy of Thomson Broadcast Solutions endeavours to

ensure that help will be quickly on hand in the unlikely

event of anything going wrong. The guiding principles

of the Thomson Broadcast Solutions first line

maintenance philosophy are speed and cost

effectiveness. First line maintenance is dedicated to

keeping your camera operational, despite a fault, by

module replacement and the replacement of minor

mechanical parts by the user.

Purpose of this manual

The provision of correct information is the first step in

ensuring the operational integrity of the camera.

Information on the operation of the camera is to be

found in the Operators’s Manual.

This technical manual is an integral part of the service

policy. It ensures that you will be able to install and setup your camera to meet the requirements of your

environment. This information on the installation of the

camera is contained in Section 2 of the manual. The

remaining sections of the manual provide first line

service information so that suitably qualified service

personnel can detect and repair faults, normally by

module replacement.

Structure of this manual

The manual is divided into five different sections:

Section 1: Safety Instructions

Outlines the safety precautions that must be taken

when using the camera.

Section 2: Installation.

Gives instructions on the integration of the camera into

the operating environment and the customization of

certain hardware functions

Section 3: Replacements.

Gives information on the replacement of components

at first line level.

Section 4: Adjustments.

Contains the adjustment procedures to be followed to

obtain the best performance.

Section 5: Exploded Views

Because of the complexity of some of the components,

second line service can only be carried out at the

specially equipped service centres and information

concerning second line maintenance is not supplied

in this manual.

Intended audience

The manual is intended as a guide to those with a

working knowledge of camera systems and installation

techniques. The first line detection and repair of faults

requires a general knowledge of test and measurement

techniques.

ii Technical Manual LDK 7500 + LDK 5490 Adapter 03.18.5

Page 3

Identification and Status

To indicate the status of a drawing, a box with the

numbers 0 to 9 is shown in the bottom-right of the

drawing. The number that is crossed-out is the status

number of the drawing. For example, in the illustration

below, the status is 1.

0 1 2 3 4

5 6 7 8 9

A sticker is used on the units themselves to identify

them and to indicate their status. For example, in the

illustration below, the top line is the 12-digit number

that identifies the unit type.

3922 406 88991

00121107 00 01

The first four digits of the number on the second line

represent a date code (year, week); the next four digits

represent the serial number for that week.

The number in the grey area indicates the status of the

unit. The last two digits represent the number that will

be given to the next status. However, if these two

digits are contained in a box, then this is the current

status. For example, in the illustration above, the

current status of the unit is 01.

Line 3

This is the status of the PCB.

The digit after the first slash is the status. If there is

no number before the slash, it means that the status

is less than 10, a 1 before the slash means the status

is between 10 and 19, a 2 before the slash means

between 20 and 29 etc.

Example:

VR4567891012 means status 4

VR3/78901234 means status 37.

Example of LDK number:

LDK 4501/01 means 8926 450 10101

LDK 4500/00 means 8926 450 00001

Numbers of printed circuit board assembly

- 3922 406 xxxxx or 3922 407 xxxxx

Number (screened in PCB layout) of printed circuit

board assembly: 3922 411xxxxx (not a spare part).

Line 1 3922 407 00000

Line 2 123456AA0101

Line 3 VR/0123456789

Line 1

This is the code number of the printed circuit board

assembly (PCB).

Line 2

This is the serial number of the PCB. The first 6 digits

and the 2 letters are for internal use. The last four digits

reperesent the date of the manufacturing: wwyy.

Example:

123456AA1402 means the PCB is manufactured in

week 14 of the year 2002.

03.18.5 Technical Manual LDK 7500 + LDK 5490 Adapter iii

Page 4

iv Technical Manual LDK 7500 + LDK 5490 Adapter 03.18.5

Page 5

Section 1

Safety Instructions

This section outlines the precautions that must be taken into account when using the adapter.

Contents

Safety Summary ................................................ 1-2 Cautions and Warnings ...................................... 1-2

Safety Instructions Technical Manual LDK 7500 + LDK 5490 Adapter 1-1

Page 6

Safety Summary

Cautions and Warnings

This informaton is intended as a guide for trained and

qualified personnel who are aware of the dangers

involved in handling potentially hazardous electrical/

electronic equipment. It is not intended to contain a

complete list of all safety precautions which should be

observed by personnel in using this or other electronic

equipment.

The installation, maintenance and service of this

equipment involves risks both to personnel and

equipment and must be performed only by qualified

personnel exercising due care.

Personnel engaged in the installation, operation,

maintenance or servicing of this equipment are urged

to become familiar with First Aid theory and practises.

During installation and operation of this equipment,

local building safety and fire protection standards

must be observed.

Before connecting the equipment to the power supply

of the installation, the proper functioning of the protective

earth lead of the installation needs to be verified.

Whenever it is likely that safe operation is impaired,

the apparatus must be made inoperative and secured

against any unintended operation. The appropriate

servicing authority must then be informed. For example,

safety is likely to be impaired if the apparatus fails to

perform the intended function or shows visible damage.

When performing service, be sure to read and comply

with the warning and caution notices appearing in the

manuals. Warnings indicate danger that requires correct

procedures or practices to prevent death or injury to

personnel. Cautions indicate procedures or practices

that should be followed to prevent damage or destruction

to equipment or property.

WARNING

THE CURRENT AND VOLTAGES PRESENT IN THIS

EQUIPMENT ARE DANGEROUS. ALL PERSONNEL

MUST AT ALL TIMES FOLLOW THE SAFETY

REGULATIONS.

ALWAYS DISCONNECT POWER BEFORE REMOVING

COVERS OR PANELS.

ALWAYS DISCHARGE HIGH VOLTAGE POINTS

BEFORE SERVICING.

NEVER MAKE INTERNAL ADJUSTMENTS, PERFORM

MAINTENANCE OR SERVICE WHEN ALONE OR WHEN

FATIGUED.

IN CASE OF AN EMERGENCY ENSURE THAT THE

POWER IS DISCONNECTED.

ANY INTERRUPTION OF THE PROTECTION

CONDUCTOR INSIDE OR OUTSIDE THE APPARATUS,

OR DISCONNECTION OF THE PROTECTIVE EARTH

TERMINAL, IS LIKELY TO MAKE THE APPARATUS

DANGEROUS. INTENTIONAL INTERRUPTION IS

PROHIBITED.

USE ONLY FUSES OF THE TYPE AND RATING

SPECIFIED.

This product has been designed and tested according

to EN60065.

CAUTION

To prevent risk of overheating, ventilate the

product correctly.

Connect the product only to a power source with

the specified voltage rating.

Do not allow system ground currents to exceed

1.5A in the outer shield of the triax cable or 0.2A

in other cable shields.

1-2 Technical Manual LDK 7500 + LDK 5490 Adapter Safety Instructions

Page 7

Symbol Colour Explanation

Red High voltage terminal at which

a voltage, with respect to an

other terminal, exists or may

be adjusted to 1000V or more.

Yellow/Black Live part.

Yellow/Black This marking indicates that the

operator must refer to an

explanation in the Instruction

Manual, or that a specific

component must be replaced

by the component specified in

the documentation for safety

reasons.

White/Black Protective earth (ground)

terminal.

Cathode ray tubes

Components marked on the circuit diagram are

critical for safety and include those specified to comply

with X-ray emission standards for units using cathode

ray tubes and those specified for compliance with

various regulations regarding spurious radiation

emission.

When servicing units that use cathode ray tubes

(CRTs), the cathode ray tubes themselves, the high

voltage circuits and related circuits are specifically

chosen so that they comply with recognized codes

pertaining to X-ray emission.

Consequently, when servicing, replace the cathode

ray tubes and other parts with specified parts only. Do

not attempt to modify these circuits as any unauthorized

modification can increase the high voltage value and

cause X-ray emission from the cathode ray tube.

Handle the cathode ray tube only when wearing

shatterproof goggles and after discharging the high

voltage completely.

Safety Instructions Technical Manual LDK 7500 + LDK 5490 Adapter 1-3

Page 8

1-4 Technical Manual LDK 7500 + LDK 5490 Adapter Safety Instructions

Page 9

Section 2

Installation

This section provides information which is relevant when the camera is to be used for the first time.

Packing and unpacking instructions together with information on the integration of the camera into

your studio system are provided. The procedures for the customization of certain hardware functions

and connector information is also provided.

Contents

Packing/Unpacking ............................................ 2-2

Hardware Customization .................................... 2-2

Attaching an Adapter ......................................... 2-3

Detaching an Adapter ......................................... 2-3

Connectors ........................................................ 2-4

Installation Technical Manual LDK 7500 + LDK 5490 Adapter 2-1

Cables and breakout box.................................... 2-8

Specifications .................................................. 2-10

Camera head dimensions ................................. 2-11

Adapter dimensions ......................................... 2-12

Page 10

Packing/Unpacking

Hardware Customization

Inspect the shipping container for evidence of damage

immediately after receipt. If the shipping container or

cushioning material is damaged, it should be kept until

the contents of the shipment have been checked for

completeness and the units have been checked

mechanically and electrically.

The shipping container should be placed upright and

opened from the top. Remove the cushioning material

and lift out the contents.

The contents of the shipment should be checked

against the packing list. If the contents are incomplete,

if there is mechanical damage or defect, or if the units

do not perform correctly when unpacked, notify your

Thomson Multimedia Broadcast Solutions sales or

service centre within eight days. If the shipping

container shows signs of damage or stress, notify the

carrier as well.

If a unit is being returned to Thomson Multimedia

Broadcast Solutions for servicing, try to use the

containers and materials of the original packaging.

Attach a tag indicating the type of service required,

return address, model number, full serial number and

the return number which will be supplied by your

Thomson Multimedia Broadcast Solutions service

centre.

If the original packing can no longer be used, the

following general instructions should be used for

repacking with commercially available materials:

a. Wrap unit in heavy paper or plastic.

b. Use strong shipping container.

c. Use a layer of shock-absorbing material around all

sides of the unit to provide firm cushioning and

prevent movement inside container.

d. Seal shipping container securely.

e. Mark shipping container FRAGILE to ensure careful

handling.

The camera head is delivered in a ready-to-use state,

however, there are occasions when it might be

necessary to re-adjust some functions after, for

example, fitting a new lens.

A large number of functions can be set-up using the

control facilities of the menu system. In addition to this

software set-up there are some functions which can be

selected or adjusted internally in the camera.

Refer to the next chapters for instructions.

Lens matching

When a camera is supplied with a lens it is not

necessary to perform any of the following adjustments

as the lens is already matched to the camera. However,

if you wish to change to a different type of lens or the

lens is not supplied with your camera, back focus,

white shading and auto iris adjustment procedures

may have to be performed.

• Colour balance.

If required, perform the gain adjustment of the

preprocessor board and/or white shading adjustment

procedures, described in section 4.

• Auto Iris Adjustment

If a different lens either works too slow or overshoots

too much with the auto iris control, adjust the

potentiometer on the lens to obtain acceptable

operation. Refer to the lens documentation.

• Back Focus Adjustment

To adjust the back focus of the lens refer to the

documentation of the lens.

2-2 Technical Manual LDK 7500 + LDK 5490 Adapter Installation

Page 11

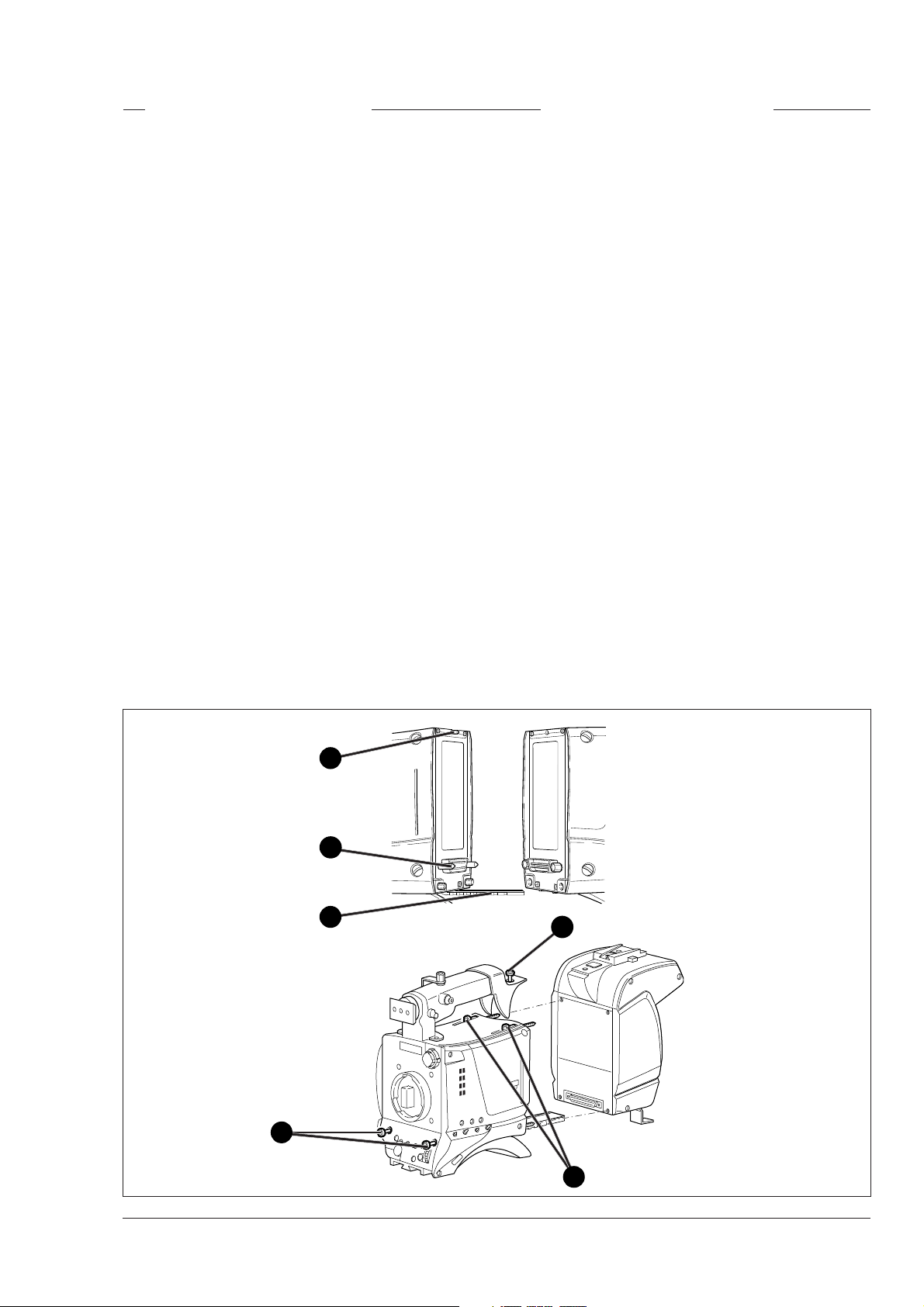

Attaching an Adapter

Detaching an Adapter

The adapter can be used with various HD camera

heads. To attach the adapter to the camera proceed as

follow the steps in the order given:

Caution

Do not connect this HD adapter to an SD camera head

- connectors and guide pins are not compatible.

Caution

Be extremely careful. Do not allow the guide pins to

damage the pins of the connector.

Caution

Tightening the screws in the wrong order could

result in mechanical damage to the camera.

a. Using the rail

(1) on the bottom of the camera head

as a guide, fit the guide pins (2) on either side of the

connector and the guide pin (3) at the top rear of the

camera head into the corresponding slots of the

adapter.

b. First, tighten the two horizontal screws (4) on the

top of camera.

c. Next, tighten the two horizontal screws (5) at the

front of the camera.

d. Lastly, tighten the vertical screw (6) in the handle

of the camera.

To detach the adapter from the camera head follow the

steps for attaching it in the reverse order.

Caution

Loosening the screws in the wrong order could

result in mechanical damage to the camera.

3

2

1

r

Clea

1

A

r

a

le

C

/4

1

D

N

2

B

P

r 4

ta

S

6

/1

1

D

3

C

PN

r 6

ta

S

4

/6

1

D

4

D

sN

u

c

ft fo

o

S

6

5

4

Installation Technical Manual LDK 7500 + LDK 5490 Adapter 2-3

Page 12

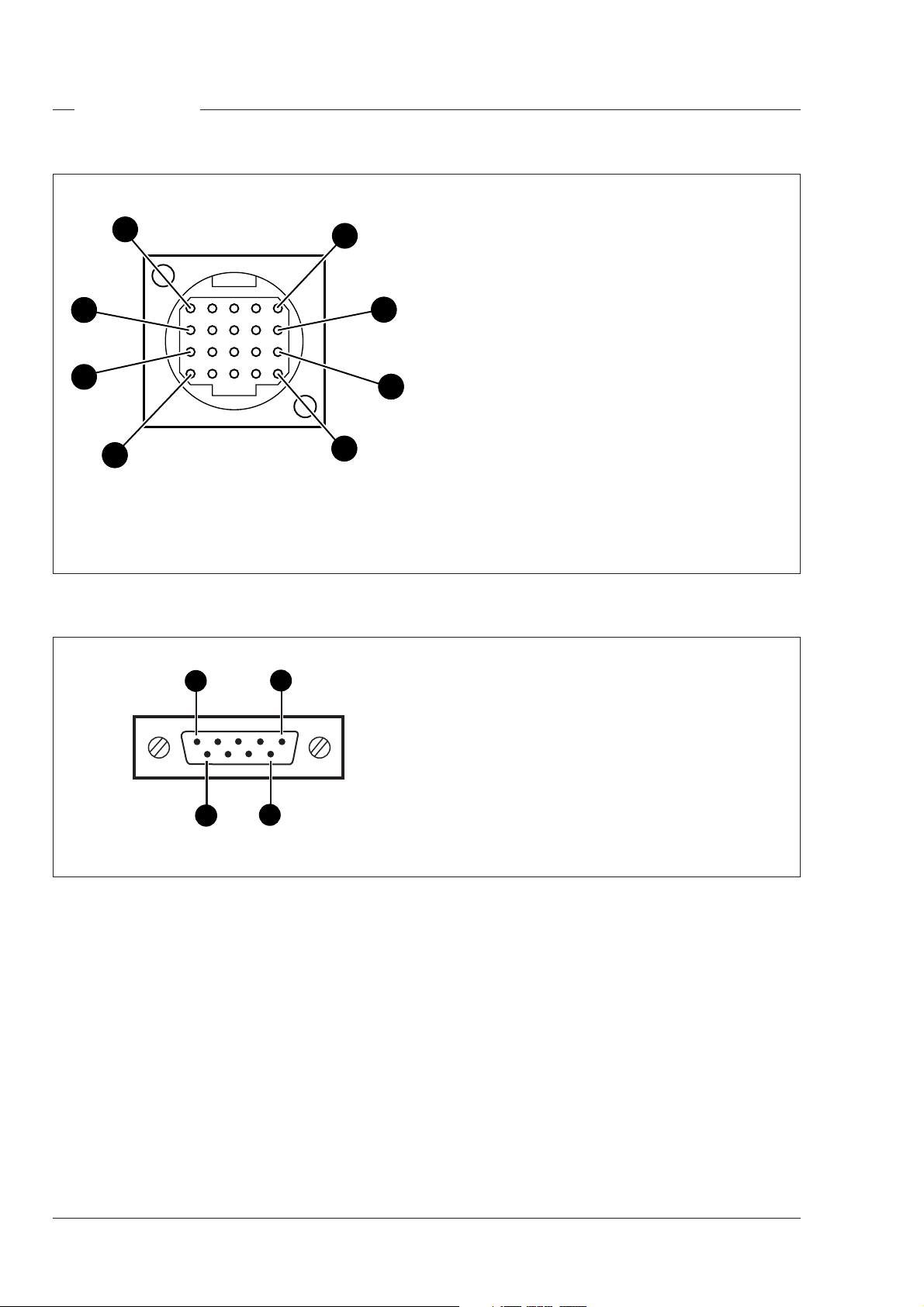

Connectors

Viewfinder connector

1

6

11

16

Hirose 20-pole female; panel view

5

20

10

15

1. -80V (not used)

2. n.c.

3. GND

4. INTN-D

5. vf ext video (not used)

6. n.c.

7. vf video ret

8. SDA-D

9. SCL-D

10. vf ext video ret (not used)

11. GND

12. vf video

13. Pb vf ret

14. Pr vf ret

15. GND

16. +batt

17. +batt

18. Pb vf

19. Pr vf

20. shield

Cable 20-pin male connector:

Part number 5322 320 12159

RS232 connector

1

6

D-conn 9-pin male; panel view

5

1. SPARE

2. RS-RXD

3. RS-TXD

4. RS-DTR

5. RS-DGND

6. RS-DSR

7. RS-RTS

8. RS-CTS

9. +12V

9

2-4 Technical Manual LDK 7500 + LDK 5490 Adapter Installation

Page 13

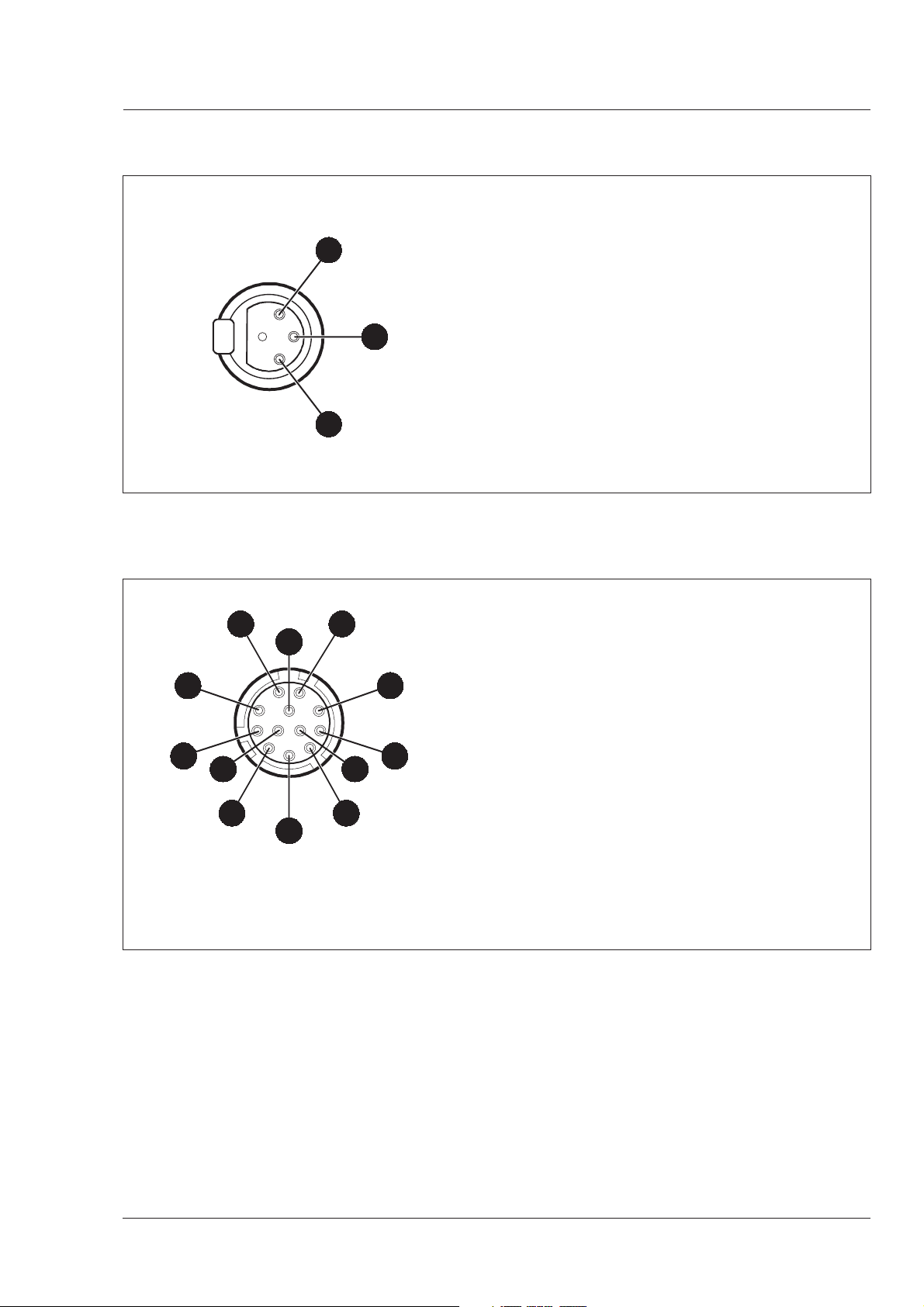

Audio microphone connector

XLR 3-pole female

Lens connector

8

7

12

1

2

9

1

10

6 4

5

11

1. Audio Screen

2. Audio In

3. Audio Return

Microphone impedance >200 ohm

Sensitivity controlled via camera menu: -64 dBu to -22 dBu.

3

2

3

Signal at pin 2 of audio input is in phase with signal at pin 2

of audio output on Breakout box.

1. Ext. Video On/Off

2. VTR Trigger Switch

3. -batt

4. Momentary Iris

5. IrisControl

6. + batt

7. Iris Follow

8. Lens Servo

9. Range Extender

10. Zoom Follow

11. Focus follow*

12. Spare

* not standard on lens

Hirose 12-pole female; panel view

Cable 12-pin male connector:

Installation Technical Manual LDK 7500 + LDK 5490 Adapter 2-5

Part number 5322 265 41208

Page 14

Multicore connector

2

1

5

4

8

9

12

14

B

16

17

18

21

23+3-pin male; panel view

Panel connector part number 3922 040 03231

3

22

A

1 Audio X

2 Audio Shield

3 Audio Y

6

7

4 Tally in (active >3V; imped. 10KOhm)

5 -Batt

6 +Batt

7 Record out (stop < 0.2V; start >4.5V; imped. 1KOhm)

11

10

13

15

8 -Batt sense

9 -Batt

10 +Batt

11 +Batt sense

12 -Batt

13 +Batt

14 TXD

15 RXD

C

20

19

16 TXD ret

17 Playback in

18 CVBS

19 Gen Lock in (HD tri-level sync. 0.6Vpp, 75 Ohm)

23

20 RXD ret

21 Playback ret

22 CVBS ret

23 Gen Lock in ret

A Dual Link A (see table)

B HD SDI (see table)

C Dual Link B (see table)

Viper signal output

Processing modes

BNC connectors Multicore pins FilmStream HD Stream R, G, B Y, Cr, Cb

HDSDI-A A Dual link 4:2:2* HDSDI 4:2:2* Dual link 4:2:2 HDSDI 4:2:2

Viewing B HDSDI 4:2:2** HDSDI 4:2:2** HDSDI 4:2:2 HDSDI 4:2:2

HDSDI-B C Dual link 0:2:2* HDSDI 4:2:2* Dual link 0:2:2 HDSDI 4:2:2

* no video processing

** monitoring quality only

Power input connector

1. - Batt

1

4

2. - Batt sense

3. + Batt sense

4. + Batt (+10.5V.......+17V)

2

3

XLR4-pin male; panel view

2-6 Technical Manual LDK 7500 + LDK 5490 Adapter Installation

Page 15

Power output connector

1

4

Hirose 4-pole female; panel view

Cable 4-pin male connector:

Obtainable from Hirose part number HR10A-7P-4P

2

3

LCP connector

9

1

10

8

7

12

11

6 4

5

1. Gnd

2. On air (TTL level; H= on air)

3. Housing

4. + Batt (max. 2A)

1. -

2. RS-232 RXD

3. RS-232 TXD

2

3

4. -

5. ground

6. -

7. -

8. -

9. +Batt

10. -

11. -

12. Housing

Hirose 12-pin male; panel view

Installation Technical Manual LDK 7500 + LDK 5490 Adapter 2-7

Page 16

Cables and breakout box (options)

Cables

To connect the multicore connector of the camera to

the breakout box the following cables are optionally

available:

HD Cable Assy 10m Full Function LDK8175/01

HD Cable Assy 40m Full Function LDK8175/04

HD Cable Assy 10m Standard LDK8175/11

HD Cable Assy 40m Standard LDK8175/14

In the standard cables the following pins are not

connected: 1, 2, 3, 14, 15, 16, 17, 18, 19, 20, 21, 22,

23 and B (see multicore connector pinning).

AUDIO

Breakout box option (LDK 8275)

The breakout box has the following connectors:

• Multicore in

• HDSDI A out (2x BNC)

• HDSDI B out (2x BNC)

• Viewing HDSDI out (2x BNC)

*

*

*

• CVBS out

• Sync. in

• Playback in

• Control

• Power in 12 Vdc

• Power in 24 Vdc

• Audio out

* terminate (75 Ohm) if not used

POWER

12 VDC

24 VDC

Important: Terminate all unused HDSDI output BNC connectors using the 75-Ohm terminator plugs supplied.

Control connector

9-pin male; panel view

HDSDI VIEWING

BA

1

6

5

9

HDSDI

SELECT

CONTROL

CVBS SYNC PLAYBACK

1. Tally in (active >3V; imped. 10KOhm)

2. RS-RXD

3. RS-TXD

4. -

5. RS-DGND

6. VTR start/stop (stop < 0.2V; start >4.5V imped. 1KOhm)

7. -

8. -

9. + Batt (+10.5V.......+17V)

2-8 Technical Manual LDK 7500 + LDK 5490 Adapter Installation

Page 17

Power input connector 24 Vdc

2

1. - Batt

2. + Batt (+17V.......+30V)

Use the SELECT switch to choose this input.

Fischer 2-pin male; panel view

Cable 2-pin female connector:

Fischer part number WS105Z087/7.2

Power input connector 12 Vdc

1

2

XLR 4-pin male; panel view

1

4

3

Note

If the DC output connector of the camera is drawing 18W or

more and a 50m cable or longer is used, then the power

supplied to this socket will not be sufficient to operate the

system. Power the camera locally to use cables lengths

greater than 50m.

1. - Batt

2. - Batt sense

3. + Batt sense

4. + Batt (+10.5V.......+17V)

Use the SELECT switch to choose this input.

Note

If the DC output connector of the camera is drawing 18W or

more and a 40m cable or longer is used, then the power

supplied to this socket will not be sufficient to operate the

system. Power the camera locally to use cables lengths

greater than 40m.

Audio connector

1. Shield

21

3

XLR 3-pin male; panel view

Installation Technical Manual LDK 7500 + LDK 5490 Adapter 2-9

2. Audio in

3. Audio return

Signal at pin 2 of audio output is in phase with signal at

pin 2 of audio input on camera.

Sensitivity controlled in camera: -64 dBu to -22 dBu.

Page 18

Specifications

General data

Power requirements: 12 Vdc nominal (11.5 to 17 Vdc)

Power consumption: 44 W approx. (incl. 2-inch VF and

Operating temperatures: -20°C to +40°C (-4°F to +113°F)

Storage temperatures: -20°C to +60°C (-4°F to +140°F)

Weight: 4.3 kg (9.7 lbs) approx. (incl. 2-inch

Dimensions: 197 x 117 x 349 mm (H x W x L)

Viewfinder CRT: 2" monochrome

2" Viewfinder resolution: >600 TV lines (centre)

Output Modes: FilmStream mode (RGB 10-bit log)

Camera Head

Pick-up device: 3x2/3" HD-DPM

Picture elements: 9.2 million pixels

Aspect Ratio: 16:9 (1.77:1) in 1080 or 720 lines

Frame rates: - 1080p: 23.98, 24, 25, 29.97 fps

Smear: No vertical smear

Optical system: F1.4 prism system

Optical filters: 1st Wheel Clear, 2-stop, 4-stop, 6-

Electronic colour filters: RGB, YCrCb modes:

Digital quantization: 12-bit A-to-D

Digital signal processing: > 22 bits (not active in FilmStream

FilmStream adapter)

VF and FilmStream adapter)

HDStream (YUV 10-bit log)

RGB (4:4:4)

YUV (4:2:2)

+TM

CCDs

1920 (H) x 4320 (V) effective

or 2.37:1 in 1080p mode

(segmented frame output)

- 1080p: 23.98 fps with 3:2 pull-down

to give 1080i59.94

- 1080i: 50, 59.94 Hz

-720p: 23.98, 25, 29.97 fps with 2:2/

3:2 frame repeat to give 50, 59.94 Hz

-720p: 50, 59.94 Hz

stop ND

2nd Wheel Clear, 4-point star, 6point star, soft-focus

3200K, 4700K, 5600K, 7200K, Auto

white.

HDStream mode:

3200K, 5600K, Thru (no correction).

FilmStream mode (viewing channel

only):

3200K, 4700K, 5600K, 7200K, Thru

mode)

Sensitivity: 2000 lux (186 ft cd) at F9.0 (typical,

1080p24 video mode). Effective

ASA320 in FilmStream mode

Gain: FilmStream mode (viewing channel

only): -6, 0, +6, +12 dB

-3dB to +12dB in 3dB steps (user

definable presets in video modes)

S/N ratio: 54 dB in Y (typical, in video modes)

Modulation depth: 40% at 27 MHz

Exposure control: Down to 1/1000 sec.

Variable shutter: appox. 50 to 310 degrees

Connectors

Front microphone input: 1x XLR-3 female, balanced, +48V

Viewfinder: 20-pin connector

Lens out: 12-pin connector

LDK 5490 FilmStream adapter

Dual link HD SDI out: BNC 2x, SMPTE 372M, 0.8 Vpp;

75 Ohm; 1.5 Gb/s (FilmStream or full

resolution RGB 10-bits)

HD SDI out: BNC 1x, SMPTE 292M, 0.8 Vpp;

75 Ohm; 1.5 Gb/s (viewing output in

FilmStream and HDStream modes)

CVBS out: BNC 1x, 1.0 Vpp; 75 Ohm, standard

definition - viewing quality.

Viewfinder out: BNC 1x, Y-signal of viewfinder or

external video, 1 Vpp; 75 Ohm

DC In: XLR-4, 12 Volts dc

DC Out: 4-pole Fischer, 12 Volts, 1.5A,

(unregulated)

LCP: 12-pole Hirose, LCP-100 local control

panel

Multicore: 23+3 pole, record start, return video

(SD) in, genlock in, DC in, camera

control, tally, CVBS out, audio out,

HD SDI out, Dual link HD SDI out

2-10 Technical Manual LDK 7500 + LDK 5490 Adapter Installation

Page 19

Camera head dimensions

Installation Technical Manual LDK 7500 + LDK 5490 Adapter 2-11

Page 20

Adapter dimensions

2-12 Technical Manual LDK 7500 + LDK 5490 Adapter Installation

Page 21

Section 3

Replacements

This section gives information on the procedures to follow when replacing printed circuit boards and

mechanical components at first line level.

Contents

Introduction ........................................................ 3-2

Handgrip ............................................................ 3-2

Replacements Technical Manual LDK 7500 + LDK 5490 Adapter 3-1

Printed circuit boards ......................................... 3-3

Front unit ........................................................... 3-4

Page 22

Introduction

Handgrip

The instructions given in this section are restricted to

those modules which can be replaced at the first line

service level. These modules include:

• The handgrip

• The printed circuit boards

• The front unit

After a printed circuit board has been replaced it is

sometimes necessary to carry out adjustments to

match the new boards to your camera and so maintain

the performance levels. The relevant adjustment

procedures are given in Section 4.

The procedures for removing the modules should be

followed in reverse order when remounting the units.

To remove the handgrip proceed as follows:

a. Remove the viewfinder from its support bracket on

the handgrip.

1

b. Loosen the screw

securing the handgrip to the

top of the adapter.

c. Loosen the two socket head screws

2

securing the

handgrip to the front of the camera.

1

2

2

lear

C

1

A

r

a

e

Cl

/4

1

D

N

2

B

r 4P

Sta

1/16

D

N

3

C

P

6

r

Sta

1/64

D

N

4

D

s

u

c

o

t f

Sof

3-2 Technical Manual LDK 7500 + LDK 5490 Adapter Replacements

Page 23

Printed circuit boards

Gaining access to camera head boards

To access the printed circuit boards remove the left

side cover of the camera head as follows:

a. Unscrew the four screws on the left side panel.

b. Swing down the cover.

Clear Clear

A 1

Star 4P ND1/4

B 2

Star 6P ND 1/16

C 3

Soft focus ND 1/64

D 4

Location of boards

The boards in the camera head are numbered as

follows:

1

Sync monitoring board

2

Data board

3

Front driver board

Gaining access to adapter boards

To access the printed circuit boards remove the left

side cover of the adapter as follows:

a. Unscrew the three screws on the left side panel.

b. Remove the cover.

Location of adapter boards

The boards in the adapter are numbered as follows:

4

Power board

5

HDSDI output board

6

Miscellaneous HDSDI board

1

2

3

7

4

5

6

8

Removing a board

To remove a printed circuit board proceed as follows:

a. Pull up the top print ejector 7 and pull down the

bottom print ejector 8 to release the printed circuit

board from its connector.

b. Pull horizontally on these ejectors to slide the

board clear of the camera.

Replacements Technical Manual LDK 7500 + LDK 5490 Adapter 3-3

Page 24

Front unit

To remove the front unit the following steps have to be

carried out:

• Loosen the two top screws

• Open the camera left side cover

• Open the camera right side cover

• Remove DVP board

• Remove the front unit

Opening the left side cover

To open the left side cover proceed as follow:

a. Loosen the four screws 1 at the front of the

camera.

b. Swing down the cover

1

Clear Clear

A 1

Star 4P ND1/4

B 2

Star 6P ND 1/16

C 3

Soft focus ND 1/64

D 4

Opening the right side cover

To remove the right front cover proceed as follows:

a. Unscrew the four retaining screws

1 and swing the

right front cover down.

b. Disconnect the B, R and G coax cables from the

DVP board using the correct tool (part no. 5322 395

10802)

c. Unscrew the two top retaining screws

2 of the DVP

board and swing the board downwards.

d. Reach in behind the board and disconnect the flat

cable from the connector at the bottom of the

board.

e. Disconnect the flat cable 3 that comes from the

cover, from the motherboard connector 4.

f. Loosen the screw 5 and remove the retaining tie 6

that restrains the cover.

g. Remove the cover.

2

B G R

6

5

4

1

1

x4

3

3-4 Technical Manual LDK 7500 + LDK 5490 Adapter Replacements

Page 25

Removing the DVP board

To remove the DVP board proceed as follows:

h. Unscrew the two bottom retaining screws

DVP board from the plastic clips and remove the

board.

i. Unscrew and disconnect the connector

8

from the

Front.

B G R

7

7 of the

8

Removing the front unit

To remove the front unit proceed as follows:

a. To ease the removal of the front unit remove the

1

adapter screws

completely.

b. Unscrew the four retaining screws 2 of the front

unit.

c. Move the front unit slightly upwards and forward

and disconnect the flat cable that comes from the

front from the connector on the connector board of

the camera.

d. Remove the front unit.

lear

1

A

2

Clear C

1/4

ND

2

B

Star 4P

ND 1/16

33

C

Star 6P

D 1/64

N

4

D

oft focus

S

2

1

Replacements Technical Manual LDK 7500 + LDK 5490 Adapter 3-5

Page 26

3-6 Technical Manual LDK 7500 + LDK 5490 Adapter Replacements

Page 27

Section 4

Adjustments

This section contains the adjustment procedures to be followed to obtain the best performance from

the camera. These procedures need only be used if, following a module replacement, the camera

does not perform according to specifications.

Contents

Introduction ........................................................ 4-2

Test Equipment ................................................. 4-3

Set-up Instructions ............................................. 4-3

Video ADC Automatic Calibration ....................... 4-4

Pre-processor Calibration ................................... 4-4

Adjustments Technical Manual LDK 7500 + LDK 5490 Adapter 4-1

3200K Adjustment ............................................. 4-4

Sawtooth Calibration .......................................... 4-4

Flare Adjustment ................................................ 4-5

Software Download ............................................ 4-5

Video Monitoring Adjustment ............................. 4-7

Page 28

Introduction

This camera is factory tested and adjusted for operational

use. Under normal circumstances, the internal automatic

calibration procedures do not need to be started and the

internal potentiometers do not need to be adjusted.

There are two situations that might require some

realignment of the camera:

a. When a lens is fitted.

b. When a printed circuit board has been replaced.

When a lens is fitted the following alignment procedures

should be carried out in the order given:

1. Run the internal 3200K calibration procedure.

2. Adjust the white shading via the menu system.

3. Adjust the flare.

4. Adjust the back focus (see lens manual for this

adjustment).

If a printed circuit board is replaced, refer to table 4-1 to

see which adjustments must be carried out to realign

the camera. For a particular board, carry out the

procedures in the order given.

If it is discovered that the camera is misaligned, the

following procedures are given as a guide for competent

service personnel, who have a thorough knowledge of

the camera and have the use of calibrated equipment,

to realign the camera.

If no improvement can be achieved or an adjustment is

out of range, please contact your local supplier or the

nearest Thomson Multimedia Broadcast Solutions

Service Centre.

The camera head adjustment procedures are designed

as separate units. Within a numbered procedure do not

change the position of switches or jumpers unless

instructed to do so in the procedure.

Table 4-1 Adjustment procedures on board replacement

Printed Circuit Board

Digital video board

Pre-processor board

Lens plate assemble

Data Board

Sync. / monitoring board

Adjustment Procedure

1. Video ADC automatic calibration (internal)

2. Sawtooth calibration (internal)

1. Pre-processor calibration (internal)

1. 3200K adjustment

2. White shading adjustment

3. Flare adjustment

1. Software download

1. Video monitoring adjustment

4-2 Technical Manual LDK 7500 + LDK 5490 Adapter Adjustments

Page 29

Test Equipment

Set-up Instructions

The following is a list of equipment required to carry out

the adjustment procedure:

• Set of board extenders LDK 5820/01

• Oscilloscope (with cursor measurement)

• Spotlight 3200K

• Focus test chart

• Black hole test chart

• White PortaPattern test chart

• White 3200K test chart

• Waveform monitor

CAUTION:

Do not attempt to improve camera performance

by adjusting individual potentiometers, jumpers or switches

as this may lead to complete misalignment of the camera.

CAUTION:

Do not realign individual potentiometers, jumpers or switches

not mentioned in this chapter or earlier in this manual.

These adjustment points are for factory use only.

Before carrying out any adjustments the following steps

are recommended:

• Attach an adapter to the camera.

• Install the camera on a tripod.

• Attach the lens and the necessary cables.

• Allow the camera to warm-up.

CAUTION:

Switch off the power supply to the camera

before removing or replacing printed circuit boards.

Adjustments Technical Manual LDK 7500 + LDK 5490 Adapter 4-3

Page 30

Video ADC Automatic Calibration

The following is an automatic internal calibration procedure to adjust the analogue-digital convertors.

(There are not pre-conditions for this calibration.)

a. In the menu system select the Service menu.

b. Select Calibrations.

c. Select Video ADC and run the procedure.

Sawtooth Calibration

The following is an automatic internal calibration procedure to adjust the internal gain of the DVP board.

(There are not pre-conditions for this calibration.)

a. In the menu system select the Service menu.

b. Select Calibrations.

c. Select Sawtooth and run the procedure.

Pre-processor Calibration

The following is an automatic internal calibration procedure to adjust the analogue-digital convertors.

(There are not pre-conditions for this calibration.)

a. In the menu system select the Service menu.

b. Select Calibrations.

c. Select PreProc and run the procedure.

3200K Adjustment

The following is an automatic internal calibration procedure to set the 3200K colour temperature.

a. Recall the standard factory file.

b. Shoot the white test chart illuminated with a 3200k spotlight (nominal video).

c. In the menu system select the Service menu.

d. Select Calibrations.

e. Select 3200K and run the procedure.

4-4 Technical Manual LDK 7500 + LDK 5490 Adapter Adjustments

Page 31

Flare Adjustment

The following is an adjustment procedure to correct the flare introduced by the lens.

a. Recall the standard factory file.

b. Close the lens and set the black level to approximately 10mV.

c. With the menu system select the green signal.

d. Shoot the black hole test chart (100% video).

e. In the menu system select the Video menu.

f. Select Flare.

g. View the waveform monitor and adjust the green flare so that there is no difference in the black level.

h. Repeat this adjustment for blue and red.

Software Download

The following procedure should be carried out to update the software.

a. Connect the PC to the RS232 connector of the camera.

b. Follow the instruction on the PC to download the software.

Adjustments Technical Manual LDK 7500 + LDK 5490 Adapter 4-5

Page 32

Video Monitoring Adjustment

ZR234

A50

B50

Sync. / Monitoring Board

X1B1

A1

4-6 Technical Manual LDK 7500 + LDK 5490 Adapter Adjustments

Page 33

Video Monitoring Adjustment

Set-up

1. Switch off power. Place sync. monitoring board on service extender. Switch on power.

2. Switch on colour bar.

Viewfinder output level

3. Connect oscilloscope to X1-B45.

4. Adjust the potentiometer on the sync. monitoring board to obtain the correct output amplitude VF output signal.

Measure at: Adjust with: Required result: Correct:

X1-B45 ZR234 700mV

0.2V

100

90

10

0%

5. Switch off power. Return sync. monitoring board to its position in the camera.

10µS

VB+700mV

Adjustments Technical Manual LDK 7500 + LDK 5490 Adapter 4-7

Page 34

4-8 Technical Manual LDK 7500 + LDK 5490 Adapter Adjustments

Page 35

Section 5

Exploded Views

Contents

HD Camera head............................................... 5-2

Camera head basic ...........................................5-3

Left cover assembly........................................... 5-4

Exploded Views Technical Manual LDK 7500 + LDK 5490 Adapter 5-1

Right cover assembly ........................................ 5-5

Shoulder pad assembly .....................................5-6

Handgrip assembly ............................................5-7

Page 36

5-2 Technical Manual LDK 7500 + LDK 5490 Adapter Exploded Views

Page 37

Exploded Views Technical Manual LDK 7500 + LDK 5490 Adapter 5-3

Page 38

5-4 Technical Manual LDK 7500 + LDK 5490 Adapter Exploded Views

Page 39

Exploded Views Technical Manual LDK 7500 + LDK 5490 Adapter 5-5

Page 40

5-6 Technical Manual LDK 7500 + LDK 5490 Adapter Exploded Views

Page 41

Exploded Views Technical Manual LDK 7500 + LDK 5490 Adapter 5-7

Page 42

5-8 Technical Manual LDK 7500 + LDK 5490 Adapter Exploded Views

Loading...

Loading...