Page 1

Prod

Prog

Cam +Floor

Eng

Camera Base Station

Camera

Communication

On Air Base

Station

Camera

Connected

Test

3922 496 31331 August 2009 v1.0

LDK 4582

User’s Guide

HD Fiber Base Station

Page 2

Declaration of Conformity

We, Grass Valley Nederland B.V., Kapittelweg 10, 4827 HG Breda, The

Netherlands, declare under our sole responsibility that this product is in

compliance with the following standards:

- EN60065 : Safety

- EN55103-1: EMC (Emission)

- EN55103-2: EMC (Immunity)

following the provisions of:

a. the Low Voltage directive 2006/95/EC

b. the EMC directive 2004/108/EC

FCC Class A Statement

This product generates, uses, and can radiate radio frequency energy and if

not installed and used in accordance with the instructions, may cause

interference to radio communications.

It has been tested and found to comply with the limits for a class A digital

device pursuant to part 15 of the FCC rules, which are designed to provide

reasonable protection against such interference when operated in a

commercial environment.

Operation of this product in a residential area is likely to cause interference in

which case the user at his own expense will be required to take whatever

measures may be required to correct the interference.

Copyright

Copyright Grass Valley Nederland B.V. 2009. Copying of this document and

giving it to others, and the use or communication of the contents thereof, are

forbidden without express authority. Offenders are liable to the payment of

damages. All rights are reserved in the event of the grant of a patent or the

registration of a utility model or design. Liable to technical alterations in the

course of further development.

Trademarks

Grass Valley and Infinity are trademarks of Grass Valley, Inc. All other

tradenames referenced are service marks, trademarks, or registered

trademarks of their respective companies.

Website

Visit the Grass Valley public website to download the latest user’s guide

updates and additional information about your broadcast product:

www.grassvalley.com

Page 3

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 3

Table of contents

Chapter 1 – Introduction

1.1 Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.1.1 Fiber transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1.2 Modular construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1.3 Audio and intercom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.3 Packing/unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2 – Installation

2.1 Control bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2.2.1 Base Station earthing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Connecting the studio intercom system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Connecting the studio signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.1 ISO, On Air and Call signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 External audio level control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6 Auxiliary connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.6.1 Private data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 3 – Setup

3.1 Base Station controls and indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.2 Setting up the Base Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.2.1 Using the internal BS menu to set up the Base Station . . . . . . . . . . . . . . . . . .28

3.2.2 Using the OCP 400 to set up the Base Station . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3 Using the Base Station system menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3.1 Entering the system menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.3.2 Finding your way . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.3 Leaving the Systems Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.3.4 Making changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.5 Using the Recall File to undo changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.6 Base Station user levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3.7 Video menu - special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4 Setting up reference and timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4.1 Output signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.4.2 Adjustment procedure for HD timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.4.3 Adjustment procedure for SD timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.5 Intercom set up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5.1 Base Station - studio interface set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.5.2 Base Station headset set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.5.3 Voice mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Page 4

4 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 4 – Maintenance

4.1 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.1.1 Base Station indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.1.2 Fiber transmission diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.1.3 Sync/Encoder HD board diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.2 Replacements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.2.1 Board locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.2.2 Replacing the power unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.3 Replacing dust filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Chapter 5 – Menu structure and contents

5.1 Menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.1.1 Top menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5.1.2 Video menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

5.1.3 Monitoring menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.1.4 Audio/Intercom menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

5.1.5 SDTV menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

5.1.6 System menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

5.1.7 Files menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.1.8 Diagnostics menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

5.2 Menu contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

5.2.1 Video menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

5.2.2 Monitoring menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

5.2.3 Audio/intercom menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

5.2.4 SDTV menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

5.2.5 System menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.2.6 Files menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

5.2.7 Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Chapter 6 – Connectors

6.1 Base Station connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

6.2 Power module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.2.1 Mains power connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.3 Communication module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3.1 Digital audio output (1+2) connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3.2 Digital audio output (3+4) connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3.3 Audio output (1 & 2) connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.3.4 Intercom connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.3.5 Signalling connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

6.3.6 Auxiliary connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.3.7 Network connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

6.4 BNC connector board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

6.4.1 External video input connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.4.2 Main video output connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

6.4.3 SD and monitoring connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6.4.4 Teleprompter and reference connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6.5 Transmission module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6.5.1 Hybrid fiber connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

6.6 LDK 4541/10 Engineering intercom module (option) . . . . . . . . . . . . . . . . . . . . . . . . 75

6.6.1 Headset connector (front side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Page 5

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 5

Chapter 7 – Specifications

7.1 Specifications for the LDK 4582 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.2 Specifications for optional modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

7.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Page 6

6 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

End-of-life product recycling

Grass Valley’s innovation and excellence in product design also extends to the programs we’ve

established to manage the recycling of our products. Grass Valley has developed a

comprehensive end-of-life product take back program for recycle or disposal of end-of-life

products. Our program meets the requirements of the European Union’s WEEE Directive and

in the United States from the Environmental Protection Agency, individual state or local

agencies.

Grass Valley’s end-of-life product take back program assures proper disposal by use of Best

Available Technology. This program accepts any Grass Valley branded equipment. Upon

request, a Certificate of Recycling or a Certificate of Destruction, depending on the ultimate

disposition of the product, can be sent to the requester.

Grass Valley will be responsible for all costs associated with recycling and disposal, including

freight, however you are responsible for the removal of the equipment from your facility and

packing the equipment ready for pickup.

For further information on the Grass Valley product take back system please contact Grass

Valley at + 800 80 80 20 20 or +33 1 48 25 20 20 from most other countries. In the US and

Canada please call 800-547-8949 or 530-478-4148. Ask to be connected to the EH&S

Department. In addition, information concerning the program can be found at:

www.grassvalley.com/environment

Page 7

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 7

Important information

Read these instructions carefully and retain them for future reference.

During installation and operation of this equipment, local building safety and fire protection

standards must be observed.

Before connecting the equipment to the power supply of the installation, verify the proper

functioning of the protective earth lead.

Whenever it is likely that safe operation is impaired, the apparatus must be made inoperative

and secured against any unintended operation. The appropriate servicing authority must then

be informed. For example, safety is likely to be impaired if the apparatus fails to perform the

intended function or shows visible damage.

Any changes or modifications not expressly approved in this manual could void your authority

to operate this equipment.

Cautions and Warnings

Read and comply with the warning and caution notices that appear in the manual.

– Warnings indicate danger that requires correct procedures or practices to prevent

death or injury to personnel.

– Cautions indicate procedures or practices that should be followed to prevent damage

or destruction to equipment or property.

Warnings

To prevent fire or shock hazard, do not expose the unit to rain or moisture.

To avoid electrical shock, do not remove covers or panels. Refer servicing to qualified

personnel only.

In case of an emergency ensure that the power is disconnected.

Use only fuses of the type and rating specified.

Connect the product only to a power source with the specified voltage rating.

The Base Station must always be connected to protective earth. Do not interrupt the

protection conductor inside or outside the unit. Do not disconnect the protective earth

terminal. Intentional interruption is prohibited and is likely to make the unit dangerous.

To prevent risk of overheating, ventilate the units correctly.

For safety reasons the Base Station must be mounted in a 19-inch rack which has safety covers

according to IEC65. When two Base Stations are mounted above each other, the minimum

distance between them must be 50 mm or the rack must be force-air cooled.

Page 8

8 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Fiber-optic transmission units

Laser safety statement (Europe)

Fiber-optic transmission units are classified as a "CLASS 1 Laser Product" according to EN

60825-1, Safety of Laser products. Class 1 laser products are considered safe and do not

result in biological hazard if used according to the instructions.

Laser safety statement (US)

Fiber-optic transmission units are classified as a "CLASS 1 Laser Product" according to

21CFR 1040.10 of the US Food and Drug Administration (FDA) Center for Devices and

Radiological Health.

Use of controls, adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

To ensure proper use of this product, please read this instruction manual carefully and retain

for future reference. Should the unit ever require maintenance, contact an authorized service

location.

Fiber-optic cable precautions

Fiber-optic cables and connectors are easily damaged; take the following percautions into

account:

– Do not bend the cable beyond the minimum permissible bend range specified for the

cable.

– Avoid kinks in the cable.

– Avoid subjecting the cable to a high tension force (even momentarily).

– Do not twist the cable when connecting it to equipment.

– Insert connectors straight and fully into their corresponding sockets.

– In fiber-optic cable systems always put the dust caps on cable and panel connectors

immediately after disconnecting a cable. Keep the dust caps clean.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

PRODUKT

Page 9

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 9

Cleaning fiber-optic connectors

WARNING

Never clean an optical connector attached to a fiber that is carrying light.

Particles of foreign matter on the tip of a ferrule can have a disabling effect on fiber-optic

transmission. Fiber-optic connectors need to be cleaned every time they are mated and

unmated; it is essential that fiber-optic users develop the necessary discipline to always clean

the connectors before they are mated.

Use a commerially available cleaning kit specifically designed for fiber-optic connectors and

follow the manufacturer's instructions carefully.

• The connector sections to be cleaned include the tips and sides of ferrules, the interior

walls of alignment sleeves, and the interior and exterior of connector shells.

• For plugs, the interior surfaces of alignment sleeves and the tips of ferrules are to be

cleaned with a cleaning stick treated with the appropriate fluid. (Cleaning sticks with a

slender design are available that allow alignment sleeves to be cleaned without having to

detach them.)

• For jacks, it is important to clean both the tips and sides of the completely protruding

ferrules.

• Both the male and female connector shells tend to attract dust and metal particles, so it is

important to clean both the insides and outsides.

• The fiber end face and ferrule must be absolutely clean before it is inserted into a

transmitter or receiver.

• Mate the connector immediately! Don't let the connector lie around and collect dust

before mating.

• Air can be used to remove lint or loose dust from the port of a transmitter or receiver to be

mated with the connector. Never insert any liquid into the ports.

Page 10

10 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

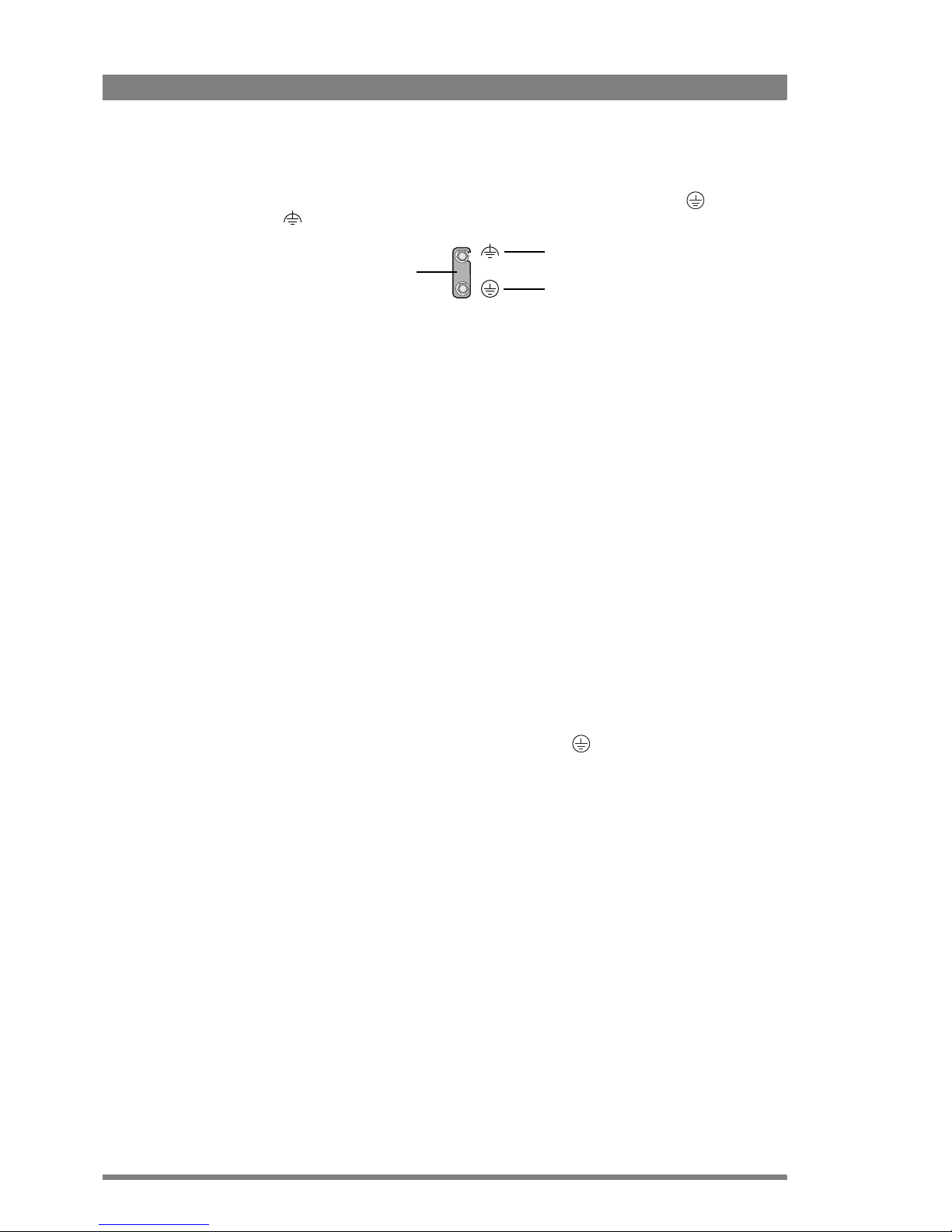

Base Station earthing

The rear of the unit has two separate screw terminals for protective earth (PE) and

video earth (VE). These are normally connected by a metal strap.

The protective earth terminal is internally connected to the protective earth conductor of the

power cable. In normal circumstances the connection between the protective earth and the

video earth should not be broken. If required, the central earth connection wire of the studio

can be connected to terminal PE in accordance with VDE regulation 0800/part2.

Only if the studio (or OB van) is equipped with separate protective and video earth systems

may the metal strap be removed. Under these circumstances the video earth terminal must be

connected to the central functional earth potential (video earth) of the studio. This earth

potential should have functional protective and noiseless earth (FPE) qualities as stated in the

VDE regulation 0800/part2. A low impedance interconnection of both earth conductors must

be provided at the central studio earthing point.

Mains lead wiring for UK users

The wires in the mains lead are coloured in accordance with the following code:

GREEN and YELLOW- EARTH

BLUE- NEUTRAL

BROWN- LIVE

As the colours of the wires in the mains lead of this apparatus may not correspond with the

coloured markings identifying the terminals in your plug proceed as follows:

• The wire coloured GREEN AND YELLOW must be connected to the terminal on the plug

marked with the letter E or by the safety earth symbol

or coloured GREEN or GREEN

AND YELLOW.

• The wire coloured BROWN must be connected to the terminal marked with the letter L or

coloured RED.

• The wire coloured BLUE must be connected to the terminal marked with the letter N or

coloured BLACK.

Ensure that your equipment is connected correctly - if you are in any doubt consult a

qualified electrician.

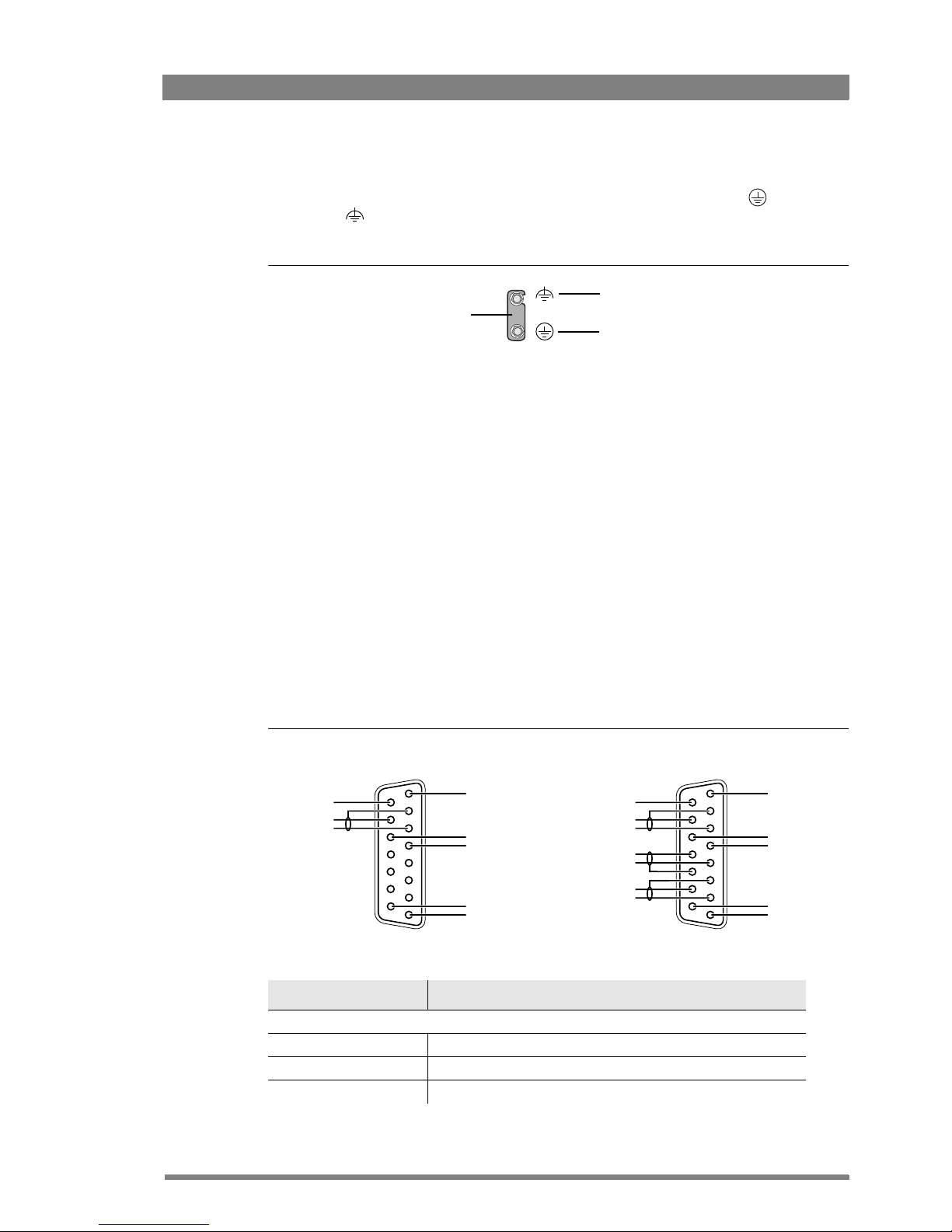

Metal strap

VE

PE

Page 11

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 11

Chapter 1 - Introduction

Chapter 1

Introduction

1.1 Technology

The LDK 4582 HD Fiber Base Station is the perfect interface between your HD camera and the

rest of your system. The heavy-duty base station provides state-of-the-art technology in a

compact package. The high level of modularity guarantees ideal matching with any type of

application; you can use the system in a studio or for mobile field production, for HD or for SD

production.

The Base Station is only 2U high yet offers full broadcast functionality and quality.The low

height means that rack space is saved. Its low power consumption and efficient internal

cooling eliminate the need for space between adjacent units. Sliding rails are additionally

available for easy access to the back panel. The wings on either side of the back panel protect

the connectors from damage, including the hybrid fiber connector. The hybrid fiber connector

itself can easily be mounted at different angles to suit all mounting requirements.

Operational controls

You can access the Base Station menu, which contains all operational settings, from an

Operational Control Panel. In addition to the operational menu, the installation and service

menus can be activated from the Base Station by pressing a switch behind the front panel. The

Base Station is compatible with all existing control system components.

1.1. 1 Fiber transmission

The HD fiber system allows video transmission and remote control of cameras up to a distance

of 4,000 m (13,000 ft) and beyond, using industry standard fiber optic cable. It is based on

30 MHz full-bandwidth 4:2:2 transmission (Y/Cr/Cb components). All video and data signals are

transmitted digitally to ensure long cable runs without any loss of quality.

Page 12

12 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 1 - Introduction

1.1.2 Modular construction

The modular concept makes it easy to expand the functionality by simply adding new modules.

Quick exchange of the modules for servicing or the ability to swap modules between Base

Stations is another benefit.

External video inputs

The external video input module provides two analog video inputs and loop-through analog

outputs. The signal can be PAL or NTSC, and does not need to be clamped. It can also be nonsynchronized. The external video input module can be replaced in future by a digital one.

High quality SD outputs

Besides standard high-definition outputs, the Base Station can be optionally equipped with

simultaneous high-end SD outputs. This offers ultimate flexibility: produce in SD one day, and

in HD the next, or do both simultaneously. The optional LDK 4530/40 High Quality SD module

adds three 270 Mb/s SDI outputs.

1.1.3 Audio and intercom

The audio and advanced intercom module provides 4-channel intercom, 2-channel digital audio

(AES/EBU compliant) and 2-channel high-quality analog audio from the camera. The audio

channels from the camera head are passed to the different outputs via balanced line drivers on

the module for clean transparent sound. Both analog audio channels are available as digital

outputs on the Base Station. Gain levels can be externally controlled.

In the installation menu of the Base Station, a choice is provided between a 4-wire or a 2-wire

intercom system. A 1kHz test-tone generator and voicemail are available. The voicemail stores

messages from the Program, Production or Engineering channels for the camera operator.

By adding the engineering intercom module, a 5-channel full-featured intercom is possible. The

engineering intercom module provides a 2-channel intercom between camera operator and

engineering. The module fits into the front of the unit and facilitates the plugging in of a

headset and level adjustment for both ear muffs. It is ideal for a simple intercom facility in a

standalone mode of operation, or to expand the 4-channel advanced intercom to a 5-channel

intercom.

Page 13

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 13

Chapter 1 - Introduction

1.2 Features

• Low height: only 2U high, 19-inch rack unit.

• Flexible due to its modular construction.

• The digital transmission backbone and power module meet the most demanding

broadcasting needs.

• 3 channels SD-SDI or HD-SDI return video inputs available.

• Heavy-duty concept with low power consumption, ideal for Outside Broadcast (OB) vans.

• Fiber allows video transmission and remote control of cameras up to a distance of

4,000

m (13,000 ft) and beyond.

• Full camera control via the C2IP Ethernet-based network.

• Two-wire or four-wire intercom compatible with international standards.

• HD and simultaneous high-quality SD outputs (optional).

Page 14

14 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 1 - Introduction

1.3 Packing/unpacking

Inspect the shipping container for evidence of damage immediately after receipt. If the

shipping container or cushioning material is damaged, it should be kept until the contents of

the shipment have been checked for completeness and the units have been checked

mechanically and electrically. The shipping container should be placed upright and opened from

the top. Remove the cushioning material and lift out the contents. The contents of the

shipment should be checked against the packing list. If the contents are incomplete, if there is

mechanical damage or defect, or if the units do not perform correctly when unpacked, notify

your sales or service centre within eight days. If the shipping container shows signs of damage

or stress, notify the carrier as well.

If a unit is being returned to for servicing, try to use the containers and materials of the original

packaging. Attach a tag indicating the type of service required, return address, model number,

full serial number and the return number which will be supplied by your service centre. If the

original packing can no longer be used, the following general instructions should be used for

repacking with commercially available materials:

1. Wrap unit in heavy paper or plastic.

2. Use a strong shipping container.

3. Use a layer of shock-absorbing material around all sides of the unit to provide firm

cushioning and prevent movement inside container.

4. Seal shipping container securely.

5. Mark shipping container “FRAGILE” to ensure careful handling.

Page 15

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 15

Chapter 2 - Installation

Chapter 2

Installation

2.1 Control bus

The Base Stations are each connected to the control network hub or router via an Ethernet

cable (straight-through, not cross-over). The OCP 400 operational control panels and, if

required the MCP 400 Master Control Panel, are also connected to the Ethernet network via a

hub or router.

An OCP 400 operational control panel can also be connected directly to the Base Station using

a cross-over Ethernet cable.

The IP address and other options for the Ethernet connection can be set up in the Base

Station System menu. These items can also be set up remotely using a network

configuration tool such as Grass Valley’s NetConfig.

☞

Note

☞

Note

By default the Ethernet connection is set up for automatic IP assignment.

2.2 Power supply

Caution

Connect the Base Station only to a power source with the specified voltage rating. Use only

fuses of the type and rating specified.

The Base Station must always be connected to protective earth. Do not interrupt the

protection conductor inside or outside the unit. Do not disconnect the protective earth

terminal. Intentional interruption is prohibited and is likely to make the unit dangerous.

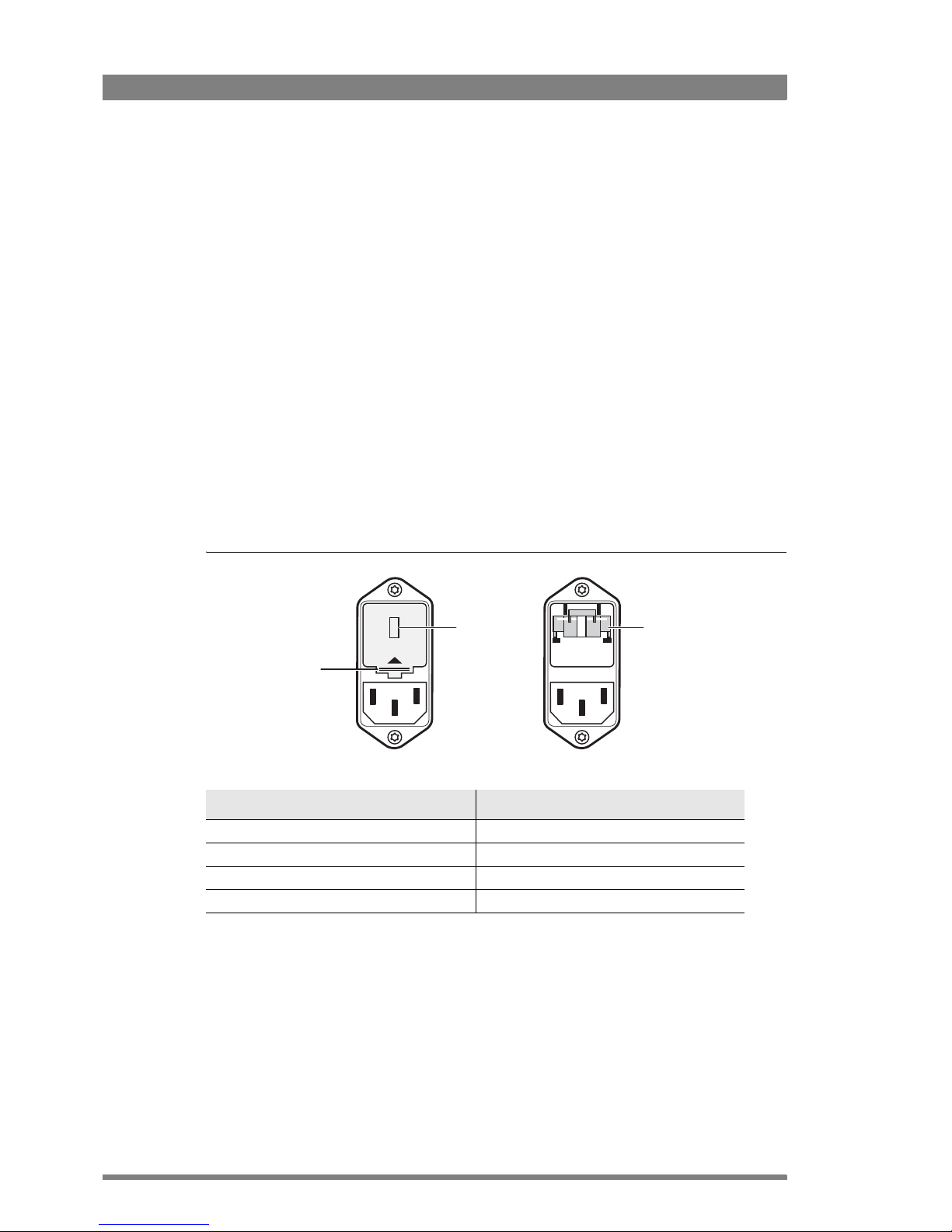

Before connecting your unit to the power supply check the fuse type (230 VAC or 115 VAC)

on the IEC power connector at the rear of the Base Station.

If the fuse type shown corresponds to your power supply voltage, connect the power supply

for the Base Station to the IEC connector at the rear.

Page 16

16 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 2 - Installation

If the fuse type does not correspond to your power supply voltage you must change the fuses

before connecting the supply as follows:

1. Insert a small screwdriver into the slot above the pins of the IEC connector and unclip the

fuse holder unit.

2. Insert you finger under the indication unit and pull it out.

3. Rotate the indication unit 180° so that the correct indication for you voltage supply is

displayed at the back of the Base Station (230 or 115).

4. Slide the indication unit securely back into its slot.

5. Insert the appropriate fuses into the alternative fuse holder which is delivered separately

with the Base Station (4 AT fuses are 22 mm long and fit into the 230 fuse holder; 10 AT

fuses are 32 mm long and fit into the 115 fuse holder). The type of fuse holder is marked

on the holder.

6. Slide the fuse holder securly back into the IEC connector until it clips into place.

7. Check again that you have used the correct fuses and that the corresponding indication is

shown.

8. Connect the power supply for the Base Station to the IEC connector at the rear.

Figure 2-1. Base Station fuses

Function Val ue

Mains input voltage 230 VAC or 115 VAC

Fuses 4AT (230 VAC) or 10AT (115 VAC)

Mains frequency 47 to 63 Hz

Power consumption 270 Watt (470 VA)

230

230

Fus e t ype

Insert small

screwdriver here

to open clip

Indication unit

Page 17

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 17

Chapter 2 - Installation

2.2.1 Base Station earthing

The rear of the unit has two separate screw terminals for protective earth (PE) and

video earth (VE). These are normally connected by a metal strap.

Figure 2-2. Base Station earthing

The protective earth terminal is internally connected to the protective earth conductor of the

power cable. In normal circumstances the connection between the protective earth and the

video earth should not be broken. If required, the central earth connection wire of the studio

can be connected to terminal PE in accordance with VDE regulation 0800/part2.

Only if the studio (or OB van) is equipped with separate protective and video earth systems

may the metal strap be removed. Under these circumstances the video earth terminal must be

connected to the central functional earth potential (video earth) of the studio. This earth

potential should have functional protective and noiseless earth (FPE) qualities as stated in the

VDE regulation 0800/part2. A low impedance interconnection of both earth conductors must

be provided at the central studio earthing point.

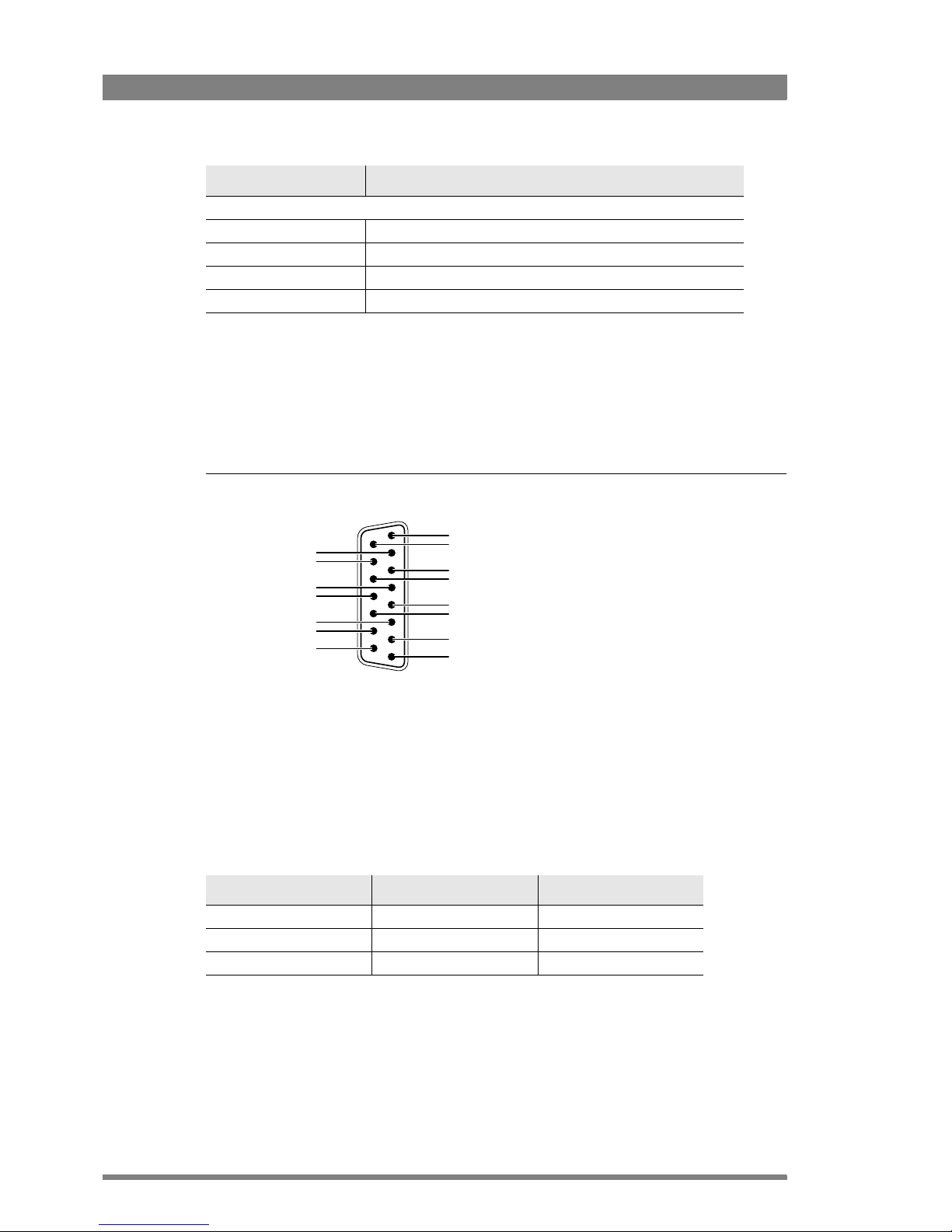

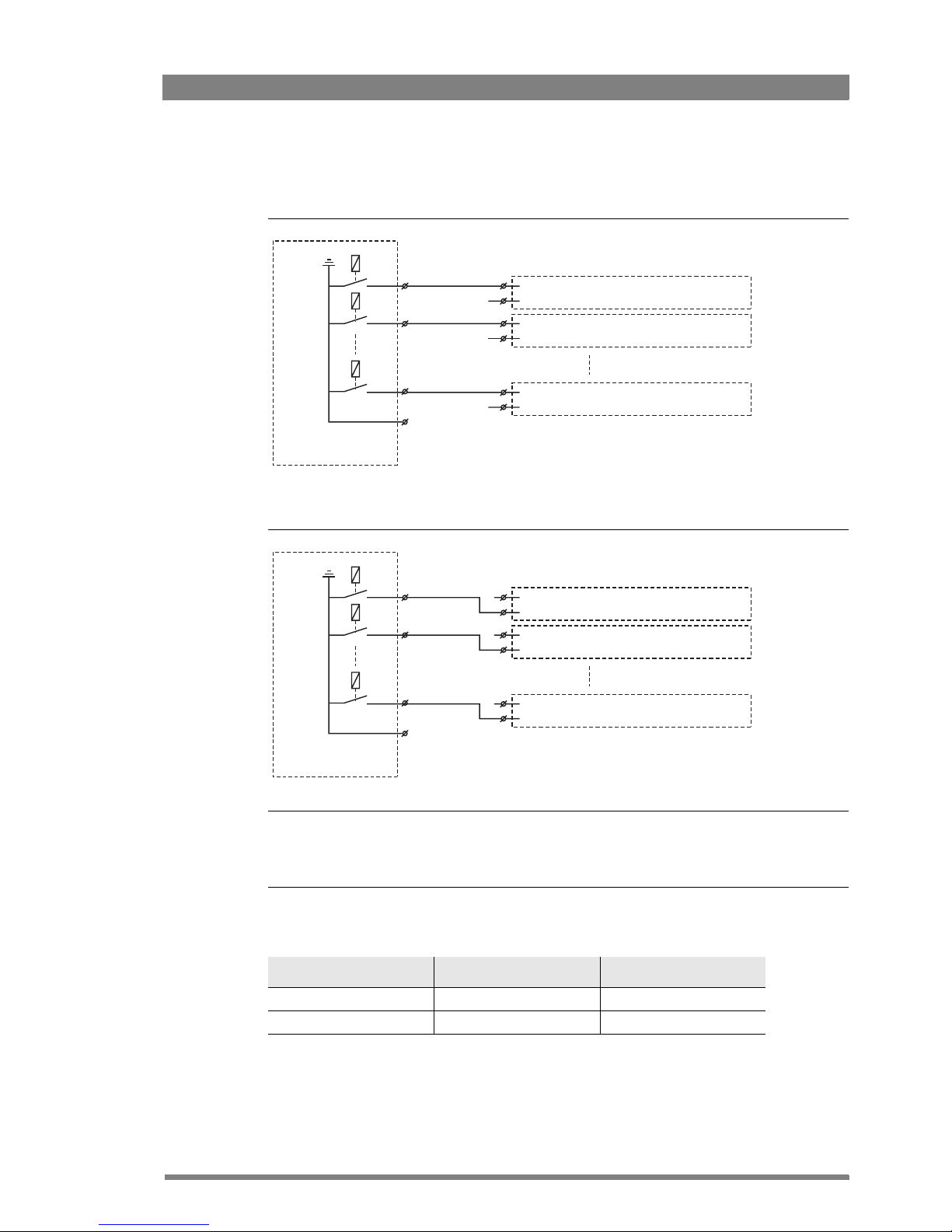

2.3 Connecting the studio intercom system

Connect the studio intercom system to the rear of the Base Station. The wiring of the

panel connector is shown below for two-wire and four-wire systems.

Figure 2-3. Intercom connection

Metal strap

VE

PE

Function Valu e

2-wire

Signal level 0 dBu (RMS)

Load impedance 200 Ω

DC level 40 VDC (max.)

-

+

-

+

-

+

8

1

15

9

-

+

-

+

8

1

15

9

Two-wire Four-wire

Housing

Prod

Housing

Eng in/out

Prod in/out

Housing

Eng in/out

Prod in/out

Housing

Prog in ret

Prog in

Prod in ret

Prod in

Eng in ret

Eng in

Page 18

18 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 2 - Installation

2.4 Connecting the studio signalling

Connect the studio signalling system to the rear of the Base Station. The wiring of the

panel connector is shown below:

Figure 2-4. Signalling connector

2.4.1 ISO, On Air and Call signals

There are several connection methods for the ISO (On Air Yellow), On Air and Call signalling

functions: dry contact, common ground, voltage level and open circuit/voltage level.

A selection in the SYSTEM > SIGNALLING menu allows you to make the activity state of the

function (Active or Inactive) correspond to a particular input signal. There are two leads for each

connection - Send and Return.

4-wire

Output signal level +6 or 0 dBu (RMS) selectable

Output impedance 50 Ω (max.), symmetrical

Input signal level +6 or 0 dBu (RMS) selectable

Impedance 9 KΩ (min.), symmetrical

Function Val ue

1

8

9

15

Call out send

Call out return

On Air send

On Air return

Audio 1 level

Audio 2 level

GND

Preview out send

Preview out return

ISO in send

ISO in return

Call in send

Call in return

+5 VDC

Housing

Function Send pin Return pin

ISO 3 11

On Air 4 12

Call 2 10

Page 19

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 19

Chapter 2 - Installation

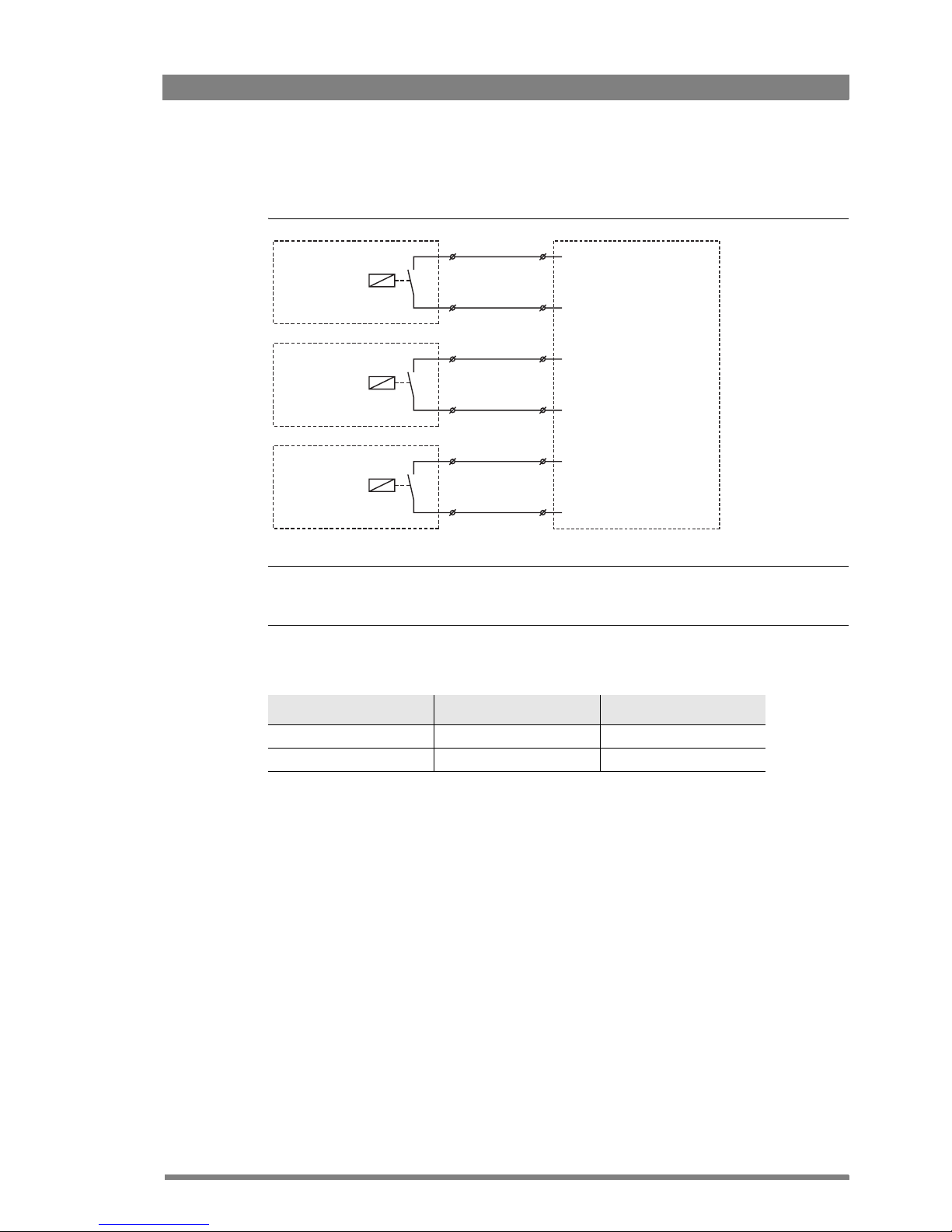

Dry contact

Figure 2-5. Dry contact

☞

Note

☞

Note

A common return (not ground!) can be used for all three functions (ISO, On Air and Call)

If a contact is closed, the corresponding function is Active or Inactive, depending on the

selection the SYSTEM > SIGNALLING menu:

ISO 1a

ISO 1b

On-Air (Tally) 1a

On-Air (Tally) 1b

Call 1a

Call 1b

ISO in ext. send (pin 3)

ISO in ext. return (pin 11)

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

Call in ext. (pin 5)

Call in ext. return (pin 13)

External ISO signalling

(dry contact)

External On-Air signalling

(dry contact)

External Call signalling

(dry contact)

Menu setting Input is shorted: Input is open:

LH (low-high) Function is Active Function is Inactive

HL (high-low) Function is Inactive Function is Active

Page 20

20 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 2 - Installation

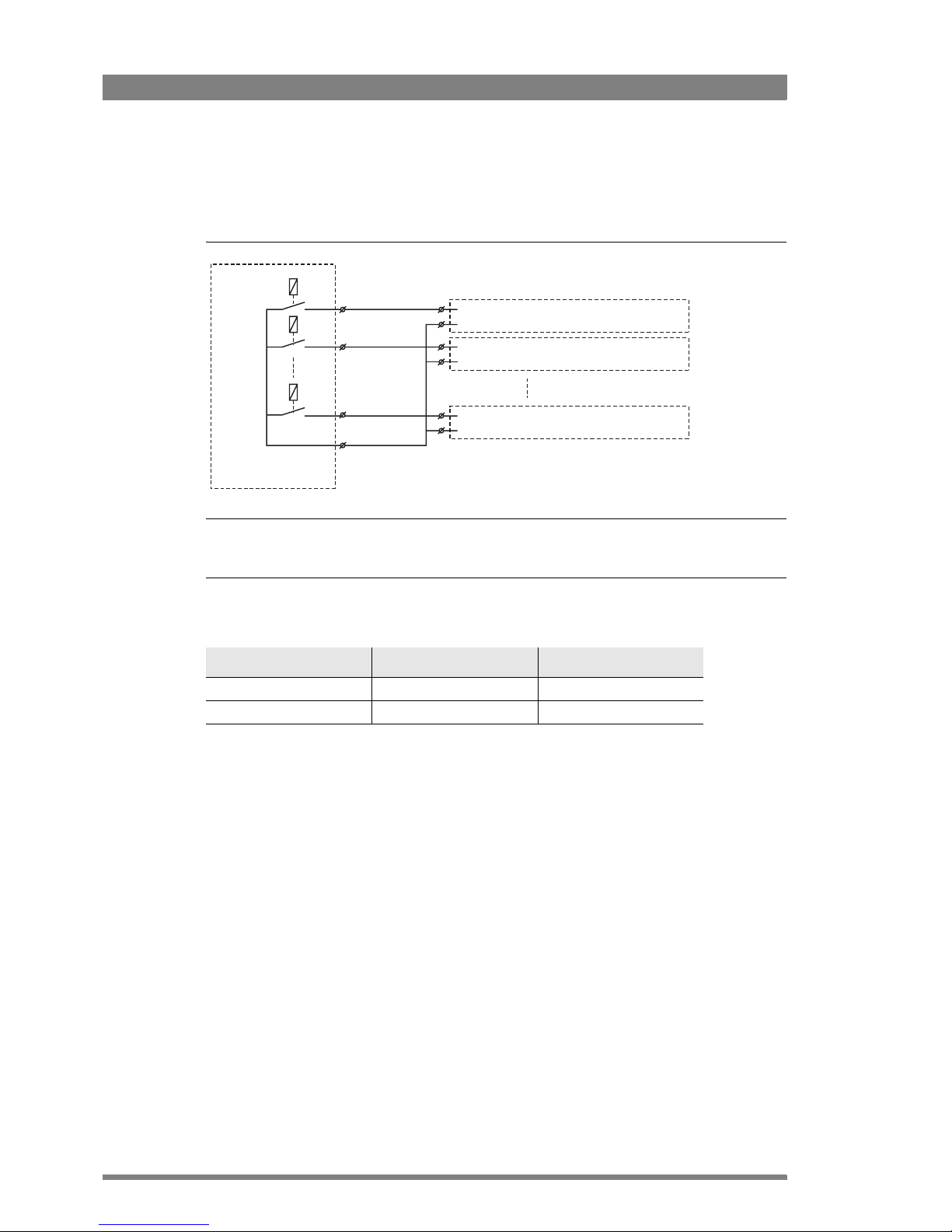

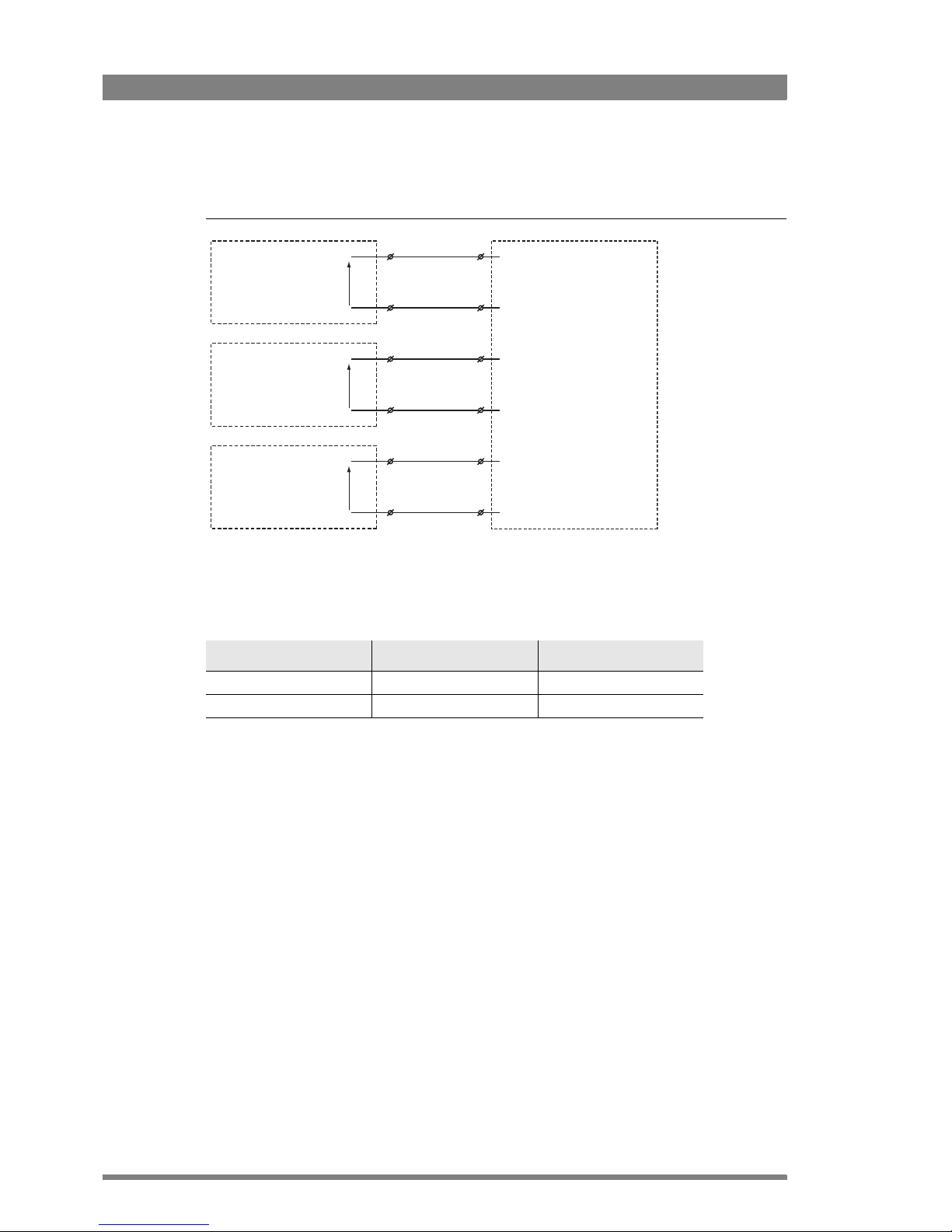

Dry contact with multiple Base Stations

This is an example of an On Air signalling with multiple Base Station using common contact.

Figure 2-6. Dry contact with common contact

☞

Note

☞

Note

Use either Send or Return only, but do not mix.

If a contact is closed, the corresponding function is Active or Inactive, depending on the

selection the SYSTEM > SIGNALLING menu:

On-Air (Tally) 1

On-Air (Tally) 2

On-Air (Tally) n

Common

External On-Air signalling

(common contact)

On-Air in ext. send (pin 4) Signalling connector

On-Air in ext. return (pin 12) Base Station 1

Signalling connector

Base Station 2

Signalling connector

Base Station n

On-Air in ext. send (pin 4)

On-Air in ext. return (pin 12)

On-Air in ext. send (pin 4)

On-Air in ext. return (pin 12)

Menu setting Input is shorted: Input is open:

LH (low-high) Function is Active Function is Inactive

HL (high-low) Function is Inactive Function is Active

Page 21

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 21

Chapter 2 - Installation

Common ground

Figure 2-7. Common ground

Figure 2-8. Common ground using returns

☞

Note

☞

Note

Ensure that a reliable ground coupling exists between the control device ground and the Base

Station ground.

If a contact is closed, the corresponding function is Active or Inactive, depending on the

selection the SYSTEM > SIGNALLING menu:

On-Air (Tally) 1

On-Air (Tally) 2

On-Air (Tally) n

External On-Air signalling

(common ground contact)

On-Air in ext. (pin 4) Signalling connector

On-Air in ext. return (pin 12) Base Station 1

Signalling connector

Base Station 2

Signalling connector

Base Station n

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

On-Air (Tally) 1

On-Air (Tally) 2

On-Air (Tally) n

External On-Air signalling

(common ground contact)

On-Air in ext. (pin 4) Signalling connector

On-Air in ext. return (pin 12) Base Station 1

Signalling connector

Base Station 2

Signalling connector

Base Station n

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

On-Air in ext. (pin 4)

On-Air in ext. return (pin 12)

Menu setting Input is shorted: Input is open:

LH (low-high) Function is Active Function is Inactive

HL (high-low) Function is Inactive Function is Active

Page 22

22 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 2 - Installation

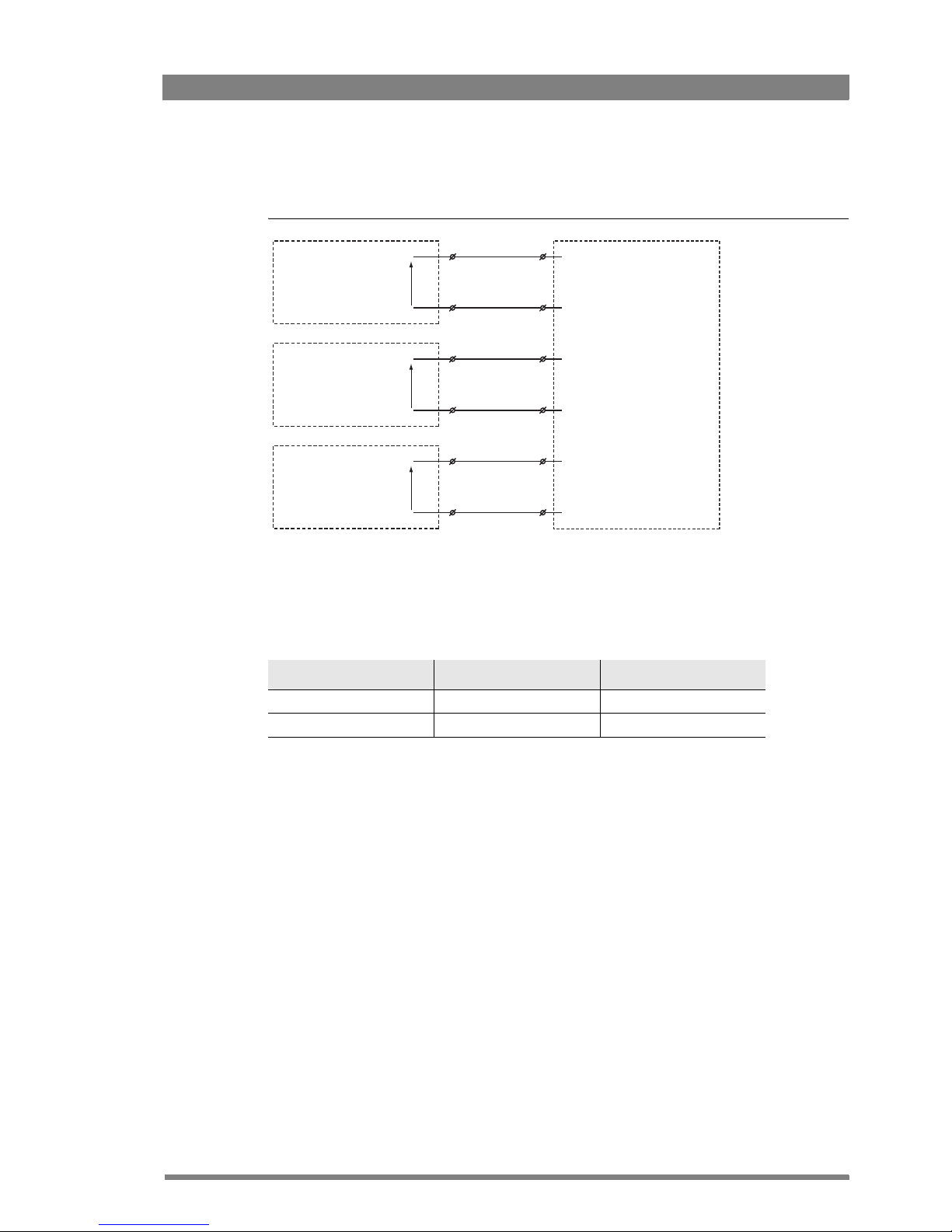

Voltage level

Figure 2-9. Voltage level

Apply a DC voltage to the inputs (respect polarity). If the voltage is low (0 to 2.5 VDC), the

function is Active (or Inactive). If the voltage is high (4 to 24 VDC) the function is Inactive (or

Active). The function state depends on the selection the SYSTEM > SIGNALLING menu:

Menu setting Input is 0 to 2.5V: Input is 4 to 24V:

LH (low-high) Function is Active Function is Inactive

HL (high-low) Function is Inactive Function is Active

ISO 1a

0 .. 2.5 V

DC

4 .. 24 V

DC

0 .. 2.5 V

DC

4 .. 24 V

DC

0 .. 2.5 V

DC

4 .. 24 V

DC

ISO 1b

On-Air (Tally) 1a

On-Air (Tally) 1b

Call 1a

Call 1b

ISO in ext. send (pin 3)

ISO in ext. return (pin 11)

On-Air in ext. send (pin 4)

On-Air in ext. return (pin 12)

Call in ext. send (pin 5)

Call in ext. return (pin 13)

+

-

+

-

+

-

Page 23

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 23

Chapter 2 - Installation

Open circuit/Voltage level

Figure 2-10. Open circuit/Voltage level

Leave the circuit open or apply a DC voltage to the inputs (respect polarity). If the circuit is

open, the function is Active (or Inactive). If the voltage is high (4 to 24 VDC) the function is

Inactive (or Active). The function state depends on the selection the SYSTEM > SIGNALLING

menu:

Menu setting Input is open Input is 4 to 24V

OH (open-high) Function is Active Function is Inactive

HO (high-open) Function is Inactive Function is Active

ISO 1a

Open/

4..24 V

DC

Open/

4..24 V

DC

Open/

4..24 V

DC

ISO 1b

On-Air (Tally) 1a

On-Air (Tally) 1b

Call 1a

Call 1b

ISO in ext. send (pin 3)

ISO in ext. return (pin 11)

On-Air in ext. send (pin 4)

On-Air in ext. return (pin 12)

Call in ext. send (pin 5)

Call in ext. return (pin 13)

Page 24

24 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 2 - Installation

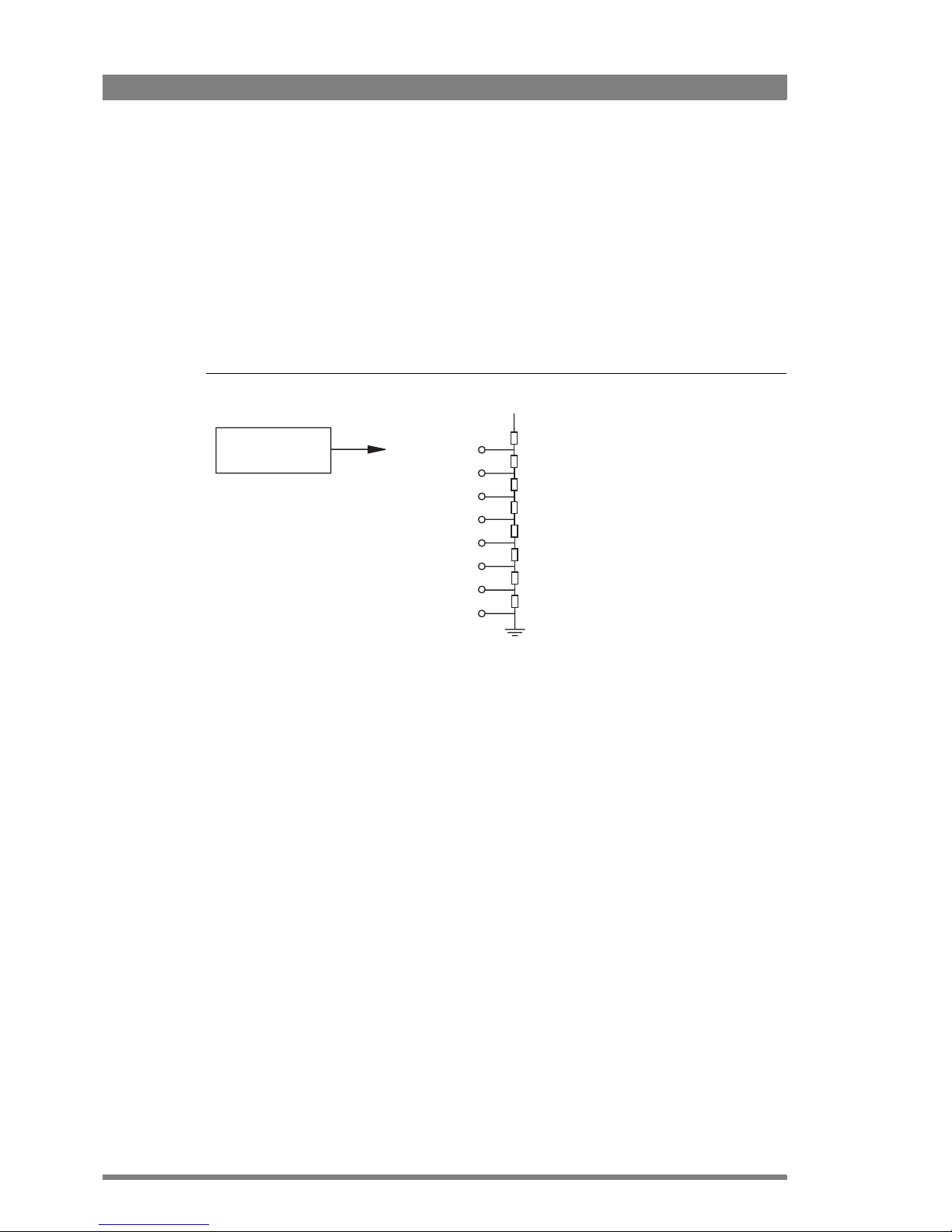

2.5 External audio level control

The camera audio level for channel 1 and 2 can be externally controlled by the base

station. In the camera menu, go to the

INSTALL > AUDIO > AUDIO GAIN MODE item and

select Ext.

On the OCP 400, push the SETUP button and choose the Cam(era) submenu. Use the

NEXT button to scroll to the

REM AUDIO menu and select Rem.

Apply a DC voltage to pins 6 and 14 of the signalling connector to control the levels of

audio channels 1 and 2 respectively, as shown in the figure below:

Figure 2-11. Audio level control

The actual audio level depends on the setting of the selection switches at the back panel of the

camera adapter. When Mic is selected, the maximum gain level is -64 dBu, while maximum

Line level is -32 dBu.

Audio 1 level (pin 6)

Audio 2 level (pin 14)

Mic/Line Mic/+5 VDC (pin 7)

GND (pin 15)

1k

1k

1k

1k

1k

1k

1k

1k

+4.3V

+3.7V

+3.1V

+2.5V

+1.9V

+1.3V

+0.7V

0V

-22/+12dBu

-28/+4dBu

-34/-2dBu

-40/-8dBu

-46/-14dBu

-52/-20dBu

-58/-26dBu

-64/-32dBU

Page 25

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 25

Chapter 2 - Installation

2.6 Auxiliary connections

2.6.1 Private data

Private data channels can be used for the transmission of serial data via the transmission

cable. For example, electronic scriptboard or character data for a video display unit or pan

and tilt data can be transmitted to the camera. The input and output signals are available

on the auxiliary connectors of the camera and Base Station.

Figure 2-12. Private data on auxiliary connector

Remember that the propagation-delay times are different for different cable lengths,

especially if a return signal is involved. At maximum lengths of 2,400 m (7,900 ft) the total

delay is at least 25 μs and can be more than 30 μs depending on the type of cable.

The duty cycle difference between input and output is max. 5%.

Function Valu e

Bitrate 100 kbits/s

Input level TTL, possible RS-232 ("0"= 0V +/- 0.5V; "1"= 5V +/- 0.5V)

Input impedance 100 kΩ

Output impedance 150 Ω

Max. load approx. 1 kΩ

5

1

9

6

Private data in

Private data out

Page 26

26 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 2 - Installation

Page 27

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 27

Chapter 3 - Setup

Chapter 3

Setup

3.1 Base Station controls and indicators

Figure 3-1. Base Station controls

Control or indicator Description

Display During normal operation the display shows the number of the camera connected

to the Base Station. When the set-up control (located behind the left front cover)

is activated, the display shows a two letter code to identify the setup function .

The display can be switched on or off via the Base Station menu system.

Intercom volume control Adjusts the volume of the selected intercom

channel being monitored on the connector below.

Only available when the

optional LDK 4541

2-channel Engineering

intercom module is installed.

Intercom selection

switch

Use this switch to select the intercom channel

that is monitored on the connector below.

Camera communication

indicator

This green LED lights when the communications between Camera and Base

Station are OK.

On=Air and ISO

indicators

The red LED lights when the Camera is On Air. If the Camera is selected as ISO

Camera the yellow LED lights.

Power switch Switches the power supply to the Base Station on and off. A built-in light lights to

indicate that the power is On.

Prod

Prog

Cam +Floor

Eng

Camera Base Station

Camera

Communication

On Air Base

Station

Camera

Connected

Test

Display

Intercom

volume

control

Intercom

selection

switch

Camera

communication

indicator

Powe r

switch

Base

Station

indicator

Camera

indicators

On Air

indicators

Page 28

28 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 3 - Setup

Refer to the chapter “Maintenance” on page 41 for more detailed information about these

indicators.

3.2 Setting up the Base Station

The Base Station is set up using either:

1. The internal Base Station menu behind the front cover of the Base Station or

2. An OCP 400 attached to the Base Station

3.2.1 Using the internal BS menu to set up the Base Station

Push the clasp at the bottom of the left front cover to the left and remove the front cover to

access the Rotary/Push button on the Data Board:

Rock the button to the left or right to select the required item. The display shows the

abbreviation of the selected item.

Base Station indicator This green LED lights when the Base Station is operationally ready.

Camera indicators These bi-colour Test LEDs lights red or yellow to indicate the camera and

transmission status.

Control or indicator Description

Prod

Prog

Cam +Floor

Eng

Camera Base Station

Camera

Communication

On Air Base

Station

Camera

Connected

Test

Left front

cover

Open

clasp

Prod

Prog

Cam +Floor

Eng

Camera Base Station

Camera

Communication

On Air Base

Station

Camera

Connected

Test

Segment

display

Rotary /

Push button

Page 29

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 29

Chapter 3 - Setup

Menu items

There are four items that can be accessed via the internal menu:

System menu

When “NN” is displayed, push the Rotary/Push button twice to enter the

System Menu. The Rotary/Push button can be used to navigate through the

menu system, however, it is more convenient to use the OCP

400 connected to the Base

Station.

☞

Note

☞

Note

When accessed from the internal menu, the Base Station user level is set to Operator.

Camera number

When “CA” is displayed, push the Rotary/Push button to enter the selection

mode. Rock the button to the left or right to select an available camera

number. Push the Rotary/Push button to set the new camera number. The Base Station

automatically resets and the new camera number is shown in the display.

Subcarrier Phase adjusment

When “SC” is displayed, push the Rotary/Push button to enter the subcarrier

adjustment mode. Rock the button to the left or right to shift the subcarrier

phase. If you continue to rock the button, the shift change occurs in bigger steps. Push the

Rotary/Push button to leave the subcarrier adjustment mode.

☞

Note

☞

Note

This item is only available when a reference signal is present.

H-Phase adjustment

When “HP” is displayed, push the Rotary/Push button to enter the H-Phase

adjustment mode. Rock the button to the left or right to shift the H-Phase. If

you continue to rock the button, the shift change occurs in bigger steps. Push the Rotary/

Push button to leave the H-Phase adjustment mode.

☞

Note

☞

Note

This item is only available when a reference signal is present.

Page 30

30 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 3 - Setup

3.2.2 Using the OCP 400 to set up the Base Station

The OCP 400 can be used to set up the base station instead of the Rotary/Push button.

1. Push the Setup Menu button on the OCP to open the menu.

2. Push the selection button to choose the BS submenu.

The BS submenu appears. Use the Next button to view subsequent pages.

Files

Exit

Toggle

Prev

Next

Recall Auto Setup

Diag OCP

BS Cam

2

1

Ta bl e 3-2. Base Station set-up menu

Menu Selections Function Level Possible values

BS MONITORING Picture monitor selection S CVBS, R,G,B, Y, EXT1, EXT2,

Y/EXT1, Y/EXT2

-

-

MENU BS internal menu enable S

Next H PHASE Adjustment H-Phase B 0..99

SC COARSE Adjustment Subcarrier phase

(coarse)

B 0, 90, 180, 270

-

SC FINE Adjustment Subcarrier phase

(coarse)

B 0..99

Next NOTCH LVL Notch Depth (composite out only) B 0..99

NOTCH Notch function (composite out

only)

B On, Off

-

-

Page 31

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 31

Chapter 3 - Setup

Select the MENU item of the BS menu to access the internal menu of the Base Station. The

internal menu appears on the Base Station Text output and CVBS output (if switched on).

* Or use the rotary contol on the OCP to move up or down through the menu.

☞

Note

☞

Note

When accessed from the OCP 400, the Base Station user level is set to Operator.

3.3 Using the Base Station system menu

The menu system is used for configuring the base station. As there are a large number of

functions and set-up options available, it may require some time for you to become

familiar with them all.

The System Menu video signal is available on the Text output of the base station. The

System Menu text can also be superimposed on the CVBS output if desired.

3.3.1 Entering the system menu

Use the Rotary/Push button behind the left front cover to control some basic set-up

functions and to navigate through the menu system. The system functions of the base

station are grouped into menus and sub-menus. Rotate the Rotary/Push button to the left

or right to select the Systems Menu. The display shows the abbreviation “NN”. Push the

Rotary/Push button twice to enter. The Main menu appears on the monitor.

Figure 3-4. Main menu

Table 3-3. Base Station internal menu

Menu Selections Function Level

BS internal menu UP* UP menu S

-

DOWN* DOWN menu S

SELECT Select item S

Video

Monitoring

Audio/Intercom

SDTV

System

Files

Diagnostics

MENU OFF

Root

Page 32

32 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 3 - Setup

The main menu screen shows five items and the name of the menu. One more item is hidden

but becomes visible when you scroll down. A cursor shows your position in the menu. The

Rotary/Push button moves the cursor up and down.

3.3.2 Finding your way

Use the Rotary/Push button to move the cursor through the menu items. If a double arrow

(>>) is visible, then pressing the Rotary/Push button brings you one level lower in the

menu system. Only five items are visible in each menu. Scroll up or down to see any

additional items.

When you first enter a menu (other than the main menu) the cursor is positioned next to the

first item. The TOP and PREVIOUS entries are not immediately visible but are located above

the first item. Use the Rotary control to scroll up to them.

• Select TOP to bring you back to the MAIN menu.

• Select PREVIOUS to go back to the menu that you were in before the current one.

Figure 3-5. System menu

The SYSTEM menu above shows the items displayed when you first enter the menu and the

other items that are available by scrolling up or down with the Rotary control.

3.3.3 Leaving the Systems Menu

If you are deep within the menu structure, follow these steps to leave:

• If necessary move the cursor to the left most column with the Rotary/Push button.

• Scroll upwards until the cursor points to TOP (this is the main menu).

• Press the Rotary/Push button. The cursor now points to the Menu off item of the MAIN

menu.

• Press the Rotary/Push button to leave the system menu.

This is the recommended way of leaving the system menu. The menu system disappears after

a few seconds when you stop navigating. This delay can be set in the MONITORING > MENU

menu. However, when you enter the system menu again you enter at the last position of the

cursor and not at the top of main menu. To prevent confusion the next time you enter the

system menu, it is advisable to leave the system menu by returning to the main menu (TOP)

and selecting MENU OFF.

Camera Number

Camera Power

MCP Available

Yellow On Air

Timing

Clock

Video Mode

Teleprompter

TOP

PREVIOUS

System

1

On

Ye s

Std

10i59

Off

Page 33

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 33

Chapter 3 - Setup

3.3.4 Making changes

To find out where to change a function, consult the List of System Menu Functions at the

end of this section to find out under which menu group or subgroup the function is

located. If the cursor points to an item (and there are no double arrows to indicate a submenu) then the item pointed to has a value. The value can be:

• a toggle value (only two values)

• a list value (more than two values)

• an analogue value (variable from 00 to 99)

• or unavailable (---).

If the value is unavailable it cannot be changed. This is indicated by three dashes (---). This can

occur, for example, when a function is switched off. The analogue values associated with that

function are then unavailable. If there are only two values associated with the function, then

pressing the Rotary/Push button toggles between these two values. If a value is displayed next

to a function that is one of several possible values, then pressing the Rotary/Push button

places the cursor in a list menu indicating the value currently selected. Use the Rotary/Push

button to point to a new value.

Press the Rotary/Push button to return the cursor to the function list. If an analogue value is

displayed next to a function name, then pressing the Rotary/Push button places the cursor in

front of the value and the Rotary/Push button is used to change the analogue value. Press the

Rotary/Push button to return the cursor to the function list.

3.3.5 Using the Recall File to undo changes

If you make changes to the settings in the Systems menu and you decide not to keep

them, use the Recall File function to recall a standard or stored set of values for the

parameters. These files are available in the FILES menu.

3.3.6 Base Station user levels

The menu items are divided into two user levels. The operator level (O) is default

accessible. Menu items with user level Install (I) are only accessible if the menu level is

set to Install. To enter the Install level proceed as follows:

1. Enter the menu.

2. Navigate to the MONITORING > MENU > MENU LEVEL item.

3. Set the Menu level to Inst.

The purpose of the user levels is to restrict the set of functions which can be changed by

whoever is using the Base Station. In this way a the danger of the operator accidentally

changing critical functions while shooting is reduced.

The chapter “Menu structure and contents” on page 49 indicates which functions are available

at each user level.

☞

Note

☞

Note

When accessed from the internal BS menu, the Base Station user level is set to Operator

while the user level is set to Install when accessed from the OCP 400.

Page 34

34 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 3 - Setup

3.3.7 Video menu - special features

Auto lighting

The Auto Lighting item of the the video menu compensates for variations in the frequency

of the power supply used for gas discharge lamps (fluorescent or HMI lighting). The

frequency of power supply generators can vary from the nominal value. This variation

affects the lighting which in turn affects the colour balance. If camera system and lighting

are supplied by the same power source, then the base station auto lighting function can

automatically adjust the exposure to follow the variations and maintain a constant colour

balance. This correction only works when the camera exposure time is set to the 50

Hz or

60

Hz position.

Gain adjustment

The Gain Adjustments item of the the video menu is a special item. It combines menu

items from various other menus to help you when you are adjusting the gain. It should

only be used when carrying out the gain adjustments on the Sync/Encoder board in

conjunction with the procedure given.

Page 35

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 35

Chapter 3 - Setup

3.4 Setting up reference and timing

3.4.1 Output signal processing

The base station can be synchronized with HD Trilevel or SD Black Burst. Both references can

be adjusted to match the SD and HD output signals. This is an overview of the base station

output signal paths:

The default settings for the base station reference signals are:

• The first reference is HD Trilevel: the HD output is in time with the HD Trilevel while the

SD output signal is delayed.

• The second reference is SD Black Burst: the SD output is in time with the SD Black Burst

while the HD output signal is advanced.

☞

Note

☞

Note

There is always a processing delay in the SD output with respect to the HD video outputs.

Camera

Base Station

processing

HD Trilevel reference or

SD Black Burst reference

Scaler

HD > SD

Progr.

delay

HD output

SD output

1080i50 ~ 845 μs

1080i59.94 ~ 766 μs

720p50 ~ 826 μs

720p59.94 ~ 751 μs

approx. 25

HD lines

Page 36

36 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 3 - Setup

3.4.2 Adjustment procedure for HD timing

Tip

✎

If HD Trilevel reference is used, the HD output is in sync with the HD Trilevel reference. A

timing offset can be set with the SYSTEM > TIMING > H PHASE COARSE and H PHASE COARSE

items of the base station menu.

HD output with Black Burst reference

The SD output is in sync with the Black Burst reference. The HD output signal is ahead in time

with respect to the Black Burst reference. The HD signal can be shifted with respect to the

Black Burst reference, until it is in time with the HD output. The delay between HD and SD

outputs remains the same after this adjustment.

1. Enter the base station menu in service mode:

MONITORING > MENU > MENU LEVEL > INST > SERVICEMODE > EXEC > YES

2. Adjust the Black Burst timing with the following items:

SYSTEM > TIMING > SHIFT > PIXEL HIGH ,PIXEL LOW ,LINES HIGH,LINES LOW

☞

Note

☞

Note

This adjustment must be done for each video mode. The last setting for each of these modes

will be memorized.

t

0

t

1

t

0

HD output with

Trilevel reference

HD output with Black

Burst reference

HD Trilevel reference

Programmable delay

1 frame

shift

H-phase range

H-phase range

SD Black Burst reference

SD output

HD > SD

processing

delay

Page 37

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 37

Chapter 3 - Setup

3.4.3 Adjustment procedure for SD timing

The SD output is delayed with respect to the HD output. The SD output can be further delayed

until both outputs are synchronous, but shifted over a single frame. The adjustment of the

delay ranges from the minimal processing time to more than 1 frame.

1. Enter the base station menu in service mode:

MONITORING > MENU > MENU LEVEL > INST > SERVICEMODE > EXEC > YES

2. After factory delivery there is a fixed minimum delay between HD and SD outputs:

SDTV > TIMING > COMP

3. Set the SDTV Timing to Variable:

SDTV > TIMING > VAR

4. Adjust the SD output delay using the following items:

SDTV > TIMING > SYNC SHIFT PIXELS and SHIFT LINES

☞

Note

☞

Note

This adjustment must be done for each video mode. The last setting for each of these modes

will be memorized.

☞

Note

☞

Note

The CVBS viewing output is a non-standard output and the SD output delay adjustment does

not apply to this output.

Tip

✎

HD-Trilevel sync does not contain 4-field (NTSC) or 8-field (PAL) sequence information and

therefore will be random. If this is required Black Burst reference should be used.

Page 38

38 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 3 - Setup

3.5 Intercom set up

The studio camera systems offer extensive intercom facilities between cameraman, tracker

(floor man), Base Station and studio. To help you set up and operate the intercom system, the

following controls are available:

• Base Station menu system

• Camera head menu system

• Base Station front panel selection switch (optional)

• Camera head adapter rear panel

• Camera head switches

When setting up a system it is usually more convenient to use an OCP 400 to select your

preferences in both the Base Station and camera head menu systems.

☞

Note

☞

Note

For a fully-featured intercom system, the Base Station must be fitted with an LDK 4540/10

2

channel audio & 2/4-wire intercom module and an LDK 4541/10 2 channel Engineering

intercom module, both of which are optionally available. If either of these modules is absent,

the associated features outlined below are not available.

3.5.1 Base Station - studio interface set-up

A four-wire or a two-wire studio system can be connected to the Base Station. In the Base

Station AUDIO > INTERCOM menu, select the Wire Mode for engineering (ENG), production

(PROD) and programming (PROG). By default these values are set to four-wire.

Isolate

The isolate function completely disconnects the Base Station intercom from the studio

system. The function can be switched locally or remotely via the OCP 400.

Levels

In the four-wire mode the menu gives you a choice of either a 0dBu or a +6dBu signal level. In

the two-wire mode this level is set to 0dBu.

• Set the input and output intercom levels for the PROD and ENG channels. The range is 00

to 99; default is 50.

• Set the input level for the PROG channel.

• Set the levels for the sidetone in a two-wire system in this menu.

Page 39

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 39

Chapter 3 - Setup

3.5.2 Base Station headset set-up

☞

Note

☞

Note

The headset facilities are only available on Base Stations fitted with the LDK 4541/10 2 channel

Engineering intercom module which is optionally available.

A headset connected to the front of the Base Station is set-up via the AUDIO > INTERCOM

menu of the Base Station using the ENG headset submenu. In this menu you can select a

12 VDC phantom supply for the headset microphone and set the microphone level to 0 dB or

+20 dB.

The cameraman microphone signal and the tracker (floor) microphone signal can be individually

switched on for the headset and the levels for each can be set. You can switch on a sidetone

from the Base Station microphone and set its level.

The Base Station microphone signal is added to the ENG channel. Use the MIC ENG-OUT

function in the menu to send it to the studio engineering channel. Use the MICTOENG-CAM

function to send it to the camera.

Operation

The signal to the headset is controlled with a switch in the front of the Base Station which

selects the intercom signal to be heard in the Base Station headset. The choices are:

• PROD (production)

• PROG (programming)

• CAM+FLOOR (cameraman and tracker)

• ENG (engineering)

If CAM+FLOOR is selected, the signal that is heard depends on the values set in the ENG

Headset submenu for the CAMERAMIC and TRACKERMIC signals in the AUDIO > INTERCOM

menu of the Base Station.

☞

Note

☞

Note

If you have selected to operate a bi-directional private data channel between the Base Station

and the camera in the

AUDIO > INTERCOM menu of the Base Station, then the tracker

microphone signal is not available in the Base Station and the Program signal is not available in

the camera.

Page 40

40 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 3 - Setup

3.5.3 Voice mail

Voice Mail is an intercom message storage function.

☞

Note

☞

Note

Voice mail is only available if the AUDIO > INTERCOM > INTERCOM > CALL item is set to voice.

Recording

Recording starts automatically at the start of a message. A new message erases the previous

recorded message. The maximum message length is 16 seconds. Longer messages are

recorded in a retroloop. Only the last 16 seconds are available for playback. Select the intercom

channels to be recorded via the Base Station menu items

AUDIO > INTERCOM > INTERCOM > VOICE MAIL > RECORD ENG, PROD and PROG.

☞

Note

☞

Note

The voice mail box can only contain one message. If voice mail recording starts from an other

intercom channel the previous message is erased.

Listening to the message

Push the camera call button to start playing out the recorded voice mail to the camera headset.

Push the call button again to stop playing the voice mail message.

Page 41

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 41

Chapter 4 - Maintenance

Chapter 4

Maintenance

4.1 Diagnostics

4.1.1 Base Station indicators

Figure 4-1. Base Station indicators

Camera communication indicator

This green LED lights when communication between camera and Base Station is OK.

On Air/ISO indicators

The red On Air LED lights when the camera is On Air. The yellow LED light when the

camera is selected as ISO camera.

Base Station indicator

This green LED lights when the Base Station is operationally ready.

Prod

Prog

Cam +Floor

Eng

Camera

Communication

On Air

Base

Station

Camera

Connected

Test

Camera

communication

indicator

On Air/ISO

indicators

Base Station

indicator

Camera

indicators

Page 42

42 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 4 - Maintenance

Camera Test indicator

This bi-colour LED lights red or yellow to indicate the Camera and transmission status:

• Red lights continuously – cable short circuit OR an interrupted cable core. On the

OCP

400, the Cable LED (red) lights continuously.

• Red flashes – Cable open circuit (no camera is connected). On the OCP 400, the Cable

LED (red) flashes.

• Yellow – Camera power was switched off from the OCP 400 or MCP 400.

Camera Connected indicator

This green LED lights when the camera is connected (and camera power is not switched off by

the OCP 400, MCP 400 or Base Station menu)

4.1.2 Fiber transmission diagnostics

First order diagnostics are available in both camera and base station menus. They are also

available on the control panels (OCP

400, MCP 400). The set of diagnostic information contains

four items (two items per direction: CAM --> BS and BS --> CAM):

• Transmission status: this indicator provides a value of the optical power level, to inform

the user whether the optical attenuation level is acceptable or not. This status indication

has four values: OK, Critical, Error, No Signal

• Optical margin level: This item indicates the guard before the connection is in error range.

The unit of this indication is dB.

The following table shows the status indications and the values that correspond with these

indications:

☞

Note

☞

Note

The power/margin indicator is refreshed every one or two seconds. However, a full signal loss

will be shown directly.

Communication

indicator

Camera Test

indicator

Cam Connected

indicator

Remark

off off green Camera power is switched off by the

camera power switch.

off yellow off Camera power is switched off by the

OCP 400, MCP 400 or BS menu.

Status Power (mW) Power (dBm) Margin (dBm) Description

OK > 0.040 > -14 18 Fiber transmission is ok

Critical 0.015 .. 0.040 -18 .. -14 18 Signal level is critical but the system

will work.

Error 0.005 .. 0.015 -14 .. -23 18 Signal level is not OK: a working

system is not guaranteed.

No signal < 0.005 < -23 18 No signal received.

Page 43

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 43

Chapter 4 - Maintenance

4.1.3 Sync/Encoder HD board diagnostics

The LED indicators on the Sync/Encoder board show the status of the board and the signal

locking as follows:

Figure 4-2. Sync/Encoder HD board

Indicator Description

Init. Fail Lights (red) when a configuration or initialisation error occurs or when the bus

clock or video synchronization pulses are missing.

Sync Lock Lights (green) when horizontal and vertical lock are OK.

Ext. Ref. Avail. Lights (green) when an external synchronization signal is present.

Burst Lock Lights (green) when the subcarrier/H-phase lock is OK.

Init. Fail

Sync Lock

Ext. Ref. Avail.

Burst Lock

Page 44

44 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 4 - Maintenance

4.2 Replacements

4.2.1 Board locations

Figure 4-3. Base Station board locations

4.2.2 Replacing the power unit

Removing the power unit

• Loosen the screw at the rear of the power unit.

• With your thumb push up the lever, as shown below, and pull the power unit out of the

Base Station.

Figure 4-4. Removing the power unit

Camera Base Station

fiber power

Prod

Prog

Cam +Floor

Eng

Camera

Communication

On Air

Base

Station

Camera

Connected

Test

Digital output

board

Data

board

Sync encoder

board

Transmission

board

HQ SD

board (option)

Power module

fiber

Engineering intercom

module (option)

Audio intercom

board

Camera Base Station

Camera

Communication

On Air

Base

Station

Camera

Connected

Test

Page 45

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 45

Chapter 4 - Maintenance

Installing the Power Unit

• Put the power unit into the guides and push until the lock clicks.

• Check that the power unit is correctly locked.

• Tighten the screw at the rear of the Power Unit.

WARNING

Make sure that the power unit is firmly placed and that the locking lever is in the correct

vertical position as indicated below.

Figure 4-5. Locking the power unit

Camera Base Station

Camera

Communication

On Air

Base

Station

Camera

Connected

Test

Wrong

Correct

Page 46

46 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 4 - Maintenance

4.2.3 Replacing dust filters

Side-inlet

1. Remove 4 screws.

2. Slide back support with dust filter out of base station.

3. Remove dust filter.

4. Place clean dust filter in back support.

5. Slide back support with dust filter into base station.

6. Fix support with 4 screws.

Figure 4-6. Replacing side dust filters

Page 47

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 47

Chapter 4 - Maintenance

Front-inlet

1. Remove PCB front cover.

2. Remove dust filter.

3. Place clean dust filter.

4. Put back PCB front cover.

5. Remove front cover Power Unit.

6. Remove dust filter.

7. Place clean dust filter.

8. Return front cover Power Unit to its position.

Figure 4-7. Replacing front dust filters

PCB front cover

Powe r Unit cover

Page 48

48 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 4 - Maintenance

Page 49

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 49

Chapter 5 - Menu structure and contents

Chapter 5

Menu structure and contents

5.1 Menu structure

The structure of the main menus and their submenus are shown on the following pages.

The first column shows the user level: Install (“I”) or Operator (“O”). You only see menu

functions whose user level is equal to or less than the user level set on your unit. Where

appropriate, the default value of the function in the standard factory file is shown after the

function.

5.1.1 Top menu structure

Video menu - contains those functions which affect the picture quality.

Monitoring menu - contains the functions which determine how items in the video

monitor are displayed.

Audio/Intercom - contains those functions which control various aspects of audio and

intercom.

SDTV menu - settings related to the SDTV outputs of the Base Station.

System menu - contains functions that are used to set up the general configuration and

for carrying out adjustments and calibrations of the Base Station.

Files menu - this menu allows values to be stored in system and operator files, and

allows these files to be recalled as required.

Diagnostics menu - is designed to provide information on the current status of the Base

Station.

Video menu >>

Monitoring menu >>

Audio/Intercom >>

SDTV menu >>

System menu >>

Files menu >>

Diagnostics menu >>

Page 50

50 LDK 4582 HD Fiber Base Station User’s Guide (v1.0)

Chapter 5 - Menu structure and contents

5.1.2 Video menu structure

5.1.3 Monitoring menu structure

Colour Bar >> O Colour Bar Off

I Ext Black Clamp 50 I Colour Bar Type SMP

O Combine Field

O Monitoring Source Y

O Menu >> O Display Time

O Status bar >> O Menu Time 10

O Menu Level Oper.

O Service Mode -

O Studio >> O Studio Off

O Operator >> O Name -

O Camrea number Off

O Cable length Off O Operator Off

O HD out text >> O Name -

O Warning Y-pos 14

O CamName Y-pos 1

Page 51

LDK 4582 HD Fiber Base Station User’s Guide (v1.0) 51

Chapter 5 - Menu structure and contents

5.1.4 Audio/Intercom menu structure

- Cam Routing -

- Tracker Routing -

O Source Local

I Isolate Syst

I Wire Mode 4wire

O Side Tone 50

I Audio Level 1 6dB O Level 6dB

I Audio Level 2 6dB I In Ref Level 50

I Out Ref Level 50

I Audio >> Te st >>

O Intercom >> Isolate >> I Wire Mode 4wire

Eng >> O Side Tone 50

Prod >> O Level 6dB

Prog >> I In Ref Level 50

Eng Headset >> I Out Ref Level 50

Call Call