Page 1

User’s Guide

3922 496 30691 August 2009 v5.0

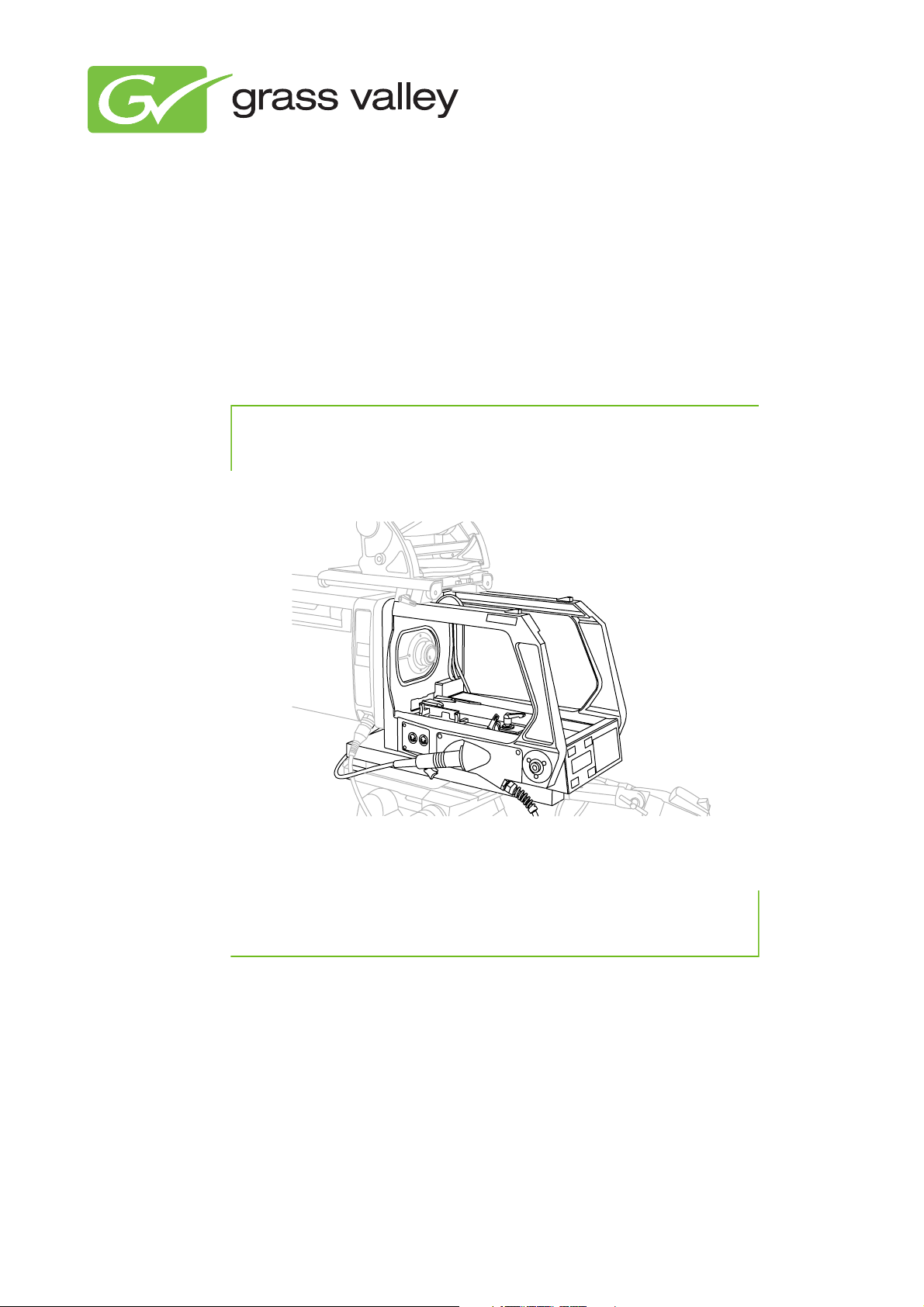

LDK 4488, LDK 4489

SuperXpander, Xpander

Page 2

Declaration of Conformity

FCC Class A Statement

We, Grass Valley Nederland B.V., Kapittelweg 10, 4827 HG Breda, The

Netherlands, declare under our sole responsibility that this product is in

compliance with the following standards:

- EN60065 : Safety

- EN55103-1: EMC (Emission)

- EN55103-2: EMC (Immunity)

following the provisions of:

a. the Low Voltage directive 2006/95/EC

b. the EMC directive 2004/108/EC

This product generates, uses, and can radiate radio frequency energy and if

not installed and used in accordance with the instructions, may cause

interference to radio communications.

It has been tested and found to comply with the limits for a class A digital

device pursuant to part 15 of the FCC rules, which are designed to provide

reasonable protection against such interference when operated in a

commercial environment.

Copyright

Trademarks

Website

Operation of this product in a residential area is likely to cause interference in

which case the user at his own expense will be required to take whatever

measures may be required to correct the interference.

Copyright Grass Valley Nederland B.V. 2009. Copying of this document and

giving it to others, and the use or communication of the contents thereof, are

forbidden without express authority. Offenders are liable to the payment of

damages. All rights are reserved in the event of the grant of a patent or the

registration of a utility model or design. Liable to technical alterations in the

course of further development.

Grass Valley and Infinity are trademarks of Grass Valley, Inc. All other

tradenames referenced are service marks, trademarks, or registered

trademarks of their respective companies.

Visit the Grass Valley public website to download the latest user’s guide

updates and additional information about your broadcast product:

www.grassvalley.com

Page 3

Table of contents

Chapter 1 – Introduction

1.1 System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.3 Options and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2 – Installation

2.1 Minimum camera requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Mounting the viewfinder support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.3 Exchanging the transmission module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Chapter 3 – Assembly

3.1 Assembly order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Tripod mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Mounting a lens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4 Mounting a camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.5 Transport position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6 Camera balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.7 Cable clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.8 Mounting a scriptboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 4 – Control panel

4.1 Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.2 LCD display panel controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.2.1 LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.2.2 Menu buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.2.3 Prev/Next buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.2.4 Item selectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.2.5 Plus/minus buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2.6 Menu function lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Panel controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.3.1 Camera menu buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.3.2 Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.3.3 Viewfinder control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.3.4 Intercom control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.3.5 Call switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Chapter 5 – Power

5.1 Switching on power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Remote power mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3 Local power mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.4 Utility power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 3

Page 4

Chapter 6 – Connectors

6.1 Left side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.1.1 Fixed utility power output (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.1.2 Variable utility power output (option, SuperXpander only). . . . . . . . . . . . . . . . .40

6.1.3 Lens interface connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.2 Right side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.2.1 Mains power supply input socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.2.2 Script light connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.2.3 Viewfinder component outputs (3x). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.2.4 External CVBS output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.2.5 Camera viewfinder connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.2.6 Top viewfinder connector (part of optional viewfinder support) . . . . . . . . . . . .43

Chapter 7 – Specifications

7.1 Specifications for LDK 4488, LDK 4489 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.2 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 5

End-of-life product recycling

Grass Valley’s innovation and excellence in product design also extends to the programs

we’ve established to manage the recycling of our products. Grass Valley has developed a

comprehensive end-of-life product take back program for recycle or disposal of end-of-life

products. Our program meets the requirements of the European Union’s WEEE Directive and

in the United States from the Environmental Protection Agency, individual state or local

agencies.

Grass Valley’s end-of-life product take back program assures proper disposal by use of Best

Available Technology. This program accepts any Grass Valley branded equipment. Upon

request, a Certificate of Recycling or a Certificate of Destruction, depending on the ultimate

disposition of the product, can be sent to the requester.

Grass Valley will be responsible for all costs associated with recycling and disposal, including

freight, however you are responsible for the removal of the equipment from your facility and

packing the equipment ready for pickup.

For further information on the Grass Valley product take back system please contact Grass

Valley at + 800 80 80 20 20 or +33 1 48 25 20 20 from most other countries. In the US and

Canada please call 800-547-8949 or 530-478-4148. Ask to be connected to the EH&S

Department. In addition, information concerning the program can be found at:

www.thomsongrassvalley.com/environment

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 5

Page 6

Important information

Read this information carefully before installing this equipment and retain them for future

reference. Read and comply with the warning and caution notices that appear in the manual.

Any changes or modifications not expressly approved in this manual could void your authority

to operate this equipment.

Safety Summary

This informaton is intended as a guide for trained and qualified personnel who are aware of the

dangers involved in handling potentially hazardous electrical/electronic equipment. It is not

intended to contain a complete list of all safety precautions which should be observed by

personnel in using this or other electronic equipment.

The installation of this equipment involves risks both to personnel and equipment and must be

performed only by qualified personnel exercising due care.

During installation and operation of this equipment, local building safety and fire protection

standards must be observed.

Before connecting the equipment to the power supply of the installation, the proper

functioning of the protective earth lead of the installation needs to be verified.

Whenever it is likely that safe operation is impaired, the apparatus must be made inoperative

and secured against any unintended operation. The appropriate servicing authority must then

be informed. For example, safety is likely to be impaired if the apparatus fails to perform the

intended function or shows visible damage.

Warnings

Warnings indicate danger that requires correct procedures or practices to prevent death or

injury to personnel.

• Do not modify this equipment;

• Installation of this equipment must only be performed by qualified personnel;

• Only mount the unit on a tripod or pedestal and head that can carry a payload of more than

50 kg;

• Grass Valley clearly states that it is unacceptable with respect to safety to use Triax cables

(for the interconnection between Base Station and the SuperXpander/Xpander) with

knowingly a short circuit between the inner and outer shield. Also the use of coax cables

or the use of patch panels with a short circuit between the inner and outer shield is

prohibited;

• Do not use any accessories other than those recommended by the manufacturer;

• In case of an emergency ensure that the power is disconnected;

• Mount equipment so that power lead can be accessed to disconnect power;

• Any interruption of the protection conductor inside or outside the apparatus, or

disconnection of the protective earth terminal, is likely to make the apparatus dangerous.

Intentional interruption is prohibited;

• Use only fuses of the type and rating specified;

• To prevent fire or shock hazard, do not expose the unit to rain or moisture.

6 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 7

Cautions

• There are no user servicable parts inside. Refer servicing to qualified personnel only or

contact your local Grass Valley representative;

• Observe local building safety, fire protection and electrical installation standards during

installation and operation of this equipment;

• Before connecting the equipment to the power supply of the installation, verify the proper

functioning of the protective earth lead;

• Whenever it is likely that safe operation is impaired, the apparatus must be made

inoperative and secured against any unintended operation.

Cautions indicate procedures or practices that should be followed to prevent damage or

destruction to equipment or property.

• Do not subject the unit to severe shocks or vibration;

• Do not expose the unit to extremes of temperature;

• To prevent risk of overheating, ventilate the product correctly;

• Connect the product only to a power source with the specified voltage rating.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 7

Page 8

Wichtige Hinweise

Lesen Sie bitte diese Hinweise genau bevor Sie diese Apparatur installieren und erhalten Sie Sie für

künftiges Nachslagen. Beachten und Lesen Sie alle mit “Achtung” und “Vorsicht”

gekennzeichneten Warnhinweise.

Änderungen haben zur Folge, dass die Garantie ungültig wird und der Benutzer für etwaige

durch die veränderte Ausrüstung verursachte Störungen haftbar gemacht werden könnte.

Sicherheit (Zusammenfassung)

Diese Informationen sind als Leitfaden für qualifiziertes Fachpersonal gedacht, das die

Gefahren beim Umgang mit potenziell gefährlicher elektrischer/elektronischer Ausrüstung

kennt. Es handelt sich dabei nicht um eine vollständige Zusammenstellung aller

Sicherheitsvorkehrungen, die beim Gebrauch dieser oder anderer elektronischer Geräte zu

beachten sind.

Die Montage, Wartung und Instandsetzung dieser Ausrüstung ist mit Risiken für Personal und

Ausrüstung verbunden und darf nur von qualifiziertem Personal vorgenommen werden, wobei

mit der nötigen Sorgfalt vorzugehen ist.

Beim Einbau und Betrieb dieser Ausrüstung müssen die örtlichen Gebäudesicherheits- und

Brandschutzvorschriften beachtet werden. Vor dem Anschluss der Ausrüstung an die

Stromversorgung der Anlage muss überprüft werden, ob der Schutzleiter intakt ist.

Wenn eine Beeinträchtigung des sicheren Betriebs wahrscheinlich ist, muss das Gerät außer

Betrieb gesetzt und gegen ungewollten Betrieb gesichert werden. Dann muss der zuständige

Kundendienst benachrichtigt werden. Eine Beeinträchtigung der Sicherheit ist zum Beispiel

dann wahrscheinlich, wenn das Gerät nicht wie vorgesehen funktioniert oder einen sichtbaren

Schaden aufweist.

Vorsicht

Mit “Vorsicht” wird auf eine Gefahr hingewiesen, die korrekte Arbeits- oder

Verfahrensweisen erfordert, um Tod oder Verletzung zu verhindern.

• An dieser Ausrüstung dürfen keine Änderungen vorgenommen werden;

• Die Montage dieser Ausrüstung darf nur von Fachpersonal vorgenommen werden;

• Diese Ausrüstung soll nur auf einem Stativ oder Sokkel und einem Kopf aufgestellt

werden die eine Last von mehr als 50 kg trägen kann;

• Grass Valley erklärt daß es im Zusammenhang mit der Sicherheit nicht gestattet ist

Triaxkabel zu verwenden (für die Verbindung zwischen Base Station und SuperXpander/

Xpander) die wissentlich ein Kurzschluß zwischen der innere und aussere Abschirmung

haben. Auch die Verwendung von Koaxialkabel oder Rangierfeldern mit einem Kurzschluß

zwischen der innere und aussere Abschirmung is nicht gestattet.

• Es sollen nur von den Hersteller empfohlene Zubehöre verwendet werden;

• Bei Eintreten eines Notfalls unbedingt die Stromzufuhr abschalten;

• Ausrüstung so montieren, daß das Netzkabel zum Abschalten der Stromzufuhr zugänglich

ist;

• Jede Unterbrechung des Schutzleiters innerhalb oder ausserhalb des Geräts oder

Trennung der Schutzleiter-anschlussklemme Könnte das Gerät fefährlich machen. Eine

absichtliche Unterbrechung ist untersagt;

8 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 9

Achtung

• Es dürfen nur Sicherungen des vorgeschriebenen Typs und Nennwerts verwendet

werden;

• Um Feuer oder Schlaggefahr vorzubeugen, soll das Produkt nie an Regen oder Feucht

ausgesetzt werden.

• Dieses Produkt enthält keine Anwenderteile. Reparatur und Wartung nur von

qualifiziertem Fachpersonal vornehmen lassen oder nehmen Sie Kontakt auf mit Ihrem

Grass Valley Vertretene;

• Beim Einbau und Betrieb dieser Ausrüstung müssen die örtlichen Gebäudesicherheitsund Brandschutzvorschriften beachtet werden;

• Vor dem Anschluss der Ausrüstung an die Stromversorgung der Anlage muss überprüft

werden, ob der Schutzleiter intakt ist;

• Wenn eine Beeinträchtigung des sicheren Betriebs wahrscheinlich ist, muss das Gerät

außer Betrieb gesetzt und gegen ungewollten Betrieb gesichert werden.

Mit “Achtung” werden Arbeitsanweisungen gekennzeichnet, die zu befolgen sind, um eine

Beschädigung oder Zerstörung der Ausrüstung bzw. von Eigentum zu verhindern.

• Dieses Produkt darf nicht an extremen stöße oder Zittern ausgesetzt werden;

• Dieses Produkt darf nicht an extremen Temperaturen ausgesetzt werden;

• Um einer Überhitzungsgefahr vorzubeugen, ist das Produkt korrekt zu belüften;

• Das Produkt darf nur an eine Stromquelle mit der vorgeschriebenen Nennspannung

angeschlossen werden.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 9

Page 10

Installation notices

For proper installation the following NEC articles should be noticed:

– Installation of equipment (NEC article 800.18);

– Avoid contact with conductors of other systems (NEC article 810.13);

– Provide extensive, separate clearance requirements for indoor and outdoor locations

(NEC article 810.18).

Tripod installation

The typical configuration for this device (SuperXpander with Triax cables and 7-inch viewfinder

mounted) has proved to be stable when used on a tripod with the following specifications:

weight 24 kg, height 120 cm, leg distance (at floor level) of 135 cm.

Note that these values are recommendations only. Always check the mechanical stability of

the device before using it.

Mains power supply chord

A mains power supply chord is not shipped with the device. To connect the device to the

mains the following power supply cord is advised: type H03 VV-F or H03 VVH2-F flexible wire:

1 mm², 250V / 10A minimum or 16 AWG.

When the device is installed in one of the following countries the power chord must be

compliant to the indicated specifications and regulations below.

Denmark

Supply cord of single-phase equipment having a rated current not exceeding 10A shall be

provided with a plug according to the Heavy Current Regulations section 107-2-D1. Class I

equipment provided with socket-outlets with earth contact or which are intended to be used in

locations where protection against indirect contact is required according to the wiring rules

shall be provided with a plug in accordance with standard sheet DK 2-1a or DK 2-5a.

Ireland

Apparatus which is fitted with a flexible cable or cord and is designed to be connected to a

mains socket conforming to I.S. 411 by means of that flexible cable or cord and plug, shall be

fitted with a 13A plug in accordance with Statutory Instrument 525:1997 - National Standards

Authority of Ireland (section 28) (13A plugs and Conversion Adaptors for Domestic Use)

Regulations, 1997.

Spain

Supply cords of single-phase equipment having a rated current not exceeding:

– 10A shall be provided with a plug according to UNE 20315:1994

CLASS I EQUIPMENT provided with socket-outlets with earth contacts, or which are intended

to be used in locations where protection against indirect contact is required according to the

wiring rules, shall be provided with a plug in accordance with UNE 20315:1994

10 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 11

Switzerland

Supply cords of equipment having a rated current not exceeding 10A shall be provided vwith a

plug complying with SEV 1011 or IEC 884-1 and the following dimension sheet:

– SEV 6534-2.1991 Plug Type 12: L+N+PE250V 10A

UK

Apparatus which is fitted with a flexible cable or a cord and is designed to be connected to a

mains socket conforming to BS 1363 by means of that flexible cable or cord and plug, shall be

fitted with a "standard plug" in accordance with Statutory Instrument 1786: 1994 - The Plugs

and Sockets etc. (Safety) Regulations 1994, unless exempted by those regulations.

Note: "Standard plug" is defined in SI 1786:1994 and essentially means an approved plug

conforming to BS 1363 or an approved conversion plug.

US

Listed, detachable, maximum 4.5 m (14.76 ft.) long; rated minimum 125V, 10A, type SJT or

type SVT flexible cord; one end terminates in NEMA 5-15P or 5-20P groundingtype attachment

plug, other end in appliance coupler.

– Listed, detachable, maximum 4.5 m (14.76 ft.) long; rated minimum 250V, 10A, type

SJT or type SVT flexible cord; one end terminates in NEMA 6-15P or NEMA 6-20P

grounding-type attachment plug, other end in appliance coupler.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 11

Page 12

Fiber-optic transmission units

CLASS 1

LASER PRODUCT

LASER KLASSE 1

PRODUKT

Laser safety statement (Europe)

Fiber-optic transmission units are classified as a "CLASS 1 Laser Product" according to

60825-1, Safety of Laser products. Class 1 laser products are considered safe and do not

EN

result in biological hazard if used according to the instructions.

Laser safety statement (US)

Fiber-optic transmission units are classified as a "CLASS 1 Laser Product" according to

1040.10 of the US Food and Drug Administration (FDA) Center for Devices and

21CFR

Radiological Health.

WARNING

Use of controls, adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

To ensure proper use of this product, please read this user’s guidel carefully and retain it for

future reference. Should the unit ever require maintenance, contact an authorized service

location.

Fiber-optic cable precautions

Fiber-optic cables and connectors are easily damaged; take the following precautions into

account:

– Do not bend the cable beyond the minimum permissible bend range specified for the

cable.

– Avoid kinks in the cable.

– Avoid subjecting the cable to a high tension force (even momentarily).

– Do not twist the cable when connecting it to equipment.

– Insert connectors straight and fully into their corresponding sockets.

– In fiber-optic cable systems always put the dust caps on cable and panel connectors

immediately after disconnecting a cable. Keep the dust caps clean.

Note

☞

This Class 1 Laser Product may only be used with other Class 1 classified products such as the

Grass Valley fiber base stations or LDK cameras equipped with Fiber adapters.

12 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 13

Cleaning fiber-optic connectors

WARNING

Always switch off power before cleaning the connectors.

WARNING

Never clean an optical connector attached to a fiber that is carrying light.

Particles of foreign matter on the tip of a ferrule can have a disabling effect on fiber-optic

transmission. Fiber-optic connectors need to be cleaned every time they are mated and

unmated; it is essential that fiber-optic users develop the necessary discipline to always clean

the connectors before they are mated.

Use a commerially available cleaning kit specifically designed for fiber-optic connectors and

follow the manufacturer's instructions carefully.

• The connector sections to be cleaned include the tips and sides of ferrules, the interior

walls of alignment sleeves, and the interior and exterior of connector shells.

• For plugs, the interior surfaces of alignment sleeves and the tips of ferrules are to be

cleaned with a cleaning stick treated with the appropriate fluid. (Cleaning sticks with a

slender design are available that allow alignment sleeves to be cleaned without having to

detach them.)

• For jacks, it is important to clean both the tips and sides of the completely protruding

ferrules.

• Both the male and female connector shells tend to attract dust and metal particles, so it is

important to clean both the insides and outsides.

• The fiber end face and ferrule must be absolutely clean before it is inserted into a

transmitter or receiver.

• Mate the connector immediately! Don't let the connector lie around and collect dust

before mating.

• Air can be used to remove lint or loose dust from the port of a transmitter or receiver to be

mated with the connector. Never insert any liquid into the ports.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 13

Page 14

14 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 15

Chapter 1

Introduction

1.1 System overview

Grass Valley™ products from Thomson offer production professionals the most

comprehensive multi-format solutions for acquisition, production, storage, and playback, and a

strong foundation for centralized, proactive status and activity monitoring.

The Grass Valley SuperXpander/Xpander is such a solution. Compatible with most LDK

camera* families, it supports box-type lenses, teleprompters and high-resolution viewfinders.

For sports and events coverage the use of large zoom lenses is a common requirement. The

SuperXpander/Xpander acts as a large lens adapter, rapidly converting a portable Triax or fiber

camera into a mobile production system. The modular transmission unit allows you to change

from Triax to fiber configurations, even in the field.

To make life even easier, your camera can remain mounted in the SuperXpander/Xpander

housing for transport, saving rigging time and precious space, and ensuring that the camera is

aligned and ready to go immediately. Alternatively, you can mount or release the camera from

the housing quickly so you can switch between pedestal, box lens, and handheld applications

working with an EFP-style lens – even during a live program.

For fast-moving sports and entertainment television, camera operators demand a large, bright,

high-resolution viewfinder. The SuperXpander/Xpander system incorporates a new 7"

monochrome viewfinder providing unprecedented degrees of freedom. The unique design of

the SuperXpander/Xpander system puts even a large viewfinder close to the optical axis of the

camera, making camera movements and positioning more intuitive for the operator to ensure

that the shot is right every time.

Secure connectors for intercom, prompt feed and other accessories are located on the base.

The SuperXpander/Xpander also provides secure mounting and balancing for the largest

prompt head.

*) Refer to the minimum camera requirements in the installation chapter.

Chapter 1 - Introduction

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 15

Page 16

Chapter 1 - Introduction

1.2 Versions

Two versions of the SuperXpander/Xpander are available:

• The LDK 4489 Xpander supports box-type lenses and features mounting capability for a

Grass Valley 7-inch viewfinder.

• The LDK 4488 SuperXpander has all Xpander functionality but it also features a control

panel at its rear, putting operational adjustments under the hand of the operator.

1.3 Options and accessories

Triax transmission modules

with Fischer connector LDK 4487/01

with ARD connector LDK 4487/06

with Lemo (4E) connector LDK 4487/11

with Lemo (3T) connector LDK 4487/16

with Lemo (BBC) connector LDK 4487/41

with Tri-Lock connector LDK 4487/51

Fiber transmission modules

with Lemo connector LDK 4487/61

with Stratos connector LDK 4487/71

with SM connector LDK 4487/81

with Fischer connector LDK 4487/91

Power and control units

Utility power unit LDK 4486

Control panel (option for the LDK 4489 Xpander) LDK 4484

Other

Transport case for SXP LDK 6986/01

Scriptboard with top light LDK 6985/01

16 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 17

Chapter 2

Installation

2.1 Minimum camera requirements

Before installing the SuperXpander/Xpander, check the camera model compatibility and

minimum software status as indicated in the table below.:

Chapter 2 - Installation

Supported camera type(s) Required software status

LDK 100, 200, 300, 400, 500 (SD) cameras Status 16 or higher

LDK 4000 camera Status 3 or higher

LDK 5000 HD-prepared camera Status 9 or higher

LDK 6000 HD camera Status 28 or higher

LDK 6200 HD high speed camera Status 6 or higher

LDK 8000 HD camera Status 2 or higher

LDK 8300 HD high speed camera no minimal status

LDK 4000 Elite HD camera no minimal status

LDK 8000 Elite HD camera no minimal status

Note

☞

If the software of your camera needs to be updated to meet the requirements, please contact

your local Grassvalley representative.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 17

Page 18

Chapter 2 - Installation

2.2 Mounting the viewfinder support

To mount the LDK 4020, LDK 4021 or LDK 4025 viewfinder on top of the SuperXpander/

Xpander you need to install the viewfinder support that was supplied with the viewfinder.

viewfinder

support

support (right

side)

Torx screws

viewfinder

socket

Mounting procedure

1. Remove the camera if it is already mounted.

2. Place the viewfinder support on top of the SuperXpander/Xpander and align the pins in the

left and right supports with the holes in the SuperXpander.

3. Make sure that the support is aligned properly.

4. Using the four Torx screws supplied, secure the viewfinder support to the SuperXpander/

Xpander (reach inside the unit and secure from underneath).

5. Attach the viewfinder support connector to the socket at the right front side.

6. Use the two internal cable clamps to guide the cable along the inside of the

SuperXpander/Xpander.

18 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 19

2.3 Exchanging the transmission module

The SuperXpander/Xpander is supplied with either a Triax or a Fiber transmission module,

depending on the base station and camera connector type you are using. You can exchange

the transmission module easily to use the SuperXpander/Xpander with a different transmission

system or connector type. To exchange the transmission module proceed as follows:

Caution

Make sure that power is switched off and both the mains power lead and the Triax or Fiber

cable are disconnected from the SuperXpander/Xpander.

1. At the left side of the SuperXpander/Xpander locate the currently installed transmission

module.

2. Unplug the flying lead from the camera adapter side.

3. Unscrew the four captive screws of the transmission module using a Torx-10 screwdriver.

Chapter 2 - Installation

SuperXpander/

Xpander

flying lead

transmission module

4. Pull the transmission module out of its bay. Note that the flying lead is attached to the

module. Store the module at a safe place. The module can also be stored in the optional

LDK

6986/01 Transport case.

5. Insert the new transmission module into the empty bay and slide it in until the front of the

module is aligned with the outside of the SuperXpander/Xpander.

6. Secure the transmission module using the four captive screws.

7. Plug the flying lead into the camera adapter.

Note

☞

Local power mode is not fully supported when using the SuperXpander/Xpander in a Fiber

configuration. Refer to the chapter “Power” on page 35.

4x captive screws

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 19

Page 20

Chapter 2 - Installation

20 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 21

Chapter 3

Assembly

3.1 Assembly order

7-inch viewfinder

Chapter 3 - Assembly

camera

studio

lens

tripod head

It is important that you assemble and disassemble the units in the right order. The correct

order of assembly is as follows:

1. Attach the SuperXpander/Xpander to the tripod.

2. Mount the lens onto the SuperXpander/Xpander.

3. Attach the camera to the SuperXpander/Xpander.

4. Mount the viewfinder onto the viewfinder support of the SuperXpander/Xpander

balance knob

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 21

Page 22

Chapter 3 - Assembly

3.2 Tripod mounting

Caution

Only mount the unit on a tripod or pedestal and head that can carry a load of more than 50 kg.

To mount the SuperXpander/Xpander on a tripod, first attach the tripod wedge plate to the

underside of the SuperXpander/Xpander as follows:

1. Lay the SuperXpander/Xpander on its side.

2. Fasten the balance knob tightly.

3. Ensure that the flat side of the tripod wedge plate is against the underside of the

SuperXpander/Xpander.

4. Secure the tripod wedge plate to the SuperXpander/Xpander by screwing four M6 x 16

screws into the holes provided.

5. Slide the SuperXpander/Xpander onto the tripod and lock in place with the tripod locking

bar and security pin.

22 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 23

3.3 Mounting a lens

SIDE VIEW

viewfinder support

retaining lever

Chapter 3 - Assembly

viewfinder support bracket

lens locking

handle

support rail slot

FRONT VIEW

balance knob

lens support rail

To mount the lens onto the SuperXpander/Xpander, proceed as follows:

1. Slide the viewfinder support back towards the rear of the SuperXpander/Xpander.

2. When the camera is mounted (in transport position) remove the lens cap before

proceeding.

3. Hook the lens onto the support rail ensuring that the upper lens pin fits into the slot in the

support rail.

4. Swing the lens downwards so that the lower lens pin fits into the hole in the front of the

SuperXpander/Xpander.

5. Turn the lens locking handle clockwise to secure the lens in place.

6. If a zoom control is used, attach the zoom control cable to the lens.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 23

Page 24

Chapter 3 - Assembly

3.4 Mounting a camera

To mount the camera into the SuperXpander/Xpander follow these instructions:

1. Make sure that the SuperXpander/Xpander is mounted firmly on the tripod.

2. Make sure that the Quick Mount plate inside the SuperXpander/Xpander is in the back

postion and that lever B is completely pulled out.

3. Slide the viewfinder support towards the front of the SuperXpander/Xpander.

4. Hold the camera at a slight angle and place the front onto the Quick Mount plate behind

the rear stud.

5. Level the camera and slide it forward slightly to rest on the Quick Mount plate.

6. Connect the lens cable from the SuperXpander/Xpander to the lens connector at the side

of the camera.

7. Connect the viewfinder cable from the SuperXpander/Xpander to the viewfinder

connector at the side of the camera.

24 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 25

Chapter 3 - Assembly

8. Push the camera all the way forward along the wedge-shaped groove until the rear stud

engages the rear of the camera. When he camera is correctly locked into position lever A

springs out.

wedge-shaped groove

Quick Mount plate

rear stud

9. Adjust the position of the camera with levers C and D so that the bayonet ring engages

the lens.

hole

LENS FIXING TOOL

10. Use the supplied lens fixing tool to turn the bayonet ring lever on the front of the camera

downwards so that the camera is connected to the lens. The adjustment pin on the

bayonet ring fits into the hole of the fixing tool.

11. Tighten the levers C and D to secure the camera.

12. Plug the flying Triax lead from the left side panel of the SuperXpander/Xpander into the

rear of the camera.

13. Connect the Triax cable from the Triaxbase station to the connector on the left side of the

SuperXpander/Xpander.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 25

Page 26

Chapter 3 - Assembly

3.5 Transport position

The SuperXpander/Xpander can be transported in a safe way without the need to remove the

camera and the viewfinder. To bring the unit into transport position proceed as follows:

1. Remove the mains power lead (if used) and the Triax or fiber cable from the

SuperXpander/Xpander. Remove any plugs from the utility power and a script board if

used.

2. If a zoom control is used, remove the zoom control cable from the lens and the zoom

control handle.

3. Turn the bayonet ring lever on the front of the camera upwards to disconnect the lens

from the camera.

4. Remove the lens as described in the section “Mounting a lens” on page 23.

5. Release lever D to loosen the camera and press lever A to release it.

6. Gently pull back the camera until lever B is pushed out and the camera is locked.

7. Tighten lever D to secure the camera. Leave lever C in the current position.

8. Slide the viewfinder support all the way back and rotate the viewfinder 180 degrees to the

left. Lift and tilt the viewfinder until it is in the lowest horizontal position and fix this

position with the proper handles.

9. The SuperXpander/Xpander is now ready for safe transportation.

3.6 Camera balance

When the lens and camera are mounted on the SuperXpander/Xpander it may be

necessary to balance the SuperXpander/Xpander on the tripod as follows:

1. Loosen the balance knob on the side of the footbed by turning it counterclockwise.

2. Move the footbed back and forth along the tripod until the best balance is achieved.

3. Ensure that the ribs mesh correctly. The red ring on the balance knob should be barely

visible.

4. Tighten the balance knob on the side of the footbed by turning it clockwise.

26 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 27

3.7 Cable clamp

When the lens and camera are mounted on the SuperXpander/Xpander it is necessary to

clamp the camera Triax or fiber cable. Proceed as follows:

1. Loosen the cable clamp on the right side of the footbed by turning it counterclockwise.

2. Put the cable into the clamp.

3. Tighten the cable clamp by turning it clockwise.

4. When connected to the camera, run the flying lead through the bottom clamp at the rear

of the SuperXpander/Xpander to keep it from blocking the control panel. When not

connected to the camera, run it through both clamps.

3.8 Mounting a scriptboard

An optional scriptboard can be mounted on the right or left side of the SuperXpander/Xpander.

To mount the scriptboard onto the SuperXpander/Xpander insert the pin into the scriptboard

hole of the SuperXpander/Xpander. Tighten the screw and adjust the scriptboard.

Chapter 3 - Assembly

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 27

Page 28

Chapter 3 - Assembly

28 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 29

Chapter 4

Control panel

4.1 Buttons

The LDK 4488 SuperXpander is equipped with a control panel at the rear of the unit . This panel

includes an LCD screen and buttons for controlling the camera and the viewfinder. The buttons

on the control panel have coloured backlighting that indicates the state of the button.

Chapter 4 - Control panel

Button state Description

Blue Function is available but not selected.

Yellow Function is selected and active.

Yellow (blinking) Function is selected but has unusual behaviour.

Off Function is unavailable.

4.2 LCD display panel controls

menu

buttons

MENU1MENU

display

panel

item

selectors

2

+-

menu

buttons

MENU3MENU

4

PREV NEXT

ON AIR POWER REMOTE

V

F

ON AIR

DIM

SELECT

INDI-

CATORVFZOOM

MARKER TEXT

CENTER

CROSSVFDETAIL

SAFE

AREA

FOCUS

ASSIST

Y/-Y Y/EXT

R/-R EXT 1

G/-G EXT 2

B/-B

EXT

ASPECT

RATIO

I

N

T

PROG

E

R

C

O

M

ENG

PROD

CALL

plus/minus

buttons

item

selectors

previous/next

buttons

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 29

Page 30

Chapter 4 - Control panel

4.2.1 LCD display

The LCD display shows menus, items and values. When no menu is selected the display

shows a status screen that includes the transmission mode and the current power status.

LDK 4488 SuperXpander

Transmiss: Triax

Local Pwr: Yes

Util Pwr: Disabled

4.2.2 Menu buttons

The system functions are divided into menus 1 to 4:

• Menu 1 contains functions for controlling the SuperXpander.

• Menu 2 contains camera functions.

• Menu 3 contains viewfinder related functions.

• Menu 4 contains lens related functions.

When a menu button is selected, it becomes yellow. Pressing a selected menu button again

returns the status screen.

4.2.3 Prev/Next buttons

The Prev and Next buttons scroll through the pages in multipage menus.

4.2.4 Item selectors

Each one of the four item selector buttons is associated with an item displayed on the

screen either at the top-left, top-right, bottom-left or bottom-right of the screen. When

you tap one of these buttons the associated item becomes active. It can now be changed

using the plus/minus buttons or toggled when the item has only two possible options.

4.2.5 Plus/minus buttons

These buttons are used to increase or decrease the value of an analog function or to

select values for a function.

30 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 31

4.2.6 Menu function lists

The following tables provide an overview of functions included in the SuperXpander control

panel. Note that the availability of some functions depends on your camera configuration.

Menu 1

switch function values description

< page 1 >

top-left LCD Backl 0..99 (50) Sets LCD backlight level.

top-right LCD Contr 0..99 (70) Sets LCD contrast level.

bottom-left LED Blue 0..99 (50) Sets light level for blue indicator LEDs.

bottom-right LED Yellow 0..99 (50) Sets Light level for yellow indicator LEDs.

< page 2 >

top-left Indicator Zm,Fc,Ir,

top-right ENG switch momentary,

bottom-left

bottom-right Zoom SW momentary,

< page 3 >

top-left Utility Power 0..12V (0) Sets the variable utility power voltage in steps of

top-right Utility Power

bottom-left Local Power Yes, No Indicates if the SuperXpander is locally (AC)

bottom-right Transmission Triax, Fiber,

< page 4 >

top-left SXP software

top-right SXP boot

bottom-left bottom-right Temperature xxC/xxF Temperature of SuperXpander (displayed in degrees

Status

version

software version

Chapter 4 - Control panel

Assignment of the indicator button to either zoom,

Zm/Fc,Zm/Ir

alternating

alternating

Disabled,

Overload, Ok,

Unavailable

Unknown

v00.00 Indicates the version of the software of the

v00.00 Indicates the version of the boot software of the

focus and/or iris indicator in the VF.

Choice between momentary of alternating

behaviour of the ENG switch.

Choice between momentary of alternating

behaviour of the Zoom switch.

0.25V.

Note: this option is only available when the utility

power is installed.

Indicates the status of the utility power.

Note: this option is only available when the utility

power is installed.

powered.

Indicates which type of transmission unit is

installed.

SuperXpander.

SuperXpander.

C and F)

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 31

Page 32

Chapter 4 - Control panel

Menu 2

switch function values description

<page 1 >

top-left ND Filter 1-4 Control of the ND Filter in the camera. If the filter is

top-right FX Filter A-D Control of the FX filter in the camera, if available.

bottom-left AutoWhite Off,Window,

bottom-right Bars On,Off Control of the Color Bar test signal.

Menu 3

switch function values description

< page 1 >

top-left Lamp Off, On Switches the 7-inch viewfinder On Air lamp and

top-right bottom-left bottom-right -

not motorized this is an indication.

Control of the Auto White balace process.

On,Fail

Lens On-Air lamps.

Menu 4

switch function values description

< page 1 >

top-left top-right Iris Ind. F1.4 .. Fclose Indication of the current Iris position in F-stops.

bottom-left Focus Ind. 0..99 Indication of the current focus position in a 0..99

range.

bottom-right Zoom Ind. 0..99 Indication of the current zoom position in a 0..99

range.

< page 2>

top-left top-right bottom-left Range Extender Off, On Indication of the lens range extender.

bottom-right -

< page 3 >

top-left Lens I/F Analog, Digital Indication of the lens interface currently in use.

top-right link state OK, Not OK indication of the status of the transmission module.

bottom-left bottom-right -

32 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 33

4.3 Panel controls

Chapter 4 - Control panel

MENU1MENU

2

+-

4.3.1 Camera menu buttons

These Up, Down and Select buttons are used to navigate and select functions in the camera

menu system. The camera menu is displayed on the viewfinder. These buttons operate in the

same way as the Rotary and Select buttons on the front of the camera.

MENU3MENU

PREV NEXT

camera menu

buttons

on air/iso

indicators

4

power

indicator

ON AIR POWER REMOTE

V

F

ON AIR

DIM

SELECT

INDI-

CATORVFZOOM

MARKER TEXT

CENTER

CROSSVFDETAIL

SAFE

AREA

FOCUS

ASSIST

Y/-Y Y/EXT

R/-R EXT 1

G/-G EXT 2

B/-B

viewfinder

controls

EXT

ASPECT

RATIO

I

N

T

PROG

E

R

C

O

M

ENG

PROD

CALL

remote

indicator

intercom

buttons

4.3.2 Indicators

The three indicators at the top of the panel show the following:

Indicator Description

On Air Lights RED when the camera is on air.

Power Lights when the SuperXpander is receiving power.

Remote Lights when the camera is in the remote control mode.

Lights YELLOW when the ISO signal is activated.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 33

Page 34

Chapter 4 - Control panel

4.3.3 Viewfinder control buttons

This group of buttons controls what is displayed in the viewfinder

Switch Function

ON AIR DIM Switches the brightness of the On Air lamp on the viewfinder up

INDICATOR Turns all indicators on the viewfinder screen On or Off

MARKER Turns the marker indicator in the viewfinder on and off.

CENTER CROSS Turns the centre cross indicator in the viewfinder on and off.

SAFE AREA Turns the safe area indicator in the viewfinder on and off.

VF ZOOM Turns the viewfinder zoom on and off.

TEXT Turns the text display in the viewfinder on and off.

VF DETAIL Turns the viewfinder detail on and off.

FOCUS ADSSIST Turns the focus assist system in the viewfinder on and off.

Y/-Y

R/-R

G/-G

B/-B

Y/EXT Y/EXT ON switches a mix of Y + EXT 1 or Y + EXT 2 signal for

EXT 1

EXT 2

EXT ASPECT RATIO Selects the aspect ratio of the external signal.

and down in steps.

Switches the R, G, B or Y signal or their inverse from the camera for

display in the viewfinder.

display in the viewfinder.

Y/EXT OFF switches only EXT 1 or EXT 2 signal for display in the

viewfinder.

Switches the External video 1 and External video 2 signal for

display in the viewfinder. Ext 1 and Ext 2 are also selectable with

the pan-bar switches at the back of the handle.

If no switch is selected the previous signal is displayed.

NOTE: the viewfinder and external selection switches on the

camera adapter are disabled.

4.3.4 Intercom control buttons

The intercom control buttons route the various intercom signals.

4.3.5 Call switch

Pressing this button sends a signal to the control panels calling for attention. An incoming call

activates the LED in the switch.

34 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 35

Chapter 5

Power

5.1 Switching on power

Use the On/Off switch on the right side panel to switch the SuperXpander/Xpander and

camera on and off. The On/Off indicator lights when the system is switched on.

Chapter 5 - Power

On/Off

switch

On

Off

T4AH 250V

local power

indicator

Active

Local

12V - 6VA

Power

active

100 - 240V~ 50-60Hz 3A

local power

mains

connector

5.2 Remote power mode

In remote power mode, the SuperXpander/Xpander, camera and viewfinder are powered by

the base station via the Triax or hybrid fiber cable. The SuperXpander/Xpander is not connected

to the mains.

Triax cable lengths

When the Triax transmission module is installed and the SuperXpander/Xpander operates in

remote power mode the maximum length of the Triax cable highly depends on the amount of

power drawn by the utility power outlet(s). All power needs to be transported via the Triax

cable.

Power

indicator

Power

Script

Light

Viewfinder BNC

Y

Pr

Ext

OUT

Pb

Viewfinder

VF Conn.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 35

Page 36

Chapter 5 - Power

The following table gives an approximation of the maximum Triax cable length versus utility

power consumption (the nominal SuperXpander/Xpander system power consumption is

already taken into account for these values).

Utility power: Triax cable (8 mm) Triax cable (11 mm) Triax cable (14 mm)

0 VA 430 m (1,400 ft) 860 m (2,820 ft) 1,720 m (5,640 ft)

25 VA 360 m (1,180 ft) 720 m (2,360 ft) 1,450 m (4,760 ft)

50 VA 300 m (980 ft) 610 m (2,000 ft) 1,220 m (4000 ft)

75 VA 260 m (850 ft) 520 m (1,700 ft) 1,030 m (3,380 ft)

100 VA 220 m (720 ft) 440 m (1,440 ft) 870 m (2,850 ft)

120 VA 190 m (620 ft) 380 m (1,250 ft) 760 m (2,500 ft)

Fiber cable lengths

The maximum length of cable that can be used without significant degradation of the video

signal is 4,000 m (13,000 ft).

– Overall fiber cable length highly depends on the optical budget, determined mainly by

the number of optical transitions (interconnections).

– The hybrid fiber cable length is also limited by the total amount of power drawn by the

SuperXander/Xpander system, including camera, viewfinder and utility power.

5.3 Local power mode

When power is provided at the mains connector, the SuperXpander/Xpander automatically

switches to local power mode. The local power active indicator lights to indicate that power is

being supplied via the mains connector.

Local power mode is recommended for high power situations and/or long Triax cable runs. As

an addition to the Triax infrastructure an LDK 4800 Triax repeater unit can be used to extend

Triax cable lengths.

Note

☞

When the SuperXpander/Xpander is used in local power mode the utility power is not available.

Note

☞

Local power mode is not fully supported when using the SuperXpander/Xpander in a Fiber

configuration. Power to the camera is still supplied by the base station while the

SuperXpander/Xpander itself and the viewfinder are powered locally.

36 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 37

5.4 Utility power

Note

☞

When the SuperXpander/Xpander is used in local power mode the utility power is not available.

Chapter 5 - Power

fixed power

output

variable power output

(SuperXpander only)

Utility Power

15V=

0-12V

DC out

50W

RED

OVERLOAD

utility power

indicator

SuperXpander

When the utility power unit is installed two power outputs are available. The socket on the left

provides a fixed voltage of 15 VDC. The socket on the right provides a variable voltage between

0 VDC and 12 VDC that can be set in the menu (menu 1 > page 3) of the control panel.

Note

☞

The maximum power consumption of the variable output should not exceed 50 W and the

power consumption of both outputs combined should not exceed 120 W. When the variable

output is not used, the fixed output can deliver max. 120 W.

Xpander

When the utility power unit is installed only one power output is available. The socket on the

left provides a fixed voltage of 15 VDC. The socket on the right is not used. Power consumption

is max. 120 W.

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 37

Page 38

Chapter 5 - Power

Power indication

The utility power indicator provides information about the power output(s):

Indicator Description

YELLOW Normal operation. Power is available.

RED Power overload on the variable power output (applies to the SuperXpander

Off (in remote mode) In remote mode this indicates that there is a power overload on the fixed

Off (in local mode) In local mode this indicates that the utility power unit is switched off.

Temperature warning system

When the temperature inside the SuperXpander/Xpander becomes too high, the variable

power output is switched off and a warning message is shown on the LCD display. When the

temperature increases even more, the fixed power output is switched off as well and another

warning message is shown.

The table below shows detailed information about the temperature warning system:

only)

power output.

Fixed output Variable output

Action

(SuperXpander only)

below 60ºC below 59 ºC normal operation

from 60 ºC up to 65 ºC from 59 ºC up to 64 ºC The following warning message is shown on

the LCD display of the control panel

(SuperXpander only).

Curr. Temp 65 ºC

UTIL SWITCH OFF TEMP

Variable: 62 ºC

Fixed: 61 ºC

65 ºC and higher 64 ºC and higher The power output is switched off and the

following warning message is shown on the

LCD display of the control panel

(SuperXpander only).

Curr. Temp 65 ºC

UTIL SWITCH OFF TEMP

Variable: OFF

Fixed: OFF

63 ºC or lower 62 ºC or lower The power ouput is switched back on again.

No warning will be shown as long as the

temperature decreases.

38 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 39

Chapter 6

Connectors

6.1 Left side view

Chapter 6 - Connectors

lens interface

connector

Fixed power

output

15V =

50W

DC OUT

Variable power output

(SuperXpander only)

5-12V =

50W

Triax connection to

Base Station

Flying lead (connects

to camera)

Triax or fiber connection

to Base Station

Utility power

outputs

Flying lead

(connects to

the camera)

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 39

Page 40

Chapter 6 - Connectors

6.1.1 Fixed utility power output (option)

4

3

XLR 4-pin male

2

Pin Description

1

1GND

2 no connection

3 no connection

4+15 VDC

6.1.2 Variable utility power output (option, SuperXpander only)

*) variable, can be set in the operation

panel.

4

3

XLR 4-pin male

Pin Description

1

1GND

2 no connection

2

3 no connection

4 0 to 12 VDC*)

6.1.3 Lens interface connector

18

1

Pin Description

1 no connection

2 no connection

3 no connection

4 Lens power (+15 VDC)

5 Lens power return

6 GND

7 Housing

8 Re A or RXD

9Re B

10 Re C or Aspect ratio follow

11 He a te r

12 Iris follow

36 19

36-pin Centronics connector

Pin Description

13 Zoom control

14 Ext switch 1

15 Ext switch 2

16 Zoom/focus local/remote

or Exit pupil pos

17 Iris control

18 Iris auto/remote or TxD

19 Zoom control

20 Focus control

21 Tally control

22 Zoom/focus local/remote

or Exit pupil pos

23 no connection

Pin Description

24 Lens ID0

25 Lens ID1

26 Lens ID2

27 Lens ID3

28 no connection

29 no connection

30 Focus follow

31 Image stabilizer

32 no connection

33 ENG switch

34 PROD switch

35 no connection

36 no connection

40 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 41

6.2 Right side view

top viewfinder connector

(part of optional viewfinder support)

flying lead

(connects to

camera

Chapter 6 - Connectors

viewfinder

connector

control panel (SuperXpander/

Xpander only)

mains power supply

input socket

100 - 240V~ 50-60Hz 3A

T4AH 250V

mains

power

connector

Active

Local

12V - 6VA

Power

script

light

connector

external output

viewfinder

outputs

power

script light

switch

power output

On

Power

Off

Script

Light

Viewfinder BNC

Y

Pr

Ext

OUT

Pb

viewfinder

outputs

(component

external

output

(CVBS)

Viewfinder

VF Conn.

viewfinder

connector

video)

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 41

Page 42

Chapter 6 - Connectors

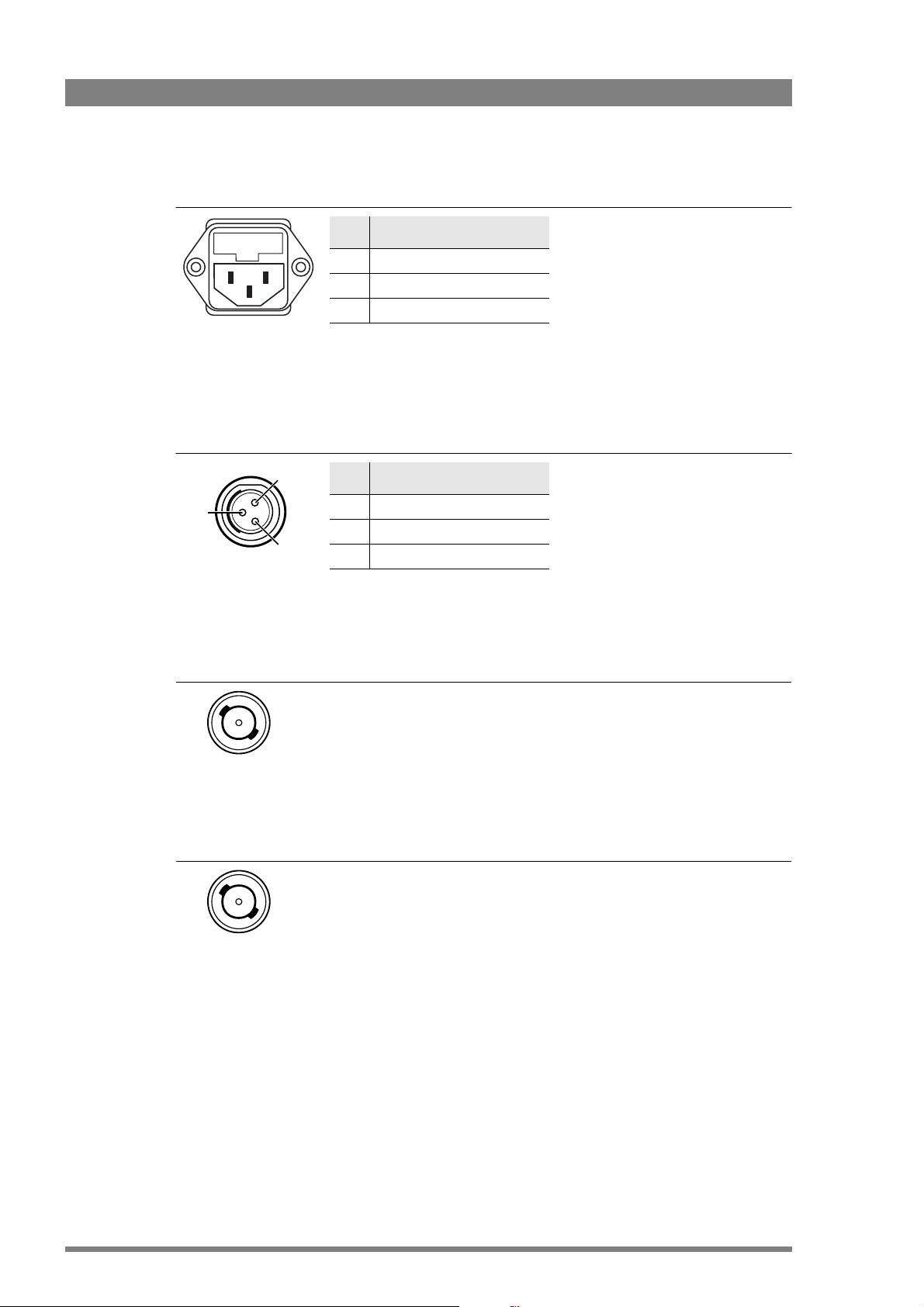

6.2.1 Mains power supply input socket

Pin Description

1

3

3-pin Euro

connector

2

1 Neutral

2Phase

3Earth

6.2.2 Script light connector

1

2

3

Fischer 3-pin female

connector

Pin Description

1 +12 VDC (max. 6 W)

2GND

3 Shield

6.2.3 Viewfinder component outputs (3x)

Mains input voltage: 100 to 240 VAC

(auto ranging)

Mains frequency: 50 to 60 Hz

Fuses (2): T4.0 A H250V

NOTE: the script light connector is

different than the one on the camera

adaptor!

Manufacturer/type: Fischer DBP 103

A052-28

BNC connector

6.2.4 External CVBS output

BNC connector

These 3 BNC sockets provide video output (component video) of the viewfinder

signal.

Y (1.0 Vpp with sync), Pr (0.7 Vpp), Pb (0.7 Vpp);

This BNC socket provides CVBS analog video output (1.0 Vpp)

The source for this output (EXT1 or EXT2) can be selected on the control panel

of the SuperXpander or in the camera (Xpander)

42 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 43

6.2.5 Camera viewfinder connector

Chapter 6 - Connectors

19 16

18 1720

11

13 1215 14

8710 9 6

5

3241

20-pin female VF-

connector

Pin Description

1 -55 VDC

2 not connected

3GND

4INTN-D

5 VF Ext video

6 not connected

7 VF video return

8SDA-D

9SCL -D

10 VF Ext video return

Pin Description

11 GND

12 VF video

13 Pb VF return

14 Pr VF return

15 GND

16 + Batt

17 + Batt

18 Pb VF

19 +Pr VF

20 Shield

6.2.6 Top viewfinder connector (part of optional viewfinder support)

18

15 9

15-pin female D-sub

connector

Pin Description

1 VF video

2 VF Ext Video

3VF Pb

4GND

5 Shield

6+15 VDC

7SCL - D

8INTN-D

Pin Description

9 VF video return

10 VF Ext video return

11 +15 V D C

12 GND

13 Shield

14 VF Pr

15 SDA-D

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 43

Page 44

Chapter 6 - Connectors

44 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Page 45

Chapter 7

Specifications

7. 1 Specifications for LDK 4488, LDK 4489

Item Val ue

Chapter 7 - Specifications

Power

Power requirements 100 to 240 VAC; 50 to 60 Hz 3 A; fuses (2x): T4.0 AH 250 V

Power consumption 250 VA max. fully equipped

Power connection IEC type 3-pin male

Environment

Operating temperatures 0°C to +45 °C (32 to +113 °F)

Storage temperatures -20 °C to +60 °C (-4 to +140 °F)

Weight (approx.) 14.4 kg (31.7 lbs) without viewfinder support

Dimensions (L x W x H) 526 x 286 x 385 mm (20.7 x 11.3 x 15.2 in) without viewfinder and

lens

Power outputs

Utility power output 1 (fixed) 15 VDC; XLR-4 female connector, P

Utility power output 2 (variable)

(SuperXpander only)

*) The maximum power consumption of the two utility outputs combined is 120 W

Script light output 12 VDC; P

Connections

Lens interface 36-pin Centronics female connector

External CVBS output 1.0 Vpp ~ 75 Ohm; BNC socket

External Components outputs Y (1.0 Vpp with sync.), Pr (0.7 Vpp), Pb (0.7 Vpp); 3x BNC sockets

VF connector (camera) 20-pin female VF connector

VF connector (top) 15-pin Sub-D connector, female

0 to 12 VDC; XLR-4 female connector, Pmax = 50 W

= 6 VA;

Fischer 3-pin female connector type DBP 103 A052-28

max

= 120 W *)

max

LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0) 45

Page 46

Chapter 7 - Specifications

1

5V =

50W

5-1

2V =

50W

DC OUT

7. 2 Dimensions

Figure 7-1. Dimensions of the LDK 4488 SuperXpander with Triax transmission unit

342 43

385

115

32

285125.5 215

5V =

5-

2V =

DC OUT

50W

50W

286

109.5 416.5

526

22036 61

46 LDK 4488, LDK 4489 SuperXpander, Xpander User’s Guide (v5.0)

Loading...

Loading...