Page 1

GGeettttiinngg SSttaarrtteedd GGuuiidde

e

Page 2

Jupiter Facility Control System Version 6.2

Getting Started Guide

Manual part no. 04-045707-003 Rev E

March 16, 2004

(c) 1996,1998, 2001, 2004 Thomson Broadcast and Media Solutions, Inc.

All rights reserved. All specifications subject to change without notice.

For customer service, please call (800)

concerning this manual, please contact: Technical Publications Department,

P.O. Box 30816, Salt Lake City, Utah 84130-0816. Phone: (801) 972-8000.

Fax: (801) 977-1602. Email: SLCtechpubs@thmulti.com

Trademark notice

Jupiter and Venus are trademarks of THOMSON. WINDOWS is a trademark of Microsoft, Inc.

547-8949.

comments or questions

For

Page 3

Introduction

Power, flexibility, and reliability—

These words describe the Jupiter

Control System best. Unfortunately,

such features make for a somewhat

intimidating and lengthy manual.

This document is designed to

simplify the set up process—adding

ease-of-use to the long list of Jupiter’s

state-of-the-art features.

1

Page 4

Page 5

GGeettttiinngg SSttaarrtteedd wwiitthh HHaarrddwwaarre

e

To the customer:

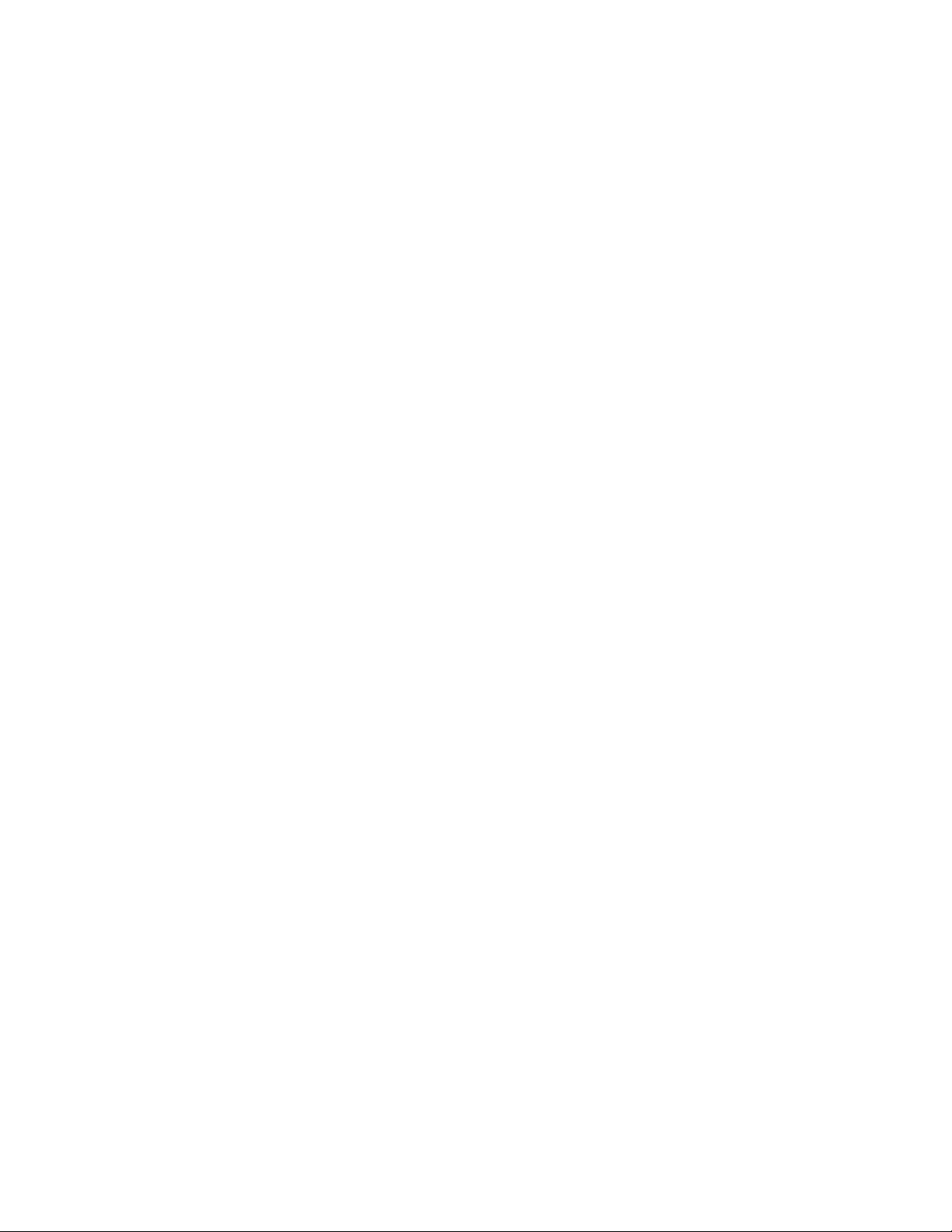

Someone once said that a picture is worth a thousand words. Concerning the Jupiter

set up, this statement is certainly true. The diagrams below should make the

hardware set up quite simple.

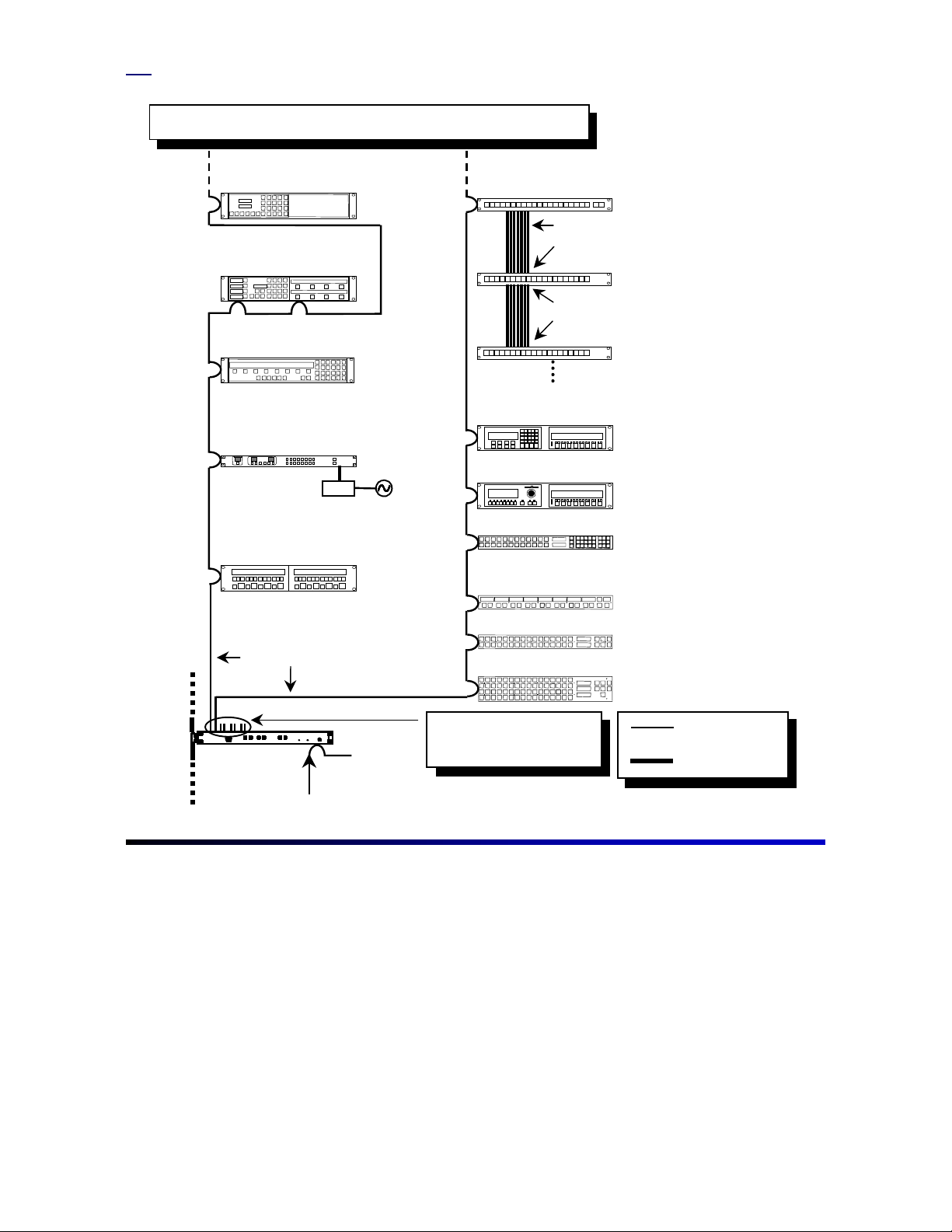

Figure 1. Connection to Philips/Thomson routing switchers

For jumper and

switch setting

information, refer

to the hardware

manual supplied

with the switcher.

15-pin CC 2010 Matrix (crosspoint bus) data cable

Binary protocol

Crosspoint bus port

SDR 400

Mars

Venus

Trinix

VM 3000

Control

Processor

LAN

House T/C

(Optional)

House sync required for

vertical interval switching.

3

Page 6

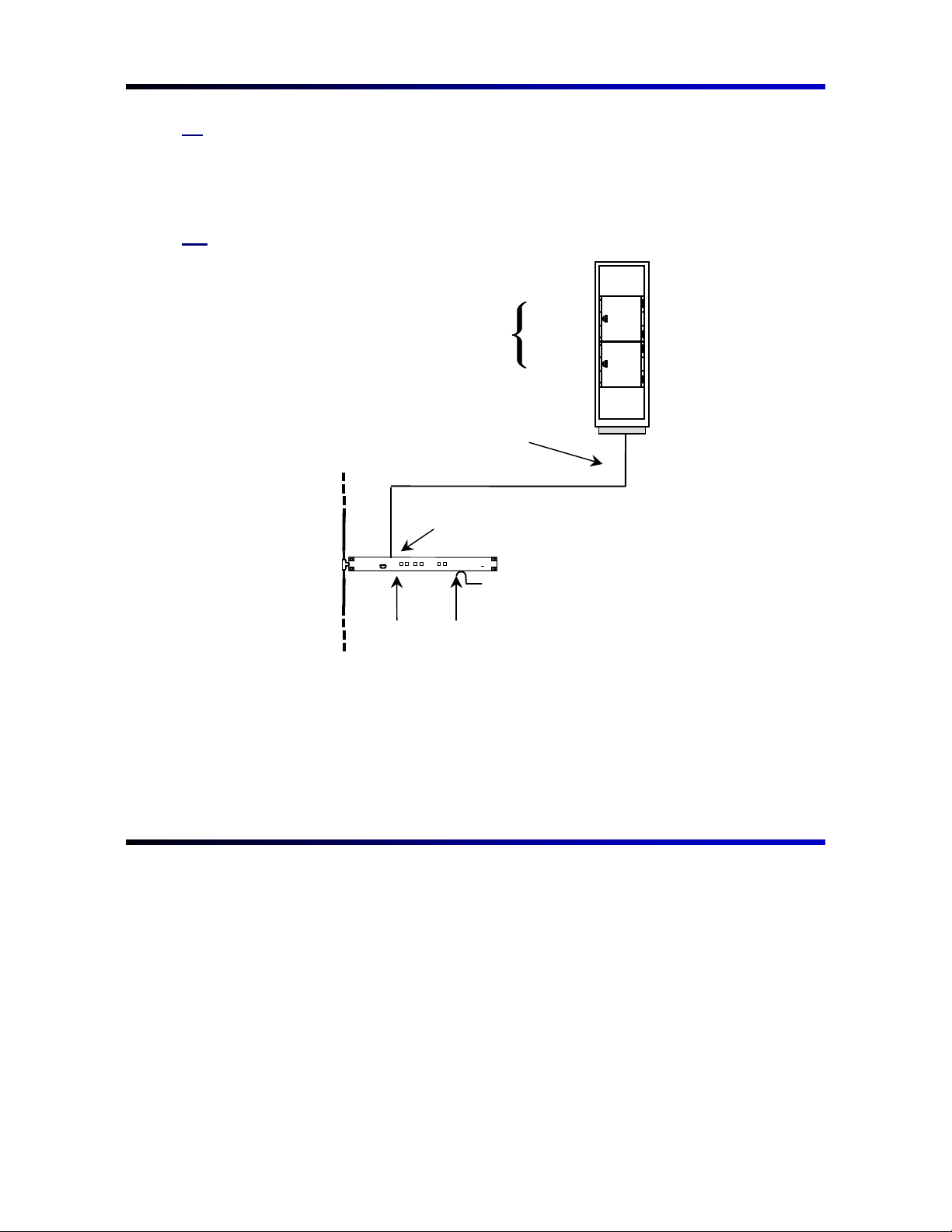

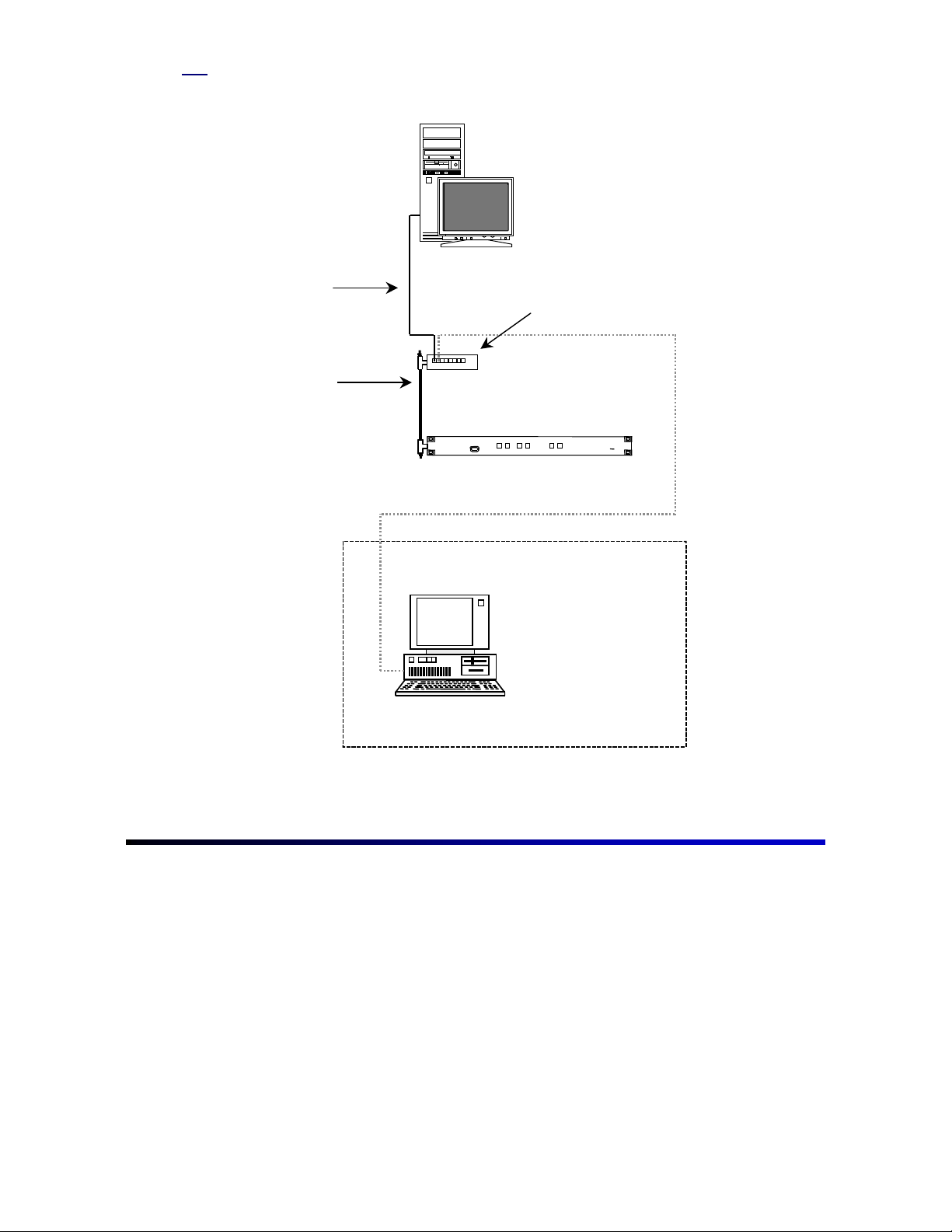

Figure 2. Control panel installation

Each port on a VM/SI 3000 has a recommended maximum quantity of control

panels. Refer to section 2 of the Installation and Operating Manual.

CP 3830 Control Panel

CP 3808 with CP 3809 expansion panel

CP 3800 Control Panel

CP 300 Series Control Panel

PS-20

MC 3010/2 Dual 4-Machine Control Panel

CP 3020 Pushbutton Control Panel

12 in. ribbon cable supplied with CP 3021

“Input" connector

CP 3021 Pushbutton

Expansion Panel

“Output" connector

“Input" connector

CP 3021 Pushbutton

Expansion Panel

Maximum of 4 CP 3021s

CP 3000 Switcher Control

with expansion panel

MC 3000 Machine Control

with expansion panel

CP 3824 Control Panel

CP 3810 Control Panel

CP 3832 Control Panel

Serial (MPK) Cables

CP 3864 Control Panel

VM/SI 3000

(VM 3000 shown)

Port connections are defined

in the MPK Devices table.

Refer to step 10.

Sync Reference

9-pin Serial data

cable

LAN cable

4

Page 7

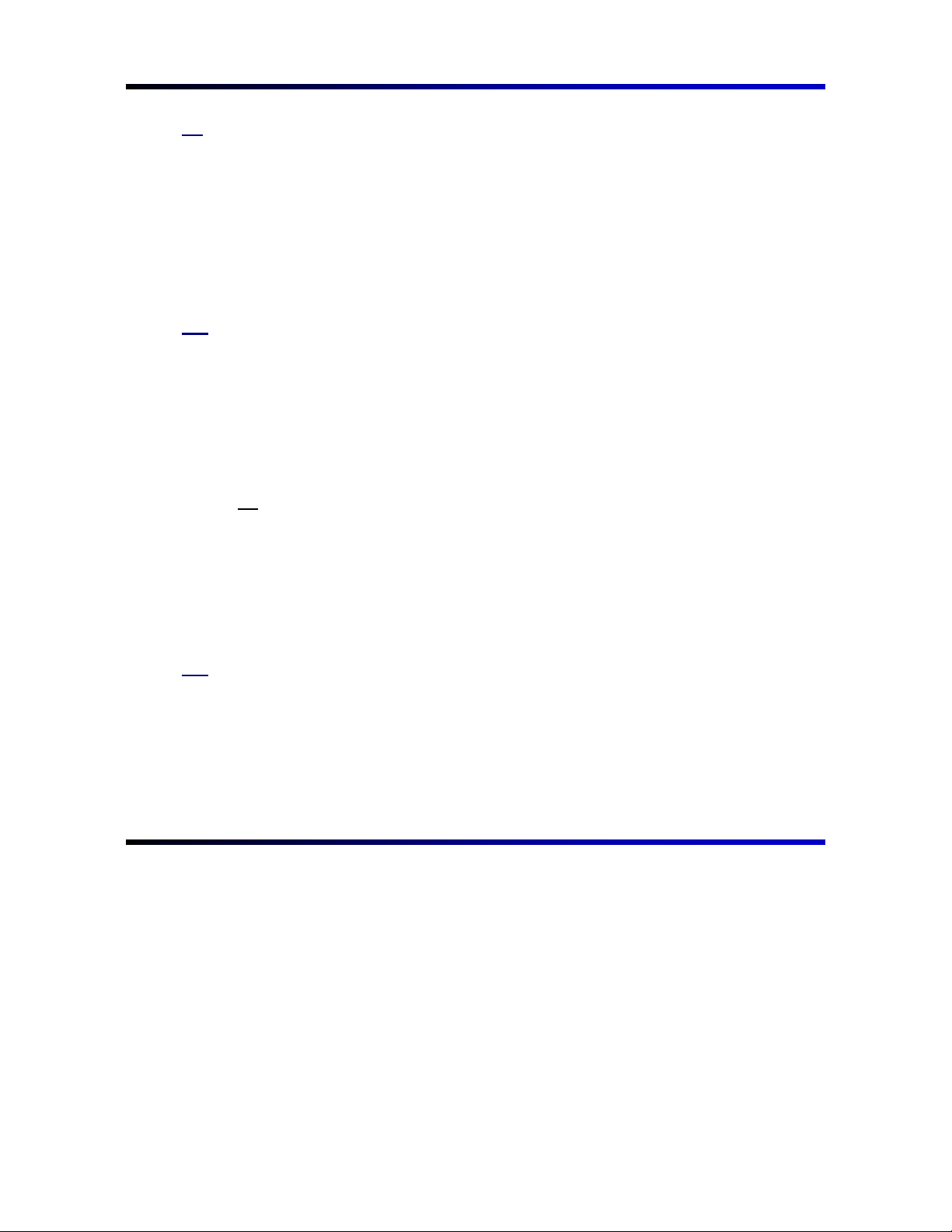

Figure 3. PC-to-VM connections

JNS File Server

with network card

10baseT LAN Cable

10base2 LAN Cable

VM/SI 3000

Control Processor

Jupiter Network Hub with BNC

and RJ45 connections

JNS Remote PC

with network card

5

Page 8

GGeettttiinngg SSttaarrtteedd wwiitthh SSooffttwwaarre

To the customer:

Due to the complexity and power of the Jupiter software, Thomson recommends

proceeding in the steps described below. Before proceeding, look through and

familiarize yourself with the Jupiter Control System Installation and Operating

Manual, part number 04-045707-002. An electronic copy is provided with the Jupiter

software.

Remember to program the system in small steps, validate tables, compile

often, and regularly backup working configuration sets.

Step 1

If the Jupiter Control System was purchased with a Venus, Triton, or Trinix router, a

factory-configured set will be provided. In such a case, the control system has

already been programmed with the factory set and will give its user numeric control of

the switcher by simply connecting the control panels and routing switcher according

to the drawings in the Documentation package. The programming is in flash memory

and no Jupiter programming is needed to obtain simple numeric switching. See the

Hardware Installation section of the Jupiter manual for details.

e

Note

Serial data cables for interconnecting control panels can be purchased from Thomson under the

following part numbers:

01-048591-001 (1 meter length)

01-048591-004 (4 meter length)

01-048591-008 (8 meter length)

01-048591-016 (16 meter length)

01-048591-032 (32 meter length)

The consumer can also build serial cables. See the Serial Data Cables subheading in Section 2

of the Jupiter manual.

Step 2

If the computer was purchased with a router from Thomson Multimedia Broadcast

Solutions, the Jupiter software and factory-configured set will already be installed. If

loading Jupiter for the first time, refer to the Field Engineering Bulletin for installation

instructions (the computer must be equipped as described under the Equipment

Required section of the FEB).

6

Page 9

Step 3

Go to the Windows desktop, click “Start > Programs > Jupiter Network Suite.” After

JNS opens, click the “Connect” button under JNS servers and wait for the computer

to complete its connections. Click “JNS Tools” in the toolbar, then click “Configuration

Editor.” This will open the Jupiter Configurator.

Note

The control system should be operational by making the connections detailed in the factory

Documentation package. If for some reason the flash memory has been corrupted, Thomson

recommends downloading the factory-configured set at this time to verify basic numeric

operation of the control system and router; the system can then be functional for wiring checkout

while more detailed sets are constructed. See the following steps to correctly download this set.

At this point, one of four scenarios may have occurred:

1. Jupiter, the file server, and router were purchased through Thomson.

2. Jupiter and the router were purchased through Thomson, but the file

server was not.

3. The Jupiter Configurator is being upgraded.

4. Jupiter was purchased without a routing switcher.

Go to the appropriate subheading of this step for the corresponding scenario.

Scenario 1

A custom set should be immediately available on the computer’s hard drive. Click

“File > Open” to open the factory-configured set. Copy the set to a new file name as

described at the end of this step.

Scenario 2

The set will be on a 3.5” floppy disk. To retrieve the set from the floppy, click “Tools >

Unzip Configuration Set.” This will open a standard Windows Explorer dialog box. In

the Toolbar of the dialog box, click the button that has a picture of a folder with an up

arrow on it. Continue to click this button until the floppy drive appears in the file

selection box. Double click the floppy drive in the main window, then double-click the

file that resembles the name of the station. Click “File > Open” to open the factoryconfigured set. Copy the set to a new file name as described at the end of this step.

7

Page 10

Scenario 3

If upgrading, the set used under the old configurator should be immediately available

through “File > Open” without unzipping the set.

Scenario 4

An entirely new set will need to be built. In this scenario, continue to work through

this Getting Started Guide since it is designed to familiarize the user with the basics

of the Jupiter software. However, working through section 5 of the Jupiter Installation

and Operating Manual will be necessary to successfully build a set.

Copying a set to a new name

Upon opening the set, copy the set to a new name. To do this, click “File > Save As.”

Give the set a new name. Thomson recomments naming the set 1 digit higher than

the original as in the example below. In this manner, the previous set is still available

in case errors are made on the new set.

Example:

Original factory-configured set: KXYZ-TV

New configuration set: KXYZ-TV1

Repeat this process for each modification session so that the old reliable set will

remain available.

Note

8

Although not recommended, if downloading the factory-configured set is not wanted, skip the

next step and proceed to step 5.

Page 11

Step 4

Check for errors in the set by clicking “Tools > Validate All Tables.” After finishing

validation and correcting the errors, open the compiler by clicking “Tools > Compile.”

Following the compile, return to JNS, click “JNS Applications” in the toolbar, then

click “Control Center.” When the Control Center opens, the configuration tab should

already be selected.

Check to see that the On Activation option is set to “Select and Reboot.” Select the

new set and click Activate. If the Control Center was open prior to the compile,

clicking Refresh List may be necessary if the newly compiled set does not appear.

Downloading will begin and a red LED alarm will illuminate on all devices connected

to the LAN. Make certain that the control panels are connected to the factoryprogrammed ports and have the appropriate protocols. See Documentation package

included with this document or look in the Serial Protocol table (step 6) and the MPK

Devices table (step 10) to see where the control panels are programmed to connect.

The VM 3000 should respond with the alarm LED illuminating and occasionally

blinking, indicating the reception of data. After a period of time (approximately up to 1

minute), the control panels should change from the “device not connected” message

to valid switcher status.

9

Page 12

Once the set has been downloaded, attempt to make a few switches. For control

panel operating instructions, refer Section 6 in the Installation and Operating Manual

for the particular control panel. If the system does not perform the switches, work

through the checklist below.

Troubleshooting Checklist

If the system does not go on-line or switch properly, go through the following

checklist and verify the correct settings or connections.

1. Control panels are connected to the proper ports with the correct

protocols as defined in the MPK Devices and Serial Protocol tables.

2. The control panel cables are pinned correctly (if self-made). Each

twisted pair in this cable

3. Black burst or sync has been connected to the VM 3000s.

4. The VM 3000 rotary switches on the top of the board are set to “00.”

5. CC 2010 (crosspoint bus) cables are connected from the VM 3000 to

the routing switchers.

6. The LAN cables are properly connected.

!

All BNC LAN connections are made and terminated with 50-ohm

terminators at each end. LAN cable is 50-ohm type cable. Avoid

5 meter lengths. Minimum length should be 20 inches.

!

All twisted pair 10baseT using RJ45 connectors for the CM 4000

are connected to the Jupiter network hub.

must

be individually shielded.

10

7. CM, VM, and SI addresses match the entries in the Network

Description table (see step 5).

8. Control panel addresses match the entries in the MPK Devices table.

9. Check the Switcher Description table and verify that the physical

level assignment coincides with the levels to which the switchers are

set. The switchers will have a sheet attached describing their levels.

Also, the Documentation package will describe the levels of the

switcher.

Page 13

Step 5

After the set has been downloaded and the system is operational, the Jupiter system

is now ready to be customized.

Note

If a Saturn Master Control switcher is present, Thomson recommends programming it after the

Venus and Jupiter are programmed and operational. The Saturn requires the switcher to be set

up correctly for it to function properly.

Be certain that the copy of the factory-configured set is the selected set. With the

mouse pointer, click “Jupiter > Network Description.” Skip the Password table for now

(if password levels are needed, they can be entered later).

At this time, the names of the VM 3000, SI 3000, and CM 4000s can be changed. If

changes are made to these names, changes will automatically be made in other

tables, such as Serial Protocol, Switcher Description, and MPK Devices. These

tables are described later in this document.

Having been entered at the factory, the board addresses should be correct. These

device addresses are labeled on the back of the VM 3000s, SI 3000s, and other

control boards and should be double-checked for accuracy.

download without these being correct.

After changes are made and the data is

The system will not

satisfactory, close this window by clicking OK.

11

Page 14

Step 6

Step 7

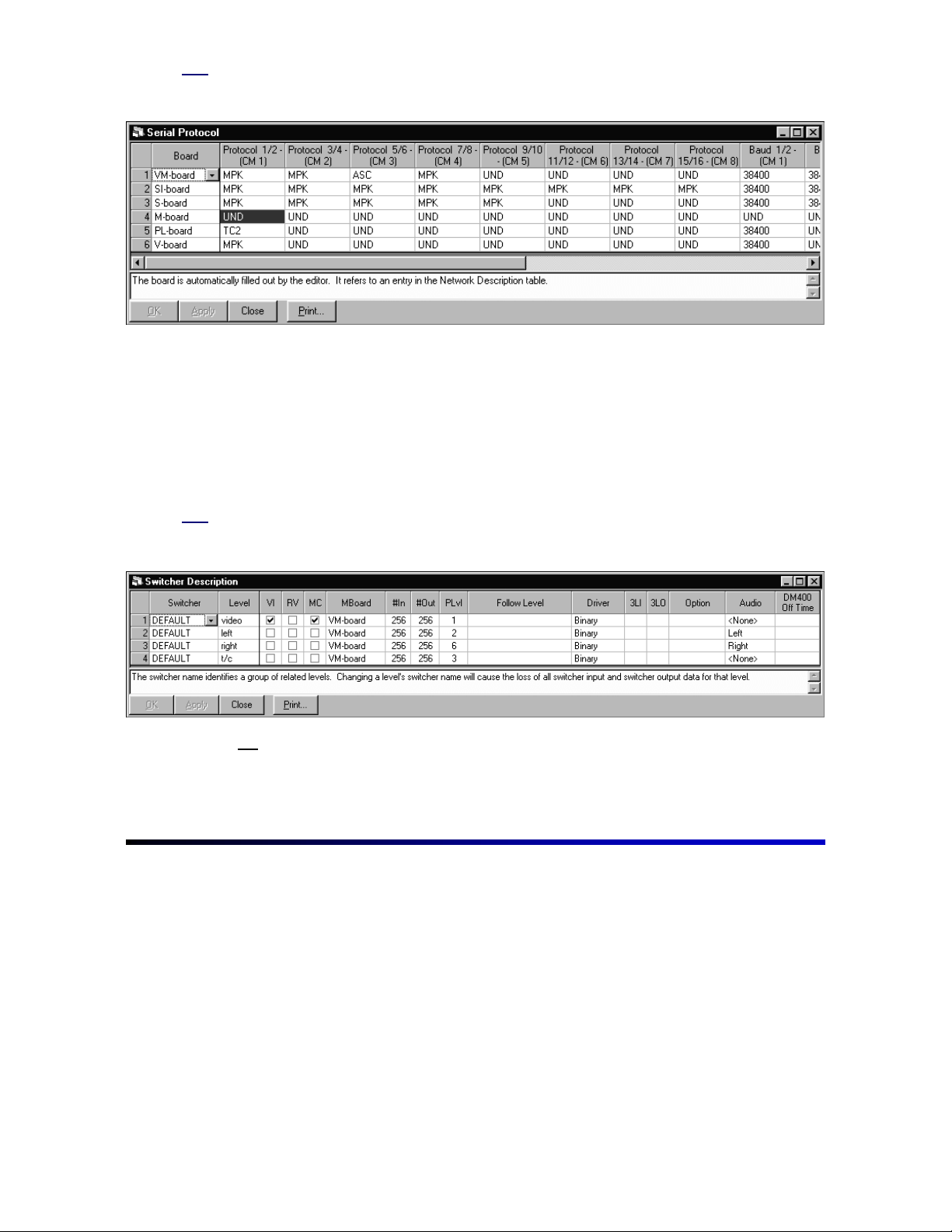

Next open the

Serial Protocol table

:

The devices described in the Network Description table appear here also. This table

sets up the type of devices that will be connected to the VM 3000, SI 3000, and CM

4000 ports. The factory configuration will probably contain all MPK entries. (MPK =

message per keystroke; this protocol is for all Thomson control panels.) Changes can

be made at this time, but keeping the system simple at this stage is the best advice.

Return later to add more complicated devices. Close this window by clicking OK. See

the Serial Protocol subheading under section 5 of the Jupiter manual for more details

about this table.

Next open the

Switcher Description table

:

12

Note

Changing switcher names or level names may cause data in the

to be lost.

tables

Switcher Input and Output

Page 15

Step 8

The factory-configured set will usually contain all switcher levels with the name of the

switcher (i.e., VENUS, TRINIX, TRITON, MARS, etc.), otherwise it will have a

switcher name of

DEFAULT

. Once again, making minimal changes to this table at

this time is advised. Possible changes may be to switcher names or level names.

More involved customizing of this table can be done in later steps.

(Thomson does

not recommend changing the switcher names if the Switcher Input and Output

tables have already been customized.)

When finished, click OK. See the Switcher

Description subheading under section 5 of the Jupiter manual for more details about

this table.

Open the

Switcher Input table

:

The factory-configured set will contain numeric representations for all source

designations. Enter the mnemonic names for the sources. Note that a switcher will

have several levels associated with it and columns of numbers for each level (the

column headings are taken directly from the Switcher Description table). These are

“crosspoints-to-switch” numbers and can be modified at this time if necessary.

Example:

In this example, “BARS” will switch crosspoints 000 for all the levels.

13

Page 16

Step 9

Example:

In this example, “BARS” will only switch crosspoints 000 video and left and right

audio since no entries were made to SDV, AES, and time code.

Example:

In this example, “BARS” will switch crosspoints 000 for all levels except time code,

which will switch input 030 crosspoint.

Open the

Switcher Output table

:

Note that the column headings here (except for Name, Security, S-T, and Password)

were also taken directly from the Switcher Description table. As in the previous table,

assign mnemonic name associations to the destinations. At this time, leave the

security board S-T and password entries blank in order to minimize the complexity at

this stage. If an output password protection is needed, it can be added later. Refer to

section 5 of the Jupiter manual for more details. Click OK to exit this screen.

14

Page 17

Step 10

Example:

In this example, “VTR1” will only receive video, left audio, right audio, and time code.

Example:

In this example, “MON1” will only receive video since no entries were made to left,

right, SDV, AES, and time code.

If control panels other than CP 3000s or CP 3800s are being used, refer to the

subheading in section 5 of the Jupiter manual pertaining to Control Panel Sets. Upon

completing the input, output, and level Control Panel Sets, return to step 10 and

continue.

Open the

MPK Devices

table:

The factory-configured set will contain all control panels with numeric input, output,

and level sets, which directly refer to the numeric entries in the Switcher Input and

Output sets as well as the levels defined in the Switcher Description table. At this

stage, setting up only a few control panels is recommended, preferably at least one

of these being a control panel that can control the entire matrix, such as a CP 3000,

or a CP 320. Print the contents of the MPK Devices table (see “Printing” in section 5

of the manual), then delete the control panels that will not be programmed—such as

those for machine control and tally. Clicking the row number in front of the control

panel will select the entire row. Press Delete.

15

Page 18

Two reasons for approaching the programming process this way are: First, setting up

a minimal amount of data for the first encounter with Jupiter will minimize

troubleshooting and also make it easier for Thomson technical support to help,

should problems arise. Second, control panels using numeric inputs and outputs will

not compile if the Switcher Input and Output tables have been changed to mnemonic

designations in the Switcher Input and Output tables.

After deciding on which control panels to set up for this stage, rename them by

double-clicking the device name to be changed if desired. Enter the new name,

naming them for the particular location where they will be in service. For example, if a

panel was designated to be used in Studio A, naming it “STUDIO” may prove to be

useful. For device type, move to the device type box, click the drop-down menu, and

make the appropriate selection from the list.

The next box (“Expansion”) is for control panels with an expansion panel; check the

box if this particular type is present, or leave it unchecked for all other panels.

Assign a VM 3000, SI 3000, or CM 4000 and a port to which this panel will connect;

the control panel must be physically connected to the port being assigned. Also, note

that this may be different than the port to which the panel is connected for the factoryconfigured set. If so, proper reconnection of the control panels must be made prior to

downloading this set. The port also must be set up to be an MPK port in the Serial

Protocol table.

Assign the appropriate input, output, and level sets. Each control panel can use a

different set or use a common set depending on the desired customization of the

access to the routing switcher. Do not program Sequence Sets or Overrides at this

time—this can be done later if necessary.

16

Note

The control panels might now be assigned to different ports than they were with the factory

configured set. The correct connections need to be made if this applies.

Note

Different types of control panels cannot use the same Input and Output sets. CP 3000 and CP

320 panels must have different set types created for them. However, copying a set and

modifying it to match the panel can save much time. Refer to section 5 of the Jupiter manual

under “CP Input Sets—Copying a CP Input Set for Use with a Different Panel Type” for more

information.

Note

The above description applies to CP 3000-type panels. Refer to Section 4 of the Installation and

Operating Manual for specific control panels.

Page 19

Step 11

Step 12

Note

Having accurate data, valid control panel address numbers, and appropriate control panels

connected to the correct ports is imperative. Studying the Jupiter manual for any peculiar

programming needs to make this table work is important.

At this point, enough data is available for the set to provide functional switcher control

even though many of the other tables have not been completed. Check for errors by

selecting “

compile the set by clicking “

about any problems that it might find while trying to compile. If the

Tools > Validate All Tables

Tools > Compile

,” and correct any errors that appear. Now

.” The compiler will give messages

compiler

identifies

errors, fixing the problem is imperative for a successful download even if validating

the tables identified no errors. With a little patience, the errors can be corrected and a

successful compile can be made; this step is one of the main reasons for keeping the

programmed data simple to this point.

Now that the set has been compiled, download the set and check that proper

crosspoint switches are made for what has been programmed. Return to the Jupiter

Network Suite and click “JNS Applications in the toolbar, then “Control Center.” The

screen will look like that in step 4.

Refer to step 4, which describes proper downloading, including the checklist to go

through if the download is not successful (see CP 3000 operation in the Jupiter

manual for additional help on control panel operation). The correct status should be

returned and everything should be functional to this point if programmed correctly.

Note

Note

If obtaining a successful download was not possible and the factory-configured set downloaded

and was functional, then the recently built set has a problem. It may be a problem that was not

detected by the validation process or the compiler. Troubleshooting the data entered is

necessary and the set must be validated by a successful download indicating that everything is

working before programming any more data. At this stage, troubleshooting will be much easier. If

the factory set has not been downloaded, Thomson recommends performing a download with

the factory set and verifying that all the hardware is functional. Refer to steps 1 through 4.

In some cases, it may be necessary to connect a probe terminal to the VM 3000 to aid customer

service in troubleshooting. See Appendix C of the Jupiter manual (“probe connections and

protocol”).

17

Page 20

Step 13

Congratulations! The set is working and ready to have additional programming. If

additional programming is desired, copy the newly compiled and downloaded set and

name it one digit higher.

Example:

New set: KXYZ-TV1

Copy of the new set: KXYZ-TV2

Step 14

Note

Using a modular means of programming is extremely important. Although set “KXYZTV1” works, leave this as is and add an additional block of data to “KXYZ-TV2,” which is

an exact copy. In this manner, set KXYZ-TV1 is readily available, and only the changes

between KXYZ-TV1 and KXYZ-TV2 need to be adjusted for troubleshooting. For each

programming session, validate, compile, download, and verify that the set works, then

copy the set to the next highest number. In this manner, the highest number is always the

most current set, and the next to highest number contains programmed data that

functions properly. Therefore, any problems are narrowed down to the block of data

entered in the last revision. With this concept in mind, keeping each block of data small

makes troubleshooting easier. After many revisions have been made (up to “KXYZ-20”),

deleting the first 15 versions and starting set naming back at “KXYZ-TV” is fine as long as

this data has been validated, compiled, and downloaded. Then, proceed in this manner

copying to a higher digit every time changes or additional data is entered.

Now that the modular style of programming is a familiar method, Thomson suggests

the following steps:

Select set “KXYZ-TV2” and add all the CP 3000 type panels, validate all tables,

compile, and download. Next, add CP 300 series panels and associated sets. Each

time, remember to copy to a higher set. After all control panels are programmed and

functioning, the next step might be to program the Machine Control functions. This

orderly method of programming will be the most efficient in terms of troubleshooting

and making the system operational. As the programming gets more complicated,

refer to the Jupiter manual often.

18

As noted earlier, organize the programming so that the switcher and machine control

systems are operational and thoroughly examined before programming the Saturn.

See the Saturn manual for details about Saturn tables.

Page 21

For Additional Help

North America Parts and Service

Please call toll-free

You will be forwarded automatically to the parts

and service representative nearest you.

International Parts and Service

Contact your local THOMSON representative.

1-800-547-8949

Page 22

Loading...

Loading...