Page 1

DVCPRO UPGRADE

Installation Manual

071-0516-02

MARCH 2000

PROFILE Family

VIDEO FILE SERVERS

Page 2

Copyright Copyright © 2000 Grass Valley Group Inc. All rights reserved. Printed in the United

States of America.

This do cument m ay not be copied i n whole o r in part , or other wise repr oduced

except as sp ec ifi ca ll y permit ted under U. S. copyri gh t law , wi th out the prior writ ten

consent of Grass Valley Group Inc., P.O. Box 59900, Nevada City, California

95959-7900

Trademarks Grass Valley, GRASS VALLEY GROUP, Profile and Profile XP are either

registe red trad em arks or trad ema rk s of Gras s Va ll ey Gr oup in the Uni ted Stat es

and/or other countries. Other trademarks used in this document are either

registered trademarks or trademarks of the manufacturers or vendors of the

associated products. Grass Valley Group products are covered by U.S. and foreign

patents, issued and pending. Additional infor m ation regarding

Grass Valley Grou p's tradem arks and oth er propri etary right s may be fou nd at

www.grassvalleygroup.com.

Disclaimer Product options and specifications subject to change without notice. The

informati on in this manual is furnished fo r informat ional use only, is subject to

chang e witho ut notic e, an d shou ld not b e cons trued as a com mitme nt by G rass

Valley Group. Grass Valley Group as sumes no res ponsibility or liability f or any

errors or inaccu racies that may appear in this publication.

U.S. Government

Restricted Rights

Legend

Revision Status

Use, duplication, or disclosure by the United States Government is subject to

restrictions as set forth in s ubparagraph (c )(1)(ii) of t he Rights in Tech nical Data

and Comp ut er So ftwa re clau se at DFA RS 25 2.277 -7 013 or in su bpara gra ph c(1 )

and (2) of the Comm ercial Co mputer So ftware Re stricte d Rights cl ause at FAR

52.227-19, as applicable. Manufacturer is Grass Valley Group Inc., P.O. Box

59900, Nevada City, California 95959-7900 U.S.A.

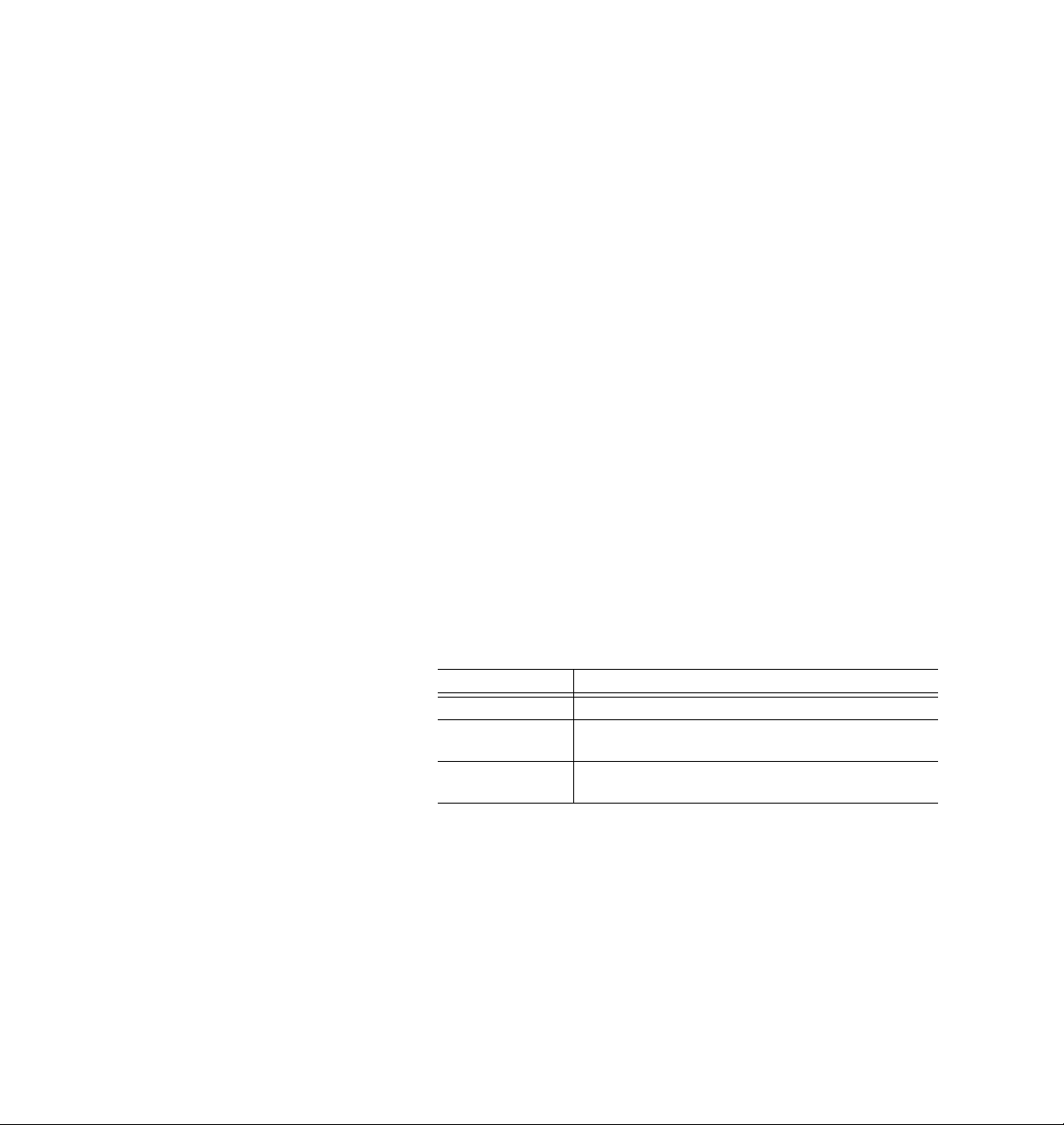

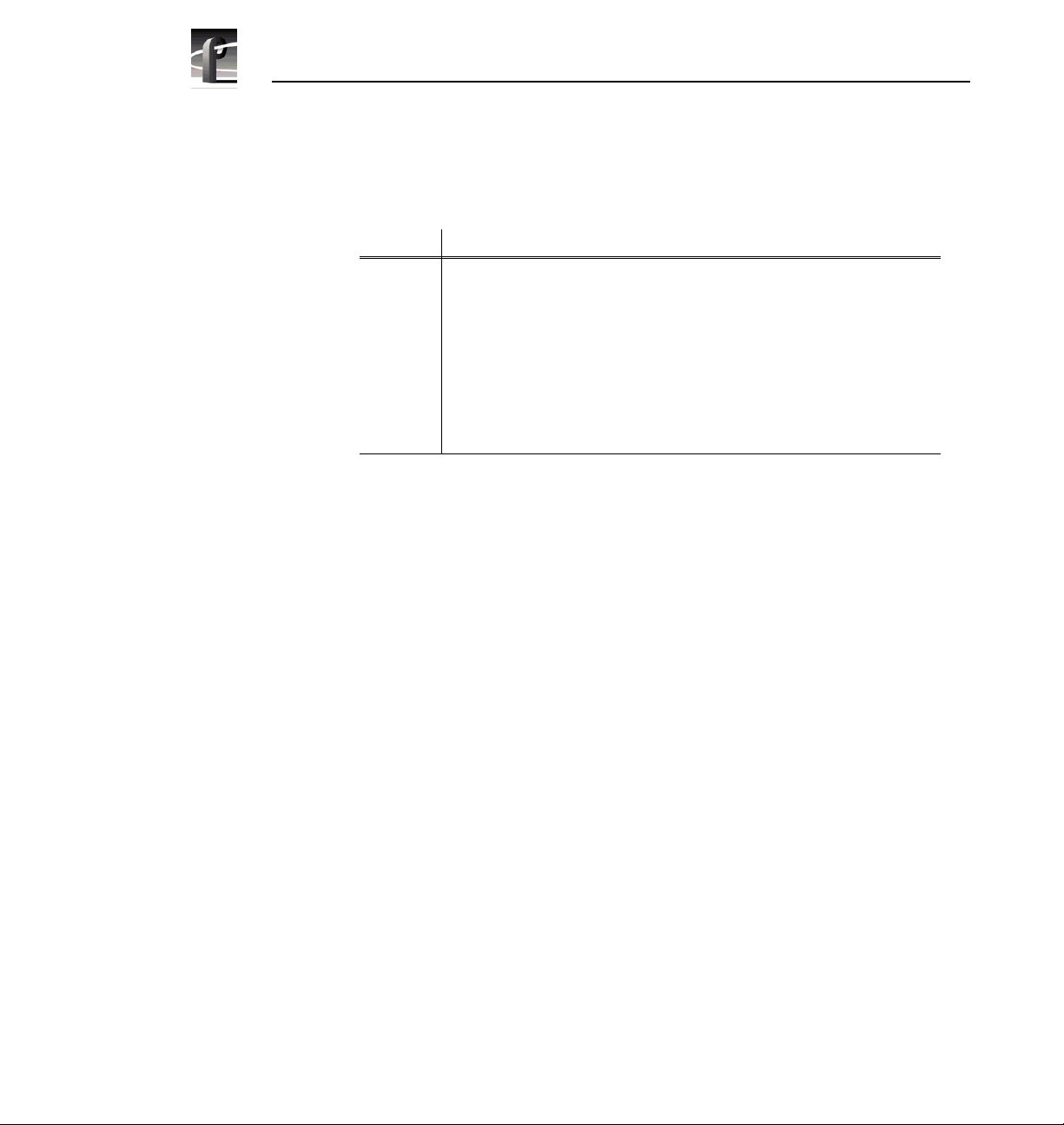

Rev Date Description

March, 1999 Original issue. Manual Part Number 071-0516-00.

October, 1999 Revised to include two-codec board.

Manual Part Numbe r 071-0516-01.

March, 2000 Revised to include DVCPRO 50.

Manual Part Numbe r 071-0516-02.

Page 3

Contents

Grass Valley Group Product Support ............................................................ ............ .. 5

General Safe ty Su mm ary .......................... ........................ ................. ....................... .. 6

Certifications and Compliances................................................................................... 9

Before You Begin ........................................................................................................ 11

Installation Summary.... ................. ....................... ........................ ....................... 12

Upgrading Pro file System Software................................. ................. ........... 12

Updating Profile Circuit Board Firmware.. .................................................... 12

Master and Slave EDR Memory Requirements........................................... 13

Installing Additional Upgrade Kits............................................ ....... ....... ............ .. 14

Kit Contents......................................................................................................... 14

Tools Required............... ........................ ........................ ................ ..................... 14

Electro sta tic Precaution s..... ........................ ........................ ....................... ......... 15

DVCPRO Operation al Consideration s...................... ................ ........................ ........... 16

DVCPRO System Timing Considerations............................................................ 16

Restrictions When Using JPEG and DVCPRO.................................................... 17

Removing the Profi le Unit from the Rack ................... ................. ....................... ......... 18

Removing the Chassis Covers.................................................................................... 20

Removing the Board Hold-down Brackets .................................................................. 22

Installing the DVCPRO Boards.................................................................................... 24

Installing Boards in an Option DV or PDR400 Unit ........................ ....... .......... .... 26

Installing Boards in a non-Option DV Unit ........................................................... 30

Installing Boards in an Early PDR200 Unit.................. .......... .. ....... ....... .......... .... 32

Removing Circui t Bo a r d s ...... ................ ................. ................ ..................... 32

Reinstalling the Boards ............................................................................... 34

Reassemblin g the Pr o file Chassis ............... ................ ........................ ................. ...... 36

Verifyi ng In stallation............... ........................ ........................ ....................... .............. 38

Using Configuration Manager to Verify Installation.............................................. 38

Performing Functional Tests................................................................................ 39

Updating an Emergency Repair Disk .......................................................................... 40

Connecting Audio Clock and Sharcnet Cables............................................................ 41

ASPB Audio Clock and Sha rcn e t Cabling Examples............. ................ .............. 42

Two Serial Digital I/O Boards and One ASPB ........................... .................. 42

Three Seria l Di gi tal I/O Boards and Two ASPB s.................. ....................... 44

Two Analog Composite I/O Boards and One ASPB.................................... 46

Three Analog I/O Boards and Two ASPBs... ................. ........................ ...... 48

Detailed Expl a n at ion Of ASPB Cabling............................ ................. .................. 50

Audio Clock Cabling..................................................................................... 50

Sharcnet Cabling ......................................................................................... 52

DVCPRO Board Installation 3

Page 4

Board Location Guide................................ ........................ ........................ .................. 53

Video Router to Motherboard Relationship.......................................................... 53

Video Router I/O Connections ............................................................................ 54

Selecting a Board Location.................................................................................. 56

Troubleshooting.................................. ................... .............. ................... ............ ......... 58

Troubleshooting Aid............................................................................................. 58

Figures

1 Removing the Profile unit from the instrument rack........................................ 19

2 Removing the fron t a n d rea r chassis covers .................. ................ ................ 21

3 Removing the circuit board hold-down brackets............................................. 23

4 Screw locations for board mounting board bracket ........................................ 27

5 Reconnect the SCSI cables............................................................................ 28

6 Installing the five-slotted PCI Interconnect board .................................. ......... 29

7 Stick-on label location..................................................................................... 37

8 Configuration Manager showing DVCPRO boards ......................................... 39

9 ASPB cabling with two Seri a l Digital I/O board s a nd one ASPB.................... 43

10 ASPB cabling with three Serial Digital I/O boards and two ASPBs................ 45

11 ASPB cabling with two Analog Composite I/O boards and one ASPB........... 47

12 ASPB cabling with three Analog Composite I/O boards and two ASPBs....... 49

13 Audio clock g r o ups an d refe r e n ce sele ction.......................... ................ ......... 50

Tables

1 DVCPRO upgrade kit nomencla ture .............................................................. 11

2 List of kit cont ents ........................ ................. ........................ ....................... .. 14

3 Board locat ion s .................................... ................ ........................ .................. 24

4 Summary of board installation procedures .................................................... 25

5 Cabling for two Serial Digital I/O boards and one ASPB ............................... 42

6 Cabling for three Serial Digital I/O boards and two ASPBs ........................... 44

7 Cabling for two Analog Composite I/O boards and one ASPB ...................... 46

8 Cabling for three Serial Digital I/O boards and two ASPBs ........................... 48

9 Board location chart ...................................................................................... 55

10 Board I/O requirements and restrictions

for a PDR 200 with DVCPRO boards ................................................. 57

11 PDR200 DVCPRO upgrade procedure troubleshooting table ....................... 58

4 DVCPRO Board Installation

Page 5

Grass Valley Group Product Support

You can get technical assistance, check on the stat us of problems, or

report new proble ms by contacting our Product Support Grou p.

United States and Canada

Monday–Friday 5:30AM–5:00PM Pa cific Ti me

(800) 547-8949

Europe

Monday–Friday 9:00AM–5:30PM

France 01 69 86 83 47 United Ki ngdom 01628 405830

Germany 0221 9477 446 Other +44 1628 405840

Italy 02 25086606

Asia and South America

Australia

- from overseas

Beijing 86-10-62351230

Brazil 55-11-3741-8422 Taiwan 886-2-27571571

Hong Kong 852-25856655

02-9888 0100

61-2-9888 0100

ext. 711

Japan 81-3-3448-3111

Korea 82-2-528-5299

Mexico 52-5-666-6333

Singapore 65-356-3900

World Wide

24-hour Emergency Hotline (530) 478-4148 (Contract and warranty

customers)

W orld Wide Web http://www.grassvalleygroup.com/support/

FTP Site ftp.grassvalleygroup.com

Users Group profile-users@grassvalleygroup.com

DVCPRO Upgrade Installation 5

Page 6

General Safety Summary

General Safety Summary

!

WARNING: These instructions are for use by qualified

service personnel only. To avoid personal injury, do not

perform any servicing unless you are qualifie d to do so.

Refer to all safety summaries before performing service.

Review the following safety precautions to avoid personal

injury and prevent damage to this product or any products

connected to it.

While using this product, you may need to a ccess other parts

of the system. Read the general safety summary in other

system manuals for warnings and cautions related to

operating the system.

Injury Precautions

Do Not Service

Alone

Disconnect Power To avoid electric shock while servi cing, disconne ct the main

Use Care W h en

Ser vicing W ith

Power On

Do not perform inte rnal se rvice or a dju stment of this product

unless another person capable of render ing first aid and

resuscitation is pres ent.

power by means of the power cord.

Dangerous voltages or currents may exist in this product.

Disconnect power and remove battery (if applicable) before

removing protective panels, soldering, or replacing

components.

Avoid Exposed

Circuitry

Do Not Operate

Without Product

Covers in Place

6 DVCPRO Upgrade Installation

To avoid injury while servicing, remove jewelry such as

rings, watches, and other metallic objects. Do not touch

exposed connections a nd compone nts when p ower is pres ent.

To avoid electric shock or fire hazard, do not operate this

product with covers or panels removed.

Page 7

Product Damage Precautions

Do Not Operate in

Wet/Damp

Conditions

Do Not Opera te i n an

Explosive

Atmosphere

To avoid electric shock, do not op erate this pr oduct in we t or

damp conditions.

To avoid injury or fire hazard, do not operate this product in

an explosive atmosphere .

Product Damage Precautions

Use the Proper

Voltage Setting

Provide Proper

Ventilation

Do Not O p er ate If

You Suspect

Product Failures

Ensure that the line selec tor is in the proper position for the

power source before applying power.

Prevent product overhea ting by providing proper vent ilation.

If you suspect there is damage to this product, have it

inspected by qualifie d servic e personnel.

Safety Terms and Symbols

Terms in This

Manual

These terms may appear in this manual:

!

!

WARNING: Warning statements identify conditions or

practices that can result in personal injury or loss of life.

CAUTION: Caution statements identify conditions or

practices tha t can result in damage to the equipment or other

property.

DVCPRO Upgrade Installation 7

Page 8

General Safety Summary

Terms on the

Product

Symbols on the

Product

!

These terms may appear on the product:

DANGER indicates a personal injury hazard imme diately

accessible as you read the marking.

WARNING indicates a personal injury hazard not

immediately accessible as you read the marking.

CAUTION indicates a hazard to property, including the

product.

The following symbols may appear on the product:

DANGER high voltage

Protective ground (eart h) ter minal

ATTENTION – refer to manual

8 DVCPRO Upgrade Installation

Page 9

Certifications and Compliances

Certifications and Compliances

FCC Emission

Control

Canadian EMC

Notice of

Compliance

This equipment has bee n tested and found to co mply with the

limits for a Class A digital de vice, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against ha rmful interference when the equipment

is operated in a comm ercial environ m en t . This eq uip m en t

generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with this installation

manual, may cause harmful interf erence to radio

communications. Oper ation of t his equipment in a residential

area is lik ely to cause harmful interference in which case the

user will be requi red t o corr ect the interference at his or her

own expense. Changes or modifications not expressly

approved by Grass Valley Group can affect emission

compliance and could void the user’s author ity to operate this

equipment.

This digital appar atus does not exceed the Class A limits for

radio noise emissions from a digital apparatus set out in the

Radio Interferenc e Regulations of the Canadian Department

of Communications.

Le présent appareil num érique n’émet pas de bruit s

radioélectriques dépassant les li mites applicables aux appareils

numériques de la classe A préscrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des

Communications du Canada.

EN55022 Class A

Warning

For products that comply with Class A. In a domestic

environment, this product may cause radio interference, in

which case the user may be required to take adequate

measures.

DVCPRO Upgrade Installation 9

Page 10

Certifications and Compliances

Certification

Category Standard

Safety Designed /te sted for co m p liance w it h:

UL1950 – Safe ty of Info rmation Technolo gy Equipme nt, inclu ding Ele ctrica l

Business Equipment (Thir d Edition, 1995)

IEC 950 – Safety of Information Technology Equipment, including

Electrical Business Equipment (Second edition, 1991)

CAN/CSA C22.2, No. 950-95 – Safety of Information Tec hnology

Equipment , including Electrical Busin ess Equipment

EN60950 – Safety of Information Tec hnology Equipment, including

Electrical Business E quipment (includes Appendix ZB)

10 DVCPRO Upgrade Installation

Page 11

Before You Begin

NOTE: Profile System S oftware version 3.2 or higher must be installe d before

you install any DVCPRO boards. For more information, see “Upgrading

Profile System Software” on page 12.

This installation manual explains how to install the DVCPRO boards in the

PDR200 Video File Server. Included are procedure s for installing the DVCPRO

boards in both a DVCPRO-ready (Option DV) PDR200 and a

non-DVCPRO-ready PDR200.

There are two DVCPRO upgrade kits for the PDR200 as shown in Table 1.

The PDFDV04 upgrade kit inc ludes o ne DVCPRO CODEC board whi ch featu res

four DVCPRO 25 codecs. Each codec can be used for DVCPRO 25 record and

playback. Each pair of DVCPRO 25 codecs can be u sed as a single DVCPRO 50

codec for DVCPRO 50 record and playback.

The PDFDV02 upgrade kit inc ludes o ne DVCPRO CODEC board whi ch featu res

two DVCPRO 25 Codecs. Each codec can be used for DVCPRO 25 record and

playback. The pair of DVCPRO 25 codecs can be used as a single DVCPRO 50

codec for DVCPRO 50 record and playback.

Before You Begin

To install an additiona l two-codec DVCPRO CODEC board in a PDR400, you

can use the instru cti ons fo r ins tal ling boar d s in a DVCPRO-rea dy s ystem . The

PDFDV02 two-codec board must be installe d in slot J12.

NOTE: Grass Valley Group s upports a to tal of six DVCPRO 25 codecs i n th e

Profile syste m. Gras s Valley Group doe s not support the DVCPRO B oards in

systems with MPEG boards installed.

Table 1. DVCPRO upgrade kit nomen clature

Kit Nomenclature DVCPRO Board Features

PDFDV04 DVCPRO Code c 4 DVCPRO 25 Codecs

PDFDV02 DVCPRO Codec 2 DVCPRO 25 Codecs

DVCPRO Upgrade Installation 11

Page 12

DVCPRO Board Installation

Installation Summary

The following l ists the tasks for c ompleting the DVCPRO upgrade . You may not

have to perform all the tasks listed, depending on your unit’s serial number and

previous upgrades, if any, you have performed.

To install the DVCPRO upgrade you must:

1. Upgrade Profile system software to version 3.2 or higher.

2. Update Profile circuit board firmware.

3. Install additional Master and Slave EDR board memory if required.

4. Install the DVCPRO board and verify perfor mance.

5. Update Windows NT 4.0 Emergency Repair Disk.

The following sec tions give more information on completing each of these tasks.

The procedure starts on page 18.

Upgrading Profile System Software

The Profile system soft ware installed in the PDR200 must be version 3.2 or higher

to support the DVCPRO boards. This software should have been ordered and

received along with this DVCPRO upgrade kit. To chec k the softwa re version

installed in your Prof ile sys tem, open the Vrd Panel applic ation a nd choose

About VdrPanel

displayed wi ndow. I f you do not ha ve s oftware v ersion 3. 2 or hi gher, c ont act your

Grass Valley Group represen tative.

Help |

. The software version is listed as the product version in the

NOTE: Complete software upgrade instr uctions are located in the Profile

System Software Release Notes inclu ded with your software kit. Be sure to

thoroughly read the release notes before upgrading your Profile system

software.

Updating Profile Circuit Board Firmware

After you install the corr ect version of Profile system software, you may need to

update the firmware of some Profile circuit boards. Profile system software

provides the software utilities for doing this. The procedures are described in the

release notes and in the Profile Utilities chapter of the Profile Family User

Manual.

12 DVCPRO Upgrade Installation

Page 13

Installation Summary

Master and Slave EDR Memory Requirements

The DVCPRO upgrade requires 64-megabyte s of memory on both the Master and

the Slave Enhanced Disk Recorder (EDR) Boards. If you order ed your PDR200

recently, the Master and Slave EDR boards already have 64 megabytes of

memory. If you have an earlier model (seri al number B029999 or below), you

must install additional memo ry if you have not done s o already. To see the amount

of memory you have on the Master and Slave EDR boards, check in the Profile

Log for messages regarding memory size. To vie w the Profile Log, double click

the Profile Log shortcut on the Windows NT 4.0 desktop . If your Profile system

has been running for a long time, the text regar ding memory size may have

scrolled out of th e Profile Log . In this ca se, you can re boot the Profi le sy stem and

check the Profile Log again.

If your system does not have the required memory, you will need two service

kits— one kit for the Master and one for the Slave—each with two 32-megabyte

SIMMs.

If you normally opera te with a large video file system (greater than 2500 clips as

might be the case in commercial cache applications) Grass Valley Group

recommends that you have 32 megabytes of local memory installed for the i960

real-time system (RTS) proc essor on the Master EDR board to enhance system

performance. If you ordered your PDR200 recently, you already have

32 megabytes of i960 local memory i nstalle d. If you ha ve an earli er model (ser ial

number B039999 or below), you should install ad ditional memory if you have not

done so already. Check the Profile Log for messages r egarding RTS memory size.

If your system does not have 32-megabytes of real time system (RTS) processor

memory, you will need one kit for this upgrade, c ontaining one 32-megabyte

SIMM, replacing the existing 16-megabyte SIMM.

NOTE: You should have obtained service kits for these memor y upgrades at

the same time yo u received the DV CPR O up grad e k it. If you ne ed to insta l l

these memory upgrades, do so before installing the DVCPRO boards. Refer

to the procedures in the memory kits for speci fic instructions. If for some

reason you have not obtained the kits, contact your Grass Valley Group

representative.

DVCPRO Upgrade Installation 13

Page 14

DVCPRO Board Installation

Installing Additional Upgrade Kits

If you ordered both DVCPRO upgrade kits (PDFDV04 and PDFDV02), you can

install them both at the same time using the procedur es in this manual.

If you have ordered other upgrade kits, such as a video I/O board upgrade or the

Audio Signal Proces sor Board (ASPB) upgrade, you can install them at the sa me

time while the Prof ile ch assis is open .

Kit Contents

The DVCPRO upgrade kit includes all the items listed in Table 2

Table 2. List of kit co ntents

Qty. Item

1 D V C PRO Board (two or four codecs)

1 5 Slot PCI Interconnect

1 Board i d entifica tion label st rip

4 Sharcnet cable

4 Replacement tie wraps for bundling cables

1 Disposable ESD ground strap

5 Anti-static bags for board storage

1 This Installation Manual

Tools Required

Tools required to install the board are (not supplied in this kit):

• A Torx tool with T10 and T15 tips.

14 DVCPRO Upgrade Installation

Page 15

Electrostatic Precautions

CAUTION: All Profile system circuit boards h ave components that are h ighly

!

!

sensitive to electrostatic discharge (ESD). To protect these components from

damage and to maintain product reliability, take the following precaut ions

when handling the circuit board:

• Handle all circuit boards in a static- prote cted area capable of controlling

static charge on conductiv e materials, people, and nonconductive

materials. Stat ic-protect ed areas inclu de nonstatic table tops a nd nonstatic

floor mats.

• While out of the chassis, place boards in the ESD static-s hielded bags

(provided with this kit) until you install them.

• Wear ESD grounding straps when handling boards outside of their ESD

static-shielded bags.

• H andle the circuit boards only by the ed ges and avoid touching the printed

wires on the back of the circuit board as much as possible.

Electrostatic Precautions

DVCPRO Upgrade Installation 15

Page 16

DVCPRO Board Installation

DVCPRO Operational Considerations

This section describes DVCPRO operational issues which you need to consider

when placing your Profile syst em back into ope ration after completing the

upgrade. These include:

• DVCPRO System Timing Considerations

• Restrictions When Using JPEG and DVCPRO

DVCPRO System Timing Considerations

The DVCPRO 25 co decs used in Pr ofile syst ems are a ctually pai rs of codecs.

Because of t his paired codec archite cture, so me restric tions apply to the DVCPRO

codecs which require the following system timing limitations:

1. You must supply a Reference In signal to the Profile system.

2. All video signals that you want to record with a DVCPRO codec must be

synchronous with the Reference In signal.

3. If you want to use the DVCPRO 2 5 codecs a s indepe ndent codecs, all of your

video inputs must be auto-timed to the Refer ence input. In Configuration

Manager, se le ct Enab l e Au to-T im ing fo r each i npu t. Y ou must en s ure that

each input actual ly auto-tim es by checking that the Auto-Tim ed indic ator in

the Video Input dialog box is lit. Refer to “Using the Profile Configuration

Manager” in the Profile Family User Manual for more information on

Auto-Timing.

4. If you are unable to auto-time an input , or if you wish to use the DVCPRO

codecs for BVW Insert/Edit operations , you may onl y use one of the codec s

from each pair, DVCPRO25 #1, DVCPRO25 #3, and DVCPRO25 #5. Note

that the second DVCPRO25 codec from each pair must not be used

(DVCPRO25 #2, DVCPRO25 #4, and DVCPRO25 #6).

16 DVCPRO Upgrade Installation

Page 17

Restrictions When Using JPEG and DVCPRO

Restrictions When Using JPEG and DVCPRO

After completing the DVCPRO upgrade, the JPEG Codecs on the Master and

Slave Enhan ce d Di sk Re co rder boards remai n availab l e as res ou rces for

record/play channels or for transcoding clips between JPEG and DVCPRO. In

some configurati ons, the operation of one of the JPEG codecs may be restr icted as

follows:

- When both JPEG #2 and DVCPRO25 #4 are used, they must both be

connected to the sa me video input vi a the internal vi deo crosspoint r outer,

otherwise, the wrong video input may be recorded.

When you are using DVCPRO25 #4 and you need to configure a JPEG channel,

use one of the other three JPEG codecs available to avoid any restrictions.

DVCPRO Upgrade Installation 17

Page 18

DVCPRO Board Installation

Removing the Profile Unit from the Rack

You can inst all the boa rds with the Profi le chassis fully e xtended on the rack s lides

if the instrument rack is adequately anchored to prevent tipping, and if the re is

sufficient slac k in the cabl es connected to the rear panel to allow the chassis to

fully extend on the slides. If you decide to keep the c hassis in the rack during the

installati on, it is a good idea to loosen any screws that need to be removed from

the back of the Profile unit before s lidi ng it forwa rd on the r acks. You wi ll have to

read the appropriate installation procedure first to determine which screws must

be loosened.

WARNING: Unless the instrument rack is adequately anchored, the rack

!

could tip when the chassis is extended on the rack slides. To avoid possible

injury, make sure the rack is secured firmly before extending the Profile

chassis on the rack slides.

If you cannot or do not want to install DVCPRO boards with the Profile chassis

extended on the rack slide s, use the following procedure to remove the unit f r om

the instrument rack:

1. Remove all cables connected to the rear of the Profile unit. If you have not

done so already, label all cable s before removing them to make it easier to

reconnect them later.

2. Loosen the front-panel r etaining screw (Êin Figure 1).

3. Grasp the handles and pull the chassis out (Ë in Figure 1) until the slides

latch. This holds the Profile chassis firmly in position.

WARNING: To avoid personal injury, at least two people must remove the

!

Profile chassis from the rack—it is too heavy for one person to lift.

4. With a person on each side of the unit, press in both track stop latch buttons

(Ì in Figure 1) and care fully s lide the Prof ile c hassis free of the tr acks (Í in

Figure 1).

5. Place the Pro f ile u nit on an ESD -p rot ect e d wo rk surface.

NOTE: Now is probably a good time to clean the front filter of your Profile

unit. With a strong vacuum, you can clean the filter through the front cover.

18 DVCPRO Upgrade Installation

Page 19

4

3

Stop latch button

(each side)

Removing the Profile Unit from the Rack

1

2

0169-2

Figure 1. Removing the Profile uni t from the i nstrument rack

DVCPRO Upgrade Installation 19

Page 20

DVCPRO Board Installation

Removing the Chassis Covers

To remove th e chass is covers from the Pro file u nit:

NOTE:

rear

1. Turn Profile system power off and remove the power cord .

2. Loosen the fr ont pa nel r etaining sc rew and pull the cha ssis out f rom the rack

3.

NOTE: Store the chassis screws in a cont ainer so that you do not lose them.

They must all be reinstalled as they are require d to meet the EMI

specificati ons for the video file server.

4. Use the Torx tool with the T10 tip to remove the rear chassis cover (

The front chassis cover must be removed first because it overlaps the

cover.

until the slide secti ons latch. If the rack is not anchored firmly, remove the

chassis from the rack (see the instructions under “Removing the Profile Unit

from the Rack” on page 18).

Use the Torx tool with the T10 tip to remove the top screws from the front

chassis cover (Ê

side screws . Set cover aside.

Figure 2). Set the cover aside.

in Figure 2) and use the T15 tip to remove the pan-headed

in

Ë

20 DVCPRO Upgrade Installation

Page 21

9675-9

Removing the Chassis Covers

2

1

Figure 2. Removing the front and rear chassis covers

DVCPRO Upgrade Installation 21

Page 22

DVCPRO Board Installation

Removing the Board Hold-down Brackets

There are two hold-down brackets loc a ted in the circuit board area of the chassis

that must be removed in order to install other boards.

To remove the board hold-down brackets:

1. Use the Torx tool with the T10 tip to remove the exterio r screw (Êin

Figure 3) that secures the rear board hold-down bracket.

2. Lift the bracket (

3. Use the Torx tool with the T10 tip to remove the interior scre w (Ìin

Figure 3) that secures the front board hold-down bracket.

4. Lift the bracket (

NOTE: Now would be a good time to do the memory upgrades mentioned in

“Master and Slave EDR Memory Requirements” on page 13.

in Figure 3) up and out of the chassis and set it aside.

Ë

in Figure 3) up and out of the chassis and set it aside.

Í

22 DVCPRO Upgrade Installation

Page 23

Removing the Board Hold-down Brackets

3

4

2

9675-2

Figure 3. Removing the circuit board hold-down brac kets

1

DVCPRO Upgrade Installation 23

Page 24

DVCPRO Board Installation

Installing the DVCPRO Boards

This sectio n describes how to install the DVCPRO boards in the PDR200. In this

procedure, you will be instructed to remove the three-slotted PCI Interconnect

board and replace it with the five- slotted board provided in this upgrade kit. The

center slot on the five-slotted PCI board must be aligned with the Master EDR

board in s lot J10. All other boards conne cting to the PCI Interconnect board must

be installed in the board slot s shown in Table 3.

Table 3. Board locations

Board Required

Board Slots

Slave EDR J8

Fibre Cha nnel (if installed) J9

Master EDR J10

DVCPRO CODEC (PDFDV04) J11

DVCPRO CODEC (PDFDV02) J12

If you have an Option DV (DVCPRO-ready) PDR200, the circuit boards are

already in the required boa rd slots. All you have to do is install the DVCPRO

boards. Other PDR200 configurations r equire moving boards to other slot

locations to free up the required slots. For this reason, there are three procedures

in this section which give step by step instructions for all the possible PDR200

configurations.

Refer to Table 4 to determine which procedure you should follow, then proceed.

24 DVCPRO Upgrade Installation

Page 25

Installing the DVCPRO Boards

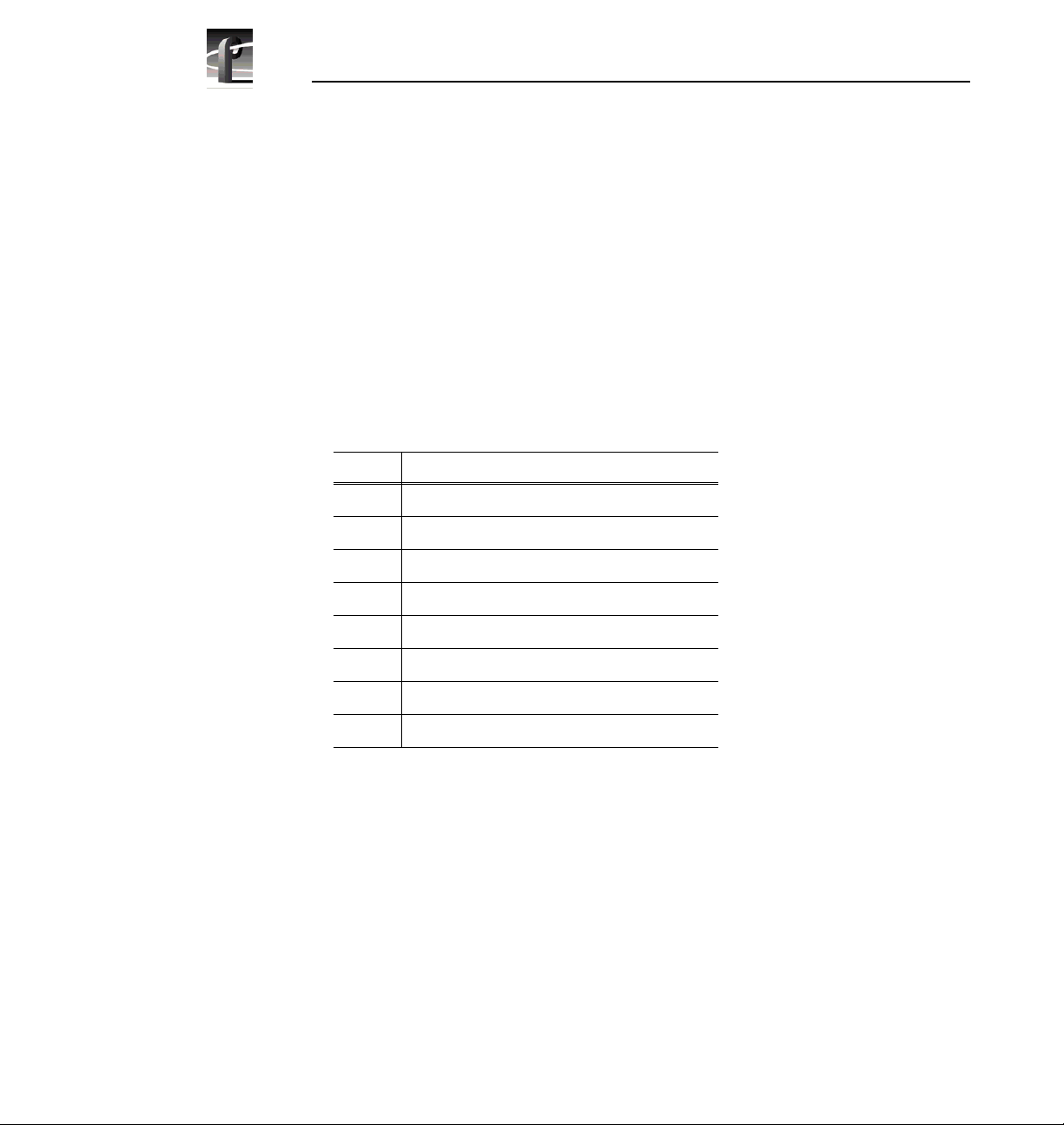

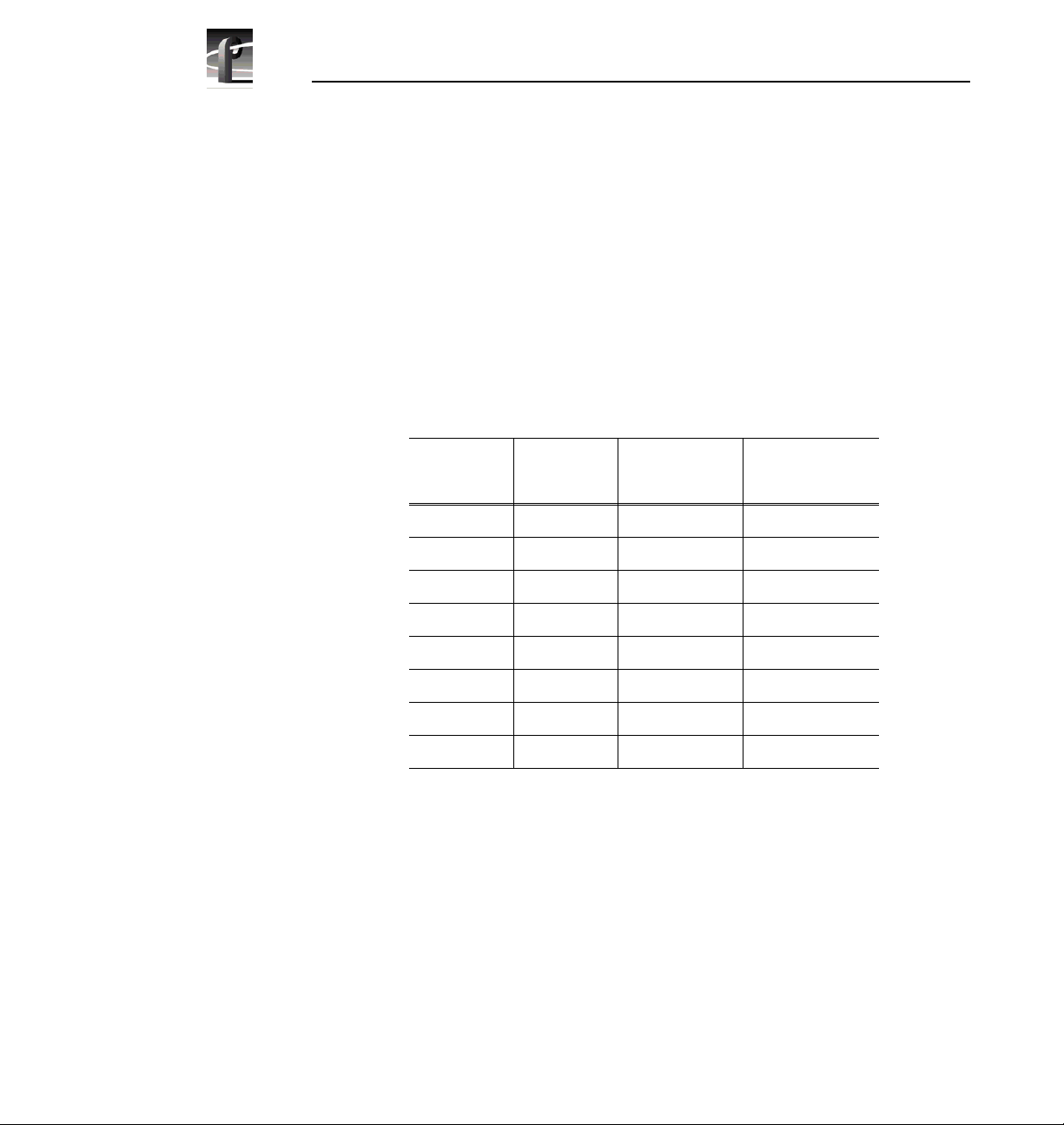

Table 4. Summary of board in stallation procedures

Procedure Serial Number Page

Installi ng Boards in an Option D V or PDR400 Unit

(or PDR400 systems with one four-codec board)

Installing Boards in a non-Option DV Unit B030000 or above 30

Installi ng Boards in an Early PD R200 Unit B029999 or below 32

B042553 or above

(B010000 for PDR400)

26

DVCPRO Upgrade Installation 25

Page 26

DVCPRO Board Installation

Installing Boards in an Option DV or PDR400 Unit

Follow these instructions to install the DVCPRO boards in a DVCPRO-ready

PDR200 (Option DV), or in a PDR400 system.

1. Remove the three-slotted (five-slotted in PDR400) PCI Interconnect board

and remove all cables connected to Profile boards, such as SCSI, Sharcnet,

or audio clock cables (look at Figure 9 on page 43 if you need help

identifying the Shar cnet and audio clock cables). Label each cable bef ore

removing it and draw a simple diagram to make it easier to reconnect the

cables later. Remove any cable tie wraps, if necessary.

NOTE: Be certain to label the SCSI cables before removing th em so that you

can reconnect them properly. If the A and C SCSI cables are reversed, the file

system will appear to be corrupted.

2. Remove the board bracket for slot J11 if you are installing a four-codec

DVCPRO CODEC board. If you are installing the two-codec DVCPRO

CODEC board, remove the board bracket for J12.

CAUTION: Forcing the board into the slot may result in bent connectors on

!

!

the mother board. Carefully follow the instructions in step 3 to avoid

damaging hardware.

3. Install the four-codec DVCPRO CODEC board (PDFDV04) in slot J11. If

you are installing a two-codec DVCPRO CODEC board (PDFDV02), install

it in J12. To install th e boar d s corre ctl y:

- Align the board with the connectors on the motherboard. Make sure that

the board is in the board guide at the front edge.

- With the extractor on the front end of the board in the up position, press

down on the board firmly until it is seated.

- As you pus h the bo ard i nto the connecto rs, yo u will feel the boa rd e ngage

first one, then another set of contacts in the connector. The board is

properly seate d when the top o f the r ear mounting br acket is re sting on t he

rear chassis wall shelf.

4.

Use the Torx tool with the T15 tip to install the

of the board bracket inside thechassis (Ê in Figure 4)

panel at the bottom of the board bracket (Ë in Figure 4).

26 DVCPRO Upgrade Installation

mounting screws in the top

and through the rear

Page 27

Installing Boards in an Option DV or PDR400 Unit

1

2

9040-13

Figure 4. Screw locati ons for board mounting board bracket

DVCPRO Upgrade Installation 27

Page 28

DVCPRO Board Installation

Slave EDR (J8)

Master EDR (J10)

SCSI D

SCSI B

SCSI C

SCSI A

0516-6

Figure 5. Reconnect the SCSI cables

5. Connect the SCSI cables, as shown in Figure 5.

6. Install the five-slotted PCI Interconnect board. This board is a high-speed

bus used to move data be tween boards with PCI connectors. Align the center

keys on the PCI I nterconnect board wit h the keys on the Mast er EDR board

in slot J10. Using appropriate pressure, press down firmly on the

interconnect board to en sure that it is properly seated (see Figure 6).

28 DVCPRO Upgrade Installation

Page 29

Four-codec

DVCPRO

(PDFDV04)

(J11)

Two-codec

DVCPRO

(PDFDV02)

(J12)

Master EDR

(J10)

Alignment Keys

Installing Boards in an Option DV or PDR400 Unit

Fibre Channel

(J9)

Slave EDR

(J8)

PCI Interconnect

Board

0516-7

Figure 6. Installing the fiv e-slotted PCI Intercon nect board

7. If you plan to install additiona l video I/O or audio boards, do so now using

the instructions pr ovided with each field installation kit.

8. Connect the audio clock and Sharcnet c ables according to the diagram you

drew earlier or see “Connecting Audio Clock and Sharcnet Cables” on

page 41.

9. Follow the reassembly instructions under the heading “Reassembling the

Profile Cha ssis ” on page 36.

WARNING: To avoid personal injury from electri cal shock and/or damage to

!

!

disk drives, do not apply power until all covers are in place and secured.

DVCPRO Upgrade Installation 29

Page 30

DVCPRO Board Installation

Installing Boards in a non-Option DV Unit

A non-Option DV PDR200 (with serial number B030000 or above) already has

the Master EDR board in the correct slot J10 (see Table 3 on page 24), but the

Slave EDR board must be moved from J11 to J8. It is possible that you have an

analog composit e or serial digit al component I/O boards installed in slots J8. It is

also possible that you ha ve a board in the slot required by the two-code d DVCPRO

CODEC board, slot J12. These boards must be moved to perform the upgr ad e.

To install DVCPRO boards in a non-Option DV PDR200:

1. Remove the three-slotte d PCI Inte rconnect board and remove all cables

connected to Profile boards, such as SCSI, Sharcnet, or audio clock cables

(look at Figure 9 on page 43 if you need help identifying the Sharcnet and

audio clock cable s). Label each cable befor e removing it and draw a simple

diagram to make it easier to reconnect the cabl es later. Remove any cable tie

wraps, if necessary.

NOTE: Be certain to label the SCSI cables before removing them so that you

can reconnect them properly. If the A and C SCSI cables are reversed, the file

system will appear to be corrupted.

2. If there is a board installed in slot J8, remove the board. For complete

instructions on removing circuit boards, see “Removing Circuit Boards” on

page 32.

CAUTION: Forcing the board into the slot may result in bent connectors on

!

!

the mother board. Carefully follow the instructions in step 3 to avoid

damaging hardware.

3. Remove the Slave EDR boa rd from slot J11 a nd install i t in slot J 8. To install

the board correctly:

- Align the board with the connectors on the motherboard. Make sure that

the board is in the board guide at the front edge.

- With the extractor on the front end of the board in the up position, press

down on the board firmly until it is seated.

- As you pus h the bo ard i nto the connecto rs, yo u will feel the boa rd e ngage

first one, then another set of contacts in the connector. The board is

properly seate d when the top o f the r ear mounting br acket is re sting on t he

rear chassis wall shelf.

30 DVCPRO Upgrade Installation

Page 31

Installing Boards in a non-Option DV Unit

4. Install the DVCPRO boards as follows:

a. If you have a four-codec DVCPRO CODEC board (PDFDV04 kit) install

it in slot J11.

b. If you have a two-codec DVCPRO CODEC board ( PDFDV02 kit ) install

it in slot J12. If you already have a board in slot J12, remove it to install

the DVCPRO CODEC board.

5. Reinstall any video I/O or audi o boards that you had to remove to make room

for other boards. (For information on appropriate slots for video and audio

boards, see “Board Location Guide” on page 53.)

6.

Install the boa rd bra cket s crews. Use the Tor x tool with the T15 tip to i nsta ll

mounting screws in the top

the

(Ê in Figure 4 on page 27)

board bracket (Ë in Figure 4 on page 27).

7. Connect the SCSI cables, as shown in Figure 5 on page 28.

8. Install the five-slotted PCI Interconnect board. This board is a high-speed

bus used to move data be tween boards with PCI connectors. Align the center

keys on the PCI I nterconnect board wi th the keys on the Mast er EDR board

in slot J10. Using appropriate pressure, press down firmly on the

interconnect board to en sure that it is properly seated (see Figure 6 on

page 29).

of the board bracket insi de thechassis

and through the rear panel at the bottom of the

9. Connect the audio clock and Sharcnet c ables according to the diagram you

drew earlier or see “Connecting Audio Clock and Sharcnet Cables” on

page 41.

10. Follow the reassembly instructions under the heading “Reassembling the

Profile Cha ssis ” on page 36.

CAUTION: To avoid personal i nj ury fro m elec trical shock and/or damage to

!

!

disk drives, do not apply power until all covers are in place and secured.

DVCPRO Upgrade Installation 31

Page 32

DVCPRO Board Installation

Installing Boards in an Early PDR200 Unit

If you have an early PDR200 (serial number B029999 or below), you can install

DVCPRO boards by following this procedur e. It may be necessary to remove

some or all of the boards in slots J5 through J15 in order to follow the

recommendations for DVCPRO inst allation. In doi ng so, you may lose some slots

otherwise use d for video I/O boards. To rei nstall EDR and Fibr e Channel boards,

follow the slot order shown in Table 3 on page 24. Table 3 also shows where the

DVCPRO boards must go.

For further gu ida nc e on bo ard plac em en t, refe r to “Board Location Guide” on

page 53. Follow the instr uctions under “Selecting a Board Location” on page 56.

Also, it will be helpf ul to make a copy of Table 9 on page 55 to chart the pla cement

of boards in their proper slot s.

Removing Circuit Boards

Use the following procedure to remove one or more circuit boards—as many as

necessary—from the motherboard, in order to make room installing DVCPRO

boards:

1. Remove the three-slotte d PCI Inte rconnect board and remove all cables

connected to Profile boards, such as SCSI, Sharcnet, or audio clock cables

(look at Figure 9 on page 43 if you need help identifying the Sharcnet and

audio clock cable s). Label each cable befor e removing it and draw a simple

diagram to make it easier to reconnect the cables later.

NOTE: Be certain to label the SCSI cables before removing th em so that you

can reconnect them properly. If the A and C SCSI cables are reversed, the file

system will appear to be corrupted.

32 DVCPRO Upgrade Installation

Page 33

Installing Boards in an Early PDR200 Unit

2. It may be necessary to remo ve the top board bracket screw that mounts any

adjacent circuit boards to al low more give so board removal is easier (refer

to Figure 4 on page 27 for the location of the top screw). Use the Torx tool

with the T15 tip to do so.

3. Use the Torx tool with the T15 tip to remove the screws from the top of the

board bracket inside the chassis (Ê in Figure 4 on page 27) and the screw

through bottom of the board bracket through the rear panel outside the

chassis (Ëin Figure 4 on page 27).

CAUTION: To avoid damage to the circuit board when removing or

!

!

installing it:

- Do no t rock the circ uit board from side to side in the EISA bus

connector — pull straight up to remove.

- Do no t grasp or push on the rear- panel connectors when removing or

installing circuit boards in the card slots.

4. Extract the circuit board:

- I f t he cir cuit boar d i s tal l, us e the extractio n l ever on t he f ront of t he boa rd

and the extractio n ring at the back of the board to lift the circuit board free

of the connectors on the motherboar d.

- F or shorter c ircuit boa rds, care fully gr asp the boa rd and lif t upward t o free

the circuit board from the motherboa rd connectors. You might need to

remove an adjacent tall board to get enough room for a safe hold on the

shorter board.

5. You may also need to remove board brackets for empty slots to prepare for

the installation of new or moved boards. If this is necessary, refer to ste p 3.

6. Place removed boards in the supplied antistatic bags. Fold the bags over to

protect the boards from any ESD exposure .

DVCPRO Upgrade Installation 33

Page 34

DVCPRO Board Installation

Reinstalling the Boards

Now that you have removed the boards from the chassis, you a re ready to reinstall

them, along with DVCPRO boards. See Table 3 on page 24 for placement of

Master and Slave EDR, Fibr e Channel, and DVCPRO boar ds. For i nfo rmation on

placing other boards, refer to “Board Location Guide” on page 53.

CAUTION: Forcing a board into the slot m ay result in bent connectors on the

!

!

mother board. Read the following in structions to avoid damaging hardware.

To install the boards corre ctly:

- Align the boards with the connectors on the motherboard. Make sure the

board is in the board guide at the front edge.

- With the extractor on the front end of the board in the up position, press

down on the board firmly until it is seated.

- As you pus h the bo ard i nto the connecto rs, yo u will feel the boa rd e ngage

first one, then a second set of contacts in the connector. The board is

properly seate d when the top o f the r ear mounting br acket is re sting on t he

rear chassis wall shelf.

1. Install the DVCPRO boards as follows:

a. If you have a four-codec DVCPRO CODEC board (PDFDV04 kit) install

it in slot J11.

b. If you have a two-codec DVCPRO CODEC board ( PDFDV02 kit ) install

it in slot J12. If you already have a board in slot J12, remove it to install

the DVCPRO CODEC board.

Reinstall the video I/O and audi o boards that you had to move out to make room

for the DVCPRO boards. (For information on placing other boards, refer to

“Board Location Guide” on page 53.)

2.

Install the boa rd bra cket s crews. Use the Tor x tool with the T15 tip to i nsta ll

the mounting screws in the top

Figure 4 on page 27) and through the rear panel at the bottom of the board

bracket (Ë in Figure 4 on page 27).

3. Connect the SCSI cables, as shown in Figure 5 on page 28.

34 DVCPRO Upgrade Installation

of the board bracket insid e thechassis (Ê in

Page 35

Installing Boards in an Early PDR200 Unit

4. Install the five-slotted PCI Interconnect board. This board is a high-speed

bus used to move data be tween boards with PCI connectors. Align the center

keys on the PCI I nterconnect board wi th the keys on the Mast er EDR board

in slot J10. Using appropriate pressure, press down firmly on the

interconnect board to en sure that it is properly seated (see Figure 6 on

page 29).

5. Connect the audio clock and Sharcnet c ables according to the diagram you

drew earlier or see “Connecting Audio Clock and Sharcnet Cables” on

page 41.

6. Follow the reassembly instructions under the heading “Reassembling the

Profile Cha ssis ” on page 36.

WARNING: To avoid personal injury from electri cal shock and/or damage to

!

!

disk drives, do not apply power until all covers are in place and secured.

DVCPRO Upgrade Installation 35

Page 36

DVCPRO Board Installation

Reassembling the Profile Chassis

To reassemble the Profile chassis:

1. Apply stick-on labe ls on the Profile chassi s rear panel to help identif y all new

board locations (see Figure 7).

2. Bundle any loose cables with the tie wraps pr ovided.

3. Use the Torx tool with the T10 tip to reinstall the rear board hold-down

bracket (see Figure 3 on page 23). Make sure that boards in the chassis fit

into the grooves in the bracket .

CAUTION: To prevent damage to an Analog Composite Monitor board, do

!

!

not install a short board extensi on on the front hold-down bracket at the

Monitor board location.

4. If necessary, move or remove any sh ort board extensions on the front board

hold-down bracket. Then use the Torx tool with the T10 tip to reinstall the

bracket (see Figure 3 on page 23).

5. Use the Torx tool with the T10 tip to r einsta ll the re ar chassis c over wit h the

screws previously removed.

NOTE: When reinstalling rear and front chassis covers, start all the screws

before tightening them. This ensures that the screw threads are properly

aligned, and will help avoid stripping threads or breaking screws.

6. Use the Torx tool with the T10 and T15 tips to reinstall the front chassis

cover with the screws previously removed.

7. Reinstall the Profile chassis in the rack and reconnect as labeled a ll external

cables previously removed.

8. Apply power to the Profile system and check the presence of the DVCPRO

board with the procedure under “Verifying Insta llati o n” on page 38.

36 DVCPRO Upgrade Installation

Page 37

Reassembling the Profile Chassis

Labels

Figure 7. Stick-on la bel location

9676-26

DVCPRO Upgrade Installation 37

Page 38

DVCPRO Board Installation

Verifying Installati on

Verifying instal lation consists of:

• Using Configuration Manager to Verify Installation

• Performing Functional Tests

Using Configuration Manager to Verify Installation

You can use the Configuration Manager to verif y the proper initialization of the

DVCPRO CODEC boards by looking a t the bottom of the Configur ation Manager

window to ensure DVCPRO boards appear in the slots w here t hey are ins tal le d

(J11 and J12).

To check for recognitio n and initializ ation of the DVCPRO boards in a PDR200:

1. From the Windows NT 4.0 desktop, open the Configurat ion Manager

window by choosing

Manager

2. Check the bot tom of th e window for the prese nce o f the DVC PRO boards a s

shown in Figure 8.

.

Start | Programs | PDR Applications | Configuration

3. Choose

38 DVCPRO Upgrade Installation

File | Exit.

Page 39

DVCPRO

Boards

Performing Functional Tests

Figure 8. Configuration Manager showing DVCPRO boards

Performing Functional Tests

After verifying installation using Configuration Manager, you should perform

functional tests depending on your application, before placing the Profile system

back into operation. For instance you can:

• Use VdrPanel o r Tool B ox Editor to ve rify that you can c onfigu re DVCPRO

video, audio, and timecode resources, and then record and play on all

available channels. This will help detect any problems with the DVCPRO

board for video, or Sharcnet and Audio Clock cabling for audio. For

information on configu ring VdrPanel or Tool Box Editor, as well as

recording and playing clips, see the appropriate chapters in the Profile

Family User Manual.

• Use Media Manager to convert media with the Transcode Utility and to

perform media transfers over Fibre Channel, if a Fibre Channel board is

installed. For information on the Transcode Utility and copying or moving

media over Fibre Channel, see the cha pter on Media Manager in the Profile

Family User Manual.

DVCPRO Upgrade Installation 39

Page 40

DVCPRO Board Installation

Updating an Emergency Repair Disk

Whenever you upgrade your software or change your system configuratio n, Grass

Valley Group strongly recommends that you update the emergency repair disk

shipped with your Profile system. This will allow you to restore system

configuration in the event the operating system has a major problem.

To update your emergency r epair disk, you need the 3.5-inch floppy disk labeled

Emergency Repair Disk that was shipped with your Profile system, or any blank

3.5-inch floppy disk properly labeled.

NOTE: The emergency repai r disk is Profil e system specific. Make sure that

the emergenc y re p air dis k is clearl y mar k ed wi t h the uni t’s serial number.

To update the Emergency Repair Disk:

1. From the Start menu, choose the

2. Enter

3. When the Setup dialog box appea rs, clic k

4. Insert your exis ting emergenc y repair d isk or a bl ank 3.5-in ch fl oppy di sk in

5. When the operation is com plete , remove th e emerge ncy repair disk f rom t he

This completes the DVCPRO upgrade instal lation procedure.

rdisk /s in the R un dialog box, then pres s the Ente r key or cli ck OK. The

Saving Configurati on progress bar appears.

disk.

the Profile system floppy drive and click OK. The Formatting Disk progress

bar appears.

Profile system and store it in a safe location.

RUN command.

Yes to cr e a te a n emer g en c y re pa ir

40 DVCPRO Upgrade Installation

Page 41

Connecting Audio Clock and Sharcnet Cables

Connecting Audio Clock and Sharcnet Cables

This section describes how to connect coaxial audio clock cables and Sharcnet

ribbon cables between the Audio Signal Proce ssing Boar ds (AS PB) and the vi deo

I/O boards. It includes four cabling examples that cover most DVCPRO

configuration s for the PDR200. If after looking at the cabling examples you still

have a question about how to connect ASPB cabling in your system, refer to

“Detailed Explanation Of ASPB Cabling” on page 50. General guidelines are

given there to help you connect cabl es as requir ed. After you have connected all

the ASPB cables, return to the installation procedure you were following.

Read the following paragraphs which give a brief functional description of the

cables connected to the ASPB, then proceed by looking at the cabling examples.

• Audio Clock Cables - These cables connect the ASPB to the video input

boards. The ASPB uses the clock signals from the video boards as a

reference to synchro nize audio sampling to non-synchronous video feeds.

• Sharcnet Ribbon Cables to Serial Digital Video I/O boards - The Sharcnet

ribbon cables carry the embedded audio signals to and from the ASPB.

• Sharcnet Cables Between ASPBs - If two ASPBs are installed in a unit, they

must be connected together using the se Sharcnet ribbon cables.

DVCPRO Upgrade Installation 41

Page 42

DVCPRO Board Installation

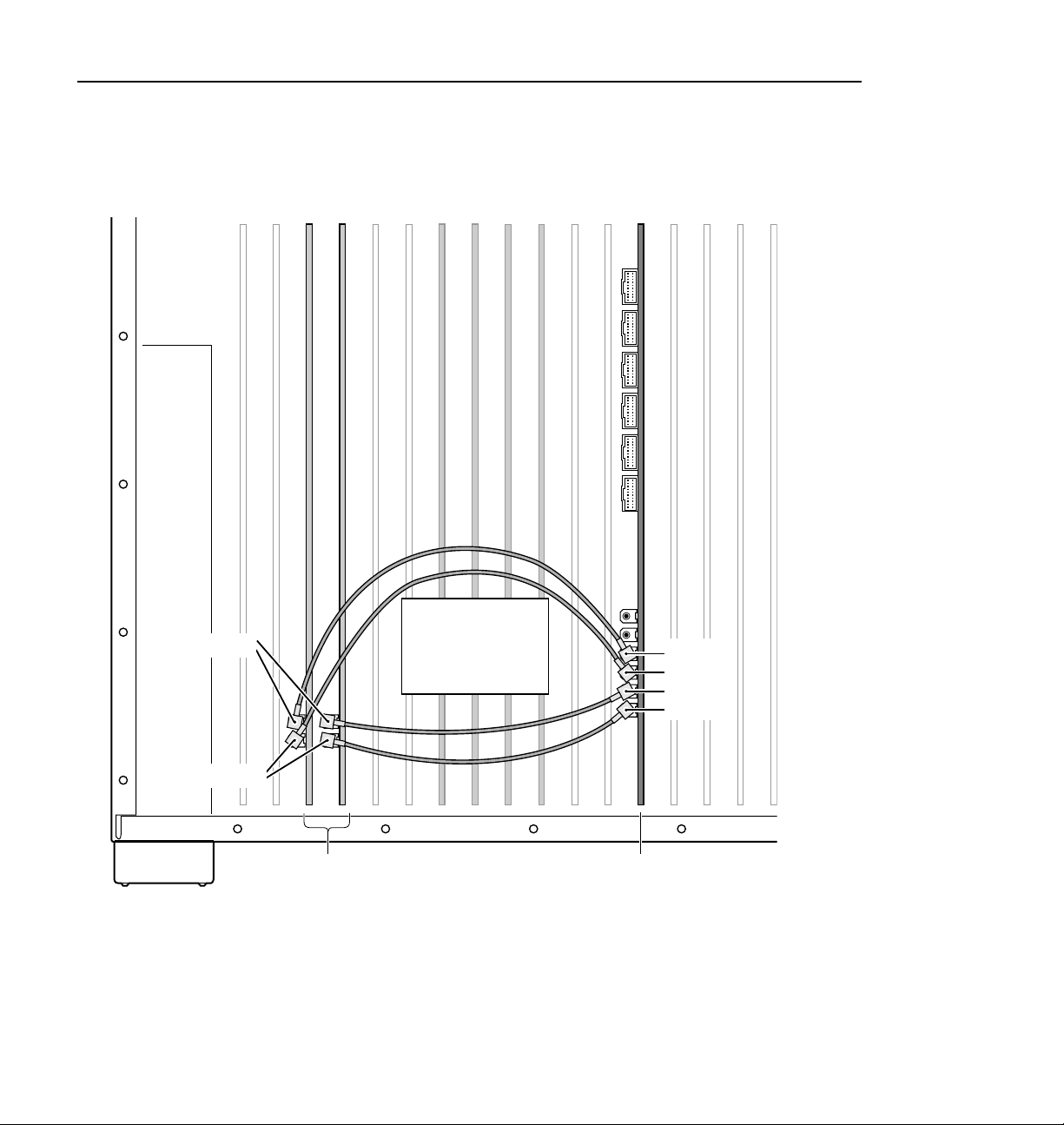

ASPB Audio Clock and Sharcnet Cabling Examples

This section shows four ASPB cabling examples that cover most DVCPRO

configurations for the PDR200. Find the example that matches your system and

use it to reconnect the ASPB cabling. Even though some board locations may be

different than yours, the cabling rules remain the same.

Two Serial Digital I/O Boards and One ASPB

The example in Tabl e 5 and Figure 9 shows audio clock and Sharcnet cabling for

a PDR204D having two Serial Digital I/O boards and one ASPB.

Table 5. Cabling for two Seri al Digital I/O boards and one ASPB

Cable Type Serial Digital

I/O Slot

Sharcnet J14 Sharcnet In Sharcnet Out 1

Sharcnet J14 Sharcnet Out Sharcnet In 1

Sharcnet J15 Sharcnet In Sharcnet Out 2

Sharcnet J15 Sharcnet Out Sharcnet In 2

Audio clock J14 Channel A Audio 1

Audio clock J14 Channel B Audio 2

Audio clock J15 Channel A Audio 3

Audio clock J15 Channel B Audio 4

Serial Digital I/O

Connection

ASPB1

Connection

(J5)

42 DVCPRO Upgrade Installation

Page 43

ASPB Audio Clock and Sharcnet Cabling Examples

J17 J13J16

Sharcnet In

Sharcnet Out

Channel B

J11 J9

J15 J14 J6J7

J12

PCI Interconnect Bd.

J10

DVCPRO CODEC

(Do not place cabling

on top of board.)

Fibre Channel

Master EDR

J8

Slave EDR

J4 J3 J2

J5

Sharcnet Out 1

Sharcnet Out 2

Sharcnet In 2

Sharcnet In 1

Audio 4

Audio 3

Audio 2

Audio 1

J1

Channel A

Serial

Digital I/O

Figure 9. ASPB cabling with two Serial Digital I/O boards and one ASPB

ASPB

0516-1

DVCPRO Upgrade Installation 43

Page 44

DVCPRO Board Installation

Three Serial Digital I/O Boards and Two ASPBs

The example in Ta ble 6 and Figure 10 shows audio clock and Sharcnet c abling f or

a PDR204D having three Serial Digital I/O boards and two ASPBs.

Tabl e 6. Cabling for three Serial Digital I/O boards and two ASPBs

Cable Type Serial Digital

I/O Slot

Sharcnet N/A N/A Sharcnet

Sharcnet N/A N/A Sharcnet

Sharcnet J13 Sharcnet In Sharcnet Out 1 N/A

Sharcnet J13 Sharcnet Out Sharcnet In 1 N/A

Sharcnet J14 Sharcnet In Sharcnet Out 2 N/A

Sharcnet J14 Sharcnet Out Sharcnet In 2 N/A

Sharcnet J15 Sharcnet In N/A Sharcnet Out 1

Sharcnet J15 Sharcnet Out N/A Sharcnet In 1

Audio clock J13 Channel A Audio 1 N /A

Audio clock J13 Channel B Audio 2 N/A

Audio clock J14 Channel A Audio 3 N/A

Audio clock J14 Channel B Audio 4 N/A

Audio clock J15 Channel A N/A Audio 1

Serial Digital I/O

Connection

ASPB 1

Connection

(J5)

Expansion 2

Expansion 1

ASPB 2

Connection

(J7)

Sharcnet

Expansion 1

Sharcnet

Expansion 2

Audio clock J15 Channel B N/A Audio 2

44 DVCPRO Upgrade Installation

Page 45

ASPB Audio Clock and Sharcnet Cabling Examples

J17 J13J16

Sharcnet In

Sharcnet Out

Channel B

J11 J9

J15 J14 J6J7

J12

Two-codec

DVCPRO (PDFDV02)

PCI Interconnect Bd.

J10

Four-codec

DVCPRO (PDFDV04)

(Do not place cabling

on top of board.)

Fibre Channel

Master EDR

J8

Slave EDR

J4 J3 J2

J5

Sharcnet Out 1

Sharcnet Out 2

Sharcnet In 2

Sharcnet In 1

Sharcnet

Expansion 1

Sharcnet

Expansion 2

Audio 4

Audio 3

Audio 2

Audio 1

J1

Channel A

Serial

Digital I/O

Figure 10. ASPB cabling with three Serial Digi tal I/O boards and two ASPBs

ASPB2 ASPB1

0516-9

DVCPRO Upgrade Installation 45

Page 46

DVCPRO Board Installation

Two Analog Composite I/O Boards and One ASPB

The example in Ta ble 7 and Figure 11 shows audio clock c ablin g for a PDR204A

having two Analog Composite I/O boards and one ASPB.

Table 7. Cabling for two Analog Composite I/O boards and one ASPB

Cable Type Analog

Composite I/O

Board

Slot

Audio clock J14 Channel A Audio 1

Audio clock J14 Channel B Audio 2

Audio clock J15 Channel A Audio 3

Audio clock J15 Channel B Audio 4

Analog

Composi t e I/O

Board

Connection

ASPB1

Connection

(J5)

46 DVCPRO Upgrade Installation

Page 47

ASPB Audio Clock and Sharcnet Cabling Examples

J17 J13J16

Channel B

J11 J9

J15 J14 J6J7

J12

PCI Interconnect Bd.

J10

DVCPRO CODEC

(Do not place cabling

on top of board.)

Fibre Channel

Master EDR

J8

Slave EDR

J4 J3 J2

J5

Audio 4

Audio 3

Audio 2

Audio 1

J1

Channel A

Analog

Composite I/O

Figure 11. ASPB cabling with two Analog Composite I/O boards and one ASPB

ASPB

0516-2

DVCPRO Upgrade Installation 47

Page 48

DVCPRO Board Installation

Three Analog I/O Boards and Two ASPBs

The example in Ta ble 8 and Figure 12 shows audio clock c ablin g for a PDR204A

having three Analog Composite I/O boards and two ASPBs.

Tabl e 8. Cabling for three Serial Digital I/O boards and two ASPBs

Cable Type Analog

Composite

I/O Board

Slot

Sharcnet N/A N/A Sharcnet

Sharcnet N/A N/A Sharcnet

Analog

Compos ite I/O

Board

Connection

ASPB 1

Connection

(J5)

Expansion 2

Expansion 1

ASPB 2

Connection

(J7)

Sharcnet

Expansion 1

Sharcnet

Expansion 2

Audio clock J13 Channel A Audio 1 N /A

Audio clock J13 Channel B Audio 2 N/A

Audio clock J14 Channel A Audio 3 N/A

Audio clock J14 Channel B Audio 4 N/A

Audio clock J15 Channel A N/A Audio 1

Audio clock J15 Channel B N/A Audio 2

48 DVCPRO Upgrade Installation

Page 49

ASPB Audio Clock and Sharcnet Cabling Examples

J17 J13J16

Channel B

J11 J9

J15 J14 J6J7

J12

Two-codec DVCPRO (PDFDV02)

PCI Interconnect Bd.

J10

Master EDR

Four-codec DVCPRO (PDFDV04)

(Do not place cabling

on top of board.)

J8

Slave EDR

Fibre Channel

J4 J3 J2

J5

Sharcnet

Expansion 1

Sharcnet

Expansion 2

Audio 4

Audio 3

Audio 2

Audio 1

J1

Channel A

Analog

Composite I/O

Figure 12. ASPB cabling with three Analog Composite I/O boards and two ASPBs

ASPB2 ASPB1

0516-8

DVCPRO Upgrade Installation 49

Page 50

DVCPRO Board Installation

Detailed Explanation Of ASPB Cabling

If you are fo llowing one of the cabling examp les, this s ection is for reference on ly.

Read this information if you have questions about the ASPB cabling.

Audio Clock Cabling

When the Profile system records, audio sampling must be r eferenced to t he video

signal, otherwise audio artifacts will occur. The ASPB hardware and Prof ile

software allows the you to select the appropriate audio sample reference for

recording as follo w s:

• When recording synchronous video feeds, use “system clock” derived from

house reference and supplied to the ASPB through its motherboard

connector.

• When recording non-synchronous video feeds, use the reference signal

supplied by the video input card over an Audio Clock coaxial cable

connected t o the AS PB .

Each ASPB has four audio clock input connectors for attaching an audio clock

reference. These connectors are attached by coaxial cable to the video input

boards. The cables carry a 27MHz refere nce signal derived from the video input

to the ASPB. This signal is used as a reference for the audio phase lock loops.

(See Figure 13.)

Audio

Sample PLLs

Audio Clock1

Audio Clock2 Group2

Audio Clock3 Group3

Audio Clock4

Figure 13. Audio clock groups and reference selectio n

Reference

Select

Crosspoint

System Clock

(from Genlock bd. through

the Motherboard connector)

Group1

Group4

Audio

Sample Clocks

Group1 Clock

(Channels 1-4)

Group2 Clock

(Channels 5-8)

Group3 Clock

(Channels 9-12)

Group4 Clock

(Channels 13-16 )

0047-14

50 DVCPRO Upgrade Installation

Page 51

Detailed Explanation Of ASPB Cabling

A single ASPB supports 16 audio channels. These 16 channels are divided into

four audio groups with four audio channe ls in each group. Group 1 consists of

channels 1 to 4. Group 2 consists of channels 5 to 8, and so on up to Group 4.

There is a phase lock l oop and a udio sample cloc k for eac h audio group 1 thr ough

4 as seen in Figure 13. You can also see in Figure 13 how the Reference Select

Crosspoi nt allow s sele ct ion o f the ref eren c e to the A ud io Sa mp l e Phas e L ock

Loops. Profile software allows the user to se lect the appropria te reference for the

Audio Sample Phase Lock Loops, either “system clock” derived from house

reference or one of the four audio clocks derived from video inputs.

When the potentia l for recording non-synchronous video feeds exists, it becomes

important to se lect the cor rect vi deo refe rence and to have the coa xial a udio cl ock

cables connected properly.

Here are the audio clock cabling guidel ines.

• Profile software recognizes and numbers video inputs beginning with

Channel A of the board in the lowest numbered motherboard slot.

• When two ASPBs are installed, ASPB1 is the ASPB in the lower number

board slot and ASPB2 is in the higher numbered slot.

• Profile software refers to the four ASPB audio clock references as

“Video Input 1” through “Video Input 4”.

• ASPB1 audio clocks 1 through 4 should be connected to video inputs 1

through 4.

• ASPB2 audio clocks 1 through 4 should be connected to video inputs 4

through 8, if installed.

• Audi o clock reference s connected to ASPB1 cannot be used by ASPB2. The

opposite is also true, references attached to ASPB2 cannot be used by

ASPB1.

NOTE: Do not connect any audio c lock cables to the connectors on the four

channel Composite Analog Video Output board. These are system clock

connectors and are not used because the ASPB receives system clock through

its motherboard connecto r.

DVCPRO Upgrade Installation 51

Page 52

DVCPRO Board Installation

If your Profile unit has one ASPB, you can connect only four audio clock

references t o it. If y our Profil e u nit has two ASPBs install ed, a to tal of e ight audio

clocks can be connected.

In practice, if your Pro file unit has more vid eo inputs than the number of ASPB

clock inputs, you should connect audio clocks from video inputs that might

record video that is not genlocked to your house reference.

Any video inputs that are not supplying a record clock to the ASPB should be

locked to your house reference, if audio is to be associated with those inputs.

Otherwise, audio clock errors could occur during recording.

For more information on audio input clocking refer the Audio Configuration

information in the Profile Family User Manual.

Sharcnet Cabling

Serial digital I/ O boards (SDI boards) with Sharcnet connectors have embedded

audio capabilit y. These SDI boa rds extrac t audio fro m incoming vide o, rout e it to

the ASPB, and receive audio output from the ASPB to be embedded in the serial

digital stream. Sharcnet cables are used to route the audio between the ASPB and

SDI boards.

On both the ASPB and SDI board there are Sharcnet In and a Sharcnet Out

connectors. These are shown in Figure 9 on page 43. In general, ASPB Sharcnet

Outs are conn ected to SDI Sharcn et Ins, and ASPB Sharcnet Ins are c onnected to

SDI Sharcnet Outs. Simple enough, but connection order is important.

Here are the guidelines for making the Sharcnet connections:

• Beginning with the ASPB in the lowest numbered slot (ASPB1), Sharcnet

In1/Out1 are connected to Sharcnet Out /In of the serial digital video board

in the lowest numbered slot.

• Next, Sharcnet In2/Out2 are connected to Sharcnet Out/ In of the serial

digital video board in the next higher numbered slot.

• The pattern above continues for ASPB2 if two ASPBs are installed.

• The Exact number of Sharcnet cables will vary depending on how many

serial digital video I/O boards are installed.

• When two ASPBs are installed, Sharcnet Expansion 1 conn ectors on each

board are connected the Sharcnet Expansion 2 connectors on the other.

52 DVCPRO Upgrade Installation

Page 53

Board Location Guide

This board l ocation gui de is pro vided to help y ou in stall the DVCPRO boards in a

PDR200 Video File Server that is not an Option DV, that is, not shippe d from the

factory as DVCPRO ready. The board layout for an Option DV PDR200 eases

DVCPRO board installation, but other systems may require that you move

existing boards to accommodate the DVCPRO boards. This guide will help you

do that.

If you move any circuit boar ds, remember that some boards must oc cupy specific

slots, while others can be installed in almost any slot as long as their I/O

requirements are met (see Table 10 on page 57). The board location guide

identifies the vid eo router inputs and outputs of each Profile board currently

available, as well as the input and output connections on the video router

connectors on the motherboard.

This guide provides a general approach to board location. It explains the

relationship between the motherboard and video router connectors and provides

tables, charts and examples to as sist you in installing boards.

Video Router to Motherboard Relationship

Board Location Guide

The video router provides and contr ols video data to twelve connectors on the

motherboard. These video dat a connectors are align ed with the main motherboard

connectors for s lots J5 through J16. Since the Referenc e Genlock (Ref Gen) boar d

must occupy J16 to pro vide the nece ssary syste m clocks, thi s discussi on excl udes

J16.

When choosing a slot for a board, the major constraint f or a slot is how the board

connects to the video router . Not all boards require the same number of video I/O

connections, and not all video dat a connectors provide the same number of video

I/O connections. Therefore, you must know how many input and output

connections the board need s, if any, and the slots available tha t meet those needs.

Table 10 on page 57 lists each of t he boards which may be installed in the Profile

system and the recommended slots, possi ble alternatives, and restrictions f or each

board. If more than one slot is recommended or possible for a board, those slots

are listed in the order of preference.

DVCPRO Upgrade Installation 53

Page 54

DVCPRO Board Installation

Video Router I/O Connections

Now let’s look at the video router connections available at slots J5–J15. Table 9

shows a board location workshee t that shows the video router input and output

connections. The worksheet is blank except for the 5 board slots reserved for the

boards that are connected by the PCI Interconnect board. In this chart:

• The

Slot column lists each slot on the motherboard connected to the video

router.

• The

Board column is where you write the boards currentl y insta lled and the

name of the board you want to install.

• The

Input column identifies input connections available to the installed

boards from the video router. The numbers in the blocks correspond to the

order input connections are assigned at the video router connector.

• The

Output column identifies output connections availa ble from the

installed boar ds to the video rou ter. The numbers in t he blocks corre spond to

the order output connections are assigned at the video router connect or.

• The shaded blocks in the diagram indicate video router connections shared

between slots. A shar ed connec tion is avail abl e to eithe r slot, but not both at

the same time. For instance:

- The shaded input blocks betwe en slots J5 and J6, slots J7 and J8, slots J10

and J11, and slots J12 and J13 indicate shared input connections.

- The sha ded output blocks be tween slots J8 and J9, slots J10 and J11, and

slots J12 and J13 indicate shar ed output connections.

54 DVCPRO Upgrade Installation

Page 55

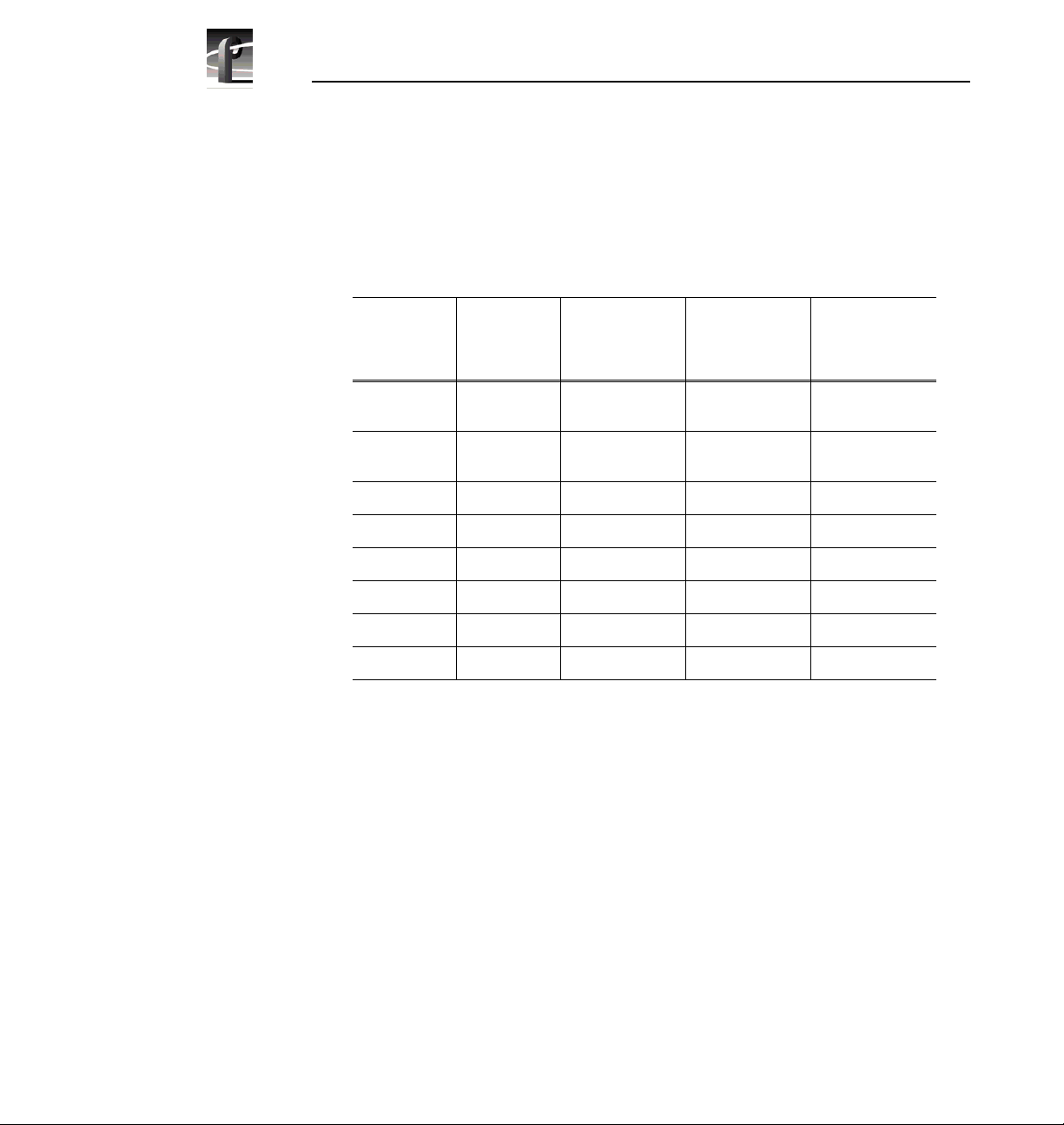

Video Router I/O Connections

Table 9. Board location chart

Slot Board Input

J5

J6

J7 1 1

J8 Slav e Enhanced Disk Recor der

J9 Fibre Channel (if installed) 1

J10 Master Enhanced Disk Recorder 1

J11

J12 DVCPRO CODEC (PDFDV02) 1

J13 2 4 3

J14 1 1

J15 1 1

DVCPRO CODEC (PDFDV04)

b

a. Shaded areas indicate router points shared between board slots ;

or out p ut is used by the bo a r d

.

a

Output

1

23

62

5

4

31

2

1

2

3

42

5

6

2

1

22

2

4

3

2

1

2

3

4 3 4

12

23

23

3

indicates which input

1

2

3

1

3

3

3

3

3

3

3

3

3

3

2

3

3 4

4 3

1

1

3

2

3

3 4

4 3 3

2

3

1

3

1

3

2

3

1

2

2

b. I f JPEG #2 and DVCPR O25 #4 are used , they must both be co nnec ted to the same video

input via the internal vid eo crosspoint router, otherw ise, the wrong video input may be

recorded. T o avoid this restriction, use one of t he other three JPEG co decs available in

the system.

a

3

DVCPRO Upgrade Installation 55

Page 56

DVCPRO Board Installation

Selecting a Board Location

Here’s how to use the tables to select a location for a board. Make a copy of

Table 9 t o use as a temp lat e fo r recording inform at io n for board pla cem en t .

1. Write the board na me in Table 9 and, referring to Table 10, put a check mark

3

) in each input and output block used by each board currently installed in

(

your Profile system. Start with the 1 block for each board.

2. Look in Table 10 to see the input and output requirements and both the

recommended slot and alternative slots for the board you want to install.

3. Look in Table 10 for a slot with the required video router connections

available. Starting with t he 1 block, put an 8 in each block that corresponds

to an input and output requirement for the newly added board. If the

recommended slot is occupie d, or there are not enough input or output blocks

available, lo ok at the al te rnat i ve slo ts.

4. If all input and output requirements for the board match the available ones

for the slot, write the board na me in the

the board.

NOTE: If you ca n’t find an open slot with the I/O connections which meets

the I/O requirements of the board you want to instal l, y ou will have to move

existing boards. You can use Table 9 and Table 10 to experiment with various

board locations before deciding on one.

Board column for the slot and install

56 DVCPRO Upgrade Installation

Page 57

Selecting a Board Location

Table 10. Board I/O requirements and restrictions for a PDR200 with DVCPRO boards

Board Video Router

Connection

Requirements

Inputs Outputs

CPU n/a n/a J1 None Reserved for PC card only. PC/VGA/LAN

VGA n/a n/a J2 None ISA only. Parallel p ort in S/N B050000 and U p

LAN n/a n/a J3 None EISA connection only. May be empty in

SCSI n/a n/a J4 None EISA connection only

RefGen n/a n/a J16 None Reference genlock

RS-422 n/a n/a J17 None EISA only