Page 1

Adder II User Guide

M4046-9900-102

24 July 2014

Page 2

Notices

Copyright & Trademark Notice

Copyright © 2006–2014, Grass Valley. All rights reserved.

Belden, Belden Sending All The Right Signals, and the Belden logo are trademarks or

registered trademarks of Belden Inc. or its affiliated companies in the United States and

other jurisdictions. Grass Valley, Miranda, Adder II are trademarks or registered trademarks

of Grass Valley. Belden Inc., Grass Valley, and other parties may also have trademark rights

in other terms used herein.

Terms and Conditions

Please read the following terms and conditions carefully. By using Adder II documentation,

you agree to the following terms and conditions.

Grass Valley, a Belden Brand (“Grass Valley”) hereby grants permission and license to owners

of Adder II to use their product manuals for their own internal business use. Manuals for

Grass Valley products may not be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose unless

specifically authorized in writing by Grass Valley.

A Grass Valley manual may have been revised to reflect changes made to the product

during its manufacturing life. Thus, different versions of a manual may exist for any given

product. Care should be taken to ensure that one obtains the proper manual version for a

specific product serial number.

Information in this document is subject to change without notice and does not represent a

commitment on the part of Grass Valley.

Warranty information is available in the Support section of the Grass Valley Web site

www.miranda.com).

(

Title Adder II User Guide

Part Number M4046-9900-102

Revision 24 July 2014

ii

Page 3

Table of Contents

1 Adder II System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the Adder II system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Adder II Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Base Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Input/Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Laser Radiation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FCC Part A Manual Notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CE Approved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Setting Up an Adder II System . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing and Configuring the Adder II System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Fiber Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Verifying Optical Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Coaxial Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Other Display messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Other Base Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Data Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

+18/+24 Audio Level Reference Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Signal Generator/Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Analog TX and RX Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Analog TR Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Analog TX Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Analog RX Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Local and Remote Gain Control of Analog Audio Modules . . . . . . . . . . . . . . . . . . . . . . . . .18

Selecting Channels to Modify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Setting Gains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Setting Phantom Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

AES 8 TX and RX Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

External AES Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Intercom Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4-wire (balanced). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Clear-Com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Nulling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Powered (Wet) and Unpowered (Dry) Intercom Systems . . . . . . . . . . . . . . . . . . . . . . 23

RTS Telex. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Installing/Removing Intercom Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

iii

Page 4

Table of Contents

Data Transport Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

A2-DATA-8 Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Legacy Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

AES 16 input and output modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Clear-Com Intercom Modules (original version). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Diamondback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Setting 75 Mbps operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

IntercomCable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4-Wire XLR 5-pin to two XLR 3-pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Adder II to Clear-Com Matrix Plus Intercom Stations . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Adder II to Clear-Com Matrix Plus Intercom Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Issues and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Accessory List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

iv

Page 5

Adder II System Overview

This chapter provides an overview of the Adder II system by presenting the system

components and identifying the main component items.

About the Adder II system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Adder II Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1

Page 6

Adder II System Overview

About the Adder II system

About the Adder II system

The Adder II is a high-performance link for transporting analog and digital audio, two and

four wire intercoms, and various data formats using lightweight fiber optic cable. As a

modular system, the Adder II is highly configurable and scalable for use as a point-to-point

signal transport.

The Adder II features include:

• Up to 64 bi-directional channels of audio

• Four intercom module slots providing up to eight intercom channels

• Data and GPI capabilities

• Remote audio gain control

• Phantom mic power

• Industry leading latency and signal-to-noise specifications

An Adder II system is constructed from single RU frames that interface to a common

backplane, allowing the system to be sized to various requirements. Analog and AES TX and

RX frames can be combined with Intercom and Data frames to create an audio system that

is perfectly suited to your particular application. Whether you need 32 x 32 analog or 32

analog to 16 AES signals in just one direction, with or without intercoms and data, Adder II

gives you maximum flexibility.

Analog modules come in rows of 16 while AES modules are in rows of 8 and 16. In this way,

an AES TX can interface to an analog RX, thus bypassing the need for expensive D-A and AD converters. With ultra-low latency, delay is never an issue.

Analog TX modules feature preamps that allow 0, 10, 20, 30, 40, and 50 dB of gain

adjustments plus 12/48V phantom power via a convenient faceplate controls and LED

display. The Adder II includes remote control of these functions. With an optical budget

exceeding 25 dB, the Adder II can operate across the theater or across town.

Operation can be on one or two fibers or two standard coaxial cables. It is dual-wavelength

and can be easily converted to WDM single-fiber operation. GPI's and data channels are on

DB-9 connectors with RS-232, RS-422, and RS-485 ports. A built-in signal analyzer features

an LED bar graph and signal generator with three different tone frequencies and three level

choices in both the analog and digital domains.

The Adder II ships pre-configured and requires minimal onsite configuration.

2

Page 7

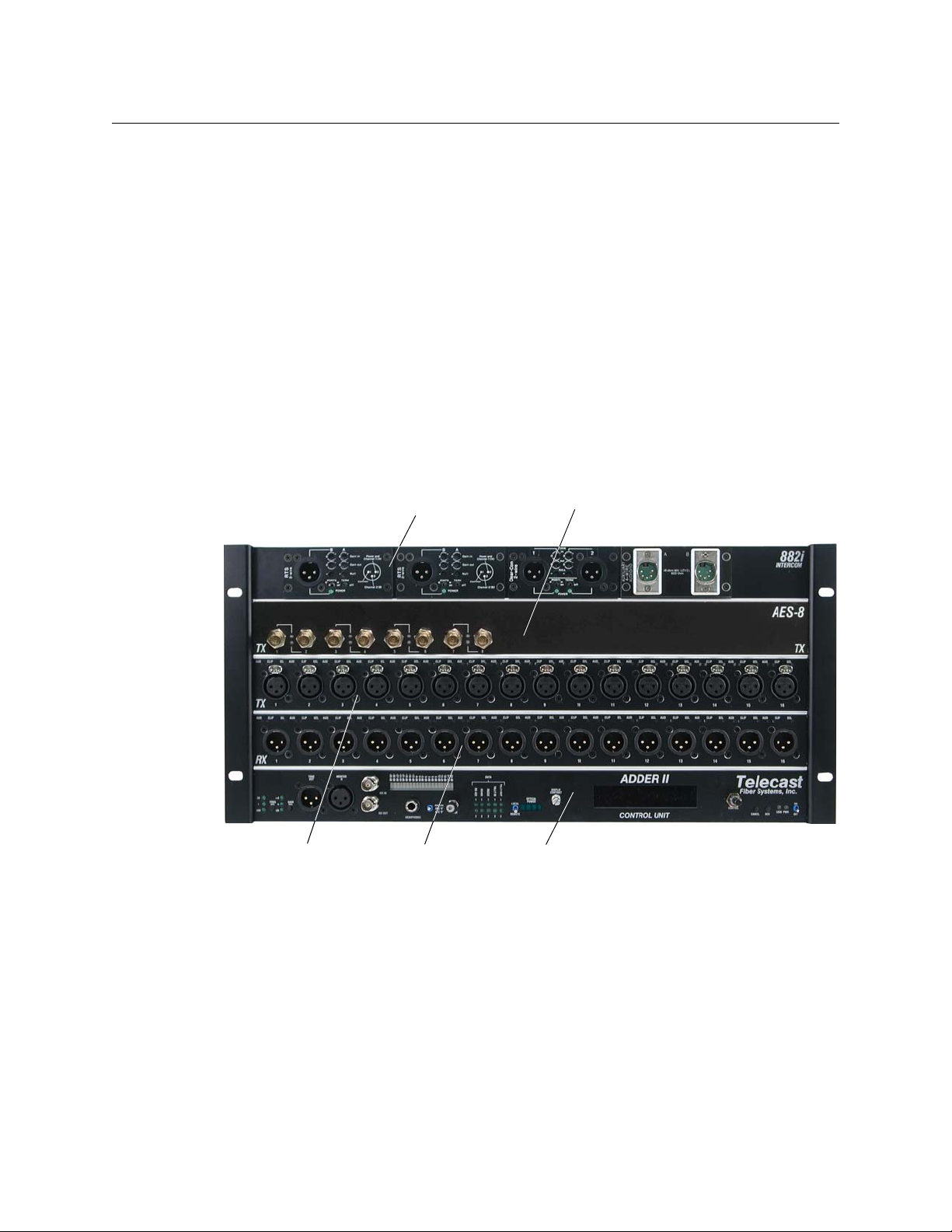

Adder II Components

Base Unit

Each end of an Adder system consists of at least two parts: One base frame with control unit

and one or more input/output (I/O) modules.

Base units are common to all Adder II’s no matter how large or small. This is the optical I/O

and the first building block of all systems. The base frame also has the on/off switch for the

system, the local gain controller, the data I/O’s, and to thetone generator/analyzer.

Input/Output Modules

Each Adder II can be configured with one to nine input/output modules depending upon

the frame size selected. All I/O modules are one RU high.

Adder II

User Guide

Fig. 1-1: Adder II Base Control Unit Front Panel

Fig. 1-2: Input and Output modules

The input /output modules, also referred to as “banks”, can be any of a range of input or

output modules including analog or digital audio and intercom.

• For analog signals, banks are 16 wide.

• For AES signals, banks are 8 wide (16 channels).

• Otherwise, the base is always bank 0.

The next row up is Bank 1, etc. as long as all signaling is analog. If intercom modules are

installed, this module would always be the top-most module.

Systems are delivered pre-configured and each frame will be a mirror image of the other, so

that if Bank 2 on one end is a TX module, then Bank 2 on the other end will be an RX

3

Page 8

Adder II System Overview

I/O Module, Bank 4

When Intercom module is installed it is

always in the top position

I/O Module

Bank 3

I/O Module

Bank 2

I/O Module

Bank 1

Base System Control Unit

(always lowest module)

Front Panel

module. It is possible to do analog to digital conversion between frames, so one end can be

analog and the other end can be digital/AES.

Each Adder II can accommodate one or two 12 VDC power inputs @ 3 Amps via 4-pin XLR or

terminal strip. Grass Valley’s ADAP-AC-04 is an acceptable external DC power supply.

Depending on version, there may be a third 12-18VDC input for intercoms.

If you require re-configuration of your Adder II system, it should be returned to Grass Valley.

Call our support department (see

Materials Authorization) number.

When removing the Adder II from the shipping boxes, check everything over for any

damage, including missing optical caps, bent metal or pins, and case scratches. Be assured

that the utmost care was taken in building and packing your Adder II, so report any damage

to the carrier and to Grass Valley.

Front Panel

Contact Us on page 37) and request an RMA (Return

4

Fig. 1-3: Adder II 5RU System Front Panel

Page 9

Rear Panel

Speaker on/off

switch

Speaker

Remote Bus

(not supported)

I/O Module, Bank 2 and up

Blank rears

Base System Control Unit

(always lowest module)

AES Sync In

GPIO and Serial

Data Ports

Redundant fiber System

interconnection

Coax system

interconnection

Audio level

standard

Redundant

DC Power

Intercom (wet)

Power

Adder II

User Guide

Fig. 1-4: Adder II 4RU System Rear Panel

5

Page 10

Adder II System Overview

Laser Safety

Laser Safety

WAR NIN G: Class 1 Laser. Do not stare into a connector port or fiber.

Laser Radiation

The unit is a CDRH Class 1 laser device. Although this means it is Eye Safe, you must avoid

looking directly at, or staring into, the laser beam located on an ST connector or on the end

of a fiber.

Infrared radiation is produced at the fiber connection port on the front of the unit and at

the end of unterminated optical fibers that are attached to this port. Avoid any direct

exposure to the light that comes from these sources.

Do not enable the laser when there is no fiber attached to the fiber connection port.

Do not attempt any type of service to this instrument other than what is instructed in this

manual. Refer any servicing needs to Grass Valley, a Belden Brand (see

page 37).

Contact Us on

FCC Part A Manual Notice

This equipment has been tested and found to comply with the limits for a Class-A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user must correct the

interference at their own expense.

CE Approved

This is a Class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate corrective measures.

6

Page 11

Setting Up an Adder II System

This chapter provides an overview of the Adder II components and features and explains

how to set them up.

Installing and Configuring the Adder II System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Other Base Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Analog TX and RX Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Local and Remote Gain Control of Analog Audio Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

AES 8 TX and RX Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Intercom Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Legacy Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

IntercomCable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7

Page 12

Setting Up an Adder II System

Installing and Configuring the Adder II System

Installing and Configuring the Adder II System

To install and configure the Adder II system, follow these steps

1 Connect the power cables (see Power Requirements on page 9).

2 Connect the fiber and coaxial cables (see Connections on page 10).

3 Configure the data transport protocols (see Data Transport on page 13).

4 Configure the audio levels (see +18/+24 Audio Level Reference Settings on page 14).

5 Configure the Signal Generator (see Analog TR Modules on page 16).

6 Configure the Analog TR, TX, and RX modules (see Analog TX and RX Modules on

page 16).

7 Configure the Gain Control and Analog audio modules (see Local and Remote Gain

Control of Analog Audio Modules on page 18).

8 Configure the AES 8 TX and RX modules (see AES 8 TX and RX Modules on page 20).

9 Connect the Intercom modules (see Intercom Modules on page 21).

10 Interface with Legacy systems (see Legacy Systems on page 26).

11 Wire the Intercom cables (see IntercomCable Wiring on page 28).

8

Page 13

Power Requirements

Adder II Systems are largely “Plug and Play”, but there are several steps that must be

followed to ensure the reliability of your system. Providing reliable DC power and having

properly installed fiber optic cables are critical in maintaining reliable operation.

Any power supply used with your Adder II must provide a minimum of 3 amperes,

continuous, at 12 to 18 VDC. Power input is either through two 4-pin XLR-M connectors or

two terminal strips located on the left side of the rear panel that provide for full power

redundancy; see the table below for pinout and

outlets are within reach of their six-foot power cords.

Adder II

User Guide

Figure 2-1 for location. Be sure that AC

Fig. 2-1: Power Input Location

Pin Description

Pin 1 Ground

Pin 2 No connection

Pin 3 No connection

Pin 4 + VDC

Grass Valley’s ADAP-AC-04 meets the power requirements for Adder II, but any other

suitable DC supply may be used. Note that a fully loaded 125 Mb/sec system (64 bidirectional channels) can draw up to 5 Amps.

Once power is applied to the rear panel, the front-right mounted switch on the Base unit is

used to “power-on” the system.

• A Green LED near the input XLR’s indicates the presence of DC power.

• ARed LED next to the power switch on the front panel indicates that DC is present.

• A Green LED indicates that power is On.

Frames equipped with an 882i intercom bank will require it’s own 12-18 VDC power

connection to the INTERCOM POWER INPUT 30VDC above the MAIN input. The same wiring

conventions apply.

9

Page 14

Setting Up an Adder II System

1310 NM

Fiber I/O

1550 NM

Fiber I/O

Coaxial

I/O

Connections

Connections

Fiber Connections

WAR NIN G:

Never look directly into the unit of a connected optical fiber while any component of

the system is operating. Eye damage is possible.

Use the onboard optical power meter as a means of testing the optical signal at both

ends of your optical link.

An infrared laser diode that is coupled to the fiber generates the optical output from each

TX. User connections are made at bulkhead ST type connector s on the rear panel (see

Figure 2-2). You can use either single mode or multimode fiber, but take care to never mix

types of fiber in a given run. Once you employ WDMs into the system, their type will dictate

the type of fiber to use.

The RX inputs use an InGaAs pin diode and amplifier to convert the optical signal back into

an electrical signal.

Fig. 2-2: Fiber and Coax I/O Locations, Rear Panel

10

There are several ways to configure fiber in your Adder II systems:

• 1310 only: two fibers connect the IN’s of each to the OUT’s of the other in the 1310nm

optical window.

• 1550 only: two fibers connect the IN’s of each to the OUT’s of the other in the 1550nm

optical window.

• 1310 in one direction and 1550 in the other: requires only one fiber per link but

requires the addition of either an internal or an external WDM.

Page 15

In either scenario, you can make two links and the Adder II will automatically switch links

Optical Power

Display

LINK LED

should one fail. This solution offers complete and automatic optical redundancy (see

Figure 1-1).

Once you choose your method of connection, inspect the fiber ends and clean them with

Kim-Wipes that have been wet with pure isopropyl alcohol. Fingerprints or other dirt on the

optical connector end surfaces will reduce the received optical signal level.

Note that, unlike previous Adder systems, the fiber has priority in the Adder II. This means

that the system will always look for a link on the fiber ports first and then on the coaxial

ports. But also note that the coax path can be used as a redundant path.

Verifying Optical Link

Once both ends are powered up and your fiber connections are made, it becomes a simple

matter to verify how you are connected and the status of your optical link.

In the center of each Base faceplate there is a 4-Segment display labeled OPTICAL POWER.

The actual location is indicated in

Adder II

User Guide

Figure 2-3.

Fig. 2-3: Optical Power Display and LINK LED Location, Front panel

• With the switch to the REMOTE position, the display will indicate the optical power at

the other end of the link if the link is good. Otherwise it will display N/A as shown in

Figure 2-1.

• With the switch in the LOCAL position, the display will indicate both the INPUT that the

frame is linked to and the received optical power in dBm’s. The second two photos, in

Figure 2-4, show that the box is looking at both inputs A and B, but that there is no

optical power present. If the link is good, a value for the optical power would be

indicated. An optical power reading between -5 and -22 dBm will be optimal.

Fig. 2-4: Optical Power Display – various conditions

In addition to the optical power readings, a Green LOCK LED on the right side of the Base

faceplate (next to the power switch) indicates that the frame is properly linked. A Red LED

indicates no link/lock (see

Figure 2-2).

11

Page 16

Setting Up an Adder II System

Coaxial Connections

If the switch is on the REMOTE position and the frame on the other side of the link is not

locked, the display will indicate NoLk.

Coaxial Connections

Figure 2-2 above shows the position of the COAXIAL I/O (labeled 75/125 MBPS) on the rear

panel of the Base. As an alternative to using fiber, the Adder II system can support full

operation on two coaxial cables of up to 300m (1000 ft) in length.

When not linked, the system looks for an active link on the fiber and COAX ports. In this way

(and unlike previous Adder versions), the coax canserve as a redundant path in conjunction

with one or both of the optical paths.

Fig. 2-5: Link LOCK Status LEDs

Connection is simply a 75 Ohm coaxial cable from the OUT on each frame to the IN on the

other.

The COAX ports are also used (the Adder II must in 75 Mbps mode) when paired with bidirectional DiamondBack II’s or DiamondBack 4x4’s. See

more information.

Other Display messages

A fiber or coax break (depending on configuration) or loss of signal from one end of the link

to the other will result in the message Communication Lost.

The message Illegal configuration or loopback will appear if you pair two chassis that

have a TX module in one chassis for which there is no corresponding RX module in the

other.This message will also appear if you loop back the fiber or coax so that the chassis is

talking to itself. The message goes away as soon as you press any button.

Legacy Systems on page 26 for

12

Page 17

Other Base Features

Data Transport

The Adder II Base units have built-in data support for:

• 2 Tally (GPI)

•2 RS-422

•2 RS-485

•2 RS-232

Adder II

User Guide

Fig. 2-6: Data Connectors on Base Rear Panel

The pin-outs for the DB-9 connectors are described on the rear panel above the connectors

Tab le 2-1(see Figure 2-7 for position). Note that these pinouts are non-standard,so

and in

you will require custom cables.

Fig. 2-7: Data LEDs

Front panel LED indicators will flash with data traffic or stay constant Green in the case of a

closed (shorted) Tally/GPI.

The Adder II accepts and multiplexes up to two RS-232, two RS-422, and two RS-485 digital

data signals and two remote relay closures. The other side of the link then receives the

13

Page 18

Setting Up an Adder II System

+18/+24 Audio Level Reference Settings

aggregate data, restores the digital signals and provides switch closures. The number of

data channels is fixed and independent of the number of audio channels in the assembly.

Both data input and output are accomplished on the same connector.

Digital signal connections are made via 9-pin D connectors; see Figure 2-6. The connection

specifications are listed in Tab le 2-1; note that these pinots do not conform to standard

serial pinouts and custom cable wiring will typically be required when connecting to thirdparty devices. Several interconnection cables are described in

page 28. A 110 Ohm terminating resistor placed across the balanced inputs may be needed

if input cable lengths are in excess of six feet.

PIN Conns 1 & 2 Conns 3 & 4 Conns 5 & 6 Conns 7 & 8

1 422 TX (-) 485 TX/RX (-)

2 GPI Out (+) 485 TX/RX (+)

3 GND GND GND GND

4 232 RX

5 422 RX (-)

6 422 TX (+) 232 TX

7 GPI Out (-)

8 GPI In (+)

IntercomCable Wiring on

9 422 RX (+)

Table 2-1: Data pin-outs

Contact closure input is activated by pin 8 on contact to ground or to a TTL logic 0 signal

level. Contact closure output is established by an isolated, normally open, dry contact built

onto the Main PC Board. The eight digital I/O connectors are AMP 747905-2, D-sub female

or equivalent.

Additional data ports can be added in groups of 8 with A2-DATA-8 I/O strips.

+18/+24 Audio Level Reference Settings

The rear-panel +18/+24 switch toggles the Input analog audio encoder that can be set at

either 18db or 24db. This will determine the level where analog input audio will clip. It is

not necessary that both ends of the link be set the same.

14

Fig. 2-8: +18/24 Switch Location

Page 19

Signal Generator/Analyzer

The integrated audio signal generator/analyzer is a convenient way to confirm signal

presence for both analog and digital (AES) audio signals.

Tone for analog signals is accessed via the XLR-Male connector TONE OUT using standard

XLR audio cable. Three different frequencies (20Hz, 400HZ and 1k Hz) are available at three

different audio levels (-20, 0 and +8 db) to allow easy channel verification/identification.

Selection is via the small buttons on the lower right side of the base unit (see

For digital signals, tone (Line Level @ 1Khz) is available on the AES OUT BNC.

A built-in speaker is accessed via XLR-Female connector MONITOR IN (for analog signals)

using standard XLR audio cable. Digital signals are monitored via the AES IN BNC. The

speaker is directly associated with the audio level bar graph that will indicate audio levels

from -33 to +24 db. Speaker volume is controlled via the VOLUME knob.

Adder II

User Guide

Figure 2-10).

Fig. 2-9: Analog/Digital Signal Generator/Analyzer

In order to monitor analog and AES signals properly, payattention to the switch to the left

of the VOLUME knob.

Fig. 2-10: AUD MON On/Off Switch

When monitoring only analog signals, the switch can remain in the top ANALOG position.

For AES signals, A refers to the left component and B to the right component of a given AES

signal. Be sure you are monitoring the correct “side” of your digital signals.

Use of the headphone jack (1/4” standard) automatically disables the external speaker.

There is also a switch on the rear of the frame for disabling the speaker.

15

Page 20

Setting Up an Adder II System

2

1

2

3

Input (female) Output (male)

Line Level Inputs and Outputs

Analog TX and RX Modules

Analog TX and RX Modules

The modules in your system are factory-configured for your specific requirements. It is not

recommended to try to change the configuration.

Analog audio I/O is via 3-pin XLR connectors with industry standard wire locations (see

table below). Analog TX and RX modules are in groups of 16 channels.

The XLR connectors are located on the front panel of each module.

• On the input modules, XLR connectors are female Neutrik type NC3FPR-H.

• On the output modules, XLR connectors are male Neutrik type NC3MG-H (refer to

Figure 2-7).

PIN SIGNAL

1 Ground

2 Balanced I/O (+)

3 Balanced I/O (-)

Fig. 2-11: XLR Connectors on TX and RX Modules

Analog TR Modules

Adder II Analog TR modules have eight line level inputs and eight line level outputs as on

the same single module as shown in

There are no gain pr phantom adjustments for the 8x8 module. LEDs show AUD Signal

presence and CLIP only.

16

Figure 2-12.

Fig. 2-12: Analog TR Module

Page 21

Analog TX Modules

Adder II Analog TX modules are 16 inputs wide as shown in Figure 2-13 .

• AUD: blinks Green with audio presence

• CLIP: glows Red when audio levels are clipping

• SEL: glows Blue to show that the channel is selected for adjustment

Adder II

User Guide

Fig. 2-13: Analog TX Module and Analog TX LED indications

Each input accepts a mono audio signal on a male XLR. Input levels can be mic or line level

and gains as well as phantom mic power can be set from the bottom base unit.

Input parameters can be set for individual channels or entire modules/banks.

Analog RX Modules

The analog RX modules feature 16 XLR-M outputs. The module faceplate is shown in

Figure 2-14.

Each output has 3 associated LEDs as shown in Figure 2-14 .

• AUD: blinks Green with audio presence

• CLIP: glows Red when audio levels are clipping

• SEL: glows Blue to show that the channel is selected for adjustment

Fig. 2-14: Analog RX Module and Analog RX LED indications

Each output provides a mono audio signal on a male XLR. Levels can be set at either side of

the link.

17

Page 22

Setting Up an Adder II System

Local and Remote Gain Control of Analog Audio Modules

Local and Remote Gain Control of Analog Audio Modules

Analog gains are adjusted via a knob and two buttons on the Base Unit. The following

selection describes procedures for making input adjustments. Control location is indicated

Figure 2-15. Note that adjustments for an audio path can be set from either end of the

in

link.

Fig. 2-15: Local gain controller/selector

The process starts by pressing the ACK button and then dialing the control knob indicate

the proper “Bank” or module. All modules except the base and 882i can be addressed. An

attempt to address an audio path that does not contain an analog TX will result in the

message gain ”[FIXED]”. An example of this might be an AES TX connected to an analog RX.

Remember that the Base Control Unit occupies Bank 0, so that the first module up is Bank 1,

the second is Bank 2, etc. Once you have found the analog module that requires

adjustment, press the ACK button to acknowledge that you are in position to select

channels to modify.

You may press the CANCEL button at any time to start the process over from the beginning.

Once you have selected the proper Bank, you can now opt to select one channel or make a

universal change to all of the channels in that Bank.

Selecting Channels to Modify

By using the knob to scroll to Chan:ALL, you can change gain and phantom voltage for all

16 inputs in one step.

and blinking. LED’s above the channels will remain illuminated to show that a change has

been made from unity gain or no phantom voltage.

Figure 2-13 shows that the SEL LEDs for all 16 inputs are illuminated

18

Fig. 2-16: Starting point

Page 23

Adder II

User Guide

If you wish to only change a parameter for a single input, rotate the knob until the desired

channel is indicated in the display AND the proper SEL LED is flashing over the

input/inputs.

Fig. 2-17: All Channels selected

Once you are satisfied with your selection, press the ACK button. The SEL LED will remain

blinking as long as you are working on that particular input/inputs and will remain on to

show that some parameter for that channel has been changed.

Figure 2-18 shows that we

will be working on Channel 2.

Setting Gains

Once you have selected a channel (or channels) to work on, you can adjust gain and

phantom power settings.

Once the ACK button is pressed to select an input or inputs, GAIN will flash in the display.

You may now use the control knob to toggle through six gain options; 0db, +10db, +20db,

+30db, +40db and +50db. Once the desired gain level is displayed, press the ACK button to

set.

Fig. 2-18: Channel 2 selected

Figure 2-14 shows the display when adjusting gain for channel 2.

Fig. 2-19: Setting Gain

Figure 2-14 shows that the gain was set to +50db.

19

Page 24

Setting Up an Adder II System

AES LEDs

Setting Phantom Voltage

Setting Phantom Voltage

Once the gain change is acknowledged, Volts will flash. Use the control knob to toggle

between the three phantom voltage options: 0V, 12V, and 48V. Once the desired voltage

level is displayed, press the ACK button to set.

phantom power to 48V.

Note that there will be a short delay while the inputs are updated with the new settings.

The Adder II system will remember any gain or phantom settings between power ups.

If a frame is linked to a different frame, the settings from the analog TX modules will be

restored on both ends of the system. The message Synchronizing With Remote Unit will

appear as settings are restored during start-up or following a power or fiber failure. And loss

of link will result in the display of Communication Failure.

Figure 2-14 shows that we are setting the

Fig. 2-20: Setting Phantom Voltage

The Adder II will remember all settings following a power failure.

AES 8 TX and RX Modules

The TX and RX AES 8-channel modules feature BNC connectors for input and output. A

representative module is shown in

Each channel has a single green LED that indicates signal presence. All levels and other

signal parameters are as defined by the AES-3 specification (user bits are NOT maintained).

Modules come in 8 TX and 8 RX.

External AES Sync

Figure 2-21 .

Fig. 2-21: AES-8 TX and AES LEDs

20

Input AES audio is synchronized by local internal clock or can be synchronized to an

external source connected to the BNC connector located on the rear panel. Any AES digital

signal with or without audio (null word okay) can be used for this purpose.

Page 25

Intercom Modules

The 882i Intercom module can house up to 4 ADDR-AUX modules:

•Balanced 4-wire

•Clear-Com 2-wire

• RTS/Telex compatible 2-wire

Intercoms can be of any type in any location in the assembly. However, for proper operation

of the intercom channels, the same placement order must be followed at the other side of

the system. A 2-wire system can be interconnected with a 4-wire system at another Adder

II, but not all intercom functions will work (for example, calling).

4-wire (balanced)

4-wire Auxiliary (balanced) intercoms use an individual 5-pin XLR on each of the two

channels in each module (see

table. Intercom Module Gain is 0 dB.

Adder II

User Guide

Fig. 2-22: 882i Intercom Modules

Figure 2-21). XLR pin functions are given in the following

PIN FUNCTION IMPEDENCE SIGNALS

1 Ground

2 Input (+) 600 Ohm input Line: +8 dBm

3 Input (-) 600 Ohm input Mic: -32 dBm

4 Out (+) >=600 Ohm load +8 dBm

5 Out (-) >=600 Ohm load +8 dBm

Fig. 2-23: Intercom Module: 4-Wire Auxiliary (balanced)

21

Page 26

Setting Up an Adder II System

Clear-Com

Clear-Com

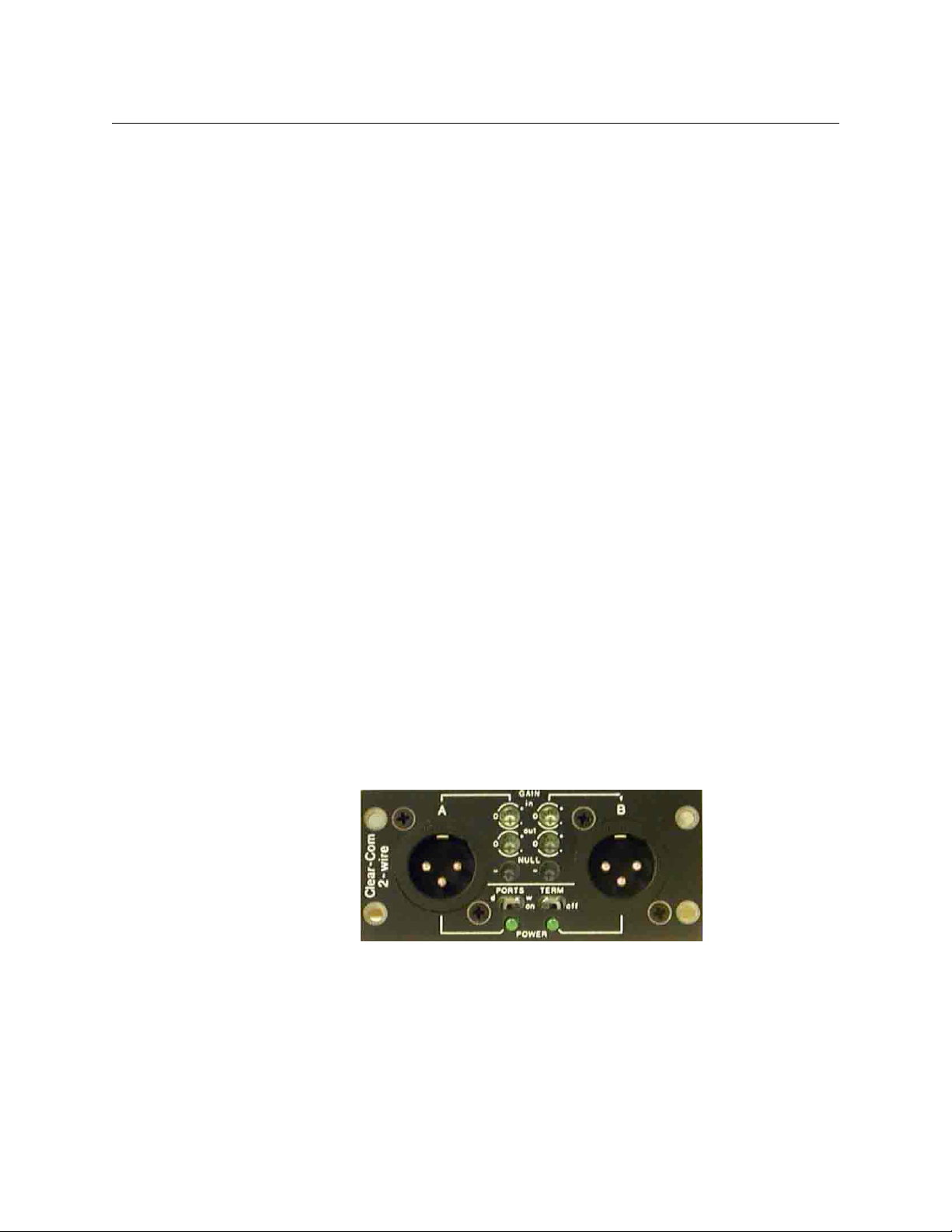

Clear-Com intercom modules have a 3-pin XLR connector for each of the A and B channels.

This Grass Valley module fully supports the Clear-Com signaling protocol and signal levels.

The Clear-Com Intercom Connections are listed in the table below.

Fig. 2-24: Clear Com module

Pin Description

Pin 1 Ground

Pin 2 +VDC Power

Pin 3 Power

• The units null by plugging in a 1/8-inch (3.5mm) stereo headset (not a TS-1) into the

connector located in the center of the unit and then adjusting the top set of pots for

optimum null.

• The second set of pots, labeled GAIN, adjust the receive gain for that channel +/-3db.

•The POWER switch controls whether 30VDC is applied to beltpacks and/or remote

stations that might be plugged into the module.

•The MODE switch should always be set to CC for Clear-Com intercom systems.

Nulling Procedure

Note: A stereo audio headset and a tweeker are needed to null these modules.

Inserting the 1/8” sub-mini stereo headset jack into the Clear-Com module turns on a tone

that nulls the system. It is important that the nulling procedure be done when all beltbacks

and other interfaces are in place. If you add additional beltpacks, it is likely that the nulling

procedure should be repeated.

As indicated on the module faceplate, the right ear serves Channel A and the left ear serves

Channel B. Do not listen to both ears at the same time as this will not allow you to carefully

discern the tone.

22

While listening to the right side, turn the adjustment pot on the top left above the mini

headset jack. The goal is to eliminate and/or minimize the nulling tone. Once you have

gotten the adjustment so that the tone is as quiet as possible, then change ears and do

Channel B while using the top right adjustment pot.

Page 27

RTS Telex

Adder II

User Guide

Powered (Wet) and Unpowered (Dry) Intercom Systems

The Grass Valley Clear-Com interface is compatible with powered or unpowered belt packs

as well as fixed equipment . Switch the Module to WET (down) when you want to use the

Adder to provide power to one or more intercom beltpacks and/or remote intercom

stations. The module will provide adequate power for approximately 4 beltpacks or 2

remote stations, or a combination thereof.

If you are supplying power to your intercom system externally with an intercom power

supply or “Master” intercom station, switch the Module to DRY (up). Many more belt packs

can be added if powered externally. Refer to your intercom manufacturer’s documentation

for additional system details.

Note: When powering a Clear-Com intercom system with an external power supply,

be sure to set the AdderII intercom module to “dry” to prevent noise, oscillation or

motor-boating.

RTS modules provide a two-channel intercom on a single 3-pin XLR connector. This module

fully supports the RTS signaling protocol and signal levels.

RTS channel operation is optimized by the use of front panel adjustments as shown in

Figure 2-25 and listed below.

• Input Gain, ± 10 dB

•Output Gain, ± 10 dB

•Null

Fig. 2-25: Intercom Module: RTS Telex

The following table lists the RTS Telex pin numbers and intercom connections. Switches are

also provided for the channel pair for:

• Dry unpowered (d), or Wet powered (w) PORTS

• 200 Ohm ON or OFF terminations TERM

Pin Description

Pin 1 Ground

Pin 2 +VDC Power & Chan 1 Audio

Pin 3 Chan 2 Audio

23

Page 28

Setting Up an Adder II System

Installing/Removing Intercom Modules

The interface is compatible with powered or unpowered belt packs, as well as fixed

equipment. You may power up to five belt packs with each intercom module. Refer to your

intercom manufacturer’s documentation for additional system details.

For operation with a belt pack, adjust the following:

• set the PORTS to w (powered)

• the TERM to ON

• center each of the INPUT gain, OUTPUT gain, and NULL controls

Readjust these controls to optimize performance as required.

Installing/Removing Intercom Modules

Before attemping any module exchange,the Adder II should be powered OFF .

Two multi-conductor cable harnesses are built into the Adder II and run behind the module

locations. These cables connect the intercom modules to power and signal sources. There

are AMP-MTA type connectors for each module on this harness; the connector fits all

module types.

• Signal is 8-pin

•Power is 2-pin

To change an intercom module in the assembly:

1Turn the power OFF.

2 Remove the four screws that hold the module in the frame.

3 Gently pull the intercom module away from the frame until you can see and remove

the two cable harnesses.

4 Replace with new module and reconnect in reverse order.

5Turn the power ON.

Fig. 2-26: Replacing Intercom Modules

24

Page 29

Data Transport Module

A2-DATA-8 module

Close up of ports on the A2-DATA-8 module

The A2-DATA-8 I/O module allows you to add additional RS-485 serial data ports to your

Adder II. The ports can be added in groups of 8. Each A2-DATA-8 module uses 8 transmit

and 8 receive channels on the fiber multiplex (the same as the A2-AM8x8-0 bidirectional

analog audio module would use.) The baud rate is automatically set to match the data

source with a maximum data rate of 112 kbps.

Adder II

User Guide

For each port there are 232, 422 and GPI I/O connections, however you can use only one

data input at a given time. The input port automatically determines the incoming signal

type. When the input is a serial data signal, the corresponding output on the other Adder II

system appears on both the RS232 and RS422 pins of the data connector.

You can achieve GPI input trigger by either tying pin 1 to ground or pin 6 to V+ (CMOS, TTL,

nominally up to +12VDC). Inputs are protected from over-voltagesand input impedance is

5k.

A2-DATA-8 Pinouts

Pin Function

1 RS422 In-, GPI-

2 GPO Relay NC

3 Ground

4 RS232 Out

5 RS422 Out +

6 RS422 In+, GPI +, RS232 In

7 GPO Relay NO

8 GPO Relay Common

9 RS422 Out-

Shroud Ground

Fig. 2-27: A2-DATA-8 module

25

Page 30

Setting Up an Adder II System

Legacy Systems

Legacy Systems

The Adder II is the latest audio over fiber multiplexer from Grass Valley, a Belden Brand

Several versions of Adder and other audio multiplexers preceded the Adder II, and some

Adder II modules are no longer manufactured. This section is for reference should you be

using this manual with an earlier system or components.

AES 16 input and output modules

16 input, 16 output, and 8 in/8-out AES modules were previously offered for the Adder II.

Each 16 Channel AES module uses two “Banks” on the base unit backplane. For modules

with 16 AES signals, for addressing purposes, the first 8 AES signals will be equivalent to one

bank and the second 8 AES signals will be addressed as the next bank. To ensure proper

channel mapping when converting to and from analog or AES, it is important to remember

that 16 channel AES’s occupy two banks.

If a 16 port AES module is used at one end, at the other end it would connect to another 16

port AES modules, two 8-port AES modules, or two 16-port analog audio modules.

Clear-Com Intercom Modules (original version)

Earlier Clear-Com intercom modules were different that the current version with different

configuration. The setup of the earlier model is described below.

Clear-Com channel operation is optimized by the use of the front panel adjustments shown

Figure 2-28 and listed below:

in

•Input Gain, ±10 dB

•Output Gain, ±10 dB

•Null

Switches are also provided for the channel pair for:

• PORTS: Dry unpowered (d), or Wet powered (w)

• TERM: 200 Ohm on or off terminations

Fig. 2-28: Intercom Module: Clear-Com

The original Clear-Com interface is compatible with powered or unpowered belt packs as

well as fixed equipment. You may power up to three belt packs with each intercom module

from the internal power supply.

26

Many more belt packs can be added if powered externally. Refer to your intercom

manufacturer’s documentation for additional system details.

For operation with a belt pack, adjust as follows:

Page 31

Readjust these controls to optimize performance as required.

The Base Unit PCB75/125 Mbs Switch

Diamondback

The Adder II is compatible with earlier Diamondback multiplexers. The Coax ports are used

and the Adder II must be set for 75 Mbps mode when paired with bi-directional

DiamondBack II’s or DiamondBack 4x4’s. When used with a Diamondback, the Adder II is

limited to 32 channels in each direction.

Setting 75 Mbps operation

Adder II

User Guide

• set the PORTS to w (powered)

• set the TERM to ON

• center each of the INPUT gain, OUTPUT gain and NULL controls

Fig. 2-29: The Base Unit PCB and 75/125 Mbs Switch

Figure 2-29 shows the Base Unit PCB. Each module is attached to its appropriate cable

header on this board. In addition, all optical and coaxial I/O, data functions and power

are handled here.

Figure 2-29 also shows the 75/125Mb switch that has a bearing on

overall system functionality.

The large switch (in the yellow circle) toggles between two different system data transport

rates.

• In 75Mb/sec mode, the system is Diamondback II compatible, but is capable of only 32

bi-directional channels plus Intercom and data.

• In 125Mb/sec mode, the system is no longer Diamondback II compatible, but can

accommodate up to 64 channels, bi-directional, plus data, and intercom.

27

Page 32

Setting Up an Adder II System

Pin 1 SIGNAL GND GND1Pin 2 Input (+)2Pin 3 Input (-)3Pin 4 Output (+)4Pin 5 Output (-)

5

XLR5F

Cha sis Cha sis Ground

600 Ohm Input

>= 600 Ohm

load

XLR 5 Pin Female Plug- Input

5

XLR FEM ALE

(solde r side )

3

1

2 4

Pin 1 SIGNAL GND GND

1

Pin 2 Input (+)2Pin 3 Input (-)3Pin 4 Output (+)4Pin 5 Output (-)

5

XLR5M

Chasis Chasis Ground

XLR 5 Pin Male Socket - Output

>= 600 Ohm load

600 Ohm Input

●●●

●

●●●

●

2

Pin 2 Audio In (+)3Pin 3 Audio In (-)1Pin 1 Signal Ground

CASE Chasis Ground

2

3

1

XLR MALE

(solder side)

2

Pin 2 Audio Out (+)3Pin 3 Audio Out (-)1Pin 1 Signal Ground

CASE Chasis Ground

2

3

1

XLR MALE

(solder side)

●●●

●

●

●

XLR5F

Female Plug

XLR3M

Male Plug

Shrink Wrap Blue label with

"???"

A B

4-Wir e

AUXILL IARY

AUDIO I / O

XLR3F

Female Plug

XLR3M

Male Plug

XLR3F

Female Plug

Audio In

Aud io I n

Audio Out

Audio Out

IntercomCable Wiring

IntercomCable Wiring

4-Wire XLR 5-pin to two XLR 3-pin

Fig. 2-30: 4-Wire XLR 5-pin to two XLR 3-pin

28

Page 33

Adder II to Clear-Com Matrix Plus Intercom Stations

Intercom Station

Adder 2

RS-422 dat a send (+ ) 1

RS-422 dat a send (-) 2

Audio s end (+ ) 3

Audio recei ve (+) 4

Audio recei ve (-) 5

Audio s end (-) 6

RS-422 dat a receive (+) 7

RS-422 dat a receive (-) 8

1GND

2Audio In (+)

3 Audi o In (-)

4 Audio Out (+ )

5 Audio Out (-)

XLR FEMALE

5F PLUG

(sol der side)

3

1 5

2 4

5 RS-422 Input (-)

4 RS-422 Input (+)

3GND

6 RS-422 Output (-)

1 RS-422 Output (+)

RJ45 Modular 8-pin

18

1

8

9-pin D Male

XLR FEMAL E

5F PLUG

PUSH

Telecast

Fiber Systems, Inc.

ADDER II

CONTROL UNI T

TONE

OUT

MONITOR

HEADPHONES

VOLUME

ANALOG

AES “A”

AES “B”

LOCAL

REMOTE

GAIN

SEL

FREQ

SEL

20

1

400

+50-20

AES IN

AES OUT

1

2

1

2

1

2

1

2

1

2

OPTICAL

POWER

LOCK PWR

CONTROL

ON

OFFCANCEL ACK

TALLY OUT

TALLLY IN

RS232

RS485

RS422

DATA

24 dB

21 dB

18 dB

15 dB

15 dB

12 dB

9 dB

6 dB

3 dB

0 dB

-3 dB

-6dB

-9 dB

-12 dB

-15 dB

-18 dB

-21 dB

-24 dB

-27 dB

-30 dB

-33 dB

1

ETH PWR

By

Tel ecast

Fi ber Syst ems , Inc.

Adder I I T X16L

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

PUSHPUSHPUSH PUSH PUSHPUSHPUSH PUSHPUSH PUSH PUSH PUSHPUSH PUSH PUSH PUSH

1

ETH PWR

By

Tel ecast

Fiber Systems, Inc.

Adde r II RX16

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

A

4-Wire

AUXILLIARY

AUDIO I/O

B

A

4-Wire

AUXILLIARY

AUDIO I/O

B

A

4-Wire

AUXILLIARY

AUDIO I/O

B

A

4-Wire

AUXILLIARY

AUDIO I/O

B

Adder II

User Guide

Fig. 2-31: Adder II to Clear-Com Matrix Plus Intercom Stations

29

Page 34

Setting Up an Adder II System

Int er com Frame

Adder 2

RS-422 dat a rec ei ve (+) 1

RS-422 dat a rec ei ve (-) 2

Audio receive (+) 3

Audio send (+) 4

Audio send (-) 5

Audio receive (-) 6

RS-422 data s end (+) 7

RS-422 data s end (-) 8

1GND

2 Audio In (+)

3 Audio In (-)

4 Audio Out (+ )

5 Audio Out (-)

XLR FEM ALE

5F PLUG

(solder side )

3

1 5

2 4

5 RS-422 Input (-)

4 RS-422 Input (+)

3GND

6 RS-422 Output (-)

1 RS-422 Output (+ )

RJ45 Modular 8-pin

18

1

8

9-pin D Male

XLR FEMAL E

5F PLUG

PUSH

Telecast

Fiber Systems, Inc.

ADDER II

CONTROL UNIT

TONE

OUT MONITOR

HEADPHONES

VOLUME

ANALOG

AES “A”

AES “B”

LOCAL

REMOTE

GAIN

SEL

FREQ

SEL

201400

+50-20

AES IN

AES OUT

1

2

1

2

1

2

1

2

1

2

OPTICAL

POWER

LOCK PWR

CONTROL

ON

OFF

CANCEL ACK

TALLY OUT

TALLLY IN

RS232

RS485

RS422

DATA

24 dB

21 dB

18 dB

15 dB

15 dB

12 dB

9 dB

6 dB

3 dB

0 dB

-3 dB

-6dB

-9 dB

-12 dB

-15 dB

-18 dB

-21 dB

-24 dB

-27 dB

-30 dB

-33 dB

1

ETHPWR

By

Tel ecast

Fiber Systems, Inc.

Adde r II TX16L

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

PUSHPUSHPUSH PUSH PUSHPUSHPUSH PUSHPUSH PUSH PUSH PUSHPUSH PUSH PUSH PUSH

1

ETH PWR

By

Tel ecast

Fiber Systems, Inc.

Adde r II RX1 6

23 45 67 8910111213141516

A

4-Wire

AUXILLIARY

AUDIO I/O

B A

4-Wire

AUXILLIARY

AUDIO I/O

B

A

4-Wire

AUXILLIARY

AUDIO I/O

B

A

4-Wire

AUXILLIARY

AUDIO I/O

B

Adder II to Clear-Com Matrix Plus Intercom Frame

Adder II to Clear-Com Matrix Plus Intercom Frame

Fig. 2-32: Adder II to Clear-Com Matrix Plus Intercom Frame

30

Page 35

Troubleshooting

This chapter list common issues with the Adder II system and provides solutions to these

issues.

Issues and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Accessory List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

31

Page 36

Troubleshooting

Issues and Solutions

Issues and Solutions

Symptom Possible Cause Corrective Action

No Power No power adapter

No Optical Link Bad Fiber

Bad power adapter

Mispatched fiber

Lossy fiber or dirty fiber

connections

Replace AC-DC Supply with a known

functional one.

Verify that there is a link at both ends via

optical power meter and LINK LED.

Clean ends and/or reduce the number

of interconnections to achieve optical

power within range (-5 to -22 dBm).

Accessory List

The following accessories are available from Grass Valley:

• Portable optical power meter

• Fiber and coaxial cables built to custom lengths

Signal Generator/

analyzer not working

Overall audio levels

too high or low

Clipping audio Too muc h gain Ensure that gains for each channel are

Speaker turned OFF Activate speaker using rear panel

switch.

Frame not set to match

audio console

Use +18/+24 switch on rear panel to set

level at which audio will clip.

set properly for the input signal.

32

Page 37

Specifications

General

Data Transmission Method........................ Digital Time Division Multiplexing (TDM)

Aggregate Data Rate.............................................................. 75 or 125 Mbps (selectable)

Latency......................................... ~1 millisecond plus 5 microseconds per km of fiber

Interchannel Phase Delay........................................................................<1 degree at 1kHz

Optical Fiber Connectivity

Operating Wavelength.................................................................... 1310 nm and 1550 nm

Fiber connector.................................................................................................................ST type

Recommended fiber type .................................................................................. Single mode

................................................................................ 2-fiber system 1-fiber (WDM) system

TX Output into cable...................................................................................... -7 dBm -8 dBm

RX Sensitivity..................................................................................................-32 dBm -31 dBm

Link budget (maximum) ................................................................................... 23 dB - 25 dB

Recommended distance limit...................... 20 km (singlemode), 5 km (multimode)

Coax Connectivity

Impedance...................................................................................................................... 75 Ohms

Recommended cable.........................................................................................Belden 1694A

Connector..................................................................................................................................BNC

Distance limitation.............................................................................305 meters (1000 feet)

Audio, Analog...........................................................................................................

Analog Audio Connectors.............................. 3-pin XLR (female on TX & male on RX)

Transmission Method..................................................... Digital, 24-bit, 48 ksamples/sec

Input Impedance, Analog.....................................................................10k Ohms balanced

Output Impedance ...................................................................................30 Ohms balanced

Line Input Setting............................................................................................+24 dBm (peak)

Maximum Input Level...................................................................................................................

Unity Gain (0 dB)...................................+18 dBM peak / +24 dBm peak (selectable)

+10 dBM Input Setting ........................................... + 8 dBM peak / +14 dBm peak

+20 dBm Input Setting............................................- 2 dBM peak / + 4 dBm peak

+30 dBm Input Setting............................................- 12 dBM peak / - 6 dBm peak

+40 dBm Input Setting........................................... - 22 dBM peak / - 16 dBm peak

+50 dBm Input Setting........................................... - 32 dBM peak / - 26 dBm peak

Maximum Output Level

(from 30 Ω balanced)................+18 dBm @ 1kHz, 600 ohm, switchable to +24 dBm

Frequency Response (@ 8 dBm).......................................±0.2 dB from 20 Hz to 20 kHz

Total Harmonic Distortion + Noise......... <0.05% from 20 Hz to 20 kHz (@ +8 dBm)

33

Page 38

Specifications

.....................................................................................................<0.01% at 1 kHz (@ +18 dBm)

Intermodulation Distortion (SMPTE) . <0.04%, 60 Hz + 3 kHz mixed 4:1 @ +8 dBm

Signal to Noise Ratio (A-weighted) .............. >95 dB, 20 Hz -20 kHz, ref. to +18 dBm

Audio, Digital ...........................................................................................................

AES/EBU Inputs and Outputs .................................................. unbalanced, 75-ohm BNC

Transmission MethodAES/EBU Digital Audio Pair conforming to AES3 specifications

External Sync......................................................................................................BNC, rear panel

Sample Rate......................................................................................................................... 48 kHz

User Bits ................................................................................................................Not supported

Serial Data Transmission.........................................................................................

Data Connector..............................................................................................9-pin Female "D"

RS232 ............................................................................................ ±8 Vp-p level, 20 kBps max.

RS422/RS485 ...............................................................Balanced TTL levels, 150 kBps max.

Jitter.............................................................................................................. <330 ns (3.07 MS/s)

Latency............................................................................ ~ 0.90 us plus 5 us per km of fiber

Intercom (882i module)...........................................................................................

Total intercom channels.............................................................................................................8

Intercom compatibility (per module)......................................................................................

................................................................. 4-Wire: 2 balanced, non-powered, 5-pin XLR-M

............................................................. Clear-Com: 2 unbalanced, powered, 3-pin XLR-M

...............................................RTS: 1 unbalanced, powered, dual-channel, 3-pin XLR-M

Signal-to-noise ratio (A-weighted)............................................................................. >90 dB

Frequency response ......................................................... +1/-3 dB, 80Hz-20kHz, +8 dBm

Contact Closure / GPIO ............................................................................................

Connector..............................................................................2 9-pin Female "D" connectors

Input contacts....... Normally High TTL 1 level (remote contact open/open circuit)

.............................................. Short to ground TTL 0 (remote contact closed/triggered)

Output contacts............................ Form 1A SPST, "Normally Open" isolated contacts

Switch Voltage Rating............................................................................................. 50V AC/DC

Switch Current Rating.................................................................................................... 500 mA

Maximum Carry Current Rating .................................................................................500 mA

Contact Resistance.....................................................................................................< 0.5 Ohm

Mechanical/Electrical/Environmental....................................................................

2RU ................................................ 19" wide x 7.75" deep x 3.5" high, 8 lbs (3.5 kg)

3RU ................................................19" wide x 7.75" deep x 5.25" high, 9 lbs (3.5 kg)

4RU ................................................19" wide x 7.75" deep x 7.0" high, 10 lbs (3.5 kg)

5RU ............................................... 19" wide x 7.75" deep x 8.75" high, 11 lbs (3.5 kg)

6RU ............................................... 19" wide x 7.75" deep x 10.5" high, 12 lbs (3.5 kg)

7RU ...............................................19" wide x 7.75" deep x 12.25" high, 13 lbs (3.5 kg)

Power Connector.................................................... 4-pin XLR (male) x2, screw terminals

Input Voltage Range....................................................................... 12 to 18 VDC, 4.5A max.

Power Consumption

34

Page 39

(per end, all channels at full level)...................................................... 45 watts maximum

Temperature Range ............................................................................................. -40° to +60°C

Humidity Range ...........................................................................0 to 90% non-condensing

Adder II

User Guide

35

Page 40

Specifications

36

Page 41

Grass Valley Technical Support

For technical assistance, please contact the Grass Valley Technical Support center nearest

you:

Contact Us

Americas

Office hours: 9:00 a.m. – 9:00 p.m. (EST)

Telephone: 1-800-224-7882

Fax: +1 514 335 1614

E-mail: support@miranda.com

Europe, Middle East, Africa, UK

Office hours: 9:00 a.m. – 6:00 p.m. (GMT)

Telephone: +44 118 952 3444

Fax: +44 118 952 3401

E-mail: eurotech@miranda.com

France

Office hours: 9:00 a.m. – 5:00 p.m. (GMT+1)

Telephone: +33 1 55 86 87 88

Fax: +33 1 55 86 00 29

E-mail: eurotech@miranda.com

Corporate Head Office

Asia

Office hours: 9:00 a.m. – 6:00 p.m. (GMT+8)

Telephone: +852 2539 6987

Fax: +852 2539 0804

E-mail: asiatech@miranda.com

China

Office hours: 9:00 a.m. – 6:00 p.m. (GMT+8)

Telephone: +86 10 5873 1814

E-mail: asiatech@miranda.com

Malaysia

Telephone: +60 3 2247 1808

EMERGENCY After Hours (Global)

Toll Free: 1-800-224-7882 (US and Canada)

Telephone: +1 514 333 1772

Grass Valley

3499 Douglas-B.-Floreani

St-Laurent, Quebec H4S 2C6

Canada

Telephone: +1 514 333 1772

Fax: +1 514 333 9828

Web: www.miranda.com

Loading...

Loading...