Page 1

8977AP-4B/4U

DIGITAL AUDIO PROCESSING MODULES

Instruction Manual

PACKAGE VERSION 1.0.0

071852100

FEBRUARY 2007

Page 2

Affiliate with the N.V. KEMA in The Netherlands

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley, Inc.

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

10 Presidential Way

3

rd

Floor, Suite 300

Woburn, MA 01801

United States

Nederland B.V.

4800 RP BREDA

The Netherlands

Weiterstadt, Germany

Brunnenweg 9

D-64331 Weiterstadt

Germany

Rennes, France

Rue du Clos Courtel

Cesson-Sevigne, Cedex

France

Technopole Brest Iroise

CS 73808

29238 Brest Cedex 3

France

17 rue du Petit Albi-BP 8244

95801 Cergy Pontoise

Cergy, France

2300 South Decker Lake Blvd.

Salt Lake City, UT 84119

United States

7140 Baymeadows Way

Suite 101

Jacksonville, FL 32256

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2000

Scope:

The design, manufacture and support of video hardware and software products and

related systems.

This Certificate is valid until: June 14, 2009

This Certificate is valid as of: August 30, 2006

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms

And Conditions For Quality And Environmental Management Systems Certifications.

Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 073004

ccredited By:

ANAB

A

Page 3

8977AP-4B/4U

DIGITAL AUDIO PROCESSING MODULES

Instruction Manual

PACKAGE VERSION 1.0.0

071852100

FEBRUARY 2007

Page 4

Contacting Grass Valley

International

Support Centers

Local Support

Centers

(available

during normal

business hours)

France

24 x 7

Australia and New Zealand: +61 1300 721 495 Central/South America: +55 11 5509 3443

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

+800 8080 2020 or +33 1 48 25 20 20

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent: +91 22 24933476

Asia

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore: +65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225 Switzerland: +41 1 487 80 02

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +39 02 48 41 46 58 S. Europe/Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1 N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel: +44 118 923 0499

Copyright © Grass Valley. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

United States/Canada

24 x 7

+1 800 547 8949 or +1 530 478 4148

Grass Valley Web Site

The www.thomsongrassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Download software updates, drivers, and patches.

4 8977AP-4B/4U — Instruction Manual

Page 5

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8977AP-4B/-4U Digital Audio Processing Modules. . . . . . . . . . . . . . . . . . . . . 9

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Software Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Module Placement in the GeckoFlex Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rear Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8900GEN-SM Genlock Submodule Installation . . . . . . . . . . . . . . . . . . . . . . . . 12

Front Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operation Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Remote Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8900NET Module Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Newton Control Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Web Page Operations and Functional Elements . . . . . . . . . . . . . . . . . . . . . . . . 24

Web Page Headers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8977AP-4B and 8977AP-4U Links and Web Pages. . . . . . . . . . . . . . . . . . . . . . . . 26

Status Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

I/O Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Functional View Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Input Status and Settings Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Delay Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Gain Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Routing & Processing Pairs Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Output Status and Settings Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

User Settings Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Genlock Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

System Config Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Slot Config Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Power-up Diagnostics Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Electronic Circuit Breaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table of Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Module Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8977AP-4B/4U — Instruction Manual 5

Page 6

Contents

Configuration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6 8977AP-4B/4U — Instruction Manual

Page 7

Preface

About This Manual

This manual describes the features of the 8977AP module series and the

corresponding rear modules in the GeckoFlex frame. As part of this family

of modular products, it is subject to the Safety and Regulatory Compliance

infomation described in the GeckoFlex Frames Instruction Manual.

This manual also has instructions for using the 8900GEN-SM submodule.

For more detailed information, refer to the 8900GEN-SM GeckoFlex Genlock

Submodule Instruction Manual available online on the Thomson Grass Valley

web site.

When using any of the fiber optic options on any GeckoFlex module, refer

to the laser compliance information in the GeckoFlex Frames Instruction

Manual for safety information.

8977AP-4B/4U — Instruction Manual 7

Page 8

Preface

8 8977AP-4B/4U — Instruction Manual

Page 9

8977AP-4B/-4U Digital Audio Processing Modules

Introduction

Two versions of the audio processing modules are available; the 8977AP-4B

with balanced audio (with the 8900BA-R rear module) and the 8900AP-4U

with unbalanced audio (with the 8900UE-R rear module.)

The 8977AP-4B and the 8977AP-4U modules provide audio processing for

four AES audio streams for delay, gain, sample rate conversion, and

genlock timing functionality.

Module Features

The 8977AP-4B and 8977AP-4U module features include:

• Up to 4 channels of AES audio streams (balanced or unbalanced

depending on the rear module type installed),

• Input audio receiver and output driver stages to restore and drive

signals over long coaxial or paired cables,

• Passing of PCM and Non-PCM audio signals (Dolby E),

• Performing sample rate conversion of the PCM audio signals,

• Provides genlock timing for the audio input signals with the

8900GEN-SM submodule to synchronize the audio input signals at

48 kHz,

• Audio delay management (fixed and/or tracking delay),

• Audio gain ensures the tuning of the level of each channel,

• Routing channel and audio processing module performs the selection

between two channels before applying dedicated processing,

• Pair routing module determines the allocation of the outputs of each

pair, and

• Remote control and monitoring support includes a web interface, a

Newton control panel, a NetConfig management system, and SNMP

monitoring with an application such as NetCentral.

8977AP-4B/4U — Instruction Manual 9

Page 10

Installation

Installation

Software Requirements

The front and the rear modules are delivered together as a set. Two choices

are available: one for balanced audio outputs with the 8900BA-R rear

module and one for unbalanced audio with the 8900UE-R rear module.

A 8900GEN-SM genlock submodule can be installed on the front 8977AP

module to provide a frame reference timing source.

The 8977AP-4B and the 8977AP-4U front modules can be plugged in and

removed from a GeckoFlex frame with power on without disrupting operation on adjacent running modules. When power is applied to the module,

LED indicators reflect the initialization process (see Power Up on page 18).

An 8900NET module with software version 4.0.2 or later is mandatory for

configuring the 8977AP-4B and 8977AP-4U modules.

The Grass Valley NetCentral application must be running version 4.1.12.8A

or later for proper operation.

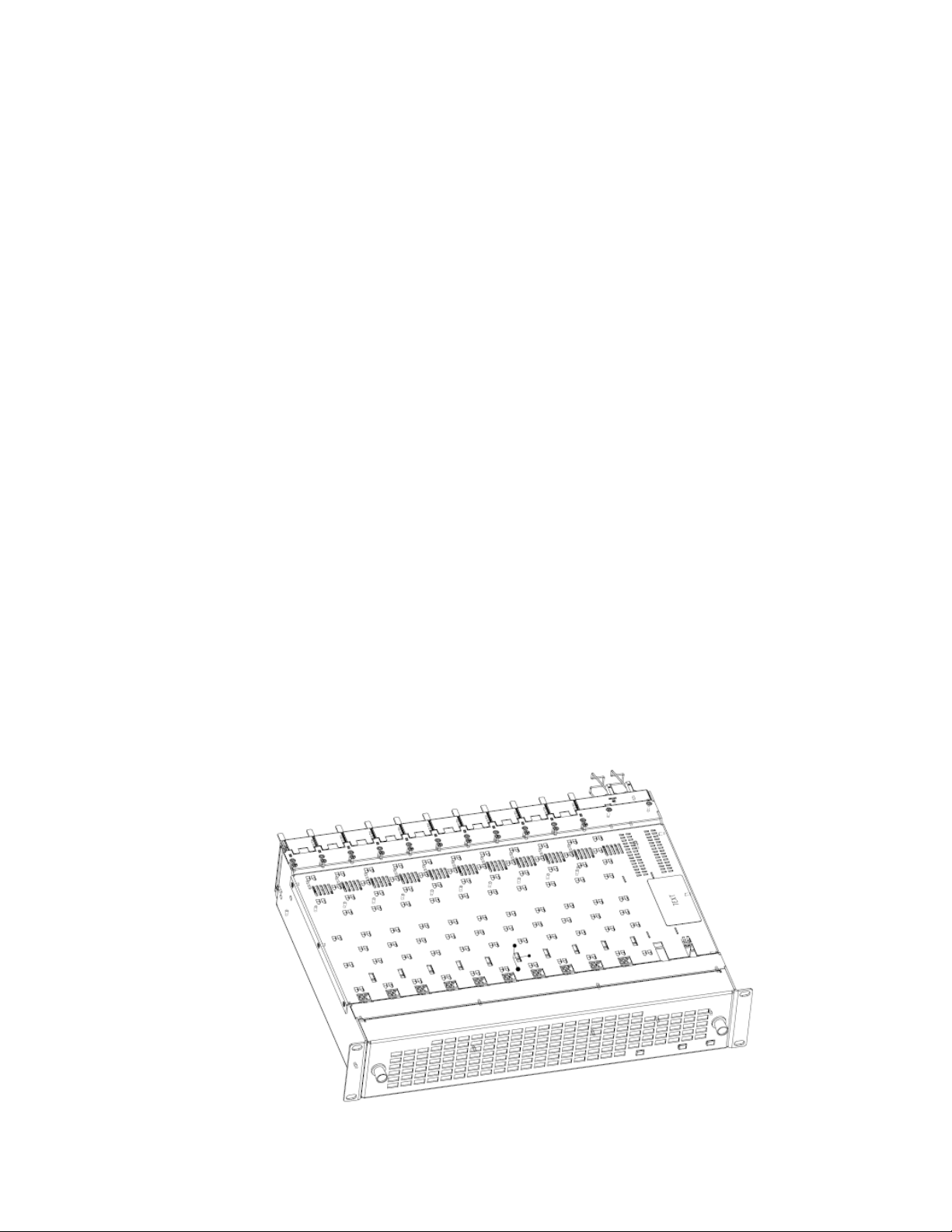

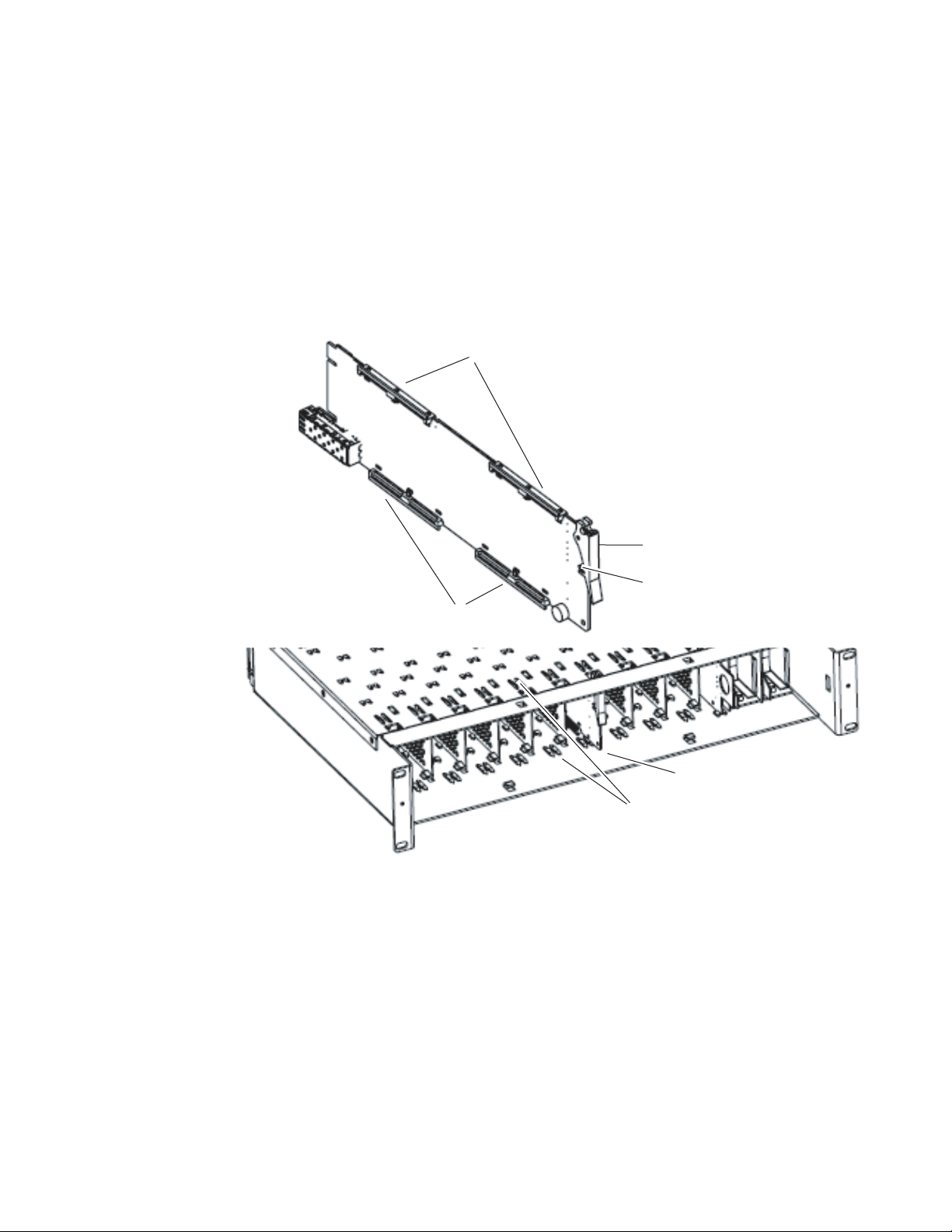

Module Placement in the GeckoFlex Frame

There are ten rear and front slot locations in the 2 RU frame to accommodate audio and video modules. The 8977AP-4B and 8977AP-4U modules

can be plugged into any one of the GeckoFlex frame slots.

Note Use standard anti-static precautions when handling modules in the frame.

Figure 1. GeckoFlex Frame

10 8977AP-4B/4U — Instruction Manual

Page 11

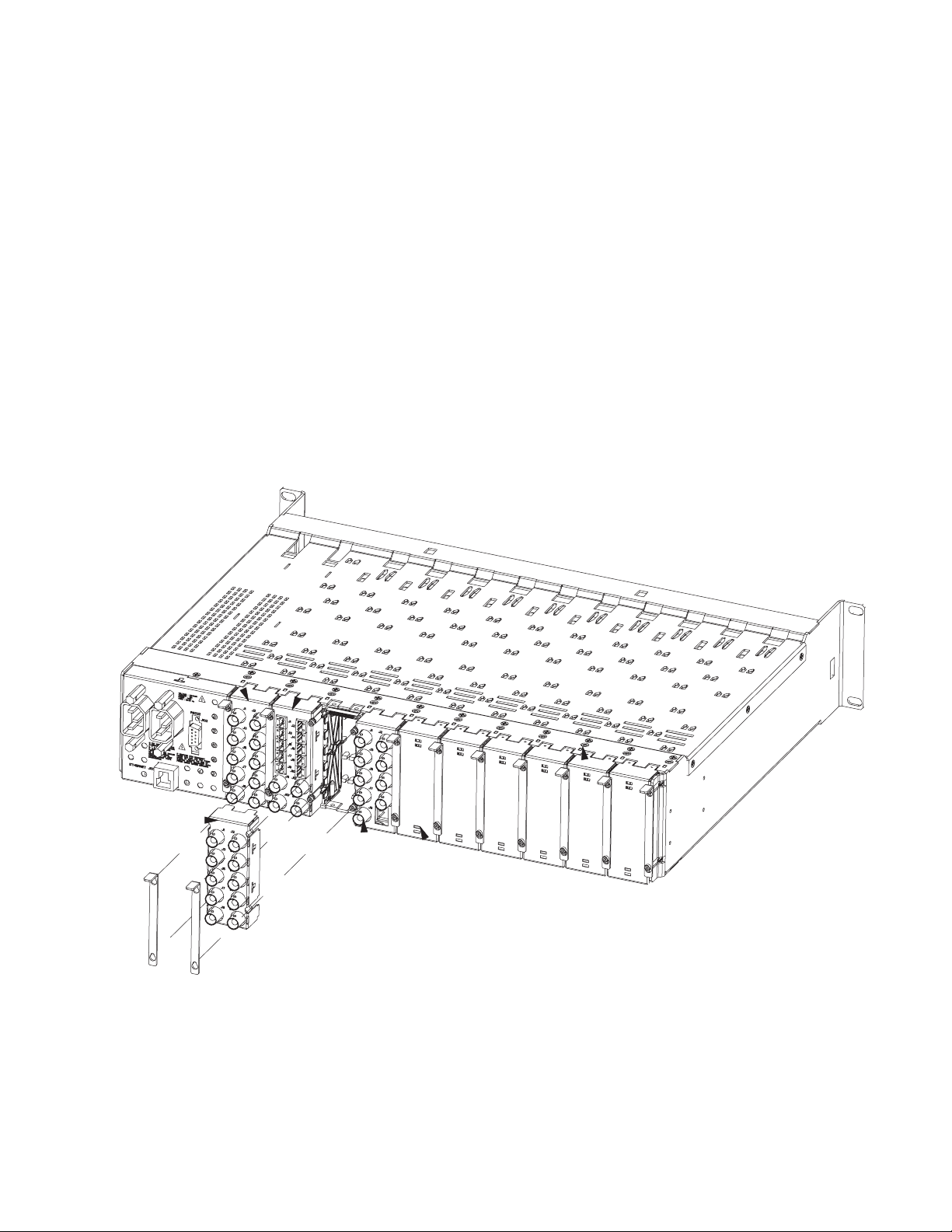

Rear Module Installation

8521_02

Note Do not completely remove the screws holding the retainer strips as they can

fall into other equipment and create a shorting hazard.

To install a rear module into the frame, follow these steps:

1. Unscrew the blank rear adapter cover (without removing the screws),

with a 2mm (5/64”) hex screwdriver (see Figure 2).

2. Remove the two retainer strips and the blank rear adapter cover using

a pair of needlenose pliers.

3. Insert the corresponding rear module in the slot.

4. Replace both retainer strips on each side of the rear module and tighten

the screws to secure the rear module.

Figure 2. Frame Rear

Installation

Note To extract the rear module, remove the front module first.

8977AP-4B/4U — Instruction Manual 11

Page 12

Installation

8900GEN-SM Genlock Submodule Installation

Conditions

Before installing the 8977AP module, you will first need to determine if and

how you want to use a genlock reference or the available frame reference

buses. The genlock timing from an 8900GEN-SM submodule can be uti

lized in several ways. Refer to 8900GEN-SM GeckoFlex Genlock Instruction

Manual available online for a complete overview of using the genlock ref

erence.

In addition to the capability of providing a local external reference to this

specific 8977AP module with an 8900GEN-SM submodule installed, slots 1

and 3 of the GeckoFlex Frame have been specifically designed to distribute

an independent frame bus reference transmitted from the 8900GEN-SM

submodule mounted on another GeckoFlex module with this capability

configured for this purpose.

If another module with a genlock submodule installed has already been

configured and installed for frame bus distribution, you may configure this

module’s output timing to lock to the Frame Bus 1 or Frame Bus 2 reference

from the other 8977AP module. In this case, the 8977AP module does not

require the use of an additional 8900GEN-SM submodule.

-

-

The use of the genlock reference is determined by the setting of the Output

Timing on the System Config web page of the module and module placement in the frame and jumper configuration as summarized below:

• Local Reference – the 8977AP with an 8900GEN-SM submodule can

have a local external reference connected to the corresponding Reference In BNC. This external timing reference will be fed to this specific

8977AP module only.

• Frame Reference 1 or 2 – when an 8977AP with an 8900GEN-SM submodule is installed in slot 1 and/or slot 3, a frame timing bus can be

enabled to distribute the external reference connected to the corresponding Reference In BNC on the rear module to all modules in the

frame that can accept a genlock reference. Slot 1 provides Frame Bus 1

and slot 3 provides Frame Bus 2.

• Internal – when no 8900GEN-SM submodule is installed on the 8977AP

module, the Output Timing can be set to Internal so the output timing

will be in an internal freerun mode (delivered by a local oscillator).

Note The internal mode is mainly implemented for test and debug purposes during

the system setup of the module or in a standalone configuration where no

timing reference is required.

12 8977AP-4B/4U — Instruction Manual

Page 13

Installation

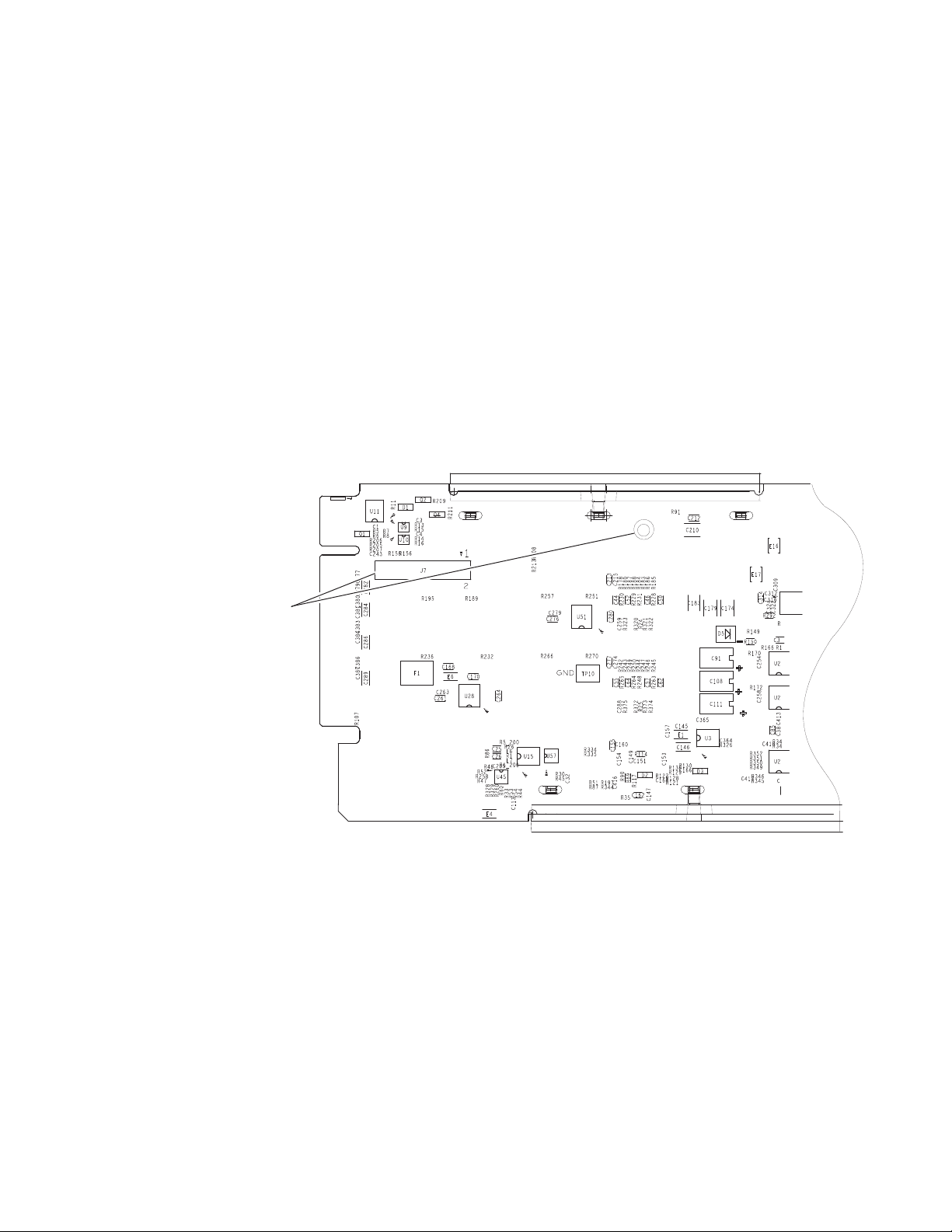

Install Genlock submodule

on back of circuit board.

Center submodule connector J1

over front module connector J7

and snap in place. From top side

of module, tighten the screw

provided to the standoff on the

circuit board.

8521_08

Installation

The 8900GEN-SM Genlock submodule will ship in a separate package, not

installed on the front module.

To install a Genlock submodule, follow these steps:

1. Locate the Genlock connector J7, on the back side of the 8977AP circuit

board (Figure 3).

2. Line up the connector on the submodule, J1, with J7 on the front

module and snap the submodule into place making sure the holes in

each circuit board line up.

3. To hold the submodule in place, attach the captive screw provided from

the top of the front module to the standoff on the submodule circuit

board.

Figure 3. Installing 8900GEN-SM Genlock Submodule

8977AP-4B/4U — Instruction Manual 13

Page 14

Installation

Frame Bus Jumpering

If you will be using this 8977AP module to distribute reference Frame Bus 1

(slot 1) or Frame Bus 2 (slot 3), you must set a jumper (GEN XMIT shown

in

Figure 4) on the front module circuit board for this purpose before

installing the module.

• Frame Bus 1 – to transmit the reference connected to the Reference In

BNC on the corresponding rear module on Frame Bus 1, set jumper J2

to

ENA (pins 1-2). This module must be installed in slot 1 of the frame

and configured on the Genlock web page (see the Genlock Web Page on

page 49) for

• Frame Bus 2 – to transmit the reference connected to the Reference In

BNC on the corresponding rear module on Frame Bus 2, set jumper J3

ENA (pins 1-2). This module must be installed in slot 3 of the frame

to

and configured on the Genlock web page (see the Genlock Web Page on

page 49) for

Note Both jumpers may be enabled. The module in slot 1 will only read the status

of jumper, J2. The module in slot 3 will only read the status of jumper, J3.

Auto in the Drive Frame Reference Bus pulldown.

Auto in the Drive Frame Reference Bus pulldown.

Figure 4. Setting Frame Bus Jumpers

8521_09

For Frame Bus 2 distribution, set

GEN XMIT jumper, J3

Pins 1-2 (ENA) or Pins 2-3 (DIS)

For Frame Bus 1 distribution, set

GEN XMIT jumper, J2

Pins 1-2 (ENA) or Pins 2-3 (DIS)

14 8977AP-4B/4U — Instruction Manual

Page 15

Front Module Installation

After installing the rear module and the 8900GEN-SM Genlock submodule

if required, install the front module as follows:

1. Unscrew and remove the front cover.

2. Insert the front module in the guides of the corresponding slot.

3. The module ejector tab (Figure 5) must be locked in its locking pin.

Figure 5. Front Module Ejection

Installation

Card Carriers

Front Module Side View

Card Carriers

Ejector Tab

Locking Pin

8521_03

Module installed

Slide top and bottom card carriers on module

over top and bottom guides on right of slot.

8977AP-4B/4U — Instruction Manual 15

Page 16

Cabling

8900BA-R

Reference Input

Audio Delay

Tracking Input

AES 1 Input

AES 2 Input

AES 3 Input

AES 4 Intput

AES 1 Output

AES 2 Output

AES 3 Output

AES 4 Output

Not Used

Not Used

8521_10

+

G

+

G

+

G

+

G

+

G

+

G

+

G

+

G

Cabling

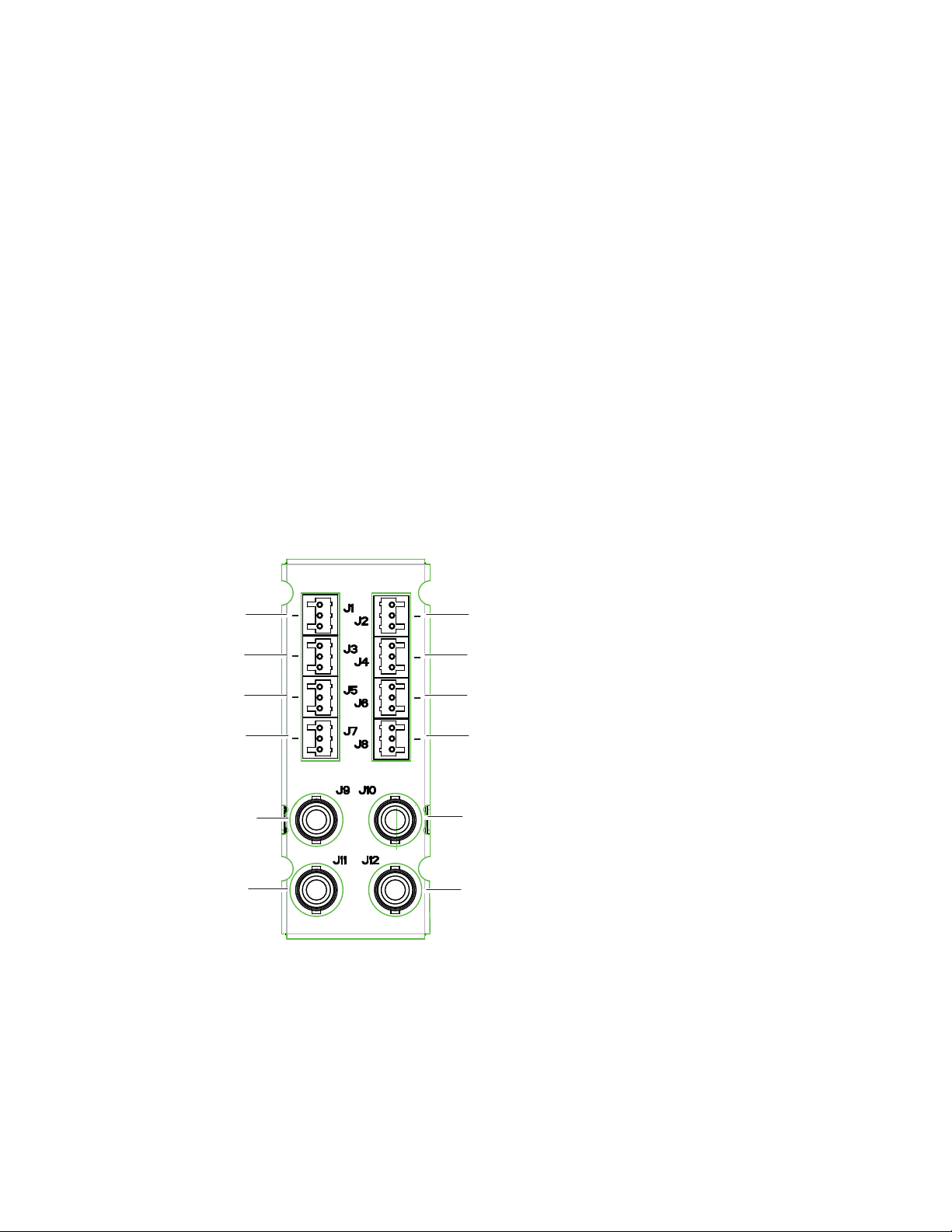

Cabling to the 8977AP-4B and 8977AP-4U modules is done on the BNCs of

the 8900UE-R rear module or the three pin connectors on the 8900BA-R rear

module. Refer to

Figure 6 (8900BA-R) and Figure 7 on page 17 (8900UE-R)

for a detailed illustration of the rear connections.

The I/O Config web page (Figure 18 on page 31 for the 8977AP-4U and

Figure 19 on page 32 for the 8977AP-4B) shows the inputs and the outputs

assigned to the different connectors of the rear modules.

The 8977AP-4B and the 8977AP-4U outputs conform to the audio standards listed in the output specifications in Tab le 3 on page 56.

Figure 6 gives the inputs and the possible audio output connections for the

8977AP-4B modules. Balanced audio pinouts (+/-/ G) are also illustrated.

Note J10 and J12 are not used in this release.

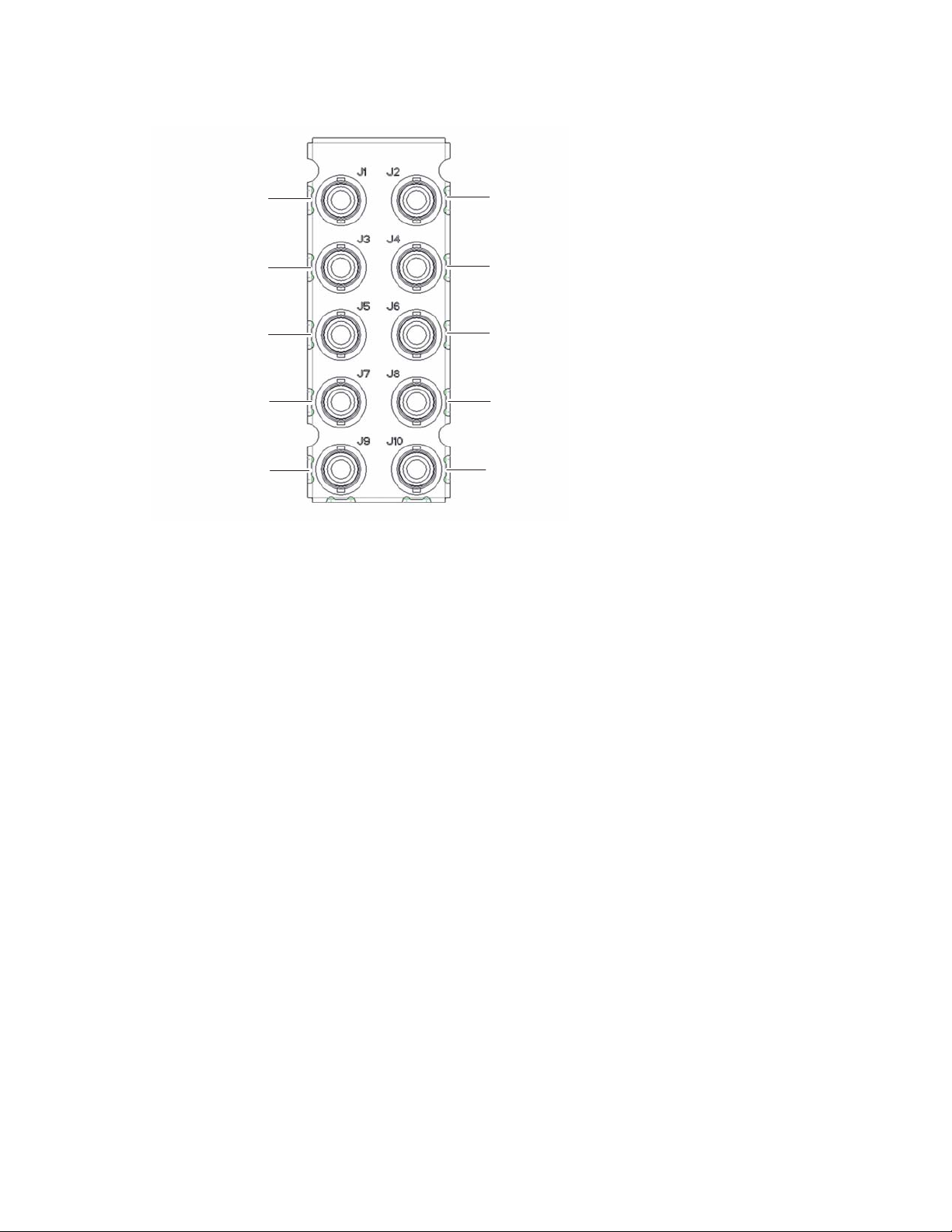

Refer to Figure 7 on page 17 for the 8900UE-R inputs and outputs illustration.

Figure 6. 8900BA-R Rear Module

16 8977AP-4B/4U — Instruction Manual

Page 17

Figure 7. 8900UE-R Rear Module

8900UE-R

Reference Input

Audio Delay Tracking Input

AES 1 Input

AES 2 Input

AES 3 Input

AES 4 Input

AES 1 Output

AES 2 Output

AES 3 Output

AES 4 Output

8521_10

Cabling

8977AP-4B/4U — Instruction Manual 17

Page 18

Power Up

Power Up

Operation Indicator LEDs

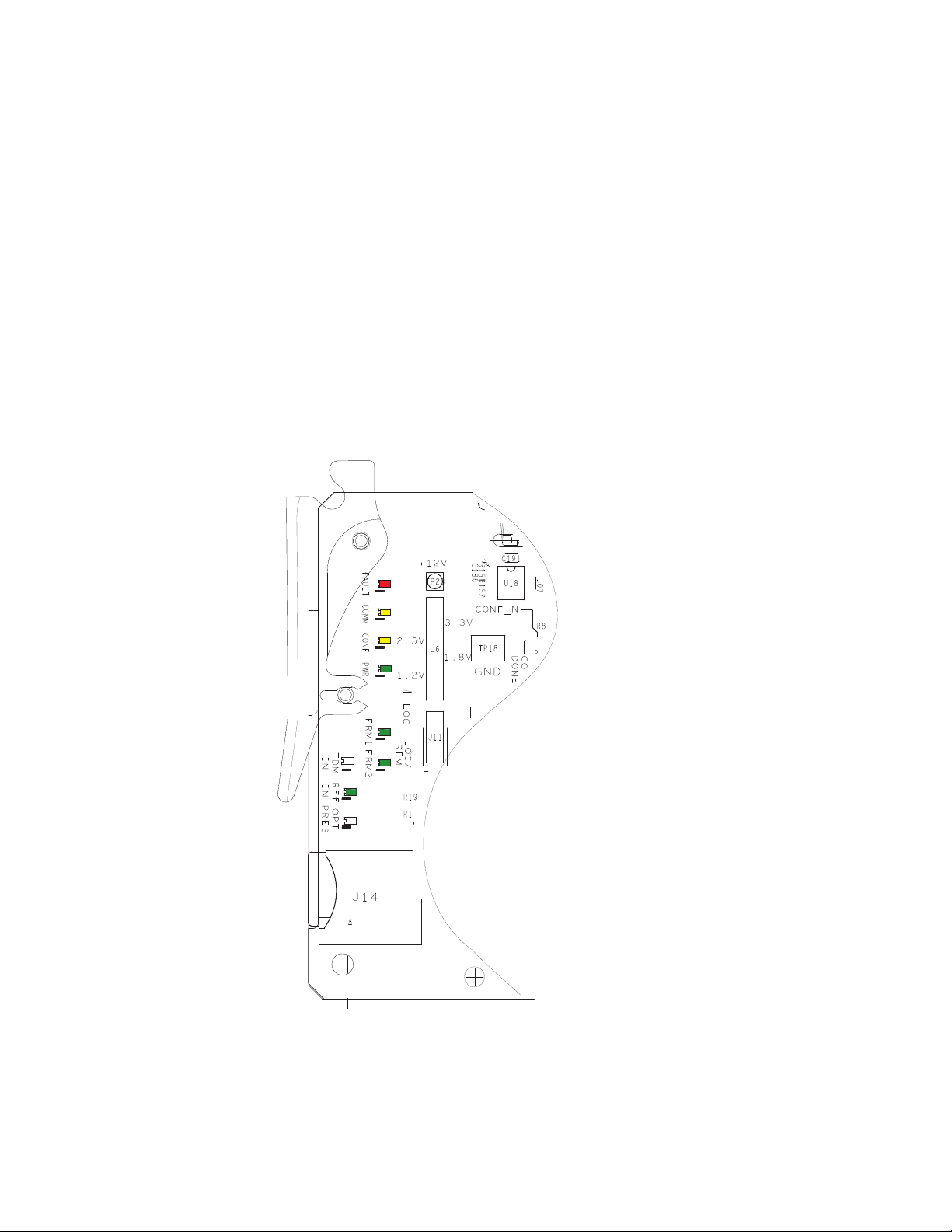

Upon power-up, the green PWR LED should light and the CONFIG,

FAULT, and COMM LEDs should illuminate during the module initializa

tion.

Note When a module is first plugged into a GeckoFlex frame, the 8900NET module

may report a momentary fault. This will clear once the module has booted up.

The on-board LED indicators on the front of the module are illustrated in

Figure 8. Refer to Tab le 1 on page 20 to see a complete list of possible oper-

ating conditions and the resulting indicator status of all LEDs.

Figure 8. LED Indicators - Front View of 8977AP Module

-

8521_06

18 8977AP-4B/4U — Instruction Manual

Page 19

Power Up

8521_07

Figure 9 shows the AES IN (1 to 8) LEDs. With a present audio input signal

connected, AES-IN (1 to 4) green LEDs should be on.

Note In this version, AES IN (5 to 8) LEDs are not used.

Figure 9. LED Indicators - Back View of the 8977AP module

8977AP-4B/4U — Instruction Manual 19

Page 20

Power Up

A red FAULT LED indicates an error situation and, when noted with the

other indicator LEDs, can indicate a specific problem area.

signal output and LED indications.

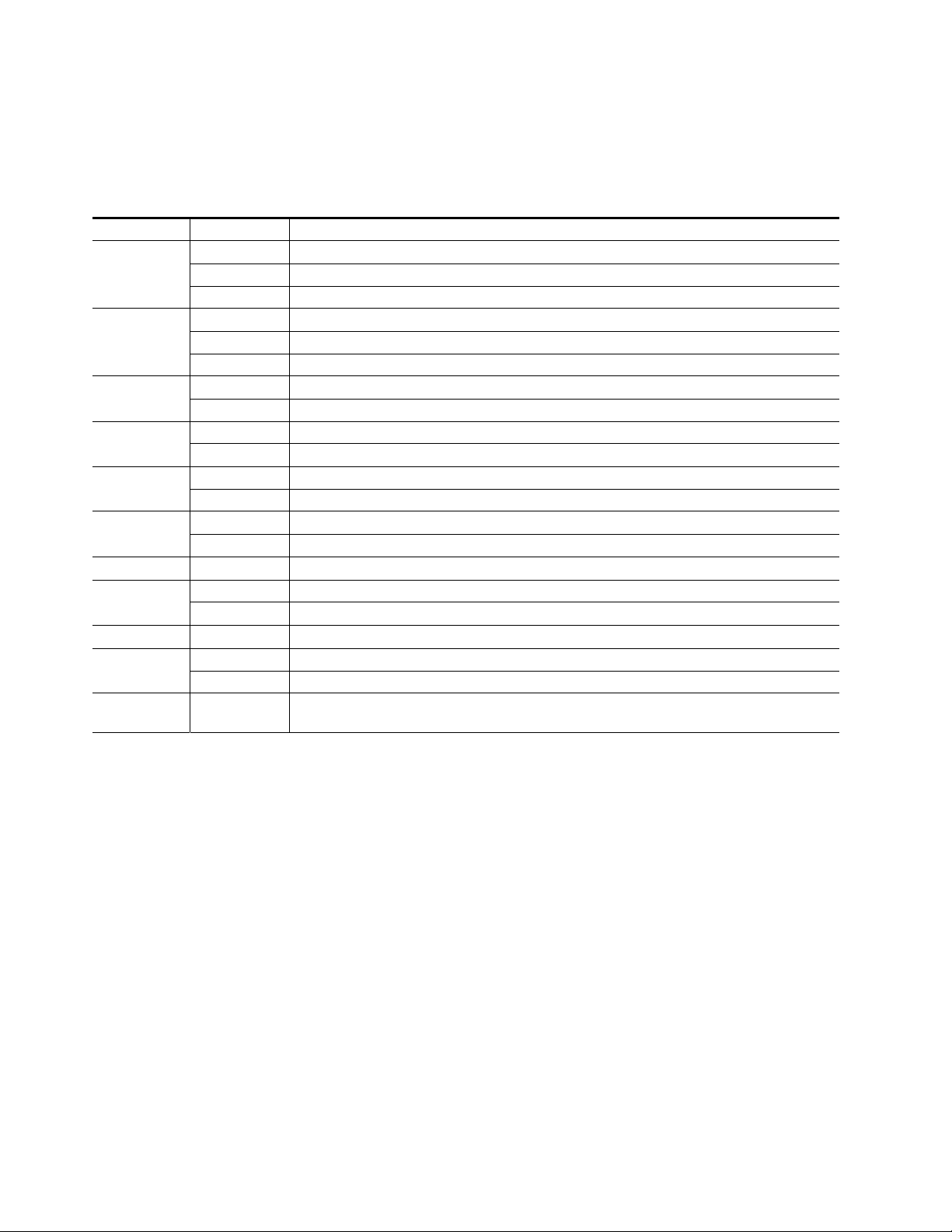

Table 1. LED Indicators

LED Indication Condition

FAULT

(red)

COMM

(yellow)

CONF

(yellow)

PWR

(green)

FRM1

(green)

FRM2

(green)

TDM IN

REF IN

(green)

OPT PRES

AES IN 1-4

(green)

AES IN 5-8

(green)

Off Normal operation

On continuously Module has detected internal fault.

Flashing Configuration problems or checking inputs and settings or missing audio

Off No activity on frame communication bus

On continuously Locate Module Command

Flashing Activity present on the frame communication bus

Off Module is in normal operation mode

On continuously Module is initializing, changing operating modes, or programming hardware

Off No power to module or modules DC/DC converter failed

On Normal operation, module is powered

Off Reference frame bus is disabled to frame on Genlock web page or no Genlock submodule is installed in slot 1

On Reference frame bus is enabled on Genlock web page and Genlock submodule is installed in slot 1

Off Reference frame bus is disabled to frame on Genlock web page or no Genlock submodule is installed in slot 3

On Reference frame bus is enabled on Genlock web page and Genlock submodule is installed in slot 3

N/A Not used in this version

Off The frame reference input coax is not present on the BNC Ref In or signal is not locked

On The frame reference input coax is present on the BNC Ref In and signal is locked

N/A

Off No AES input signal detected

On One or more AES input signal detected

N/A Not used in this version

Not used in this version

Tab le 1 describes

20 8977AP-4B/4U — Instruction Manual

Page 21

Remote Configuration

The 8977AP-4B and 8977AP-4U configuration and monitoring is performed using a web browser GUI interface or a networked Newton Control

Panel in the GeckoFlex frame (8900FFN). Each of these interfaces is

described below.

8900NET Module Information

Refer to the 8900NET Network Interface Module Instruction Manual from

4.0.2 version for information on the 8900NET Network Interface Module

and setting up and operating the GeckoFlex 8900 frame network.

Note Upgrade software and instructions for the 8900NET can be downloaded from

the Grass Valley web site. Refer to Contacting Grass Valley on page 4.

Newton Control Panel Configuration

Remote Configuration

A Newton Control Panel (hard or soft version) can be interfaced to the

GeckoFlex frame over the local network. Refer to the documentation that

accompanies the Newton Modular Control System for installation, config

uration, and operation information.

Control panel access offers the following considerations for module configuration and monitoring:

• Ability to separate system level tasks from operation ones, minimizing

the potential for on-air mistakes.

• Ability to group modular products—regardless of their physical loca-

tions—into logical groups (channels) that you can easily manipulate

with user-configured knobs.

• Recommended for real-time control of module configuration parame-

ters, providing the fastest response time.

Note Some module functions are not available with the Newton Control Panel,

such as factory default recalls.

-

8977AP-4B/4U — Instruction Manual 21

Page 22

Remote Configuration

An example of the Newton Configurator is shown in Figure 10.

Figure 10. Newton Configurator Example

Note A table of the Newton parameters is given in the Configuration Parameters

appendix on page 61.

Web Browser Interface

The web browser interface provides a graphical representation of module

configuration and monitoring.

Use of the web interface offers the following considerations:

• Provides complete access to all module status and configuration functions, including naming of inputs and outputs, factory parameter and

name default recalls, E-MEM functions, slot configurations and SNMP

monitoring controls.

• Web access will require some normal network time delays for processing of information.

• Configuration parameter changes may require pressing

processing time,

• Using the Web interface is recommended for setting up module signal

and slot names, and reporting status for SNMP and monitoring.

Enter, upload

and a manual screen refresh to become effective.

22 8977AP-4B/4U — Instruction Manual

Page 23

Remote Configuration

8431_08r1

The Links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

Content display section

displays the information page

for the selected frame or module (frame slot icons are also

active links).

Refresh button for manual

update of page

Refer to the Status web page shown in Figure 11. The 8900 modules can be

addressed by clicking either on a specific module icon in the frame status

display or on a module name or slot number in the link list on the left.

Note The physical appearance of the graphics on the web pages shown in this

manual represent the use of a particular platform, browser and version of

8900NET module software. They are provided for reference only. Web pages

will differ depending on the type of platform and browser you are using and

the version of the 8900NET software installed in your system. This manual

reflects 8900NET version 4.0.2.

For information on status and fault monitoring and reporting shown on the

Status page, refer to the Status Web Page on page 28.

Figure 11. GeckoFlex Frame Status Web Page

Note The Refresh button must be clicked to update the page after any changes.

8977AP-4B/4U — Instruction Manual 23

Page 24

Remote Configuration

Pulldown Menus

Check box

Refresh button

Coarse Adjust

Fine Adjust

Enter

Status LED

Entry Field

High Limit

Status Indicator

Low Limit

Radio button

Button

Web Page Operations and Functional Elements

The following conventions and functional elements (shown at left) are used

in GeckoFlex web page operations. (The examples shown throughout this

manual represent 8900NET software version 4.0.2 or later):

• Pulldown menus allow you to choose selections from a list.

• Clicking on a button performs an immediate action such as recall of

defaults, clearing of states, learning configurations, and selecting all or

none of a selection.

• Radio buttons are used to make a choice of one parameter in a group.

• Check boxes are used when a selection can be enabled or included in a

group. Multiple check box selections or enables can be made for some

parameters.

Refresh button (circular arrow) is provided at the top of each web page

•A

for manual refresh to view recently changed parameters.

• Each numerical adjustment control has a

Coarse adjust button (left and

right top double arrows) which increases or decreases the step value by

a factor of 10. The

Fine adjust button (left and right inside single arrows)

increases or decreases the step value by 1.

To change a value, use the arrow button controls or enter a value into

the number field and select the

Enter button (*) or use the Enter key on

your keyboard. The Status Indicator bar will follow the value selected.

Use the Low and High Limit buttons to go directly to the lowest and

highest limits for the parameter.

• An entry field allows naming of various module functions such as

input or output signals, asset tag, and slot identification.

•The

Status LED icon reports communication status for the frame slot and

is a link to the module Status web page where Warnings and Faults are

displayed.

LED colors indicate:

• Green = Pass – no problems detected.

• Yellow = Configuration error warning (presence of one warning),

configuration mismatched or input missing.

• Red = Fault condition detected (presence of one alarm).

• Graphic and arrow colors used indicate the following:

• Green = Pass – signal or reference present, no problems detected.

• Red = Fault – fault condition.

• Yellow = Warning – signal is absent or has errors.

• Gray = Not monitored.

• White = Empty or not present.

24 8977AP-4B/4U — Instruction Manual

Page 25

• Text colors indicate:

• Black: Parameter names and information which can be modified.

• Blue: Read-only information about the module.

• Red: Warning.

Web Page Headers

Each web page has a Status and Identification Header as shown in

Figure 12 (8977AP-4U) and Figure 13 (8977AP-4B) below.

The header information on each web page (except Genlock web page)

includes the following:

Model and Description are read-only generated by the module.

•

Frame Location is defined on the GeckoFlex frame configuration web

•

page.

Slot number reports the module’s location in the frame.

•

Remote Configuration

Figure 12. Status Web Page Header – 8977AP-4U

Figure 13. Status Web Page Header – 8977AP-4B

When an 8900GEN-SM submodule is installed on either module, the

header will appear a shown in Figure 14.

Figure 14. Status Web Page Header – 8977AP-4U+GEN

8977AP-4B/4U — Instruction Manual 25

Page 26

Remote Configuration

8977AP-4B and 8977AP-4U Links and Web Pages

The web interface 8900 GUI provides the following links and web pages for

the 8977AP-4B and 8977AP-4U modules (

• Status web page – reports input and output signals and frame bus communication status and module information (page 28),

• I/O Config web page – shows the rear module layout and presence of

the signals on a specific connector, allows naming of each input and

enables or disables the signal reporting (page 31),

• Functional View web page – provides a graphical block diagram of the

configuration pages for the module with links to web pages (page 33),

• Input Status & Settings web page – reports information about the audio

stream, the delay tracking and the genlock inputs (page 34),

• Delay web page – allows the adjustment of the delay on each stream

and/or each audio channel, enables or disables the delay tracking and

displays the total delay (page 36),

• Gain web page – allows the adjustment of the audio gain, gives the level

of presence and clipping (page 38),

Figure 15 on page 27):

• Routing & Processing Pairs web page – describes the process on the

inputs (page 40),

• Output Status & Settings web page – enables or disables the AES CUV

bits pass through and sets AES resolution (page 43)

• User Settings web page – allows recalling of factory defaults for all

module parameters or factory signal names and provides a save/load

configuration file function (page 46),

• Genlock web page – appears only when the optional 8900GEN-SM submodule is installed on the module. This web page provides status

reporting for the external genlock reference and controls for enabling

the Genlock, matching the reference input to a selection standard, and

setting reference signal delay (page 49),

• System Config web page – sets output timing source, Reference Restore

parameters and Primary and Secondary Phase Difference (page 52),

and

• Slot Config web page – provides Locate Module, Slot Identification and

Slot Memory functions along with links to the frame alarm configuration web page (page 54).

26 8977AP-4B/4U — Instruction Manual

Page 27

Figure 15. 8977AP Web Page Links

Remote Configuration

8977AP-4B/4U — Instruction Manual 27

Page 28

Remote Configuration

Use

this

link

Status Web Page

The Status web page (Figure 16 on page 29 for the 8977AP-4U with an

8900GEN-SM submodule installed and Figure 17 on page 30 for the

8977AP-4B with no submodule) shows the signal status of the input

signal(s) and communication with the frame bus. Color coding of the

display indicates the signal status. Refer to

tional Elements on page 24 for an explanation of the color coding. The con-

tents of the web page header is explained on page 25.

Web Page Operations and Func-

Module Physical Structure

Status is reported for each of the following audio and video signals:

• Audio inputs – indicate the status of the four audio inputs (BNC or

3-pins connectors).

• DT Input – indicates the status of the audio delay tracking input.

• Ref 1 and Ref 2 In (from frame) – the Ref 1 arrow will be green when

Frame Bus 1 has been enabled on the module in slot 1. The Ref 2 arrow

will be green when Frame Bus 2 has been enabled on the module in

slot 3 of the frame.

• Frame Bus – indicates the status of the communication bus to the

8900NET module.

• Genlock Ref In – indicates the status of the external genlock reference

signal on the BNC.

• Local Ref – indicates the status of the internally generated genlock reference signal from the 8900GEN submodule to the front module.

• Ref Out – if the module is installed in slot 1, Ref 1 out is directed to the

Ref 1 In. If the module is installed in slot 3, Ref 2 out is directed to the

Ref 2 In.

On the Status web page any alarm or warning states will cause a warning

message to appear in the double bars area below the graphic.

Note The color of the LED status is managed by the 8900NET accordingly to the

alarms status.

Status

The front, rear, and Genlock (if present) modules status is given: PASS,

WARNING, ERROR or EMPTY.

Front Module

There are information about the module, such as Part Number, Serial

Number, Hardware Revision, Package version, Firmware Version, Soft

ware Version, Boot Version and Asset Tag number are given in a properties

section at the bottom of the Status web page.

28 8977AP-4B/4U — Instruction Manual

-

Page 29

Figure 16. Status Web Page for 8977AP-4U + GEN Module

Remote Configuration

8977AP-4B/4U — Instruction Manual 29

Page 30

Remote Configuration

The Status web page in Figure 17 illustrates the 8977AP-4B with a missing

audio input and no submodule installed. Note the message and warning

between the double lines below the graphic and the color of the Status LED.

Figure 17. Status Web Page for 8977AP-4B Module

30 8977AP-4B/4U — Instruction Manual

Page 31

I/O Web Page

Use

this

link

Use the I/O Config web page for the following:

Rear Module Configuration

All of the input and output connectors on the corresponding 8977AP-4U or

8977AP-4B rear module are illustrated on the I/O Config web page.

The inputs can be configured with the following controls:

•

•

Figure 18 for the 8977AP-4U and Figure 19 on page 32 for the 8977AP-4B

show the connectors of the two different rear modules available to cable

balanced or unbalanced audios.

Remote Configuration

Signal Names – type of the desired input name (up to 12 characters) into

the corresponding boxes for each input. The status of each input is indicated by the color of the display, the legend is under the table.

Reporting – raises alarms and warnings. The Status Reporting can be

enabled or disabled by selecting or deselecting the corresponding

checkbox in the

Reporting column for each input.

Note The outputs are not monitored in this application.

Figure 18. I/O Config Web Page for the 8977AP-4U

8977AP-4B/4U — Instruction Manual 31

Page 32

Remote Configuration

Figure 19. I/O Config Web Page for the 8977AP-4B

32 8977AP-4B/4U — Instruction Manual

Page 33

Functional View Web Page

Use

this

link

The Functional View web page (Figure 21) illustrates a block diagram of the

8977AP front module showing module functions and signal paths that are

active or inactive in the current configuration. It can be used as a link map

for configuring module functions. Each block has a link to the configura

tion page for that function.

• Color coding indicates active functions and signal flow. Grayed compo-

nents are inactive due to hardware and/or software constraints. Underlined module functions are links to the web page for that function.

• Use the Functional View to configure the 8977AP modules in the order

of the signal flow.

• Each web page shown in the Functional View will have links to the

<<Previous web page, the Functional View web page and the Next >> web

page at the bottom of the web page. Use the previous links to move

through the configuration web pages or return to the Functional View

web page (Figure 20).

Figure 20. Navigation Links

Remote Configuration

-

Figure 21 describes the front module processing as shown on the Func-

tional View web page.

Figure 21. Functional View Web Page

8977AP-4B/4U — Instruction Manual 33

Page 34

Remote Configuration

Use

this

link

Input Status and Settings Web Page

Use the Input Status and Settings web page (Figure 22 on page 35) for the

following:

Audio Inputs

• Input Stream Name – the signal name defined on the I/O Config web page

will appear in this field.

Signal State – this field reports the status of the input signal Present or

•

Not Present.

Sample Rate – indicates the rate of the audio input stream.

•

•

Mode – reports the number of bits: 16, 20, or 24 bits.

Audio Mode Status – shows the audio mode: PCM or Non-PCM.

•

Force Audio Mode – chooses the audio mode: PCM (Pulse Code Modula-

•

tion – a method of storing and transmitting uncompressed digital

audio), Non-PCM (non-audio data such as Dolby E or data), or Sync

PCM (audio that already has a 48 kHz sample rate).

Note When a Force Audio Mode selection is changed, you must manually set the

AES CUV Bits Pass Through control to Enabled or Disabled as desired on

the Output Status and Settings Web Page on page 43.

• AES Error Detected – reports any errors detected since the last time the

error status was cleared (

Errors or None).

Delay Tracking Input

• Name – this name cannot be modified.

Signal State – this field reports the status of the delay tracking input

•

signal as Present or Not Present.

Link – select this link to go to the Delay web page.

•

Genlock Input

• Name – the genlock input name defined on the I/O Config web page

will appear in this field.

Signal State – this field reports the status of the input signal Present, Not

•

Present or Not Supported.

Link – select this link to go to the Genlock web page.

•

Defaults Button

Select the Defaults button to restore the default Input signal source.

34 8977AP-4B/4U — Instruction Manual

Page 35

Figure 22. Input Status and Settings Web Page

Remote Configuration

8977AP-4B/4U — Instruction Manual 35

Page 36

Remote Configuration

Use

this

link

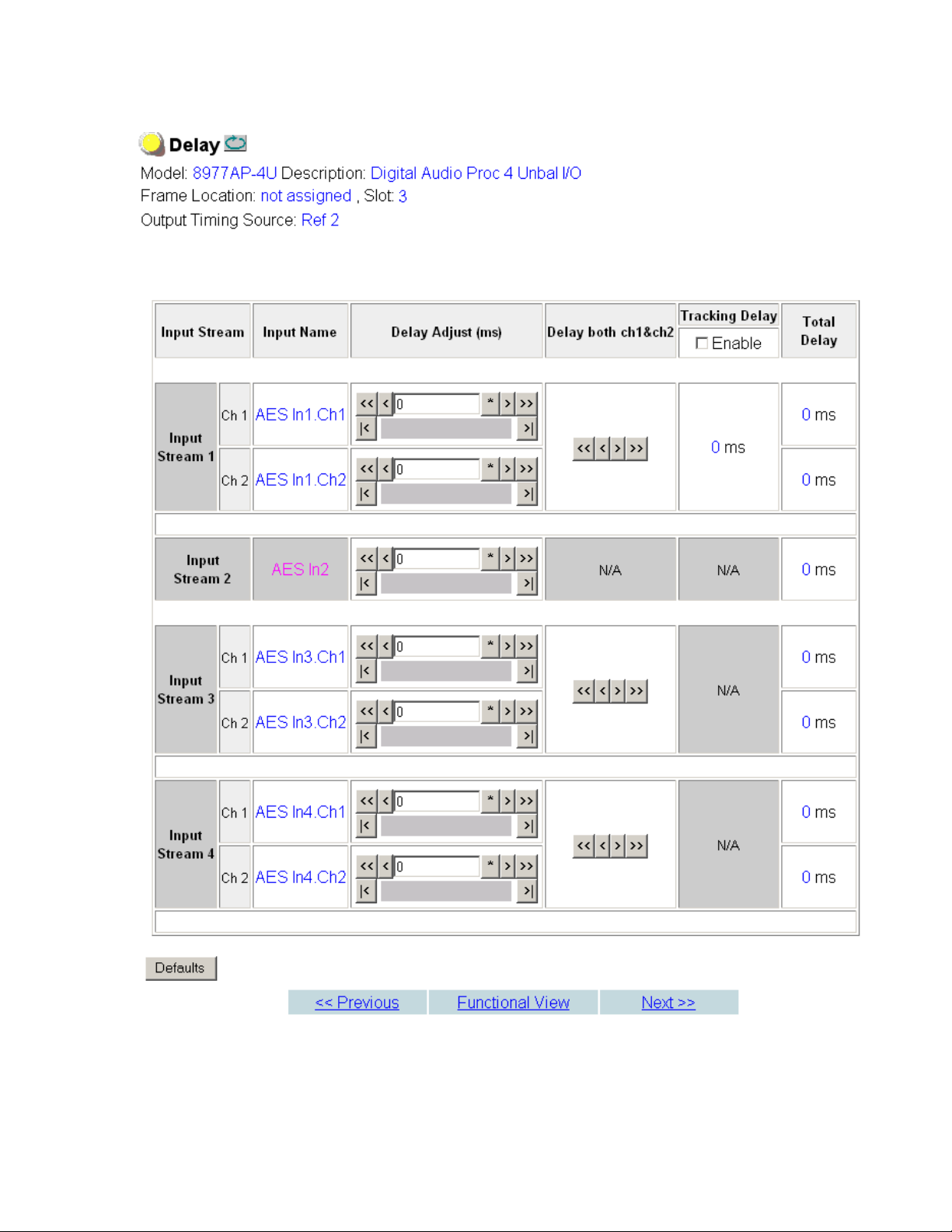

Delay Web Page

Use the Delay web page (Figure 23 on page 37) for the following:

• Input Stream – name of the input.

Input Name – name given in the I/O Config web page.

•

Delay Adjust – setting delay adjustments for each channel of the four

•

streams.

Delay both ch1&ch2 – setting delay adjustments for both channels together

•

of the four streams.

Tracking Delay – enable or disable the delay tracking. The amount of delay

•

tracking input status will be reported for each audio stream.

Total Delay – the total amount of delay (Delay Adjust + Tracking Delay)

•

will be reported in the Total Delay field for each audio stream.

Note When a delay has been applied to a channel on a stream, removing and rein-

serting the module or disconnecting and reconnecting the audio input may

cause a disturbance on the undelayed channel or stream for a period equal to

the delay.

In the case of a Non-PCM audio (input stream 2 as shown in Figure 23 on

page 37), a delay may only be applied on the stream. Channel delay shift is

not available. The input name is reported in pink.

In the case of Sync PCM audio (input streams 3 and 4 in Figure 23 on

page 37), no tracking delay is applied and the function is grayed out.

Note If a Non-PCM audio signal is detected and another audio mode is forced, a

warning “Input Stream is detected as Non-PCM” appears between the input

streams (not shown).

36 8977AP-4B/4U — Instruction Manual

Page 37

Figure 23. Delay Web Page

Remote Configuration

8977AP-4B/4U — Instruction Manual 37

Page 38

Remote Configuration

Use

this

link

Gain Web Page

Use the Gain web page (Figure 24 on page 39) for the following:

• Input Stream – name of the input stream.

Input Name – name given in the I/O Config web page.

•

Gain Adjust – adjustment for the selected channel.

•

Note Gain cannot be adjusted for channels set as Non-PCM.

• Gain both ch1&ch2 – adjusts both channels in a stream for the same

amount of gain.

Presence – the level status of each audio channel is reported as True or

•

False in the read-only channel status displays. If the level is > -40dBFS,

the presence will be reported as

Clip – the clipping of each audio channel is reported as True or False in the

•

read-only channel status displays. If the level is > -0.5dBFS, the clipping

will be reported as

True.

True.

38 8977AP-4B/4U — Instruction Manual

Page 39

Figure 24. Gain Web Page

Remote Configuration

8977AP-4B/4U — Instruction Manual 39

Page 40

Remote Configuration

Use

this

link

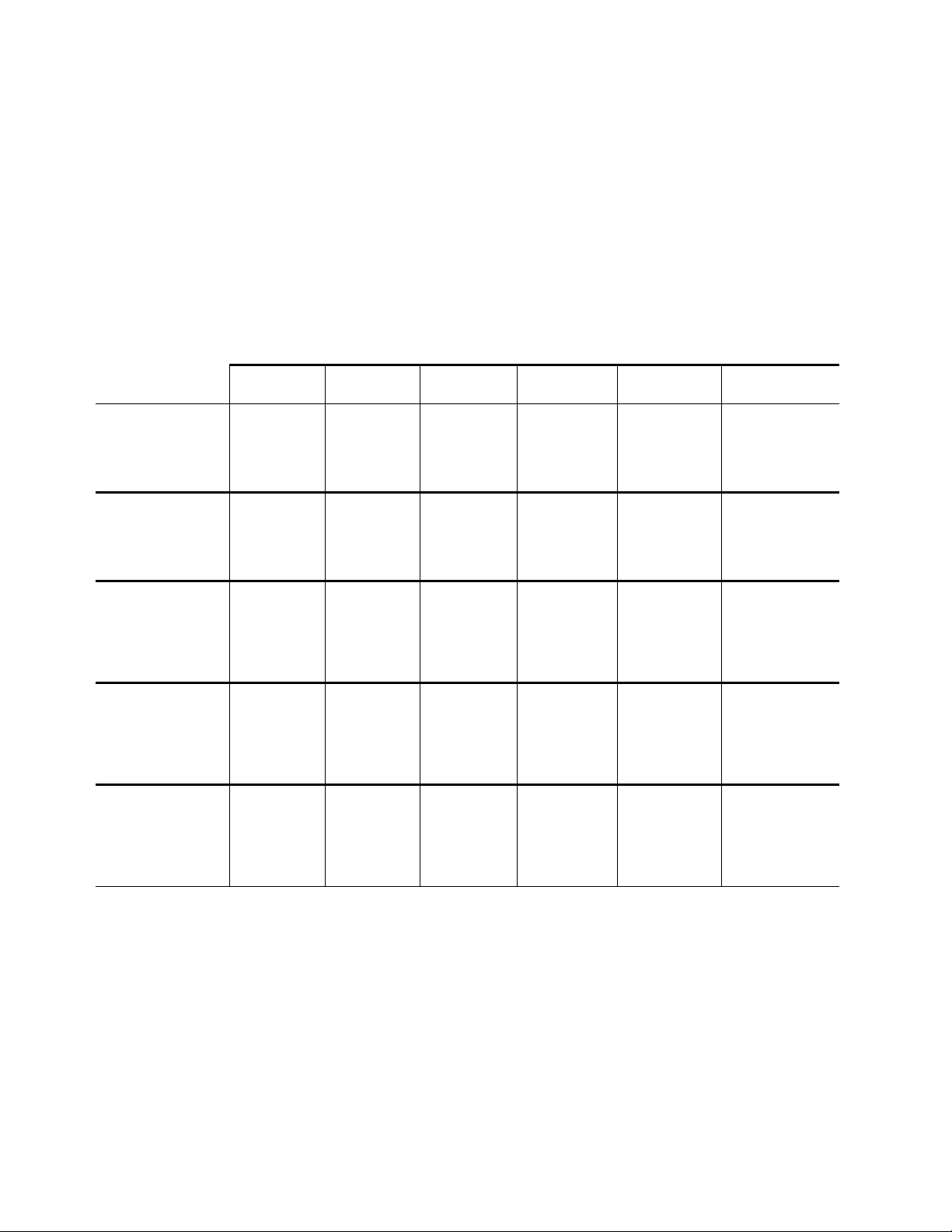

Routing & Processing Pairs Web Page

Use the Routing & Processing Pairs web pages (Figure 25 on page 41 for

Pair 1 and Pair 2 and Figure 26 on page 42 for Pair 3 and Pair 4) for the following:

• Input Channel Selection – name assigned on the I/O Config web page.

Processing – set the output processing for each channel (A and B) for

•

each audio pair (Pair 1 to 4) with the Processing pulldown to one of the

following output conditions:

• A - selects the audio present on A as the channel output.

• -A - inverts the audio present on A as the channel output.

• B - selects the audio present on B as the channel output.

• -B - inverts the audio present on B as the channel output.

• A + B - audio present on A and B are added together as the channel

output.

• -(A + B) - audio present on A and B are added together then

inverted as the channel output.

• A - B - audio present on B is subtracted from audio on A as the

channel output.

• - (A-B) - audio present on B is subtracted from audio on A then

inverted as the channel output.

• 1 kHz - places a 1 kHz (at -20 dBFS) tone on the channel output.

• 400 Hz - places a 400 Hz (at -20dBFS) test tone on the channel

output.

• Silence - forces the channel output to silence.

• ID - identifies Channels A and B with a 1 kHz tone at a -20dBFS

level that switches between Channel A and Channel B with a

repeating cadence of 1 second on Channel A (left) followed by a 3

second tone on Channel B. Each pair from 1-4 is indicated by that

number of bursts of 400 Hz at an 8 Hz rate when the 1 kHz tone

starts on a new channel.

Note An output processing mode cannot be selected on a channel with Non-PCM

audio and processing will be forced to bypass as shown in Figure 25 on

page 41.

• Output Pairs – Output names.

40 8977AP-4B/4U — Instruction Manual

Page 41

Figure 25. Routing & Processing Pairs Web Page – Pair 1 and Pair 2

Remote Configuration

8977AP-4B/4U — Instruction Manual 41

Page 42

Remote Configuration

Figure 26. Routing & Processing Pairs Web Page – Pair 3 and Pair 4

42 8977AP-4B/4U — Instruction Manual

Page 43

Output Status and Settings Web Page

Use

this

link

Use the Output Status and Settings web page (Figure 27 on page 45) to

monitor the audio outputs and to set the AES CUV Bits Pass Through and the

AES Resolution controls.

• Processed Stream Name – displays the name for each channel.

AES CUV Bits Pass Through – the control bits that are part of each subframe

•

of AES data are defined as C (Channel status), U (User), and V (Valid)

bits and the Z bit, which carries the AES block frame position block

start. For the control and status bits in the CUV positions of each audio

channel, and the Z marker for each stream (pair of channels), there is a

buffer on the module that handles the asynchronous timebase slips

between the input and output AES stream frequency.

This buffer will drop or repeat an entire block (occurring every 192 samples) of CUV bits when the two timebases cross a block boundary rather

than drop or repeat individual bits from the block.

A control is provided on the AES Outputs web page for enabling or disabling the controls bits in an AES signal called the AES C/U/V Bit Pass

Through

the AES output of the module (Pass Through disabled) or taken from

the AES stream coming from an audio input.

(Figure 27 on page 45). These bits may be generated locally at

Remote Configuration

• If the box is checked, refer to Table 2 on page 44.

• If the box is not checked, the C bit is calculated.

Note When a Force Audio Mode selection is changed on the Input Status and Set-

tings Web Page on page 34, you must manually set the AES CUV Bits Pass

Through control to Enabled or Disabled as desired.

• AES Resolution –

•If the

•If the

AES CUV Pass Through box is checked, the AES Resolution is dis-

played

chosen between 20 and 24 bits.

Non-Applicable and the AES resolution is 24 bits.

AES CUV Pass Through box is not checked, the resolution can be

8977AP-4B/4U — Instruction Manual 43

Page 44

Remote Configuration

Default Channel

Status Data mode

The module complies with all of the requirements listed below:

• When an audio input stream is processed and routed at the channel

level, the CUV bit pass through mode is automatically disabled because

the consistency of the channel status data cannot be ensured.

• The module always sets the Output channel status to PROFESSIONAL.

• The module always delivers a signal at an output sample rate of 48 kHz.

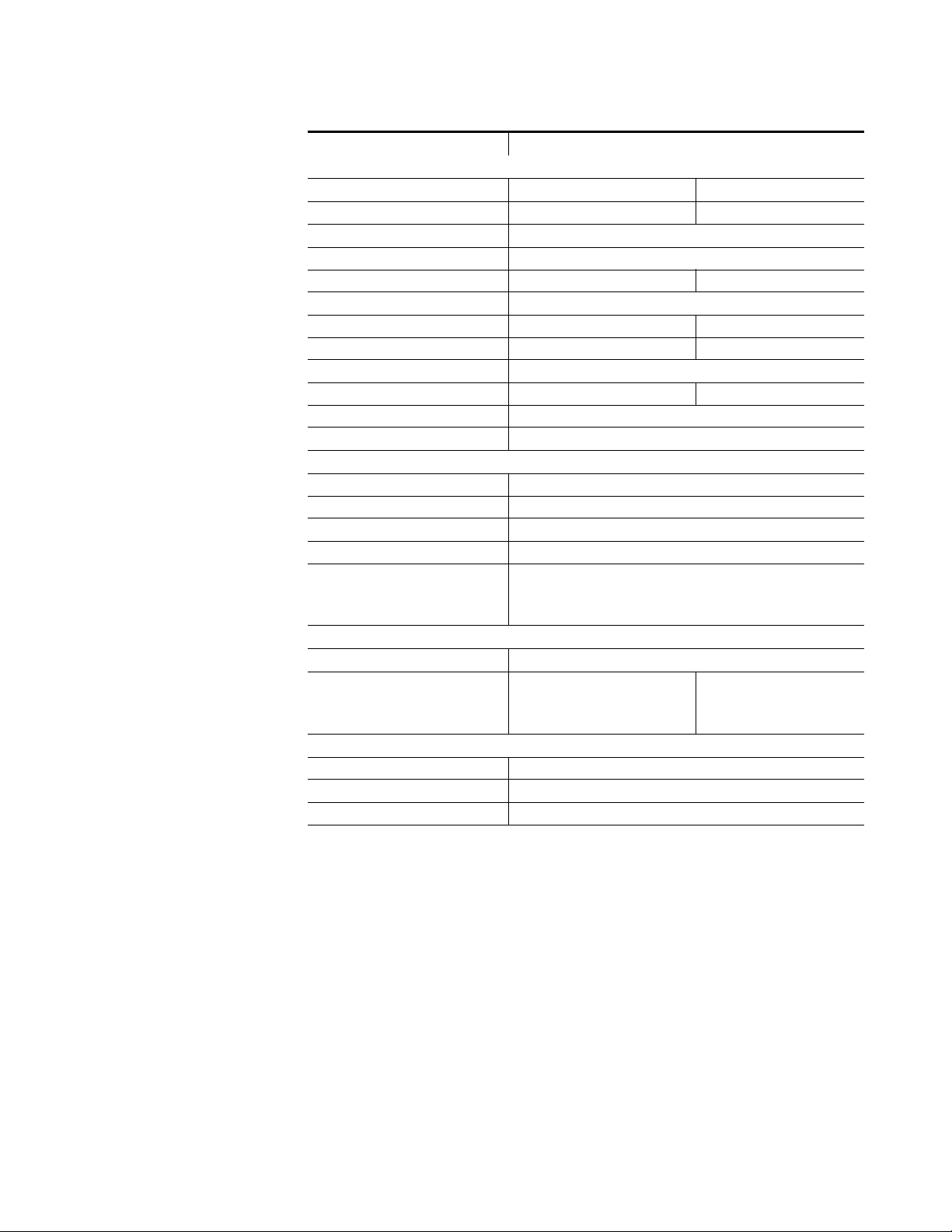

Tab le 2 reports the configuration capability and some channel status data

fields related to configuration.

Table 2. AES Output Settings: Channel Status Data Handling

PCM Mode

32 kHz

CUV Bit

Pass Though

Disable

PCM Mode

44.1 kHz

CUV Bit

Pass Though

Disable

PCM Mode

48 kHz

CUV Bit

Pass Though

Disable

PCM Mode

96 kHz

CUV Bit

Pass Though

Disable

Non-PCM

48 kHz

CUV Bit

Pass Though

Enable

Synchronous PCM

48 kHz

CUV Bit

Pass Though

Disable

Channel Status

Data Setup

AES CUV

Bit Pass Through

Enable

Output Channel

status is Consumer in

the incoming signal

AES CUV

Bit Pass Through

Enable

Output Channel

status is Professional in

the incoming signal

AES CUV

Bit Pass Through

Disable

Output Channel

status is Professional in

the incoming signal

AES Resolution

24 bits

CUV Bit

Pass Through

Enable/Disable

AES Resolution

20/24 bits

Output channel

status is

Professional

Output Sampling

Frequency

32 kHz

Output channel

status is

Professional

Output Sampling

Frequency

32 kHz

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

AES Resolution

24 bits

CUV Bit

Pass Through

Enable/Disable

AES Resolution

20/24 bits

Output channel

status is

Professional

Output Sampling

Frequency

44.1 kHz

Output channel

status is

Professional

Output Sampling

Frequency

44.1 kHz

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

AES Resolution

24 bits

CUV Bit

Pass Through

Enable/Disable

AES Resolution

20/24 bits

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

channel

Output

status is

Professional

Output Sampling

Frequency

48 kHz

AES Resolution

24 bits

CUV Bit

Pass Through

Enable/Disable

AES Resolution

20/24 bits

Output channel

status is

Professional

Output Sampling

Frequency

96 kHz

Output channel

tatus is

s

Professional

Output Sampling

Frequency

96 kHz

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

AES Resolution

24 bits

Not Applicable

Output channel

s

status i

Professional

Output Sampling

Frequency

48 kHz

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

AES Resolution

24 bits

CUV Bit

ss Through

Pa

Enable/Disable

AES Resolution

20/24 bits

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

Output channel

status is

Professional

Output Sampling

Frequency

48 kHz

44 8977AP-4B/4U — Instruction Manual

Page 45

Figure 27. Output Status and Settings Web Page

Remote Configuration

8977AP-4B/4U — Instruction Manual 45

Page 46

Remote Configuration

Use

this

link

User Settings Web Page

The User Settings web page (Figure 28) provides the following File Operations for saving and recalling user settings and factory defaults:

• Save to... and Load from... functions are provided for saving the current

module configuration to a file or loading a previously saved file, and

• Factory recall for default settings and default signal names.

Figure 28. User Settings Web Page

File Operations

Configuration files from the module may be saved to a file and stored

offline for later recall.

To save a file, do the following:

1. Save the current configuration on the module to a file by selecting the

Save to... button which will bring up the File Download screen (not

shown).

2. In the File Download screen select Save.

3. This will bring up the Save As screen shown in Figure 29 on page 47.

4. Enter a name in the File name field. This file is saved as a .bin type.

46 8977AP-4B/4U — Instruction Manual

Page 47

Figure 29. Save Module Configuration.

Remote Configuration

To load and recall a file, do the following:

1. Selecting the Load From... button on the User Settings web page

(Figure 28 on page 46) which will bring up the Load Settings web page

shown in Figure 30.

2. Enter a path and file name or select Browse... to locate the directory

where the files have been saved.

Figure 30. Load Module Configuration.

8977AP-4B/4U — Instruction Manual 47

Page 48

Remote Configuration

3. This will bring up the Choose File screen shown in Figure 31.

Figure 31. Choose File Screen

4. Select a file to load and then press Open to bring the file into the filename

field.

5. Press the Load button in the Load From... web page (Figure 30 on

page 47) to load the file to the module.

Recall Factory Defaults and Names

Use the two buttons at the bottom of the web page to do the following:

• Set Factory Defaults – select the Set Factory Defaults button to recall factory

settings to the module. Defaults for all module parameters are listed in

Table 5 on page 61.

Set Factory Names – select the Set Factory Names button to recall factory

•

signal names to the module. Defaults for all signal names are displayed

on the I/O Config web page shown in Figure 18 on page 31 and

Figure 19 on page 32.

48 8977AP-4B/4U — Instruction Manual

Page 49

Genlock Web Page

Use

this

link

The Genlock web page (Figure 32 on page 51) is present on 8977AP controls

when an 8900GEN-SM submodule is installed on the module.

Refer to the 8900GEN-SM Installation Manual available online for complete

details for configuring the 8900GEN-SM submodule.

This web page provides reporting status for the following genlock status

items:

Genlock – reports status of Genlock function as Enabled or Freerun.

•

Status – reports whether the reference input is Locked or Not Locked.

•

Firmware Version – reports the firmware version of the 8900GEN-SM sub-

•

module installed on this 8977AP module.

Hardware Revision – reports the hardware revision of the 8900GEN-SM

•

submodule installed on this 8977AP module.

Ref Input Standard – reports the reference input standard as detected by

•

the 8900GEN-SM submodule that is connected to the Genlock BNC on

the rear module.

Remote Configuration

The input standards are NTSC, PAL, 1080i/59.94, 720p/59.94, 1080i/50,

720p/50, 1080p/24, 1080sF/24, AES 48K, AES 96K, Word Clock 48K, or

Work Clock 96K.

• Output Bus Frame Rate – reports the frame rate being output on the frame

bus.

Note The Output Bus Frame Rate is always reported as an SD frame rate for all

input reference standards including audio.

• Output Bus – reports the reference bus (Ref Bus 1 or Ref Bus 2) being

output from the submodule.

Genlock Control

The Genlock submodule may be configured with the following controls:

• Genlock – select one of the radio buttons to Enable or Freerun (not locked

to external reference).

nput Standard Selection – use this control to set the input standard needed

• I

for the reference input.

Loop Bandwidth – set the loop bandwidth to Low Jitter or Fast Lock

•

depending on the type of reference input.

For example, if Low Jitter is selected and the Status is still Invalid after one

minute has passed, the input reference has excessive wander that

cannot be tracked in

is Locked after about 10 seconds.

8977AP-4B/4U — Instruction Manual 49

Low Jitter mode. Switch to Fast Lock and verify Status

Page 50

Remote Configuration

Genlock Bus Timing

Use the following controls to adjust the output timing of the genlock reference signal from this submodule:

• Line Offset – adjust the reference timing stream by standard definition

line steps up to one full frame.

Coarse Offset – provides coarse adjustment of the reference timing stream

•

by steps up to 37 ns.

Fine Offset – provides fine adjustment of the reference timing stream by

•

steps up to 37 ns.

Drive Frame Reference Bus – Set to Auto or Off. If Auto is selected, Ref 1 or

Ref 2 is provided if it is locked.

If Off is selected, the reference on the frame bus is not sent out.

Defaults Button

Select the Defaults button to restore the default genlock parameters.

50 8977AP-4B/4U — Instruction Manual

Page 51

Figure 32. Genlock Web Page

Remote Configuration

8977AP-4B/4U — Instruction Manual 51

Page 52

Remote Configuration

Use

this

link

System Config Web Page

Use the System Config web page (Figure 33 on page 53) to perform the fol-

lowing functions on the module:

Output Timing

Select the Primary and Secondary output timing source for the module as

either

on this module),

slot 1 and jumpered for outputting a Ref 1 frame bus),

submodule is mounted on module in slot 3 and jumpered for outputting a

Ref 2 frame bus) or

of each reference source will be reported in the Status and Genlock

columns.

Note The internal mode is mainly implemented for test and debug purposes during

When a secondary reference source is selected that is different than the Primary, the module can be configured to switch automatically to the Secondary selected if the Primary is lost or becomes unlocked or invalid. If you

do not want this action of switching to a Secondary, set the Primary and

Secondary sources to the same source.

Local (external reference from the 8900GEN-SM submodule mounted

Ref 1 (8900GEN-SM submodule is mounted on module in

Ref 2 (8900GEN-SM

Internal (local oscillator). The signal and genlock status

the system setup of the module or in a standalone configuration where no

timing reference is required.

Refer to 8900GEN-SM Genlock Submodule Installation on page 12 for an overview of using the 8900GEN-SM submodule for reference timing. Also refer

to the 8900GEN-SM Installation Manual available online for complete details

using this submodule for timing applications.

Reference Restore

If the Primary source has failed and a Secondary source is selected and

valid, the following controls allow you to set the module to switch back to

the Primary automatically or manually and determine the amount of time

before the Primary is restored.

• Switch to Primary – set this control to Manual if you wish to manually return

to the Primary reference when it becomes valid or locked again or

to allow the module to switch back to the Primary reference.

Reference Switchback Delay – When the control above is set for Auto, set

•

the amount of time to allow between switching from the Secondary reference back to the restored Primary. The switchback time has a

minimum recovery time of approximately 30 seconds to assure that the

Primary is locked and valid before the module switches back to that

source.

Auto

52 8977AP-4B/4U — Instruction Manual

Page 53

Remote Configuration

Primary - Secondary Phase Difference

This graphic is provided to show the total phase difference between the

Primary and Secondary reference signals. When the bar is green and

remains in the area before the horizontal indicator, the two references are in

a range where switching between the two will show no measurable distur

bance in the output video (approximately 72 ns).

When the phase difference is larger than the recommended amount, the bar

will indicate by showing a second red bar. This indicates that the phase difference is now such that switching between the two references will show a

disturbance in the output. This can be caused by a loss of one of the references or a mis-adjustment in the reference output delay of either reference.

The total phase error shown in this graphic represents approximative 1

microsecond.

Figure 33. System Config Web Page

-

8977AP-4B/4U — Instruction Manual 53

Page 54

Remote Configuration

Use

this

link

Slot Config Web Page

Use the Slot Config web page (Figure 34 on page 55) to perform the following functions on the module:

• Locate Module – selecting the Flash selection in the pulldown button

flashes the yellow COMM LED on the front of the module so it can be

located in the frame.

Slot Identification – You may identify the module by typing a specific

•

name in the

module and travels with the 8900NET module if it is moved to another

frame. Select

An asset identification may be entered in the Asset Tag field up to 31

characters. This will appear on the module Status web page and in the

NetConfig inventory report.

• Slot Memory – the slot configuration for each module is automatically

saved periodically (once an hour) to the 8900NET module in that frame.

You may also select the

current configuration for this slot. The configuration is saved on the

8900NET module. If the 8900NET module is removed or powered

down, the stored configurations are not saved.

Name field. The assigned name is stored on the 8900NET

Default to enter the factory default module name.

Learn Module Config button at any time to save the

When the Restore upon Install box has been checked, the current configuration saved to this slot is saved as slot memory. When the current

module is removed and another module of the same type is installed,

the configuration saved to the 8900NET module will be downloaded to

the new module. The box must be checked before the current module

with the saved configuration is removed.

Note Allow at least 5 seconds before inserting the new module into the slot.

Only the same module type, with the same version software should be

installed in this slot. Inserting a similar module with a different version

software can cause unexpected results. If a different type of module is

installed in this slot, a warning message will state that the original

module type has been replaced with another module type. In this case,

a

Clear button will appear allowing you to clear the stored configuration

from the previous module.

• Frame Health Reporting – This web page allows configuration of the alarms

and warnings that are reported to the external Frame Health Alarm

connector on the rear of the GeckoFlex frame. Refer to 8900NET Instruc-

tion Manual for more details.

LED Reports – This link appears when the 8900NET module has software

•

version 4.0.2 or later installed. When the link is selected, a read-only

status report of the 8900NET Hardware Switch state is given. In the

LED Reporting section of the web page, LED Reporting on the 8900NET

module can be enabled or disabled as desired.

54 8977AP-4B/4U — Instruction Manual

Page 55

Remote Configuration

• SNMP Trap Reports – Select the SNMP Trap Reports link to open the

8900NET SNMP Reporting web page. this link will only be present

when SNMP Agent software has been installed on the 8900NET

module. This web page allows configuration of which alarms and

warnings that are reported to the SNMP management software.

Refer to 8900NET Instruction Manual for more details on these links.

Figure 34. Slot Config Web Page

8977AP-4B/4U — Instruction Manual 55

Page 56

Specifications

Specifications

Table 3. 8977AP Specifications

Parameter Value

Environmental / Miscellaneous

ANSI/UL60950-1

CAN/CSA C22.2, No. 60950-01

cULus certification File number: E300838

Safety

EMC

EU marking 93/68/EEC (22/07/93)

Climatic specifications

Power consumption 6 Watts + 0.7 Watts with 8900GEN-SM submodule

Digital Audio Inputs

Digital audio input signal AES3-2003, Tech 3250-E AES3-id-2001

Number of inputs Up to 4 Up to 4

Input names AES 1, 2, 3, 4 AES 1, 2, 3, 4

Connector type Three-pin terminal blockBNC

Common range mode +/- 10V, 50Hz to 20kHz N/A

Differential voltage range 200mV to 10V p-p 200mV to 2V p-p

Input return loss > 20dB (100kHz - 128FS) > 20dB (100 kHz - 128FS)

Input impedance 110 Ohms +/- 20 % 75 Ohms +/- 20 %

Sampling rates supported (FS) 32 kHz, 44.1 kHz, 48 kHz, 96 kHz 32 kHz, 44.1 kHz, 48 kHz, 96 kHz

Sampling rate accuracy +/-100ppm +/-100 ppm

Resolution supported 16 bits, 20 bits, 24 bits 16 bits, 20 bits, 24 bits

IEC 60950-1

EN60950-1

73/23/EEC Low voltage directive

89/336/EEC directive

FCC Class A CISPR Pub. 22 (1985)

EN55103-1 (1997)

EN55103-2 (1997)

ETS 300 019-1-3 c

(Feb. 1992)

lass 3.1

Balanced Inputs Unbalanced Inputs

Safety of Information Technology

Equipment, including Electrical

Business Equipment (2003).

Safety of Information Technology

Equipment, including Electrical

Business Equipment.

Safety of Information Technology

Equipment, including Electrical

Business Equipment (2003).

Safety of Information Technology

Equipment, including Electrical

Business Equipment (2001).

(19/02/73) amended by

93/68/EEC (22/07/93)

(05/05/89) amended by

93/68/EEC (22/07/93)

Operating temperature (for

8900FFN model):

+ 0°C to + 45°C

operating humidity: 10% to 95%

non-condensing

56 8977AP-4B/4U — Instruction Manual

Page 57

Specifications

Table 3. 8977AP Specifications

Parameter Value

Digital Audio Outputs

Balanced Outputs Unbalanced Outputs

Digital audio output signal AES3-2003, Tech 3250-E AES3-id-2001

Number of outputs Up to 4

Output names AES 1, 2, 3, 4

Connector type Three-pin terminal blockBNC

Data jitter +/- 20ns

Output rise / fall time 5ns to 30ns @ 110 Ohms 37ns +/- 7ns @ 75 Ohms

Differential voltage range 2 to 7V @ 110 Ohms 1V +/- 20% @ 75 Ohms

Output return loss > 15dB (100 kHz - 128FS)

Output impedance 110 Ohms +/- 20 % 75 Ohms +/- 20 %

Sampling rates (FS) 48 kHz

Output resolution 20 or 24 bits

DT Input (Audio Delay Tracking)

Audio delay tracking input Conforming to Tektronix 118AS Interface

Number of inputs 1

Connector type BNC

Electrical interfaceOne wire serial (RS232 type) interface

BAUD = 1200

RS232 characteristics

Electrical Length (Delay)

Sync-PCM/Non-PCM throughput 280 microseconds

PCM mode throughput

Other Parameters

Maximum delay 10s in 1ms steps

Gain (40; +6dB) in 0.1dB steps

Output processing modes Silence, A, -A, B, -B, A+B, -(A+B), A-B, -(A-B), 1 kHz, 400 Hz, ID tone

Parity = Even

Bits/words = 7

Stop bits = 1

32 kHz:

44.1 kHz:

48 kHz:

96 k Hz:

3.2 ms

3.3 ms

3.9 ms

1.7 ms

8977AP-4B/4U — Instruction Manual 57

Page 58

Service

Service

Power-up Diagnostics Failure

Troubleshooting

The 8977AP modules make extensive use of surface-mount technology and

programmed parts to achieve compact size and adherence to demanding

technical specifications. Circuit modules should not be serviced in the field

unless otherwise directed by Customer Service.

If the module has not passed self-diagnostics, do not attempt to troubleshoot. Return the unit to Grass Valley (see Module Repair on page 59).

Electronic Circuit Breaker

The electronic circuit breaker works during a fault condition or an overcurrent which stops the module.

Remove the module and replace it in the frame. If the problem persists,

please contact Grass Valley Customer Service with the contacts given on

page 4.

Table of Alarms

Ta bl e 4 describes the different type of alarms generated on the module.

Table 4. List of Alarms for 8977AP Module

Status

Alarm

type

Pass Genlock module is not installed Green Genlock missing No

Fault Genlock submodule failed, replaceRedGenlock Failure No

Fault Power supply bad Red Problem of power supply Yes

Fault FPGA failure Red FPGA not loaded Yes

Warning Wrong Rear Module (incompatible with 8977AP-4U) Yellow Rear module is different of 8900UE-R Yes

Warning Wrong Rear Module (incompatible with 8977AP-4B) Yellow Rear module is different of 8900BA-R Yes

Warning Ref 1 is Not Present Yellow Ref 1 from FrameRef 1 is missing Yes

Warning Ref 2 is Not Present Yellow Ref 2 from FrameRef 2 is missing Yes

Warning Local Ref is Not Present Yellow Input ref is not detected Yes

Warning Redundant Ref in Not Present Yellow The second ref selected is missing Yes

Warning Audio Input: AES 1 Input Signal Not Detected Yellow No AES 1 input detected Yes

Warning Audio Input: AES 2 Input Signal Not Detected Yellow No AES 2 input detected Ye

Warning Audio Input: AES 3 Input Signal Not Detected Yellow No AES 3 input detected Yes

Web Page Description

LED

Status

Comments

reported

to the

8900Net

&SNMP

s

58 8977AP-4B/4U — Instruction Manual

Page 59

Service

Table 4. List of Alarms for 8977AP Module

Status

Alarm

type

Warning Audio Input: AES 4 Input Signal Not Detected Yellow No AES 4 input detected Yes

Warning Audio Delay Tracking Input: Signal Not Detected Yellow No audio delay tracking input detected after 30 seconds Yes

Pass Audio Mode: AES 1 Mismatch Mode (audio

PCM/Non-PCM mode detected different of mode

selected)

Pass Audio Mode: AES 2Mismatch Mode (audio

PCM/Non-PCM mode detected different of mode

selected)

Pass Audio Mode: AES 3 Mismatch Mode (audio

PCM/Non-PCM mode detected different of mode

selected)

Pass Audio Mode: AES 4 Mis

PCM/Non-PCM mode detected different of mode

selected)

Web Page Description

match Mode (audio

LED

Status

Green

Green

Green

Green

Comments

PCM on AES 1 status is different of the PCM setting

PCM on AES 2 status is different of the PCM setting

PCM on AES 3 status is different of the PCM setting

PCM on AES 4 status is different of the PCM setting

Note Please refer to the Figure 8 on page 18, Figure 9 on page 19, and Table 1 on

page 20 for the status meaning and the color of the LEDs.

reported

to the

8900Net

&SNMP

No

No

No

No

Module Repair

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Grass Valley repair

depot. Call your Grass Valley representative for depot location.

Refer to Contacting Grass Valley on page 4 at the front of this document for

the Grass Valley Customer Service Information number.

8977AP-4B/4U — Instruction Manual 59

Page 60

Functional Description

Functional Description

A block diagram of the 8977AP is shown in Figure 35.

Figure 35. 8977AP Block Diagram

60 8977AP-4B/4U — Instruction Manual

Page 61

Configuration Parameters

This appendix provides a complete summary of the 8977AP functions and

a comparison of the functionality available with the web page and Newton

control panel control type along with the ranges and default values for each

parameter in

Table 5. 8977AP Configuration Parameters

Ta bl e 5.

Description Default

Drive Frame Reference Bus

Input Standard Status

Genlock

Input Standard Selection NTSC

Loop Bandwidth

Line Offset

Coarse Offset

Fine Offset

Genlock

Input Frame Rate Status

Status

Output Bus

Output Frame Rate

Switch to Primary Ref

Switch Back After Primary Restored

Auto Auto/OFF GenlockGLBusDrv

Enable Enable or Freerun Genlock GLEnable

Fast LockFast Lock / Low Jitter Genlock GLLoopBW

0 [0 - 624] Genlock GLLnOff

0 [0 - 1727] GenlockGLcors

0 [0 - 255] GenlockGLfine

Status Freerun / Enabled GenlockGLstatus

Status Freerun / Invalid / Locked GenlockGLStat

Status Ref 2 / Ref 1 / Local GenlockGLOutBus

Status 29.97 / 25 / 0 Genlock GLOutFR

-Switching System Config Sw2PriRef

Auto Auto / Manual System Config RefSwBk

Range/choices

resolution

NTSC,

PAL,

1080i/59.94,

1080i/50,

720p/50,

720p/59.94,

1080p/24,

1080sf/24,

AES48K,

AES96K,

Word Clock 48K,

Word Clock 96K

NTSC,

PAL,

1080i/59.94,

1080i/50,

720p/50,

720p/59.94,

1080p/24,

1080sf/24,

AES48K,

AES96K,

Word Clock 48K,

Word Clock 96K

29.97 / 25 / 24 / 48 /

0 / 96

Web Page / Function

Name

Genlock GLInStd

Genlock GLInSEl

Genlock GLInFR

Newton Control

Panel

8977AP-4B/4U — Instruction Manual 61

Page 62

Configuration Parameters

Description Default

Reference Switchback Delay

Delay Stream 1 Channel 1

Delay Stream 1 Channel 2

Delay Stream 2 Channel 1

Delay Stream 2 Channel 2

Delay Stream 3 Channel 1

Delay Stream 3 Channel 2

Delay Stream 4 Channel 1

Delay Stream 4 Channel 2

Delay Stream 1 Both Ch1 Ch2

Delay Stream 2 Both Ch1 Ch2

Delay Stream 3 Both Ch1 Ch2

Delay Stream 4 Both Ch1 Ch2

Gain Stream 1 Both Ch1 Ch2

Gain Stream 2 Both Ch1 Ch2

Gain Stream 3 Both Ch1 Ch2